Abstract

Achieving a positive balance between energy use and environmental protection requirements has shown that soil bioregeneration could reduce the main disadvantages of tillage, that lead to increased costs and reduced profits. The aim was to assess the impact of soil bioregeneration on tillage consumption, yield, financial costs, and farmers income. For three consecutive years in the spring, after the resumption of winter wheat and rapeseed vegetation, the soil was bioregenerated under seven different scenarios. The best results were obtained using a scenario where soil was bioregenerated with a solution consisting of plant essential oils, 40 species of various herbs, marine algae extracts, mineral oils, Azotobacter vinelandii bacteria, humic acids, gibberellic acid, copper, zinc, manganese, iron, calcium, and sodium molybdate. Soil bioregeneration research has identified that fuel consumption could decrease to 23%, financial costs could decrease to 40%, and yield and farmers income from crop production could increase to 28% compared with the scenario where the soil was not bioregenerated. By applying the discovered soil bioregeneration method, the savings could reach up to EUR 3 per ha−1.

1. Introduction

According to the United Nations General Assembly Sustainable Development Goals, in the 2030 Agenda for Sustainable Development, the overarching goal is to protect the planet from degradation, including sustainable consumption and production, through the sustainable management of natural resources and urgent action on climate change to meet the needs of present and future generations by 2030. The depletion of natural resources and the negative effects of environmental degradation, including desertification, droughts, land degradation, freshwater scarcity, and biodiversity loss, add to and exacerbate the list of challenges facing humanity. Climate change is one of the greatest challenges of our time, and its negative effects are undermining the ability of all countries to achieve sustainable development. Rising global temperatures, rising sea levels, acidification of the oceans, and other effects of climate change are having a major impact on coastal zones and low-lying coastal states, including many LDCs and small island developing states. The survival of many societies and planetary biological support systems is at stake. The Sustainable Development Goals collect 17 interlinked global goals, including the promotion of sustainable agriculture, better nutrition (Objective 2), sustainable consumption and production patterns (Objective 12), and urgent action to combat climate change and its effects (Objective 13). It is therefore important to ensure sustainable food production systems and to implement sustainable agricultural practices that increase productivity and production, help maintain ecosystems, strengthen resilience to climate change, extreme weather events, droughts, floods, and other disasters, and gradually improve land and soil.

The choice of tillage technologies and machines in agriculture depends on soil structure, climatic conditions, and the crops cultivated. Mechanical action of machine working parts (cutting, soil mixing) influences chemical, physical, and biological soil properties [1,2,3]. Contradictory data regarding the effects of conventional (conventional soil tillage with plough) tillage on soil properties can be found. Application of conventional tillage reduces the stability of the soil structure (about 40–97%), the sucrose content (about 0.7–2.0 times), the urease activity (3–4 times), the average earthworm content (about 55%), and the biomass (about 3.6 times) compared with minimum (minimum soil tillage with harrows) tillage [4]. The depth distribution of soil C and N varied with tillage. Multiple studies have shown the opposite, that the C and N contents increases on the surface under minimum tillage. Conventional tillage reduces the levels of total organic carbon and total nitrogen, dissolved organic carbon, and dissolved organic nitrogen compared with minimum tillage [5].

Intensive tillage results in higher costs of energy and labor. The total operating costs of conventional tillage are 12.73% higher, and net income is 14.45% lower compared with direct sowing (seeding without any pre-tillage) [6]. Energy consumption in conventional tillage ranged from 412 to 740 MJ ha−1. Obvious differences of energy consumption were related to the production technology [7]. Conventional tillage consumes about 51.13 l ha−1 of diesel fuel, minimum tillage consumes about 27.70 l ha−1, and direct sowing consumes about 7.8 L ha−1 [8]. According to economic estimates, the cost of wheat production in conventional tillage system, analyzed in research, is about EUR 894 ha−1. (Agricultural operations cost around EUR 174 h−1, fertilizers cost around EUR 59 ha−1, employment of people costs around EUR 424 ha−1, seeds cost around EUR 90 ha−1, agrochemicals cost around EUR 29 ha−1, and water costs around EUR 115 ha−1 [9].)

The situation differs depending on the country. About 12% of farms in Germany completely abandoned conventional tillage, in Sweden, 21–79% are cultivated using minimum tillage [10]. Soil modification negatively affects nitrogen absorption and distribution in plants and reduces the yields by 67% [11]. Direct sowing results in, on average, 3.5–6.4% lower maize yield compared with conventional tillage [12]. Minimum tillage increases the amount of soil organic matter and water, as well as the abundance of endogenous and epigenetic earthworm species. It can be argued that tillage and agricultural systems have both direct and indirect effects on soil parameters [13].

In the 0–15 cm soil layer under minimum tillage, almost 19% more carbon was stored in this fraction compared with the conventional tillage. As a result, the aggregates formed on the soil surface increased aeration, water infiltration, porosity, and favorable C: N ratio (15 ± 1) and promoted microbiological activity. Under minimum tillage, which destroys the soil structure less, more plant residues accumulate in the topsoil, where mineralization is favorable and more soluble organic carbon is formed due to the activity of microorganisms.

Variety of tillage was discussed in the literature review, but due to the recent data, conventional (deep tillage with plough) and minimum (shallow tillage with harrows) tillage is still popular; although, it is not recommended for reducing environmental pollution by the majority of scientific publications. Therefore, it was decided to try applying soil bioregeneration, at least to some extent, to reduce costs and environmental pollution from conventional (deep tillage with plough) and minimum (shallow tillage with harrows) tillage.

