Different Effects of Irrigation Water Salinity and Leaching Fractions on Pepper (Capsicum annuum L.) Cultivation in Soilless Culture †

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Area, Plant Material and Growing Substrate

2.2. Irrigation, Leaching Fractions (LR) and Salinity Rates (S)

2.3. Measurements and Calculations

3. Results and Discussion

3.1. Meteorological Measurements inside the Greenhouse

3.2. Plant–Water Relationships

3.2.1. Evapotranspiration (ET) and Yield Values

3.2.2. Water Use Efficiencies (WUEs)

3.3. Results on Yield, Vegetative Growth and Selected Fruit Quality Characteristics

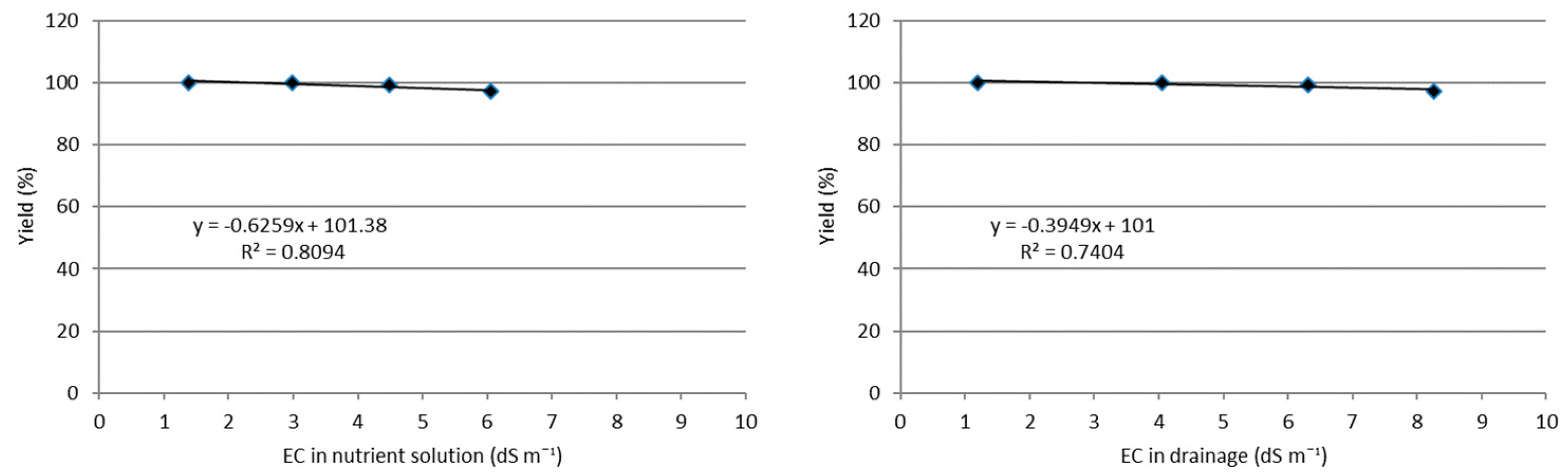

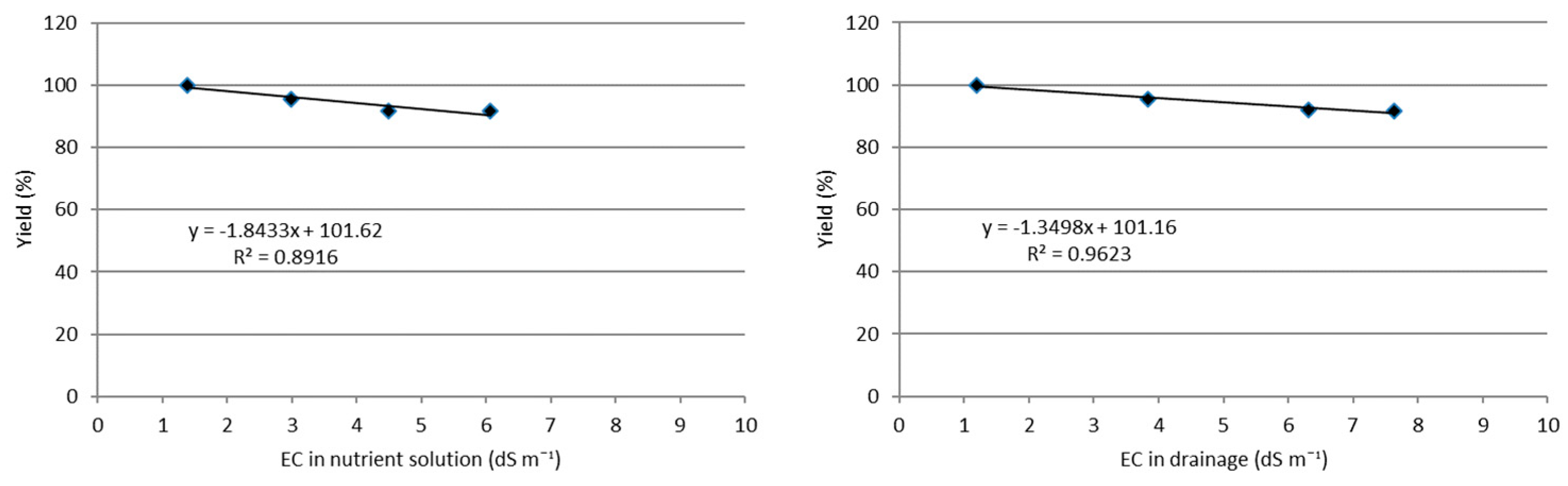

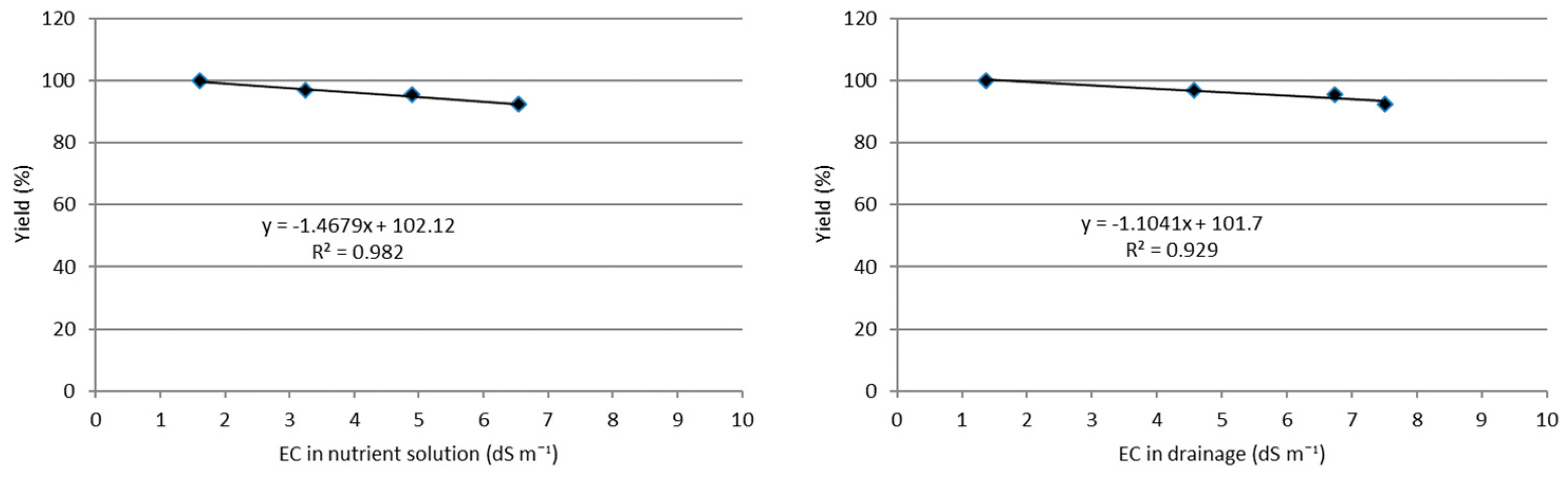

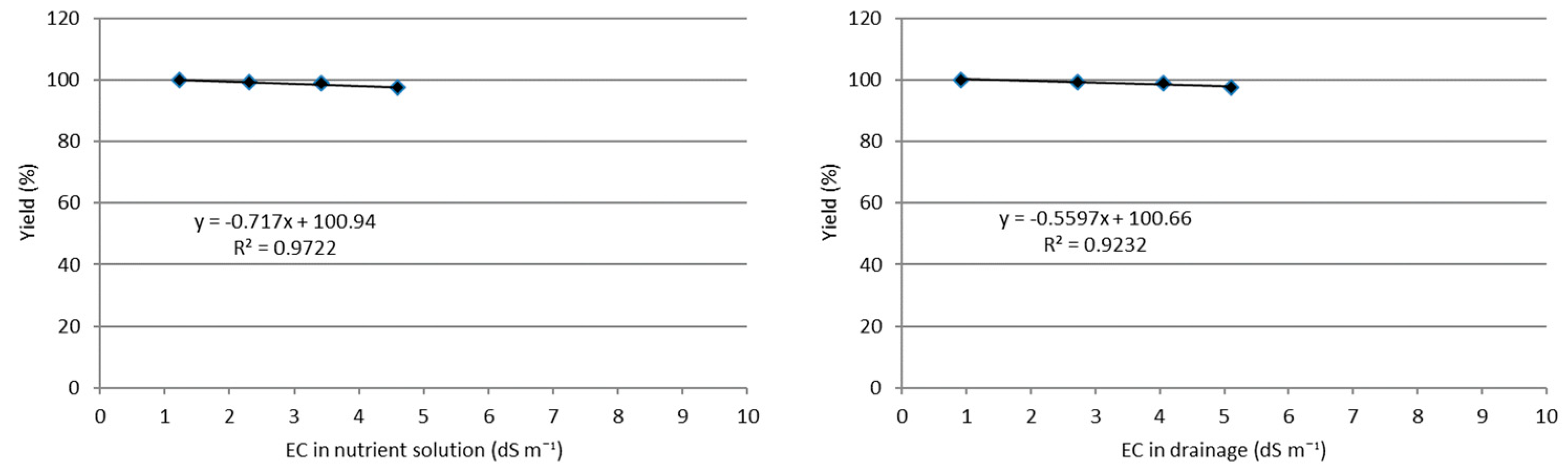

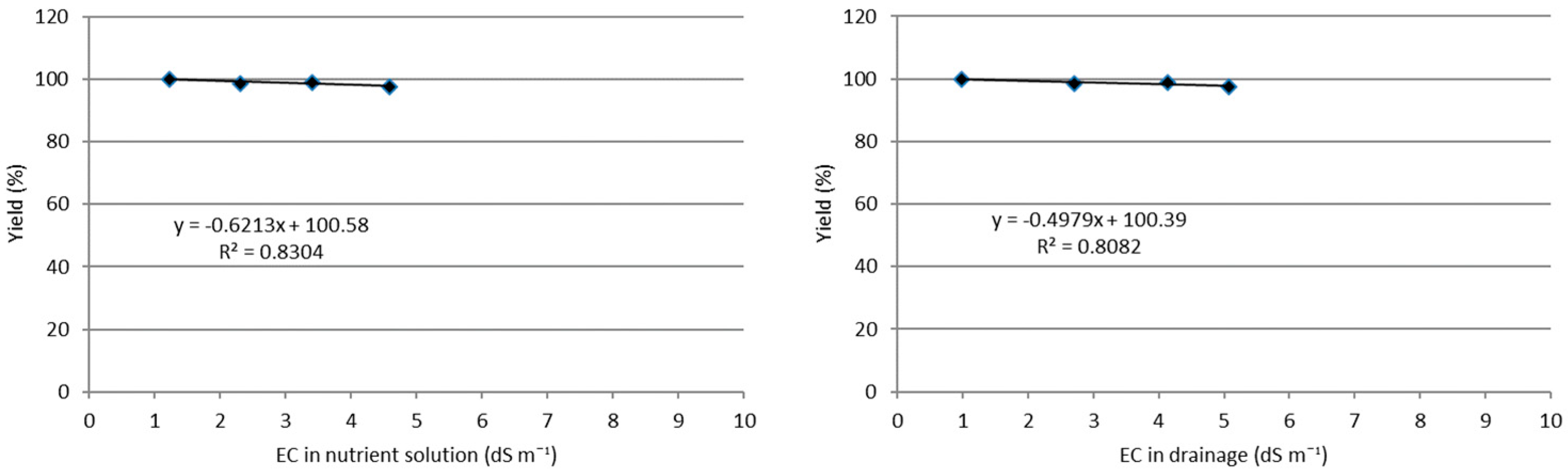

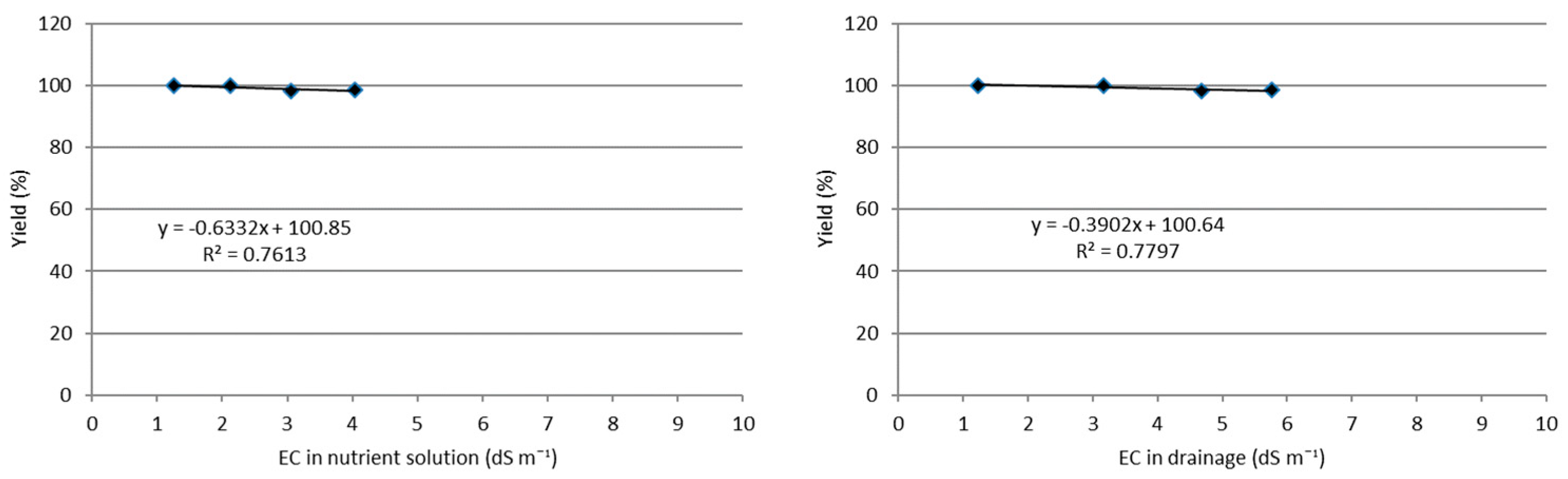

