Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones

Abstract

1. Introduction

2. Material and Methods

2.1. Scope Definition and Functional Unit

2.2. System Boundaries

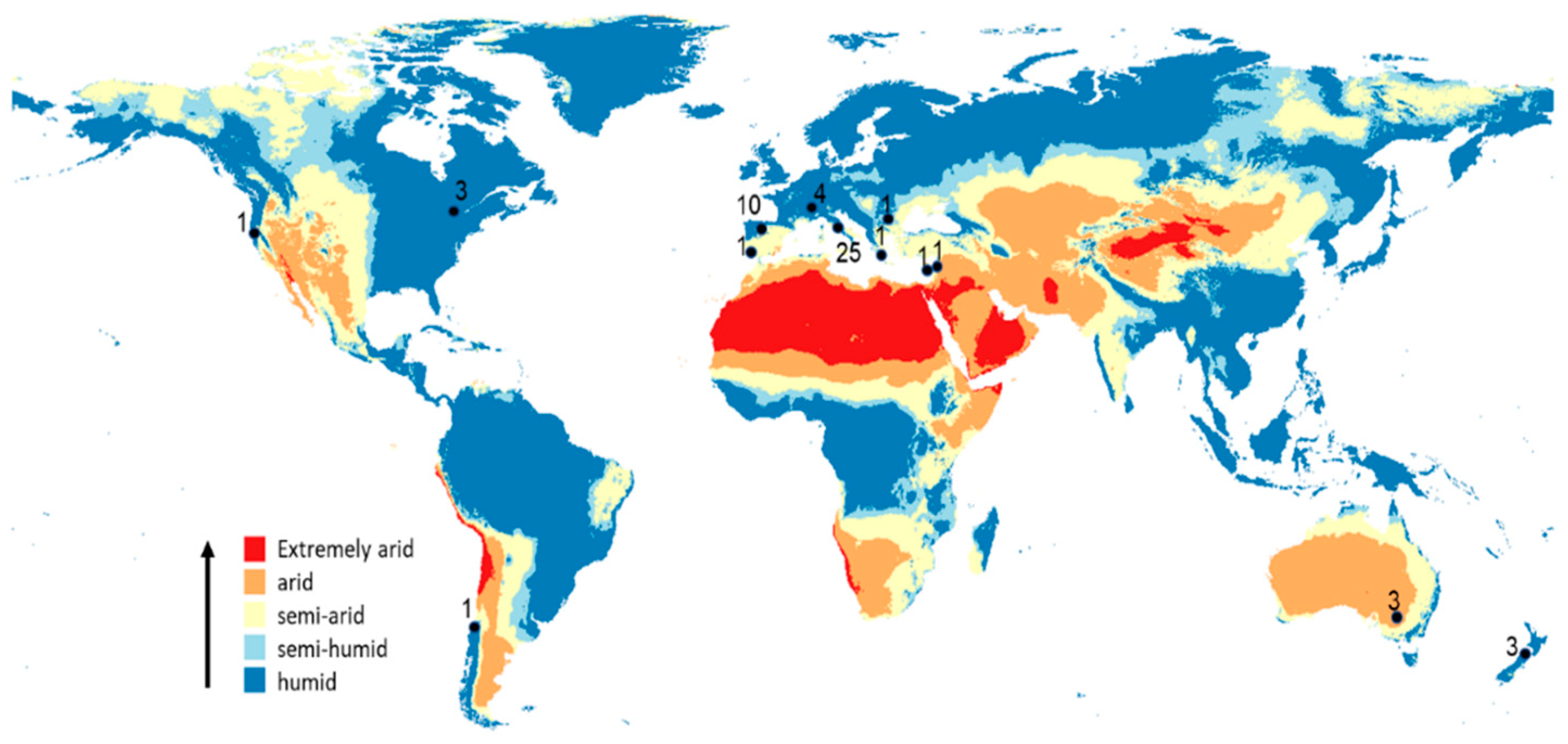