An opportunity to reduce the overall costs caused by higher energy consumption and agricultural machinery could be in the use of plant and soil protection products [9]. Crop production strategies and bioeconomic optimization models need to be developed by optimizing the costs (space, time, and quantities) and combining the objectives: increasing the yields, reducing the energy consumed, and reducing environmental pollution [14].

There exist various scientific analyses of different bioregeneration methods using biotreatment with pseudomonas, the nitrogen-fixing bacteria Azotobacter and Clostridium, yeast Saccharomyces, and the fungi Aspergillus and Penicillium. Penicillium soil contamination with petroleum products is reduced by 99% after 22 weeks [15]. Exposure to soil biocrusts significantly improves soil physicochemical properties, respiration, alkaline phosphatase, protease, and cellulose, and reduces the emission of CO2 from the soil [16,17].

In conclusion, the impact of mechanization on soil properties and compaction could predetermine changes of energy consumption and costs. Therefore, it is crucial to manage many important factors related to the relationship between the tillage systems and various efficiency indicators of soil to optimize the plant productivity and profitability. Consequently, that is worth analyzing the effects of different bioregeneration methods and finding the best in from financial and environmental aspects. This research is expected to benefit practitioners, farmers, and agricultural companies, allowing them to save time and finances and reduce environmental pollution. The aim was to assess the soil bioregeneration impact on tillage consumption, yield, financial costs, and farmers income.

2. Materials and Methods

Experimental research (three years in a row) was performed at the Vytautas Magnus University Agricultural Academy experimental station. The experimental research area (54.878337, 23.842755 (GT–19505)) of 19,200 m2 was divided into 8 experimental scenario variants (SC1–SC8), each scenario variant area was 2400 m2 (with a length of 200 m and a width of 12 m). The analysis of each scenario (SC1–SC8), evaluated in the 5 repetitions, obtained data points located randomly in each specific 50 × 12 m area by setting the average value for a given area for each scenario variant (200 × 12 m).

The lukewarm, soaked soil fields surface relief was a slightly wavy plain, with pH 6.5–7.2, total nitrogen 1.47–1.59%, humus 2.2–3.0%, assimilable phosphorus 173–235 mg kg−¹, assimilable potassium 115–189 mg kg−1, and assimilable sulphur 5.6–26.4 mg kg−¹ [18].

For three consecutive years, the effects of soil biological regeneration on the crop (wheat, wheat, and rapeseed) cultivation process were analyzed in a consistent manner. The technology cycle for winter wheat (varieties “Ada“ in the first year and “Famulus“ in the second year) and rapeseed (variety “Cult“ in the third year) included seven different scenarios for soil bioregeneration. In spring, when the vegetation of plants was renewed, the soil was biotreated by spraying different scenario bio-solutions (SC2–SC8).

For bioregeneration, the most popular and most widely used preparations for farmers and business companies were used to scientifically evaluate their efficiency and cost effectiveness. Scenarios were applied only to the spraying phase of the biopreparation, where the control variant was sprayed with water only. Other soil and plant care measures were applied unanimously to all scenarios, and are therefore not repeated in the scenario descriptions.

SC1—Control variant: Soil sprayed with 200 L ha−1 water.

SC2—Bioregeneration solution containing 200 L ha−1 water and 1 L/ha mix of Azotobacter vinelandii MVY-010 (1,2 × 1012 KSV/L); K-5770 mg/L; Ca-1730 mg/L; Na-1280 mg/L; S-1100 mg/L; P-359 mg/L; Mg261 mg/L (http://www.vatzum.lt/uploads/documents/etikets.pdf accessed on 15 March 2022). Using a microbiological preparation in which the bacteria Azotobacter vinelandii enters the soil, it captures atmospheric nitrogen (N2) and increases the amount of nitrogen (NH4) available to plants in the soil, increases the productivity of field plants, and restores the natural soil properties.

SC3—Bioregeneration solution containing 200 L ha−1 water and 2 L/ha mix of essential plant oils, 40 species of various herbal extracts, marine algae extracts, mineral oils, Azospirillum sp. (N)—bacterial colony count—1 × 109/mL; Frateuria aurentia (K) bacterial colony count—1 × 109/mL; Bacillus megaterium (P)—bacterial colony count—1 × 109/mL; Seaweed extract—10% by volume. Azospirillum spp.—captures nitrogen from the air (N); Bacillus magetarium—helps to accumulate phosphorus in the soil (P); Frateuria aurentia—accumulates potassium (K) in the soil; seaweed extract—10% by volume. Not more than 0.02% of the trace elements Mg, Mn, and Fe. Algae from seaweed retain the necessary moisture in the soil and maintain balance. N and K of organic origin are additionally nourished and 100% absorbed. Organic carbon nourishes soil microorganisms and activates them. Antioxidants neutralize the effects of adverse environmental conditions. Herbal extract strengthens the plant’s resistance to diseases, pests, and adverse conditions. Plant hormones from seaweed activate root growth. Amino acids activate cell proliferation and recovery after stress.

SC4—Bioregeneration solution containing 200 L ha−1 water and 3 L/ha mix of cold pressed seaweed extract, sugar beet molasses, patented alpine herb extract, hydrolyzed protein 2%. N—pure organic nitrogen, 3%; K2O—water-soluble potassium oxide; 83% organic matter in the dry state; 2.5–3% amino acids, most importantly—alanine, glycine, proline, glutamine—make up >60%.

