Abstract

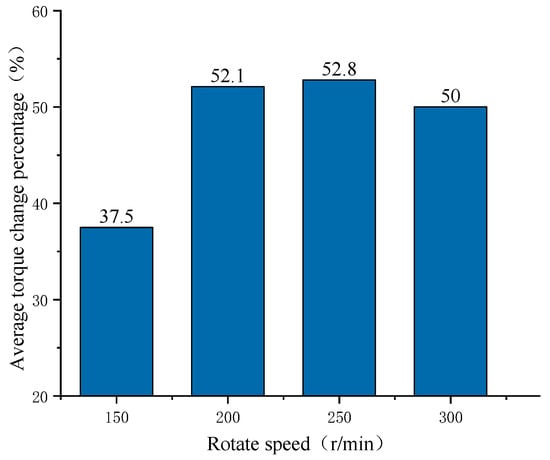

Aiming at the problem that rotary tiller knife rollers are prone to entanglement with straw in the wet and sticky soil environment of rice fields in the middle and lower reaches of the Yangtze River in China, an antitangling and sticking cutter was designed. The cutter reduces knife roller entanglement in order to reduce rotary tiller energy consumption and improve work efficiency, and its effectiveness was verified through theoretical analysis, discrete element simulation, and field trials. The design’s validity was verified through theoretical analysis, discrete element simulation, and field tests. The blade inclination design was completed through motion force analysis, and the tool geometry was optimized with a 36.87° inclination baffle and staggered arrangement. A simulation model of the soil–straw–rotary tillage knife interaction was established and we used the discrete element method to analyze the variation in torque between the antisticking knife and the China standard rotary tillage knife (IT245) at four different cutter shaft rotational speeds. In the simulation, the average torque for the antisticking knives was smaller than that of the national standard rotary tillage knives, with reductions of 37.1%, 52.1%, 52.8%, and 50.0%, respectively, demonstrating a remarkable effect. Field tests showed that the average operational efficiency of the antisticking knife was 0.57 hm2/h, with an operation qualification rate of 95.72%. The average torque results from simulation (with and without the antisticking knife) and field tests were analyzed, yielding correlation coefficients of 0.994 and 0.973 for the change curves of average torque between the antisticking knife and the national standard rotary tillage knife. This result confirms the accuracy of the simulation model and the consistency between the simulation and field test results. This study can provide some references for the design and test of antisticking of rotary tillers.

1. Introduction

Rice is one of the major grain crops in China [1]. The middle and lower reaches of the Yangtze River are the main rice-growing areas in China. However, rice straw in rotary tillage operation commonly undergoes the winding knife roller phenomenon [2] (Figure 1), which greatly reduces the rotary plow efficiency and increases energy consumption; as a result, rice sowing cannot be achieved before the land is fully prepared.

Figure 1.

Grass entanglement phenomenon of rotary tiller knife rollers.

According to data from the Ministry of Agriculture and Rural Affairs 2023 Agricultural Machinery Validation Report [3], when the traditional rotary tiller handles fields with a stubble height > 30 cm, the rate of knife roller winding is as high as 62%, which leads to a 40% decrease in operational efficiency and a 25% increase in energy consumption, and so the study of knife roller antisticking is of some significance.

In recent years, the optimization and resource utilization of agricultural machinery have made remarkable progress due to straw entanglement technology. On the basis of the principle of slip cutting, Zhang et al. [4,5] developed a straw crusher using slip-cutting principles with curved blades, while Li et al. [6] created a fixed-knife crusher that prevents banana straw entanglement through three-point support crushing. Shi et al. [7] designed a cutting table antitangling device for caraway harvesters, and Du et al. [8] optimized the rotary tiller knife configuration for efficient straw burial with minimal torque. There has been more research on the topic of antitangle technology, but there is still a slight lack of research on the wet clay soil environment. The discrete element method originated from molecular dynamics theory and has been widely used in agricultural material simulation [9,10,11]. Moreover, various straw discrete element models have been established, providing an important method for the discrete element simulation analysis of straw–tool interactions. Shi et al. [12] constructed a mechanical model of rice straw with multiple lengths using the multisphere cell method to optimize the no-tillage seeder, thereby providing a reference for the research of straw return equipment. Fang et al. [13] used five spherical cells with a 10 mm interval to construct a wheat straw model with 56 mm length and analyzed the straw displacement in the soil after rotary tillage tool plowing; compared with the soil trench test, the two results differed considerably, but the movement trend was the same. On the basis of EDEM 2024 software, Wang et al. [14] constructed a soil–rotary tillage tool–straw interaction model and conducted an analysis of the straw–soil–rotary tillage tool interaction mechanism, which effectively realized the requirements of rotary tillage antientanglement technology. Zhang et al. [15] developed a model using the discrete element method to illustrate a flat straight model with three edge curves (Archimedean helix, sinusoidal–exponential helix, and logarithmic helix) and maize residues, including stubble and stover. Li et al. [16] used the finite element and discrete element methods to establish a dynamic model of the coupled implement–straw–soil system to analyze the rotary tillage process of paddy rice. Zhang et al. [17] established an interaction model of the rotary blade–soil–straw by using the discrete element method and conducted simulation analysis to determine the factors that affect the rotary blade’s power consumption and the quality of operation. On the basis of the three-dimensional hemisphere method, Homer et al. [18] studied the soil tillage process and conducted a relevant bench test. After comparative analysis, the discrete element simulation results and test results of the difference between the smaller and the simulation process of the physical changes in the soil were found to be basically the same as those in the actual situation. The results showed that the use of the discrete element method as a soil tillage simulation tool is feasible [19,20] and that discrete element simulation is a reliable and convenient way to assist the design and ensure the reliability of the research, thus greatly improving the speed of research and development.

At present, several scholars have conducted in-depth research on antistalking straw and the interaction between implements and soil and produced more research results, mainly relating to the knife cutting straw, to reduce the phenomenon of entanglement; however, the design of the knife does not consider wet and sticky soil, resulting in adherence to the knife roller. To address this problem, this study takes rice straw as the research object, constructs a discrete element model, designs a kind of antitangling and sticking knife, and verifies the cutting effect of the knife through theoretical calculation. Moreover, through theoretical calculation and simulation optimization, the cutting effect of the knife is verified to determine the effectiveness of the designed antistalking knife in terms of reducing entanglement and flying clay and providing a reference for the optimized design of the key components of the straw-returning machine and the discrete element simulation.