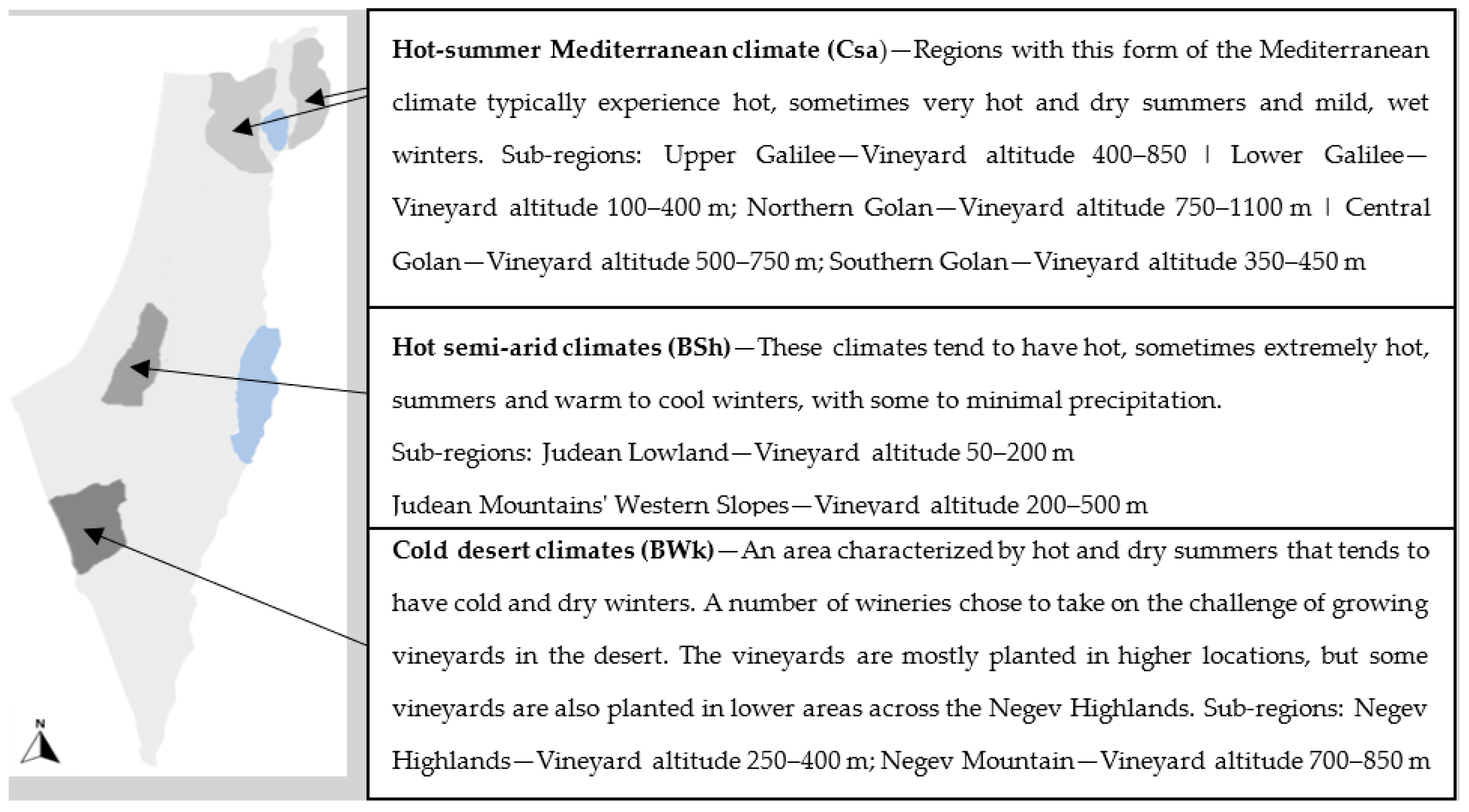

2.3. Research Location

2.4. Analysis of the Carbon Footprint (CF)

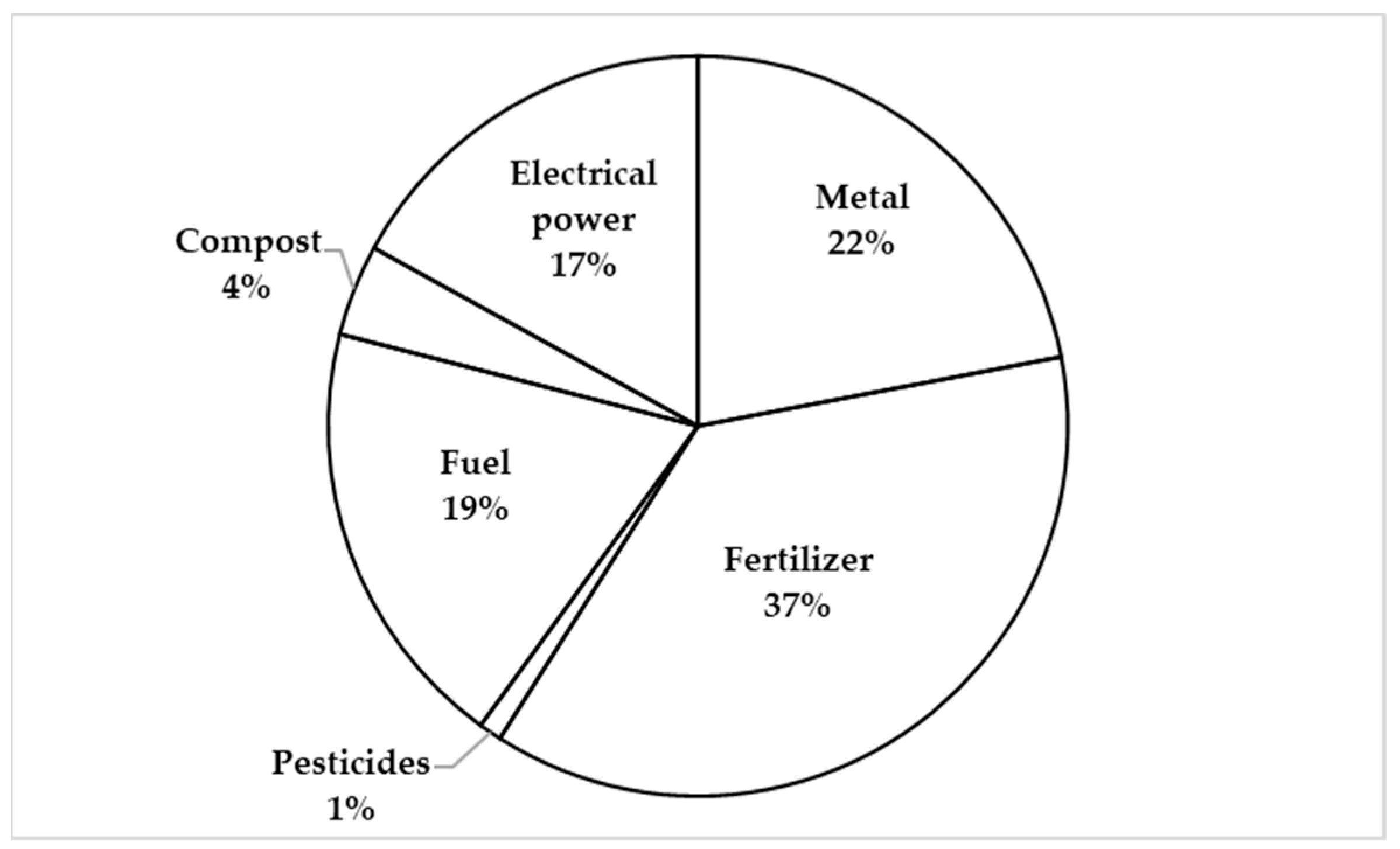

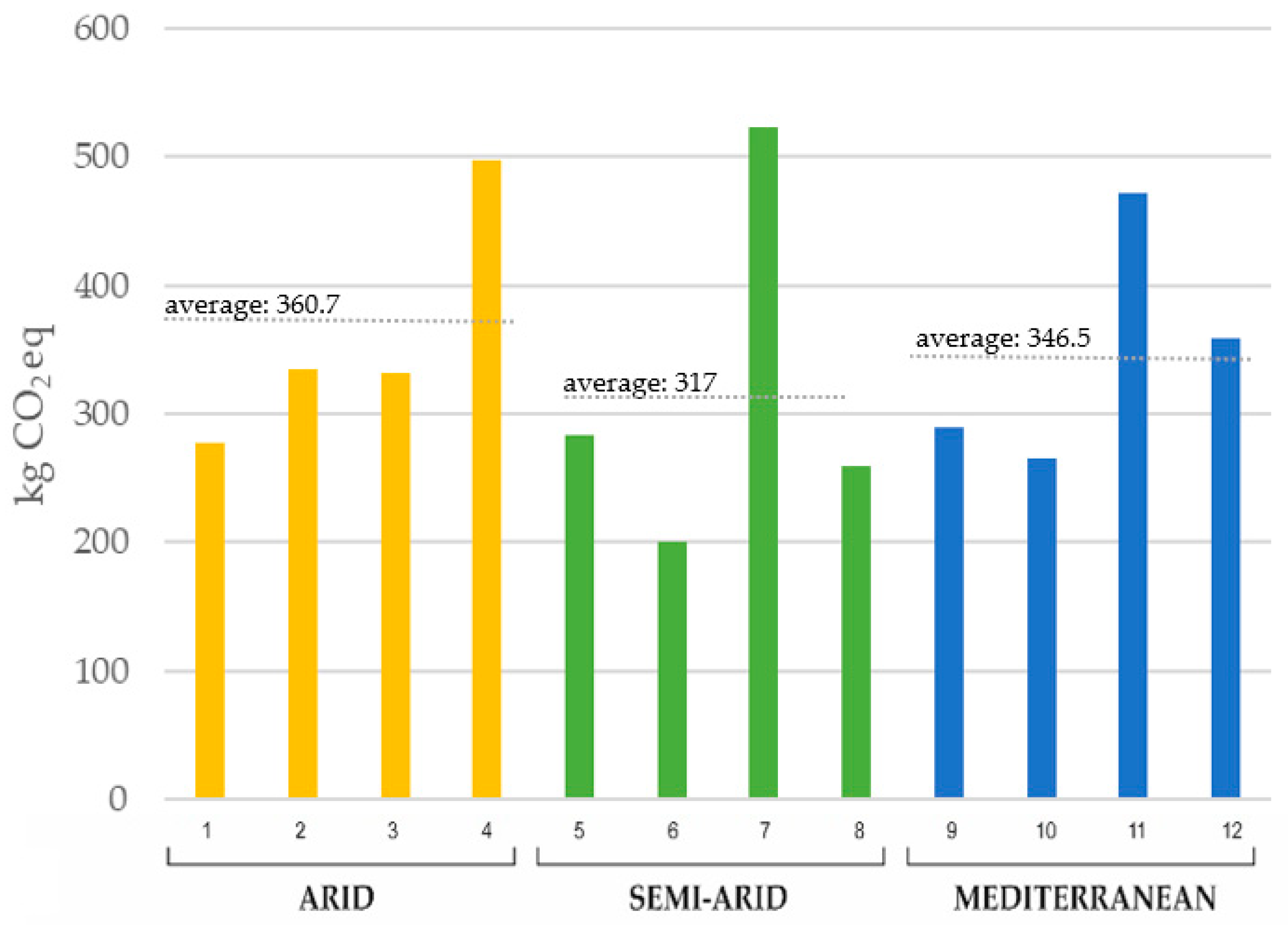

3. Results

4. Discussions

5. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- The International Organisation of Vine and Wine. Statistical Report on World Vitiviniculture in 2019. Available online: http://www.oiv.int (accessed on 1 April 2020).

- The International Organisation of Vine and Wine. State of the World Vitivinicultural Sector in 2020. Available online: https://www.oiv.int/public/medias/7909/oiv-state-of-the-world-vitivinicultural-sector-in-2020.pdf (accessed on 1 April 2021).

