Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Influencing Factors and Evaluation Indexes

2.2. Finite Element Modeling and Analysis

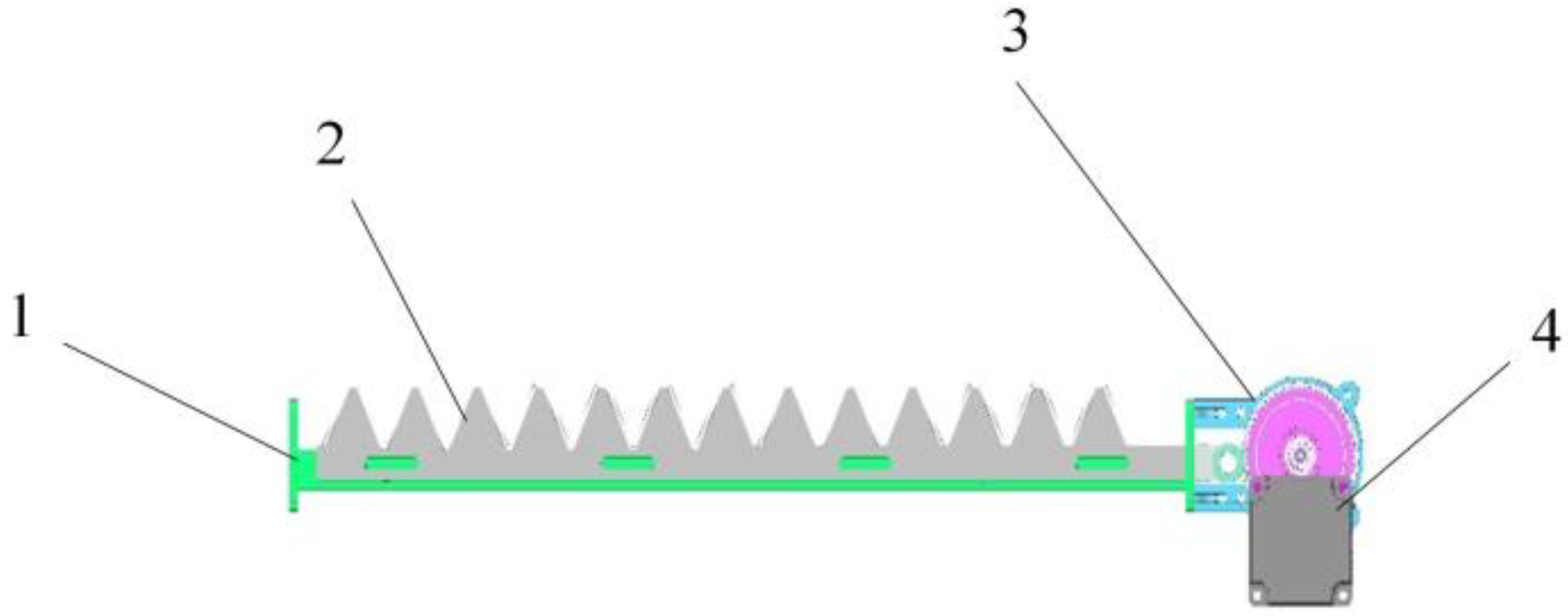

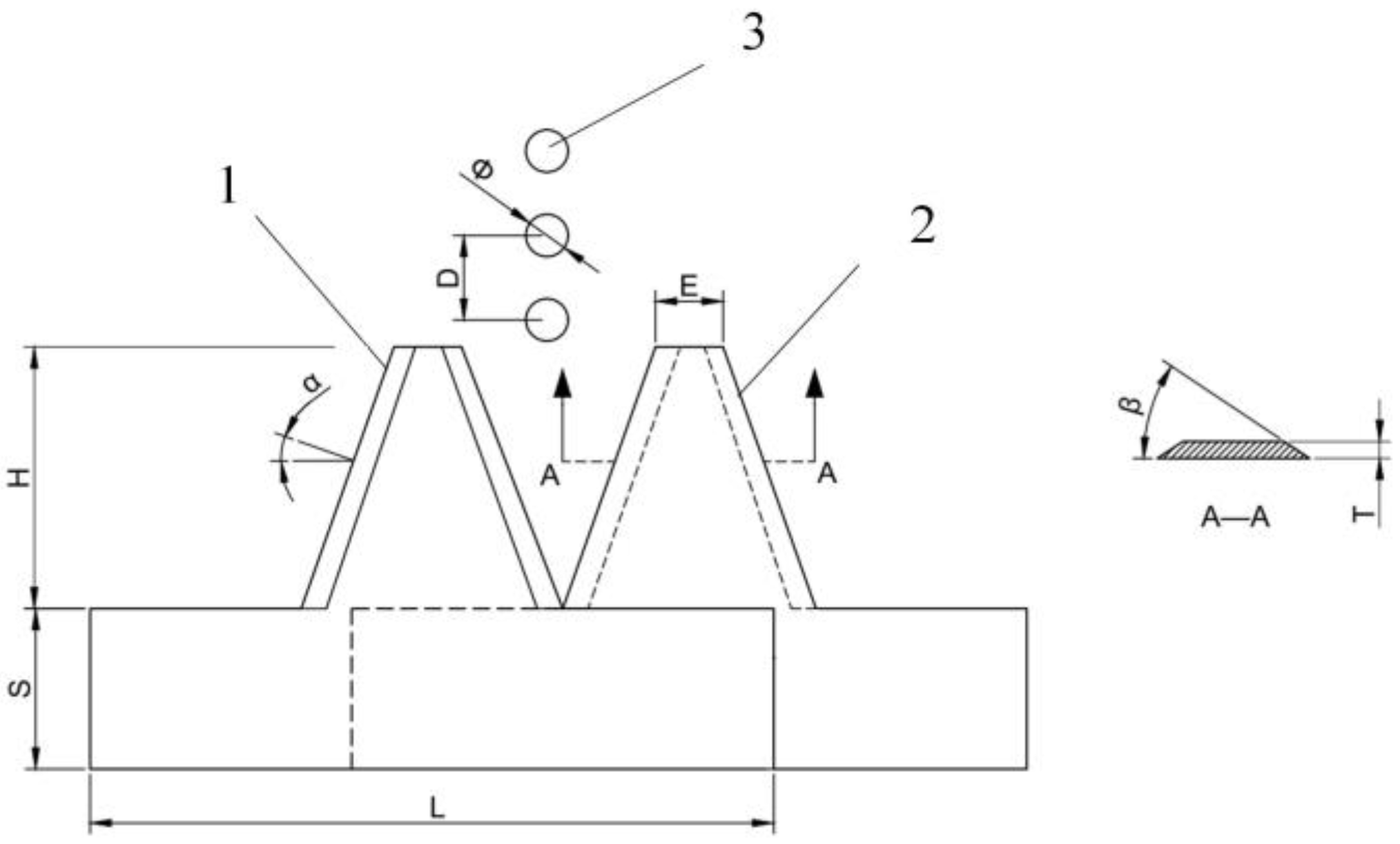

2.2.1. Geometric Model

2.2.2. Material Property Parameters

2.2.3. Meshing

2.2.4. Loads and Constraints

2.3. Orthogonal Test Design

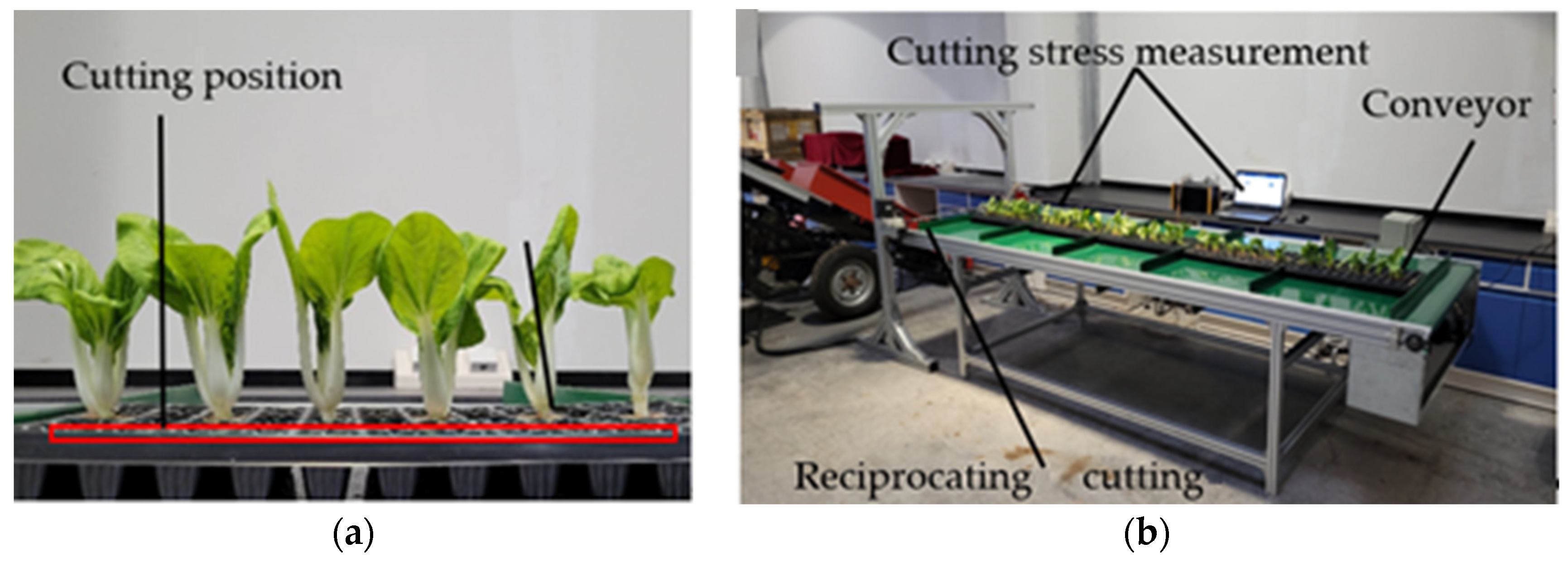

2.4. Experiment and Methods

3. Results

3.1. Post-Processing Results and Analysis of Numerical Simulation