2. Materials and Methods

2.1. Structure and Working Principle

2.1.1. Structure

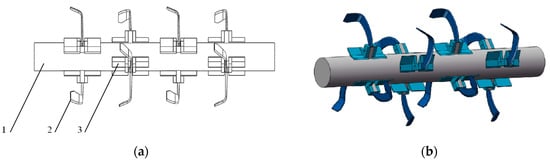

The overall structure of the antitangling and sticking cutter is shown in Figure 2 (hereafter referred to as the antitangling and sticking cutter). The device adopts a modular transmission structure design, and its core structure consists of three major parts: the drive shaft system, the national standard IT245 rotary tillage knife set, and the antisticking knife. The transmission shaft is the central drive unit, with both ends connected to the tractor power output through the flange; the surface is equipped with a standardized keyway to fix the operating components. National standard IT245 rotary tillage knives are uniformly distributed by the helix in the transmission shaft, and their blades are in line with the GB/T 5669-2017 standard [21], with quenched 65 Mn spring steel and a bidirectional crushing function. A continuous cutting surface is formed in the process of rotation. Antitangling and sticking knives are distributed on both sides of the curved knives, which produce periodic vibration while cutting off straw fibers and, together with the centrifugal force, make the tangles fall off automatically. During rotary tiller operation, the national standard rotary tiller knife and antistalking knife cut the soil and straw, and the antistalking knife throws the adhering soil and crushed straw in the sticky and wet soil environment to achieve the antistalking effect. The whole set of devices adopts a compact layout to ensure power transmission efficiency, and the overall structure considers the soil-cutting performance and antistalking design features.

Figure 2.

Schematic of overall structure of antisticking tool. (a) Working principle diagram; (b) 3D structural diagram. (1) Transmission shaft; (2) national standard IT245 rotary cutter; (3) antitangling and sticking cutter.

2.1.2. Working Principle

Regarding the design of the new knife row for use in the rotary plow knife on both sides of the machine during the mechanical traction operation, the purpose is to achieve rotary plow operation to ensure that the device has reached the goal of antisticking in terms of the stubble and wet sticky soil adhesion.

During field operation, the blades efficiently cut and break stubble and weeds in the direction of the machine’s motion. Above the knife, a beveled surface with a tilt angle further facilitates the removal of wet, sticky soil, stubble, and weeds, preventing them from adhering to the knife shaft. Additionally, the combination of knife rollers effectively throws broken soil and stubble to the rear during operation. The rotary tiller is a China Xuzhou Kyle 1804 tractor. The main performance indicators and technical parameters of the entire machine are provided in Table 1. The range of operating conditions for testing and simulation was determined by rototiller-related parameters.

Table 1.

Main technical parameters of rice tillage and sowing machine.

2.1.3. Technological Improvements

At present, rotary tillers are mainly divided into horizontal rotary tillers, vertical rotary tillers, and slanting rotary tillers [22]; these drive the rotating operation of knives through the drive shaft. The rotating direction of the knife roller of the horizontal rotary tiller is the same as the forward direction of the tractor, and the reaction force of the soil on the knife roller can push the unit forward, requiring less traction force. In sticky and wet soil, the horizontal rotary tiller drives the blade rotation through the power output shaft, which reduces the dependence on the traction force, thus reducing the risk of skidding through the transmission shaft during efforts to drive the rotation of the knife work. However, most rotary tillers do not have antistalking devices, making the machinery prone to the stalking phenomenon during operation, thus reducing the operating efficiency, increasing the energy consumption of the machinery, and making the tillers inconducive to long-time operation [23]. Therefore, the antistalking tool designed in this study is improved on the basis of the following points:

- (1)

- The tool must improve the antistalking effect. In combination with the characteristics of wet, sticky soil and rice stubble in the Jiangsu region, the use of rotary tillage knife space on both sides increases the design of the antistalking cutter, which is mainly distributed on both sides of the rotary tillage knife. Two kinds of cutters cooperate with each other in the rotary tillage knife for crushing soil and stubble breakage work. The antistalking cutter is involved in crushing soil and cutting stubble. Waste is thrown to the back of the machine tool through the back of the ramp, which does not affect the rotary tillage equipment, allowing the device to complete the crushing and antitangling of the grass. The goal of crushing and antistalking is accomplished.

- (2)

- The selection, arrangement, and structure size of rotary plow knives must be determined in order to solve the problem of entanglement. Given the gaps between rotary knives, the antistalking knives are arranged with the selected rotary knives to maximize the space between the knives, prevent the knife rollers from coming into contact with the wet and sticky soil and stubble, and thus achieve the purpose of antistalking.

2.2. Key Component Design

2.2.1. Antisticky Tool Design

Antitangling and sticking cutters are key components of the combined knife roller, and are primarily installed on both sides of the rotary tillage knife. This knife design plays a crucial role in preventing entanglement and adhesion during rotary tillage operations. The knife is made from 65 Mn steel [24], a material that incorporates manganese to enhance its strength. For example, GCr15 steel is weaker than 65 Mn steel in terms of long-term wear; PM23 steel is more costly and not suitable for use in agricultural production. This material improves the material’s mechanical properties, making it more durable than standard materials. When impacted by wet, sticky soil and root stubble, the knife can effectively chop and eject debris from the rotary tillage equipment. Additionally, it offers high resistance to impact, ensuring consistent performance in challenging conditions.

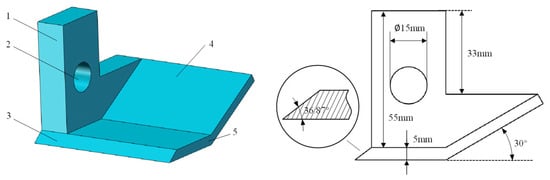

The antitangling and sticking cutter is mainly composed of five parts: the knife handle, the knife body, connecting holes, the knife blade, and the tilting baffle. The structure of the antitangling and sticking knife is shown in Figure 3. The angle between the knife handle and the knife body is 90°; the knife handle and next to the rotary cutter are fixed to the drive shaft through screws; the angle of the tilting baffle and the knife body is 30°; the furthest throwing angle of the parabola is 45°. However, due to operational resistance and friction, the actual angle should be slightly less than 45°, and so the tilt angle in this design is set to 30°. This can effectively avoid the wet and sticky soil having contact with the paddy stubble and the knife rollers; the knife blade is parallel to the drive shaft, making it convenient to cut the paddy stubble.