- Notarnicola, B.; Hayashi, K.; Curran, M.A.; Huisingh, D. Progress in working towards a more sustainable agri-food industry. J. Clean. Prod. 2012, 28, 1–8. [Google Scholar] [CrossRef]

- Benedetto, G. The environmental impact of a Sardinian wine by partial Life Cycle Assessment. Wine Econ. Policy 2013, 2, 33–41. [Google Scholar] [CrossRef]

- Bosco, S.; Claudia, D.; Mariassunta, G.; Damiano, R.; Rossano, M.; Enrico, B. Soil organic matter accounting in the carbon footprint analysis of the wine chain. Int. J. Life Cycle Assess. 2013, 18, 973–989. [Google Scholar] [CrossRef]

- Litskas, V.D.; Tzortzakis, N.; Stavrinides, M.C. Determining the carbon footprint and emission hotspots for the wine produced in Cyprus. Atmosphere 2020, 11, 463. [Google Scholar] [CrossRef]

- Wiedmann, T.; Minx, J. A Definition of Carbon Footprint. ISA Research and Consulting, Durham. 2007. Available online: http://www.censa.org.uk/reports.html (accessed on 1 March 2019).

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Lo Giudice, A. Life Cycle Assessment in the agri-food sector: An overview of its key aspects, international initiatives, certification, labelling schemesand methodological issues. In Life Cycle Assessment in the Agri-Food Sector; Springer International Publishing: Cham, Switzerland, 2015; pp. 1–56. [Google Scholar] [CrossRef]

- Rugani, B.; Vázquez-Rowe, I.; Benedetto, G.; Benetto, E. A comprehensive review of carbon footprint analysis as an extended environmental indicator in the wine sector. J. Clean. Prod. 2013, 54, 61–77. [Google Scholar] [CrossRef]

- Marras, S.; Masia, S.; Duce, P.; Spano, D.; Sirca, C. Carbon footprint assessment on a mature vineyard. Agric. For. Meteorol. 2015, 214–215, 350–356. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Kryona, Z.P.; Tsirliganis, N. Selecting south European wine based on carbon footprint. Resour. Environ. Sustain. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Gazulla, C.; Raugei, M.; Fullana, I.; Palmer, P. Taking a life cycle look at crianza wine production in Spain: Where are the bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

- Bagliani, M.; Galli, A.; Niccolucci, V.; Marchettini, N. Ecological footprint analysis applied to a sub-national area: The case of the Province of Siena (Italy). J. Environ. Manag. 2008, 86, 354–364. [Google Scholar] [CrossRef]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Da Silva, L.P.; da Silva, J.C.E. Evaluation of the Carbon Footprint of the Life Cycle of Wine Production: A Review. Clean. Circ. Bioeconomy 2022, 2, 100021. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Life cycle assessment application to the wine sector: A critical review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Nicoletti, G.M. Life cycle assessment (LCA) of wine production. In Environmentally-Friendly Food Processing; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2003; pp. 306–326. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, G.; Cellura, M.; Marvuglia, A. POEMS: A case study of an Italian wine-producing firm. Environ. Manag. 2006, 38, 350–364. [Google Scholar] [CrossRef] [PubMed]

- Petti, L.; Raggi, A.; De Camillis, C.; Matteucci, P.; Sára, B.; Pagliuca, G. Life cycle approach in an organic wine-making firm: An Italian case-study. In Proceedings of the Fifth Australian Conference on Life Cycle Assessment, Melbourne, Australia, 22–24 November 2006; pp. 22–24. [Google Scholar]

- Pizzigallo, A.C.I.; Granai, C.; Borsa, S. The joint use of LCA and emergy evaluation for the analysis of two Italian wine farms. J. Environ. Manag. 2008, 86, 396–406. [Google Scholar] [CrossRef] [PubMed]

- Pattara, C.; Raggi, A.; Cichelli, A. Life Cycle Assessment and Carbon Footprint in the Wine Supply-Chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef]

- Masotti, P.; Zattera, A.; Malagoli, M.; Bogoni, P. Environmental Impacts of Organic and Biodynamic Wine Produced in Northeast Italy. Sustainability 2022, 14, 6281. [Google Scholar] [CrossRef]

