A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method

Abstract

:1. Introduction

1.1. Maize Kernel Movement

1.2. Discrete Element Method

1.3. Aim of the Paper

2. Materials and Methods

2.1. Experiment Material

2.2. Physical Experiment

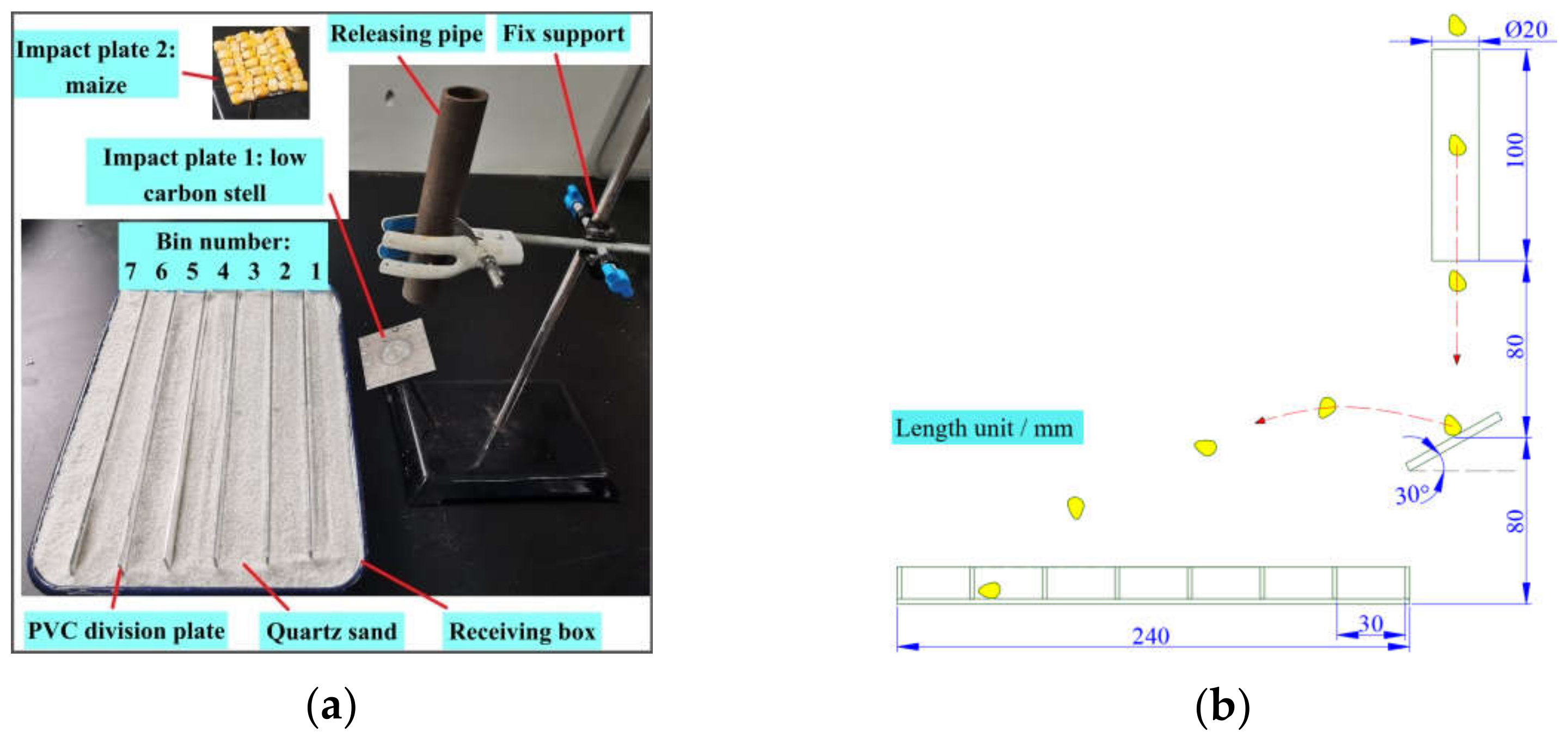

2.2.1. Inclined Surface Drop Method

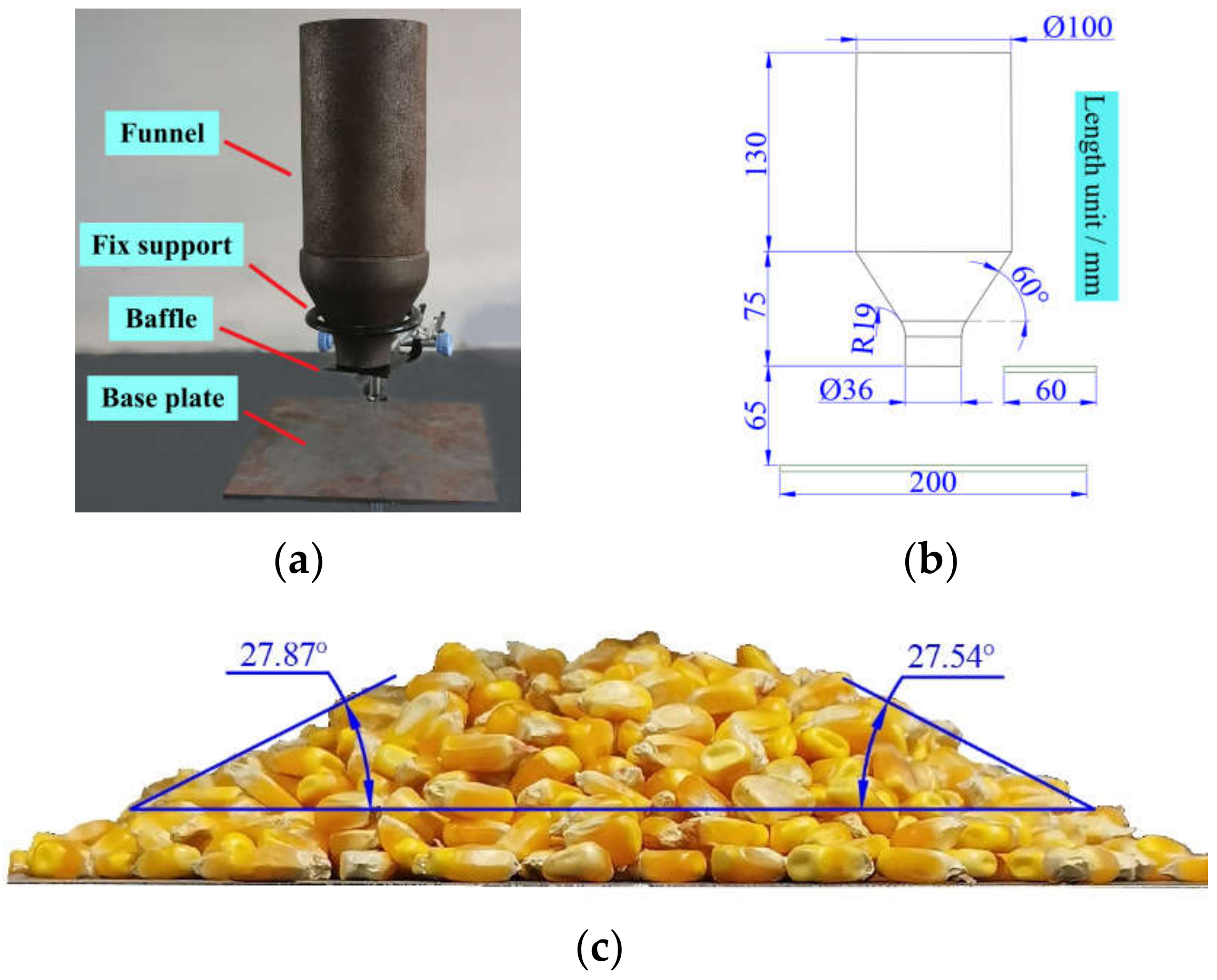

2.2.2. Funnel Method

2.3. Simulation Set-Up

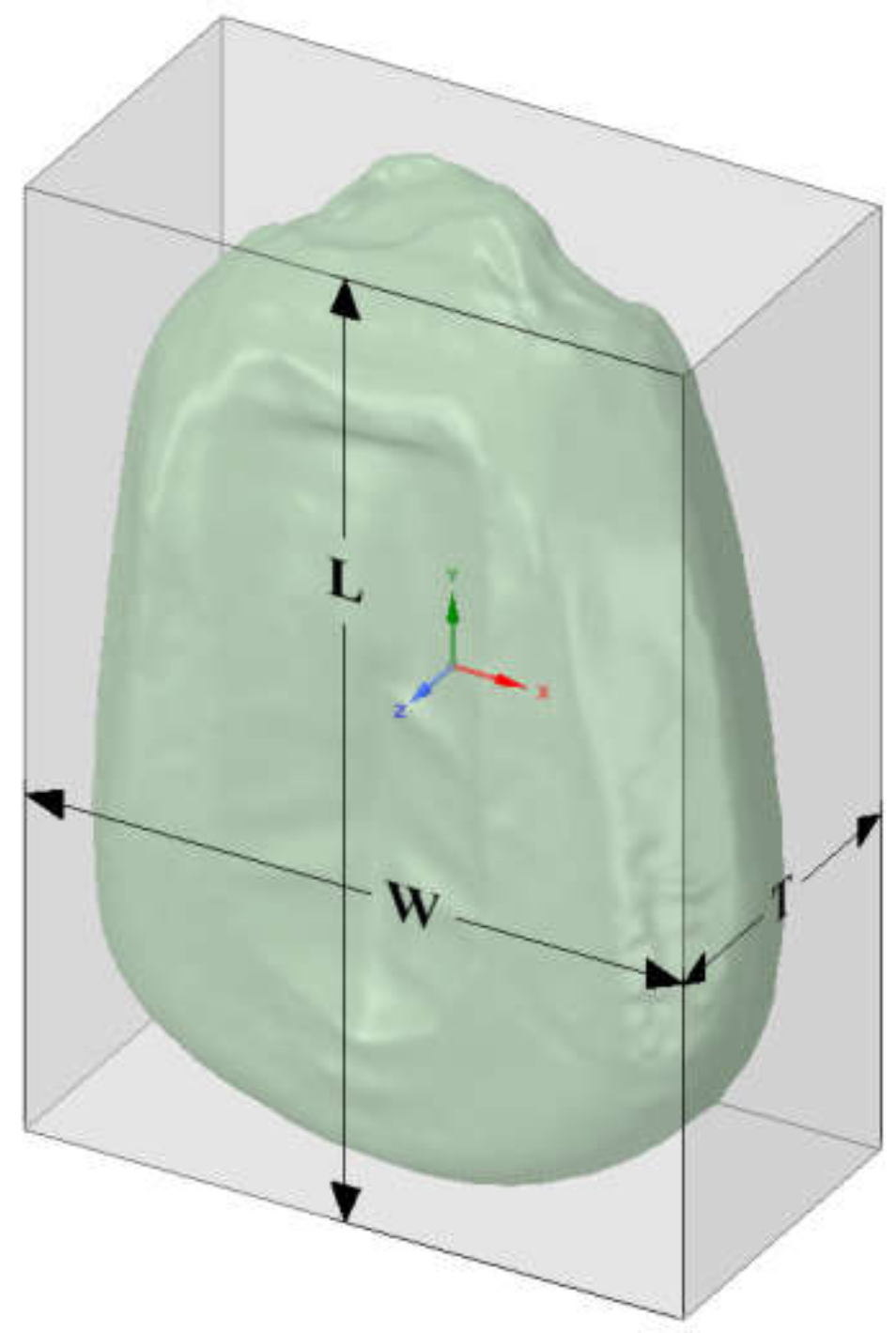

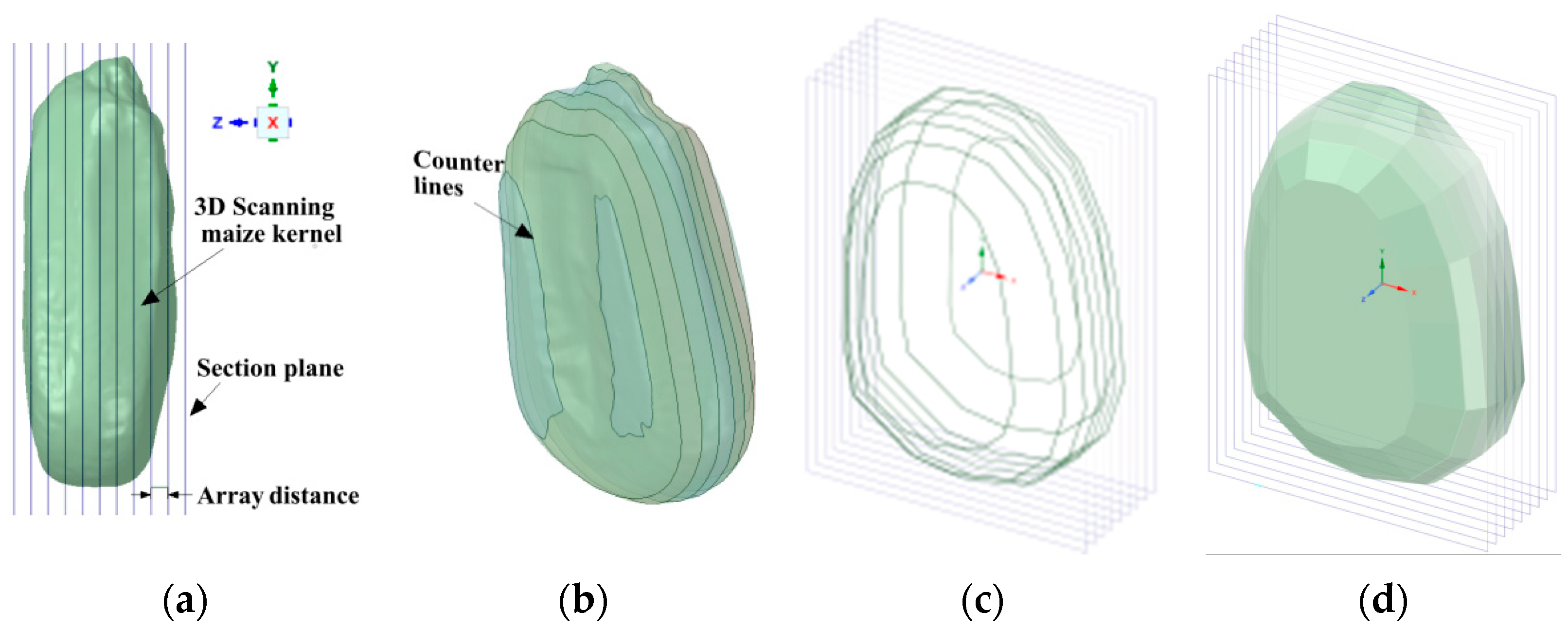

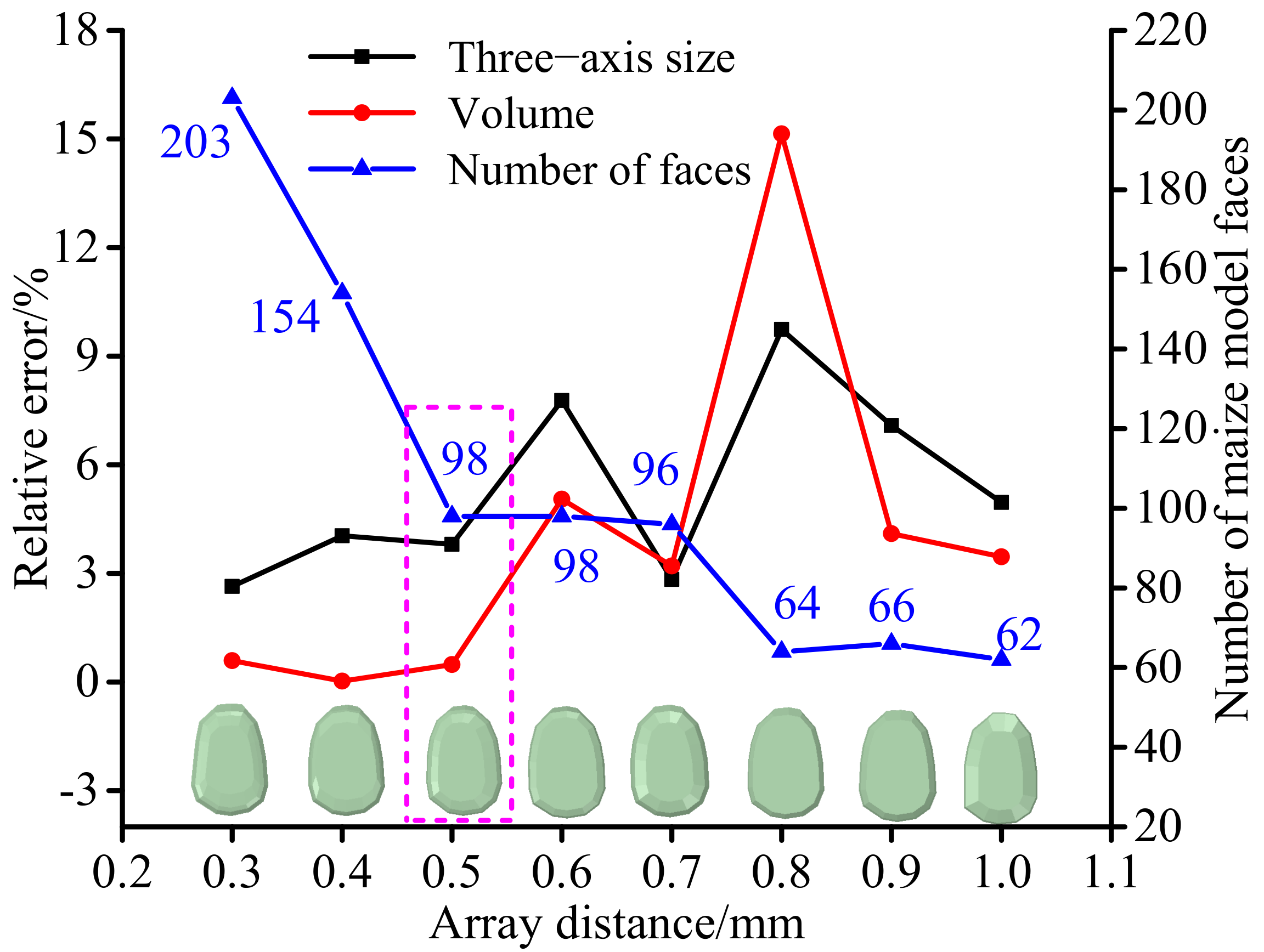

2.3.1. Construction of the Maize Kernel Model

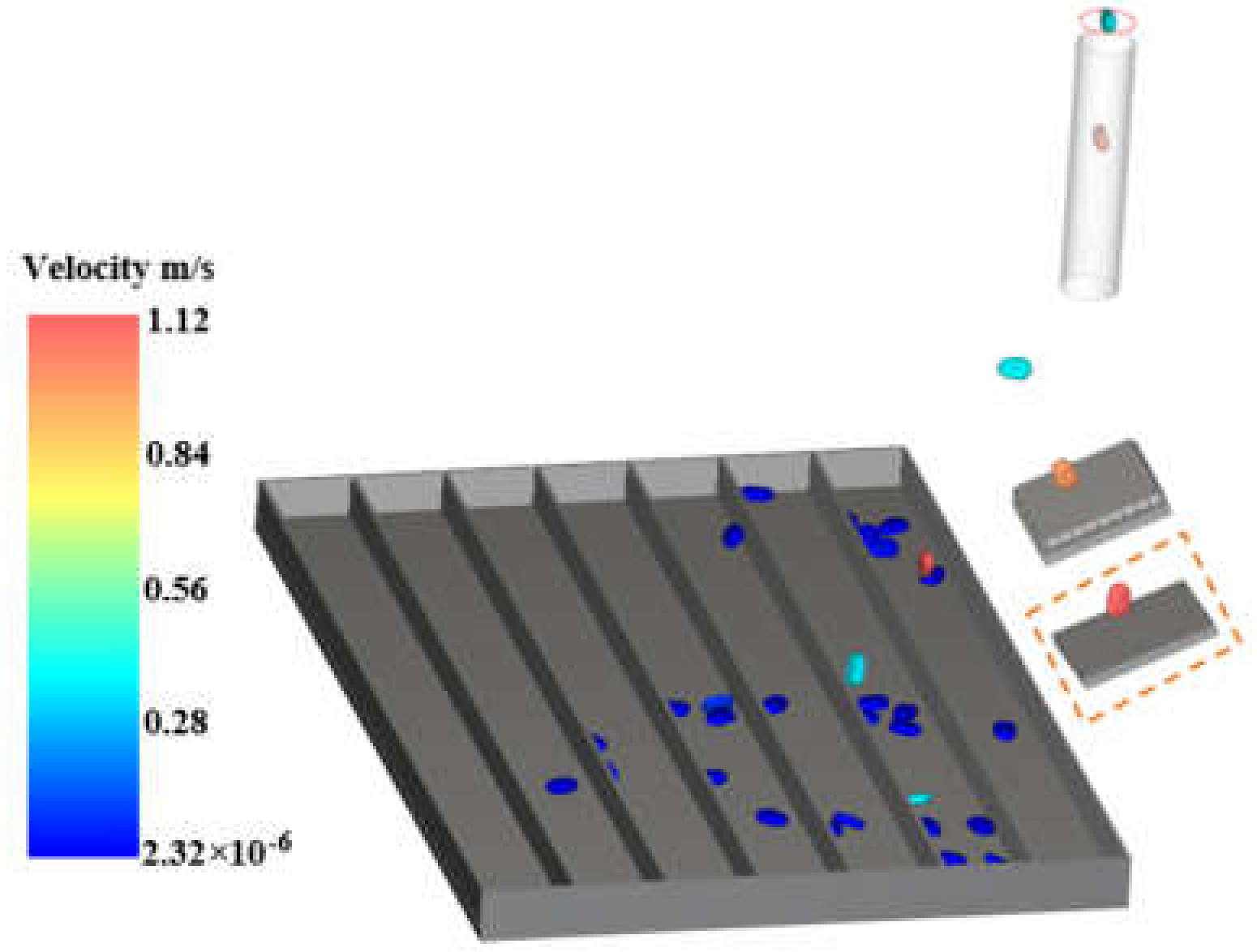

2.3.2. Calibration of Restitution Coefficients

2.3.3. Calibration of the Friction Coefficients

3. Results and Discussion

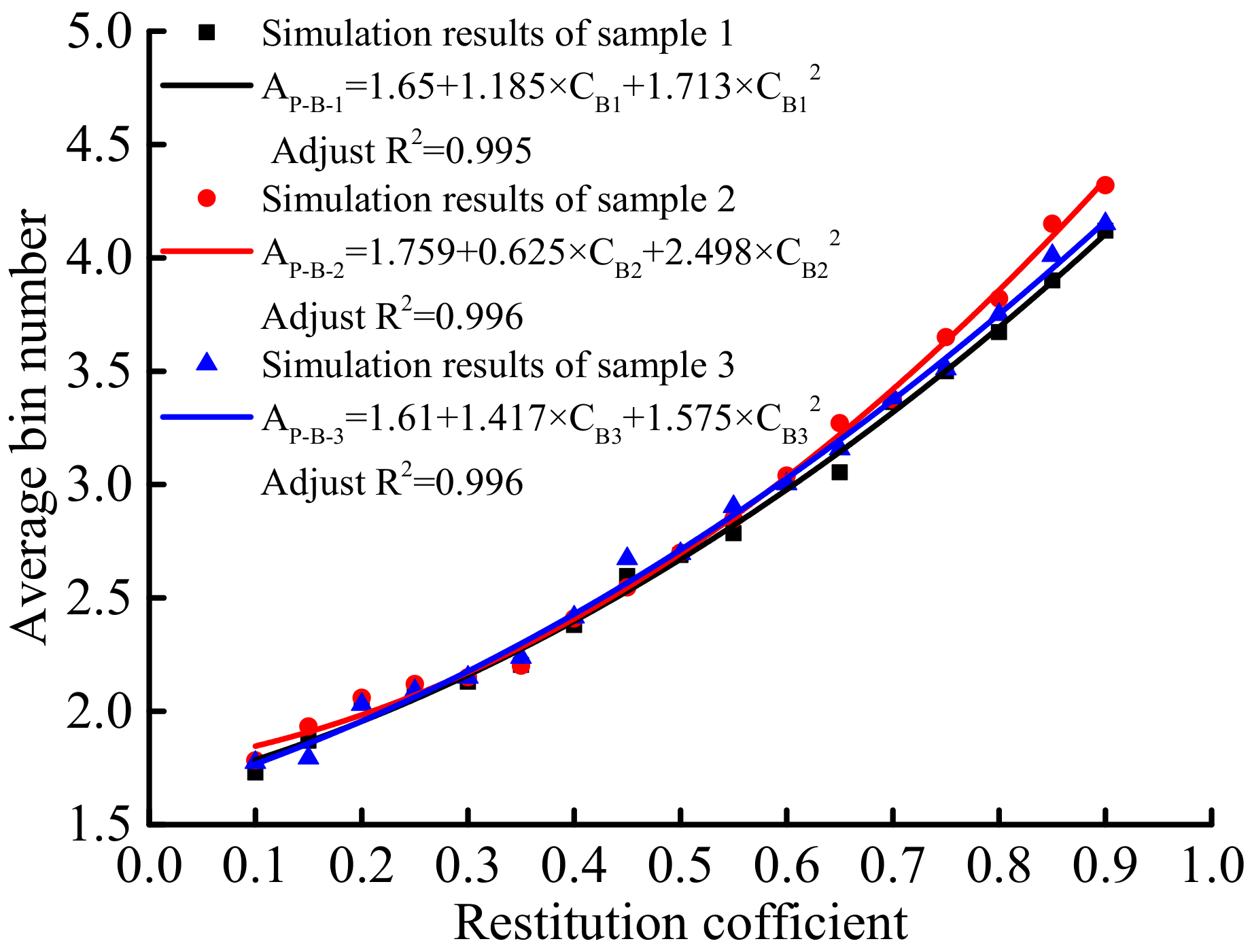

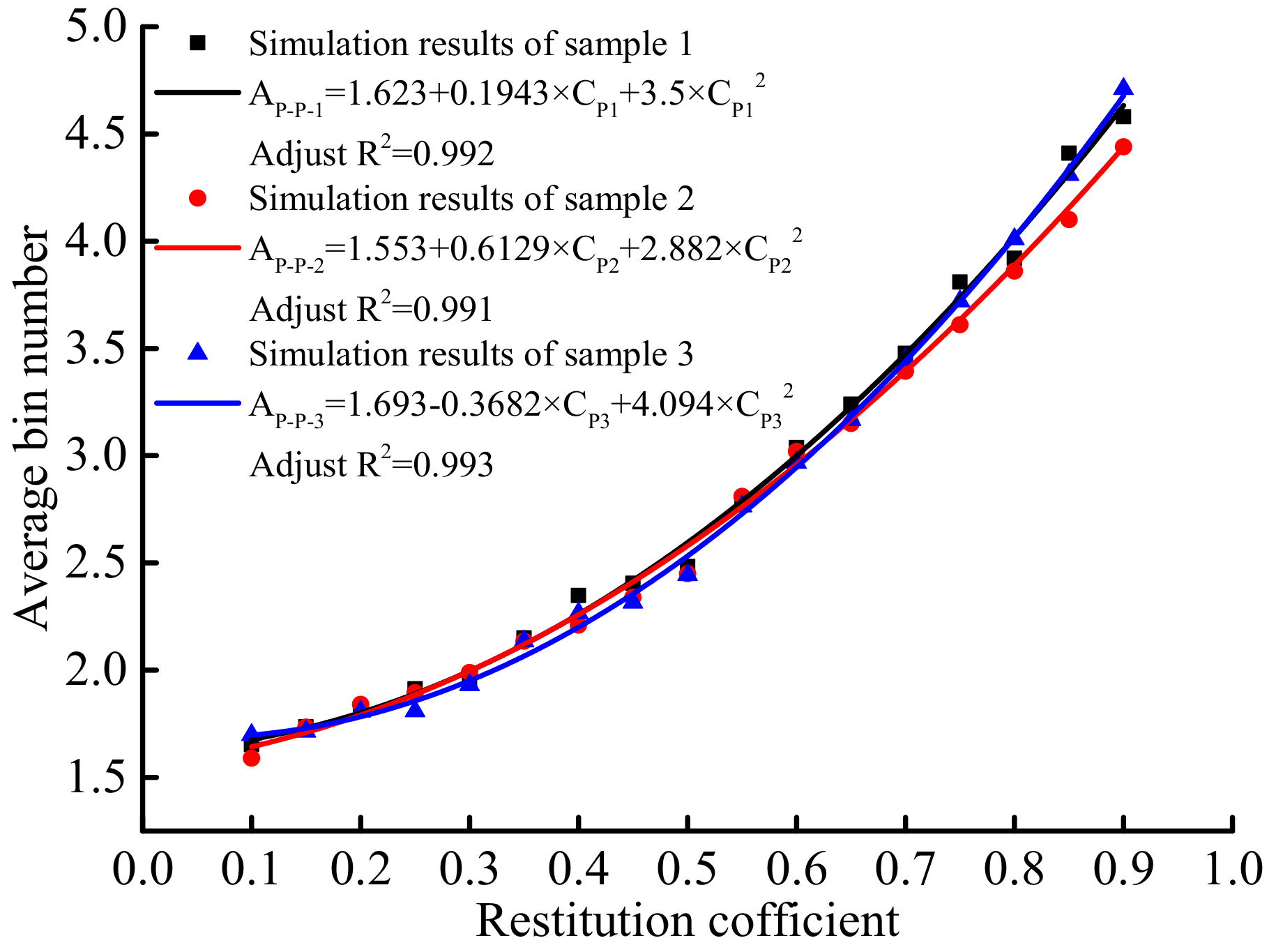

3.1. Restitution Coefficient Calibration

3.2. Parameter Calibration of the Friction Coefficient

3.2.1. Two-Level Factorial Design

