The Effects of Irrigation, Topping, and Interrow Spacing on the Yield and Quality of Hemp (Cannabis sativa L.) Fibers in Temperate Climatic Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Site Description

2.2. Soil Properties

2.3. Crop Management, Experimental Design, and Irrigation Treatments

2.4. Sampling and Laboratory Analysis

2.5. Determination of the Chemical Composition of Hemp Fibers

2.6. Data Analysis

2.7. Statistical Analysis

3. Results

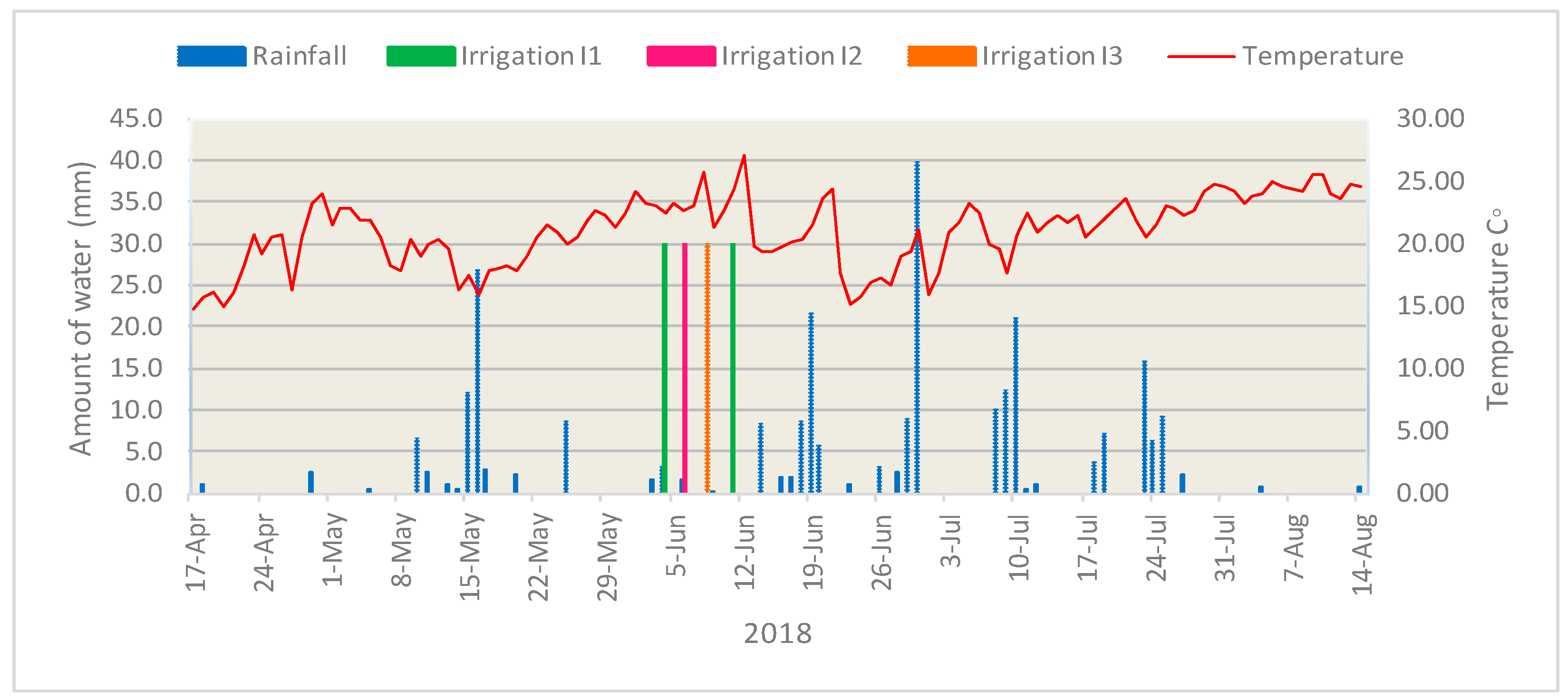

3.1. Weather Conditions and Applied Irrigation Water Amount

3.2. Yield Data, Plant Height, and Fiber Chemical Composition

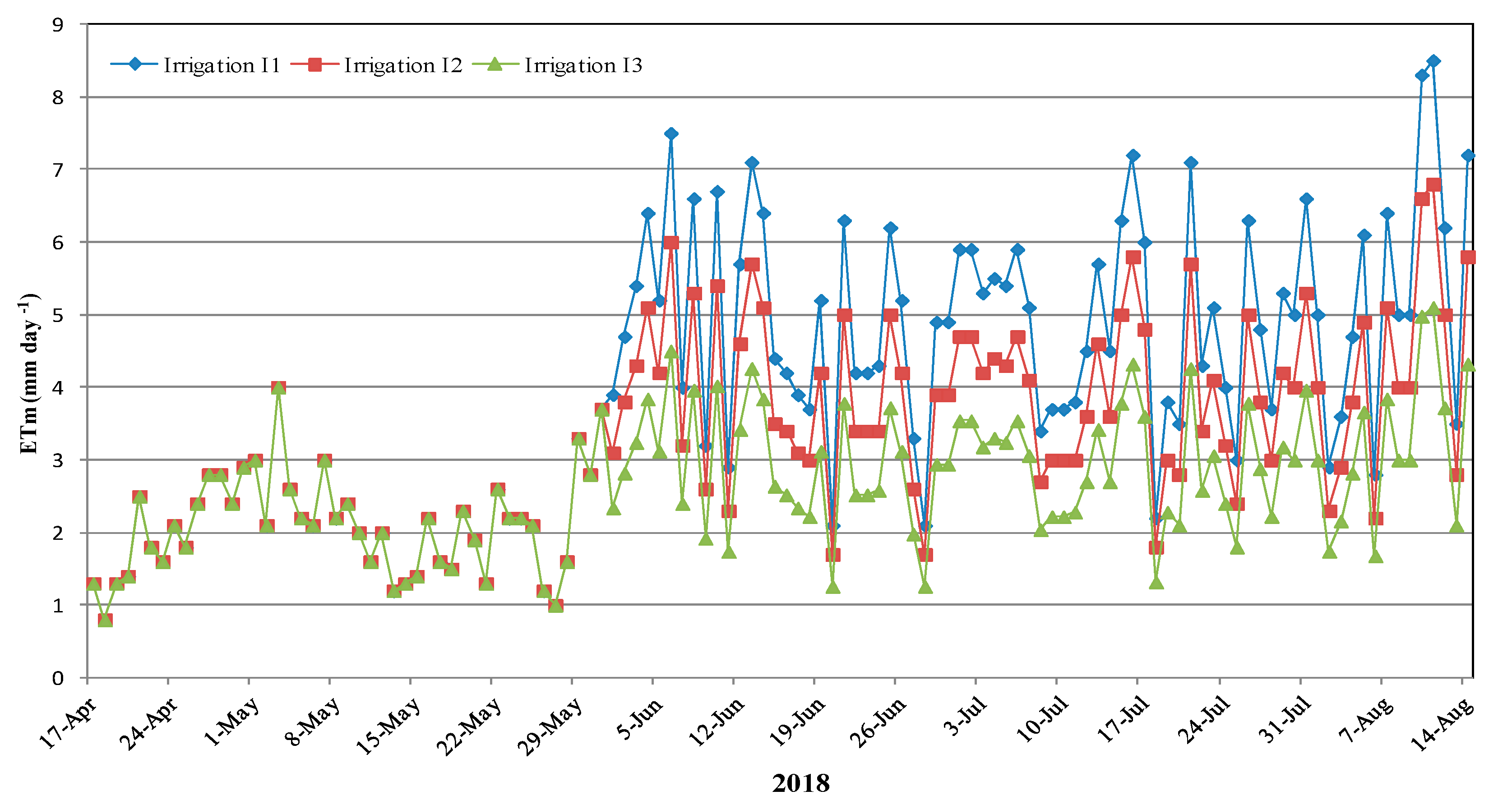

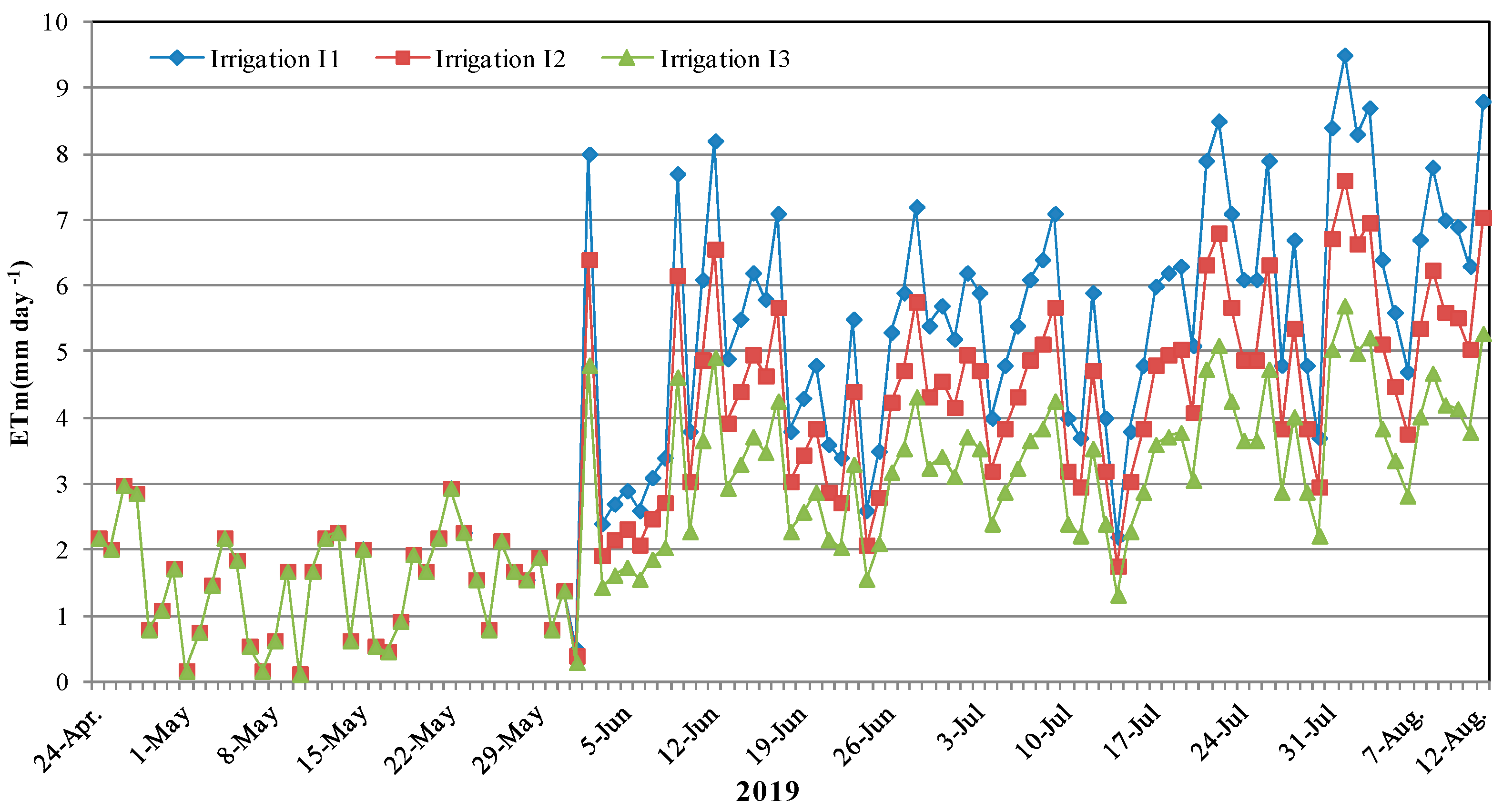

3.3. Crop Water Use

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schluttenhofer, C.; Yuan, L. Challenges towards revitalizing Hemp: A Multifaceted Crop. Trends Plant Sci. 2017, 22, 