Figure 3.

Three-dimensional modeling of antisticking tools: (1) shank, (2) connection hole, (3) blade, (4) camber stop, and (5) bending angle.

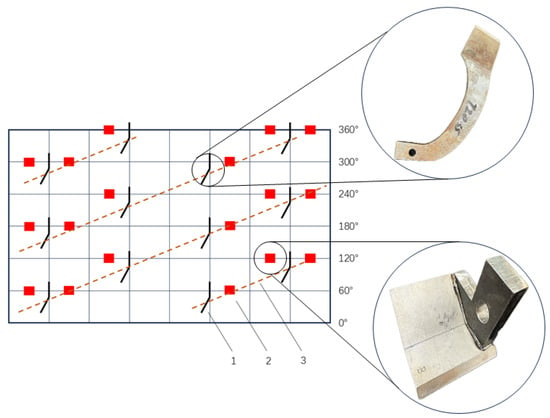

2.2.2. Tool Arrangement

To ensure load uniformity in the tool during rotary plowing, the arrangement of the two kinds of tools should be balanced to maximize the space on the drive shaft, accounting for the tool’s staggered arrangement. The number of rotary cutters on each section of the knife roller for three spaced apart from each other for 120° on the rotary cutter on both sides of the row and for three rotary cutters in a staggered arrangement can maximize rotary tillage operations and, at the same time, ensure that the antiadhesion tool is able to perform cutting for the purpose of antisticking. According to Figure 1, in the actual rotary operation, the rotary tillage knife roller wrapped in grass is mainly seen on both sides of the shaft; therefore, the antisticking tool is mainly distributed on both sides of the shaft, performing the most suitable working condition. The tool layout diagram is shown in Figure 4.

Figure 4.

Tool arrangement diagram: (1) national standard IT245 rotary cutter, (2) antitangling and sticking cutter, (3) spiral axle line.

2.2.3. Performance Analysis of Antisticking Tools

Antitangling and sticking knives were designed to solve the problem of knife rolls that are prone to grass entanglement in wet, sticky soils, and rice stubble fields [25]. These knives were designed to reduce material entanglement while cutting rice stubble and soil through specific geometric parameters and inclination settings. The cutting width and depth of antistalking knives are the key factors affecting cutting effectiveness and antistalking ability. Cutting width b indicates the width of the tool in the horizontal direction in contact with the stubble or soil, while cutting depth d is the depth of the tool vertically in the stubble or soil. Together, the two determine the contact area between the tool and the material, thus affecting the size of the cutting force.

where A is the contact area of the tool, m2; b is the cutting width of the tool, m; and d is the cutting depth, m.

The designed antistalking tool has a cutting width of 0.01 m and a depth of cut of 0.05 m. Therefore, its contact area is 5 × 10−4 m2 from Equation (1).

The cutting force Fcut is the force required by the tool to cut the rice stubble again and is affected by the stubble shear strength σs and the contact area A of the tool, given by the following equation:

where Fcut is the cutting force, N, and σs is the shear strength of rice stubble, Pa.

The shear strength of rice stubble is 5.24 × 106 Pa:

This cutting force ensures that the tool can effectively cut rice stubble, ensuring the rotary tiller’s operational efficiency under complex soil conditions.

2.2.4. Design and Analysis of Tool Inclination

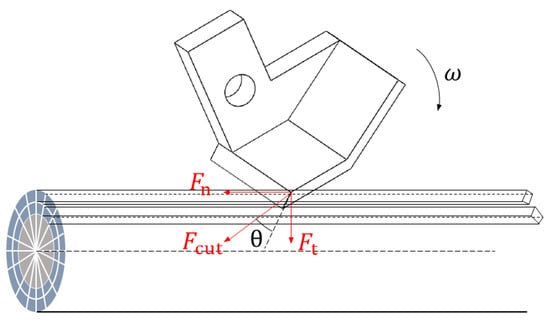

In antitangling and sticking tools for rice stubble cutting, the key lies in the tangential force and normal force of the tool, which must ensure that the tool has enough cutting capacity and can effectively prevent entanglement, as shown in Figure 5.

Figure 5.

Tool force analysis.

Cutting force Fcut is calculated on the basis of the shear strength of the rice stubble, which is decomposed into a tangential component force Ft and a normal component force Fn with the following equations: Rice straw is usually double-layered, so the blue circles represent the two layers of fibers of rice straw and ω represents the rotational angular velocity of the tool.

Ft must be large enough to ensure that the tool cuts the stubble effectively, and Fn should be as small as possible to minimize the friction and entanglement adhesion between the tool and the stubble and soil. Therefore, to ensure the tangential component force Ft and normal component force Fn reach an ideal balance, the tangential component force accounts for 60% of the cutting force.

The tool inclination angle θ enables 60% of the tools to act on the cut, while 40% acts as a normal component force.

Based on the above requirements, this value can be calculated by Equation (3). , i.e., .

The inclination angle θ of the antisticking tool was calculated at Fcut = 2620 N to be θ = 36.87° and thus can be calculated from Equations (3) and (4): ,.

Under the shear strength σs of 5.24 MPa and the tool inclination angle θ = 36.87°, the tangential component force Ft of the antistalking tool is 1572 N, and the normal component force Fn is 2096 N. A large tangential component force can help to cut the stubble, while the control of the normal component force is as limited as possible to reduce the phenomenon of the adhesion and entanglement of the stubble and the soil entanglement on the tool.

2.3. Antitangling and Sticking Tool Simulation Test Method

2.3.1. Finite Element Analysis of Antisticking Tools

Given that the antisticking blade affects objects such as weeds, straws, and stones in harsh environments, static simulation must be conducted to analyze whether its strength meets the basic standard requirements. First, a high-quality 65 Mn steel material is chosen for the antistalking blade. Scientific heat treatments give a blade surface hardness of HRC48~56 and a core hardness of HRC30~40, effectively extending the service life of the blade and ensuring that the blade still has high wear resistance and impact toughness in harsh working environments. Therefore, when working with the material data, it is necessary to select 65 Mn steel and set the material’s properties. These material parameters are shown in Table 2.

