Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot

Abstract

:1. Introduction

- (1)

- The trajectory planning problem of multiarm cooperative harvesting of straw-rotting fungus is transformed into an MTSP problem;

- (2)

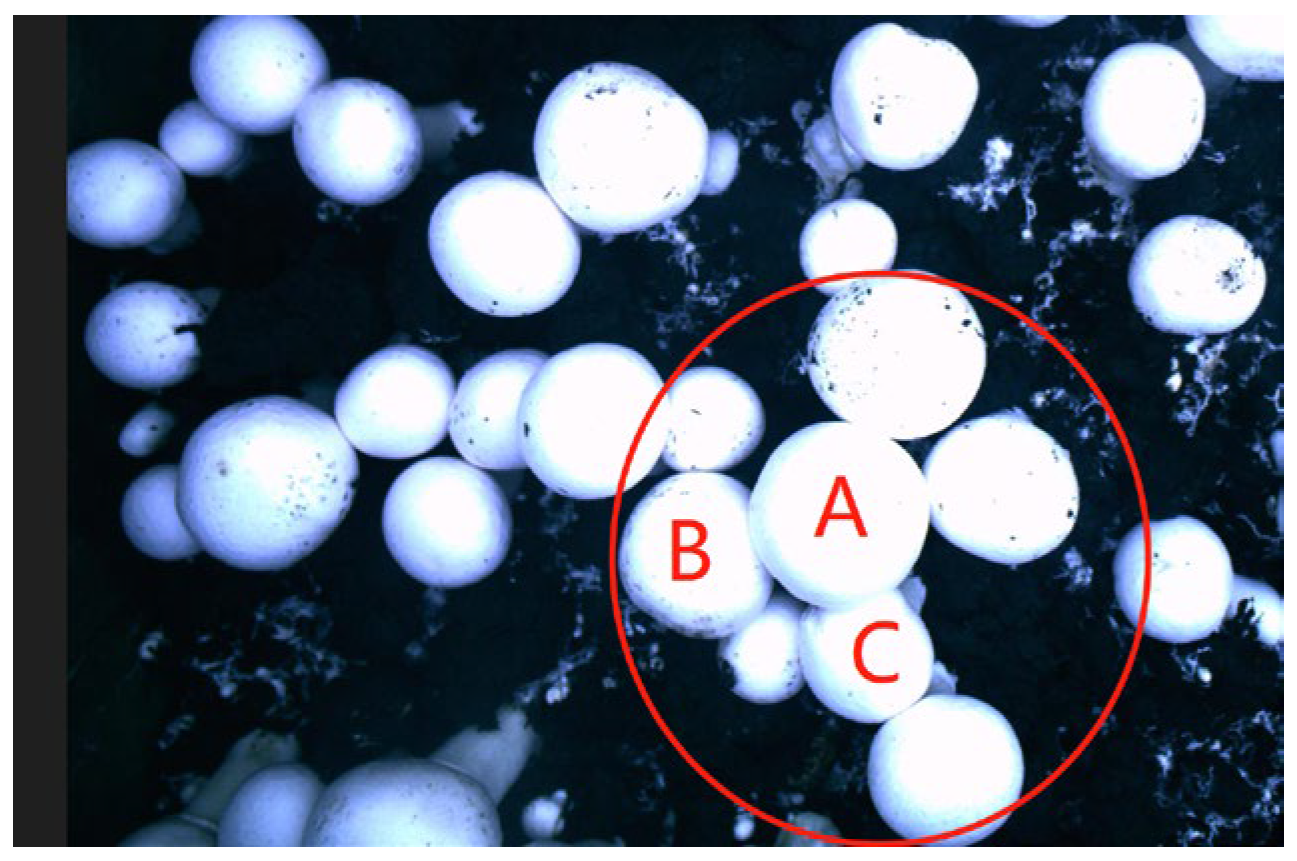

- To resolve the difficulty of accurately recognizing the fruit clusters of straw-rotting fungus due to their different shapes and uncertain density, a density-based clustering algorithm is improved by designing a new method for calculating local density, which can better meet the clustering analysis of straw-rotting fungus;

- (3)

- A multiobjective optimization model is built for the trajectory optimization of an intelligent multiarm straw rotting fungus harvesting robot;

- (4)

- The improved ant colony algorithm combined with the auction mechanism is used to achieve the shortest trajectory of each TSP problem. Meanwhile, the fruit clusters that are required to be picked in a specific order can be allocated to different arms instead of being allocated to a single arm by combining the auction mechanism with an ant colony.

