Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter

Abstract

:1. Introduction

2. Materials and Methods

2.1. Vegetable Transplanter Used in Current Study [17]

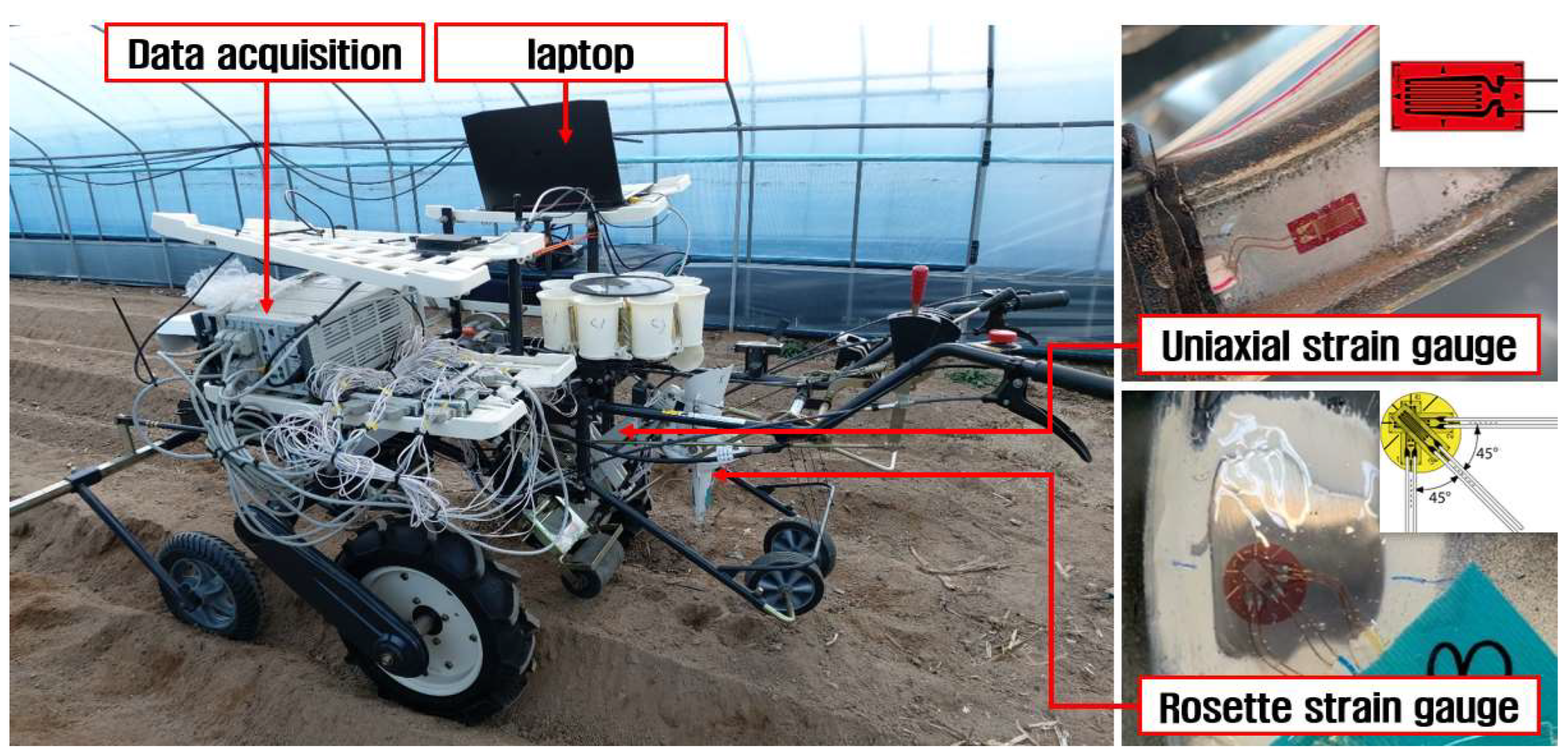

2.2. Stress Measurement

2.2.1. Stress Measurement System

2.2.2. Operating Condition

2.2.3. Analysis of Measured Data

| σ | = calculated axial stress (Pa) |

| = maximum principal stress (Pa) | |

| = minimum principal stress (Pa) | |

| = von Misses stress (Pa) | |

| = measured strain for the components of transplanting device | |