Table 2.

65 Mn steel property parameters.

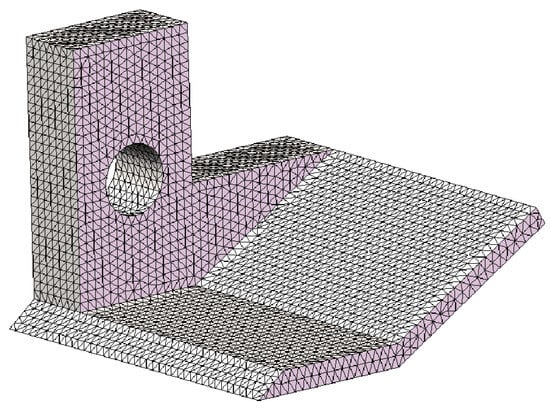

Second, the antisticking tool is meshed with a tetrahedral meshing mode because of its simple structure. To integrate the simulation accuracy and computer processing time, the appropriate grid size, usually a grid size of 2 mm, must be set. The antisticking tool mesh division is shown in Figure 6; the total number of nodes in the model after the division is 73,126, and the total number of cells is 47,412.

Figure 6.

Antitangling tool mesh model.

Once the meshing process is complete, constraints and loads must be applied. During operation, the rotary tillage cutter is bolted to the knife handle and knife seat; thus, fixed constraints are applied to the handle of the antisticking cutter during the hydrostatic simulation. The entire cutting edge of the tool, along with the tilting baffle, comes into contact with soil and straw during plowing. Therefore, a force of 500 N, parallel to the cutting direction, is applied to the entire cutting edge and tilting baffle. Finally, total deformation and stress analysis is performed using the Solutionsolver module for computational analysis.

Figure 7a shows that the maximum deformation of the antisticking tool is 9.251 × 10−5 mm at the tip of the tilting baffle, and its deformation gradually decreases from the tip of the tilting baffle to the shank, and the deformation at the shank is the smallest. As shown in Figure 7b, the maximum value of the stress of the antisticking tool is concentrated in the connection between the shank and the tilting flap, which is 1.568 × 10−1 MPa, and the stress gradually decreases from the cutter body to the outer extension. Comparison results show that the maximum stress of the antisticking tool is much lower than the permissible stress of the material. There is no large deformation in the deformation cloud diagram and no repeated stress, and so it meets the design requirements and fatigue strength requirements.

Figure 7.

Static analysis of antisticking tools: (a) deformation cloud map and (b) stress cloud map.

2.3.2. Discrete Metamodeling of Soil Straw

In discrete element simulation, the particle contact model is one of the core factors that determine simulation accuracy and realism. Contact models have two main types, namely, nonbonded contact force models and bonded contact force models, and each model is suitable for different application scenarios and simulation requirements. The selection of a suitable contact force model is crucial for the result accuracy and computational efficiency of the simulation. The basic principle of EDEM discrete element simulation is simulating the soil particle model with a ball. The radius of the soil particles is set to 8.8 mm, and the grid method is used to produce a model with a density ρ of 1800 kg/m3. The soil tank size used in the simulation is 2000 mm × 1000 mm × 300 mm, and the soil particles are produced by particle engineering to fill in the soil tank model.

In this study, the Hertz–Mindlin model with bonding is used in EDEM2024 according to the characteristics of wet and sticky soils in the southern Jianghuai River [26]; when this model is used, the bonding action forms a constraint between the soil particles, and this constraint causes tangential and normal forces to act between the particles. These two kinds of forces play a major role in the operation, which continues until the forces between the soil particles invalidate this constraint, followed by action between the soil particles. The Hertz–Mindlin model with bonding contact has been used extensively in clay and wet soils with high water content due to the presence of the bonding mechanism. The external normal bonding force Fn, normal moment Mn, tangential bonding force Fτ, and tangential moment Mτ on the soil are calculated as follows:

where , . Fn and Fτ denote bond normal and tangential force, N, respectively; Mn and Mτ denote bond normal and tangential torque, N∙m, respectively; Sn and Sτ denote bond normal and tangential stiffness, N/m3, respectively; A denotes the contact area, m2; and Rb denotes the bond radius, mm.

When, at some point, the external forces exceed the maximum tangential and normal forces of the soil bond, the bond breaks, and the interaction forces between soil particles are not constrained by the bonding action. The defining condition is as follows:

where δmax denotes the normal critical stress, Pa and τmax denotes the tangential critical stress, Pa.

The Hertz–Mindlin model with bonding contact has five parameters, namely, particle normal bond stiffness Sn, tangential bond stiffness Sτ, bonded particle normal critical stress δmax, tangential critical stress τmax, and particle bonding radius Rb. Usually, the bonding radius can be derived from the known conditions, which are mainly derived from the radius of the soil particles and the corresponding soil density and moisture content. Given that the remaining soil parameters are not conveniently measured using experiments, this study draws on the results of other researchers in this area and determines the remaining parameters [27], as shown in Table 3.

Table 3.

Material performance parameters and contact parameters.

In accordance with the straw morphology and in consideration of the uniformity of particle arrangement and simulation time length, the diameter of the rice straw particle model is set to 6 mm. Moreover, this study determines the relevant parameters of rice straw based on the experimental data and related literature [28], as shown in Table 4.

Table 4.

Rice straw parameters and contact parameters.

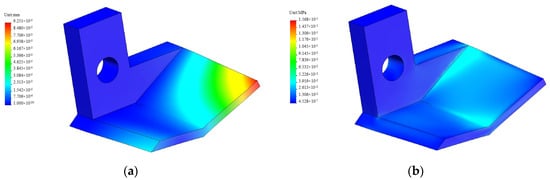

The discrete element rice straw model is decomposed into interconnected spherical particles using the above parameters. The current straw model is generally assumed to be immutable when simulated using the discrete element software, but this model cannot simulate the crushing state of the straw after interacting with the workpiece. Therefore, this study adopts the Hertz–Mindlin model with bonding to model the rice straw using particle bonding. When bonding, the size of the particles cannot be too large or too small, as this leads to inaccurate results in the simulation process. Too small a size increases the workload and the simulation time. Compared to other models such as the Hertz–Mindlin (no slip) model, which does not capture the properties of this paper under wet clay soils, the use of the Hertz–Mindlin model with bonding has been widespread and is a better representation of the bonding properties compared to other models. The parameters described in this study provide the necessary basis for the construction of the model and ensure the accuracy and reliability of the simulation results. The discrete element model is built, as shown in Figure 8a.

