Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis

Abstract

1. Introduction

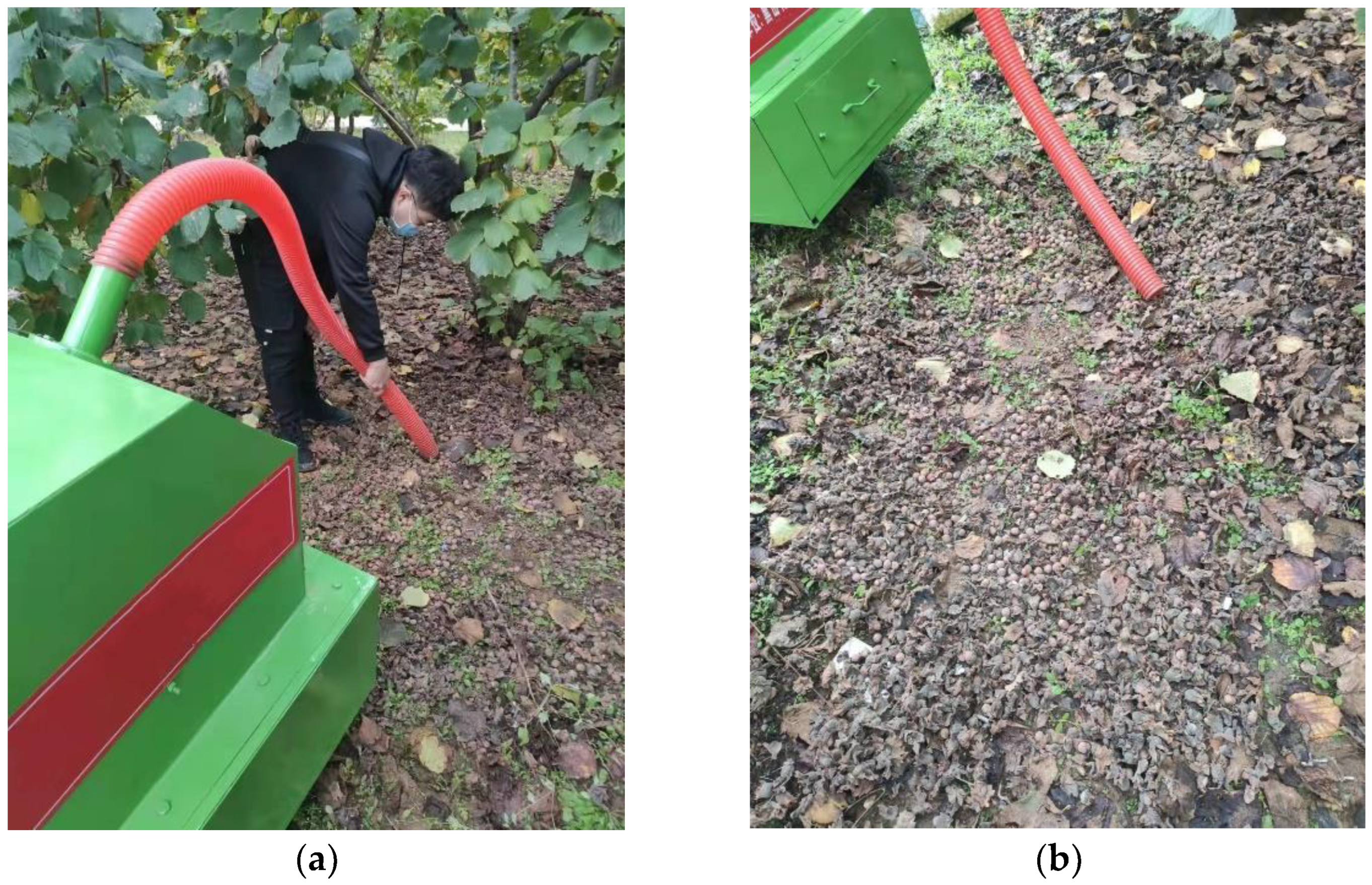

2. Materials and Methods

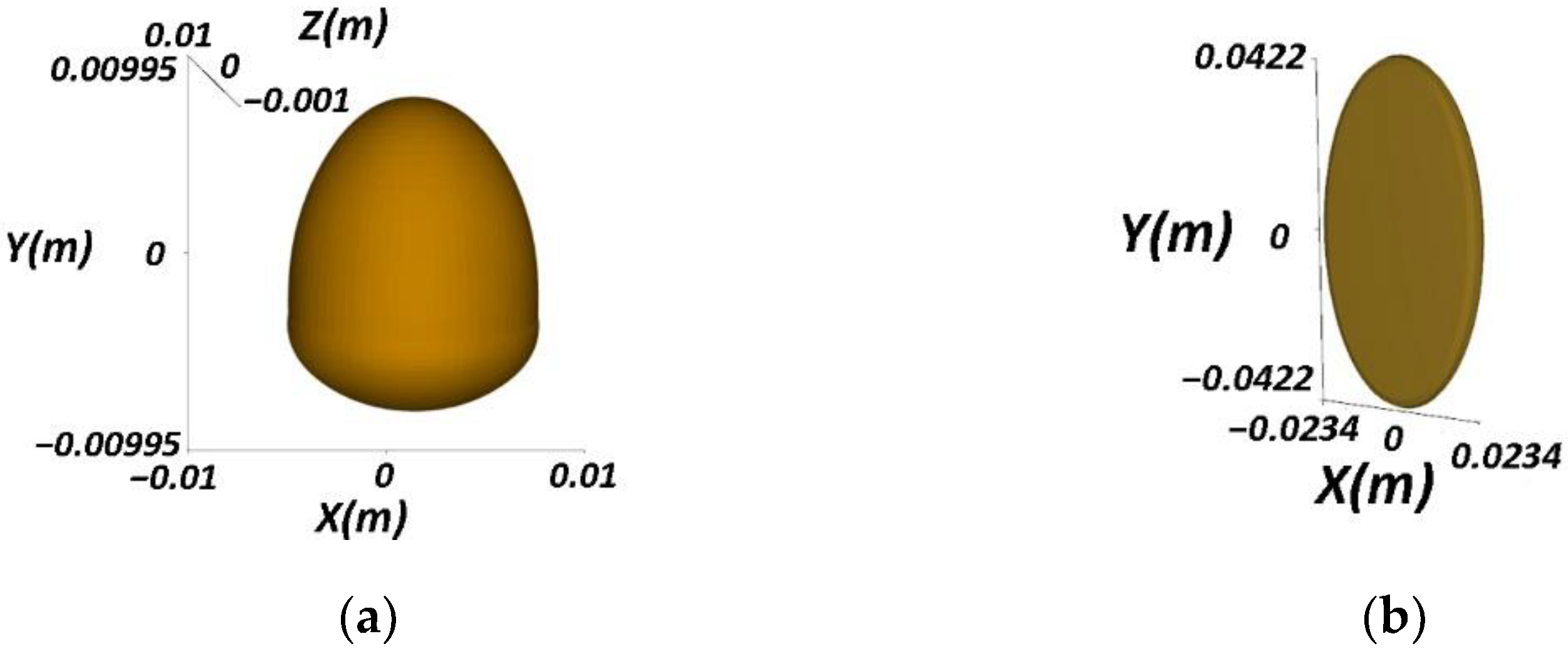

2.1. Test Materials and Their Basic Physical Characteristics