- Aranda, A.; Zabalza, I.; Scarpellini, S. Economic and environmental analysis of the wine bottle production in Spain by means of life cycle assessment. Int. J. Agric. Resour. Gov. Ecol. 2005, 4, 178–191. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Iribarren, D.; Teresa Moreira, M.; Feijoo, G. Joint life cycle assessment and data envelopment analysis of grape production for vinification in the Rías Baixas appellation (NW Spain). J. Clean. Prod. 2012, 27, 92–102. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Rugani, B.; Benetto, E. Tapping carbon footprint variations in the European wine sector. J. Clean. Prod. 2013, 43, 146–155. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Teresa Moreira, M.; Feijoo, G. Comparative life cycle assessment in the wine sector: Biodynamic vs. conventional viticulture activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Gonzalez, A.; Klimchuk, A.; Martin, M. Life cycle assessment of wine production process. In Finding Relevant Process Efficiency and Comparison to Eco-Wine Production; Royal Institute of Technology: Stockholm, Sweden, 2006. [Google Scholar]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef] [PubMed]

- Schlich, E.H. From vineyard to point of sale: Allocation of energy use and CO2-emission to entire supply chains of wine. In Proceedings of the 4th Annual Conference, American Association of Wine Economists, Davis, CA, USA, 25–28 June 2010. [Google Scholar]

- Quinteiro, P.; Dias, A.C.; Pina, L.; Neto, B.; Ridoutt, B.G.; Arroja, L. Addressing the freshwater use of a Portuguese wine (‘vinho verde’) using different LCA methods. J. Clean. Prod. 2014, 68, 46–55. [Google Scholar] [CrossRef]

- Comandaru, I.M.; Bârjoveanu, G.; Peiu, N.; Ene, S.A.; Teodosiu, C. Life cycle assessment of wine: Focus on water use impact assessment. Environ. Eng. Manag. J. (EEMJ) 2012, 11, 533–543. [Google Scholar]

- Point, E.; Tyedmers, P.; Naugler, C. Life cycle environmental impacts of wine production and consumption in Nova Scotia, Canada. J. Clean. Prod. 2012, 27, 11–20. [Google Scholar] [CrossRef]

- Colman, T.; Päster, P. Red, White, and ‘Green’: The Cost of Greenhouse Gas Emissions in the Global Wine Trade. J. Wine Res. 2009, 20, 15–26. [Google Scholar] [CrossRef]

- Herath, I.; Green, S.; Singh, R.; Horne, D.; van der Zijpp, S.; Clothier, B. Water footprinting of agricultural products: A hydrological assessment for the water footprint of New Zealand’s wines. J. Clean. Prod. 2013, 41, 232–243. [Google Scholar] [CrossRef]

- Letamendi, J.; Sevigne-Itoiz, E.; Mwabonje, O. Environmental impact analysis of a Chilean organic wine through a life cycle assessment. J. Clean. Prod. 2022, 371, 133368. [Google Scholar] [CrossRef]

- Feingersh, O.; Eitam, D. Land of Wine; Ma’ariv Library: Tel Aviv, Israel, 1988. [Google Scholar]

- The Israeli Ministry of Agriculture and Rural Development. Available online: https://www.gov.il (accessed on 1 June 2019).

- Israeli Wine Grapes Board Vine Council. Available online: https://wineboard.co.il (accessed on 1 June 2019).

- FIVS International Wine Greenhouse Gas Protocol, Version 2.0. 2016. Available online: http://wineinstitute.org (accessed on 1 April 2019).

- ADEME. La Méthode Bilan Carbone®. Agence de L’Environment et de la Maitrise de l’Energie. Available online: www2.ademe.fr (accessed on 1 August 2020).

- Australian Wine Carbon Calculator, Version 1.0. 2009. Available online: www.wfa.org.au (accessed on 1 April 2020).

- Italia Wine Carbon Calculator. 2014. Available online: http://wineobservatorysustainability.eu (accessed on 1 August 2020).

- Metz, B.; Davidson, O.R.; Bosch, P.R.; Dave, R.; Meyer, L.A. Contribution of Working Group III to the Fourth Assessment Report of the IPCC; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Ecoinvent. Version 3.9. 2022. Available online: https://v39.ecoquery.ecoinvent.org/Account/AcceptChangedEula (accessed on 1 March 2022).