3.2. Orthogonal Test Results and Significance Analysis

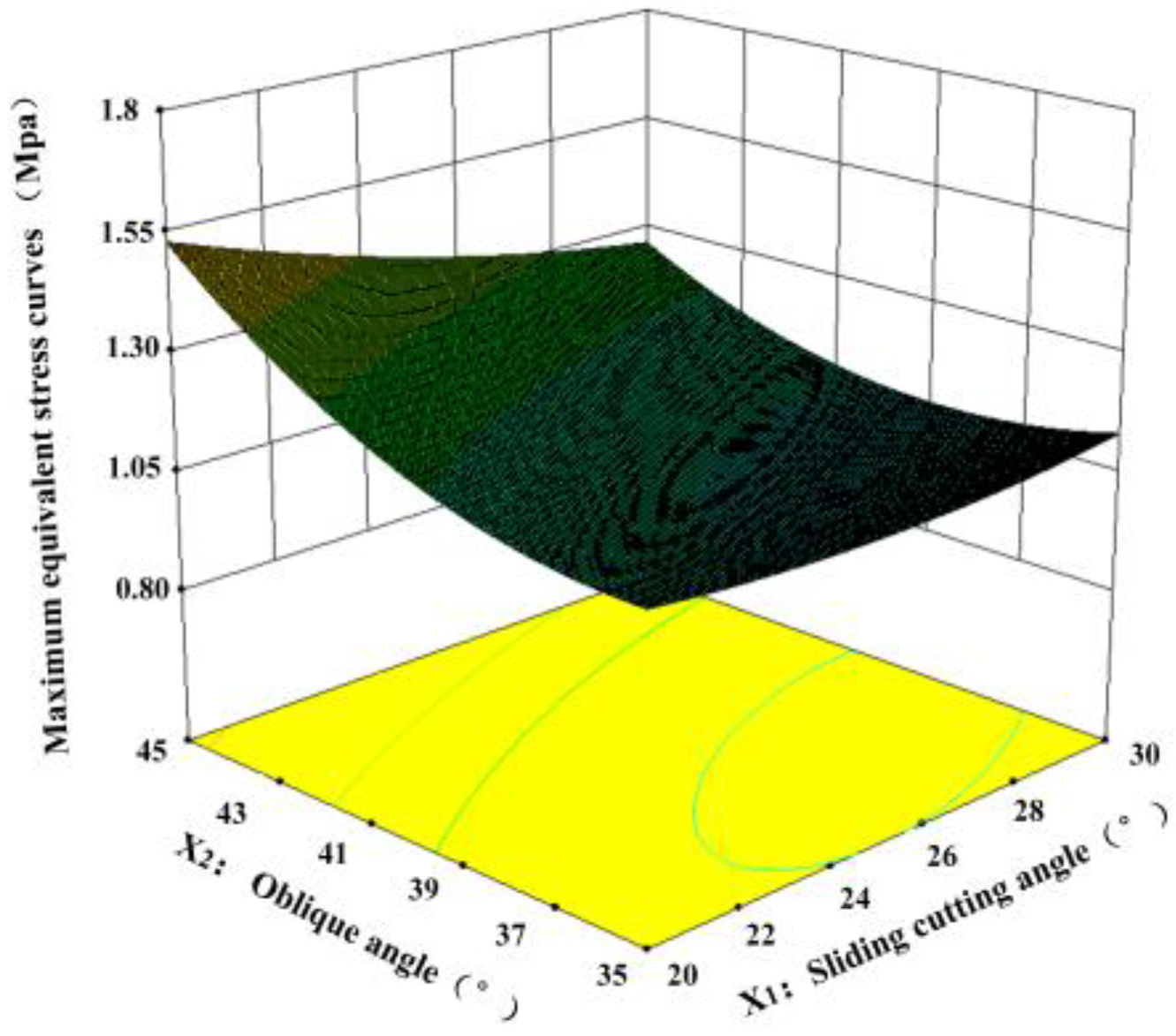

3.3. Regression Model Optimization

3.4. Analysis of Cutting Performance Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Xiao, H.R.; Yang, G.; Jin, Y.; Yang, G.; Cao, G.Q.; Zhang, J.F.; Liu, M. Design and experiment of the orderly harvester of Chinese little greens. Int. Agric. Eng. J. 2018, 27, 295–306. [Google Scholar]

- Shah, D.U.; Reynolds, T.P.S.; Ramage, M.H. The strength of plants: Theory and experimental methods to measure the mechanical properties of stems. J. Exp. Bot. 2017, 68, 4497–4516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, D.; Jing, C.; She, J.; She, J.K.; Tong, J.; Chen, Y.X. Temporal dynamics of shearing force of rice stem. Biomass Bioenergy 2012, 47, 109–114. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zhao, H.M.; Liu, B.; Ma, J.T.; He, Y.; Zhang, Y.T.; Xu, H.B. Effects of cutting parameters on cutting of citrus fruit stems. Biosyst. Eng. 2020, 193, 1–11. [Google Scholar] [CrossRef]

- Gan, H.; Mathanker, S.; Momin, M.A.; Kuhns, B.; Stoffel, N.; Hansen, A.; Grift, T. Effects of three cutting blade designs on energy consumption during mowing-conditioning of Miscanthus Giganteus. Biomass Bioenergy 2018, 109, 166–171. [Google Scholar] [CrossRef]

- Cui, Y.J.; Wang, W.Q.; Wang, M.H.; Ma, Y.D.; Fu, L.S. Effects of cutter parameters on shearing stress for lettuce harvesting using a specially developed fixture. Int. J. Agric. Biol. Eng. 2021, 14, 152–158. [Google Scholar] [CrossRef]