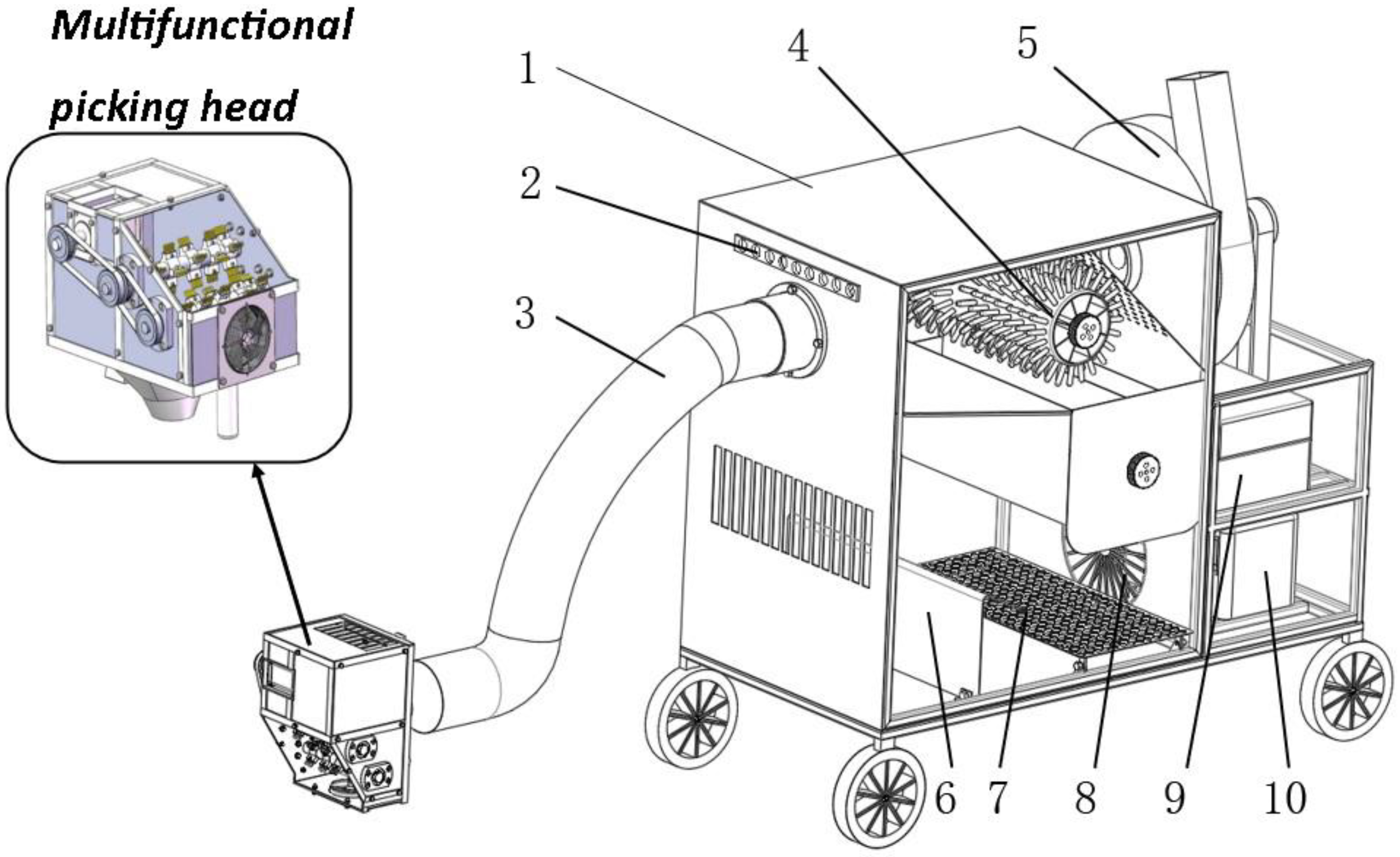

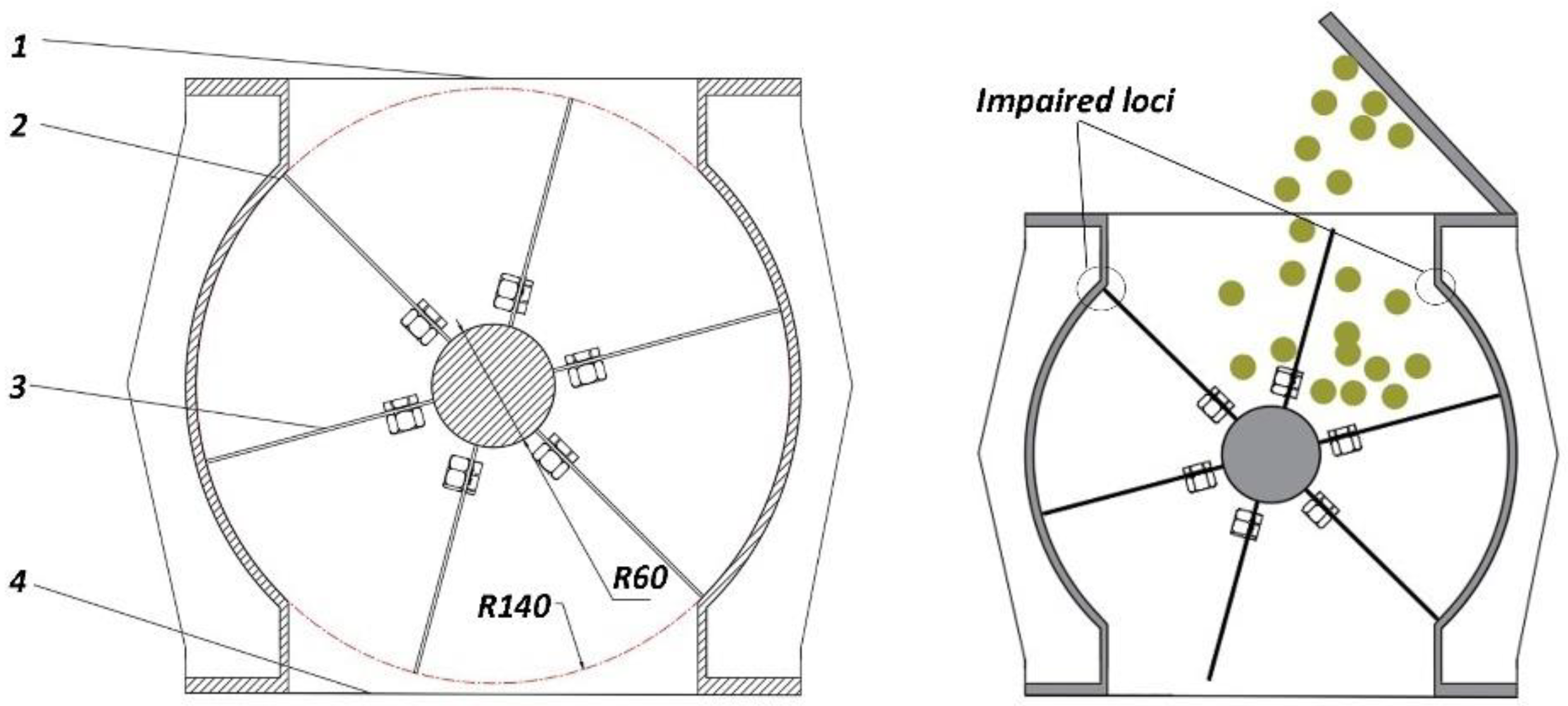

2.2. Design of the Main Components of the Hazelnut Harvester

2.3. Theoretical Analysis of CFD-DEM Coupling