| E | = modulus of elasticity (Pa) |

| = Poisson’s ratio | |

| τmax | = maximum shear stress (Pa) |

| εa | = strain measured by rosette strain gauge in horizontal direction |

| εb | = strain measured by rosette strain gauge in 45° direction |

| εc | = strain measured by rosette strain gauge in vertical direction |

2.3. Stress Simulation

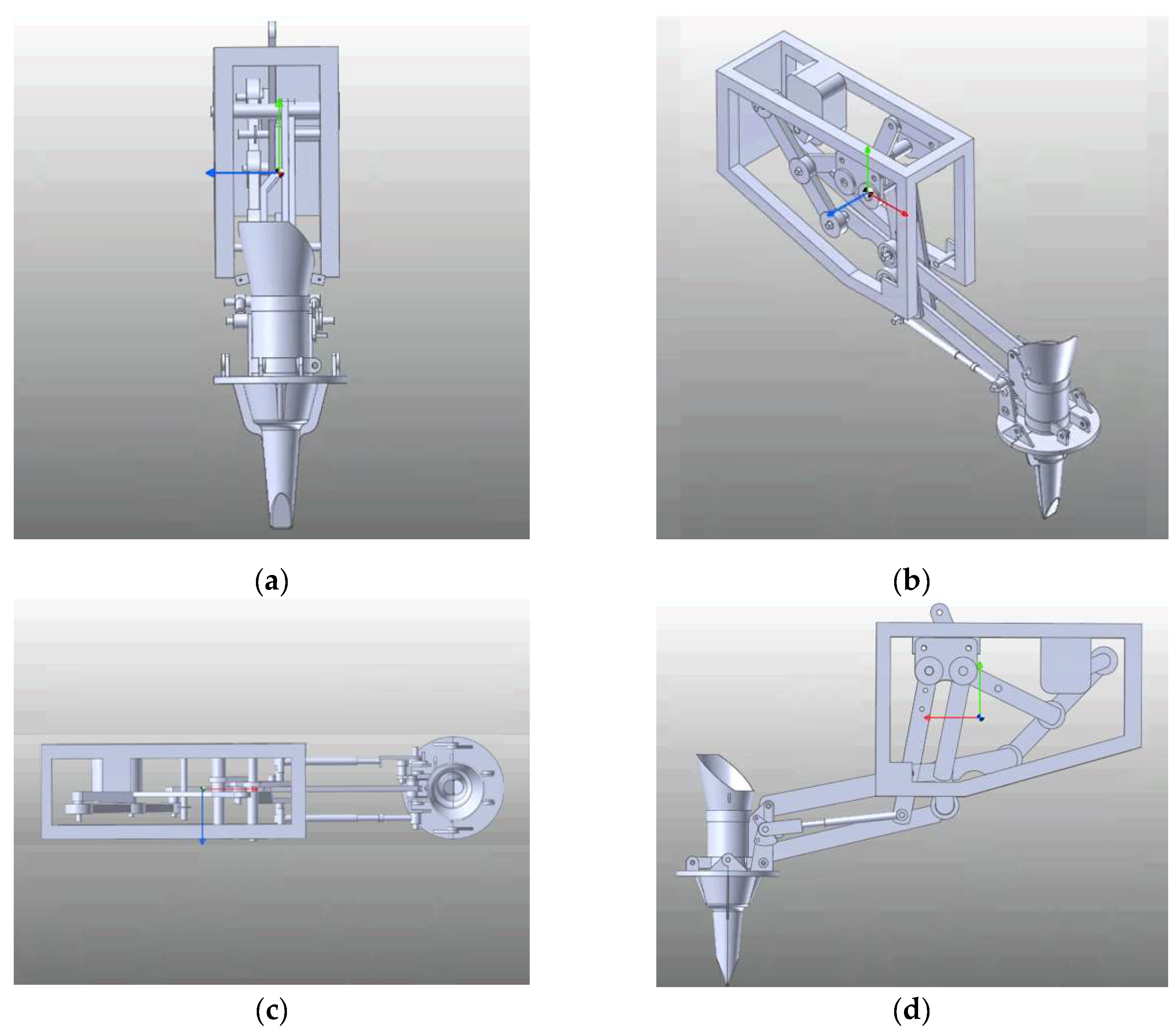

2.3.1. Dynamic Simulation Model

2.3.2. Simulation Condition

2.4. Verification of Stress Simulation

| = root mean square error | |

| = measured maximum stress in the experiment | |