SC5—Bioregeneration solution containing 200 L ha−1 water and 2 L/ha mix of plant essential oils, 40 types of various herbal extracts, marine algae extracts, mineral oils; Azotobacter chroococcum 1 × 109/mL—non-membrane, nitrogen-fixing bacteria; Azospirillum brasilense 1 × 109/mL—non-membrane, nitrogen-fixing bacteria; Phosphorus P (P2O5)—7.5%; Potassium K (K2O)—7.5%; seaweed extract—10% by volume. It captures and accumulates nitrogen (N) in the soil, and affects root growth, thus improving plant growth conditions.

SC6—Mixture of SC2 and SC3.

SC7—Mixture of SC3 and SC4.

SC8—Mixture of SC2 and SC4.

A sprayer (Amazone (Amazonen–Werke H. Dreyer GmbH and Co. KG Am Amazonenwerk 9–13, D–49205 Hasbergen–Gaste, Germany), model UF–901) with a working width of 12 m and adjustable hydraulic mixing was used to apply the bioregeneration solutions to the soil surface.

Based on advanced technology, disc harrowing and ploughing were performed during the period from August to September. Winter wheat (first and second year) and rapeseed (third year) were sown until mid-September and were harvested in July and August. Direct harvesting technology is mainly used for harvesting. Grain yield is assessed on the basis of the weight of harvested winter wheat and rapeseed per hectare. Bioregeneration was used in the same individual areas in April and May.

The meteorological conditions during the experimental research were as follows: the average of daily temperature during the month was 20.3 °C, and the average precipitation was 6.9 mm in the first year (2015), these were 16.90 °C and 114.9 mm in the second year (2016), and 17.47 °C and 55 mm in the third year (2017), respectively. The meteorological conditions were measured during the experimental research on the summer month of August, when the disc harrowing, ploughing, and harvest technological operations took place. Meteorological conditions data from a meteorological station at this location were used.

The study was carried out by analyzing different soil bioregeneration and control by the main indicators through three bioregeneration seasons in 2015, 2016, and 2017. Bioregeneration effectiveness has been determined in comparison with the control variant. In predicting the variation of meteorological conditions in the different years of experimental research and the risk of crop rotation, only the changes and differences were objectively highlighted compared with the control version of SC1 scenario, in which the bioregeneration methods were not used. The meteorological conditions have the same effect on all variants, and for this purpose a control scenario was applied methodically, so that the difference, change, and effect could be assessed under any conditions.

2.1. Assessment of the Impact of Soil Bioregeneration Efficiency on Fuel Consumption in Conventional and Minimum Soil Tillage

Investigations of soil displacement and fuel consumption in the remaining stubble after cereal harvesting were performed. Experimental studies of fuel consumption in conventional and minimum soil tillage were performed with a tractor ZETOR 10540 and a 4-body non-powered plough with a working width of 1.2 m and a depth of up to 18 ± 1.5 cm. The average soil surface moisture during tillage was 14–15%. Minimum soil tillage was performed with a disc harrow with a working width of 4 m and depth of 10 ± 1.5 cm. Conventional tillage parameters of two rods were fixed with the fingers of CBM 140.2 on both sides of the plough, mounted on the experimental tractor prepared for the research, according to the standard methodology (Standard Codes for the Official Testing of Agricultural and Forestry Tractors). The tractor front tires used in the tests were 9% worn and the rear tires were 8% worn. During the research, tractor performance indicators, such as engine speed, actual driving speed, hourly fuel consumption, traction force, and data recording time were determined. The tractor was equipped with a data logger—SKRT-21 Lite—from which the data was transferred to a computer using the SKRT-Manager software. The period for measuring parameters, calculating, and storing average values was programmed from 5 to 180 s. The tractor was equipped with a VZO 4OEM fuel flow meter to measure hourly fuel consumption. A fuel flow meter was installed in the engine fuel supply line. In addition, a fuel cooling radiator, fuel filter, and air separator were installed to ensure the quality of the fuel flow meter performance. Hansa-flex hoses and connectors were used to connect the devices. The VZO 4OEM fuel flow meter was connected to the SKRT-21 Lite data logger to measure the actual driving speed and traction resistance. Calibration of all devices was performed according to standard methodologies (Standard S296.2 of the American Society of Agricultural Engineers (ASAE), OECD Standard Codes for the Official Testing of Agricultural and Forestry Tractors, 2013). The magnitude of the error did not exceed ±2%.

2.2. Assessment of the Impact of Soil Bioregeneration Efficiency on Cost Reduction

The main cost that may affect the change in the price of tillage technological operations is that of diesel fuel. After determining the fuel consumption for tillage, the price of marked diesel fuel was chosen to be EUR 0.66 L−1, according to the tariffs for mechanized agricultural services prepared by the Lithuanian Institute of Agrarian Economics [19]. The market price of diesel fuel in Lithuania at the relevant time, for example, in 2017, was also selected for comparison, for example, for the second week of October 2017.

