Abstract

When peanuts are harvested, the high rate of pod crush and pods leakage are the main problems in the current peanut fruit picking process. Optimized peanut picking rollers help to improve peanut harvesting efficiency. This paper investigates the fruit picking system of a three-monopoly, six-row semi-feeding peanut combine harvester, in order to reduce the rate of crush and leakage of peanut pods during the picking process. Firstly, this article specifies the structure and basic parameters of peanut picking pairs of rollers. Secondly, this paper combines JKR (Johnson-Kendall-Roberts) model theory, crash model simulation analysis, a field test, and other methods. Motion and force analysis are presented in detail for the peanut picking mechanism and associated harvesting components. The optimum clamping chain speed, the angle of installation of the picking rollers to the clamping chain, and the picking rollers’ speed are determined. A three-factor, three-level regression orthogonal combination test was designed to obtain regression models for pod crushed and pods leakage rate. The regression model’s response surface analysis concluded that when the clamping chain speed is 0.84–1.2 m/s, the fruit picking roller angle is 10°–11.2° and the fruit picking roller speed is 442 r/min–500 r/min. It is the optimal working parameter for the three-monopoly six-row peanut combine harvester. At this point, the peanut harvesting requirements are met, and the overall performance is significantly improved. This paper lays the foundation for the development of the semi-feeding peanut picking system.

1. Introduction

Peanut is an important economic crop and oil crop in China, and the planting area of peanuts, has shown a year-on-year increase. Thus, peanut mechanized harvesting has become one of the important factors affecting peanut production. And picking matters most in peanut harvesting process, directly related to the efficiency and quality of the peanut harvest [1,2]. There are two main ways of picking peanuts on the market: full-feed peanut fruit picking and semi-feeding peanut fruit picking. Full-feed fruit picking is when peanut seedling and peanut pods are fed into the fruit picking roller to obtain peanut pods. This picking method results in a high impurities content. It is only suitable for drier peanuts and mostly used by picking harvesters [3,4,5]. Semi-feeding fruit picking is when only the peanut plant roots are fed into the fruit picking roller to obtain peanut pods. This method is highly adaptable to the wet and dry conditions of peanuts. Combine harvesters mostly use this method. So, the paper investigates the semi-feeding fruit picking method.

Wang Bokai designed an axial-flow peanut full-feed harvester and used Hertzian contact theory to analyze the pods and to pick spike teeth during fruit picking [6]. Hu Zhichao further optimized the semi-feeding peanut picking device by analyzing the movement during fruit picking, determining the optimum position for picking [7]. Wang Dongwei used PROE software (USA, PTC) and ANSYS software (USA, American ANSYS company) to analyze the mechanism and optimize the parameters of the curved roller picking device [8]. Nan Feifei optimized the semi-feeding peanut combine harvester to determine parameters such as fruit picking roller speed and fruit picking roller length [9]. Fang Qingliu innovatively used the TRIZ method to optimize the fruit picking mechanism to obtain the optimal feeding scheme and design of the mechanism [10]. However, research on the mechanics of the semi-feeding fruit picking mechanism is relatively weak at present.

However, China’s current semi-feeding fruit picking method uses two pairs of fruit picking rollers that rotate in opposite directions. The fruit picking blades are driven to strike the peanut root system. This method of picking peanuts is suitable for picking fresh peanut pods. This method is suitable for peanut combine harvesters. The conventional semi-feeding peanut picking mechanism mainly uses the Hertz contact theory. Only the contact between two objects under the action of external forces is considered. The surface forces between the peanut pods and the picking blade are not considered. Therefore, this paper uses the JKR theoretical model in contact mechanics to analyze the critical impact force and critical speed of impact between the picking roller and the peanut pods [11,12,13].

To enhance fruit picking performance and reduce breakage and leakage, this paper analyses and tests the fruit picking mechanism of a three-monopoly six-row semi-feeding peanut combine. Firstly, based on the physical characteristics of the peanut pods. The structure, and basic parameters of the picking pair of rollers are determined. The basic parameters are analyzed to determine the primary and secondary factors affecting the fruit picking effect. Then, the kinematic and dynamic analyses are used to determined the stable relationship between test factors and indicators. The JKR theory and collision model are established, and the collision simulation analysis of peanut pods is carried out. Through the method verified by the field test, a response surface model was constructed to optimize further the combination of the structural parameters of the fruit picking roller pair. The above research content provides a reference for the optimization of the semi-feeding peanut picking device.

2. Materials and Methods

2.1. Overall Structure and Working Principle

To meet the market demand for peanut harvesting and improve the quality of peanut pod harvesting and peanut harvesting efficiency. This fruit picking mechanism is researched through a three-monopoly, six-row semi-feeding peanut combine harvester [14]. The structural sketch is shown in Figure 1.

Figure 1.

The overall structure of the three-monopoly six-row peanut combine harvester.