Figure 8.

Discrete element model: (a) discrete element soil straw modeling; (b) work process of rotary tiller.

2.3.3. Simulation

The forward speed of the rotary tillage knife model was set as 0.5 m/s, which was used to simulate the forward speed of the rotary tillage test. The height of the knife roller was adjusted to set the plowing depth as 100 mm and the speeds of the cutter shaft as 150, 200, 250, and 300 r/min. The rotary tillage machine’s working status was divided into forward and reverse rotation, the soil-cutting process of the rotary tillage knife was top-down during the forward operation, and under the action of the cutting tension, the straw became easier to break. Therefore, the simulation model was set to positive rotation. In addition, the simulation comparison test was set up, and the above steps were repeated with the China standard IT245 rotary plow knife.

The total duration of the simulation was set to 4 s; this was divided into two distinct phases. In the first phase (0–1 s), the 100,000 soil particles required for the simulation were generated using the particle factory. In the second phase (1–4 s), the forward speed of both types of rotary tillage knives was set to 0.5 m/s to conduct the simulation test. The data-saving frequency was set to 0.001 s. A total of 10 simulation tests were performed to compare the performance of the rotary tillage knives with and without antisticking knives. The working process of the rotary tillage knives is illustrated in Figure 8b, particle velocities are shown in blue and red, respectively, from the lowest to the fastest.. According to previous strength analyses, comprehensive consideration of computer performance and computational efficiency is necessary in order to better simulate realism. If the tool is strong enough to meet the requirements of a case, as far as possible, in response to the actual application of the case, simulation intensity should be reduced.

2.4. Field Trial

This experiment was conducted in a rice field in Pukou District, Nanjing City, Jiangsu Province, China. Since the rotary tillage operation time is certain after the rice harvest, the soil type and moisture content at that time period are certain, as shown in Figure 9, which shows the state of rotary tillage operation of the tractor in the rice field. After the operation was completed, six sampling units were randomly selected, the corresponding data were measured, and the data were averaged to more accurately assess the performance of the machine [29].

Figure 9.

Rotary tillage operations in the field.

2.4.1. Average Torque

In the single test, antisticking knives were installed on the rotary tiller knife rollers, the rotary tiller knife shaft speed was set at the four speeds of 150, 200, 250, and 300 r/min, the forward speed was constant at 0.5 m/s, the plowing depth was kept at 100 mm, and the torque of the rotary tiller knives on the knife shafts in the test was measured. The test was repeated three times for each operating condition, and the average value of the three times was taken as the test result for each operating condition.

2.4.2. Operating Efficiency

A tape measure was used to measure the effective straight-line operating distance D of the prototype, and a stopwatch was used to measure the time t used for this operating distance. The measurements were repeated six times, and then Equation (11) was used to calculate the operating efficiency Q of the tangle-resistant sticking-type weed-crushing and returning machine. Finally, the average value was calculated on the basis of the six sets of calculated operating efficiencies, i.e., the average operating efficiency of the antitangle-resistant sticking-type straw-crushing and -returning machine in the rice paddy field.

where W is the value of the operating width of the crushing and returning machine, m; D is the value of the operating distance of the crushing and returning machine, m; T is the value of the operating time of the crushing and returning machine, s; and Q is the value of the operating efficiency of the crushing and returning machine, hm2/h.

2.4.3. Operational Pass Rate

Six test areas (1 m × 1 m) were sampled, as shown in Figure 10.

Figure 10.

Rice field test site.

First, a weighing balance was used to weigh the mass M of all the crushed weeds in each test area. All weeds whose length was greater than 100 mm were selected, and mass M1 was determined; then, Equation (12) was used to calculate the operation pass rate φ of each test area of the antistalking straw crusher and rice returner; finally, in accordance with the average of the six groups of the calculated operation pass rate, i.e., the average operation pass rate of the antistalking straw crusher and rice returner in the rice field, Equation (12) was used to calculate the operation pass rate of antistalking straw crusher and rice returner. The formula is as follows:

where M is the value of the total mass of weeds in the test area, g; M1 is the value of the total mass of unqualified straw in the test area, g; and φ is the qualified rate of operation of the crushing and returning machine.

3. Results

3.1. Kinetic Analysis

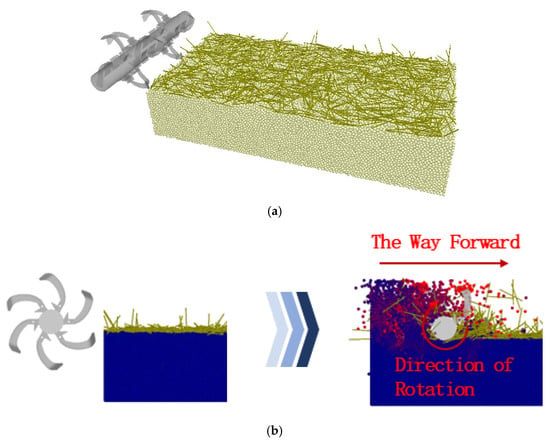

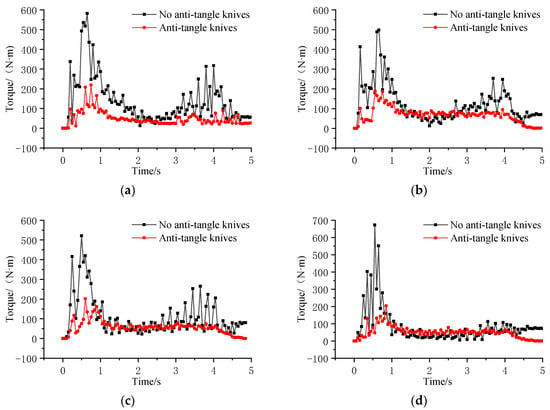

3.1.1. Torque Trend

The results show that torque on the rotary tillage knife shaft increases with rotational speed, requiring more power. The simulation identifies four stages: (1) torque rises from zero as the side cutting edge enters the soil, spiking sharply when the main cutting edge engages; (2) torque peaks at maximum plowing depth; (3) torque gradually decreases as the blades withdraw; and (4) torque returns to zero after complete soil exit. Data was collected over 0–5 s at 0.05 s intervals (100 points total) to account for varying rotation times across the tested speed range (150–300 r/min).