Based on Lithuanian agricultural and food market information systems, statistics on the prevailing average prices of wheat and rapeseed (growers) in the EU countries, EUR t−1, and fuel prices in the EU and other markets, the financial benefits which would be obtained when applying soil bioregeneration technology in Lithuania were determined, in addition to determining how this can be predicted globally. Agriculture arable land in Lithuania is more than 3 million ha (National Land Service under the Ministry), so it is possible to save money due to increased yield and reduced fuel consumption. The calculated prices of diesel fuel in the EU and other markets during the research were EUR 0.54–1.55 per liter, averaging EUR 1.045 per liter (International Road Transport Union (IRU)). Analogous forecasting can be performed in the same way when the global situation changes.

2.3. Statistical Analysis

Statistical analysis was performed using the Tukey HSD test, estimating the essential difference margin HSD05 at the 95% probability level to ensure that the differences in the means of the data are significant. In the figures, the letters indicate significant differences between the factors. The same letter indicates that there is no significant difference [20].

3. Results and Discussion

3.1. The Impact of Soil Bioregeneration on Fuel Consumption in Soil Tillage Operations

The soil bioregeneration efficiency research was carried out while measuring the fuel consumption during conventional and minimum soil tillage.

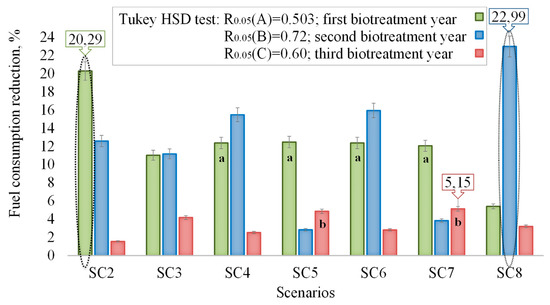

In all bioregeneration scenarios, compared with the control variant SC1, after the first year, fuel consumption in minimum soil tillage machines differed significantly. Minimum soil tillage fuel consumption ranged from 5.67 L ha−1 (SC2) to 7.12 L ha−1 (SC1). The largest reduction in fuel consumption in minimum soil tillage (about 20.29%) was found in the SC2 scenario compared with the control SC1 scenario (Figure 1).

Figure 1.

The impact of soil bioregeneration on reduction in fuel consumption in minimum tillage (columns marked with the same letter indicate no statistically significant differences; all histogram columns not marked with any letter have a significant difference with a confidence level of 95%).

The significant bioregeneration effect was calculated by calculating how much the fuel consumption was reduced using bioregeneration compared with the SC1 control variant. Compared with the control variant, the percentage change in each scenario was also calculated. This means that bioregeneration was efficient and reduced fuel consumption compared with the control variant where bioregeneration was not applied.

In 2016, major changes in fuel consumption of minimum soil tillage machines were twice as high as those in 2015 due to different meteorological conditions. The highest bioregeneration efficiency was determined by affecting the soil in SC8 scenario, with the largest reduction in average fuel consumption in minimum tillage machines being 23% (Figure 1 and Figure 2). The efficiency of the SC8 scenario is explained by the effect of soil bioregeneration on the increase in soil temperature and porosity and the decrease in soil density and hardness.

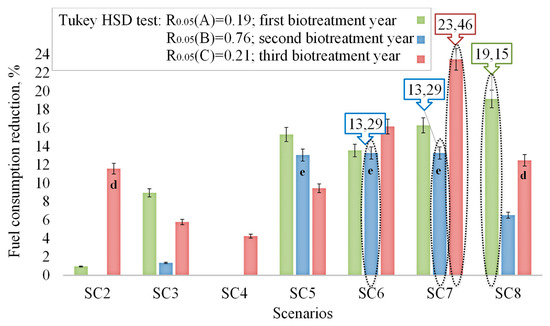

Figure 2.

Dependence of soil bioregeneration on fuel consumption under conventional soil tillage (columns marked with the same letter indicate no statistically significant differences; all histogram columns not marked with any letter have a significant difference with a confidence level of 95%).

Fuel consumption for minimum soil tillage decreased to 44% using soil bioregeneration for three years and ranged from 5.91 to 6.14 L ha−1. The control scenario was 6.24 L ha−1. It was determined according to the most efficient soil bioregeneration scenarios—SC3, SC5, and SC7—which reduced fuel consumption of minimum soil tillage by 4.18, 4.86, and 5.15%, respectively (Figure 1 and Figure 2).

Scenarios for the use of biological treatment (from 71% to 85%) effectively reduced fuel consumption. The average fuel consumption of conventional tillage machines in 2015 ranged from 18.34 L ha−1 to 23.66 L ha−1 (hourly from 15.8 L h−1 to 12.1 L h−1). In 2016, the highest average fuel consumption of conventional tillage machines was recorded in scenarios SC1 (24.04 L ha−1), SC2 (24.48 L ha−1), and SC4 (24.10 L ha−1) (Figure 2).

The obtained values, converted from L h−1 to L ha−1, were the same as those obtained using soil bioregeneration efficiency scenarios (Figure 3). In 2015, using one-factor (A) analysis of variance, there were no significant differences in the SC2 scenario compared to the control SC1 scenario. There were significant differences between the control scenario SC1 and the scenarios SC5, SC6, SC7, and SC8 in 2016.

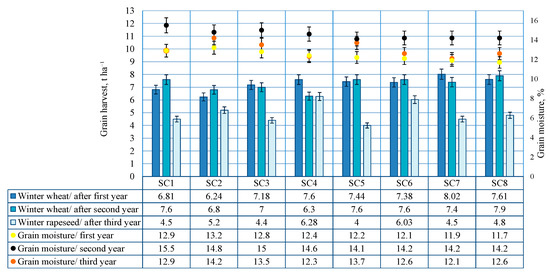

Figure 3.