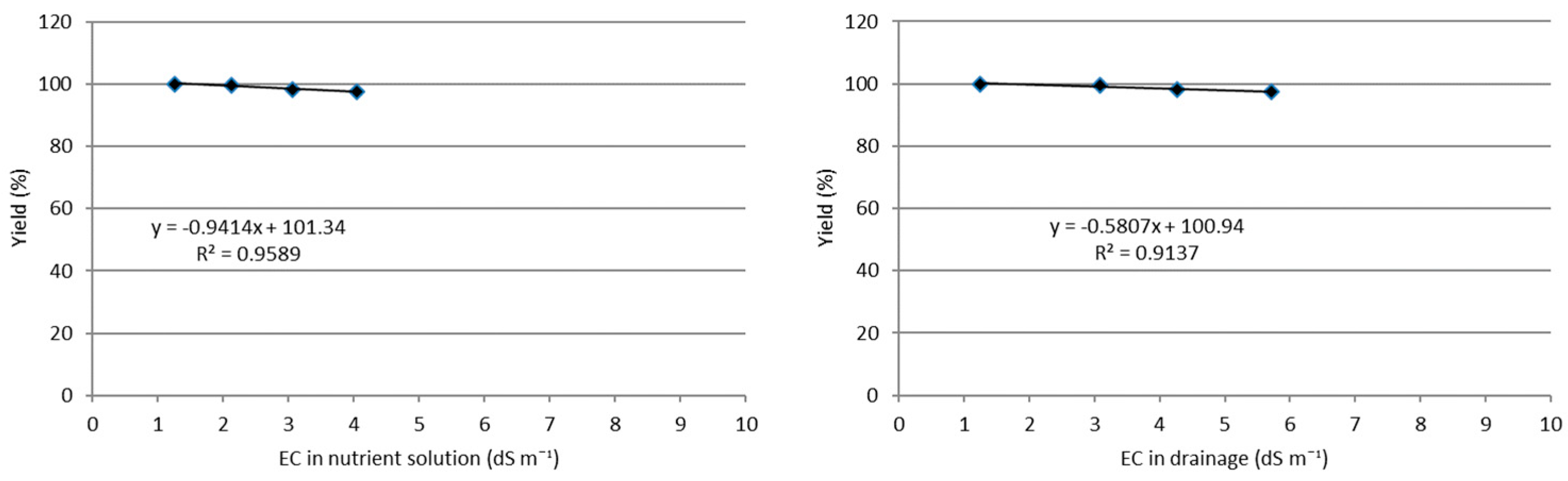

3.3.1. Yield

Fruit Weight

Number of Fruits per Unit of Area

3.3.2. Vegetative Development

Plant Height

Plant Stem Diameter

3.3.3. Selected Fruit Quality Characteristics

Fruit’s Dry Matter Content

Amount of Water-Soluble Dry Matter

EC Value of Fruit Juice

The pH Value of the Juice

Amount of Titratable Acid

Vitamin C

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hale, M.G.; Orcutt, D.M. The Physiology of Plants Under Stress; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1987; 206p. [Google Scholar]

- Sivritepe, N.; Eriş, A. Studies on Salt Resistance in Grapevines and Some Factors Affecting Salt Resistance. In Proceedings of the 4th Viticulture Symposium, Yalova, Turkey, 20–24 October 1998; Book of Proceedings. pp. 56–63. [Google Scholar]