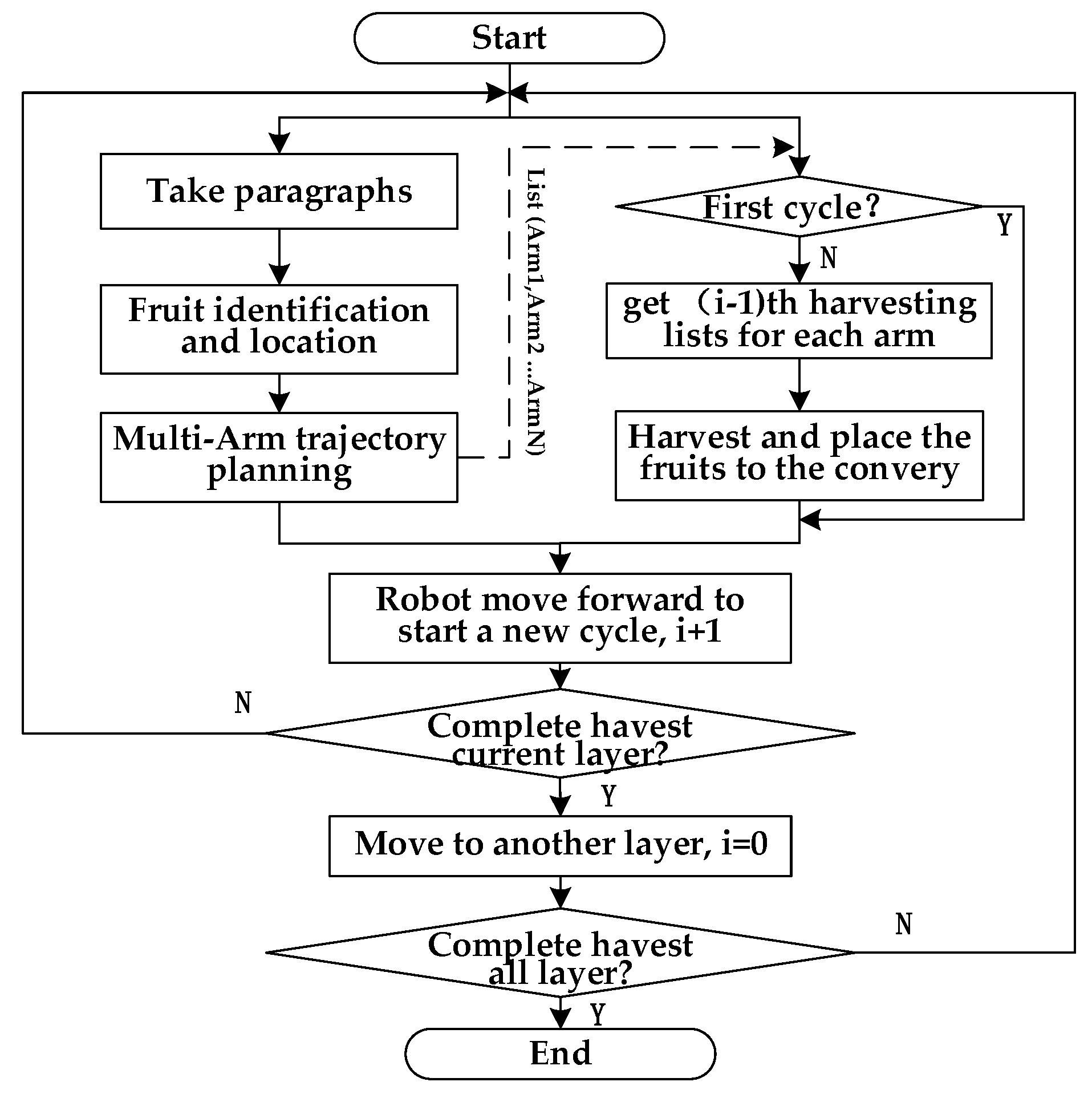

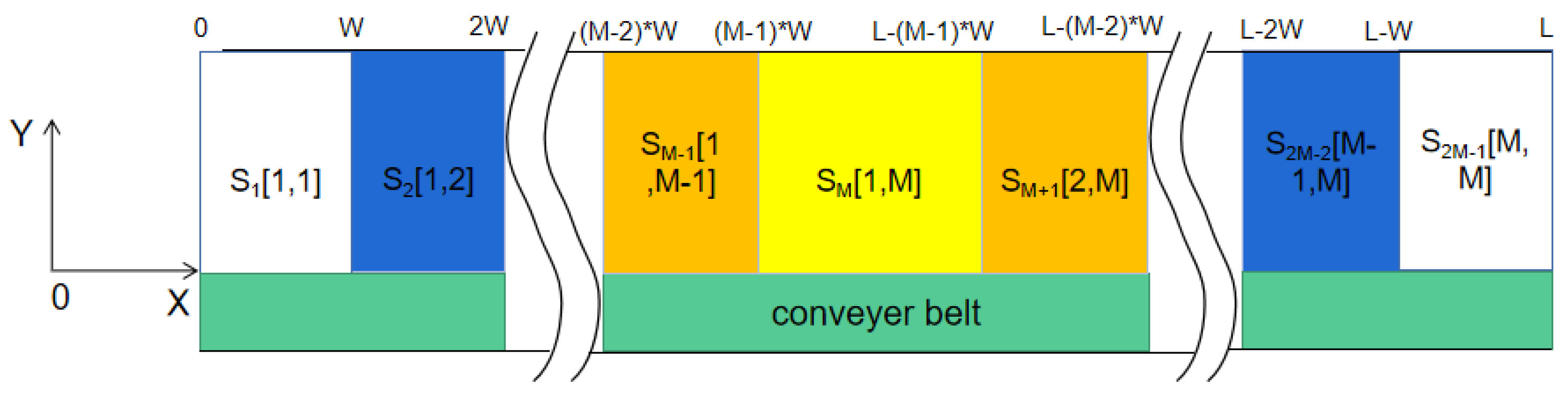

2. Description of Multiarm Cooperative Harvesting Trajectory Planning Problem

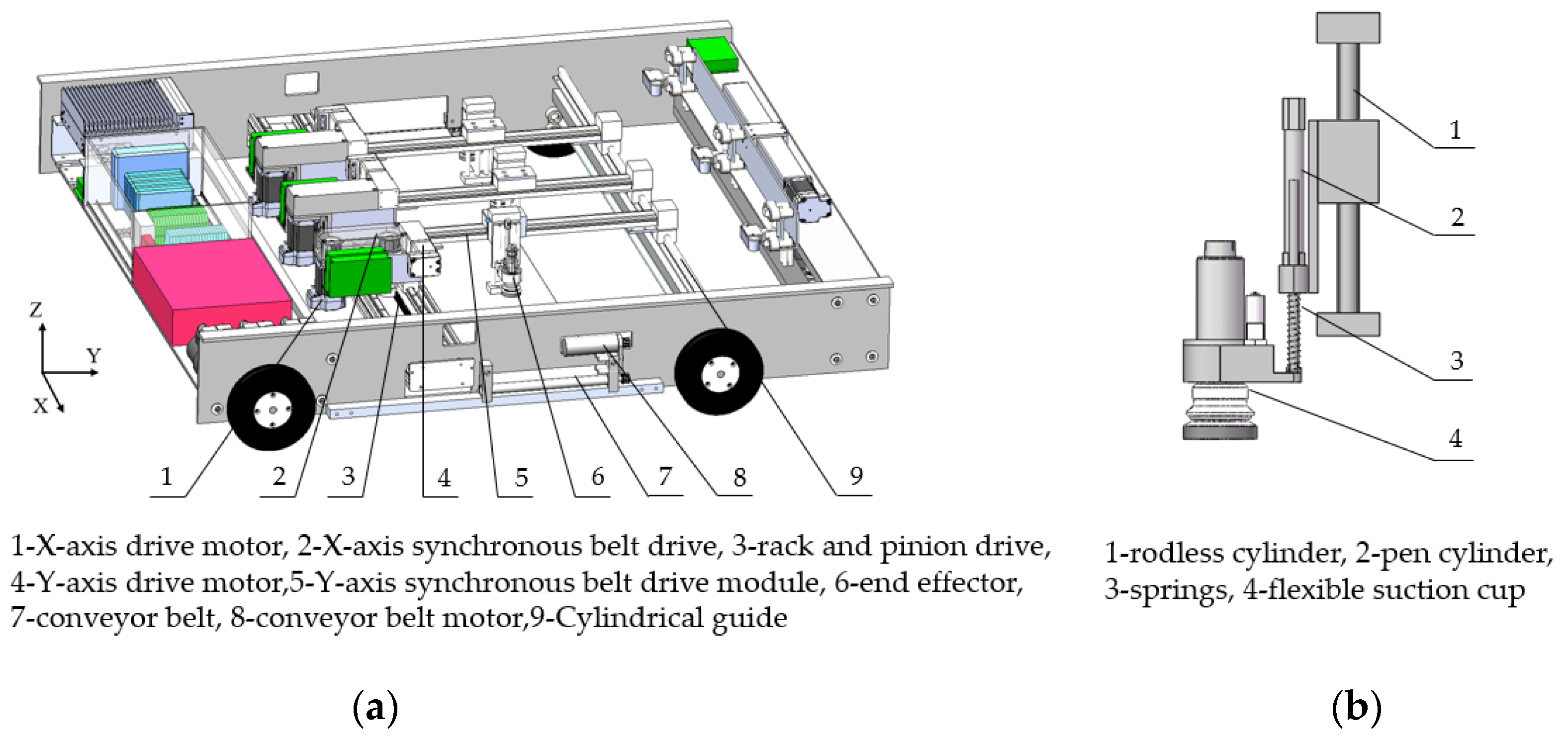

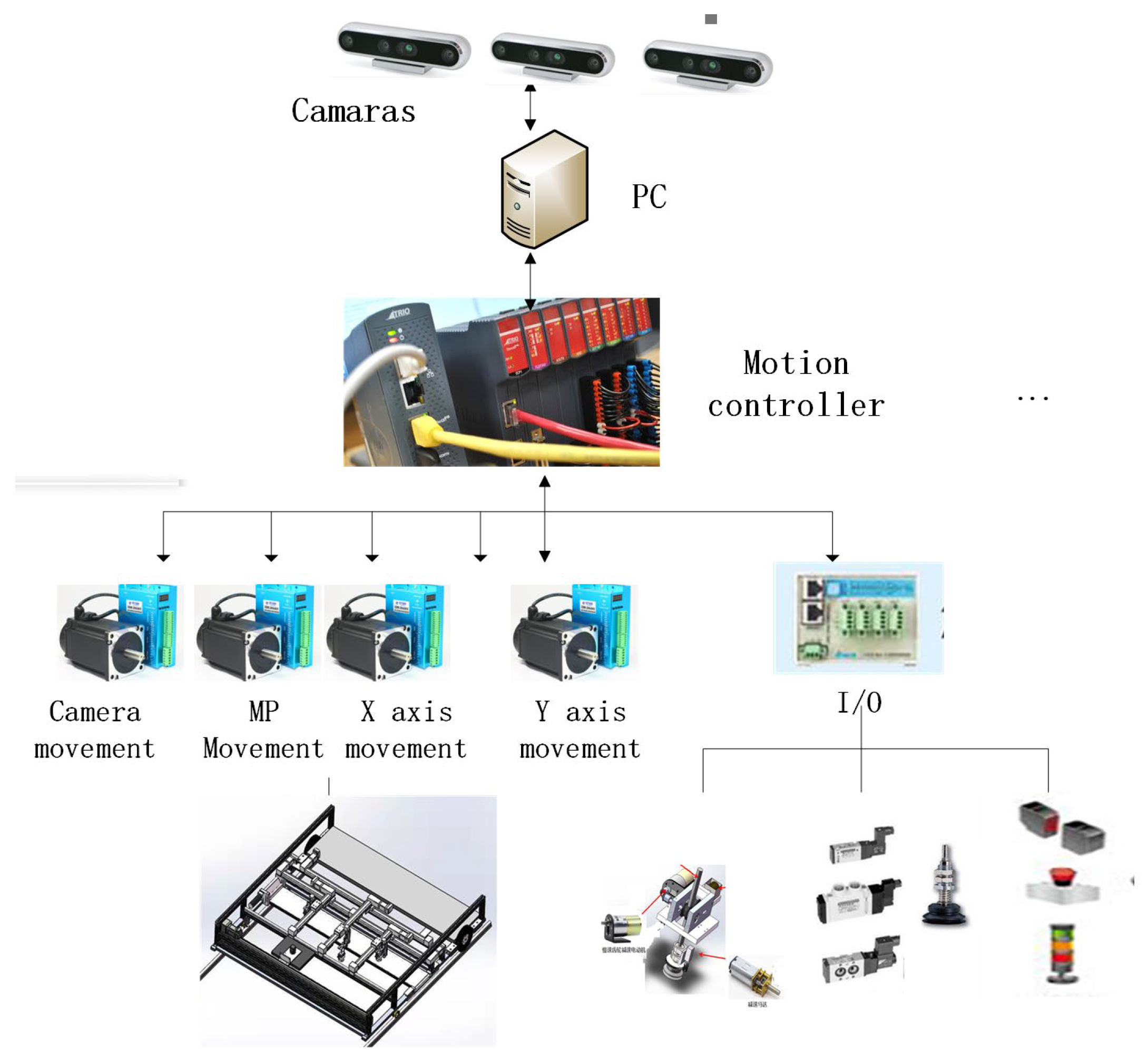

2.1. Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot

2.2. Accessibility Analysis of Multiple Harvesting Arms

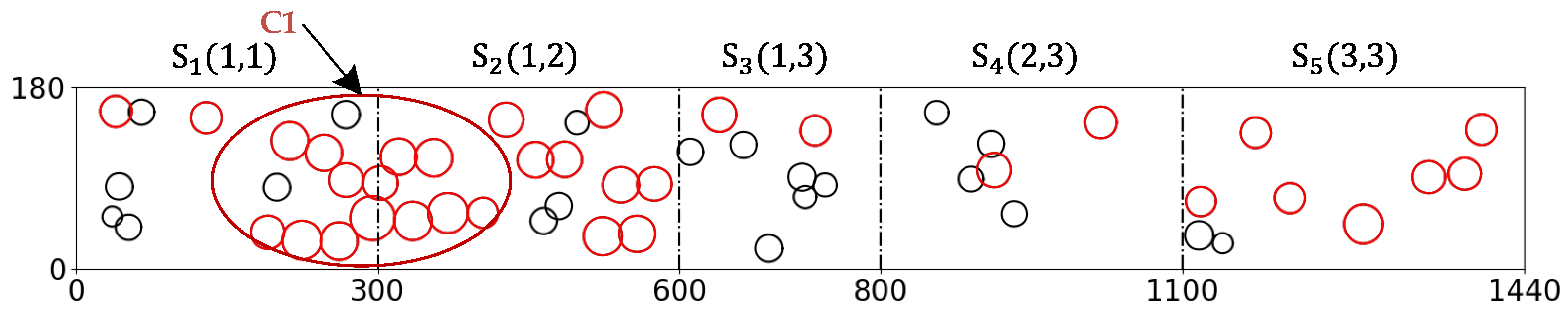

2.3. Description of Trajectory Planning for Multiarm Cooperative Harvesting

- (1)

- Each harvesting arm’s accessible region is limited by the SISS region shown in the above section;

- (2)

- To avoid collision between the adjacent harvesting arms, a safety distance Dist is required;

- (3)

- After completing the harvesting tasks, each harvesting arm should go back to its start point independently, which is (0,0), (W,0),…,((M − 1) × W,0).

