As one of the main sources of protein nutrition in human daily life, the importance of poultry eggs and related products is self-evident. From 2010 to 2030, global egg production will be increased by 35%, with Asia contributing 64.8% to the total global growth [

1]. In the preliminary processing of eggs, such as cleaning, testing, transportation, and other procedures, eggshell damage may occur, and bacteria and other microorganisms may enter the eggs from the cracks and cause spoilage before infecting the surrounding good eggs. This may not only lead to a shortened shelf life and lowered value but also make the food unsafe to eat, causing economic losses to enterprises in the end. Traditional eggshell crack detection mainly depends on artificial light or the sound produced upon impact to the eggs to identify cracked ones, which not only sets high requirements for the experience and physical condition of workers, but the efficiency and reliability cannot meet the growing market demand. Therefore, it is of great significance for consumers, enterprises, and agricultural modernization to study a highly reliable, non-destructive, and automatic cracked egg removal system [

2].

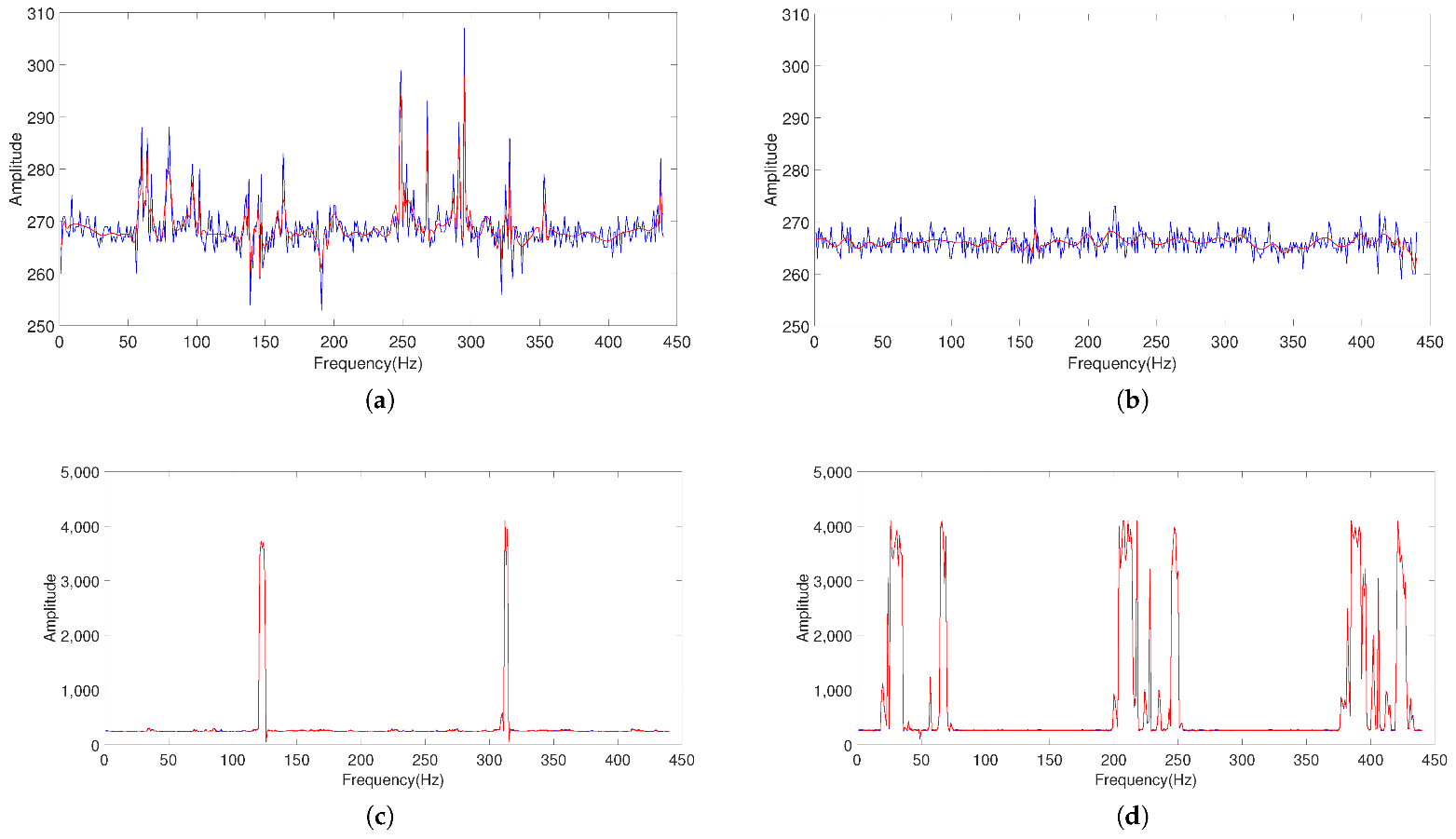

In recent years, researchers both nationally and internationally have been trying to find an automatic online approach to detecting eggshell cracks so as to lower labor intensity and improve the efficiency and accuracy of detection. The related research mainly focuses on acoustic analysis and machine vision. Acoustic analysis has been proven to be an effective method for detecting cracked eggs [