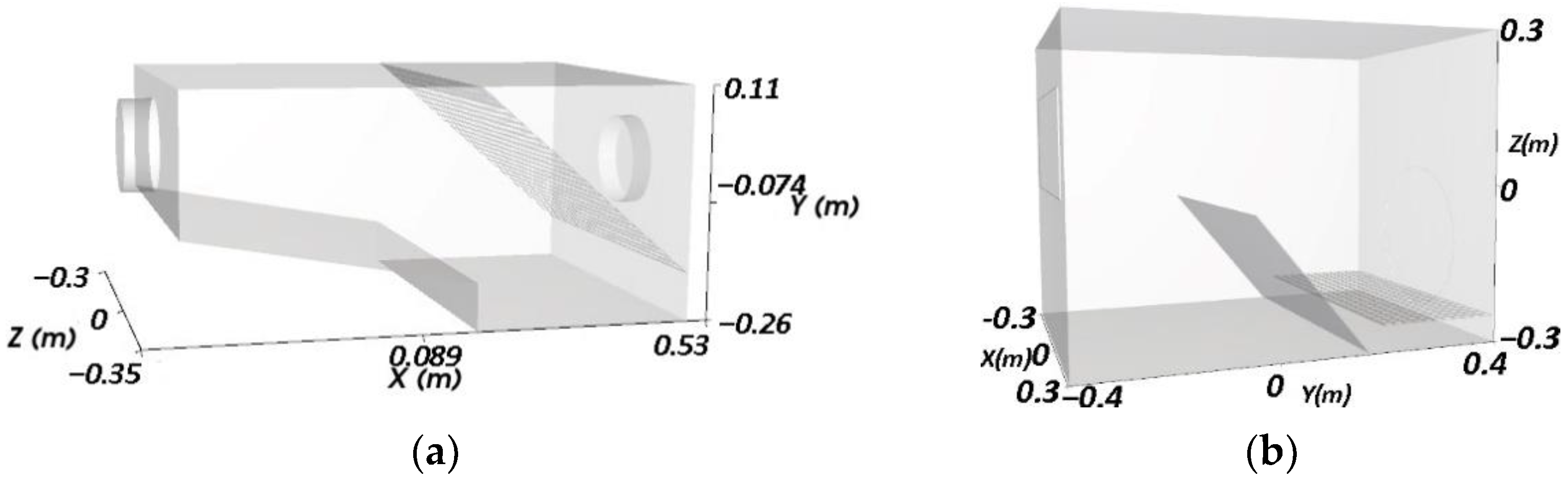

2.4. Hazelnut Harvester Simulation Parameters’ Setting

2.5. Box–Behnken Experimental Design

3. Results and Discussion

3.1. Basic Physical Characteristics of the Experimental Samples