3.2.2. Response Surface Methodology Analysis

3.3. Test Validation

3.3.1. Verification of Restitution Coefficients

3.3.2. Verification of Dynamic Friction Coefficients

3.4. Limitations of the Study

4. Conclusions

- (1)

- The maize kernel model was constructed by combining 3D scanning and the section method. The relative errors of the sizes of the three axes and the volume between the particle model and the real maize kernel were 3.81% and 0.48%, respectively.

- (2)

- The restitution coefficients between the maize kernel and low-carbon steel plate and between maize kernels were calibrated by improving the inclined surface drop method. Moreover, the dynamic friction coefficients between the maize kernel and low-carbon steel plate and between maize kernels were calibrated using the funnel method by considering the AoR with the discharging time.

- (3)

- Validation tests were carried out, and the maximum relative errors between the simulated and measured values obtained with the inclined surface drop method and funnel method were 4.38% and 6.98%, respectively, which verified the feasibility and accuracy of the particle model construction and parameter calibration method.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, Y.; Ravindran, V.; Wester, T. Influence of feeding coarse corn on performance, nutrient utilization, digestive tract measurements, carcass characteristics, and cecal microflora counts of broilers. Pultry Sci. 2014, 93, 607–616. [Google Scholar] [CrossRef] [PubMed]

- Metzger, M.; Glasser, B. Simulation of the breakage of bonded agglomerates in a ball mill. Powder Technol. 2013, 237, 286–302. [Google Scholar] [CrossRef]

- Dey, S.; Dey, S.; Das, A. Comminution features in an impact hammer mill. Powder Technol. 2013, 235, 914–920. [Google Scholar] [CrossRef]

- Ghodki, B.; Goswami, T. DEM simulation of flow of black pepper seeds in cryogenic grinding system. J. Food Eng. 2017, 196, 36–51. [Google Scholar] [CrossRef]