- Steenwerth, K.L.; Strong, E.B.; Greenhut, R.F.; Williams, L.; Kendall, A. Life cycle greenhouse gas, energy, and water assessment of wine grape production in California. Int. J. Life Cycle Assess. 2015, 20, 1243–1253. [Google Scholar] [CrossRef]

- International Organization for Standardization. Greenhouse Gases: Carbon Footprint of Products: Requirements and Guidelines for Quantification and Communication; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Litskas, V.D.; Irakleous, T.; Tzortzakis, N.; Stavrinides, M.C. Determining the carbon footprint of indigenous and introduced grape varieties through Life Cycle Assessment using the island of Cyprus as a case study. J. Clean. Prod. 2017, 156, 418–425. [Google Scholar] [CrossRef]

- Harb, W.; Zaydan, R.; Vieira, M. Improving environmental performance in wine production by life cycle assessment: Case of Lebanese wine. Int. J. Life Cycle Assess. 2021, 26, 1146–1159. [Google Scholar] [CrossRef]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district in Tuscany, Italy. Ital. J. Agron. 2011, 6, e15. [Google Scholar] [CrossRef]

- Kavargiris, S.E.; Mamolos, A.P.; Tsatsarelis, C.A.; Nikolaidou, A.E.; Kalburtji, K.L. Energy resources’ utilization in organic and conventional vineyards: Energy flow, greenhouse gas emissions and biofuel production. Biomass Bioenergy 2009, 33, 1239–1250. [Google Scholar] [CrossRef]

- Litskas, V.D.; Karaolis, C.S.; Menexes, G.C.; Mamolos, A.P.; Koutsos, T.M.; Kalbourtji, K.L. Variation of energy flow and greenhouse gas emissions in vineyards located in Natura 2000 sites. Ecol. Indic. 2013, 27, 1-7.–7. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vazquez-Rowe, I.; Teresa Moreira, M.; Gumersindo Feijoo, G. The use of carbon footprint in the wine sector: Methodological assumptions. Assess. Carbon Footpr. Differ. Ind. Sect. 2014, 2, 269–298. [Google Scholar]

| Inputs | Unit | National Average | Standard Deviation | Mediterranean Average | Semi-Arid Average | Arid Average |

|---|---|---|---|---|---|---|

| The infrastructure phase | ||||||

| cardboard | kg | 0.3 | 0.1 | 0.4 | 0.3 | 0.3 |

| plastic | kg | 0.8 | 0.0 | 0.9 | 0.6 | 0.8 |

| metal | kg | 17.6 | 1.5 | 20.4 | 13.4 | 18.9 |

| fuel | km | 43.7 | 20.4 | 43.3 | 18.7 | 69.1 |

| First three years | ||||||

| Field work fuel | L | 2.6 | 2.1 | 4.0 | 2.0 | 1.6 |

| NPK fertilizer (Active Ingredient) | kg | 1.5 | 1.5 | 1.6 | 1.8 | 1.0 |

| Pesticides (Active Ingredient) | L | 0.6 | 1.2 | 1.2 | 0.6 | 0.0 |

| compost | kg | 0.4 | 0.3 | 0.6 | 0.1 | 0.6 |

| water | m3 | 32.1 | 18.0 | 29.0 | 17 | 50.0 |

| electrical power | kWh | 12.8 | 7.1 | 8.0 | 7 | 20.0 |

| The fruitful years | ||||||

| Field work fuel | L | 15 | 14 | 24 | 12 | 9 |

| NPK fertilizer (Active Ingredient) | kg | 17 | 18 | 18 | 23 | 12 |

| Pesticides (Active Ingredient) | L | 0.23 | 0.25 | 0.09 | 1 | 0 |

| compost | kg | 0.67 | 0.65 | 2 | 1 | 0 |

| water | m3 | 201 | 90 | 152 | 177 | 276 |

| electrical power | kWh | 91 | 90 | 61 | 71 | 141 |

| Vineyard No | Arid | Semi-Arid | Mediterranean | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| The infrastructure phase | ||||||||||||

| Carton | 0.4 | 0.0 | 0.4 | 0.3 | 0.2 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| Plastic | 1.5 | 1.1 | 1.3 | 1.3 | 0.8 | 1.0 | 1.4 | 1.2 | 1.6 | 1.4 | 1.6 | 1.3 |

| Metal | 97.2 | 69.8 | 84.7 | 79.1 | 36.3 | 60.2 | 84.8 | 70.8 | 92.2 | 79.0 | 92.3 | 88.7 |