3. Mathematical Model of Multiarm Cooperative Harvesting Trajectory Planning Problem

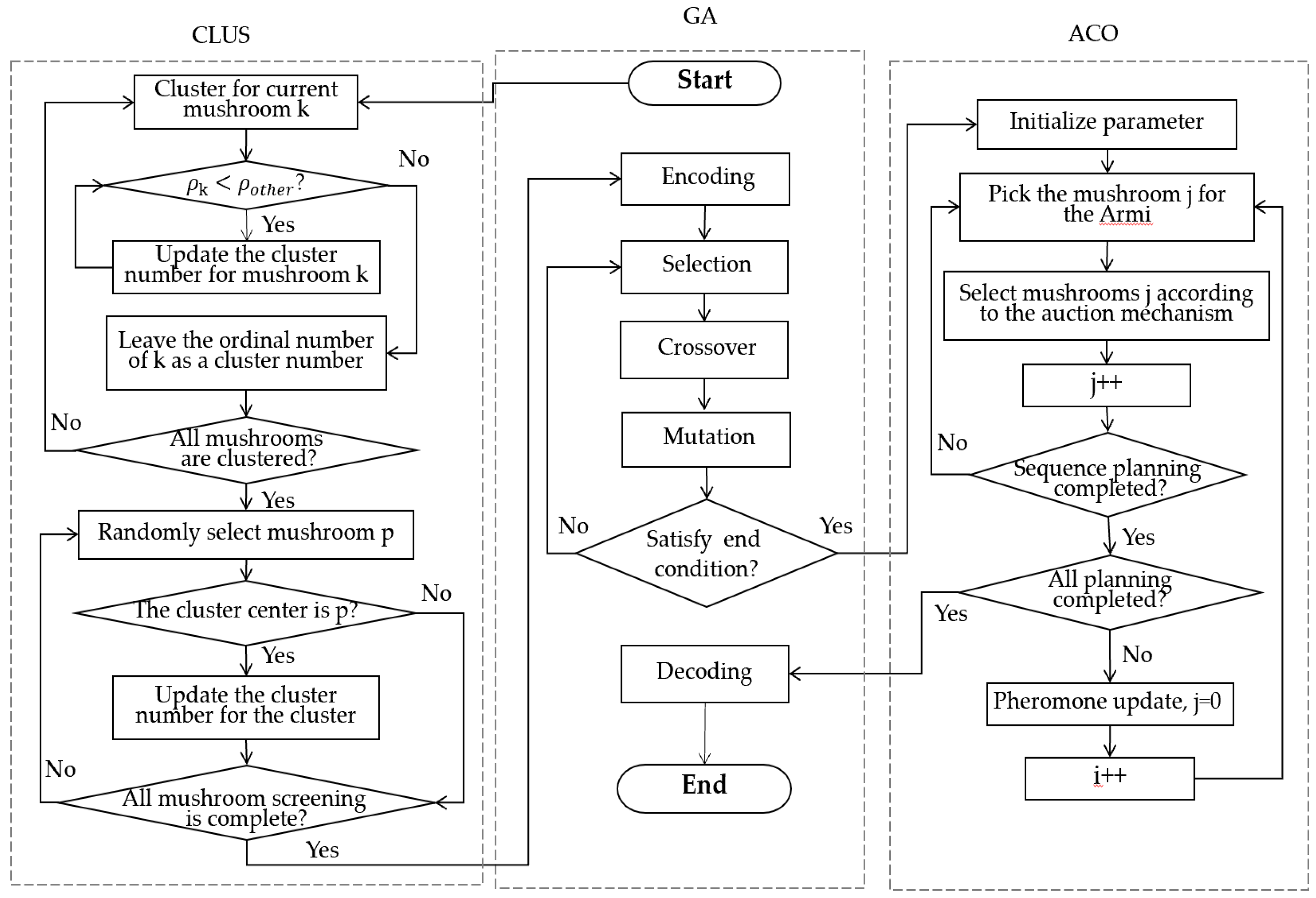

4. Multiobjective Optimization Algorithm for Multiarm Cooperative Harvesting Trajectory

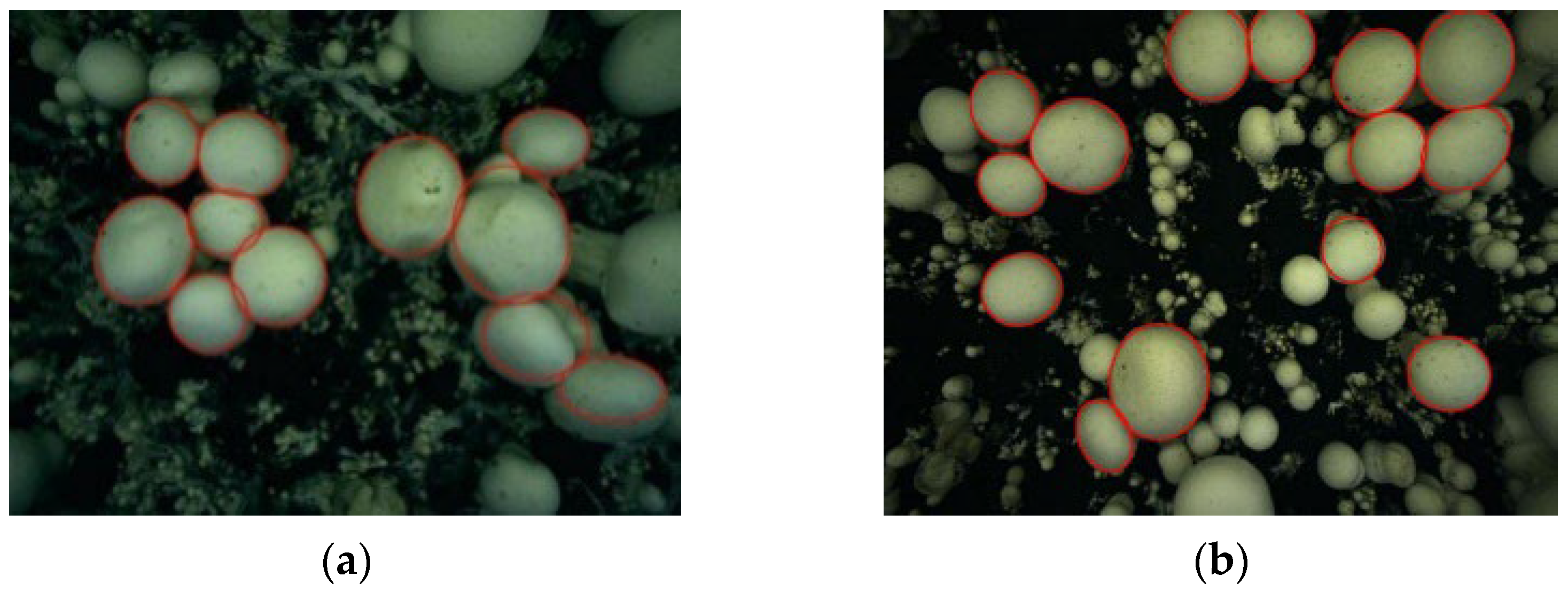

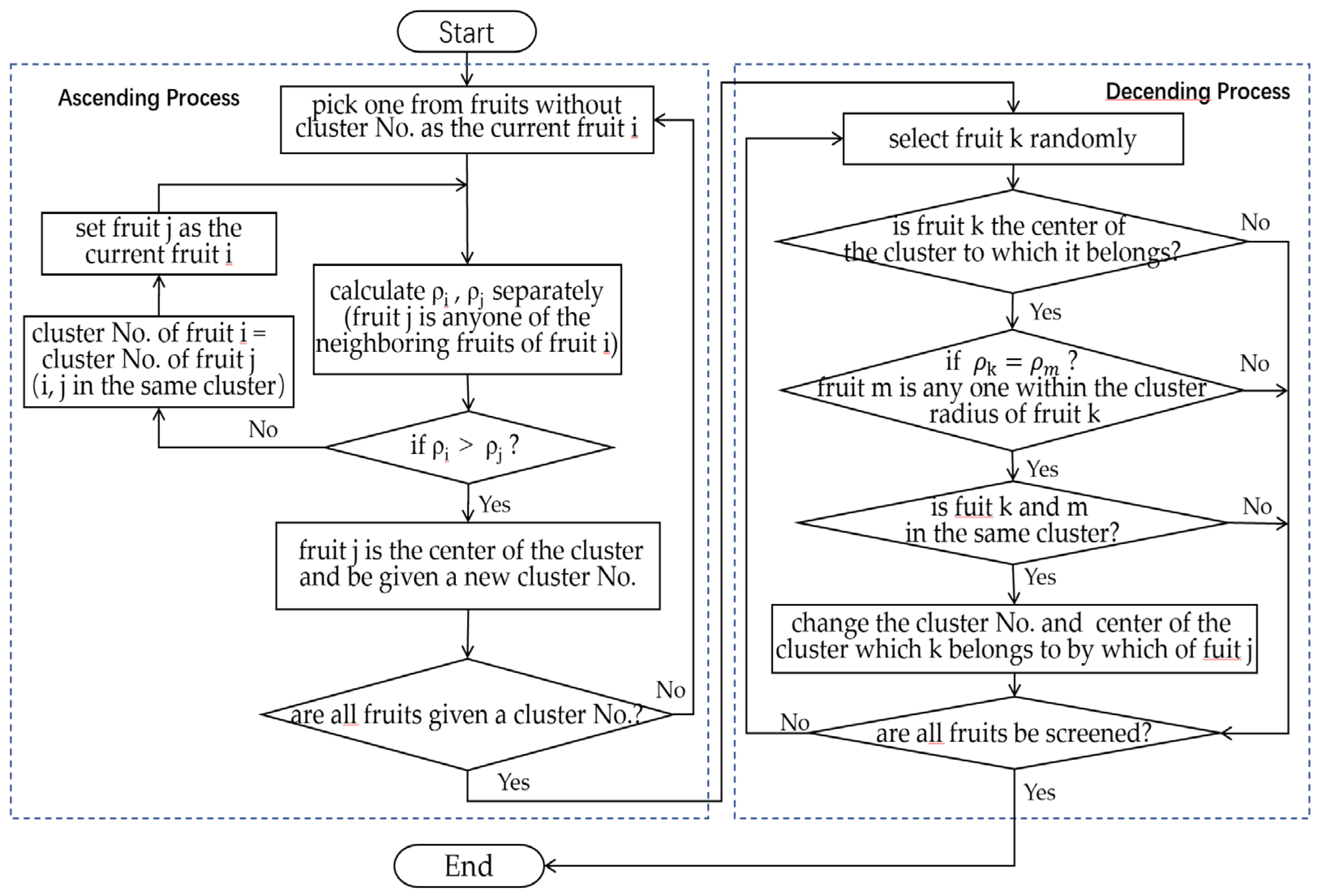

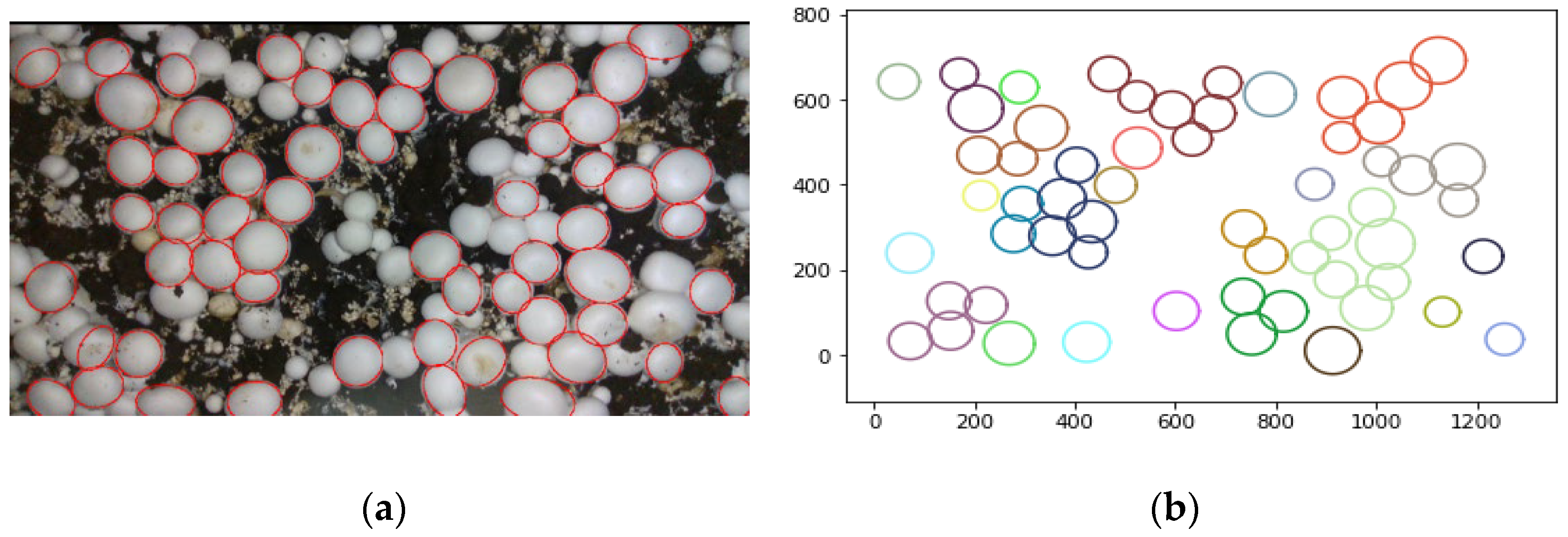

4.1. Clustering Algorithm Optimization for Fruits of Straw-Rotting Fungus

4.1.1. Fruit Clustering Definition

- (1)

- If Dij, the center distance between fruit i and j, is less than or equal to the sum of their radius, as Equation (15), fruits i and j belong to the same cluster;