3]. Li Sun et al. built an equivalent mechanical model based on an automatic excitation device and analyzed the transient impact. They used cross-correlation analysis and Bayesian classification to detect eggshell cracks, which could reach a detection level of 97% [

4]. P. Coucke et al. proposed exciting the eggs with a small impact hammer and extracting the spectral features of acoustic signals as the input vector of the classification algorithm, whose detection accuracy could reach 90% [

5]. A non-destructive detection technique proposed by Cho et al. based on acoustic impulse response employed eight frequency domain indexes, such as the average area of the power spectrum, as input vectors, where multivariate discriminant analysis and multivariate regression analysis were used to establish a classification model. Its detection accuracy could reach 95% [

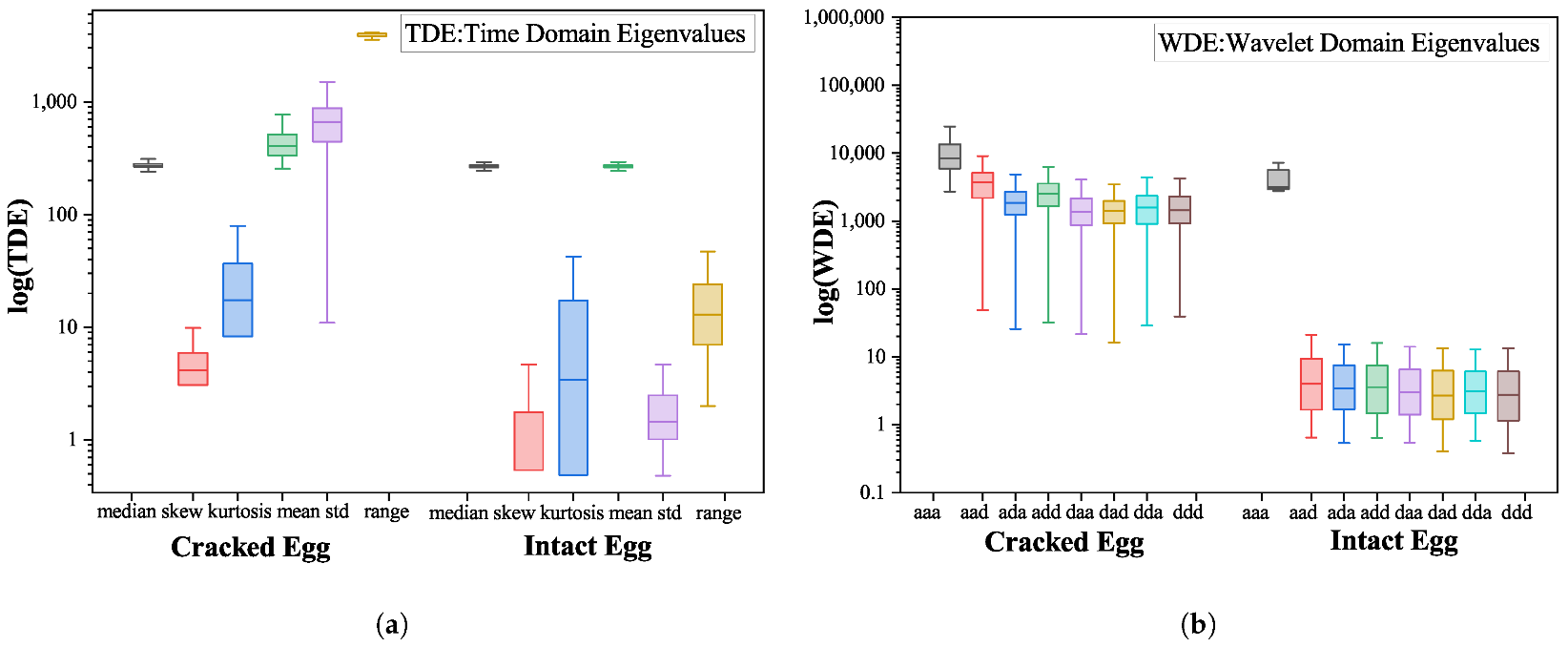

6]. Deng et al. proposed a crack detection method based on a continuous wavelet transform and support vector machine (SVM). They integrated four wavelet features such as the first resonance scale and achieved a detection accuracy of 98.9% [

7]. Sun et al., based on acoustic resonance, analyzed the difference in the frequency response signals between intact eggs and cracked eggs, extracted five excitation resonance frequency characteristics, such as the spectral peak, as input vectors, and achieved a detection accuracy of 96.11% [

8]. Lai et al. measured the acoustic signals of intact duck eggs and cracked duck eggs, and they selected the five most significant frequency features as the input vectors in logistic regression analysis. The overall detection accuracy could reach 87.6% [

9]. Wang et al. developed an excitation device driven by solenoids, producing sound signals by striking the eggs. The time domain and frequency domain features of 12 kinds of sound signals were extracted while using a neural network with feature dimension reduction as the classifier. The detection accuracy was as high as 99.2% in the training set, but it was slightly lower—about 95%—in the test set [