3.2. Analysis of Simulation Results

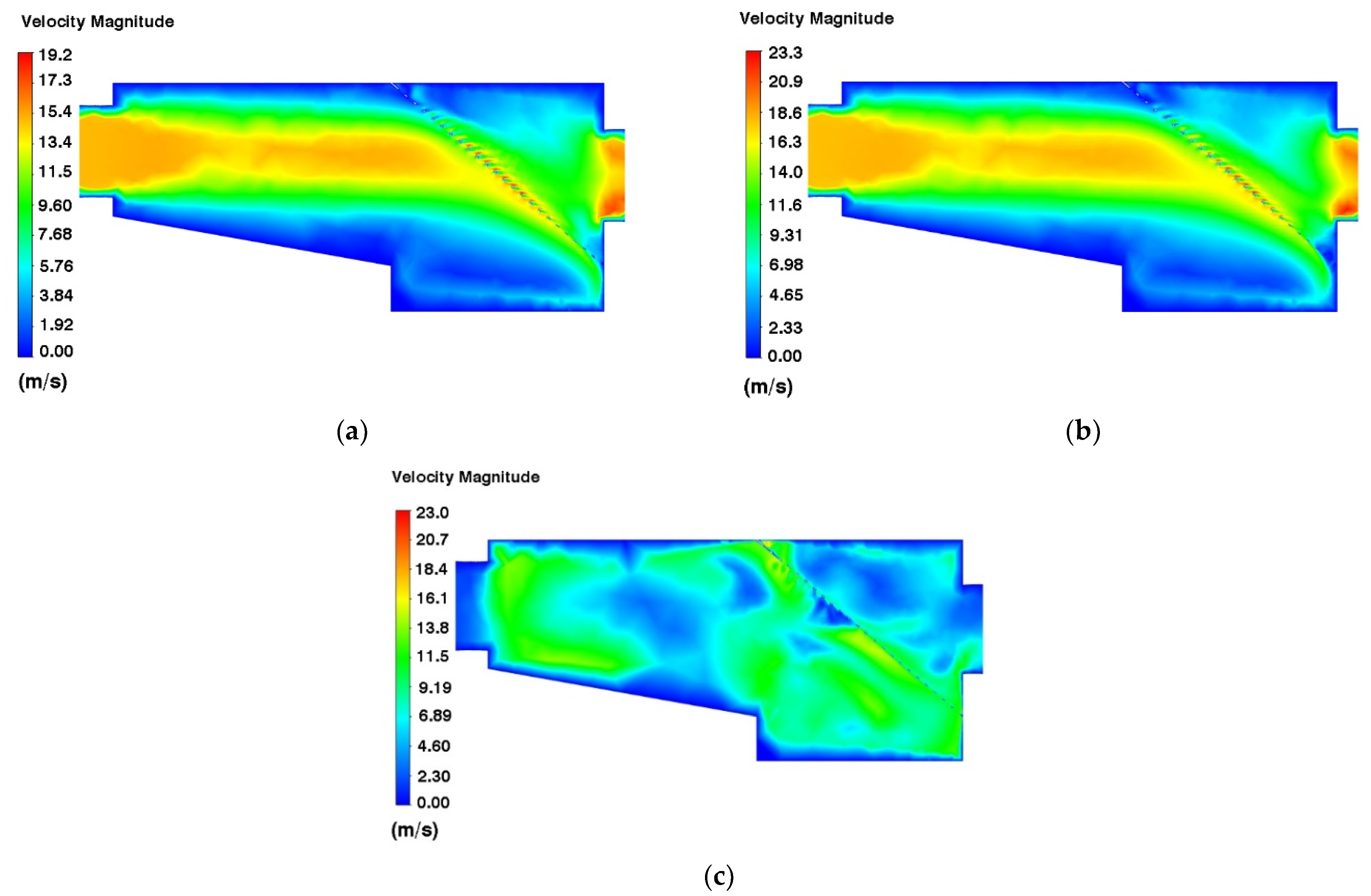

3.2.1. Terminal Speed Analysis of the Pick-Up Device

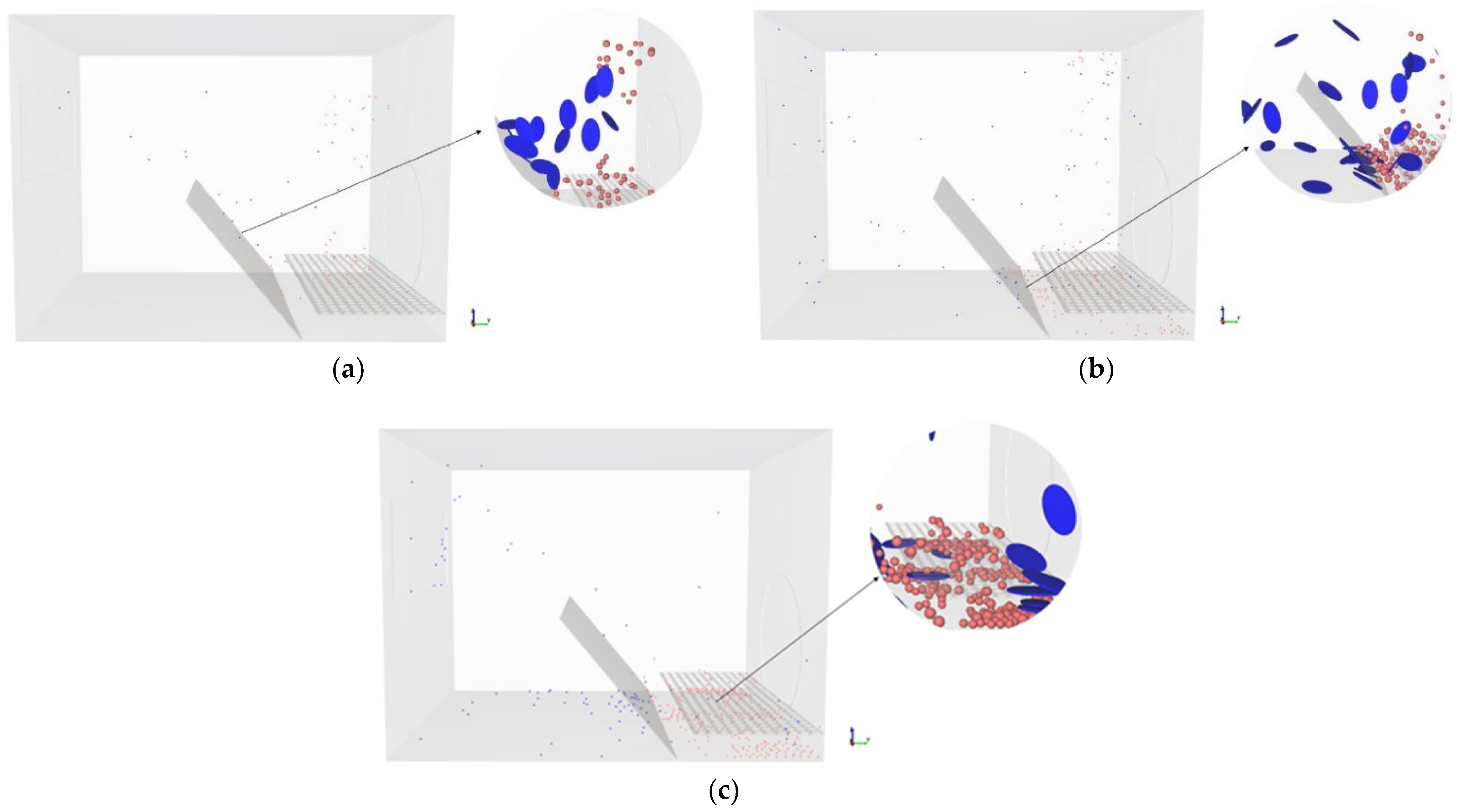

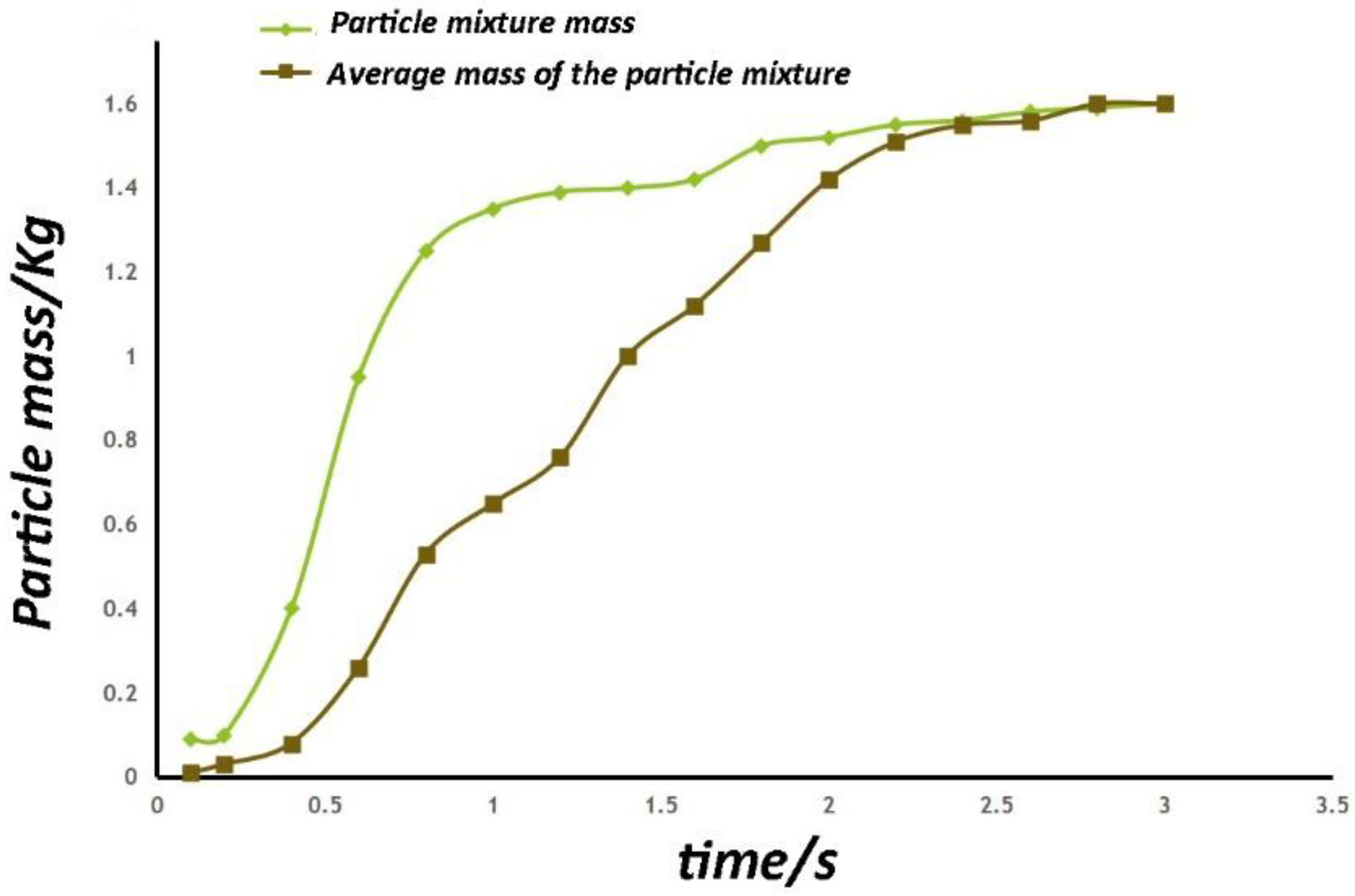