- Toneva, P.; Epple, P.; Breuer, M. Grinding in an air classifier mill—Part I: Characterisation of the one-phase flow. Powder Technol. 2011, 211, 19–27. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Veikle, E. Determination of material and interaction properties of maize and wheat kernels for DEM simulation. Biosyst. Eng. 2020, 195, 208–226. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, Y.; Cheng, Y. CFD-DEM modeling of rod-like particles in a fluidized bed with complex geometry. Powder Technol. 2019, 344, 673–683. [Google Scholar] [CrossRef]

- Jiménez-Herrera, N.; Barrios, G.; Tavares, L. Comparison of breakage models in DEM in simulating impact on particle beds. Adv. Powder Technol. 2018, 29, 692–706. [Google Scholar] [CrossRef]

- Coetzee, C.J. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Chen, Y.; Cai, W.; Zou, X. Extrusion mechanical properties of fresh litchi. Trans. Chin. Soc. Agric. Eng. 2011, 27, 360–364. [Google Scholar]

- Zhang, W.; Xie, J.; Zhang, X. Finite element analysis of mechanical properties of whole fresh jujubes. Food Sci. 2016, 37, 100–104. [Google Scholar]

- Yang, Z.; Sun, J.; Guo, Y. Effect of moisture content on compression mechanical properties and frictional characteristics of millet grain. Trans. Chin. Soc. Agric. Eng. 2015, 31, 253–260. [Google Scholar]

- Peng, F.; Wang, H.; Fang, F. Calibration of discrete element model parameters for pellet feed based on injected section method. Trans. Chin. Soc. Agric. Mach. 2018, 49, 140–147. [Google Scholar]

- Wang, Y.; Liang, Z.; Zhang, D. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar]

- Aghajani, N.; Ansaripour, E.; Kashaninejad, M. Effect of Moisture Content on Physical Properties of Barley Seeds. J. Agric. Sci. Technol. 2011, 14, 161–172. [Google Scholar]

- ROCKY DEM. DEM Technical Manual; Engineering Simulation and Scientific Software (ESSS): Florianópolis, Brazil, 24 January 2020. [Google Scholar]