- (2)

- If fruits i and j are in the same cluster, while fruits j and k are in the same cluster, then fruits i and k are also in the same cluster;

- (3)

- If the center distance between fruit i and any other fruit fails to satisfy Equation (15), then the fruit i does not belong to any cluster, which is called discrete fruit.

4.1.2. Local Density Calculation

4.1.3. Improved Density-Based Clustering Algorithm

4.2. Genetic Algorithm

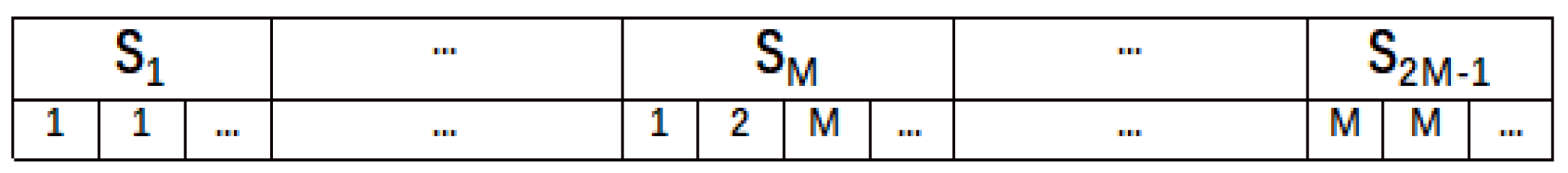

- (1)

- Encoding

- (2)

- Selection operator

- (3)

- Crossover operator

- (4)