10]. The detection approach for cracked eggs based on acoustic signals is very effective, and its accuracy can basically meet the requirements for application. However, this approach is susceptible to such factors as an uneven eggshell thickness, surrounding noise, the egg shape, crack position, striking angle, and so on. Moreover, a lack of stability or knocking with too much strength may cause secondary damage to the eggs [

11,

12]. In addition, the detection of egg cracks based on machine vision has also made great progress [

13,

14]. Elster et al. first applied machine vision technology to eggshell crack detection and could find the cracked eggs among the samples with an accuracy of 95.6%. However, it took 25.3 s to identify a cracked egg, which was relatively slow [

15]. The cracked egg detection system designed by Gooddrum et al. was able to adjust the speed of the rotating device according to the size of the egg. Three images were taken for each egg at an interval of 120° near the equator, with a recognition accuracy of up to 90% [

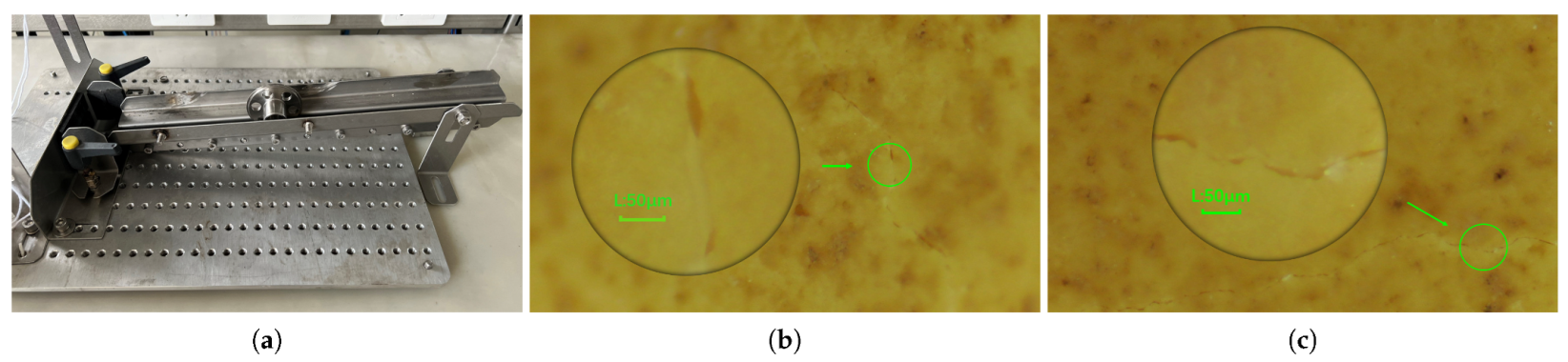

16]. Li et al. proposed a vacuum pressure chamber-based detection system which imposed a vacuum pressure of 18 kPa to enlarge the microcrack and reached a detection accuracy of 100% under a situation without stains [

17]. However, at present, this method is only in the laboratory stage, so it cannot be used in actual industrial production lines. Wang et al. proposed a method for detecting cracks in eggs using multi-information fusion of a natural light image and polarization image with an accuracy of 94% [

18]. Bao et al. aimed at the phenomenon of dark spots on the surface of eggshells under backlight conditions, adopted a negative LOG operator for image enhancement, set a threshold to eliminate black spots, and finally detected cracks through the LFI index, with the detection accuracy being up to 92.5% [

19]. Muammer proposed a machine vision detection system based on deep learning, in which six images of egg surfaces were captured in the process of the continuous rotation of an egg, and the depth features were extracted by a pretrained residual network in parallel and then input into the BiLSTM network to carry out the detection of cracked eggs. The accuracy rate was up to 99.17% under experimental conditions [

20]. Most of the above research methods were implemented in a laboratory environment, and in industrial production, the identification accuracy will be greatly affected due to the difference in the size, shape, depth, and other features of eggshell cracks, as well as such factors as the shooting angle and bright spots and stains on the shell. Therefore, it is still an urgent problem to study a new method that can meet the requirements of automatic detection of eggshell cracks in industrial production.