When the three-monopoly, six-row peanut combine is harvested. The centering device separates the peanut plants to be harvested. In contrast, the gear rotates toward the peanut plants to be harvested. The peanut plants are lifted and gathered into a central position. At the same time, the excavating device breaks the peanut’s main roots and loses the soil under the action of the forward force of the machine. With the cooperation of the centering and excavating devices, the peanut plants move backward according to inertia into the clamping chain [15]. During the clamping and conveying process, the soil removal device reciprocates left and right on the peanut to remove soil and impurities from the root system of the peanut plant. The three rows of peanut plants are gathered in the middle and sent to the picking section. The clamping chain transports the peanut plant, and the root system enters the fruit picking roller. The peanut picking rollers pick off the peanut pods. The peanuts are dropped by gravity into the cleaning device, where the heavier soil and other impurities are sieved off by the reciprocating movement of the cleaning device. At the same time, the lighter leaves and membranes are blown out by the blower. It is completing the secondary demising operation. After sorting, the peanut pods are driven by the L-shaped conveyor belt into the fruit collection box and equipped with a hydraulic device that allows the package to be tilted for subsequent bagging operations. When the picking operation is completed, the picked peanut plants are transported backward with the clamping conveyor chain and finally thrown into the field by the clamping chain powered by guide rails and seedling guiding devices. After the fruit picking operation is completed, the picked peanut plants are transported backward with the clamping conveyor chain and finally thrown into the field by the clamping chain powered by guide rails and seedling guiding devices.

2.1.1. Structure of Peanut Picking Roller Device

The three-monopoly six-row peanut combine harvester has a semi-feeding roll picking system. Three clamping chains primarily combine this harvester. Transport of peanut plants with pods to the picking roller. The fruit picking rollers are driven by the relative rotation of the fruit picking blades. The peanut pods pass between two picking rollers rotating at high speed. The outer tangential direction of the picking rollers’ blades causes tugging, beating, and pulling forces on pods, stalks, roots, etc., and by constant shearing, squeezing, and other details—full contact between picking roller blades and peanuts. The peanuts pass through the back end of the picking roller to complete the complete shedding of the peanut pods [16,17]. The peanut picking roller device is shown in Figure 2.

Figure 2.

Structure of peanut picking roller device.

2.1.2. Structural Parameter Analysis of Peanut Picking Roller

Fruit picking rollers as the core component of the three-monopoly six-row semi-feeding peanut combine harvester. Its structural parameters include fruit picking rollers’ diameter, fruit picking rollers’ length, fruit picking rollers’ angle, fruit picking rollers’ speed, etc. Each fruit-picking pair of rollers is arranged with four rows of fruit-picking blades, which are welded to the rollers in the shape of a cross. And the two rollers are rotated relative to each other under the control of the steering gear [18]. As is shown in Figure 3.

Figure 3.

Working schematic of double-roller for picking.

As in Figure 3, when the peanut roots enter the rectangular picking area of the fruit picking pair of rollers. Physical measurements of the fruit and root systems of different peanut varieties were carried out to effectively separate the peanut pods from the vine and avoided the loss and fragmentation of peanut pods. As is shown in Table 1.

Table 1.

Geometric dimensions of peanut.

According to Table 1, determining the average height of the peanut fruit system for 120–131 mm, and the average length of the root system for 128–134 mm, which gives the result CO = 65 mm and AO = 67 mm. The Pythagorean theorem can be known as OC = 93.4 mm. So, the picking roller rotary diameter is 187 mm. Taking integer value as 190 mm.

During actual operation in the field, when the angle of synthetic movement of the peanut plant relative to the ground is less than 90°. The peanut plant feeding volume is higher than the clamping volume satisfied by the peanut clamping mechanism, resulting in plant blockage and missed clamping. In practice, it is necessary to appropriately increase the clamping mechanism’s transmission speed to avoid such conditions by setting the peanut plant’s absolute movement angle, and the vehicle body’s forward momentum greater than 90°. At the same time, for the three-monopoly, six-row peanut combine harvester. The increased feed volume and the higher requirements. Bring many peanut pods into full contact with the picking rollers for the picking roller length adjustment. Meanwhile, the size of the fruit picking rollers should be increased. The picking roller should not be so long that the peanut pods are broken due to excessive contact. The formula for calculating the length of the fruit picking pair of rollers is as follows:

where L is fruit picking roller length, mm; vg is clamping chain conveying speed, m/s; t is fruit picking time, s.

Therefore, in actual field operations, the angle between the peanut clamping mechanism and the ground is taken to be 30° to 40°. The vehicle’s speed fluctuates slightly up and down at 0.625 m/s during the field operation. After a comprehensive analysis of the above data, the clamping chain transmission speed in this experiment was between 0.7 m/s and 1.2 m/s [19]. The clamping chain transmission speed factor levels were 0.7 m/s, 0.9 m/s and 1.2 m/s, respectively.

The three-monopoly six-row clamping chain homing speed is approximately 0.9 m/s. The peanut seedlings enter the fruit picking rollers and are picked in a process lasting approximately 1 s. So, the length of the fruit picking rollers is about 900 mm. The relative speed of the picking rollers is also an essential factor in the picking effect. Too fast a speed of the picking pair of rollers leads to an increase in the rate of peanut pods crushed. The slow speed of the picking drum resulted in incomplete picking of the peanut pods. Resulting in the loss of peanut pods.

The formula for calculating the speed of the peanut picking pair of rollers is as follows:

The equation for the maximum impact velocity that a peanut pod can withstand is as follows:

where Nw is spindle speed, r/min; D is fruit picking roller diameter, mm; n is ultimate peanut impact speed, r/min.

According to Equations (2) and (3), the speed of the fruit-picking pair of rollers is 450 r/min. The maximum impact velocity that the peanut can withstand is 8.95 m/s. The picking roller has a return torque of 190 mm.

The configuration of this peanut combines the harvester’s fruit picking mechanism. It forms an inclined arrangement of clamping conveyor chains and fruit-picking pairs of rollers and attaching chains with a certain angle to the fruit-picking roller shaft. When the clamping position of the peanuts in the clamping chain does not change, the root system of the peanuts entering the picking roller changes, enabling the root system of the peanut pods to be fully covered in the picking roller [20,21,22]. In this case, there are no dead spots for fruit picking, and it is less likely that fruit will leak.