- Sonneveld, C. Effects of Salinity on Substrate Grown Vegetables and Ornamentals in Greenhouse Horticulture. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2001; 151p. [Google Scholar]

- Sevgican, A. Covered Vegetable Gardening (Soilless Agriculture); Volume-II; Faculty of Agriculture, Ege University Publications: Izmir, Turkey, 2002. [Google Scholar]

- Quamme, H.A.; Stushinoff, C. Resistance to Environmental Stress. In Methods in Fruit Breeding; Moore, J.N., Janick, J., Eds.; Purdue University Press: West Lafayette, India, 1983; pp. 242–266. [Google Scholar]

- Akat, O. The Effects of Different Salinity Levels and Leaching Rates on Gerbera Plant Growth, Yield, Quality and Water Consumption. Ph.D. Thesis, Institute of Science and Technology, Ege University, Izmir, Turkey, 2008. [Google Scholar]

- Sonneveld, C.; Voogt, W. Chemical Analysis in Substrate Systems and Hydroponics—Use and Interpretation. Acta Hortic. 2001, 548, 247–259. [Google Scholar] [CrossRef]

- Sonneveld, C.; Baas, R.; Nijssen, H.M.C.; De Hoog, J. Effect of Salinity Substrate Grown Vegetables and Ornamentals in Greenhouse Horticulture. J. Plant Nutr. 2000, 22, 1033–1048. [Google Scholar] [CrossRef]

- Munns, R.; Termaat, A. Whole Plants Responses to Salinity. Aust. J. Plant Physiol. 1986, 13, 143–160. [Google Scholar] [CrossRef]

- Rhoades, J.D.; Kandiah, A.; Mashali, A.M. Chapter: 2, Saline Waters as Resources. In The Use of Saline Waters or Crop Production; FAO Irrigation and Drainage Paper, 48; Food and Agriculture Organization of The United Nations: Rome, Italy, 1992; pp. 5–10, 133. [Google Scholar]

- Grattan, S.R.; Hanson, B. Crop Salt Tolerance, Agricultural Salinity and Drainage Handbook for Water Managers; University of California Irrigation Program; University of California: Davis, CA, USA, 1993; pp. 5–10. [Google Scholar]