3.2.2. Analysis of the Working Process of the Sorting Device

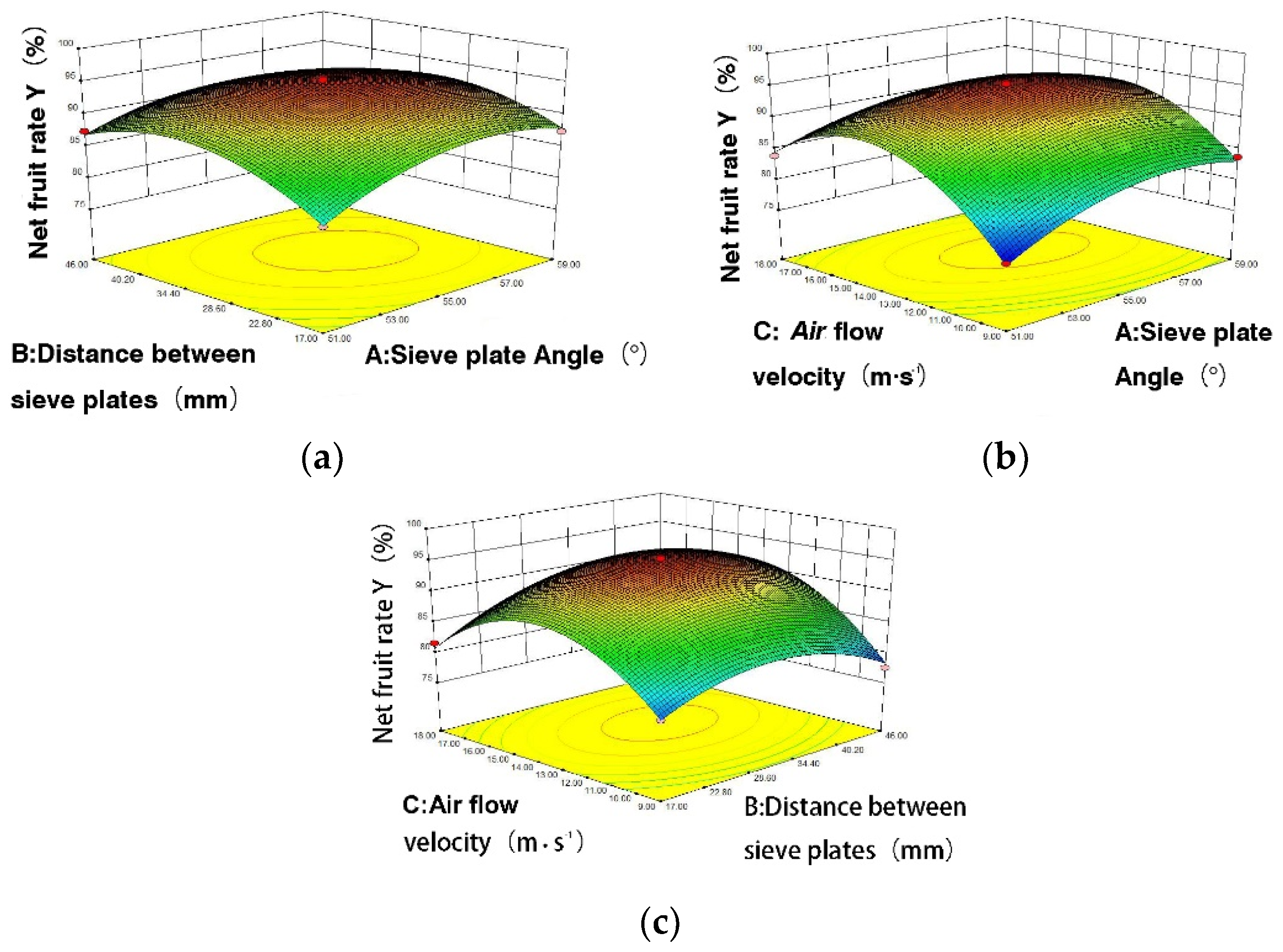

3.3. Analysis of Experimental Design Results

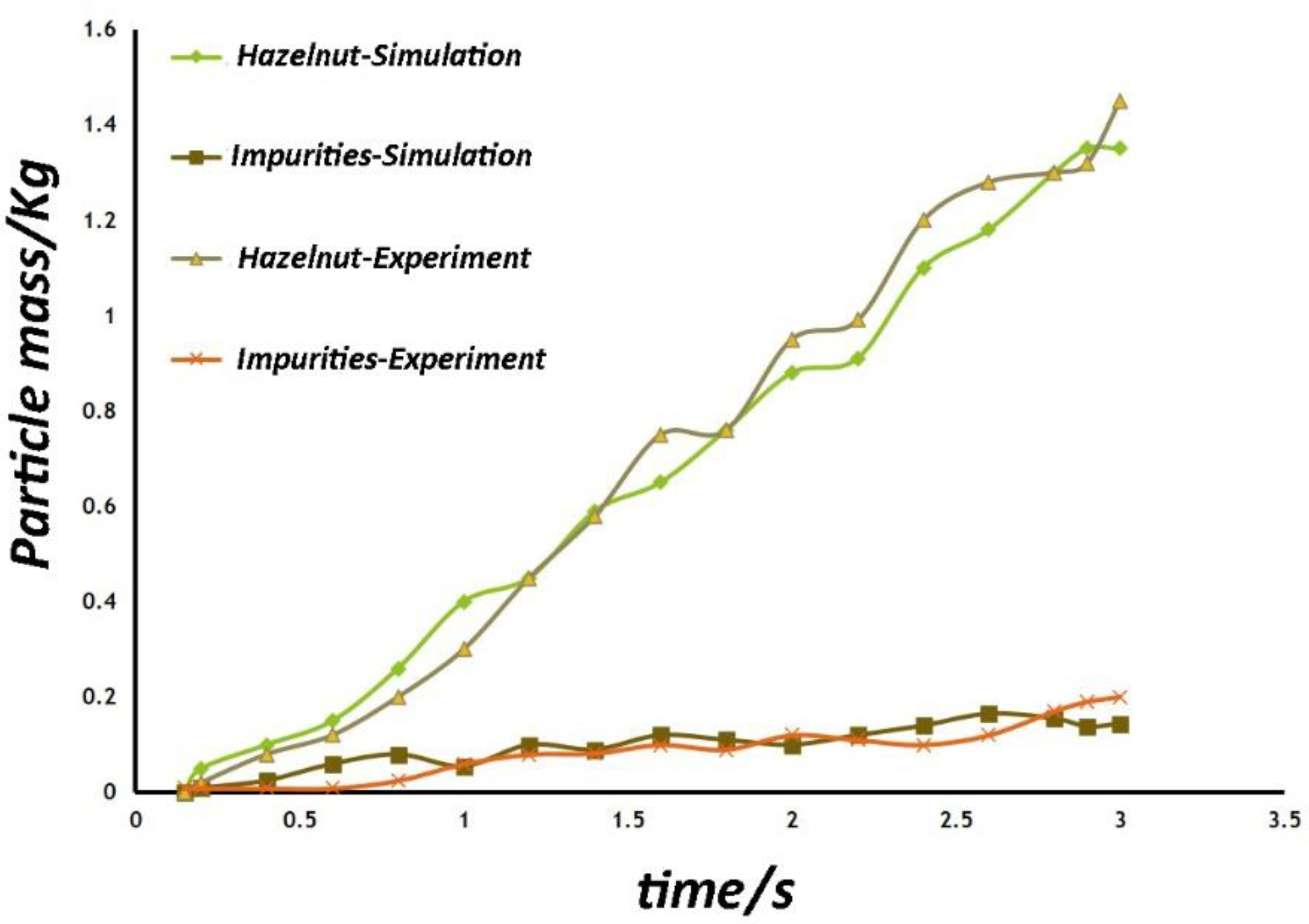

3.4. Parameter Optimization and Comparison Experiments

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Loghavi, M.; Mohseni, S.H. The effects of shaking frequency and amplitude on detachment of lime fruits. Iran Agric. Res. 2006, 24, 27–38. [Google Scholar]