The ideal peanut picking process is shown in Figure 4: peanut pods from the bottom up into the picking area ABCD. AB is obtained by parallel movement of the clamping conveyor chain. The equation according to the position relationship is as follows:

where a is the angle between the clamping conveyor chain and fruit picking rollers; b is the clamping angle between peanut plant and clamping chain; l is the height of the peanut family, mm; L is the length of the fruit picking rollers, mm.

Figure 4.

Schematic diagram of peanut picking process. a is the angle between the clamping conveyor chain and fruit picking rollers; b is the clamping angle between peanut plant and clamping chain.

During the peanut plant body in the clamping chain conveying process, the angle between the peanut plant and clamping chain is approximately 90°. The height of the peanut fruit system varies according to the variety, so the angle between the clamping conveyor chain and the fruit picking pair of rollers can be derived as 6.89–13.47°. Take the integer range of 6–14°.

The final picking roll diameter is 187 mm. The fruit picking roller length is 900 mm. The angle between the clamping chain and fruit picking roller angle is 6.5–13.5°. It was clamping and conveying a speed of 0.9 m/s. The maximum velocity of the impact that the peanut can withstand is 8.95 m/s. The picking roller speed is 450 r/min, and the picking roller torque is 190 N·m [23,24]. The roller angle factor levels are determined as three based on the integer interval calculated above, −6°, 10°, and 14°, respectively.

2.2. Research on the Mechanism of Picking Roller

2.2.1. Kinetic Analysis of Peanut Picking Processes

Establishing a right-angle coordinate system in the fruit picking area perpendicular to the drum. X and Y axes coincide with the fruit picking blades. The force analysis at the point of contact between the peanut pod and the leaf is shown in Figure 5. Fc represents the impact force of the picking roller blades on the peanut pods. The point is directed perpendicular to the picking blade; N denotes the reaction force of Fc. It represents the force exerted by the peanut pod root system on the plucked roller in the direction co-linear and opposite to Fc; f represents the friction between the peanut pod and the picking blade. Its direction is perpendicular to the impact force Fc; mg indicates the gravity of the peanut pods themselves. This gravity includes the peanut root system and the peanut seedling stalk. The force is directed vertically downwards. The angle between this force and the impact force is θ1; Fa represents the centrifugal force generated by the high-speed rotation of the fruit picking rollers. Its direction varies from moment to moment and is always perpendicular to the direction of the speed of rotation; F1 denotes the force between the peanut stalk and the pod. F2 indicates the point between the seedling vine and the peanut stalk. This force’s direction is approximately the same as the direction of friction. F3 represents the diagonal upward pull of the clamping chain, the angle between the direction of this force and the direction of the reaction force given by the pods to the picking blade is θ2.

Figure 5.

Stress analysis diagram of peanut picking process. F1 denotes the force between the peanut stalk and the pod, N; F2 is the force between the seedling vine and the peanut stalk, N; F3 is the diagonal upward pull of the clamping chain, N; Fc is the impact force of the picking roller blades on the peanut pods, N; N is the reaction force of Fc, N; mg is gravity, N; f is the friction between the peanut pod and the picking blade, N.

The friction equation is as follows:

The centrifugal force equation is as follows:

where μ is the coefficient of friction between pods and picking leaves, take 0.3; ω is the drum speed, rad/s; R is the radius of rotation of the fruit picking rollers, cm.

The equilibrium equations for peanut plants on the X and Y axes are expressed as follows:

The results are as follows:

where F1 is the tension between the fruit stalk and the pod, N; F2 is the tension between the seedling vine and the fruit stalk, N; F3 is the tension generated by the clamping chain on the peanut plant, N; Fa is the centrifugal force generated by the high-speed rotation of the fruit picking rollers, N; ω is the drum speed, rad/s; m is the equal mass of peanut plant body and impurities, kg; g is the gravitational acceleration of the peanut plant body and impurities, take 10 m/s2. Fc is the impact force of the picking roller blades on the peanut pods, N; N is the force generated by the peanut pods and roots on the blades of the picking roller, N; θ1 is the angle between gravity and impact force, rad; θ2 is the angle between the pulling force and the reaction force of the impact, rad.

This result leads to the following: when the basic parameters of the fruit picking rollers have been determined, the size of the pull produced by the fruit picking roller on the peanut is influenced by the speed of the fruit picking roller and the angle of the fruit. The linear rate generated by the rotation of the picking blade is proportional to the speed of the picking roller [25,26]. The speed of the fruit picking rollers is proportional to the size of the pulling force of the fruit picking device.

2.2.2. Kinematic Analysis of Peanut Picking Process

The peanut plant and pods enter the picking area and complete the separation of the fruit seedlings and the final picking process. Throughout, the peanut has two main directions of speed. Firstly, the peanut plant body moves diagonally upwards with the clamping chain. The peanut pods are driven by the peanut seedling vine and root system so that the peanut pods have a horizontal upward speed. Secondly, as the fruit picking roller makes a circular motion, it drives the fruit picking roller blades to rotate. And the fruit picking roller blades produce a slapping effect on the peanut so that the peanuts get a vertical downward speed [27].

The pod’s movement can be approximated as a parabola when detached from the plant body. When separated, the peanut pods’ initial velocity can be seen as a combination of the clamping chain’s forward speed and the picking rollers’ rotation.

The velocity and displacement of the peanut pods after detachment are shown in Figure 6. Thus, the equation for the speed of the pods after they have detached from the plant is as follows:

Figure 6.