| Fuel | 4.8 | 4.1 | 0.9 | 21.4 | 3.3 | 0.3 | 1.9 | 3.0 | 1.6 | 0.7 | 2.3 | 2.4 |

| Sub-Total | 103.9 | 75.0 | 87.3 | 102.1 | 40.6 | 61.7 | 88.6 | 75.3 | 95.8 | 81.5 | 96.6 | 92.9 |

| First three years | ||||||||||||

| Truck fuel | 5.4 | 2.5 | 3.0 | 12.6 | 0.4 | 0.1 | 6.5 | 0.7 | 0.9 | 0.5 | 2.9 | 0.8 |

| Field work fuel | 0.9 | 2.9 | 2.4 | 1.6 | 1.6 | 3.6 | 20.6 | 2.8 | 17.4 | 5.5 | 21.1 | 5.5 |

| Fertilization | 6.9 | 1.9 | 6.4 | 10.6 | 0.0 | 3.7 | 17.7 | 40.5 | 17.4 | 11.4 | 8.0 | 10.5 |

| Pesticide | 0.1 | 0.1 | 0.3 | 0.2 | 0.1 | 0.2 | 13.5 | 0.2 | 0.3 | 0.3 | 4.2 | 15.5 |

| Compost | 7.7 | 5.4 | 6.6 | 6.1 | 0.0 | 0.0 | 7.1 | 0.0 | 7.7 | 5.7 | 5.1 | 0.0 |

| Electricity | 7.5 | 6.4 | 36.7 | 9.6 | 3.0 | 2.7 | 4.2 | 4.4 | 6.6 | 5.7 | 5.1 | 6.4 |

| Sub-Total | 28.4 | 19.3 | 36.7 | 40.7 | 5.1 | 10.3 | 69.6 | 48.5 | 46.3 | 30.0 | 52.2 | 38.7 |

| The fruitful years | ||||||||||||

| Truck fuel | 2.8 | 5.9 | 0.5 | 9.2 | 0.8 | 0.1 | 9.9 | 0.7 | 19.2 | 14.4 | 81.3 | 0.8 |

| Field work fuel | 4.9 | 16.7 | 13.5 | 8.9 | 9.2 | 20.3 | 116.6 | 15.7 | 76.4 | 31.3 | 121.9 | 31.3 |

| Fertilization | 23.4 | 9.5 | 80.6 | 191.5 | 85.5 | 128.4 | 173.7 | 90.2 | 74.8 | 64.1 | 97.4 | 203.3 |

| Pesticide | 0.0 | 0.8 | 1.5 | 0.7 | 1.7 | 0.9 | 3.6 | 4.0 | 0.2 | 0.2 | 1.2 | 0.4 |

| Compost | 0.0 | 12.4 | 0.0 | 0.0 | 4.4 | 0.0 | 26.9 | 0.0 | 14.6 | 12.5 | 20.4 | 0.0 |

| Electricity | 68.0 | 60.0 | 114.8 | 47.6 | 29.8 | 40.8 | 54.9 | 24.7 | 41.5 | 35.6 | 25.5 | 21.9 |

| Sub-Total | 99.1 | 105.1 | 210.8 | 257.9 | 131.4 | 190.6 | 385.6 | 135.3 | 226.6 | 158.0 | 347.7 | 257.7 |

| System Total | 231.5 | 199.4 | 334.8 | 400.7 | 177.1 | 262.6 | 543.8 | 259.1 | 368.8 | 269.5 | 496.5 | 389.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hefler, Y.T.; Kissinger, M. Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones. Agriculture 2023, 13, 303. https://doi.org/10.3390/agriculture13020303

Hefler YT, Kissinger M. Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones. Agriculture. 2023; 13(2):303. https://doi.org/10.3390/agriculture13020303

Chicago/Turabian StyleHefler, Yuval Tamar, and Meidad Kissinger. 2023. "Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones" Agriculture 13, no. 2: 303. https://doi.org/10.3390/agriculture13020303

APA StyleHefler, Y. T., & Kissinger, M. (2023). Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones. Agriculture, 13(2), 303. https://doi.org/10.3390/agriculture13020303