- Oztan, B. How Plants Benefit from Water in Saline Soils; Farmer Brochures Series; Ministry of Agriculture and Forestry of the Republic of Turkey: Ankara, Turkey, 1962. [Google Scholar]

- Gurgulu, H. Topraksız Tarımda Farklı Tuzluluk ve Yıkama Oranları Uygulanarak Yetiştirilen Biberde (Capsicum annuum L.) Su Tüketimi, Verim ve Bazı Meyve Kalite Parametrelerinin Belirlenmesi-Determination of Evapotranspiration, Yield and Some Quality Parameters of Pepper (Capsicum annuum L.) under Different Salt and Leaching Fractions in Soilless Culture. Ph.D. Thesis, Department of Agricultural Structures and Irrigation, Ege University, Izmir, Türkiye, 2015. [Google Scholar]

- Niemiec, M.; Chowaniak, M.; Sikora, J.; Szelag-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Selected Properties of Soils for Long-Term Use in Organic Farming. Sustainability 2020, 12, 2509. [Google Scholar] [CrossRef]

- Komorowska, M.; Niemiec, M.; Sikora, J.; Gródek-Szostak, Z.; Gurgulu, H.; Chowaniak, M.; Atilgan, A.; Neuberger, P. Evaluation of Sheep Wool as a Substrate for Hydroponic Cucumber Cultivation. Agriculture 2023, 13, 554. [Google Scholar] [CrossRef]

- Avadi, A.; Aissani, L.; Pradel, M.; Wilfart, A. Life cycle inventory data on French organic waste treatments yielding organic amendments and fertilisers. Data Brief 2020, 28, 105000. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szelag-Sikora, A. Evaluation of the chemical composition of raw common duckweed (Lemna minor L.) and pulp after methane fermentation. J. Elem. 2018, 23, 685–695. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szelag-Sikora, A.; Gródek-Szostak, Z.; Kubon, M.; Komorowska, M. The Effect of the Addition of a Fat Emulsifier on the Amount and Quality of the Obtained Biogas. Energies 2020, 13, 1825. [Google Scholar] [CrossRef]

- Caruso, G.; Villari, G.; Melchionna, G.; Stefano Conti, S. Effects of cultural cycles and nutrient solutions on plant growth, yield and fruit quality of alpine strawberry (Fragaria vesca L.) grown in hydroponics. Sci. Hortic. 2011, 129, 479–485. [Google Scholar] [CrossRef]

- Vanipriya, C.H.; Maruyi Malladi, S.; Gupta, G. Artificial intelligence enabled plant emotion xpresser in the development hydroponics system. Mater. Today Proc. 2021, 45, 5034–5040. [Google Scholar] [CrossRef]

- Smith, D.L. Rockwool in Horticulture; Grower Books: London, UK, 1987; 153p. [Google Scholar]

- Yurtseven, E.; Baran, H.Y. Effect of Irrigation Water Salinity and Water Amounts on Yield and Mineral Matter Content in Broccoli. Turk. J. Agric. For. 2000, 24, 185–190. [Google Scholar]

- Ozturk, A. The Effect of Saline and Normal Water Applied at Different Growth Periods on Some Characteristics and Salinity of Eggplant (Solanum melongena L.) Plant. J. Selçuk Univ. Fac. Agric. 2002, 16, 14–20. [Google Scholar]

- Chartzoulakis, K.; Klapaki, G. Response of Two Greenhouse Pepper Hybrids to NaCl Salinity During Different Growth Stages. Sci. Hortic. 2000, 8, 247–260. [Google Scholar] [CrossRef]

- Anonymous. 2013. Available online: http://www.altintohumculuk.com.tr/urunler (accessed on 8 July 2013).

- Karacali, I. Conservation and Marketing of Garden Products, 3rd ed.; Faculty of Agriculture, Ege University Publications: Bornova, Turkey, 2002; p. 469. [Google Scholar]

- Baille, A. Principles and Methods for Predicting Crop Water Requirements in Greenhouse Environments. CIHEAM-Options Mediterr. 1996, 31, 177–187. [Google Scholar]

- Kaman, H. Geleneksel Kısıntılı ve Yarı Islatmalı Sulama Uygulamalarına Bazı Mısır Cesitlerinin Verim Tepkileri. Ph.D. Thesis, Department of Agricultural Structures and Irrigation, Cukurova University, Adana, Türkiye, 1999; p. 53. [Google Scholar]

- Castilla, N.; Hernandez, J.; Abou Hadid, A.F. Strategic crop and greenhouse management in mild winter climate areas. Acta Hort. 2004, 633, 183–196. [Google Scholar] [CrossRef]

- Maas, E.V.; Hoffman, G.J. Crop Salt Tolerance-Current Assessment. J. Irrig. Drain. Div. ASCE 1977, 103, 115–134. [Google Scholar] [CrossRef]

- Katerji, N.; Van Hoorn, J.W.; Hamdy, A.; Mastrorilli, M. Salinity Effect on Crop Development and Yield Analysis of Salt Tolerance According to Several Classification Methods. Agric. Water Manag. 2003, 62, 37–66. [Google Scholar] [CrossRef]