- Yu, Q.; Liu, Y.; Chen, X. Calibration and experiment of simulation parameters for panax notoginseng seeds based on DEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–132. [Google Scholar]

- Beakawi Al-Hashemi, H.; Baghabra Al-Amoudi, O. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Liu, Y.; Zong, W.; Ma, L. Determination of three-dimensional collision restitution coefficient of oil sunflower grain by high-speed photography. Trans. Chin. Soc. Agric. Eng. 2020, 36, 44–53. [Google Scholar]

- Hou, Z.; Dai, N.; Chen, Z. Measurement and calibration of physical property parameters for agropyron seeds in a discrete element simulation. Trans. Chin. Soc. Agric. Eng. 2020, 36, 46–54. [Google Scholar]

- Santos, D.; Barrozo, M.; Duarte, C. Investigation of particle dynamics in a rotary drum by means of experiments and numerical simulations using DEM. Adv. Powder Technol. 2016, 27, 692–703. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Li, H. Calibration of simulation parameters for potato minituber based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135. [Google Scholar]

- Dai, F.; Song, X.; Zhao Wu, Y. Simulative Calibration on contact parameters of discrete elements for covering soil on whole plastic film mulching on double ridges. Trans. Chin. Soc. Agric. Mach. 2019, 50, 49–56. [Google Scholar]

- Li, Y.; Li, F.; Xu, X. Parameter calibration of wheat flour for discrete element method simulation based on particle scaling. Trans. Chin. Soc. Agric. Eng. 2019, 35, 320–327. [Google Scholar]

- Wen, X.; Yuan, H.; Wang, G. Calibration method of friction coefficient of granular fertilizer by discrete element simulation. Trans. Chin. Soc. Agric. Mach. 2020, 51, 115–122. [Google Scholar]

- Derakhshani, S.; Schott, D.; Lodewijks, G. Micro–macro properties of quartz sand: Experimental investigation and DEM simulation. Powder Technol. 2015, 269, 127–138. [Google Scholar] [CrossRef]

- Cao, K.; Hao, B. Modern China Feed Engineering; Shanghai Scientific and Technology Literature Press: Shanghai, China, 2014; pp. 374–462. [Google Scholar]

- Huang, K.; Chen, X.; Chen, P. Simulation and experimental analysis of mass transfer in drying a single corn kernel. J. Eng. Thermophys. 2017, 38, 2005–2010. [Google Scholar]

- GB 1353-2018; Maize. Standardization administration: Beijing, China, 13 July 2018.

- JJD 264-2008; Measuring instruments for cereals density. The Central People’s Government of People’s Republic of China: Beijing, China, 23 November 2008.

- Han, Y.; Jia, F.; Tang, Y. Influence of granular coefficient of rolling friction on accumulation characteristics. Acta Phys. Sin. 2014, 63, 173–179. [Google Scholar]

- Barmwal, P.; Kadam, D.; Singh, K. Influence of moisture content on physical properties of maize. Int. Agrophys. 2012, 26, 331–429. [Google Scholar] [CrossRef]

- Zhao, W. Rersearch on Combined Type of Spiral Bar Tooth Threshing Mechanism for Seed Corn. Doctoral Dissertation, Northwest A&F University, Xian, China, 1 November 2012. [Google Scholar]

- Ma, W.; You, Y.; Wang, D. Parameter calibration of alfalfa seed discrete element model based on RSM and NSGA-II. Trans. Chin. Soc. Agric. Mach. 2020, 51, 136–144. [Google Scholar]

- Gustafson, R.J.; Thompson, D.R.; Sokhansanj, S. Temperature and stress analysis of corn kernel—Finite Element Analysis. Trans. ASABE 1979, 22, 955–960. [Google Scholar] [CrossRef]

- Han, D. Optimization Simulation and Experimental Research of Inside Filling Air-Blowing Maize Precision Seed-Metering Device. Doctoral Dissertation, China Agricultural University, Beijing, China, 1 June 2018. [Google Scholar]

- Singh, S.; Finner, M.; Rohatgi, P. Structure and mechanical properties of corn kernels: A hybrid composite material. J. Mater. Sci. 1991, 26, 274–284. [Google Scholar] [CrossRef]

- Dong, P.; Guo, Y.; Hou, J. Study on the grinding method and parameter for testing corn breakage resistance. J. Maize Sci. 2019, 27, 124–129. [Google Scholar]

- Yan, H. A New Kind of Method for the Optimizated Design of Combination Inner-Cell Corn Precision Seed Metering Device. Doctoral Dissertation, Jilin University, Changchun, China, 1 December 2012. [Google Scholar]

- Wang, X. A Multi-Sphere Based Modelling Method for Maize Grain Assemblies. Master Dissertation, Jilin University, Changchun, China, 1 June 2017. [Google Scholar]