- Mutation operator

4.3. Improved Ant Colony Algorithm

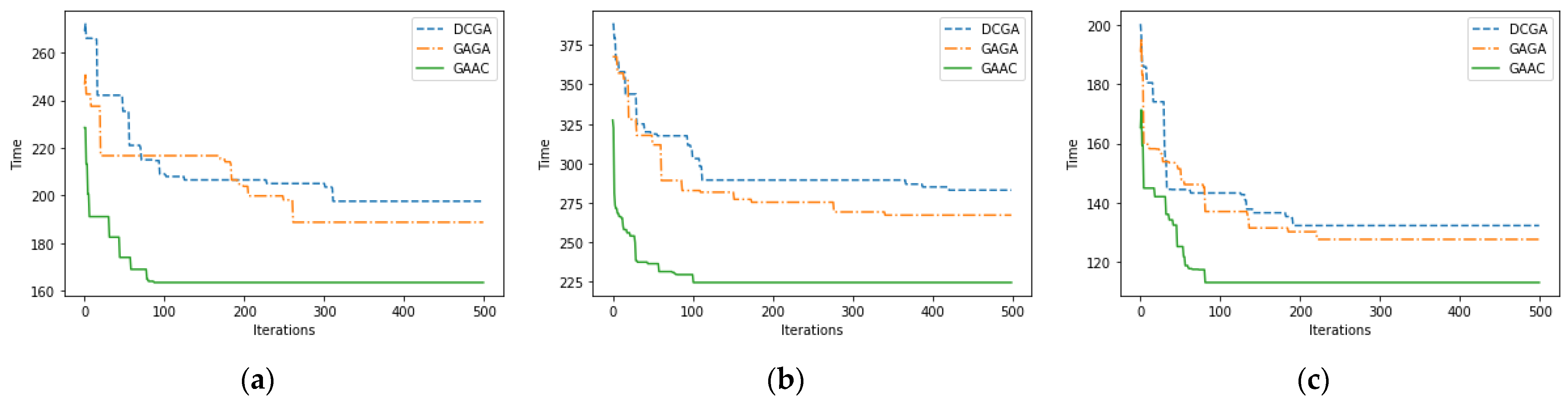

5. Experiments and Analysis

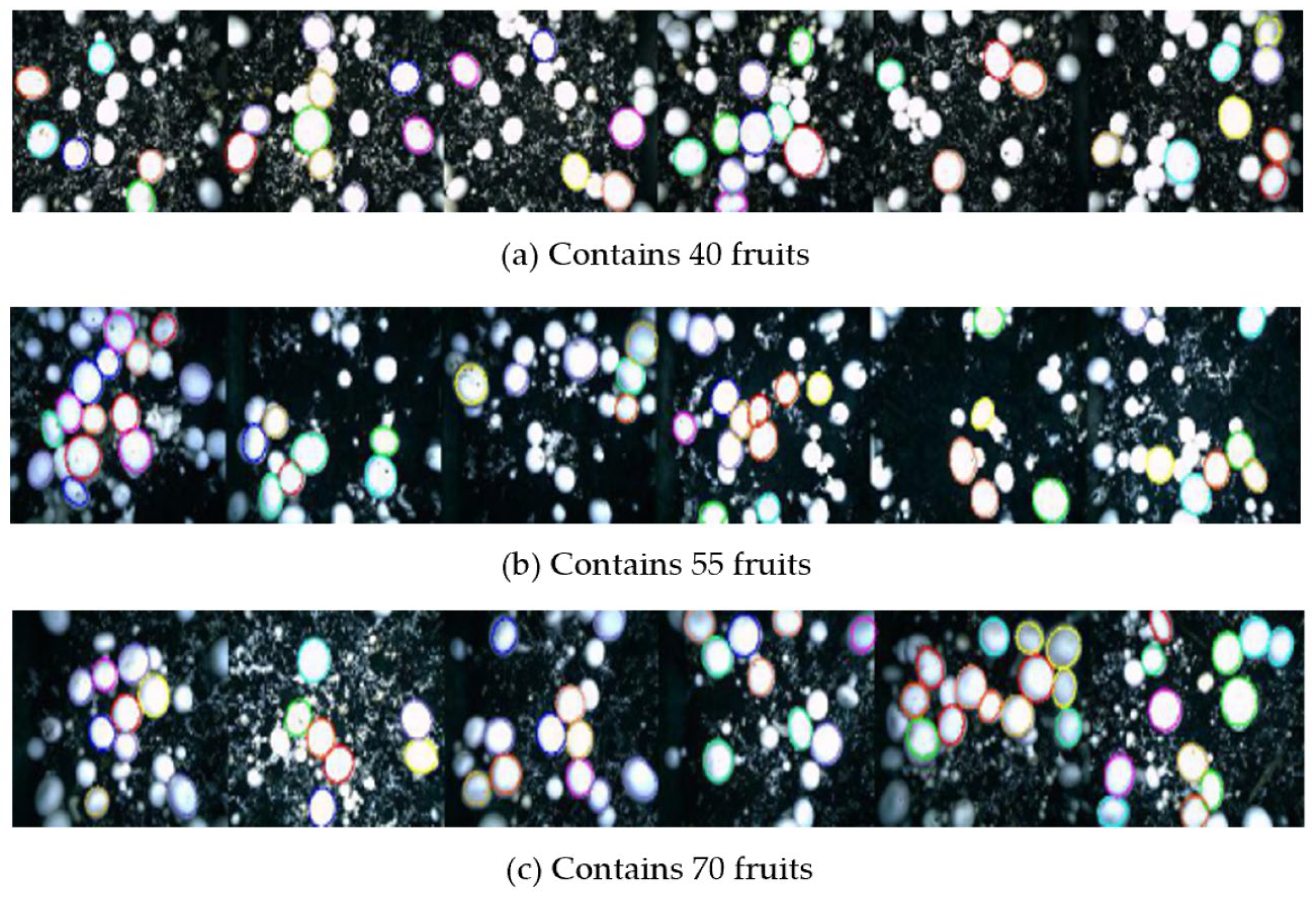

5.1. Experiments of Clustering Algorithm

5.2. Experiments of Multiobjective Optimization Algorithm for Multiarm Cooperative Harvesting Trajectory

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Group | Number of Fruits | Detail Information of Fruits |

|---|---|---|

| a | 40 | (168.43, 136.53, 163.29, 0.0), (72.03, 129.46, 170.47, 0.0),(130.93,121.4,165.45,0.0), (183.02,162.07,149.93,0),(75.41,10.54,170.04,0),(33.48,35.3,190.66,0),(11.47,98.3,212.67,0),(84.48,168.46,173.35,0),(62.15,75.78,183.99,0),(13.53,133.29,188.81,0),(124.38,8.55,159.71,0),(406.7,39.63,143.94,0),(431.28,77.04,134.9,0),(288.84,157.6,169.56,0),(296.91,43.28,170.86,0),(399.99,87.99,158.08,0),(332.95,7.87,162.36,0),(262.74,170.84,160.23,0),(325.74,175.71,168.02,0),(514.44,43.76,156.76,0),(702.29,35.59,172.61,0),(646.05,34.69,171.18,0), (763.04,101.5,154.61,0),(874.45,137.36,156.47,0),(892.59,65.13,159.9,0),(825.83,162.81,161.57,0),(741.06,76.6,167.01,0),(1087.35,28.05,152.2,0),(1049.77,102.33,159.7,0),(1128.99,53.9,166.76,0),(1165.21,13.61,173.77,0),(1013.76,10.89,175.49,0),(1167.15,171.3,161.97,1),(1054.98,64.92,169.91,1),(1385.3,155.13,173.38,2), (1312.73, 160.07, 175.86, 2.0), (1239.82, 172.1, 176.6, 3.0), (1274.88, 117.37, 179.35, 3.0), (1236.71, 9.1, 168.9, 4.0), (1347.87, 167.54, 160.21, 4.0) |

| b | 55 | (56.71,93.06,163.55,0.0),(167.53,97.5,155.25,0.0),(132.8,114.33,156.23,0.0),(134.06,77.44,135.51,0.0),(229.94,9.72,159.53,0),(111.97,80.42,142.6,0),(172.3,6.49,160.79,0),(186.14,36.68,153.34,0),(309.16,127.35,170.77,0),(257.31,124.79,170.59,0),(258.59,34.41,172.91,0),(294.92,20.13,170.75,0),(293.61,58.17,178.57,0),(387.83,78.1,139.3,0),(326.2,142.62,171.57,0),(332.02,172.98,173.62,0),(331.68,4.6,174.6,0),(449.56,176.44,179.32,0),(260.4,6.76,165.98,0),(256.9,106.31,250.58,0),(330.21,51.61,159.84,0),(558.02,96.99,154.04,0),(675.93,90.7,158.23,0),(538.99,162.97,171.9,0),(590.67,158.46,147.43,2),(587.62,143.37,160.68,2),(846.49,100.02,145.07,0),(813.59,151.48,152.09,0),(823.82,67.78,155.26,0),(807.23,124.87,148.15,0),(877.89,104.9,155.6,4),(878.81,86.16,155.87,4),(832.51,29.5,159.6,0),(908.39,50.74,169.97,0),(879.47,8.38,160.7,0),(741.88,81.64,184.95,0),(1186.72,90.04,162.32,3),(1140.91,100.87,159.13,3),(1172.68,40.46,169.81,3),(1150.34,71.37,160.56,3),(1347,148.08,151.3,0),(1315.87,126.89,158.6,0),(1282.68,61.11,149.35,0),(1278.79,148.58,163.01,0),(1312.53,159.13,147.72,0),(1316.57,45.91,154.21,0),(1231.16,60.71,167.48,0),(1350.77,36.87,165.88,0),(1308.44,78.13,163.01,0),(1245.3,141.76,174.2,0),(1373.8,166.04,151.64,0),(1384.82, 18.79, 172.77, 4.0), (1378.14,137.58,162.09,4.0),(1329.02, 93.26, 136.63, 5.0), (1309.99, 9.79, 173.65, 5.0) |

| c | 70 | (36.54,51.33,173.4,0.0),(34.66,18.28,172.73,0)(38.94,163.27,161.22,0.0),(39.91,156.28,169.74,0.0),(43.31,81.47,159.44,0.0),(43.32,12.06,168.63,0.0),(52.59,40.87,167.5,0),(61.23,155.52,153.22,0),(62.45,9.62,183.5,0),(181.64,103.87,144.54,0),(230.97,80.64,171.97,0),(268.83,153.14,161.5,0),(270.25,23.83,174.2,0),(273.84,146.9,172.97,0),(284.45,49.35,157.29,0),(291.88,60.67,169.3,0),(299.04,74.55,181.48,0),(351.08,113.39,162.1,0),(372.31,9.62,153.22,0),(386.24,135.54,167.47,0),(402.12,68.05,207.25,0),(574.22,101.72,166.15,0),(586.16,114.01,158.9,0),(590.18,165.77,157.53,0),(611.49,163.4,160.1,0),(626.03,69.38,172.7,0),(628.9,19.62,175.28,0),(631.23,105.9,183.47,0),(633.71,59.05,175.13,0),(635.86,18.45,164.45,0),(640.67,139.46,150.91,0),(641.93,113.39,152.45,0),(652.2,105.64,172.64,0),(661.64,155.52,169.74,0),(669.45,9.62,178.28,0),(699.63,109.9,172.31,0),(705.25,69.05,267.25,0),(765.4,8.45,166.08,0),(878.4,45.15,168.06,0),(1018.96,145.14,172.04,0),(1114.33,12.86,174.04,0),(1115.94,179,177.31,0),(1116.67,32.84,154.18,0),(1117.28,105.43,159.69,0),(1118.38,66.59,162.1,0),(1122.56,18.75,153.22,0),(1122.93,163.7,183.5,0),(1130.49,162.3,239.41,0),(1274.22,60.15,153.1,0),(1280.38,60.58,168.15,0),(1283.99,159.01,147.51,0),(1320.04,45.58,155.63,0),(1331.13,126.89,158.6,0),(1334.07,148.09,151.35,0),(1341.03,78.13,163.01,0),(1363.14,166.09,151.68,0),(1378.89,36.51,167.16,0),(1380.81,94.34,174.28,0),(1397.66,137.94,163.47,0),(277.82,174.17,165.13,1),(318.43,169.18,164.42,1),(1127.94,37.02,146.94,2),(1115.54,18.48,164.17,2),(1311.72,148.48,163.4,3), (1317.97, 141.62, 173.72, 3.0), (1325.74, 8.28, 177.16, 3.0), (336.15, 131.55, 249.33, 4.0), (305.25, 88.58, 157.51, 4.0), (611.4, 128.39, 144.99, 5.0), (612.86, 94.02, 152.85, 5.0) |