The impact of soil bioregeneration on the yield and moisture of winter wheat (first and second year) and winter rapeseed (third year).

In 2015, the highest significant efficiency of the bioregeneration scenario in reducing the fuel consumption of conventional tillage machines, compared with the control SC1, was evident in scenarios SC5, SC6, SC7, and SC8, where changes ranged from 13.6% to 19.2%. In 2016, the change in the same scenarios did not reach the levels of 2015, and changes ranged from 6.9% to 14.1%.

SC8 was identified as the most efficient scenario, achieving reduction in fuel consumption of up to 19.2% in the first year of bioregeneration. The SC8 scenario was the most efficient because the soil temperature and porosity were higher compared with the control and some other scenarios. In addition, the soil density and hardness were lower under this scenario.

Fluctuations in the fuel consumption of conventional tillage partially highlight a similar trend as in the assessment of minimum soil tillage after crop rotation from wheat to rapeseed in 2017. Soil bioregeneration efficiency for fuel consumption reduction established in all soil bioregeneration scenarios and varied from 13.59 to 17.76 L ha−1. The highest significant efficiency of the soil bioregeneration scenario—reduction in fuel consumption of conventional tillage machines to 23% compared with the control SC1—was after the third soil biological treatment in 2017 (Figure 2).

Other researchers have confirmed that, over time, soil is mechanically adjusted during tillage, which affects its chemical, physical, and biological properties [21], and that fuel consumption can be reduced by optimizing complex technological processes [22,23,24,25,26,27]. Previous researchers have identified very important and appropriate measures to reduce fuel consumption [22,28,29] related to mechanized operations and the level of mechanization, as well as the use of soil nutrients [30].

Therefore, by replacing mineral fertilizers with nutrients (N, P, and K), soil bioregeneration and organic waste can maintain or increase the organic carbon content of the soil. This would increase porosity, reduce the energy consumption of soil tillage, and reduce the impact of global warming on synthetic fertilizers [31].

The most important goal of any tillage is to change the properties of the soil by mechanical means to create optimal conditions for the cultivation of crops. The aim is to promote arable farming in order to reduce production costs and protect the soil and the environment. In developed agricultural countries, deep plowing is increasingly abandoned and sowing is performed in minimally tilled or uncultivated soils. In the United States, Canada, Latin America, Australia, etc., where soil erosion is severe, large areas of soil have been cultivated without plowing for several decades.

However, according to global and Lithuania statistics (the latter being where the research of the article was conducted), there is still a tradition of conventional tillage—plowing. Deep plowing is an energy- and labor-intensive tillage method. Therefore, this work aimed to improve this situation where traditional working is applied.

However, in order to remain competitive in the market and future perspectives, it is recommended to introduce new tillage and sowing technologies that reduce the cost of crops and conserve the most expensive asset, the soil.

3.2. The Impact of Soil Bioregeneration on the Yield and Grain Moisture

The impact of different bioregeneration methods on the yield and grain/seed moisture of winter wheat (first and second growing year) and winter rapeseed (third growing year) was evaluated (Figure 3).

In the first year, after soil bioregeneration, the yield of almost all bioregeneration scenarios was higher compared with the control variant. Analogous studies in the second year showed that bioregeneration in SC8 resulted in higher yields, while the other scenarios had lower yields or the same yield as the control variant. The two-year average data showed that, in the SC5–SC8 bioregeneration variants, the yield was 4.17%–7.64% higher, and in SC2–SC4 variants it was 1.39% to 9.72% lower than in the control variant (7.2 t ha−1). In the third year, the winter rapeseed yield determined in the control variant was 4.5 t ha−1. The yield of the SC8, SC2, SC4, and SC6 soil bioregeneration scenarios was 6.67%–39.56% higher, one scenario (SC7) was the same, and the yield of winter rapeseed was 2.22%–11.11% lower in the SC3 and SC5 scenarios. This means that it is worth analyzing the different effects of bioregeneration and finding the best one that could be useful in all practical ways—both financially and environmentally. When we achieve higher yields, we must apply SC8, SC2, SC4, and SC6 of the analyzed bioregeneration scenarios.

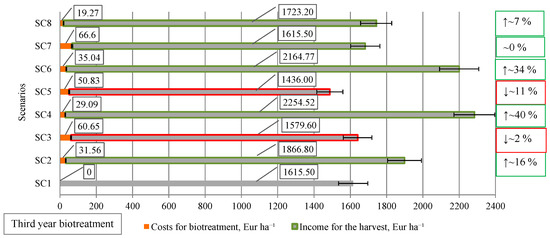

3.3. The Impact of Soil Bioregeneration on Cost Reduction

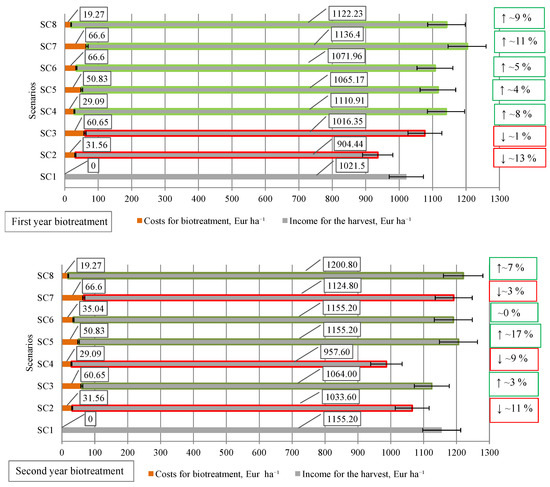

Differences in soil biological regeneration efficiency for yield and monetary benefit were determined as a percentage change in farmers income (increase/decrease) compared with the control. Increased yields due to soil bioregeneration are estimated to be dependent on yields (EUR ha−1) in terms of average purchase prices by average purchase prices in EU countries (EUR t−1) (average prices of cereals and rapeseeds (growers) in EU countries), but the final benefit (EUR; %) was confirmed by estimating the additional costs for bio-measures and was proved to be a cost-effective investment (Figure 4).