| = measured maximum stress in the stress simulation | |

| = number of stress measurement locations |

2.5. Maximum Stress and Static Safety Factor

| SF | = static safety factor |

| Sy | = yield strength (Pa) |

| = maximum axial stress (Pa) | |

| = maximum von Mises stress (Pa) |

3. Results and Discussion

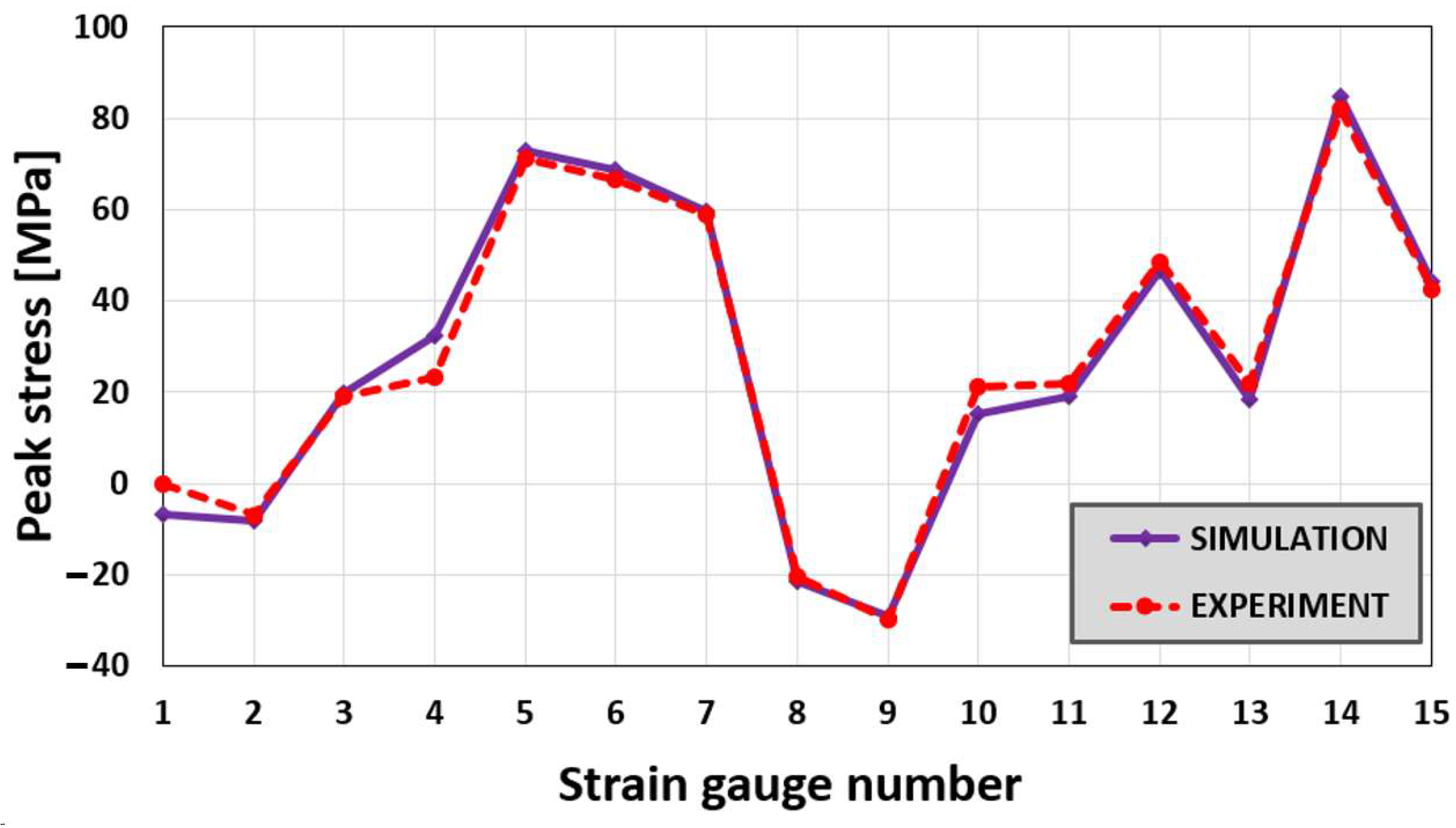

3.1. Verification of Stress Simulation

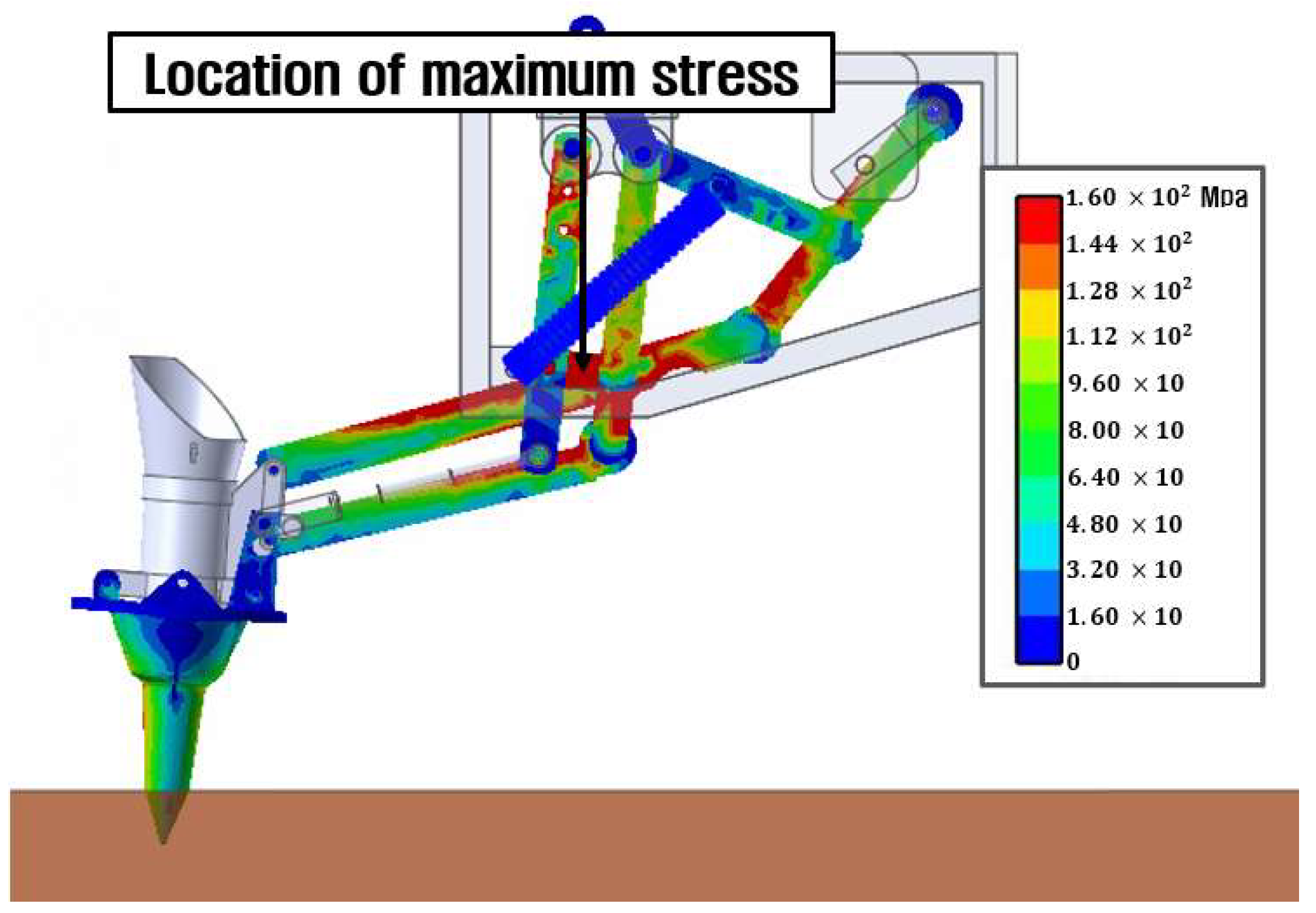

3.2. Maximum Stress and Static Safety Factor Based on Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hwang, S.-J.; Park, J.-H.; Lee, J.-Y.; Shim, S.-B.; Nam, J.-S. Optimization of main link lengths of transplanting device of semi-automatic vegetable transplanter. Agronomy 2020, 10, 1938. [Google Scholar] [CrossRef]

- Yang, Q.; Huang, G.; Shi, X.; He, M.; Ahmad, I.; Zhao, X.; Addy, M. Design of a control system for a mini-automatic transplanting machine of plug seedling. Comput. Electron. Agric. 2020, 169, 105226. [Google Scholar] [CrossRef]

- Tsuga, K. Development of fully automatic vegetable transplanter. Jarq Jpn. Agric. Res. Q. 2000, 34, 21–28. [Google Scholar]