- Polat, R.; Gezer, I.; Guner, M. Mechanical harvesting of pistachionuts. J. Food Eng. 2007, 79, 1131–1135. [Google Scholar] [CrossRef]

- Peterson, D.L.; Whiting, M.D.; Wolford, S.D. Fresh-market quality tree fruit harvester. Appl. Eng. Agric. 2003, 19, 539–543. [Google Scholar]

- Zhou, Z.Y.; Kuang, S.B.; Chu, K.W.; Yu, A.B. Assessments of CFD–DEM models in particle–fluid flow modelling. J. Fluid Mech. 2010, 661, 482–510. [Google Scholar] [CrossRef]

- Yu, A.B.; Xu, B.H. Particle-scale modelling of gas–solid flow in fluidisation. J. Chem. Technol. Biotechnol. 2003, 78, 111–121. [Google Scholar] [CrossRef]

- Muggli, F.A.; Holbein, P.; Dupont, P. CFD calculation of a mixed flow pump characteristic from shutoff to maximum flow. ASME J. Fluids Eng. 2002, 124, 798–802. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; de Baerdemaeker, J.; Baelmans, M. Effect of a cross-flow opening on the performance of a centrifugal fan in a combine harvester. Biosyst. Eng. 2010, 105, 247–256. [Google Scholar] [CrossRef]

- Karim, A.A.; Nolan, P.F. Modelling reacting localized air pollution using Computational Fluid Dynamics (CFD). Atmos. Environ. 2011, 45, 889–895. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Tanaka, T.; Tsuji, Y. Numerical simulation of two-dimensional fluidized beds using the discrete element method (comparison between the two- and three-dimensional models). Powder Technol. 1998, 96, 129–138. [Google Scholar] [CrossRef]

- Rong, D.G.; Horio, M. Behavior of particles and bubbles around immersed tubes fluidized bed at high temperature and pressure: A DEM simulation. Int. J. Multiph. Flow 2001, 27, 89–105. [Google Scholar] [CrossRef]

- Ibsen, C.H.; Helland, E.; Hjertager, B.H.; Solberg, T.; Tadrist, L.; Occelli, R. Comparison of multi-fluid and discrete particle modelling in numerical predictions of gas particle flow in circulating fluidised beds. Powder Technol. 2004, 149, 29. [Google Scholar] [CrossRef]

- Chu, K.W.; Yu, A.B. Numerical simulation of the gas–solid flow in three-dimensional pneumatic conveying bends. Ind. Eng. Chem. Res. 2008, 47, 7058–7071. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Vince, A.; Yu, A.B.; Barnett, G.D.; Barnett, P.J. CFD–DEM study of the effect of particle density distribution on the multiphase flow and performance of dense medium cyclone. Miner. Eng. 2009, 22, 893–909. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A. CFD–DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Gao, X.J. Study on Precision Seeding Technology and Device Based on High-Speed Centrifugal Filling-Clearing. Ph.D. Thesis, China Agricultural University, Beijing, China, 2021. (In Chinese with English Abstract). [Google Scholar]

- Brosh, T.; Kalman, H.; Levy, A.; Peyron, I.; Ricard, F. DEM-CFD simulation of particle comminution in jet-mill. Powder Technol. 2014, 257, 104–112. [Google Scholar] [CrossRef]

- Ren, B.; Zhong, W.Q.; Chen, Y.; Chen, X.; Jin, B.S.; Yuan, Z.L.; Lu, Y. CFD-DEM simulation of spouting of corn-shaped particles. Particuology 2012, 10, 562–572. [Google Scholar] [CrossRef]

- Ding, L.; Yang, L.; Wu, D.H.; Li, D.Y.; Zhang, D.X.; Liu, S.R. Simulation and experiment of corn air suction seed metering device based on DEM-CFD coupling method. Trans. Chin. Soc. Agric. Mach. 2018, 49, 48–57. [Google Scholar]

- Guzman, L.; Chen, Y.; Landry, H. Coupled CFD-DEM simulation of seed flow in an air seeder distributor tube. Processes 2020, 8, 1597. [Google Scholar] [CrossRef]

- Arzu, Y.; Vedat, D.; Adnan, D. Comparison of computational fluid dynamics-based simulations and visualized seed trajectories in different seed tubes. Turk. J. Agric. For. 2020, 44, 599–611. [Google Scholar]

- Pasha, M.; Hassanpour, A.; Ahmadian, H.; Tan, H.S.; Bayly, A.; Ghadiri, M. A comparative analysis of particle tracking in a mixer by discrete element method and positron emission particle tracking. Powder Technol. 2015, 270, 569–574. [Google Scholar] [CrossRef]

- Landry, H.; Thirion, F.; Lague, C.; Roberge, M. Numerical modeling of the flow of organic fertilizers in land application equipment. Comput. Electron. Agric. 2006, 51, 35–53. [Google Scholar] [CrossRef]

- Mori, Y.; Sakai, M. Development of a robust Eulerian-Lagrangian model for the simulation of an industrial solid-fluid system. Chem. Eng. J. 2021, 406, 126841. [Google Scholar] [CrossRef]

- Pei, C.L.; Wu, C.Y.; England, D.E.; Byard, S.; Berchtold, H.; Adams, M. DEM-CFD modeling of particle systems with long-range electrostatic interactions. AIChE J. 2015, 61, 1792–1803. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Rai, K.T.; Tsuji, T.; Washino, K.; Tanaka, T.; Oshitani, J. Upscaled DEM-CFD model for vibrated fluidized bed based on particle-scale similarities. Adv. Powder Technol. 2020, 31, 4598–4618. [Google Scholar] [CrossRef]