Figure 4.

The impact of soil bioregeneration on cost reduction and farmers income from winter wheat and winter rapeseed production. The columns marked in red color show a reduction in cost and farmers income due to soil bioregeneration. The columns marked in green color show an increase in cost and farmers income due to bioregeneration and its efficiency (columns marked with the same letter indicate no statistically significant differences; all histogram columns not marked with any letter have a significant difference with a confidence level of 95%).

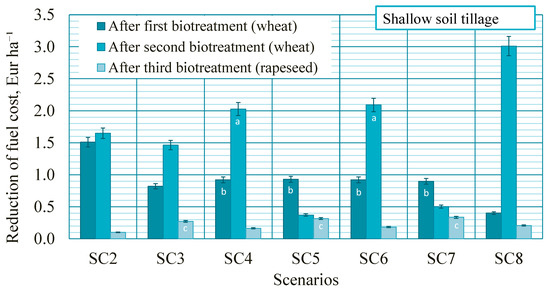

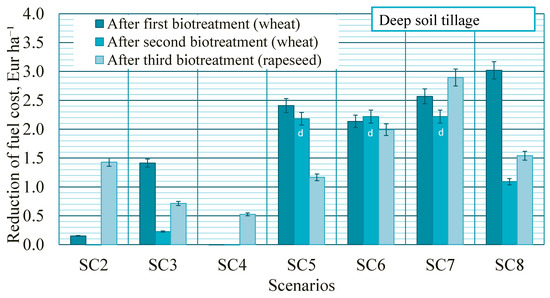

After assessing the impact of soil bioregeneration on cost reduction, farmers income from the first soil bioregeneration was obtained. It ranged from EUR 904 ha−1 to EUR 1136 ha−1 for wheat “Ada” in 2015; from EUR 957 ha−1 to EUR 1200 ha−1 after the second soil bioregeneration for wheat “Famulus“ in 2016; and from EUR 1436 ha−1 to EUR 2254 ha−1 after the third soil bioregeneration for rapeseed “Cult“. The ultimate monetary benefits and efficiencies of soil bioregeneration were demonstrated by increasing farmers income from 4% to 11% with 5 soil bioregeneration variants in the first year, from 3% to 17% with 4 soil bioregeneration variants in the second year, and from 7% to 40% with 5 soil bioregeneration variants in the third year (Figure 5 and Figure 6).

Figure 5.

The impact of soil bioregeneration on fuel cost reduction under minimum tillage. Same letters indicate no significant differences between the treatments.

Figure 6.

The impact of soil bioregeneration on fuel cost reduction under conventional tillage. Same letters indicate no significant differences between the treatments.

The efficiency of soil bioregeneration in reducing the cost of diesel fuel allowed us tp assess the opportunity of reducing expenses for fuel under both minimum and conventional soil tillage to approximately EUR 3 ha−1. Lower fuel consumption reduced the total CO2eq in soil tillage operations; the estimated reduced amount in arable soils in Lithuania could reach and correspond to approximately EUR 337 million, according to the approximate price of CO2 (11.51 euros ha−1). Bioregeneration could be even more efficient in the future based on analysts’ forecasts that the projected prices for 2020 would increase by 22% to EUR 18.36 t−1 if the European Commission ultimately passed legislation to bring current emission targets in line with the Paris Climate Agreement.

In addition, other researchers have shown a positive effect of different bioregeneration methods on changes in soil organic carbon, which is particularly evident in deeper layers at depths of 10–20 cm and in winter wheat and winter rapeseed yields, with energy efficiency ratios of 4.84 for winter wheat and 5.11 for winter rapeseed [32]. Scientists found that the benefits of the proposed bacterial bioregeneration are the reduction in pest attacks in agricultural crops, soil ecology with the help of bacteria, favorable development of agricultural ecosystems, especially high crop yields, and higher quality agricultural products [32].

4. Conclusions

The fuel consumption results of the soil tillage technological operation suggest that bioregenerated soil was easier to cultivate and the tillage process consumes less fuel. Soil tillage saved an average of 5.82%–21.82%, and in some cases even up to 36.2% of diesel fuel compared with the control (3.88 L ha−1). The best multi-year averages were achieved under the SC7 scenario (3.04 L ha−1), when soil was bioregenerated with essential oils of plants, 40 types of various herbs, marine algae extracts, mineral oils, Azotobacter vinelandii bacteria, humic acids, gibberellic acid, copper, zinc, manganese, iron, calcium, and sodium molybdate. Soil bioregeneration reduced the amount of fuel used for conventional soil tillage. Assessing the impact of soil bioregeneration on the percentage reduction in conventional soil tillage fuel consumption, it was found that, compared with the control, the fuel consumption was reduced the most in SC7 (17.2%), SC6 (14.2%), SC5 (12.9%), and SC8 (12.6%) scenarios.