- Zhang, C.L.; Chen, L.Q.; Xia, J.F.; Zhang, J.M. Effects of blade sliding cutting angle and stem level on cutting energy of rice stems. Int. J. Agric. Biol. Eng. 2019, 12, 75–81. [Google Scholar] [CrossRef]

- Esgici, R.; Pekitkan, F.G.; Ozdemir, G. Cutting parameters of some grape varieties subject to the diameter and age of canes. Fresenius Environ. Bull. 2019, 28, 167–170. [Google Scholar]

- Du, D.D.; Wang, J.; Qiu, S.S. Analysis and test of splitting failure in the cutting process of cabbage root. Int. J. Agric. Biol. Eng. 2015, 8, 27–34. [Google Scholar]

- Boyda, M.G.; Omakli, M.; Sayinci, B.; Kara, M. Effects of moisture content, internode region, and oblique angle on the mechanical properties of sainfoin stem. Turk. J. Agric. For. 2019, 43, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Clementson, C.L.; Hansen, A.C. Pilot study of manual sugarcane harvesting using biomechanical analysis. J. Agric. Saf. Health 2008, 14, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Vu, V.D.; Ngo, Q.H.; Nguyen, T.T.; Nguyen, H.C.; Nguyen, Q.T.; Nguyen, V.D. Multi-objective optimization of cutting force and cutting power in chopping agricultural residues. Biosyst. Eng. 2020, 191, 107–115. [Google Scholar] [CrossRef]

- Ma, P.B.; Li, L.Q.; Wen, B.Q.; Xue, Y.H.; Kan, Z.; Li, J.B. Design and parameter optimization of spiral-dragon type straw chopping test rig. Int. J. Agric. Biol. Eng. 2020, 13, 47–56. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, B.; Li, X.W.; Yin, G.D.; Chen, Q.M.; Xia, C.H. Bench cutting tests and analysis for harvesting hemp stalk. Int. J. Agric. Biol. Eng. 2017, 10, 56–67. [Google Scholar] [CrossRef] [Green Version]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Cutting energy characteristics of Miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Effect of blade oblique angle and cutting speed on cutting energy for energy cane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- Allameh, A.; Alirzadeh, M.R. Specific cutting energy variations under different rice stem cultivars and blade parameters. Idesia 2016, 34, 11–17. [Google Scholar] [CrossRef]

- Zhao, J.L.; Huang, D.Y.; Jia, H.L.; Zhuang, J.; Guo, M.Z. Analysis and experiment on cutting performances of high-stubble maize stalks. Int. J. Agric. Biol. Eng. 2017, 10, 40–52. [Google Scholar]

- Stopa, R.; Komarnicki, P.; Kuta, ł.; Szyjewicza, D.; Słupska, M. Modeling with the finite element method the influence of shaped elements of loading components on the surface pressure distribution of carrot roots. Comput. Electron. Agric. 2019, 167, 105046. [Google Scholar] [CrossRef]

- Meng, Y.; Wei, J.D.; Wei, J.; Chen, H.; Cui, Y.S. An ANSYS/LS-DYNA simulation and experimental study of circular saw blade cutting system of mulberry cutting machine. Comput. Electron. Agric. 2019, 157, 38–48. [Google Scholar] [CrossRef]

- Yang, W.; Yang, J.; Liu, Z.H.; Liang, Z.X.; Mo, J.L. Dynamic simulation experiment of one-blade cutting sugarcane process. Trans. Chin. Soc. Agric. Mach. 2011, 27, 150–156. [Google Scholar]

- Huang, H.D.; Wang, Y.X.; Tang, Y.Q.; Zhao, F.; Kong, X.F. Finite element simulation of sugarcane cutting. Trans. Chin. Soc. Agric. Eng. 2011, 27, 161–166. [Google Scholar]