The torque point line diagrams of the two tools obtained by simulation are shown in Figure 11. The torque produced by the antisticking tool is considerably smaller than that of the nonsticking tool; both tools exhibit instantaneous peak torques within 0–1 s due to the initial impact load upon soil entry. Multiple peaks appear in the nonsticking tool, reflecting intermittent soil engagement and periodic root entanglement resistance. At 150 r/min, the antisticking tool’s maximum torque is 218.8 N∙m compared to a value of 581.7 N∙m for the nonsticking tool; its torque is consistently lower, showing clear drag reduction. At 200 r/min, the antisticking tool reaches a maximum torque of 188.9 N∙m versus 497.7 N∙m for the nonsticking tool, with slightly higher torque in 1.5–2.5 s but an overall smoother profile and clear drag reduction. At 250 r/min, the maximum torques are 201.5 N∙m (antisticking) and 521.5 N∙m (nonsticking), with similar torque values from 1 to 2.5 s but a gentler overall trend for the antisticking tool, emphasizing its drag-reducing advantage. At 300 r/min, the antisticking tool achieves 203.6 N∙m, significantly lower than the value of 672.4 N∙m achieved for the nonsticking tool, though torque remains relatively constant in 1–5 s, making drag reduction less evident during this interval.

Figure 11.

Torque variation curves of the rototiller with and without antisticking knives at four axle speeds: (a) 150 r/min, (b) 200 r/min, (c) 250 r/min, (d) 300 r/min.

3.1.2. Average Torque Trend

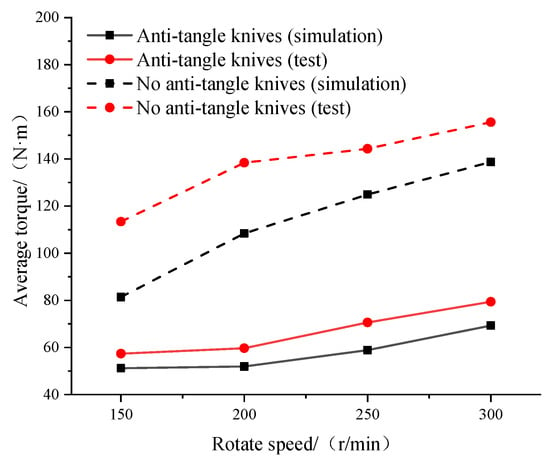

The torque pattern of the two types of tools was further analyzed by averaging the torque of the tool axis from 0 to the peak and then to 0 during the simulation (Table 5). At 150 r/min, the average torque is 51.2 and 81.4 N∙m for the antisticking tool and the nonsticking tool, respectively; at 200 r/min, the average torque is 51.9 and 108.4 N∙m for the antisticking tool and the nonsticking tool, respectively; at 250 r/min, the average torque is 58.9 and 58.9 N∙m for the antisticking tool and the nonsticking tool, respectively; and at 250 r/min, the average torque is 58.9 and 58.9 N∙m for the antisticking tool and the nonsticking tool, respectively. At 250 r/min, the average torque was 58.9 and 124.9 N∙m for the antisticking tool and nonsticking tool, respectively, and at 300 r/min, the average torque was 69.3 and 138.7 N∙m for the antisticking tool and nonsticking tool, respectively, and the average torque for the antisticking tool was even smaller, with decreases of 37.1%, 52.1%, 52.8%, and 50.0%, respectively.

Table 5.

Average torque simulation values at four spindle speeds with and without antisticking tools.

The simulation results show that in the typical operating speed range (150–300 r/min), the antisticking tool exhibits better dynamics than the national standard rotary cutter. When the rotational speed of the cutter shaft was set to 150, 200, 250, and 300 r/min, the working torque of the antisticking tool was maintained at a lower level, and its torque fluctuation amplitude was reduced by 37.1–52.8% compared with that of the conventional tool. This improvement in mechanical properties is due to the optimized design of the antistalking structure, which effectively reduces the cutting resistance and soil straw adhesion rate through the synergistic effect of the cutting edge and the tilting baffle, which is consistent with the demand to reduce the power consumption of agricultural machinery in actual production. The average torque variation reduction rate of the antistalking tool under different working conditions is shown in Figure 12.

Figure 12.

Average torque reduction rate for antisticky tool simulation.

3.2. Field Trial Analysis

The test results show that the rice straw-crushing rate of the antistalking rotary tillage knife increased in comparison with the traditional rotary tillage knife operation, and the crushing effect is shown in Figure 13. Moreover, the winding of the knife roller, the winding of the straw was reduced, the antistalking effect had great improvement, and the rice straw was only partially entangled. After the experimental test, the average operating efficiency of the antistalking tool is 0.57 hm2/h, and the operation pass rate is 95.72%.

Figure 13.

Antisticking rotary tiller operation: (a) before rotary tillage, (b) after rotary tillage.

The average torque obtained by averaging the results of three sets of tests for each speed is shown in Table 6.

Table 6.

Mean torque applied to field trials with and without antisticking tools.

As shown in Table 6, when the operating conditions are the same, the average torque gradually increases with the increase in the knife shaft speed, which is consistent with the actual torque change of the tool. The torque of the antitangling and sticking tool is much smaller than that of the nontangling and sticking tool, which is due to the adhesion of sticky and wet soil and the entanglement of straw. Given the friction and interference torque between the transmission parts of the rotary tiller in the field test, the torque collected in the field test is biased, and the test value is always larger than the simulation value.

As shown in Figure 14, comparing the simulated and experimental mean torque curves with and without the antisticking tool showed that the correlation coefficient between the simulated and experimental mean torque curves for the antisticking tool was 0.994, with a maximum relative error of 16.6% from the simulated curve. This may be due to the simplification of the contact parameter of the viscous particles in the discrete element model of the soil. By contrast, the simulation test correlation coefficient for the nonsticky tool was 0.973, with a maximum relative error of 28.2%, which is due to the presence of debris and large clods in the soil and the interference between the components in the rotary tiller in the field test.