The winter wheat yield results show that, in 4 out of the 7 soil bioregeneration scenarios, the yield was between 4.17% and 7.64% higher than in the control variant (7.2 t ha−1), and in 3 scenarios it was 1.39% and 9.72% lower. The yield of winter rapeseed in 4 scenarios was between 6.67% and 39.56% higher than the control variant, in 1 it was the same, and in 2 it was between 2.22% and 11.11% lower.

Cost reduction and farmers income from winter wheat production could increase between 4% and 11% after one year of soil bioregeneration, between 3% and 17% after two years of soil bioregeneration, and between 7% and 40% after three years of soil bioregeneration.

Modelled fuel cost savings could reach up to EUR 3 ha−1, which could be up to EUR 9 million per year accounting for all the arable land in Lithuania. The method of soil bioregeneration was superior according to the described methodology, ensuring reduction in fuel consumption and soil cultivation costs and increasing farmers income. The best bioregeneration scenarios can benefit farmers both financially and environmentally, so that they do not use resources unnecessarily and do not pollute the environment—wasting time and money. When we achieve higher yields, the soil should be bioremediated with a solution consisting of plant essential oils, various herbs, marine algae extract, mineral oils, Azotobacter vinelandii bacteria, humic acids, gibberellic acid, copper, zinc, manganese, iron, calcium, and sodium molybdate.

5. Patent

Šarauskis Egidijus; Naujokienė Vilma; Vaitauskiene Kristina. A way to reduce fuel consumption in crop production using a biological preparation. Patent no. LT 6470 B. Vilnius, 10/11/2017, 5 pages. http://www.vpb.lt/db_patentai/rezult-singl.php?id=X531540 accessed on 25 October 2021.

Author Contributions

Conceptualization, K.L. and V.N.; methodology, E.Š.; software, V.N.; validation, A.B.; investigation, V.N.; data curation, K.L.; writing—original draft preparation, E.Š.; writing—review and editing, V.N.; visualization, V.N. and A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data will be provided individually by contacting the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Noor, R.S.; Hussain, F.; Umair, M. Evaluating selected soil physical properties under different soil tillage systems in arid southeast rawalpindi, pakistan. J. Clean WAS 2020, 4, 41–45. [Google Scholar] [CrossRef]

- Hamzei, J.; Seyyedi, M. Energy use and input–output costs for sunflower production in sole and intercropping with soybean under different tillage systems. Soil Tillage Res. 2016, 157, 73–82. [Google Scholar] [CrossRef]

- Brennan, A.; Meng, Y.; Holmes, J.; Hill-McManus, D.; Meier, P. Potential benefits of minimum unit pricing for alcohol versus a ban on below cost selling in England 2014: Modelling study. BMJ 2014, 349, g5452. [Google Scholar] [CrossRef]

- Romaneckas, K.; Kimbirauskienė, R.; Adamavičienė, A.; Buragiene, S.; Sinkevičienė, A.; Sarauskis, E.; Jasinskas, A.; Minajeva, A. Impact of sustainable tillage on biophysical properties of Planosol and on faba bean yield. Agric. Food Sci. 2019, 28, 101–111. [Google Scholar] [CrossRef][Green Version]

- Kobierski, M.; Lemanowicz, J.; Wojewódzki, P.; Kondratowicz-Maciejewska, K. The Effect of Organic and Conventional Farming Systems with Different Tillage on Soil Properties and Enzymatic Activity. Agronomy 2020, 10, 1809. [Google Scholar] [CrossRef]

- Pandiaraj, T.; Yadav, P.; Singh, D.K. Cost Effective Conservation Agriculture for Sustaining the Farm Income. Agric. Environ. e-Newsl. 2020, 1, 5–14. [Google Scholar]

- Mileusnić, Z.; Petrović, D.; Đević, M. Comparison of tillage systems according to fuel consumption. Energy 2010, 35, 221–228. [Google Scholar] [CrossRef]

- Saldukaitė, L.; Šarauskis, E.; Lekavičienė, K.; Savickas, D. Predicting energy efficiency and greenhouse gases reduction potential under different tillage management and farm size scenarios for winter wheat production. Sustain. Energy Technol. Assess. 2020, 42, 100841. [Google Scholar] [CrossRef]

- Houshyar, E.; Grundmann, P. Environmental impacts of energy use in wheat tillage systems: A comparative life cycle assessment (LCA) study in Iran. Energy 2017, 122, 11–24. [Google Scholar] [CrossRef]

- Arvidsson, J. Energy use efficiency in different tillage systems for winter wheat on a clay and silt loam in Sweden. Eur. J. Agron. 2010, 33, 250–256. [Google Scholar] [CrossRef]

- Skuodienė, R.; Karčauskienė, D.; Čiuberki, S.; Repšienė, R.; Ambrazaitiene, D. The influence of primary soil tillage on soil weed seed bank and weed incidence in a cereal-grass crop rotation. Zemdirb. Agric. 2013, 100, 25–32. [Google Scholar] [CrossRef][Green Version]

- Romaneckas, K.; Avizienyte, D.; Adamaviciene, A.; Buragiene, S.; Kriauciuniene, Z.; Sarauskis, E. The impact of five long-term contrasting tillage systems on maize productivity parameters. Agric. Food Sci. 2020, 29, 6–17. [Google Scholar] [CrossRef]