- Qiu, M.M.; Meng, Y.M.; Li, Y.Z.; Shen, X.B. Sugarcane stem cut quality investigated by finite element simulation and experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Xie, L.X.; Wang, J.; Cheng, S.M.; Zeng, B.S.; Yang, Z.Z. Optimisation and finite element simulation of the chopping process for chopper sugarcane harvesting. Biosyst. Eng. 2018, 175, 16–26. [Google Scholar] [CrossRef]

- Luo, Y.Q.; Ren, Y.H.; Zhou, Z.X.; Huang, X.M.; Song, T.J. Prediction of single-tooth sawing force based on tooth profile parameters. Int. J. Adv. Manuf. Technol. 2016, 86, 641–650. [Google Scholar] [CrossRef]

- Liu, Q.; Mathanker, S.K.; Zhang, Q.; Hansen, A.C. Biomechanical properties of miscanthus stems. Trans. Asabe 2012, 55, 1125–1131. [Google Scholar] [CrossRef]

- Maughan, J.D.; Mathanker, S.K.; Grift, T.; Hansen, A.C. Impact of Blade Angle on Miscanthus Harvesting Energy Requirement. In Proceedings of the 2013 Kansas City, Kansas City, MI, USA, 21–24 July 2013. [Google Scholar]

- Moiceanu, G.; Voicu, P.; Paraschiv, G.; Voicu, G. Behaviour of miscanthus at cutting shear with straight knives with different edge angles. Environ. Eng. Manag. J. 2017, 16, 1203–1209. [Google Scholar] [CrossRef]

- Yang, W.; Zhao, W.J.; Liu, Y.D.; Chen, Y.Q.; Yang, J. Simulation of forces acting on the cutter blade surfaces and root system of sugarcane using FEM and SPH coupled method. Comput. Electron. Agric. 2020, 180, 105893. [Google Scholar] [CrossRef]

- Liu, D.; Xiao, H.R.; Jin, Y.; Cao, G.Q.; Shen, C.; Yang, G.; Zhang, J.F.; Liu, M. Mechanical properties test and analysis on the stalks of Chinese little greens. Int. Agric. Eng. J. 2018, 27, 38–43. [Google Scholar]

- Salarikia, A.; Ashtiani, S.M.; Golzarian, M.R.; Mohammadinezhad, H. Finite element analysis of the dynamic behavior of pear under impact loading. Inf. Process. Agric. 2017, 4, 64–77. [Google Scholar] [CrossRef]

- Ahmadi, E.; Barikloo, H.; Kashfi, M. Viscoelastic finite element analysis of the dynamic behavior of apple under impact loading with regard to its different layers. Comput. Electron. Agric. 2016, 121, 1–11. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Mojaver, M.; Azdast, T.; Park, C.B. Polyethylene waste gasification syngas analysis and multi-objective optimization using central composite design for simultaneous minimization of required heat and maximization of exergy efficiency. Energy Convers. Manag. 2021, 247, 114713. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, M.Z.; Lu, Y.; Huang, D.Y.; Zhuang, J. Design of bionic locust mouthparts stubble cutting device. Int. J. Agric. Biol. Eng. 2020, 13, 20–28. [Google Scholar] [CrossRef]

- Xie, L.X.; Wang, J.; Cheng, S.M.; Zeng, B.S.; Yang, Z.Z. Optimisation and dynamic simulation of a conveying and top breaking system for whole-stalk sugarcane harvesters. Biosyst. Eng. 2020, 197, 156–169. [Google Scholar] [CrossRef]

- Hu, H.N.; Li, H.W.; Wang, Q.J.; He, J.; Lu, C.Y.; Wang, Y.B.; Wang, C.L. Performance of waterjet on cutting maize stalks: A preliminary investigation. Int. J. Agric. Biol. Eng. 2019, 12, 64–70. [Google Scholar] [CrossRef]