The movement track after pod separation process. v0x is the initial horizontal velocity of the peanut pod after it has detached from the root, m/s; v0y is the initial vertical velocity of the peanut pod after it breaks away from the roots, m/s; vx is the horizontal velocity of the peanut pods after they have detached from the roots, m/s; vy is the vertical velocity of the peanut pod after it has detached from the root, m/s. v is the rate of synthesis of peanut pods after detachment from the roots.

The direction equation is as follows:

The equation for the displacement of the pods falling away from the plant is as follows:

The direction equation is as follows:

This result is the ideal state for moving peanuts off the root system. However, during actual movement, there are frictional collisions between pods, stalks, branches, and leaves. The speed changes accordingly. The velocity of the pods after detachment was determined by calculation to fluctuate between 6 and 9 m/s.

2.3. Peanut Picking force Simulation Modelling

2.3.1. Analysis of Peanut Pod Collision Modeling

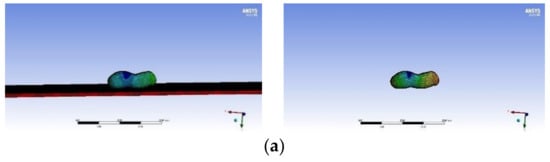

The impact area of the fruit picking roller blades on the peanut pods is small. In this paper, to simplify the complexity of the simulation, Simplification of the peanut pod collision model using software to become a simulation of the impact of individual peanut pods by picking pairs of roller blades. Simulation of collision mode settings for lateral, longitudinal, and vertical collision. The collision process is shown in Figure 7.

Figure 7.

Peanut pod simulation model of different collision modes. (a) Lateral collisions; (b) Longitudinal collisions; (c) vertical collision.

The meshing of the collision model using Hyper mesh, a Hyper works pre-processing software. The total number of meshes in the simulation model is 28,041. The number of peanut picking roller blade grids is 12,413, and the number of peanut pod grids is 15,628. The model after meshing is shown in Figure 8.

Figure 8.

Drawing grid with the simulation model.

After the Hyper mesh meshes, the file is imported into the Workbench LS-Dyna module for a collision simulation. The simulated collision process is shown in Figure 9 This paper sets the material properties of the model in LS-Dyna. And import the models of peanut pods. And picking peanut roller blades into the software, respectively. To simulate the forces on peanut pods under impact loading, set the peanut picking rollers to three speeds: 400, 450, and 500 r/min. Add fixed restraints to the base of peanut pods. Also set to pick peanut pods for contact during working collisions. The contact section contains surface contact and self-contact of the individual components. The final simulation time is set to 10 ms, output contact forces, directional deformation, mass energy, etc.

Figure 9.

Simulation process of peanut pod collision. (a) Lateral collisions; (b) Longitudinal collisions; (c) Vertical collision.

This paper applies different speeds of 400, 450, 500, and 550 r/min to the fruit picking roller blades. By adjusting the different rates of the fruit picking rollers, collision contact forces of 19 N, 35 N, 67 N, and 84 N are obtained. It increases contact forces as speed increases. The change rule is shown in Figure 10 The analysis shows that the contact force of the peanut pod and the rotation speed of the fruit picking roller is approximately linearly related [28,29,30].

Figure 10.

Contact force as a function of speed at different speeds.

The above condition leads to the following results. When the speed of the fruit picking roller is 400 r/min, the collision contact force is ideally 19 N, at which point the peanut pods are incompletely removed. When the fruit picking roller speed is 450 r/min, the collision contact force is 35 N in the ideal condition, which can satisfy the fruit picking demand in the perfect shape. Variability in the distribution of peanut pods and seedling vines from plant to plant during the actual peanut harvest. Irregular and oscillatory transfer of work when peanut pods are hit by picking roller blades. This periodic oscillation causes the impact force also to show fluctuating variations. Therefore, in this test, the minimum critical speed of the fruit picking rollers was 400 r/min.

2.3.2. Critical Impact Force Analysis Based on the JKR Model

The maximum speed of the picking rollers is governed by the breakage of the peanut pod shells during the picking process, with the assurance that the peanut pods are not damaged and can be picked off simultaneously. In this paper, the JKR theoretical model in contact mechanics is used for analysis. The critical impact force between the fruit picking roller and the peanut pod is mainly analyzed, and so is the critical speed of the impact between the fruit picking roller and the peanut pod. The traditional semi-feeding peanut picking mechanism is primarily based on the Hertz contact theory. Only the contact between two objects under external forces is considered, not the surface forces between the peanut pods and the picking blade. Because fresh peanuts are moist when dug out of the soil, the surface force between the knife roller and the peanuts must be considered. Normal contact forces between peanut pods or between peanut pods and the hob are based on the Johnson-Kendall-Roberts theory [31].

where VJKR is the normal contact force, N; δ is the amount of overlap, mm; γ is surface tension, N/m; E is the equivalent modulus of elasticity, Pa; α is the amount of tangential overlap, mm; R is the equivalent contact radius, mm; E1,E2 is the contact modulus of elasticity, Pa; U1,U2 is the contact Poisson’s ratio; R1,R2 is the contact radius, mm.

When the surface energy γ = 0, the JKR normal elastic force becomes Hertz-Mindin’s normal force, the formula is as follows:

The JKR contact model provides attractive cohesion even when the peanut pods are not in direct contact with the picking roller blades. The equation for the maximum normal and tangential gap with cohesion is as follows:

where ac is the normal maximum gap at non-zero cohesion, mm; δc is the tangential maximum clearance at non-zero cohesion, mm.