References

- Guo, H.; Ren, P.; Huang, C. Green prevention and control technology of straw rotting fungus. Edible Med. Mushrooms 2019, 3, 218–221. [Google Scholar]

- Noble, R.; Reed, J.N.; Miles, S.; Jackson, A.F.; Butler, J. Influence of mushroom strains and population density on the performance of a robotic harvester. J. Agric. Eng. Res. 1997, 52, 215–222. [Google Scholar] [CrossRef]

- Schiau, H.G. Considerations on the evolution of mushrooms harvesting systems. Res. Sci. Today 2013, 7, 170–182. [Google Scholar]

- Reed, J.N.; Tillett, R.D. Initial experiments in robotic mushroom harvesting. Mechatronics 1994, 4, 265–279. [Google Scholar] [CrossRef]

- Reed, J.N.; Mrilles, S.J.; Butler, J.; Baldwin, M.; Noble, R. Automatic mushroom harvester development. J. Agric. Eng. Res. 2001, 78, 15–23. [Google Scholar] [CrossRef]

- Yu, G.H.; Luo, J.M.; Zhao, Y. Region labeling technology and mushroom image segmentation method based on sequential scanning algorithm. J. Agric. Eng. 2006, 4, 139–142. [Google Scholar]

- Lu, C.P.; Liaw, J.J.; Wu, T.C.; Hung, T.F. Development of a Mushroom Growth Measurement System Applying Deep Learning for Image Recognition. Agronomy 2019, 9, 32. [Google Scholar] [CrossRef] [Green Version]

- Kuchinskiy, N.A. Development of an Autonomous Robotic Mushroom Harvester. Master’s Thesis, The University of Western Ontario, London, ON, Canada, 2016. [Google Scholar]

- Huang, M.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Picking dynamic analysis for robotic harvesting of Agaricus bisporus mushrooms. Comput. Electron. Agric. 2021, 32, 185–256. [Google Scholar] [CrossRef]

- Lu, W.; Wang, P.; Wang, L.; Deng, Y. Design and experiment of flexible gripper for mushroom non-destructive picking. Trans. Chin. Soc. Agric. Mach. 2020, 51, 28–36. [Google Scholar]

- Yang, S.; Ni, B.; Du, W.; Yu, T. Research on an improved segmentation recognition algorithm of overlapping Agaricus bisporus. Sensors 2022, 22, 3946. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a robotic harvesting mechanism for button mushroom. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Mohanan, M.G.; Salgaonkar, A. Robotic mushroom harvesting by employing probabilistic road map and inverse kinematics. BOHR Int. J. Future Robot. Artif. Intell. 2021, 1, 1–10. [Google Scholar] [CrossRef]

- Yang, Y. Key Techniques for Automatic Mushroom Picking System Based on Machine Vision. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Hu, X.M.; Wang, C.; Yu, T. Design and application of visual system in the Agaricus bisporus picking robot. JOP Conf. Ser. 2019, 1187, 032034. [Google Scholar]

- Tinoco, V.; Silva, M.F.; Santos, F.N.; Rocha, L.F.; Santos, L.C. A review of pruning and harvesting manipulators. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions, ICARSC 2021, Santa Maria da Feira, Beja, Portugal, 28–29 April 2021; pp. 155–160. [Google Scholar]

- Nas, B.; Nrv, A.; Vsh, A.; Vd, A. Cotton harvester through the application of machine learning and image processing techniques. Mater. Today Proc. 2021, 47, 2200–2205. [Google Scholar]

- Zion, B.; Mann, M.; Levin, D.; Shilo, A.; Rubinstein, D.; Shmulevich, I. Harvest-order planning for a multiarm robotic harvester. Comput. Electron. Agric. 2014, 103, 75–80. [Google Scholar] [CrossRef]

- Xiong, Y.; Ge, Y.; Grimstad, L.; From, P.J. An autonomous strawberry-harvesting robot: Design, development, integration, and field evaluation. J. Field Robot. 2020, 37, 202–224. [Google Scholar] [CrossRef] [Green Version]

- Rong, J.; Wang, P.; Yang, Q.; Huang, F. A field-tested harvesting robot for oyster mushroom in greenhouse. Agronomy 2021, 11, 1210. [Google Scholar] [CrossRef]

- Barnett, J.; Duke, M.; Chi, K.A.; Shen, H.L. Work distribution of multiple cartesian robot arms for kiwifruit harvesting. Comput. Electron. Agric. 2020, 169, 105202. [Google Scholar] [CrossRef]

- Jia, B.C.; Yang, S.Z.; Yu, T. Research on three picking arm avoidance algorithms for agaricus mushroom picking robot. In Proceedings of the 2020 IEEE International Conference on Advances in Electrical Engineering and Compute Applications, AEECA 2020, Dalian, China, 25–27 August 2020; pp. 325–328. [Google Scholar]

- Kurtser, P.; Edan, Y. Planning the sequence of tasks for harvesting robots. Robot. Auton. Syst. 2020, 131, 103591. [Google Scholar] [CrossRef]

- Venkatesh, P.; Singh, A. Two metaheuristic approaches for the multiple traveling salesperson problem. Appl. Soft Comput. 2015, 26, 74–89. [Google Scholar] [CrossRef]

- Zhang, H. The Area Divison of Express Delivery Terminal and Vehicle Routing Problem with Balance. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Yin, Y. Research on Path Optimization of Warehouse Robot Based on Improved Genetic Algorithm. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2019. [Google Scholar]

- Xu, X.; Yuan, H.; Mark, L.; Marcello, T. Two phase heuristic algorithm for the multiple-travelling salesman problem. Soft Comput. 2018, 22, 6567–6581. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Wang, Y. Path planning of multi-UAV cooperative search for multiple targets. Electron. Opt. Control. 2019, 26, 35–38. [Google Scholar]

- Dong, X.; Cai, Y. A novel genetic algorithm for large scale colored balanced traveling salesman problem. Future Gener. Comput. Syst. 2019, 95, 727–742. [Google Scholar] [CrossRef]

- Luo, Z.; Feng, S.; Liu, X.; Che, J.; Wang, R. Method of area coverage path planning of multi-unmanned cleaning vehicles based on step by step genetic algorithm. J. Electr. Measur. Instr. 2020, 34, 43–50. [Google Scholar]

- Wang, M. Cooperative Task Assignment and Path Planning for Multi-Uavs Bird-Driving System at the Airport. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Lu, Z.; Zhang, K.; He, J.; Niu, Y. Applying K-means clustering and genetic algorithm for solving MTSP. Proceedings of Bio-inspired Computing–Theories and Applications-11th International Conference, BIC-TA 2016, Xi’an, China, 28–30 October 2016; pp. 278–284. [Google Scholar]

- Kencana, E.N.; Harini, I.; Mayuliana, K. The performance of ant system in solving multi traveling salesmen problem. Proc. Comput. Sci. 2017, 124, 46–52. [Google Scholar] [CrossRef]

- Necula, R.; Breaban, M.; Raschip, M. Tackling the bi-criteria facet of multiple traveling salesman problem with ant colony systems. In Proceedings of the IEEE 27th International Conference on Tools with Artificial Intelligence, Vietrisul Mare, Italy, 9–11 November 2015; pp. 873–880. [Google Scholar]

- Changdar, C.; Pal, R.K.; Mahapatra, G.S. A genetic ant colony optimization based algorithm for solid multiple travelling salesmen problem in fuzzy rough environment. Soft Comput. 2017, 21, 4661–4675. [Google Scholar] [CrossRef]

- Yang, S.Z.; Jia, B.C.; Yu, T. Research on Path Planning Algorithm of Multi-Arm Collaborative Picking for Agaricus Bisporus Intelligent Picking Robot. In Proceedings of the 5th IEEE/IFToMM International Conference on Reconfigurable Mechanisms and Robots, Toronto, ON, Canada, 12–14 August 2021; pp. 776–796. [Google Scholar]