| Contact Type | No. Sample | Average Bin Number of Maize Kernels |

|---|---|---|

| p-w | Sample 1 | 3.91 ± 0.038 |

| Sample 2 | 3.80 ± 0.026 | |

| Sample 3 | 3.55 ± 0.028 | |

| p-p | Sample 1 | 2.86 ± 0.033 |

| Sample 2 | 2.75 ± 0.035 | |

| Sample 3 | 2.55 ± 0.027 |

| No. Sample | AoR/(°) | Discharging Time/(ms) |

|---|---|---|

| Sample 1 | 27.10 ± 0.93 | 2320 ± 35.51 |

| Sample 2 | 28.52 ± 1.26 | 2382 ± 29.33 |

| Sample 3 | 29.60 ± 1.07 | 2583 ± 42.84 |

| Parameter | Value(s) |

|---|---|

| Bulk density of maize kernels/(g/L) | 782.57, 769.06 and 739.00 |

| Young’s modulus of maize kernels/(Mp) | 374.93, 269.58 and 186.33 |

| Poisson’s ratio of maize kernels | 0.40 |

| Density of low-carbon steel/(kg/m3) | 7850 |

| Young’s modulus of low-carbon steel/(Mp) | 2.06 × 105 |

| Poisson ratio of low-carbon steel | 0.30 |

| Factor Level | pps | ppd | CP | pbs | pbd | CB |

|---|---|---|---|---|---|---|

| −1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 |

| +1 | 0.5 | 0.4 | 0.6 | 0.4 | 0.5 | 0.8 |

| No. Sample | AP-B | CB | AP–P | CP |

|---|---|---|---|---|

| Sample 1 | 3.91 | 0.856 | 2.86 | 0.567 |

| Sample 2 | 3.80 | 0.789 | 2.75 | 0.547 |

| Sample 3 | 3.55 | 0.750 | 2.55 | 0.505 |

| No. | Contact Parameters | AoR/(°) | Discharging Time/(ms) | |||||

|---|---|---|---|---|---|---|---|---|

| pps | ppd | CP | Pbs | pbd | CB | |||

| 1 | 0.1 | 0.4 | 0.1 | 0.1 | 0.5 | 0.8 | 32.18 | 2540 |

| 2 | 0.1 | 0.4 | 0.6 | 0.1 | 0.2 | 0.3 | 32.00 | 2620 |

| 3 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 14.25 | 1765 |

| 4 | 0.5 | 0.1 | 0.1 | 0.1 | 0.5 | 0.3 | 20.43 | 2063 |

| 5 | 0.5 | 0.4 | 0.6 | 0.1 | 0.5 | 0.3 | 31.68 | 2700 |

| 6 | 0.5 | 0.1 | 0.6 | 0.4 | 0.2 | 0.3 | 16.07 | 1820 |

| 7 | 0.5 | 0.1 | 0.1 | 0.4 | 0.5 | 0.8 | 25.24 | 2020 |

| 8 | 0.5 | 0.4 | 0.6 | 0.4 | 0.5 | 0.8 | 38.50 | 2630 |

| 9 | 0.1 | 0.1 | 0.1 | 0.4 | 0.2 | 0.8 | 10.43 | 1810 |

| 10 | 0.1 | 0.1 | 0.6 | 0.4 | 0.5 | 0.3 | 20.63 | 2076 |

| 11 | 0.5 | 0.1 | 0.6 | 0.1 | 0.2 | 0.8 | 11.00 | 1775 |

| 12 | 0.5 | 0.4 | 0.1 | 0.1 | 0.2 | 0.8 | 28.82 | 2530 |

| 13 | 0.1 | 0.4 | 0.6 | 0.4 | 0.2 | 0.8 | 25.71 | 2440 |

| 14 | 0.1 | 0.4 | 0.1 | 0.4 | 0.5 | 0.3 | 32.01 | 2560 |

| 15 | 0.5 | 0.4 | 0.1 | 0.4 | 0.2 | 0.3 | 35.29 | 2590 |

| 16 | 0.1 | 0.1 | 0.6 | 0.1 | 0.5 | 0.8 | 19.27 | 2175 |

| Source | AoR | Discharging Time | ||||||

|---|---|---|---|---|---|---|---|---|

| Coefficient Estimate | Mean Square | F-Value | p-Value | Coefficient Estimate | Mean Square | F-Value | p-Value | |

| Model | - | 177.55 | 15.07 | <0.01 | - | 2.95 × 105 | 31.28 | <0.01 |

| X1: pps | 1.28 | 26.41 | 2.24 | 0.17 | 8.88 | 1260.25 | 0.13 | 0.72 |

| X2: ppd | 7.43 | 883.06 | 74.96 | <0.01 | 319.13 | 1.63 × 106 | 172.63 | <0.01 |

| X3: CP | −0.25 | 0.90 | 0.08 | 0.79 | 22.38 | 8010.25 | 0.85 | 0.38 |

| X4: pbs | 0.89 | 12.70 | 1.08 | 0.33 | −13.87 | 3080.25 | 0.33 | 0.58 |

| X5: pbd | 2.90 | 134.36 | 11.40 | <0.01 | 88.38 | 1.25 × 105 | 13.24 | <0.01 |

| X6: CB | −0.70 | 7.86 | 0.67 | 0.44 | −17.12 | 4692.25 | 0.50 | 0.50 |

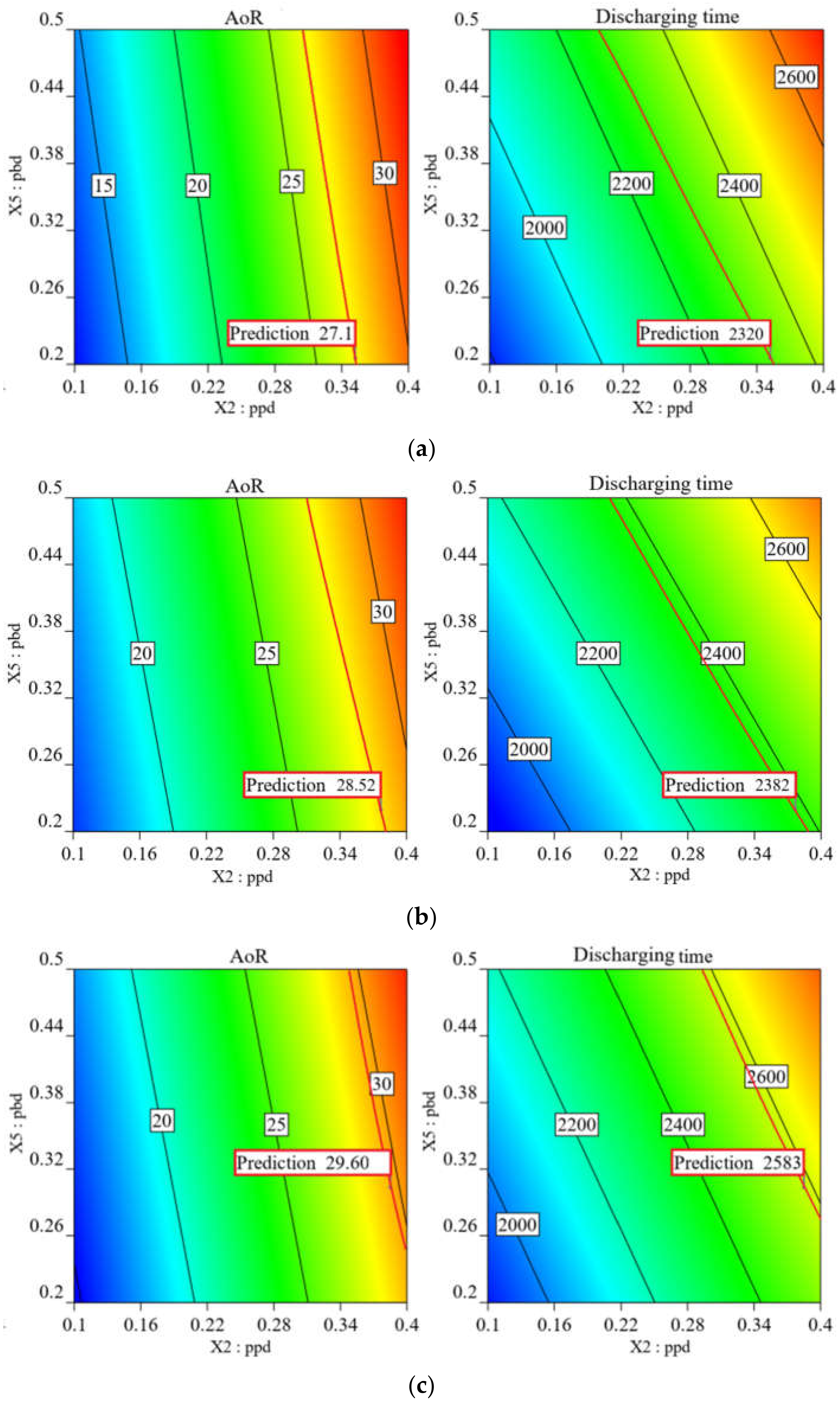

| No. | Factor Levels | Simulation Results | ||||||

|---|---|---|---|---|---|---|---|---|

| X2: ppd | X5: pbd | Sample 1 | Sample 2 | Sample 3 | ||||

| AoR/(°) | Discharging Time/(ms) | AoR/(°) | Discharging Time/(ms) | AoR/(°) | Discharging Time/(ms) | |||