- Jo, J.S.; Okyere, F.G.; Jo, J.M.; Kim, H.T. A study on improving the performance of the planting device of a vegetable transplanter. J. Biosyst. Eng. 2018, 43, 202–210. [Google Scholar] [CrossRef]

- Park, J.-H.; Hwang, S.-J.; Nam, J.-S. Operational characteristics of a domestic commercial semi-automatic vegetable transplanter. J. Agric. Life Sci. 2018, 52, 127–138. [Google Scholar] [CrossRef]

- Min, Y.B.; Kang, J.K.; Ryu, C.S. Development of onion transplanter: Analysis of a transplanting locus on the type of transplanting devices for a vegetable transplanter. J. Agric. Life Sci. 2015, 49, 289–294. [Google Scholar] [CrossRef]

- Kumar, G.V.P.; Raheman, H. Vegetable transplanters for use in developing countries—A review. Int. J. Veg. Sci. 2008, 14, 232–255. [Google Scholar] [CrossRef]

- Tian, S.; Qiu, L.; Kondo, N.; Yuan, T. Development of automatic transplanter for plug seedling. IFAC Proc. 2010, 43, 79–82. [Google Scholar] [CrossRef]

- Kim, W.-S.; Kim, Y.-S.; Kim, Y.-J.; Choi, C.-H.; Inoue, E.; Okayasu, T. Analysis of the load of a transplanter PTO shaft based on the planting distance. J. Fac. Agric. Kyushu Univ. 2018, 63, 97–102. [Google Scholar] [CrossRef]

- Kim, W.-S.; Kim, Y.-S.; Kim, T.-J.; Nam, K.-C.; Kim, T.-B.; Han, T.-H.; Im, R.-G.; Kim, Y.-H.; Kim, Y.-J. Effects of planting distance and depth on PTO load spectrum of a small riding-type transplanter. Int. J. Agric. Biol. Eng. 2020, 13, 57–63. [Google Scholar] [CrossRef]

- Sri, M.; Hwang, S.-J.; Nam, J.-S. Experimental safety analysis for transplanting device of the 4-bar link type semi-automatic vegetable transplanter. Agronomy 2022, 12, 1890. [Google Scholar] [CrossRef]

- Radhakrishnan, V.M. Multiaxial fatigue—An overview. Sadhana 1995, 20, 103–122. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Griepentrog, H.W.; Vougioukas, S.G. Country road and field surface profiles acquisition, modelling and synthetic realisation for evaluating fatigue life of agricultural machinery. J. Terramech. 2016, 63, 1–12. [Google Scholar] [CrossRef]

- Yurdem, H.; Degirmencioglu, A.; Cakir, E.; Gulsoylu, E. Measurement of strains induced on a three-bottom moldboard plough under load and comparisons with finite element simulations. Measurement 2019, 136, 594–602. [Google Scholar] [CrossRef]

- Kešner, A.; Chotěborský, R.; Linda, M.; Hromasová, M.; Katinas, E.; Sutanto, H. Stress distribution on a soil tillage machine frame segment with a chisel shank simulated using discrete element and finite element methods and validate by experiment. Biosyst. Eng. 2021, 209, 125–138. [Google Scholar] [CrossRef]

- Shao, X.; Song, Z.; Yin, Y.; Xie, B.; Liao, P. Statistical distribution modelling and parameter identification of the dynamic stress spectrum of a tractor front driven axle. Biosyst. Eng. 2021, 205, 152–163. [Google Scholar] [CrossRef]

- Paulson, I.W.P.; Dolovich, A.T.; Noble, S.D. Development of a dynamic simulation model of a towed seeding implement. J. Terramech. 2018, 75, 25–35. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Balvanz, L.R.; Hatfield, J.L.; Ghorbani, S. Discrete element modeling of cultivator sweep-to-soil interaction: Worn and hardened edges effects on soil-tool forces and soil flow. J. Terramech. 2019, 82, 1–11. [Google Scholar] [CrossRef]

- Xie, Z.; Shi, W.; Tian, Q.; Zheng, Y.; Tan, L. Fatigue life assessment and damage investigation of centrifugal pump runner. Eng. Fail. Anal. 2021, 124, 105256. [Google Scholar] [CrossRef]

- Juvinall, R.C.; Marshek, K.M. Machine Component Design, 5th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2020; pp. 338–340. [Google Scholar]

- Harwell, M. A strategy for using bias and RMSE as outcomes in Monte Carlo studies in statistics. J. Mod. Appl. Stat. Methods 2019, 17, 5. [Google Scholar] [CrossRef]