- Wang, J.; Yang, W.; Sun, X.; Li, X.; Tang, H. Design and experiment of spray and rotary tillage combined disinfection machine for soil. Int. J. Agric. Biol. Eng. 2019, 12, 52–58. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.N.; Li, H.W.; Wang, Q.J.; He, J.; Lu, C.Y.; Wang, Y.B.; Liu, P. Anti-blocking performance of ultrahigh-pressure waterjet assisted furrow opener for no-till seeder. Int. J. Agric. Biol. Eng. 2020, 13, 64–70. [Google Scholar] [CrossRef]

- Huang, J.; Tian, K.; Shen, C.; Zhang, B.; Liu, H.L.; Chen, Q.M.; Li, X.W.; Ji, A. Design and parameters optimization for cutting-conveying mechanism of ramie combine harvester. Int. J. Agric. Biol. Eng. 2020, 13, 94–103. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Cui, Q.L.; Guo, Y.M.; Li, H.B. Experiment and analysis of cutting mechanical properties of millet stem. Trans. Chin. Soc. Agric. Mach. 2019, 50, 146–155. [Google Scholar]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Tool holder width S/mm | 19 | Cutter top width E/mm | 8 |

| Cutter unit length L/mm | 80 | Cutter thickness T/mm | 2 |

| Cutter edge height H/mm | 31 | Oblique angle β/° | 35, 40, 45 |

| Sliding–cutting angle α/° | 20, 25, 30 | Stalk diameter Φ/mm | 5 |

| Material | Stalk | Blade |

|---|---|---|

| Density ρ/ kg·m−3 | 800 | 7850 |

| Young’s modulus EX/Mpa | 20.5 | 2.0 × 105 |

| Young’s modulus EY/Mpa | 20.5 | 2.0 × 105 |

| Young’s modulus EZ/Mpa | 3.5 | 2.0 × 105 |

| Shear modulus GXY/Mpa | 7.88 | 7.7 × 104 |

| Shear modulus GXZ/Mpa | 1.35 | 7.7 × 104 |

| Shear modulus GYZ/Mpa | 1.35 | 7.7 × 104 |

| Poisson’s ratio μXY | 0.35 | 0.3 |

| Poisson’s ratio μXZ | 0.3 | 0.3 |

| Poisson’s ratio μYZ | 0.3 | 0.3 |

| Level | Test Factors | ||

|---|---|---|---|

| Sliding–Cutting Angle X1 (°) | Oblique Angle X2 (°) | Average Cutting Speed X3 (mm/s) | |