- Cao, X.; Yan, H.; Huang, Z.; Ai, S.; Xu, Y.; Fu, R.; Zou, X. A Multi-Objective Particle Swarm Optimization for Trajectory Planning of Fruit Picking Manipulator. Agronomy 2021, 11, 2286. [Google Scholar] [CrossRef]

- Xu, H.; Hu, Z.; Zhang, P.; Gu, F.; Wu, F.; Song, W.; Wang, C. Optimization and Experiment of Straw Back-Throwing Device of No-Tillage Drill Using Multi-Objective QPSO Algorithm. Agriculture 2021, 11, 986. [Google Scholar] [CrossRef]

- Saxena, A.; Prasad, M.; Gupta, A.; Bharill, N.; Patel, O.P.; Tiwari, A.; Er, M.J.; Ding, W.; Lin, C.T. A review of clustering techniques and developments. Neurocomputing 2017, 267, 664–681. [Google Scholar] [CrossRef] [Green Version]

- Sisodia, D.; Sisodia, S.; Saxena, K. Clustering techniques: A brief survey of different clustering algorithms. Int. J. Latest Trends Eng. Technol. 2012, 1, 82–87. [Google Scholar]

- Karna, A.; Gibert, K. Automatic identification of the number of clusters in hierarchical clustering. Neural. Comput. Appl. 2022, 34, 119–134. [Google Scholar] [CrossRef]

- Boonchoo, T.; Ao, X.; Liu, Y.; Zhao, W.; He, Q. Grid-based dbscan: Indexing and inference. Pattern Recognit. 2019, 90, 271–284. [Google Scholar] [CrossRef]

- Liu, F.; Wen, P.; Zhu, E. Efficient grid-based clustering algorithm with leaping search and merge neighbors method. JOP Conf. Ser. 2017, 1, 12122–12132. [Google Scholar] [CrossRef] [Green Version]

- Melnykov, V. Challenges in model-based clustering. WIREs Comput. Stat. 2013, 5, 135–148. [Google Scholar] [CrossRef]

- Bechini, A.; Marcelloni, F.; Renda, A. Tsf-dbscan: A novel fuzzy density-based approach for clustering unbounded data streams. IEEE Trans. Fuzzy Syst. 2022, 30, 623–637. [Google Scholar] [CrossRef]

- Zhu, Y.; Ting, K.M.; Jin, Y.; Angelova, M. Hierarchical clustering that takes advantage of both density-peak and density-connectivity. Inform. Syst. 2022, 103, 101871. [Google Scholar] [CrossRef]

| Algorithm 1. |

|---|

| Input: N // set of all mature fruits Output: Unit[] //set of cluster centers corresponding to each fruit 1 Initialization(); 2 UpProcess(a,b); // a is the data coordinate and b is the data serial number. 3 c = b; // If no other point within the cutoff distance has a higher cluster density than it, its cluster center is itself 4 while i < n do; 5 if i! = b and density[i]> = density[b]; // The local density of i is greater than the input fruit 6 Distance = math.sqrt((N[i][0]-a [0])^2+(N[i][1]-a [1])^2); 7 rc = Clu[i][2]+a [2] // Cluster radius 8 if x1<=x2: // Two fruits are clustered 9 c=i; 10 break; 11 return c; 12 while i < n do; #Ascending process, computing the cluster center for each fruit 13 Unit[i]=UpProcess(N[i],i) 14 return Solution; |

| Algorithm 2. |

|---|

| Input: Unit[] // The set of cluster centers obtained during the ascent Output: Unit[ ] // The final set of cluster centers corresponding to each fruit 1 Initialization(); 2 DownProcess(a,b); 3 if a == b; // If the cluster center of the data point is itself 4 return b; 5 else; 6 a = DownProcess(Unit[a],a); 7 return a; 8 for i in range(n); // Descending process, if the cluster center of a data is another point, it will be merged into its subclass. 9 if i == Unit[Unit[i]]; // If it is the cluster center with another point, select one of the points as the cluster center and merge the two. 10 Unit[i] = i; 11 if Unit[Unit[i]]! = Unit[i]; // If the final cluster center corresponding to the point is found Unit[i] = DownProcess(Unit[i],i); 12 return Solution; |

| Group | Num of Fruits | Num of Cluster | Num of Discrete Points | The Recognition Success Rate of Clustered Fruits | ||

|---|---|---|---|---|---|---|

| K-Means | Gaussian Mixture | Improved Clustering Algorithm | ||||

| 1 | 40 | 18 | 12 | 82% | 88% | 99% |

| 2 | 40 | 25 | 20 | 78% | 85% | 99% |

| 3 | 55 | 27 | 16 | 72% | 80% | 98% |

| 4 | 55 | 38 | 27 | 68% | 78% | 96% |

| 5 | 70 | 36 | 28 | 63% | 73% | 96% |

| 6 | 70 | 45 | 36 | 57% | 66% | 95% |

| AVG | 55 | 189 | 139 | 68% | 78% | 97% |

| Num of Fruits | Algorithm | Avoid Times | Harvesting Time(s) | Harvesting Efficiency(pcs/h) | Harvesting Success Rate |

|---|---|---|---|---|---|

| 40 | DCGA | 2 | 130.21 | 1106 | 96% |

| GAGA | 1 | 126.54 | 1138 | 98% | |

| IGAACMO | 0 | 113.81 | 1265 | 100% | |

| 55 | DCGA | 5 | 196.16 | 1009 | 90% |

| GAGA | 3 | 185.42 | 1068 | 94% | |

| IGAACMO | 1 | 161.31 | 1227 | 98% | |

| 70 | DCGA | 9 | 283.29 | 890 | 82% |

| GAGA | 6 | 267.95 | 940 | 87% | |

| IGAACMO | 2 | 224.64 | 1122 | 96% |

| Group | Num of Fruits | Ratio of Cluster | Harvesting Efficiency (pcs/h) | Harvesting Success Rate | ||||

|---|---|---|---|---|---|---|---|---|

| GAGA | DCGA | IGAACMO | GAGA | DCGA | IGAACMO | |||

| 1 | 40 | 20% | 1162 | 1182 | 1308 | 98% | 99% | 100% |

| 2 | 42 | 38% | 1112 | 1141 | 1258 | 97% | 98% | 100% |

| 3 | 45 | 58% | 1046 | 1093 | 1114 | 92% | 95% | 98% |

| 4 | 49 | 21% | 1068 | 1114 | 1238 | 95% | 98% | 100% |

| 5 | 52 | 30% | 1027 | 1074 | 1232 | 92% | 95% | 98% |

| 6 | 57 | 45% | 992 | 1034 | 1205 | 90% | 94% | 98% |

| 7 | 60 | 60% | 931 | 983 | 1161 | 85% | 90% | 95% |

| 8 | 62 | 23% | 945 | 1008 | 1186 | 86% | 91% | 97% |

| 9 | 67 | 46% | 892 | 947 | 1132 | 81% | 87% | 96% |

| 10 | 70 | 57% | 849 | 896 | 1106 | 78% | 85% | 95% |

| AVG | 54.4 | 41% | 977 | 1025 | 1183 | 88% | 92% | 97% |

| Algorithm | Avoid Times | Harvesting Time(s) | Harvesting Success Rate | N1:N2:N3 |

|---|---|---|---|---|

| GAAC (assigned to the same arm) | 1 | 126.29 | 100% | 03:17:14 |

| IGAACMO (assigned to different arms) | 1 | 105.25 | 100% | 13:12:09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Jia, B.; Yu, T.; Yuan, J. Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot. Agriculture 2022, 12, 986. https://doi.org/10.3390/agriculture12070986

Yang S, Jia B, Yu T, Yuan J. Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot. Agriculture. 2022; 12(7):986. https://doi.org/10.3390/agriculture12070986

Chicago/Turabian StyleYang, Shuzhen, Bocai Jia, Tao Yu, and Jin Yuan. 2022. "Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot" Agriculture 12, no. 7: 986. https://doi.org/10.3390/agriculture12070986

APA StyleYang, S., Jia, B., Yu, T., & Yuan, J. (2022). Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot. Agriculture, 12(7), 986. https://doi.org/10.3390/agriculture12070986