JKR cohesion reaches a maximum when the actual contact interval between the peanut pods and the picking blade is less than the maximum tangential clearance at non-zero cohesion. The formula is as follows:

According to the JKR model, the contact radius of the contact surface after contact under the combined effect of external load and contact forces on the contact surface is given by the following equation:

The equation for the displacement of the normal contact force is as follows:

The equation for the pressure distribution on the contact surface is as follows:

Therefore, the equation for the contact force between the peanut pod and the flat plate of the picking blade based on the JKR model is as follows:

When the contact force between the peanut pod and the picking blade is greater than the maximum strength force that the peanut pod can withstand, the peanut pod will break and be damaged. Therefore, the full critical state force for peanut pods during the picking process is Ftot.

Based on tests and a review of relevant information, relevant data can be obtained (Table 2). Bringing the data into Equation (27) results in a maximum critical speed of 500 r/min for the fruit picking roller.

Table 2.

Relevant material data.

Note: Yu Hua 14 (The peanut variety of Yu Hua 14 belongs to the pearl bean type, and the growth period of summer sowing is about 110 days. The plant type is erect. The plant height is 39.7 cm, the lateral branch is 44.7 cm long, and there are eight branches, six fruiting branches, and 10.8 fruits per plant. The leaves are obovate, dark green, and medium to large. The pods are cocoon-shaped, weighing 166.7 g, and the seeds are pink and peach-shaped).

It follows that the maximum critical impact speed between the peanut and the picking roller blade during fruit picking is related to the modulus of elasticity of the peanut and the picking roller blade itself, Poisson’s ratio, and the size of the pod itself. Combined with the above data analysis, the number of fruit picking roller speed factors are divided into three groups, 400 r/min, 450 r/min, and 500 r/min, respectively.

2.4. Field Trials

2.4.1. Field Trial Program

The trial was conducted on 23 September 2021 at the trial site in Jiaozhou County, Qingdao City, Shandong Province (120°33′ E, 36°07′ N). The peanut variety used in the trial was “Yuhua 14”. The agronomic pattern of peanut planting is monopoly double row planting with a monopoly spacing of 750 mm and a plant spacing of 263 mm, yielding 4000 kg/hm. Each plant of this variety of peanuts is divided into 10 to 14 branches. Single plant peanut pod yield around 220 g, peanut fruit arranged neatly and centrally. The test equipment includes a WT-CF series high precision electronic scale (Changzhou Wantai Balance Instruments Ltd.), steel frame tape measure (Hunan Maojun Baogong Electronics Ltd., range 0~150 m, accuracy 1 mm). Each test plot is a 30 m long 1-monopoly lot, and three replicate trials are used for each round, with the final average taken and recorded. This paper randomly selected ten peanut plants for this experiment [32,33]. Their statistics are shown in Table 3.

Table 3.

Statistics of peanut plant parameters.

2.4.2. Field Trial Conditions

The test machine was used for field trials with a three ridge six-row peanut combine harvester, and the test data was calculated and obtained by sampling and weighing. The field trial site is shown in Figure 11.

Figure 11.

Field trial. (a) Front of the machine in working condition; (b) Working condition of the side of the machine.

According to the Agricultural Industry Standard of The People’s Republic of China—Operation Quality of Peanut Harvester [34]. The pod crushed rate P1 and the peanut pod miss leakage rate P2 were used as test indicators to evaluate the picking performance.

The formula for calculating the pod crushed rate in the test index is set as follows:

where P1 is the crushing rate, %; M1 is the weight of the broken pods, kg; M2 is the weight without broken pods, kg.

The formula for calculating the pod leakage rate in the test index is set as follows:

where P2 is the missed pick rate, %; W1 is the weight of the unpicked peanut pods kg; W2 is the weight of the peanut pods that have been picked, kg.

3. Results and Analysis

3.1. Analysis of Simulation Tests for Multi-Factors

3.1.1. Test Factors Codes

To obtain better performance parameters of the peanut picking pair of rollers and verify the theoretical analysis’s rationality, a three-factor, three-level quadratic regression orthogonal combination test is conducted. This paper determines the experimental factors affecting fruit picking performance through theoretical analysis. The test factors affecting peanut picking performance were determined: clamping chain speed, fruit picking roller angle, and fruit picking roller speed. The test used crushing rate and leakage pick rate as response indicators. Therefore, this paper analyzes the test results and establishes a response surface model. The optimal combination of parameters for the three main factors affecting peanut crush and missed pick rate was finally determined. The test factor level codes are shown in Table 4.

Table 4.

Test factors codes.

3.1.2. Multi-Factor Test Results and Analysis

A three-factor, three-level quadratic regression orthogonal test was carried out with clamping chain speed, fruit picking roller angle, and fruit picking roller speed as test factors, and pod crushed rate and pods leakage rate as evaluation indicators. The results were analyzed according to the obtained data, and the significance analysis of the main factors affecting the index was carried out. The test results are shown in Table 5.

Table 5.

Results of the multi-factor test.

3.1.3. The Relationship between Test Factors and Evaluation Indicators

A multiple regression fit analysis was carried out on the data in Table 4 using Design-Expert software. Development of orthogonal response surface regression models for pod crushed rate and pod leakage rate with three independent variables: clamping chain speed, picking roller angle, and picking roller speed. Analysis of variance (ANOVA) was performed on the test data, as shown in Table 6 and Table 7.

Table 6.

Pod crushed rate analysis of variance.

Table 7.

Pod leakage rate analysis of variance.