- Fadier, E.; la Garza, C.D. Safety design: Towards a new philosophy. Saf. Sci. 2006, 44, 55–73. [Google Scholar] [CrossRef]

- Bluff, E. Safety in machinery design and construction: Performance for substantive safety outcomes. Saf. Sci. 2014, 66, 27–35. [Google Scholar] [CrossRef]

| Item | Specification |

|---|---|

| model/manufacturer/nation | KTP-30/TONGYANGMOOLSAN, Seoul, South Korea |

| length/width/height (mm) | 2125/1180/1510 |

| weight (kg) | 199 |

| engine: rated power (kw)/rated sped (rpm) | 3.4/1800 |

| planting distance (mm) | 300–500 |

| maximum working speed (m/s) | 0.4 |

| working efficiency (h/10a) | 1.5–2.0 |

| length/width/height (mm) | 2125/1180/1510 |

| weight (kg) | 199 |

| Item | Specification |

|---|---|

| density, ρ (kg/m3) | 7.85 × 103 |

| modulus of elasticity, E (GPa) | 207 |

| Poisson’s ratio, ν | 0.3 |

| yield strength, Sy (MPa) | 210 |

| yield strength in shear, Ssy (MPa) | 105 |

| ultimate strength, Sut (MPa) | 380 |

| fatigue strength of 106 cycles, Sn (MPa) | 190 |

| Gauge | Item | Specification |

|---|---|---|

| uniaxial strain gauge | model/manufacture/nation | KYOWA KFGS-5-350-C1-11 L10M3R/KYOWA/Tokyo, Japan |

| gauge factor (%) | 2.12 ± 1.0 | |

| gauge length (mm) | 5 | |

| gauge resistance (%) | 351.2 Ω ± 0.4 | |

| rosette strain gauge | model/manufacture/nation | KYOWA KFGS-1-350-D17-11 L5M3S/KYOWA/Tokyo, Japan |

| gauge factor (%) | 2.11 ± 1.0 | |

| gauge length (mm) | 1 | |

| gauge resistance (%) | 350.0 Ω ± 0.7 |

| Item | Specification |

|---|---|

| model/manufacture/nation | TG009E/HBK/Darmstadt, Germany |

| length/width/height (mm) | 177/161/386 |

| weight (kg) | 5 |

| number of channels | 16 |

| sampling rate (Hz) | Up to 320 |

| Item | Value | |

|---|---|---|

| interaction between hopper and ground | stiffness coefficient | 35 |

| damping coefficient | 0.03 | |

| dynamic friction coefficient | 1.0 |

| Strain Gauge Number | Measured Maximum Stress (MPa) | Maximum Stress Derived by Simulation (MPa) | RMSE |

|---|---|---|---|

| S1 | −6.30 | −6.74 | 3.3117 |

| S2 | −6.97 | −8.33 | |

| S3 | 19.11 | 19.88 | |

| S4 | 23.28 | 32.35 | |

| S5 | 71.27 | 72.72 | |

| S6 | 66.67 | 68.82 | |

| S7 | 58.99 | 59.47 | |

| S8 | −20.32 | −21.34 | |

| S9 | −29.81 | −29.17 | |

| S10 | 21.10 | 15.17 | |

| S11 | 21.98 | 19.12 | |

| S12 | 48.59 | 46.83 | |

| S13 | 21.94 | 18.21 | |

| S14 | 81.81 | 84.71 | |

| S15 | 42.65 | 44.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markumningsih, S.; Hwang, S.-J.; Kim, J.-H.; Jang, M.-K.; Nam, J.-S. Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter. Agriculture 2024, 14, 42. https://doi.org/10.3390/agriculture14010042

Markumningsih S, Hwang S-J, Kim J-H, Jang M-K, Nam J-S. Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter. Agriculture. 2024; 14(1):42. https://doi.org/10.3390/agriculture14010042

Chicago/Turabian StyleMarkumningsih, Sri, Seok-Joon Hwang, Jeong-Hun Kim, Moon-Kyeong Jang, and Ju-Seok Nam. 2024. "Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter" Agriculture 14, no. 1: 42. https://doi.org/10.3390/agriculture14010042

APA StyleMarkumningsih, S., Hwang, S.-J., Kim, J.-H., Jang, M.-K., & Nam, J.-S. (2024). Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter. Agriculture, 14(1), 42. https://doi.org/10.3390/agriculture14010042