Figure 14.

Simulation and test average torque trends with and without antitangle tools.

4. Discussion

At present, there are many studies related to the antitangling problem faced by rotary tiller operation knife rollers. This paper designs a kind of antitangling knife for more effective operation in wet and sticky soil. At present, other scholars’ studies mainly discuss the relationship between the knife and the soil alone or between the knife and the straw directly, and studies combining the knife–soil–straw topics are relatively less common. In simulation experiments, the problem of the soil particles sticking is less researched. There are fewer studies, and most of the knives designed are vertical knives, which only increases the cutting strength, but the adhesion phenomenon still occurs in the sticky and wet soil environment. This paper combines these problems, considers the combination of the three in the simulation environment, and addresses the problem of soil particle adhesion. The designed knives greatly improve the soil adhesion situation. Field tests show that the antiadhesion cutter has a better working performance compared with the national standard rotary plow cutter and meets the working requirements in sticky and wet soil.

The antitangling cutter designed in this paper marks a big improvement on the existing studies in this field. Zhu [30] designed a kind of slant-cut-stubble side-throw antiblocking device via the slant-cut method of cutting the surface of the straw and stubble and throwing them onto both sides of the seedling belt to complete the function of antiblocking. The stubble breaking rate in the field test is 92.89%. The antistalking cutter designed in this paper reaches 95.72% efficiency in field tests; the operational efficiency is better than that of the design of Li Yue and others for a fixed dumping knife antitangling banana straw-crushing machine. They used the fixed-knife dumping knife design and layout to complete the crushing of straw and knife roller antitangling. The optimization of the placement of the fixed dumping knife only increases the cutting of straw. In the viscous and wet soil, the fixed dumping knife antitangling banana straw-crushing machine variant of the straw-crushing machine cannot prevent the soil stalks from becoming entangled in the knife rollers during field experiments. In the field experiment, the qualified rate of the fixed dumping knife antistalking banana straw crusher and returner was 94.9%, which was smaller than the operating efficiency of the antistalking knife designed in this paper. Therefore, combined with the existing research, the antitangling knife designed in this paper can improve the operating efficiency of the rotary tiller and achieve the effect of antitangling with regard to the knife roller.

5. Conclusions

- (1)

- An antistalking tool was designed, and the working principle of the tool was elaborated. Through motion force analysis, the blade inclination of the antistalking tool, which has strong crushing ability and soil planing ability, was designed. Compared to other related studies, this tool is more effective for the antitwisting of knife rolls in wet clay soils.

- (2)

- The finite element analysis of the antisticking tool verified that the tool can meet the actual working requirements and the design of the antisticking tool effectively solved the problems of soil adhesion and straw entanglement.

- (3)

- Using the discrete element simulation technique, combined with the establishment of the tool–soil–straw mutual contact model, a simulation study was carried out to investigate the operation process of the tool with or without antisticking properties at a forward speed of 0.5 m/s and a plowing depth of 100 mm. The torque of the tool with and without antistalking tool was analyzed under four different working conditions, i.e., the rotational speed of the knife shaft was 150, 200, 250, and 300 r/min, and the results showed that the average torque with the antistalking tool was smaller than that of the tool without antistalking tool, with obvious decreases of 37.1%, 52.1%, 52.8%, and 50.0%, respectively.

- (4)

- The field test showed that the knife roller basically did not undergo entanglement; for the tool to meet the rotary tillage operation needs of the rice field with sticky and wet soil, the average operating rate was 0.57 hm2/h and the operation of the pass rate was 95.72%.

- (5)

- Field tests were conducted under the same working conditions, and the basic laws of torque changes of two kinds of rotary tillage knives under four working conditions were obtained. The average torque of the simulation and test of the two kinds of rotary tillage knives under four knife shaft speeds were analyzed, and the correlation coefficients of the average torque change curves with and without antisticking knives were obtained, i.e., 0.994 and 0.973, respectively. These results verified the accuracy of the simulation model and the consistency between the simulation and the field test.

Author Contributions

The four authors developed the research approach together. Conceptualization and methodology, G.G.; writing—original draft preparation, T.C.; writing—review and editing, M.X.; software and formal analysis, C.X. project administration and methodology C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by a program of China’s National Natural Science Foundation Project (Grant No. 52375251) and the Jiangsu Modern Agricultural Equipment and Technology Demonstration and Promotion Project (Grant No. NJ2023-02).

Data Availability Statement

Data will be made available on request.

Acknowledgments

This study received technical support from the College of Engineering in Nanjing Agriculture University, including the licensed software of EDEM.

Conflicts of Interest

Author Cungan Tang was employed by the company Jeegee Agri Equip Manufacturing Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, Z.; Sun, D.; Li, T.C. Effects of Water-Saving Irrigation and Reducing Phosphorus Fertilizer on Rice Yield, Phosphorus Utilization and Soil Phosphorus Balance in Black Soil. Trans. Chin. Soc. Agric. Eng. 2022, 38, 67–74. [Google Scholar]

- Wu, T.; Cai, W.; Song, X.; Tan, Y. Research on the Influence of Cutter Roll Optimization of Rotary Tiller on Its Operation Performance. J. Phys. Conf. Ser. 2023, 2419, 012016. [Google Scholar] [CrossRef]

- Sun, N.N.; Wang, X.Y. Design and Experiment of Differential Sawing Rice Straw Chopper for Turning to Field. Trans. Chin. Soc. Agric. Eng. 2019, 35, 267–276. [Google Scholar]

- Zhang, X.Y.; Wang, Z.Q.; Li, Y.; Liang, D. Design and Experiment of Sliding-Cutting and Anti-Twining Returningdevice for Banana Straw. Trans. Chin. Soc. Agric. Eng. 2018, 34, 26–34. [Google Scholar]

- Zhang, X.Y.; Yang, Y.M. Optimal Design and Experiment of Double Fixed Knife Slip-Cuttingand Anti-Tangle Banana Straw Crushing and Returning Machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 36–49. [Google Scholar]

- Li, Y.; Guo, C.F.; Yao, D.Y. Design and Experiment of Banana Straw Crushing and Returning Machinewith Anti-Wrapping Device Supported by Flailing Blade. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar]

- Shi, R.J.; Dai, F.; Zhao, W.Y.; Liu, X.L. Analysis of the Anti-Winding Mechanism for the Interaction between Flaxstem and Harvest Header in Hilly Area. Trans. Chin. Soc. Agric. Eng. 2025, 41, 11–19. [Google Scholar]

- Du, J.; Heng, Y.; Zheng, K.; Luo, C.; Zhu, Y.; Zhang, J.; Xia, J. Investigation of the Burial and Mixing Performance of a Rotary Tiller Using Discrete Element Method. Soil Tillage Res. 2022, 220, 105349. [Google Scholar] [CrossRef]

- Li, X.; Du, Y.; Liu, L.; Mao, E.; Wu, J.; Zhang, Y.; Guo, D.A. Rapid Prototyping Method for Crop Models Using the Discrete Element Method. Comput. Electron. Agric. 2022, 203, 107451. [Google Scholar] [CrossRef]

- Yan, D.; Yu, J.; Wang, Y.; Zhou, L.; Sun, K.; Tian, Y. A Review of the Application of Discrete Element Method in Agricultural Engineering: A Case Study of Soybean. Processes 2022, 10, 1305. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Modeling of Soil–Claw Interaction Using the Discrete Element Method (DEM). Soil Tillage Res. 2016, 158, 177–185. [Google Scholar] [CrossRef]

- Shi, Y.; Xin, S.; Wang, X.; Hu, Z.; Newman, D.; Ding, W. Numerical Simulation and Field Tests of Minimum-Tillage Planter with Straw Smashing and Strip Laying Based on EDEM Software. Comput. Electron. Agric. 2019, 166, 105021. [Google Scholar] [CrossRef]

- Fang, H.M.; Ji, C.Y. Simulation Analysis of Straw Movement in Straw-Soil-Rotary Blade System. Trans. Chin. Soc. Agric. Mach. 2016, 47, 60–67. [Google Scholar]

- Wang, Z.; Li, X.; Li, J.; Qiu, Y.; Gu, T.; Wang, H. Analysis of the Interaction Mechanism between Straw Soil Rotary Tillage Blade during Rotary Tillage Process. Sci. Rep. 2025, 15, 691. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, Y.; Gao, X.; Bi, Y.; Dong, J.; Zhao, H.; Zhao, P.; Jia, X. Evaluating the Influence of Straight-Plain Types of Rotary Tiller Blades with Various Edge Curves on Maize Residue Using DEM. Biosyst. Eng. 2025, 250, 49–61. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, M.; Yu, C.; Yu, Z.; Kuang, F.; Xiong, W.; Xue, K. Tool-Straw-Paddy Soil Coupling Model of Mechanical Rotary-Tillage Process Based on DEM-FEM. Comput. Electron. Agric. 2023, 215, 108410. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, M.; Chen, W.; Yuan, D.; Wu, C.; Zhu, J. Simulation Analysis and Experiments for Blade-Soil-Straw Interaction under Deep Ploughing Based on the Discrete Element Method. Agriculture 2023, 13, 136. [Google Scholar] [CrossRef]

- Horner, D.A.; Peters, J.F.; Carrillo, A. Large Scale Discrete Element Modeling of Vehicle-Soil Interaction. J. Eng. Mech. 2001, 127, 1027–1032. [Google Scholar] [CrossRef]

- Milkevych, V.; Munkholm, L.J.; Chen, Y.; Nyord, T. Modelling Approach for Soil Displacement in Tillage Using Discrete Element Method. Soil Tillage Res. 2018, 183, 60–71. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Y.; Sadek, M.A. Modelling of Soil–Seed Contact Using the Discrete Element Method (DEM). Biosyst. Eng. 2014, 121, 56–66. [Google Scholar] [CrossRef]

- GB/T 5669-2017; National Technical Committee for Standardization of Agricultural Machinery (SAC/TC 201) Rotary Tiller—Rotary Blades and Blade Holders. 2017. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT5669-2017 (accessed on 20 April 2025).

- Zheng, K.; McHugh, A.D.; Li, H.; Wang, Q.; Lu, C.; Hu, H.; Liu, W.; Zhang, Z.; Liu, P.; He, J. Design and Experiment of Anti-Vibrating and Anti-Wrapping Rotary Components for Subsoiler Cum Rotary Tiller. Int. J. Agric. Biol. Eng. 2019, 12, 47–55. [Google Scholar] [CrossRef]

- Xie, C.; Wei, W.; Zhu, Y.; Xiao, M.; Chen, T. Wear Reduction Damage Mitigation and Operational Reliability Analysis of Rotary Tiller Knives Based on the Self-Excited Vibration Theory. Comput. Electron. Agric. 2025, 231, 109991. [Google Scholar] [CrossRef]

- Karoonboonyanan, S.; Salokhe, V.M.; Niranatlumpong, P. Wear Resistance of Thermally Sprayed Rotary Tiller Blades. Wear 2007, 263, 604–608. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, Y.; Tang, Y.; Luo, W.; Ye, Z. Analysis of Blockage and Wrapping by Leaves in the Cutting Mechanism of a Sugarcane Leaf Shredder. Biosyst. Eng. 2021, 211, 152–166. [Google Scholar] [CrossRef]

- Shi, J.; Shan, Z.; Yang, H. Research on the Macro- and Meso-Mechanical Properties of Frozen Sand Mold Based on Hertz-Mindlin with Bonding Model. Particuology 2024, 88, 176–191. [Google Scholar] [CrossRef]

- Xiao, M.; Niu, Y.; Wang, K. Design of Self-Excited Vibrating Rotary Tiller and Analysis of Its Performance in Reducing Torsion and Consumption. Trans. Chin. Soc. Agric. Mach. 2022, 53, 52–63. [Google Scholar]

- Xia, J.; Zhang, P. Calibration and Verification of Flexible Rice Straw Model by Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 174–184. [Google Scholar]

- Li, Z.; Li, Y. Design and Experiment of the Banana Stalk Crushing and Returning Machine with Lengthways Double Rollers Type. J. Chin. Agric. Mech. 2020, 41, 180–184. [Google Scholar] [CrossRef]

- Zhu, A.; Xu, C.; Liu, Y.; Wang, J.; Tan, X. Design and Experiment of Oblique Stubble-Cutting Side-Throwing Anti-Blocking Device for No-Tillage Seeder. Agriculture 2024, 14, 2250. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).