The model P for peanut pod breakage rate and peanut pod missed pick rate were 0.0008 and <0.0001 (p < 0.01), respectively, as analyzed by the data in the table. The data from this regression model are highly significant. The p-values for the lack of fit were 0.2312, 0.7887. According to a regression model to optimize the working parameters of this peanut pod picker. The effect of A, B, C, and AC, on the regression model was highly significant in the pod crush rate model (p < 0.01). AB, BC and A2 had no significant effect on the regression model (p > 0.05); The impact of A, AB, AC, A2, and B2 on the regression model was highly significant in the pod leakage rate model (p < 0.01). BC, C2 had no significant effect on the regression model (p > 0.05). The response surface regression model for Y1, Y2 on the three factors is:

where Y1 is the peanut crushing rate, %; Y2 is the peanut missed pick rate, %.

The optimized equation after removing the non-significant regression term is as follows:

As seen in Table 8, in the quadratic regression model of pod crushed rate Y1 and pods leakage rate Y2 in this peanut picking trial, the p-value indicates that the two regression models are highly significant. The correction coefficient Adj R2 for the regression model for pod breakage rate Y1 was 0.9102, which shows that the model explained 91.02% of the corresponding variation, and the model could not explain only 8.98% of the data. Similarly, the regression model for pod leakage rate Y2 explains 94.48% of the corresponding variation. The model fit was good. The correlation coefficients R2 reached 0.9520 and 0.9758, respectively, indicating that the two regression models simultaneously misfitted the errors of this experiment less significantly. And it argues that the error during this experiment is small, and the experimental data has strong reliability.

Table 8.

Significance analysis of regression coefficient.

3.2. Analysis of Model Interaction Terms

Based on the regression model analysis results, the interaction response surface was plotted using data analysis software [33], as shown in Figure 12.

Figure 12.

Response surface of the influence of factor interaction on pod crushed rate. (a) Interaction between fruit picking roller angle and clamping chain speed; (b) Interaction between fruit picking roller speed and clamping chain speed; and (c) Interaction between fruit picking roller speed and fruit picking roller angle.

The law can be seen in Figure 12a. When the angle of the peanut picking roller and the speed of the clamping chain increase, the peanut pod crushed rate shows a decreasing trend. The main reason for that is the increased speed of the clamping chain and reduced time the picking rollers spend acting on the peanut pods. This paper results in a reduced pod crushed rate. As the relative angle of the peanut picking rollers increases, the minimum picking collision force increases, resulting in a higher peanut pod crushed rate. It is therefore concluded that the speed of the clamping chain has a greater influence than the angle of the picking roller in affecting the peanut pod crushed rate. Figure 12b shows that the peanut pod crushed rate trend decreases slightly as the clamping chain speed increases. And as the picking roller’s speed increases, the peanut pod crushed rate increases. The reason for this is that when the speed of the picking roller increases, the picking roller rotates rapidly, and the impact force on the peanut pods and the number of slaps increase within a certain period, leading to an increase in the pod crushed rate. The picking roller speed has a greater influence than the clamping chain speed in affecting the peanut pod crushed rate. As seen in Figure 12c, the angle of the peanut picking roller affects the effective picking distance, and the speed of the peanut picking roller directly affects the collision force. The analysis shows that the effect of the picking roll speed is higher than the picking roll angle because both factors affect the crushing rate.

As seen from Figure 13a, as the speed of the clamping chain decreases, the time it takes for the peanuts to enter the picking rollers will increase, and therefore the pod leakage rate decreases. When the peanut picking roller angle is reduced, the peanut pod collision force is reduced, resulting in a lower rate of leakage picks. It is possible to conclude that the effect of the clamping chain speed is higher than that of the picking roller angle regarding the peanut pods leakage rate. Through Figure 13b, it is easy to find out that the peanut pods leakage decreases as the picking roll speed increases. Pods leakage rate increases as the clamping chain speed increases. The main reason for this is that the effective number of pickings is directly proportional to the speed of the picking rollers. The effective number of selections is inversely proportional to the speed of the clamping chain. The clamping chain speed has a higher effect than the picking roll speed in influencing the peanut pod leakage rate. As shown in Figure 13c, the peanut pods’ leakage picking rate decreases as the picking roll speed increases—the angle of the picking roller increases, leading to the pod leakage rate increasing. The analysis shows that the speed of the picking roll has a greater influence on the rate of pod leakage picking than the angle of the picking roll. In summary of the response graph analysis, the main and secondary factors affecting peanut pod crushed rate and leakage picking rate are: picking roller speed > picking roller angle > clamping chain speed.

Figure 13.

Response surface of the influence of factor interaction on miss picking rate. (a) Interaction between peanut picking roller angle and clamping chain speed; (b) Interaction between peanut picking roller speed and clamping chain speed; and (c) Interaction between peanut picking roller speed and picking roller angle.

3.3. Experimental Optimization and Validation

The analysis was based on the results of these tests described in this paper to further improve fruit picking performance. The optimization objectives are the pod crushed rate and leakage picking rate. The optimization targets included the picking roller speed, determining roller angle, and clamping chain speed. Use Design-Expert software to optimize the regression model. The objective and constraint equations are as follows:

It concluded that when the clamping chain speed is 1.2 m/s. The relative angle between the peanut picking roller and the clamping chain is 10°. The speed of the peanut picking roller is 500 r/min. The minimum pod crushing rate is 2.8% currently. Similarly, when the clamping chain transmission speed is 0.84 m/s. The relative angle between the peanut picking roller and the clamping chain is 11.2°. The speed of the peanut picking roller is 442 r/min. There is a minimum pod leakage rate of 0.67% at the time. According to Agricultural Industry Standard of The People’s Republic of China—The Operation Quality of Peanut Harvester [34,35]. The optimum working interval for a semi-feeding peanut combine harvester adapted to a three-monopoly six-row can be derived as follows: Clamping chain speed 0.84–1.2 m/s, peanut picking roller angle 10°–11.2°, peanut picking roller speed 442 r/min-500 r/min.