| −1.682 | 16.59 | 31.59 | 231.82 |

| −1 | 20 | 35 | 300 |

| 0 | 25 | 40 | 400 |

| 1 | 30 | 45 | 500 |

| 1.682 | 33.41 | 48.41 | 568.18 |

| Parameters | Values |

|---|---|

| Average cutting speed/mm·s−1 | 0~1500 |

| Reciprocating cutting stroke/mm | 30 |

| Average feeding speed/mm·s−1 | 0~1000 |

| Resistance strain measurement range/Mpa | 0~100 |

| Resistance strain gauge sensitivity factor | 2.17 ± 1% |

| Data collection frequency/Hz | 500 |

| Data acquisition channel | 1~4 |

| Test Number | Test Factors | Test Indicators | |||

|---|---|---|---|---|---|

| X1 (α) ° | X2 (β) ° | X3 (V) mm/s | Y1 (σ1) Mpa | Y2 (σ2) Mpa | |

| 1 | 0.000 | 0.000 | 0.000 | 1.06 | 0.83 |

| 2 | −1.000 | −1.000 | 1.000 | 1.11 | 1.02 |

| 3 | −1.000 | 1.000 | −1.000 | 1.58 | 1.65 |

| 4 | 0.000 | 0.000 | 0.000 | 1.07 | 0.92 |

| 5 | 1.000 | 1.000 | 1.000 | 1.19 | 1.10 |

| 6 | 1.000 | −1.000 | 1.000 | 0.90 | 0.81 |

| 7 | 0.000 | 0.000 | 0.000 | 1.26 | 0.72 |

| 8 | −1.000 | 1.000 | 1.000 | 1.48 | 1.60 |

| 9 | 1.000 | −1.000 | −1.000 | 1.17 | 1.17 |

| 10 | 0.000 | 1.682 | 0.000 | 1.62 | 1.74 |

| 11 | 0.000 | −1.682 | 0.000 | 1.25 | 1.17 |

| 12 | −1.682 | 0.000 | 0.000 | 1.34 | 1.31 |

| 13 | 0.000 | 0.000 | −1.682 | 1.20 | 1.10 |

| 14 | 0.000 | 0.000 | 0.000 | 1.10 | 0.96 |

| 15 | −1.000 | −1.000 | −1.000 | 1.05 | 0.90 |

| 16 | 1.000 | 1.000 | −1.000 | 1.24 | 1.17 |

| 17 | 0.000 | 0.000 | 0.000 | 1.08 | 0.95 |

| 18 | 0.000 | 0.000 | 0.000 | 1.07 | 0.92 |

| 19 | 1.682 | 0.000 | 0.000 | 1.12 | 1.10 |

| 20 | 0.000 | 0.000 | 1.682 | 0.99 | 0.82 |

| Source | Sum of Squares | Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.61 | 9 | 0.068 | 10.48 | 0.0005 |

| X1 | 0.087 | 1 | 0.087 | 13.43 | 0.0044 |

| X2 | 0.26 | 1 | 0.26 | 40.04 | <0.0001 |

| X3 | 0.037 | 1 | 0.037 | 5.75 | 0.0375 |

| X1X2 | 0.036 | 1 | 0.036 | 5.63 | 0.0392 |

| X1X3 | 0.0098 | 1 | 0.0098 | 1.51 | 0.2469 |

| X2X3 | 0.00045 | 1 | 0.00045 | 0.069 | 0.7975 |

| 0.016 | 1 | 0.016 | 2.52 | 0.1437 | |

| 0.16 | 1 | 0.16 | 25.05 | 0.0005 | |

| 0.0028 | 1 | 0.0028 | 0.44 | 0.5214 | |

| Residual | 0.065 | 10 | 0.0064 | ||

| Lack of Fit | 0.036 | 5 | 0.0071 | 1.22 | 0.4149 |

| Pure Error | 0.029 | 5 | 0.0058 | ||

| Cor. Total | 0.68 | 19 |

| Source | Sum of Squares | Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1.46 | 9 | 0.16 | 17.18 | <0.0001 |

| X1 | 0.12 | 1 | 0.12 | 12.56 | 0.0053 |

| X2 | 0.49 | 1 | 0.49 | 51.53 | <0.0001 |

| X3 | 0.051 | 1 | 0.051 | 5.35 | 0.0433 |

| X1X2 | 0.14 | 1 | 0.14 | 14.31 | 0.0036 |

| X1X3 | 0.031 | 1 | 0.031 | 3.31 | 0.0990 |

| X2X3 | 0.0018 | 1 | 0.0018 | 0.19 | 0.6718 |

| 0.15 | 1 | 0.15 | 16.36 | 0.0023 | |

| 0.53 | 1 | 0.53 | 56.20 | <0.0001 | |

| 0.0041 | 1 | 0.0041 | 0.44 | 0.5227 | |

| Residual | 0.094 | 10 | 0.00093 | ||

| Lack of Fit | 0.052 | 5 | 0.010 | 1.21 | 0.4207 |

| Pure Error | 0.043 | 5 | 0.0086 | ||

| Cor. Total | 1.56 | 19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Lv, X.; Yi, Z. Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture 2022, 12, 2131. https://doi.org/10.3390/agriculture12122131

Wang W, Lv X, Yi Z. Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture. 2022; 12(12):2131. https://doi.org/10.3390/agriculture12122131

Chicago/Turabian StyleWang, Wei, Xiaolan Lv, and Zhongyi Yi. 2022. "Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment" Agriculture 12, no. 12: 2131. https://doi.org/10.3390/agriculture12122131

APA StyleWang, W., Lv, X., & Yi, Z. (2022). Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture, 12(12), 2131. https://doi.org/10.3390/agriculture12122131