- Saarinen, J.A.; Reinikainen, O. Peat Substrate and Self-Regulating Irrigation-an Environmentally Sound Method. Acto Hort. 1995, 401, 435–442. [Google Scholar] [CrossRef]

- Zheng, Y.; Graham, T.; Richard, S.; Dixon, M. Can Low Nutrient Strategies Be Used for Pot Gerbera Production in Closed-Loop Subirrigation. Acta Hortic. 2005, 691, 365–372. [Google Scholar] [CrossRef]

- Orgaz, F.; Fernandez, M.D.; Bonachela, S.; Gallardo, M.; Fereres, E. Evapotranspiration of Horticultural Crops in an Unheated Plastic Greenhouse. Agric. Water Manag. 2005, 72, 81–96. [Google Scholar] [CrossRef]

- Incrocci, L.; Malorgio, F.; Barola, A.D.; Pardossi, A. The Influence of Drip Irrigation or Subirrigation on Tomato Grown in Closed-Loop Substrate Culture with Saline Water. Scientia Hort. 2006, 107, 365–372. [Google Scholar] [CrossRef]

- Ekmekci, E.; Apan, M.; Kara, T. The Effect of Salinity on Plant Growth. J. Ondokuz Mayıs Univ. Fac. Agric. 2005, 20, 118–125. [Google Scholar]

- Grattan, S.R. How Plants Responds to Salt, Agricultural Salinity and Drainage; Hanson, B., Grattan, S.R., Fulton, A., Eds.; University of California Irrigation Programme; University of California Davis: Davis, CA, USA, 1993; pp. 3–5. [Google Scholar]

- Grattan, S.R.; Grieve, C.M. Mineral Nutrient Acquistion and Response by Plants Grown in Saline Enviroments. In Handbook of Plant and Crop Stress; Pessaraklı, M., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 1994; 696p. [Google Scholar]

- Pokluda, R.; Kobza, F. Effect of Climate Conditions on Properties of Hydroponic Nutrient Solution. Acta Hortic. 2001, 559, 611–617. [Google Scholar] [CrossRef]

- Meric, M.K. Comparison of Irrigation Programs and Plant Growing Systems in terms of Water Use Efficiency in Greenhouse Hydroponic Tomato Cultivation. Ph.D. Thesis, Institute of Science and Technology, Ege University, Bornova, Turkey, 2006. [Google Scholar]

- Rubio, S.; Rodrigues, A.; Saez, A.; Dizon, M.B.; Galle, A.; Kim, T.H.; Santiago, J.; Flexas, J.; Schroeder, J.; Rodriguez, P.L. Triple Loss of Function of Protein Phosphatases Type 2C Leads to Partial Constitutive Response to Endogenous Abscisic Acid. Plant Physiol. 2009, 150, 1345–1355. [Google Scholar] [CrossRef] [PubMed]

- Kesmez, G.D. The Effect of Potassium on Salt Resistance, Water Use and Vegetative Growth in Tomato (Lycopersicon esculentum) under Salinity. Master’s Thesis, Department of Agricultural Structures and Irrigation, Institute of Science and Technology, Ankara University, Ankara, Turkey, 2003. [Google Scholar]

- Cerda, A.; Bingham, F.T. Yield, Mineral Composition and Salt Tolerance of Tomato and Wheat as Affected by NaCl. Agrochimica 1978, 12, 140–149. [Google Scholar]

- Gungor, Y.; Yurtseven, E.; Artik, N. The Effect of Irrigation Water Salinity on Soybean Chemical Composition. TUBİTAK (Scientific and Technological Research Council of Turkiye). Doğa Turk. J. Agric. For. 1993, 17, 443–449. [Google Scholar]

- Sonmez, I.; Sonmez, S. Tuzluluk ve Gubreleme Arasındaki İliskiler: Relations Between Salinity and Fertilization. Tarımın Sesi Derg. (Voice Agric. Mag.) 2007, 16, 13–16. [Google Scholar]

- Irshad, M.; Yamamoto, S.; Eneji, A.E.; Endo, T.; Hona, T. Urea and Manure Effect on Growth and Mineral Contents of Maize Under Saline Conditions. J. Plant. Nutr. 2002, 25, 189–200. [Google Scholar] [CrossRef]

- Navarro, J.M.; Garrido, C.; Flores, P.M. The Effect of Salinity on Yield and Fruit Quality of Pepper Grown in Perlite. Span. J. Agric. Res. 2010, 8, 142–150. [Google Scholar] [CrossRef]

- Tepe, A.; Kaya, H.; Batmaz, G.; Ozkan, C.F.; Demirtaş, E.I. The Effect of Saline Irrigation Water Applications on Yields of Some Pepper Pure Lines. Batı Akdeniz Tarımsal Arastırma Enst. J. West. Mediterr. Agric. Res. Inst. 2011, 28, 1–11. [Google Scholar]

- Uras, D.S.; Sonmez, S. Farklı Toprak Teksturlerinde Yetistirilen Biber Bitkisinin Vitamin C, Toplam Klorofil İcerikleri ve K/Na Oranı Uzerine Sulama Suyu Tuzluluk Duzeylerindeki Degisimin Etkileri: Effects of Changes in Irrigation Water Salinity Levels on Vitamin C and Total Chlorophyll Content and K/Na Ratio of Pepper (Capsicum annuum L.) Grown in Different Soil Textures. Izmir, Turkey, 2010; pp. 526–531. ISSN 1018-8851. Available online: https://avesis.akdeniz.edu.tr/yayin/2367d2b0-5cf6-46cc-a92f-c83846f09856/farkli-toprak-teksturlerinde-yetistirilen-biber-bitkisinin-capsicum-annuum-l-vitamin-c-toplam-klorofil-icerikleri-ve-k-na-orani-uzerine-sulama-suyu-tuzluluk-duzeylerindeki-degisimin-etkileri (accessed on 15 May 2024).