4. Conclusions

- (1)

- This paper investigates the movement pattern of the peanut picking process and the force on peanut pods. The basic parameters of the independently developed three-monopoly six-row combined harvester for large-scale peanut harvesting are demonstrated. The main factors affecting the efficiency of fruit picking are explored: The transmission speed of the clamping chain holding the seedling fruit, the rate of the peanut picking pair of rollers, the installation angle of the peanut picking rollers, and the clamping chain.

- (2)

- Through kinetic analysis, the stable relationship between the test factor and the test index is determined. The basic parameters of the fruit picking roller were calculated and analyzed to determine the test factor clamping chain speed range of 0.7 m/s–1.2 m/s. The installation angle range of 6°–14° between the fruit picking roller and the clamping chain. Using the kinematic theory basis to establish a collision simulation model, the peanut pods collided in different directions to determine the minimum critical speed of the peanut picking roller. The JKR model theory determines the maximum critical value of peanut pods to avoid breaking. When picking peanuts and the test factor picking roller speed range of 400 r/min–500 r/min.

- (3)

- Validated by field trials and response surface modelling. The optimum working range of the three-monopoly six-row semi-feeding peanut combine harvester was adapted to: clamping chain speed 0.84–1.2 m/s, fruit picking roller angle 10°–11.2°, fruit picking roller speed 442 r/min–500 r/min. When the clamping chain speed was 1.2 m/s, the relative angle between the fruit picking roller and the clamping chain was 10°, and the fruit picking roller speed was 500 r/min, the lowest fruit picking crushing rate was 2.8%. Similarly, when the transmission speed of the clamping chain is 0.84 m/s, the relative angle between the picking roller and the clamping chain is 11.2°, and the speed of the picking roller is 442 r/min, there is a minimum fruit leakage rate of 0.67%.

- (4)

- This significantly reduced the breakage and leakage rates during peanut harvesting, and both were better than the industry standard [14,34,35]. The working efficiency of this three-monopoly, six-row peanut combine harvester is greater than 0.4 hm2/h. The operating efficiency of one-monopoly, two-rows of peanut combine harvesters in the market is 0.12–0.16 hm2/h. Under the condition that the missed picking rate and broken rate meet the industry standards, the peanut harvesting efficiency is greatly improved.

Author Contributions

Conceptualization, D.L. and D.W.; methodology, D.L.; software, D.L.; validation, D.L., Z.Z. and Z.C.; formal analysis, D.L. and Z.Z.; investigation, D.L.; resources, D.L.; data curation, Y.W. and Z.C.; writing—original draft preparation, D.L.; writing—review and editing, S.S.; visualization, D.L.; supervision, X.H.; project administration, D.W.; funding acquisition, D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Seeding and Field Management Mechanization Post Project (Grant NO. CARS-13) and Creation of Key Components and Intelligent Working Tools for High-Performance Seeding and Harvesting (Grant NO. 2021CXGC010813).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous oil crops, a review on mechanical harvesting state of the art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Liao, B.S. A review on progress and prospects of peanut industry in China. Chin. J. Oil. Crop. Sci. 2020, 42, 161–166. [Google Scholar]

- Yu, Z.Y.; Hu, Z.C.; Cao, M.Z.; Wang, S.Y.; Zhang, P.; Peng, B.L. Design of cleaning device of tangential flow and whole-feed peanut combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–37. [Google Scholar]

- Wang, S.Y.; Hu, Z.C.; Wu, F.; Yu, Z.C.; Cao, M.Z.; Gao, X.M. Modeling and experiment of feeding rate for full-feed peanut pickup harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–36. [Google Scholar]

- Guan, M. Research on Key Components of Full Feeding Peanut Picking Device and Picking Machine. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2016. [Google Scholar]

- Wang, B.K.; Gu, F.W.; Yu, Z.Y.; Cao, M.Z.; Wang, J.T.; Hu, Z.C. Design and Experiment of Pickup-up Mechanism of Axial-flow Full-feed Peanut Harvester. Trans. CSAM 2020, 51, 132–141. [Google Scholar]

- Hu, Z.C. Research on Key Technology of Semi-Feeding Peanut Combine. Ph.D. Thesis, Nanjing Agricultural University, Nanjing, China, 2011. [Google Scholar]

- Wang, D.W. Research on Key Devices of Peanut Combine. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2013. [Google Scholar]

- Nan, F.F. Experiment and Optimization of Key Working Parameters of Semi-Feeding Peanut Combine. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2017. [Google Scholar]

- Fang, Q.L. Innovative Design and Performance Analysis of Fruit Picking Device of Peanut Combine Harvester. Master’s Thesis, Hebei Normal University of Science and Technology, Qinhuangdao, China, 2021. [Google Scholar]

- Hu, Z.C.; Wang, H.O.; Peng, B.L.; Chen, Y.Q.; Wu, F.; Zhang, Y.H. Optimization design and experiment of half-feeding peanut picking device. Trans. CSAM 2012, 43, 131–136. [Google Scholar]

- Wang, B. Pod-picking Mechanism and Screening Characteristic Research for Bottom-feeding Four Rows Peanut Combine Harvester. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2018. [Google Scholar]

- Zhang, P. Biotribological Characteristic of Peanut Harvesting Impact-Friction Contact under Different Conditions. Agronomy 2022, 12, 1256. [Google Scholar] [CrossRef]