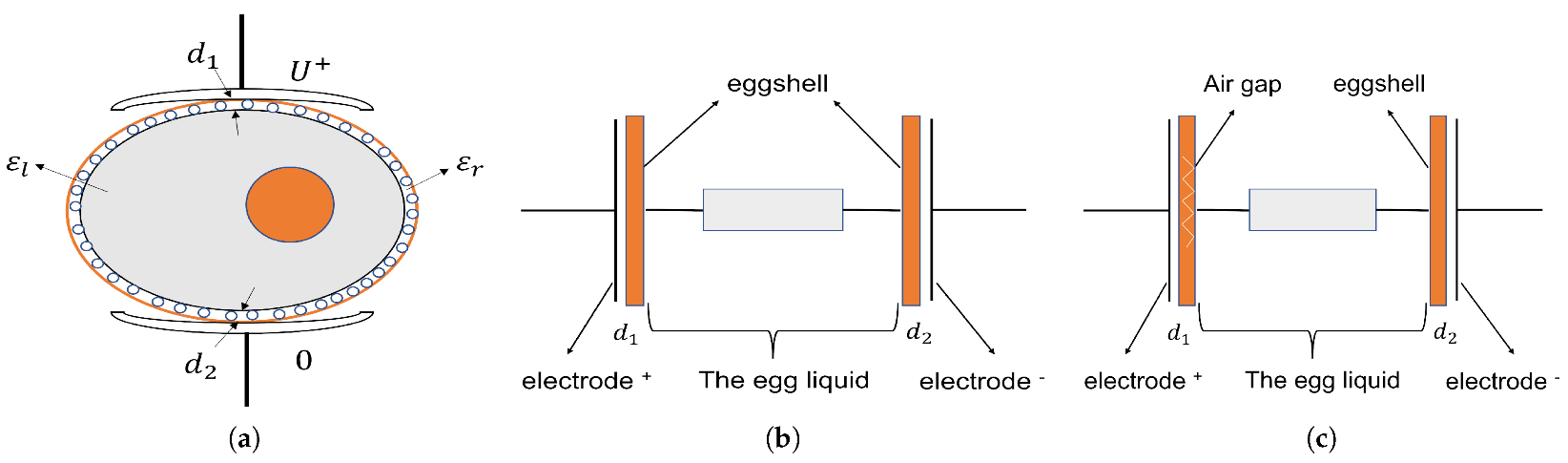

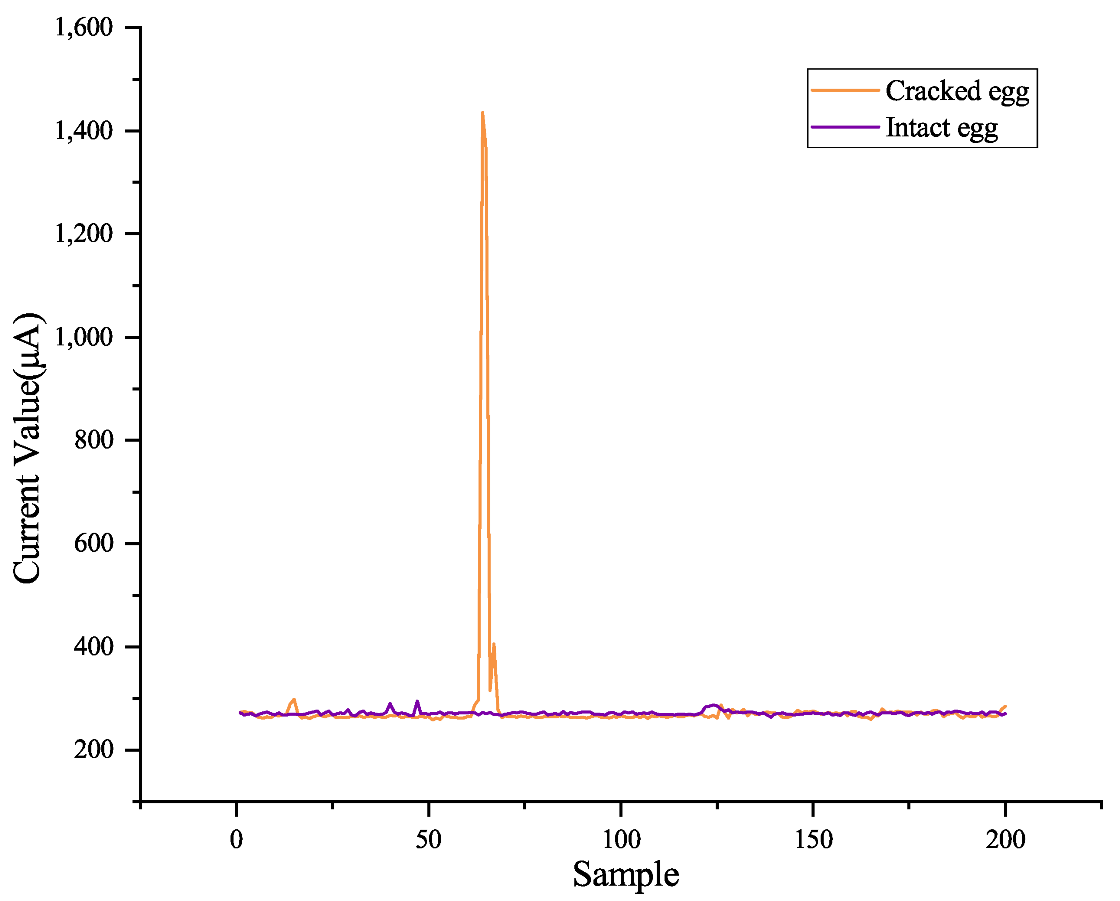

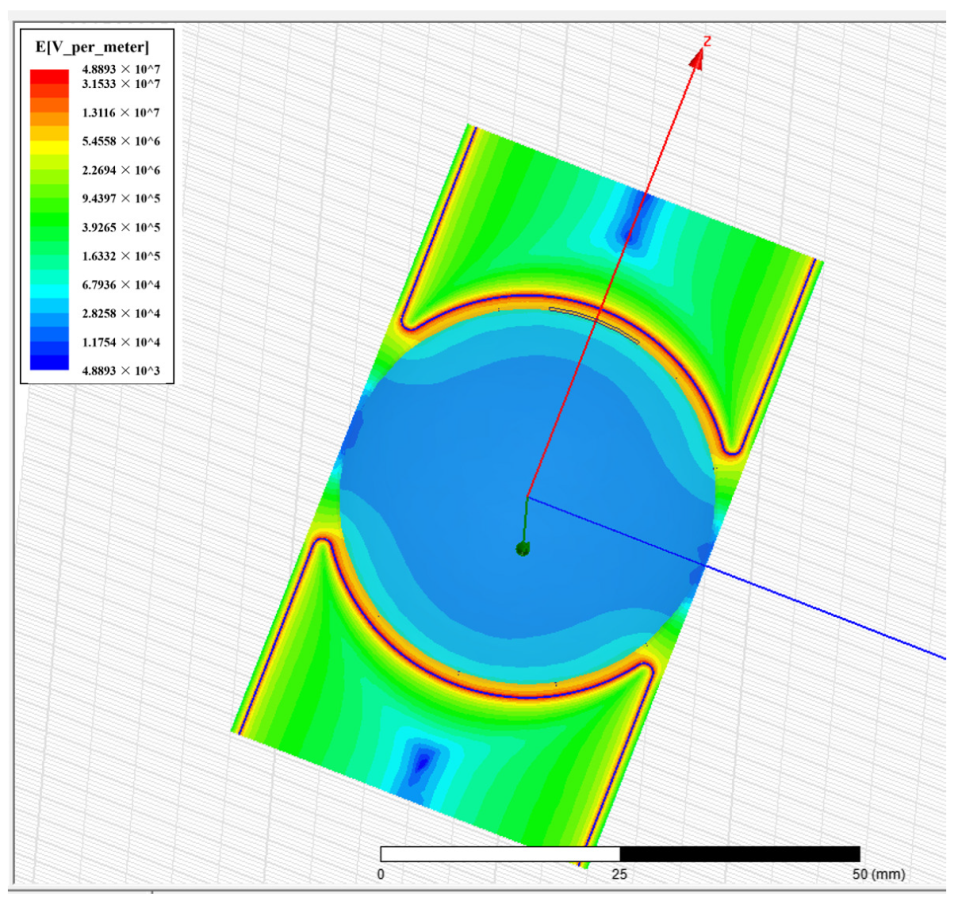

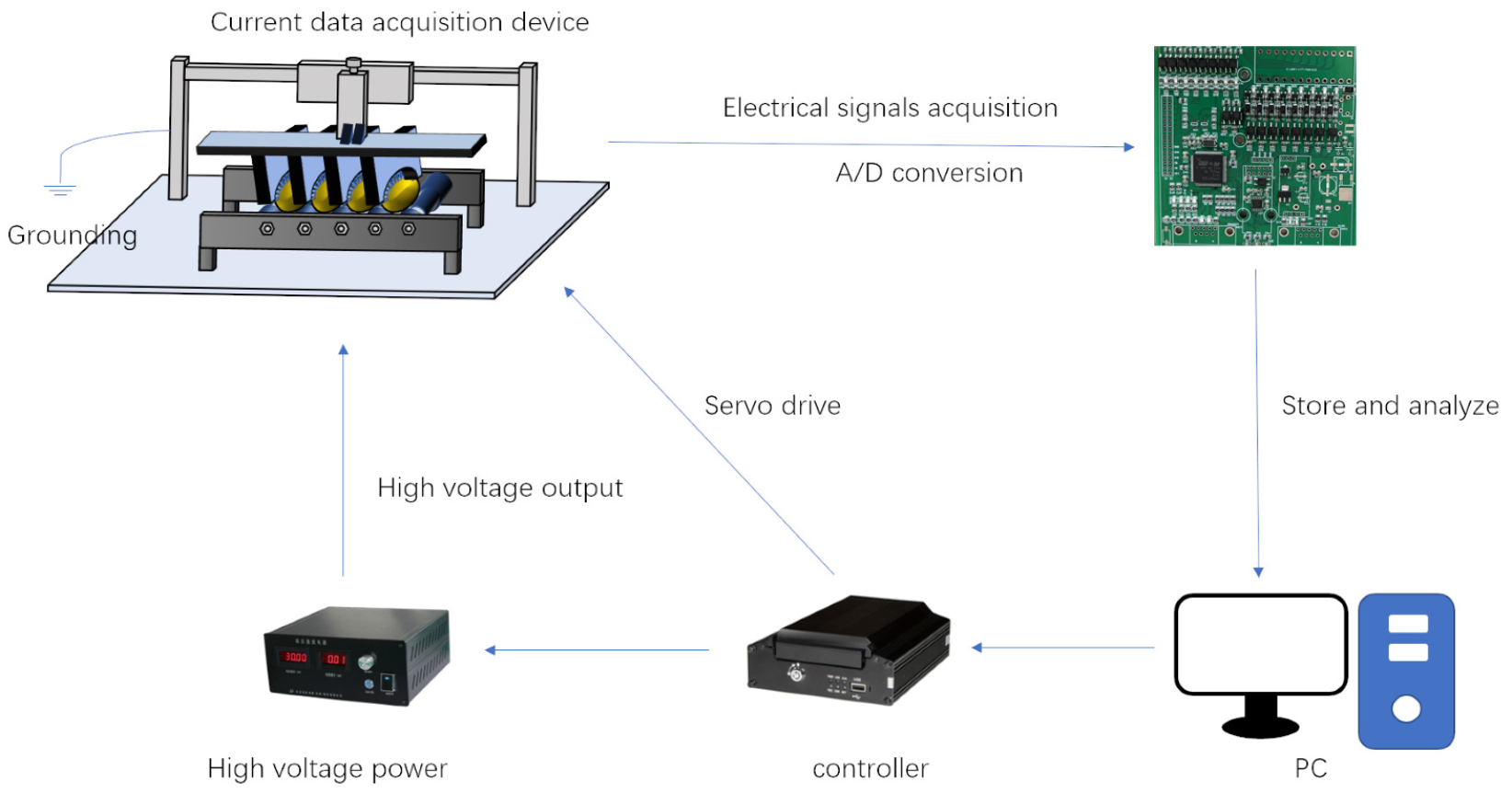

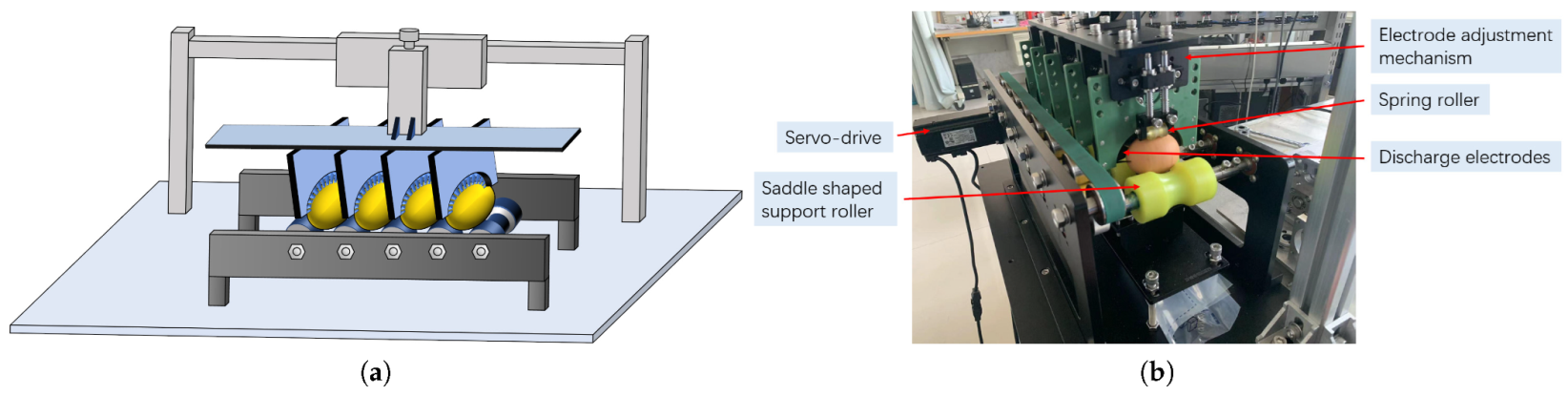

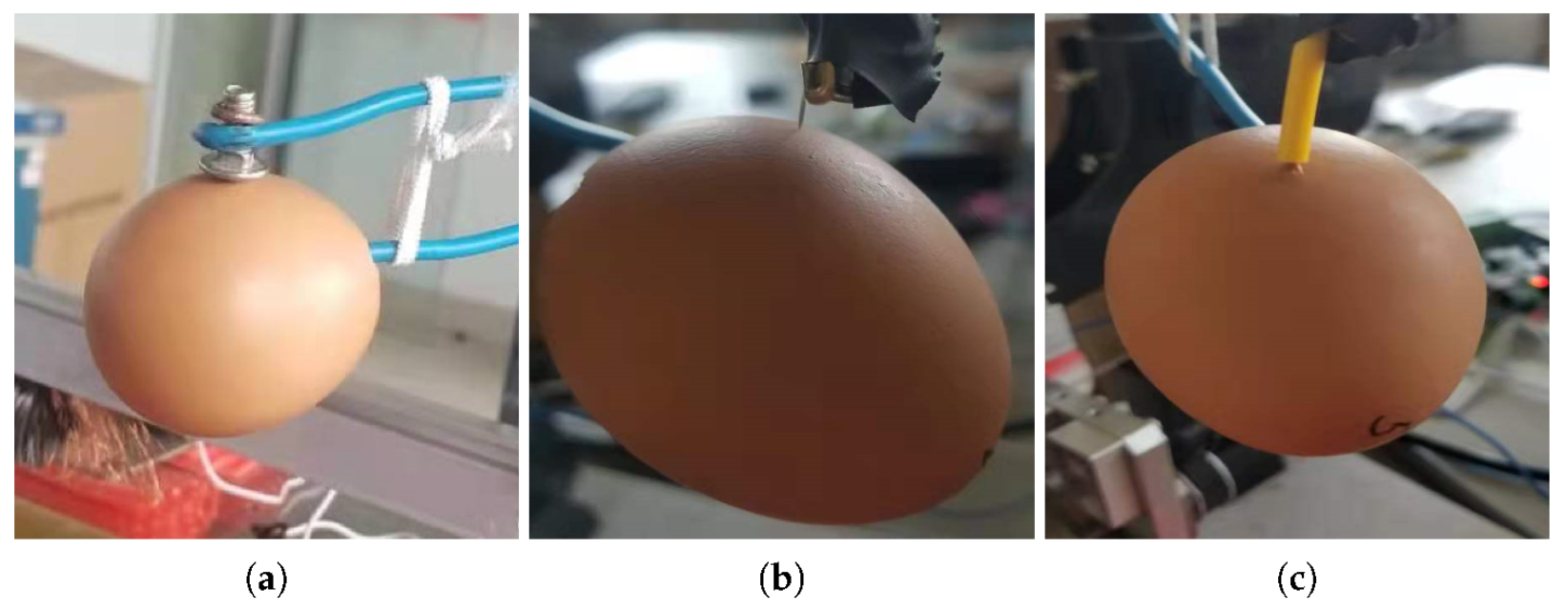

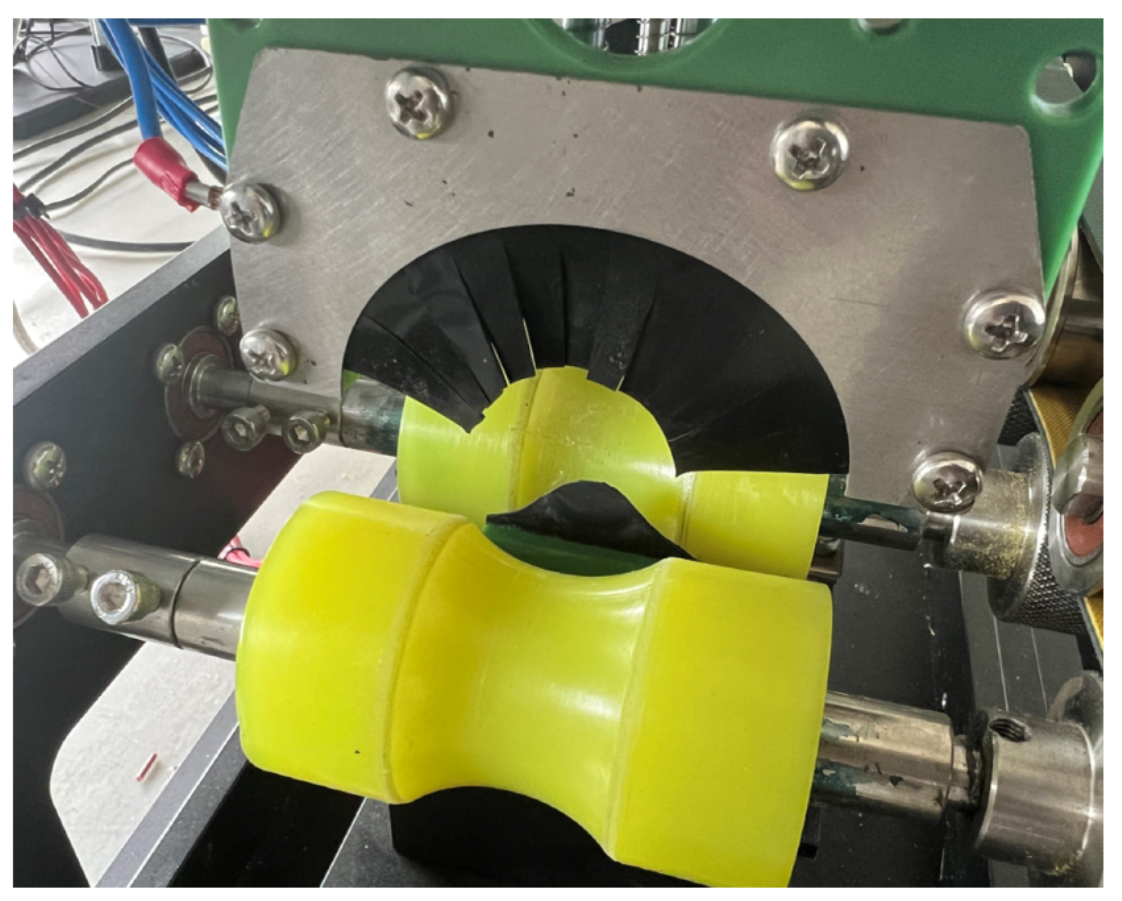

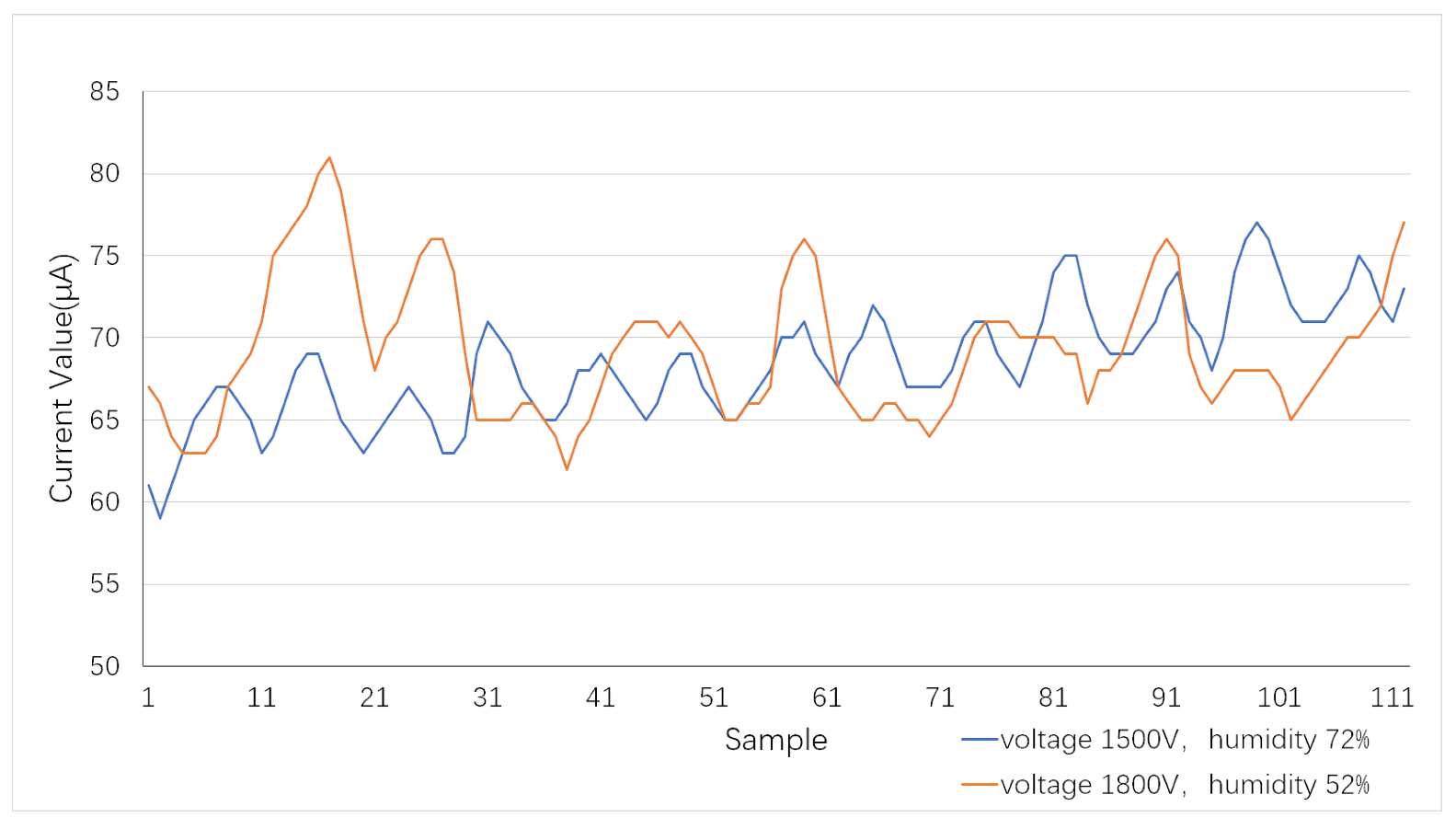

High-voltage leak detection(HVLD) is a type of common and mature non-destructive defect detection technology which is mainly