- Crittenden, J.R.; Tillberg, P.W.; Riad, M.H.; Shima, Y.; Gerfen, C.R.; Curry, J.; Housman, D.E.; Nelson, S.B.; Boyden, E.S.; Graybiel, A.M. Striosome–dendron bouquets highlight a unique striatonigral circuit targeting dopamine-containing neurons. Proc. Natl. Acad. Sci. USA 2016, 113, 11318–11323. [Google Scholar] [CrossRef]

- Chachina, S.; Voronkova, N.; Baklanova, O. Biological Remediation of the Petroleum and Diesel Contaminated Soil with Earthworms Eisenia Fetida. Procedia Eng. 2016, 152, 122–133. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Liu, M.; Zhu, J. Towards better analysis of machine learning models: A visual analytics perspective. Vis. Inform. 2017, 1, 48–56. [Google Scholar] [CrossRef]

- Todorovic, V.; Maslaric, M.; Bojic, S.; Jokic, M.; Mircetic, D.; Nikolicic, S. Solutions for More Sustainable Distribution in the Short Food Supply Chains. Sustainability 2018, 10, 3481. [Google Scholar] [CrossRef]

- Naujokienė, V.; Šarauskis, E.; Lekavičienė, K.; Adamavičienė, A.; Buragienė, S.; Kriaučiūnienė, Z. The influence of biotreatment on the reduction of energy consumption and CO2 emissions in shallow and deep soil tillage. Sci. Total Environ. 2018, 626, 1402–1413. [Google Scholar] [CrossRef]

- Tarakanov, A.O.; Skormin, V.A.; Sokolova, S.P.; Sokolova, S.S. Immunocomputing: Principles and Applications; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Jakienė, E. The effect of the microelement fertilizers and biological preparation Terra Sorb Foliar on spring rape crop. Žemes Ukio Moksl. 2013, 20, 75–83. [Google Scholar] [CrossRef]

- IPCC. Summary for policymakers In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Condor, J.; Olivera, J.; Pinedo, R. Fertilisation Methods for Commercial Yield in Three Garlic Cultivars (Allium sativum L.). Peruv. J. Agron. 2019, 3, 104–111. [Google Scholar] [CrossRef]

- Montemurro, F.; Ferri, D.; Tittarelli, F.; Canali, S.; Vitti, C. Anaerobic Digestate and On-Farm Compost Application: Effects on Lettuce (Lactuca sativa L.) Crop Production and Soil Properties. Compos. Sci. Util. 2010, 18, 184–193. [Google Scholar] [CrossRef]

- Keshavarz-Afshar, R.; Chen, C. Intensification of Dryland Cropping Systems for Bio-feedstock Production: Energy Analysis of Camelina. BioEnergy Res. 2015, 8, 1877–1884. [Google Scholar] [CrossRef]

- Damanauskas, V.; Janulevičius, A. Differences in tractor performance parameters between single-wheel 4WD and du-al-wheel 2WD driving systems. J. Terramechanics 2015, 60, 63–73. [Google Scholar] [CrossRef]

- Janulevičius, A.; Damanauskas, V. How to select air pressures in the tires of MFWD (mechanical front-wheel drive) tractor to minimize fuel consumption for the case of reasonable wheel slip. Energy 2015, 90, 691–700. [Google Scholar] [CrossRef]

- Moitzi, G.; Haas, M.; Wagentristl, M.; Boxberger, J.; Gronauer, A. Energy consumption in cultivating and ploughing with trac-tion improvement system and consideration of the rear furrow wheel-load in ploughing. Soil Tillage Res. 2013, 134, 56–60. [Google Scholar] [CrossRef]

- Khambalkar, V.P.; Katkhede, S.S.; Dahatonde, S.; Korpe, N.D.; Nage, S.M. Renewable energy: An assessment of public awareness. Int. J. Ambient Energy 2010, 31, 133–142. [Google Scholar] [CrossRef]

- Kheiralla, A.F.; Yahya, A.; Zohadie, M.; Ishak, W. Modelling of power and energy requirements for tillage implements oper-ating in Serdang sandy clay loam, Malaysia. Soil Tillage Res. 2004, 78, 21–34. [Google Scholar] [CrossRef]

- Szendrő, G.; Török, Á. Theoretical investigation of environmental development pathways in the road transport sector in the european region. Transport 2014, 29, 12–17. [Google Scholar] [CrossRef]

- Dagiliute, R.; Juknys, R. Eco-efficiency: Trends, goals and their implementation in lithuania/ekologinis veiksmingumas: Tendencijos, tikslai ir jų įgyvendinimas lietuvoje. J. Environ. Eng. Landsc. Manag. 2012, 20, 265–272. [Google Scholar] [CrossRef]

- Juknevičius, D.; Kriaučiūnienė, Z.; Jasinskas, A.; Šarauskis, E. Analysis of Changes in Soil Organic Carbon, Energy Consumption and Environmental Impact Using Bio-Products in the Production of Winter Wheat and Oilseed Rape. Sustainability 2020, 12, 8246. [Google Scholar] [CrossRef]

- Toader, M.; Georgescu, E.; Ionescu, A.M.; Șonea, C. Test of some insecticides for Tanymecus dilaticollis Gyll. control, in organic agriculture conditions. Rom. Biotechnol. Lett. 2020, 25, 2070–2078. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).