- Gao, Z.H.; Shang, S.Q.; Wang, D.W.; He, X.N.; Xu, N. Design and Test of Three Ridge Six Row Peanut Combine Harvester Picking Device. Trans. CSAM 2023, 45, 176–181. [Google Scholar]

- Zhai, X.T.; Chen, M.D. Load spectrum compiling of peanut combine harvester’s seedling clamping and conveying system. Trans. CSAM 2020, 51, 261–266. [Google Scholar]

- Ji, K.Z.; Li, Y.M.; Liang, Z.W.; Liu, Y.B.; Cheng, J.H. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture 2022, 12, 213. [Google Scholar] [CrossRef]

- Yang, H.; Cao, M.; Wang, B.; Hu, Z.; Xu, H.; Wang, S.; Yu, Z. Design and Test of a Tangential-Axial Flow Picking Device for Peanut Combine Harvesting. Agriculture 2022, 12, 179. [Google Scholar] [CrossRef]

- Hu, Z.C.; Peng, B.L.; Xie, H.X. A Semi-Feeding Peanut Harvesting and Picking Device. China Patent ZL200910212625, 5 May 2010. [Google Scholar]

- Wang, B.K.; Hu, Z.C.; Cao, M.Z.; Zhang, P.; Yu, Z.Y.; Zhang, C. Design and test of axial-flow peanut picking and harvesting machine. Trans. CSAM 2021, 52, 109–118. [Google Scholar]

- Yang, R.B.; Wang, Z.Z.; Shang, S.Q.; Chen, M.D.; Wang, J.; Wang, Z.C. Design and experiment of seedling bundle coating device for peanut combine harvester and silage machine. Trans. CSAM 2020, 51, 109–117. [Google Scholar]

- Yu, J.D.; Liu, Y.F.; Wang, D.W. Design and Experimental Study of Movable Peanut Picker. J. Agric. Mech. Res. 2021, 43, 59–65. [Google Scholar]

- Gao, L.X.; Su, Z.; Chen, Z.Y.; Liu, Z.X.; Lv, C.Y.; Li, H. Design and experiment of double roller half feeding peanut picking device in plot breeding. Journal of agricultural machinery. Trans. CSAM 2016, 47, 93–98. [Google Scholar]

- Shi, G.K.; Ding, L.P.; Zhang, Z.Y.; Ding, H.Z.; Kan, Z. Calibration and Tests for the Discrete Element Simulation Parameters of Fallen Jujube Fruit. Agriculture 2022, 12, 38. [Google Scholar] [CrossRef]

- Wang, B.; Gu, F.; Cao, M.; Xie, H.; Wu, F.; Peng, B.; Hu, Z. Analysis and Evaluation of the Influence of Different Drum Forms of Peanut Harvester on Pod-Pickup Quality. Agriculture 2022, 12, 769. [Google Scholar] [CrossRef]

- Guo, P.; Shang, S.Q.; Wang, D.W.; He, X.N.; Xu, N.; Liu, J.Q.; Yang, L.; Dong, M.M. Design and test of a trailed peanut picking and harvesting machine. J. Chin. Agric. Mech. 2021, 44, 92–97. [Google Scholar]

- Su, X.; Wang, D.W.; He, X.N.; Zhang, N.; Li, Y.C.; Chang, Z.C. Development and analysis of double disc cutter for peanut plant. J. Chin. Agric. Mech. 2020, 42, 104–108. [Google Scholar]

- Zheng, J.S. Design and experiment of peanut digging and placing machine based on two-stage harvest. J. Chin. Agric. Mech. 2022, 44, 133–139. [Google Scholar]

- Lu, R.; Liu, Z.X.; Gao, L.X.; Yang, D.X. Development of air suction cleaning device of vertical conical peanut sheller for plot planting. Trans. Chin. Soc. Agric. Eng. 2020, 36, 23–30. [Google Scholar]

- Guan, M.; Chen, Z.Y.; Gao, L.X.; Liu, Z.X.; Cheng, J.; Zhang, X.D. Research on the experimental device of multi-functional combination of peanut fruit picking. Trans. CSAM 2015, 46, 88–94. [Google Scholar]

- Wang, J.N.; Xie, H.X.; Hu, Z.C.; Liu, M.J.; Peng, J.Y.; Ding, Q.S.; Peng, B.; Ma, C.B. Optimization of Material for Key Components and Parameters of Peanut Sheller Based on Hertz Theory and Box–Behnken Design. Agriculture 2022, 12, 146. [Google Scholar] [CrossRef]

- Liu, T. Investigation on Surface Energy of High-humidity Maize Mixtures. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2021. [Google Scholar]

- Yu, X.D.; Guo, H.; Guo, W.H.; Xue, S.M.; Liu, H.S.; Ye, X.W. Design and Motion Simulation of Pneumatic Device for Pickup up Ground Jujube. J. Agric. Mech. Res. 2021, 43, 116–120. [Google Scholar]

- Chen, Y.Q.; Hu, Z.C.; Wang, S.Y.; Cao, M.Z.; Xu, H.B.; Wang, G.P.; Yan, J.C. Design and experiments of pickup device of peanut harvester after cutting peanut straws. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–8. [Google Scholar]

- NY/7502; Agricultural Industry Standard of the People’s Republic of China-Operation Quality of Peanut Harvester. Standardization Administration of the People’s Republic of China: Beijing, China, 2002.

- NY/T993; Agricultural Industry Standard of the People’s Republic of China-Operation Quality of Peanut Picker. Standardization Administration of the People’s Republic of China: Beijing, China, 2006.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).