- Kanber, R.; Kirda, C.; Tekinel, O. Irrigation Water Quality and Salinity Problems in Irrigation; Textbook Publication No: 6; Faculty of Agriculture Publications, Çukurova University: Adana, Turkey, 1992; 341p. [Google Scholar]

- Doorenbos, J.; Kassam, A.H. Yield Response to Water, Part B, Crop and Water. In FAO Irrigation and Drainage Paper 33; Food and Agriculture Organization of the United Nations: Roma, Italy, 1986. [Google Scholar]

- Tulucu, K. Irrigation of Special Plants; Faculty of Agriculture, Çukurova University General Publication No: 254, Textbooks, Publication No: A-82; Çukurova University: Adana, Türkiye, 2003. [Google Scholar]

| STOCK-A (50 L) | STOCK-B (50 L) | MICRO (50 L) | |||

|---|---|---|---|---|---|

| Nitric Acid | 1000 mL | Nitric Acid | 1000 mL | Boric Acid | 45.8 g |

| Calcium Nitrate | 2105.3 g | Potassium Nitrate | 3928.0 g | Manganese Sulfate | 46.2 g |

| Potassium Nitrate | 3928.0 g | Magnesium Sulfate | 5069.9 g | Copper Sulfate | 15.7 g |

| Iron | 230.8 g | Phosphoric Acid | 948 mL | Zinc Sulfate | 44.0 g |

| Ammonium Nitrate | 2689.0 g | Ammonium Molybdate | 1.10 g | ||

| Treatment | ET (Liters Per Plant) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 20.38 | 48.85 | 26.99 | 33.36 |

| LR2 | 23.62 | 61.76 | 33.46 | 39.46 | |

| S | S1 | 25.78 a | 68.53 a | 31.78 a | 36.80 ab |

| S2 | 22.66 a | 54.50 ab | 27.80 a | 34.54 b | |

| S3 | 19.18 a | 50.48 ab | 31.44 a | 35.50 b | |

| S4 | 20.37 a | 47.71 b | 29.89 a | 38.80 a | |

| * | * | ||||

| Treatment | Yield (kg) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 8.75 | 12.11 | 6.70 | 6.38 |

| LR2 | 9.50 | 11.75 | 7.48 | 8.11 | |

| S | S1 | 12.11 a | 14.56 a | 8.26 a | 8.22 a |

| S2 | 10.34 a | 13.16 ab | 7.21 b | 7.98 a | |

| S3 | 7.60 a | 10.75 ab | 7.08 b | 6.52 b | |

| S4 | 6.46 a | 9.24 b | 5.81 c | 6.27 b | |

| * | * | * | |||

| Treatment | Fruit Weight (g) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 22.90 | 17.48 | 20.18 | 11.11 |

| LR2 | 23.93 | 20.10 | 18.79 | 12.76 | |

| * | |||||

| S | S1 | 29.16 a | 29.52 a | 23.96 a | 16.08 a |

| S2 | 22.98 b | 18.86 b | 21.60 a | 12.11 b | |

| S3 | 22.70 b | 13.93 bc | 19.09 a | 10.55 bc | |

| S4 | 18.80 c | 12.82 c | 13.27 b | 8.99 c | |

| * | * | * | * | ||

| Treatment | Number of Fruits (pcs m−2) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 35.07 | 88.33 | 64.72 | 82.64 |

| LR2 | 37.29 | 84.86 | 75.56 | 107.64 | |

| * | |||||

| S | S1 | 42.36 a | 94.72 | 74.44 | 72.77 a |

| S2 | 37.63 a | 95.27 | 67.63 | 99.58 a | |

| S3 | 36.39 a | 85.27 | 71.38 | 97.22 a | |

| S4 | 28.33 b | 71.11 | 67.08 | 110.98 b | |

| * | |||||

| Treatment | Plant Height (cm) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 95.62 | 94.00 | 77.75 | 95.25 |

| LR2 | 102.67 | 102.17 | 81.17 | 107.42 | |

| n.s. | |||||

| S | S1 | 82.68 | 57.81 | 63.64 | 56.12 |

| S2 | 78.37 | 54.39 | 63.24 | 58.95 | |

| S3 | 79.37 | 55.50 | 57.07 | 57.83 | |

| S4 | 70.14 | 53.96 | 63.07 | 57.09 | |

| n.s. | |||||

| Treatment | Plant Stem Diameter (mm) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 12.30 | 12.12 | 10.39 | 9.95 |