used in the pharmaceutical industry and the food industry, with the advantages of high speed and high precision. In this method, electrodes are usually linked at both ends of a container with a non-flammable conducting liquid, and a high voltage is applied. Equivalent capacitance is generated between the liquid and the electrode due to the bottle wall. When the container is intact, there is a tiny current in the circuit, but if the container has cracks and leaks, the capacitance disappears and causes a discharge between the electrodes. Therefore, the discharge analysis technology can be used to detect the tiny cracks and damages of the container with high precision. Yoon S. Song et al. studied the important role the key variables play in the detection of tiny pinhole leakages in flexible bags and semi-rigid cups using high-voltage technology. They applied 0.25–10 kV to the packaging, and the results showed that the HVLD technology could detect defects of less than 10 μm [

21]. Moll et al. studied and verified the use of high voltage to detect the defects of blow-fill-seal containers with an accuracy of 100% [

22]. Sun Jun et al. studied a non-destructive method to identify egg varieties based on their dielectric properties. They used parallel plates to measure the dielectric properties of eggs at 10∼200 kHz and established a fast identification and classification model of egg varieties by using the SVM algorithm, which met the requirements of classification well [

23]. However, as far as we know, no researchers have applied the relevant research methods and ideas to the detection of cracks in poultry eggs.

Therefore, this research is aimed at proposing a novel and convenient nondestructive method to detect cracks in poultry eggs in the industrial field. The main objectives of the study are as follows: