Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact

Abstract

1. Introduction

2. Materials and Methods

2.1. Definitions

2.2. Methodology

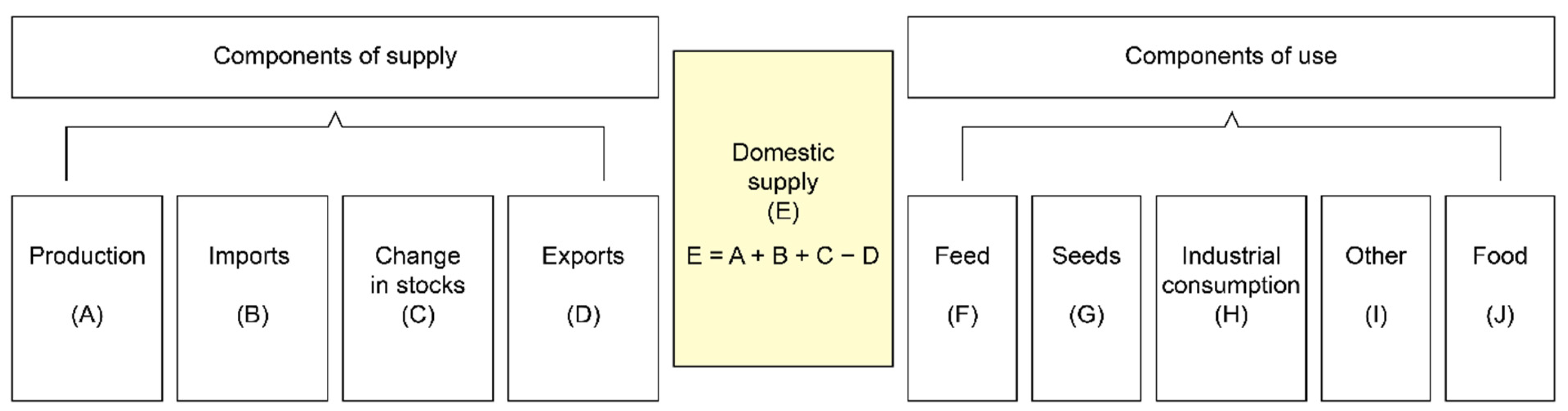

2.2.1. Mass Balance Method

2.2.2. Direct Research—Survey Questionnaires

2.2.3. Estimation of Food Waste Weight

2.2.4. Calculation of Carbon Footprint

3. Results and Discussion

3.1. Level of Losses of Food Grains on The Basis of Mass Flow Balance

3.2. Level of Consumer Cereal Losses Based on Surveys

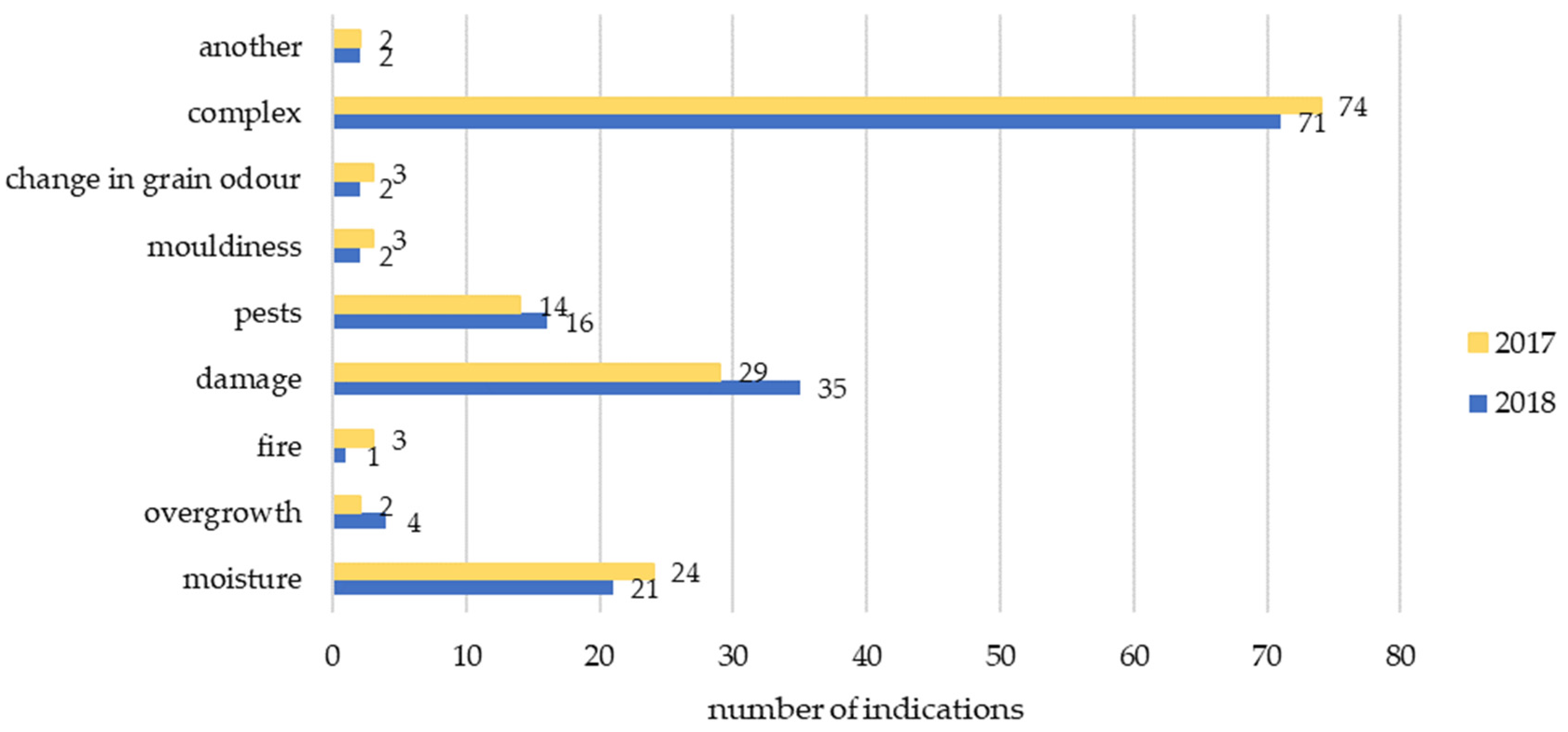

3.2.1. Causes of Food Losses in Consumer Cereal Production and Opportunities for Their Reduction

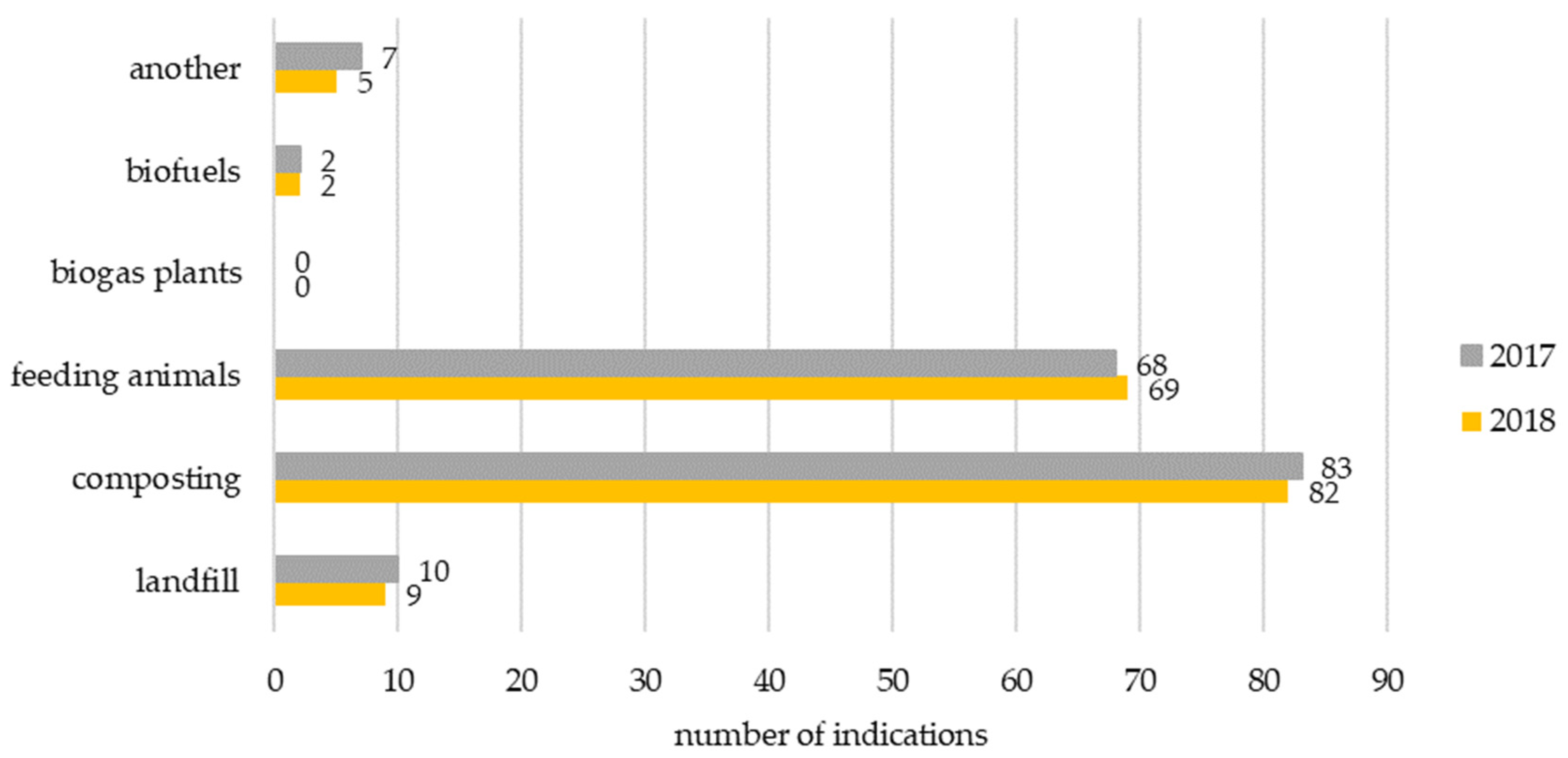

3.2.2. Ways of Waste Management

3.3. Food Waste

3.4. Environmental and Food Security Impacts of Consumer Cereal Losses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hodges, R.J.; Buzby, J.C.; Bennett, B. Postharvest losses and waste in developed and less developed countries: Opportunities to improve resource use. J. Agric. Sci. 2010, 149, 37–45. [Google Scholar] [CrossRef]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. The Metheodology of the FAO Study: Global Food Losses and Food Waste-Extent, Causes and Prevention; SIK Report No. 857; FAO: Rome, Italy, 2011. [Google Scholar]

- Scholz, K.; Eriksson, M.; Strid, I. Carbon footprint of supermarket food waste. Resour. Conserv. Recycl. 2015, 94, 56–65. [Google Scholar] [CrossRef]

- Redlingshofer, B.; Coudurier, B.; Georget, M. Quantyfying food loss during primary production and processing in France. J. Clean. Prod. 2017, 164, 703–714. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste-Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- Belc, N.; Mustatea, G.; Apostol, L.; Iorga, S.; Vladut, V.N.; Mosoiu, C. Cereal supply chain waste in the context of circular economy. E3S Web Conf. 2019, 112, 03031. [Google Scholar] [CrossRef]

- European Court of Auditors. Combating Food Waste—An Opportunity for the EU to Improve the Resource Efficiency of the Food Supply Chain; Special Report; European Court of Auditors: Luxemburg, 2016; p. 34.

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- UNEP Food Waste Index; Report 2021; United Nations Environment Programme: Nairobi, Kenya, 2021.

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and environmental losses embedded in global food waste. Resour. Conserv. Recycl. 2020, 160, 104912. [Google Scholar] [CrossRef]

- Łaba, S.; Bilska, B.; Tomaszewska, M.; Łaba, R.; Szczepański, K.; Tul-Krzyszczuk, A.; Kosicka-Gębska, M.; Kołożyn-Krajewska, D. Attempt to estimate food losses and wastage. Food Ind. 2020, 74, 10–18. [Google Scholar] [CrossRef]

- Goryńska-Goldmann, E.; Gazdecki, M.; Rejman, K.; Łaba, S.; Kobus-Cisowska, J.; Szczepański, K. Magnitude, Causes and Scope for Reducing Food Losses in the Baking and Confectionery Industry—A Multi-Method Approach. Agriculture 2021, 11, 936. [Google Scholar] [CrossRef]

- FUSIONS. Recommendations and Guidelines for a Common European Food Waste Policy Framework. Manual-Food Use for Social Innovation by Optimising Waste Prevention Strategies. Available online: http://www.eu-fusions.org/index.php/about-food-waste/280-food-waste-definition (accessed on 10 January 2022).

- Szczepańska, J. Grain market. In Selected Markets of Agri-Food Products after Poland’s Accession to the European Union; Olszańska, A., Kowalska, A., Eds.; Wydawnictwo UE: Wrocław, Poland, 2021; pp. 9–24. (In Polish) [Google Scholar]

- KOWR. (National Center for Agriculture Support). Grain Market in Poland. 2020. Available online: https://www.kowr.gov.pl/uploads/pliki/wydawnictwa/2020/Broszura_Rynek_zboz_w_Polsce_12.2020.pdf (accessed on 7 March 2022).

- Regulation (EC) No 178/2002; Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety. European Parliament: Strasbourg, France, 2002.

- Commission Delegated Decision (EU) C(2019)3211; Supplementing Directive 2008/98/EC of the European Parliament and of the Council with Regard to a Common Method and Minimum Quality Requirements for the Uniform Measurement of Food Waste Levels. European Commission: Brussels, Belgium, 2019.

- FAO. The State of Food Security and Nutrition in the World (SOFI): Safeguarding Against Economic Slowdowns and Downturns; FAO: Rome, Italy, 2019. [Google Scholar]

- Document 32008L0098; Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. European Parliament: Strasbourg, France, 2008.

- FLW (Food Loss and Waste) Protocol 2016. Food Loss and Waste Accounting and Reporting Standard. Available online: https://flwprotocol.org/wp-content/uploads/2017/05/FLW_Standard_final_2016.pdf (accessed on 20 December 2021).

- FUSIONS Estimates of European Food Waste Levels. FUSIONS Reducing Food Waste through Social Innovation. In Food Use for Social Innovation by Optimising Waste Prevention Strategies (FUSIONS); FUSIONS: Stockholm, Sweden, 2016; ISBN 978-91-88319-01-2.

- FUSIONS. Definitional Framework for Food Waste Full Report. Reducing Food Waste through Social Innovation. European Commission. 2014. Available online: https://www.eu-fusions.org/phocadownload/Publications/FUSIONS%20Definitional%20Framework%20for%20Food%20Waste%202014.pdf (accessed on 21 December 2021).

- Łaba, S.; Niedek, M.; Szczepański, K.; Łaba, R.; Kamińska-Dwórznicka, A. Regulation of the food waste measuring in the EU in the light of the need of counteracting the food wastage. Environ. Prot. Nat. Resour. 2019, 30, 1–7. [Google Scholar] [CrossRef]

- GUS (Central Statistical Office). Statistical Yearbook of Agriculture; GUS: Warsaw, Poland, 2019.

- Łopaciuk, W. Polish cereal market. Grain Mark. Status Prospect. 2019, 56, 15–34. (In Polish) [Google Scholar]

- Kwasek, M.; Borowski, M.; Kowalewska, M.; Obiedzińska, A. Analysis of food losses and wastage in the world and in Poland. In Monographs of the Multiannual Program; Kwasek, M., Ed.; IERiGŻ-PIB: Warsaw, Poland, 2016. (In Polish) [Google Scholar]

- Niedek, M.; Łaba, S.; Szczepański, K.; Krajewski, K. Quantitative methods in the study of food losses and wastage in the primary production sector. Quant. Methods Econ. 2019, 20, 263–279. (In Polish) [Google Scholar]

- Kulczycka, J.; Wernicka, M. Methods and Results of Calculating the Carbon Footprint of the Activities of Selected Entities in the Energy and Mining Industry; Institute of Mineral and Energy Economy of the Polish Academy of Sciences: Kraków, Poland, 2015. (In Polish) [Google Scholar]

- Łaba, S.; Cacak-Pietrzak, G.; Szczepański, K.; Sułek, A. Food Loss and Waste in the Production of Consumer Cereals. Przegl. Zboż-Młyn. 2020, 1, 24–29. (In Polish) [Google Scholar]

- Neethirajan, S.; Karunakaran, C.; Jayas, D.S.; White, N.D.G. Detection techniques for stored-product insects in grain. Food Control 2007, 18, 157–162. [Google Scholar] [CrossRef]

- Bencze, S.; Balla, K.; Varga, B.; Veisz, O. Effect of climate extremes on the grain yield and quality of cereals. Acta Agron. Hung. 2010, 58, 115–120. [Google Scholar] [CrossRef]

- Rozbicki, J.; Ceglińska, A.; Gozdowski, D.; Jakubczak, M.; Cacak-Pietrzak, G.; Mądry, W.; Golba, J.; Piechociński, M.; Sobczyński, G.; Stadnicki, M.; et al. Influence of the cultivar, environment and management on the grain yield and bread-making quality in winter wheat. J. Cereal Sci. 2015, 61, 126–132. [Google Scholar] [CrossRef]

- Sułek, A.; Cacak-Pietrzak, G. The influence of production technology on yielding of grain quality of spring wheat cultivars. Res. Rural Dev. 2018, 2, 42–48. [Google Scholar] [CrossRef]

- Ben Mariem, S.; Soba, D.; Zhou, B.; Loladze, I.; Morales, F.; Aranjuelo, I. Climate Change, Crop Yields, and Grain Quality of C3 Cereals: A Meta-Analysis of [CO2], Temperature, and Drought Effects. Plants 2021, 10, 1052. [Google Scholar] [CrossRef]

- Kwasek, M.; Łaba, S. Loss and food waste in primary production (agriculture) in Poland. In Food Losses and Waste in Poland. The Scale and Causes of the Problem; Instytut Ochrony Środowiska—Państwowy Instytut Badawczy: Warsaw, Poland, 2020; pp. 53–72. [Google Scholar]

- Jurga, R. Just about everything about grain damage to cereals. Przegl. Zboż. Młyn. 2011, 6, 34–37. (In Polish) [Google Scholar]

- Bryś, Z. Safe storage of cereal grains. In Training Materials. The Newest Methods of Growing and Storing Cereals for Consumption; IUNG-PIB: Puławy, Poland, 2010. [Google Scholar]

- Katagi, A.; Malashetti, I. Use of plant products for safe and economic storage of food grains. Adv. Res. J. Crop Improv. 2014, 5, 53–56. [Google Scholar]

- Klejdysz, T.; Mrówczyński, M. Methodology of Integrated Grain Storage Protection for Advisers; IOR-PIB: Poznań, Poland, 2017. (In Polish) [Google Scholar]

- Loganathan, M.; Akash, U.; Durgalakshmi, R.; Anandharamakrishnan, C. Constraints in Grain quality management: A warehouse journey. In Proceedings of the 12th International Working Conference on Stored Product Protection (IWCSPP), Berlin, Germany, 7–11 October 2018; pp. 98–100. [Google Scholar]

- Brader, A.; Lee, R.C.; Plarre, R.; Burkholder, W.; Kitto, G.B.; Kao, C.; Polston, L.; Dorneanu, E.; Szabo, I.; Mead, B.; et al. A comparison of screening methods for insect contamination in wheat. J. Stored Prod. Res. 2002, 38, 75–86. [Google Scholar] [CrossRef]

- Hagstrum, D.W.; Subramanyam, B. Fundamentals od Stored-Product Entomology; AACC International: St. Paul, MN, USA, 2006; p. 322. Available online: https://www.consilium.europa.eu/pl/policies/from-farm-to-fork/ (accessed on 15 February 2022).

- Stejskal, V.; Hubert, J.; Aulicky, R.; Kucerova, Z. Overview of present and past and pest-associated risks in stored food and feed products: European perspective. J. Stored Prod. Res. 2015, 64, 122–132. [Google Scholar] [CrossRef]

- Olejarski, P.; Węgorek, P.; Zamojska, J. Monitoring and control of stored grain insect pest in grain stores in Poland. Prog. Plant Prot. 2013, 53, 455–461. [Google Scholar]

- Rajendran, S. Postharvest pest losses. In Encyklopedia of Pest Management; Pimentel, D., Ed.; Marcel-Dekkert: New York, NY, USA, 2002; pp. 654–656. [Google Scholar]

- Nietupski, M. Competition or cooperation?—The concurrent development of grain weevil (Sitophilus granarius L.) and lesser grain borer (Rhyzopertha dominica F.) on barley grain. Prog. Plant Prot. 2020, 60, 149–156. [Google Scholar] [CrossRef]

- Nietupski, M.; Kwiatkowski, J.; Kosewska, A. Physicochemical properties of achenes of different buckwheat genotypes affecting thedevelopment of grain weevil (Sitophilus granarius L.) and lesser grain borer (Rhyzopertha dominica F.). Zemdirbyste-Agriculture 2017, 104, 311–320. [Google Scholar] [CrossRef][Green Version]

- Świerczyński, K.; Olejarski, P.; Boniecki, P. Using of artificial neuronal networks in identification process of granary weevils. J. Res. Appl. Agric. Eng. 2008, 53, 73–75. [Google Scholar]

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Wnergy: An Overview of Sustainable Approaches for Food Waste management and Nutrient Recycling. BioMed Res. Int. 2017, 2017, 2370927. [Google Scholar] [CrossRef]

- Melikoglu, M.; Turkmen, B. Food waste to Energy: Forecasting Tyrkey’s bioethanol generation potential from wasted crops and cereals till 2030. Sustain. Energy Technol. Assess. 2019, 36, 100553. [Google Scholar] [CrossRef]

- Stanciu, O.; Banc, O.; Cozma, A.; Filip, L.; Miere, D.; Mañes, J.; Loghin, F. Occurence of Fusarium mycotoxins in wheat from Europe—A review. Acta Univ. Cibiniensis Ser. E Food Technol. 2015, XIX, 35–60. [Google Scholar] [CrossRef]

- Bryła, M.; Waskiewicz, A.; Podolska, G.; Szymczyk, K.; Jędrzejczak, R.; Damaziak, K.; Sułek, A. Occurrence of 26 Mycotoxins in the Grain of Cereals Cultivated in Poland. Toxins 2016, 8, 160. [Google Scholar] [CrossRef]

- Ji, F.; He, D.; Olaniran, A.O.; Mokoena, M.P.; Xu, J.; Shi, J. Occurence, toxicity, production and detection of Fusarium mycotoxin: A review. Food Prod. Proc. Nutr. 2019, 1, 6. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.K.; Steinberger, J.; Wright, N.; Bin Ujang, Z. The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Wielicka-Regulska, A.; Mitmańska, Ż.; Kiss, M. The role and activity of food banks in reducing food losses and malnutrition in Poland. Handel Wew. 2018, 3, 395–405. (In Polish) [Google Scholar]

- Stahel, W. The Circular Economy: A User’s Guide; Routledge: London, UK; New York, NY, USA, 2019. [Google Scholar]

- FAO. Food Wastage Footprint: Impacts on Natural Resources; Summary Report; FAO: Rome, Italy, 2013. [Google Scholar]

- FAO. Food Wastage Footprint: Full-Cost Accounting; Final Report; FAO: Rome, Italy, 2014. [Google Scholar]

- Olivier, J.G.J.; Bouwman, A.F.; Van Der Maas, C.W.M.; Berdowski, J.J.M. Emission database for global atmospheric research (Edgar). Environ. Monit. Assess. 1994, 31, 93–106. [Google Scholar] [CrossRef] [PubMed]

- IPCC. Transportation. In Fifth Assessment Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Kapusta, F. Evolution of the food security of Poland and its inhabitants at the beginning of the 21st century. Zagadnienia Ekon. Rolnej 2017, 1, 161–178. [Google Scholar] [CrossRef]

| Macroregion NUTS 1 | Number of Farms | Number of Farms (Poland) | Sample Share in Population (%) |

|---|---|---|---|

| Central | 39 | 199,482 | 0.020 |

| Southwest | 15 | 79,484 | 0.019 |

| South | 31 | 174,860 | 0.018 |

| Northwest | 33 | 161,115 | 0.020 |

| West | 29 | 128,193 | 0.023 |

| Mazowieckie voivodeship | 31 | 177,812 | 0.017 |

| East | 68 | 375,736 | 0.018 |

| Total | 246 | 1,296,682 | 0.019 |

| Specification | Cereals | ||||

|---|---|---|---|---|---|

| Wheat | Rye | Barley | Oats | Maize | |

| Components of supply | |||||

| Production (A) | 10,980 | 2369 | 3304 | 1352 | 3971 |

| Imports (B) | 1067 | 30 | 361 | 33 | 714 |

| Stocks initial (Zp) | 1808 | 615 | 549 | 2084 | |

| Closing stocks (Zk) | 1487 | 505 | 433 | 1706 | |

| Change in state stocks (C) | 1607 | 110 | 1154 | 1892 | |

| Exports (D) | 3666 | 494 | 234 | 84 | 1093 |

| Domestic supply (E) | 8702 | 2016 | 3547 | 3970 | |

| Components of use | |||||

| Feed (F) | 3030 | 550 | 2391 | 3021 | |

| Seeds (G) | 548 | 159 | 181 | 23 | |

| Consumption industrial (H) | 664 | 373 | 735 | 8 | 688 |

| Other | 554 | 121 | 126 | 216 | |

| Food (J) | 3906 | 814 | 113 | 14 | 22 |

| Type of Cereal | 2014 | 2015 | 2016 | 2017 | 2018 | Mean from Years 2014–2018 |

|---|---|---|---|---|---|---|

| Wheat | 167.5 | 157.8 | 155.9 | 168.0 | 141.4 | 158.1 |

| Rye | 39.1 | 28.2 | 30.8 | 37.4 | 30.3 | 33.2 |

| Barley | 5.2 | 4.7 | 5.5 | 6.1 | 4.9 | 5.3 |

| Oats | 0.6 | 0.5 | 0.5 | 0.6 | 0.5 | 0.5 |

| Maize | 1.8 | 1.3 | 1.7 | 1.6 | 1.5 | 1.6 |

| Total | 214.2 | 192.5 | 194.4 | 213.7 | 178.6 |

| NUTS 1 Macro-Region | Number of Farms | Total Surface Area Crops (ha) | Area Under Cereals (ha) | Total Weight of Cereals Harvested (t) | Weight of Total Cereal Harvest, Average Per Farm (t) | Harvested Weight of Basic Cereals (t) | Weight of Harvested Basic Cereals, on Average Per Farm (t) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | ||

| Central | 39 | 742.98 | 772.21 | 287.15 | 297.73 | 1850.75 | 1847.4 | 47.46 | 47.37 | 1552.43 | 1547.8 | 39.81 | 39.69 |

| Southwest | 15 | 286.86 | 301.25 | 184.09 | 172.84 | 1315.25 | 1126.75 | 87.68 | 75.12 | 1143.25 | 991.25 | 76.22 | 66.08 |

| South | 31 | 307.34 | 300.78 | 191.41 | 194.52 | 1188.1 | 1167.19 | 38.33 | 37.65 | 691.9 | 805.64 | 22.32 | 25.99 |

| Northwest | 33 | 655.38 | 652.57 | 412.09 | 413.31 | 1902.13 | 1665.07 | 57.64 | 50.46 | 1644.57 | 1503.35 | 49.84 | 45.56 |

| North | 29 | 762.58 | 805.90 | 415.2 | 486.21 | 2487.61 | 2680.8 | 85.78 | 92.44 | 1500.31 | 1750.8 | 51.73 | 60.37 |

| Mazowieckie Voiv. | 31 | 497.89 | 497.00 | 262.02 | 269.25 | 1615.8 | 1457.35 | 52.12 | 47.01 | 1205.1 | 1099.95 | 38.87 | 35.48 |

| Eastern | 68 | 930.42 | 933.73 | 566.74 | 581.82 | 2849.12 | 2852.58 | 41.90 | 41.95 | 2350.12 | 2368.26 | 34.56 | 34.83 |

| Total | 246 | 4183.45 | 4263.44 | 2318.70 | 2415.68 | 13,208.76 | 12,797.14 | 53.69 | 52.02 | 10,087.68 | 10,067.05 | 41.01 | 40.92 |

| Share of Food Waste in the Volume of Production on Surveyed Farms (%) | Production Volumes in Poland for Consumption * (Thousand Tonnes) | Weight of Food Waste in Primary Production (Thousand Tonnes) | ||

|---|---|---|---|---|

| 2017 | 2018 | |||

| Total primary production | 1.03 | 41,564.35 | 40,299.2 | 507.94 |

| Of which cereals sector is | 1.12 | 11,333.38 | 9506.9 | 117.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łaba, S.; Cacak-Pietrzak, G.; Łaba, R.; Sułek, A.; Szczepański, K. Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact. Agriculture 2022, 12, 665. https://doi.org/10.3390/agriculture12050665

Łaba S, Cacak-Pietrzak G, Łaba R, Sułek A, Szczepański K. Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact. Agriculture. 2022; 12(5):665. https://doi.org/10.3390/agriculture12050665

Chicago/Turabian StyleŁaba, Sylwia, Grażyna Cacak-Pietrzak, Robert Łaba, Alicja Sułek, and Krystian Szczepański. 2022. "Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact" Agriculture 12, no. 5: 665. https://doi.org/10.3390/agriculture12050665

APA StyleŁaba, S., Cacak-Pietrzak, G., Łaba, R., Sułek, A., & Szczepański, K. (2022). Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact. Agriculture, 12(5), 665. https://doi.org/10.3390/agriculture12050665