| LR2 | 12.76 | 12.30 | 10.24 | 10.31 | |

| n.s. | |||||

| S | S1 | 9.91 a | 8.85 a | 8.39 | 6.99 |

| S2 | 9.44 a | 8.52 a | 8.23 | 7.15 | |

| S3 | 9.82 a | 8.40 ab | 7.89 | 7.09 | |

| S4 | 8.87 b | 7.94 b | 7.70 | 7.15 | |

| * | * | ||||

| Treatment | Fruit’s Dry Matter Content (%) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 6.83 | 9.81 | 7.14 | 9.68 |

| LR2 | 5.97 | 8.70 | 7.10 | 8.58 | |

| * | * | ||||

| S | S1 | 5.29 a | 7.30 a | 5.83 a | 7.02 a |

| S2 | 5.84 a | 9.08 ab | 6.41 a | 8.17 b | |

| S3 | 6.73 b | 10.38 b | 7.62 b | 9.84 c | |

| S4 | 7.72 c | 10.24 b | 8.60 c | 11.47 d | |

| * | * | * | * | ||

| Treatment | Amount of Water-Soluble Dry Matter (%) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 5.18 | 4.87 | 6.45 | 6.81 |

| LR2 | 5.08 | 4.28 | 6.44 | 6.60 | |

| n.s. | |||||

| S | S1 | 4.50 a | 4.60 ab | 5.91 a | 5.91 a |

| S2 | 4.83 a | 4.26 a | 6.21 b | 6.23 a | |

| S3 | 5.31 b | 3.89 a | 6.68 c | 7.08 b | |

| S4 | 5.86 c | 5.55 b | 6.96 d | 7.56 b | |

| * | * | * | * | ||

| Treatment | EC (dS m−1) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 5.63 | 6.23 | 5.90 | 6.52 |

| LR2 | 5.47 | 6.22 | 5.91 | 6.48 | |

| n.s. | |||||

| S | S1 | 4.98 a | 5.20 a | 5.51 a | 5.70 a |

| S2 | 5.42 b | 5.98 b | 5.68 a | 6.21 a | |

| S3 | 5.70 c | 6.82 c | 6.01 b | 7.05 b | |

| S4 | 6.08 d | 6.87 c | 6.39 c | 7.02 b | |

| * | * | * | * | ||

| Treatment | pH Value | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 5.90 | 5.70 | 6.29 | 5.98 |

| LR2 | 5.84 | 5.78 | 6.32 | 6.04 | |

| * | |||||

| S | S1 | 5.83 | 5.66 | 6.31 | 6.20 a |

| S2 | 5.83 | 5.72 | 6.31 | 5.94 b | |

| S3 | 5.89 | 5.77 | 6.34 | 5.97 b | |

| S4 | 5.89 | 5.78 | 6.25 | 5.90 b | |

| * | |||||

| Treatment | Amount of Titratable Acid (Mval 100 mL−1) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 1.54 | 2.54 | 1.16 | 0.73 |

| LR2 | 1.44 | 2.28 | 1.21 | 0.68 | |

| * | * | ||||

| S | S1 | 1.37 a | 2.14 a | 1.09 a | 0.60 a |

| S2 | 1.39 a | 2.30 ab | 1.11 a | 0.67 ab | |

| S3 | 1.55 b | 2.51 bc | 1.18 ab | 0.74 bc | |

| S4 | 1.61 b | 2.65 c | 1.35 b | 0.78 c | |

| * | * | * | * | ||

| Treatment | Vitamin C (mg 100 g−1) | ||||

|---|---|---|---|---|---|

| Production Period I | Production Period II | Production Period III | Production Period IV | ||

| LR | LR1 | 91.52 | 144.20 | 103.73 | 77.50 |

| LR2 | 84.68 | 127.36 | 95.03 | 60.77 | |

| n.s. | |||||

| S | S1 | 78.56 a | 112.92 a | 92.94 a | 67.46 |

| S2 | 122.12 b | 131.44 ab | 83.78 a | 69.93 | |

| S3 | 122.16 b | 148.44 b | 112.45 b | 64.26 | |

| S4 | 86.92 a | 150.12 b | 108.35 b | 74.86 | |

| * | * | * | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gürgülü, H.; Ul, M.A. Different Effects of Irrigation Water Salinity and Leaching Fractions on Pepper (Capsicum annuum L.) Cultivation in Soilless Culture. Agriculture 2024, 14, 827. https://doi.org/10.3390/agriculture14060827

Gürgülü H, Ul MA. Different Effects of Irrigation Water Salinity and Leaching Fractions on Pepper (Capsicum annuum L.) Cultivation in Soilless Culture. Agriculture. 2024; 14(6):827. https://doi.org/10.3390/agriculture14060827

Chicago/Turabian StyleGürgülü, Hatice, and Mehmet Ali Ul. 2024. "Different Effects of Irrigation Water Salinity and Leaching Fractions on Pepper (Capsicum annuum L.) Cultivation in Soilless Culture" Agriculture 14, no. 6: 827. https://doi.org/10.3390/agriculture14060827

APA StyleGürgülü, H., & Ul, M. A. (2024). Different Effects of Irrigation Water Salinity and Leaching Fractions on Pepper (Capsicum annuum L.) Cultivation in Soilless Culture. Agriculture, 14(6), 827. https://doi.org/10.3390/agriculture14060827