| 1 | 0.40 | 0.20 | 31.165 | 2485 | 29.950 | 2376 | 29.610 | 2400 |

| 2 | 0.10 | 0.50 | 17.045 | 2065 | 19.510 | 2143 | 17.870 | 2150 |

| 3 | 0.10 | 0.20 | 12.000 | 1766 | 15.100 | 1895 | 14.945 | 1863 |

| 4 | 0.25 | 0.35 | 21.540 | 2214 | 24.010 | 2231 | 23.720 | 2315 |

| 5 | 0.10 | 0.35 | 12.975 | 1956 | 18.330 | 1975 | 15.910 | 2052 |

| 6 | 0.25 | 0.20 | 20.170 | 2106 | 22.170 | 2251 | 21.610 | 2345 |

| 7 | 0.25 | 0.50 | 21.900 | 2435 | 22.825 | 2495 | 23.920 | 2438 |

| 8 | 0.40 | 0.50 | 32.010 | 2716 | 32.300 | 2816 | 32.740 | 2900 |

| 9 | 0.40 | 0.35 | 31.885 | 2461 | 31.010 | 2430 | 30.430 | 2648 |

| Sample 1 | Sample 2 | Sample 3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | AoR | Discharging Time | AoR | Discharging Time | AoR | Discharging Time | ||||||

| F | P | F | P | F | P | F | P | F | P | F | P | |

| Model | 118.37 | <0.01 | 112.39 | <0.01 | 88.49 | <0.01 | 33.69 | <0.01 | 550.36 | <0.01 | 44.46 | <0.01 |

| X2: ppd | 231.95 | <0.01 | 185.78 | <0.01 | 171.17 | <0.01 | 50.46 | <0.01 | 1062.42 | <0.01 | 72.98 | <0.01 |

| X5: pbd | 4.79 | 0.07 | 38.99 | <0.01 | 5.79 | 0.05 | 16.93 | <0.01 | 38.30 | <0.01 | 15.94 | <0.01 |

| Name | Sample 1 | Sample 2 | Sample 3 | |||

|---|---|---|---|---|---|---|

| Constraints | Solutions | Constraints | Solutions | Constraints | Solutions | |

| X2: ppd | 0.1–0.4 | 0.352 | 0.1–0.4 | 0.377 | 0.1–0.4 | 0.385 |

| X5: pbd | 0.2–0.5 | 0.206 | 0.2–0.5 | 0.220 | 0.2–0.5 | 0.304 |

| AOR/(°) | 27.10 | - | 28.52 | - | 29.60 | - |

| Discharging time/(ms) | 2320 | - | 2382 | - | 2583 | - |

| Desirability | - | 1 | - | 1 | 1 | |

| Sample | Number of Particles | Particle-Low-Carbon Steel Plate | Particle-Particle | ||||

|---|---|---|---|---|---|---|---|

| Experiment | Simulation | Percentage Error/(%) | Experiment | Simulation | Percentage Error/(%) | ||

| 300 | 3.91 ± 0.038 | 3.85 | 1.53 | 2.86 ± 0.033 | 2.92 | 2.09 | |

| Sample 1 | 400 | 4.01 ± 0.035 | 3.96 | 1.25 | 2.93 ± 0.036 | 2.85 | 2.73 |

| 500 | 3.87 ± 0.039 | 3.95 | 2.10 | 2.84 ± 0.029 | 2.80 | 1.41 | |

| 300 | 3.80 ± 0.026 | 3.70 | 2.63 | 2.75 ± 0.035 | 2.79 | 0.36 | |

| Sample 2 | 400 | 3.85 ± 0.031 | 3.89 | 1.04 | 2.72 ± 0.036 | 2.68 | 1.48 |

| 500 | 3.81 ± 0.024 | 3.90 | 2.36 | 2.80 ± 0.039 | 2.72 | 2.86 | |

| 300 | 3.55 ± 0.028 | 3.62 | 1.97 | 2.55 ± 0.027 | 2.60 | 1.96 | |

| Sample 3 | 400 | 3.60 ± 0.032 | 3.54 | 1.67 | 2.51 ± 0.042 | 2.40 | 4.38 |

| 500 | 3.53 ± 0.038 | 3.61 | 2.27 | 2.49 ± 0.031 | 2.58 | 3.61 | |

| Sample | Particle Mass/(kg) | AoR/(°) | Discharging Time/(ms) | ||||

|---|---|---|---|---|---|---|---|

| Experiment | Simulation | Relative Error/(%) | Experiment | Simulation | Relative Error/(%) | ||

| Sample 1 | 0.45 | 27.10 ± 0.86 | 28.31 | 4.46 | 2320 ± 35.51 | 2320 | 0.00 |

| 0.60 | 27.50 ± 1.36 | 28.56 | 3.85 | 3240 ± 39.74 | 3120 | 3.70 | |

| 0.90 | 28.01 ± 1.43 | 28.69 | 2.43 | 4200 ± 62.03 | 4465 | 6.31 | |

| Sample 2 | 0.45 | 28.52 ± 1.26 | 28.61 | 0.32 | 2382 ± 29.33 | 2410 | 1.18 |

| 0.60 | 28.69 ± 1.51 | 29.47 | 2.72 | 3200 ± 68.49 | 3330 | 4.06 | |

| 0.90 | 28.93 ± 1.46 | 29.57 | 2.21 | 4253 ± 48.03 | 4550 | 6.98 | |

| Sample 3 | 0.45 | 29.60 ± 1.07 | 30.67 | 3.61 | 2583 ± 42.84 | 2732 | 5.76 |

| 0.60 | 30.05 ± 1.22 | 31.4 | 4.49 | 3690 ± 45.21 | 3650 | 1.08 | |

| 0.90 | 30.23 ± 1.03 | 31.89 | 5.49 | 5600 ± 59.33 | 5483 | 2.09 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zeng, R.; Niu, Z.; Zhang, J. A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method. Agriculture 2022, 12, 664. https://doi.org/10.3390/agriculture12050664

Li H, Zeng R, Niu Z, Zhang J. A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method. Agriculture. 2022; 12(5):664. https://doi.org/10.3390/agriculture12050664

Chicago/Turabian StyleLi, Hongcheng, Rong Zeng, Zhiyou Niu, and Junqi Zhang. 2022. "A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method" Agriculture 12, no. 5: 664. https://doi.org/10.3390/agriculture12050664

APA StyleLi, H., Zeng, R., Niu, Z., & Zhang, J. (2022). A Calibration Method for Contact Parameters of Maize Kernels Based on the Discrete Element Method. Agriculture, 12(5), 664. https://doi.org/10.3390/agriculture12050664