- Takabatake, K.; Sakai, M. Flexible discretization technique for DEM-CFD simulations including thin walls. Adv. Powder Technol. 2020, 31, 1825–1837. [Google Scholar] [CrossRef]

- Liu, S.J.; Li, Y.W.; Hu, X.Z. Effect of particle volume fraction on the performance of deep-sea mining electric lifting pump based on DEM-CFD. J. Mech. Eng. 2020, 56, 257–264, (In Chinese with English Abstract). [Google Scholar]

- Hoomans, B.; Kuipers, J.; Van Swaaij, W. Granular dynamics simulation of segregation phenomena in bubbling gas-fluidised beds. Powder Technol. 2000, 109, 41–48. [Google Scholar] [CrossRef]

- Xu, B.; Yu, A.; Chew, S.; Zulli, P. Numerical simulation of the gas-solid flow in a bed with lateral gas blasting. Powder Technol. 2000, 109, 13–26. [Google Scholar] [CrossRef]

- Ye, M.; Van der Hoef, M.; Kuipers, J. A numerical study of fluidization behavior of geldart a particles using a discrete particle model. Powder Technol. 2004, 139, 129–139. [Google Scholar] [CrossRef]

- Ye, M.; Van der Hoef, M.; Kuipers, J. From discrete particle model to a continuous model of geldart a particles. Chem. Eng. Res. Des. 2005, 83, 833–843. [Google Scholar] [CrossRef][Green Version]

| Project Name | Project Setting |

|---|---|

| Entry Point | Inlet |

| Stop Time | 2.5 s |

| Mass Flow Rate (Hazelnut) | 1.6 kg/s |

| Mass Flow Rate (Leaves) | 0.15 kg/s |

| Type | Density/(g∙cm−3) | Poisson’s Ratio | Young’s Modulus/Pa |

|---|---|---|---|

| Hazelnut | 5.5 | 0.41 | 3.1 × 109 |

| Leaf | 0.7 | 0.38 | 2.71 × 105 |

| Type | Dynamic Friction Coefficient | Static Friction coefficient | |

| Hazel–Hazel | 0.06 | 0.45 | |

| Hazel–Leaf | 0.06 | 0.4 | |

| Leaf–Leaf | 0.05 | 0.42 |

| Level | Factor | ||

|---|---|---|---|

| Sieve Plate Angle A/(°) | Distance between Sieve Plates B/mm | Air Flow Velocity C/(m∙s−1) | |

| −1 | 51 | 17 | 9 |

| 0 | 55 | 31.5 | 13.5 |

| 1 | 59 | 46 | 18 |

| Type | Quantity/Each | Average Length/cm | Average Diameter/cm | Average Mass/g | Density/(g∙cm3) |

|---|---|---|---|---|---|

| Simple fruit | 1894 | 1.83 | 1.73 | 2.8 | 1.3 |

| Leaf | 521 | 4.5 | 3.6 | 1.07 | 0.7 |

| Test Number | Factor | Test Result | ||

|---|---|---|---|---|

| A | B | C | Net Fruit Rate Y | |

| 1 | 51 | 31.5 | 9 | 76.9% |

| 2 | 59 | 31.5 | 18 | 84.3% |

| 3 | 55 | 46 | 18 | 86.2% |

| 4 | 55 | 31.5 | 13.5 | 93.3% |

| 5 | 55 | 31.5 | 13.5 | 95.3% |

| 6 | 55 | 17 | 18 | 81.6% |

| 7 | 55 | 17 | 9 | 79.1% |

| 8 | 55 | 31.5 | 13.5 | 95.5% |

| 9 | 51 | 31.5 | 18 | 83.9% |

| 10 | 51 | 46 | 13.5 | 87.4% |

| 11 | 59 | 46 | 13.5 | 88.1% |

| 12 | 55 | 46 | 9 | 77.5% |

| 13 | 59 | 17 | 13.5 | 87.4% |

| 14 | 59 | 31.5 | 9 | 83.7% |

| 15 | 51 | 17 | 13.5 | 82.2% |

| 16 | 55 | 31.5 | 13.5 | 95.3% |

| 17 | 55 | 31.5 | 13.5 | 94.4% |

| Source | Net Fruit Rate | |||

|---|---|---|---|---|

| SS | df | F | p-Value * | |

| Model | 632.23 | 9 | 78.37 | <0.0001 |

| A | 21.45 | 1 | 23.93 | 0.0018 |

| B | 9.90 | 1 | 11.05 | 0.0127 |

| C | 44.18 | 1 | 49.29 | 0.0002 |

| AB | 5.06 | 1 | 5.65 | 0.0491 |

| AC | 10.24 | 1 | 11.42 | 0.0118 |

| BC | 9.61 | 1 | 10.72 | 0.0136 |

| A2 | 57.41 | 1 | 64.05 | <0.0001 |

| B2 | 96.71 | 1 | 107.89 | <0.0001 |

| C2 | 331.08 | 1 | 369.37 | <0.0001 |

| Residual | 6.27 | 7 | ||

| Lack of fit | 2.89 | 3 | 1.13 | 0.4361 |

| Error | 3.39 | 4 | ||

| Sum | 638.51 | 16 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, D.; Yu, H.; Zhang, R.; Li, J.; Zhao, Y.; Liu, F.; Zhang, J.; Wang, W. Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis. Agriculture 2022, 12, 2115. https://doi.org/10.3390/agriculture12122115

Ren D, Yu H, Zhang R, Li J, Zhao Y, Liu F, Zhang J, Wang W. Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis. Agriculture. 2022; 12(12):2115. https://doi.org/10.3390/agriculture12122115

Chicago/Turabian StyleRen, Dezhi, Haolin Yu, Ren Zhang, Jiaqi Li, Yingbo Zhao, Fengbo Liu, Jinhui Zhang, and Wei Wang. 2022. "Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis" Agriculture 12, no. 12: 2115. https://doi.org/10.3390/agriculture12122115

APA StyleRen, D., Yu, H., Zhang, R., Li, J., Zhao, Y., Liu, F., Zhang, J., & Wang, W. (2022). Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis. Agriculture, 12(12), 2115. https://doi.org/10.3390/agriculture12122115