917–929. [Google Scholar] [CrossRef] [PubMed]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of hemp in textiles, paper industry, insulation and building materials, horticulture, animal nutrition, food and beverages, nutraceuticals, cosmetics and hygiene, medicine, agrochemistry, energy production and environment: A review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Food and Agriculture Organization. FAOSTAT; Statistics Division, FAO: Rome, Italy, 2020; Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 4 May 2022).

- Latković, D. Hemp in Cultivation of Alternative Field Plants; Faculty of Agriculture, Novi Sad, Provincial Secretariat for Agriculture, Water Management and Forestry: Novi Sad, Serbia, 2015; pp. 1–285. [Google Scholar]

- Lisson, S.; Mendham, N. Response of fibre hemp (Cannabis sativa L.) to varying irrigation regimes. J. Int. Hemp Assoc. 1998, 5, 9–15. [Google Scholar]

- Di Bari, V.; Campi, P.; Colucci, R.; Mastrorilli, M. Potential productivity of fibre hemp in southern Europe. Euphytica 2004, 140, 25–32. [Google Scholar] [CrossRef]

- Hackett, C. Mobilizing environmental information about lesser known plants: The value of two neglected levels of description. Agrofor. Syst. 1991, 14, 131–143. [Google Scholar] [CrossRef]

- Sahin, U.; Kuslu, Y.; Kiziloglu, F.M. Response of cucumbers to different irrigation regimes applied through drip-irrigation system. J. Anim. Plant Sci. 2015, 25, 198–205. [Google Scholar]

- Pejić, B.; Sikora, V.; Milić, S.; Mačkić, K.; Koren, A.; Bajić, I. Water-yield relations of fiber hemp (Cannabis sativa L) in climatic conditions of the Vojvodina region. Ratar. Povrt. 2018, 55, 130–134. [Google Scholar] [CrossRef]

- Pejić, B.; Mačkić, K.; Randjelović, P.; Milić, S.; Sikora, V.; Bekavac, G.; Bajić, I.; Simić, D. Calculation of maize evapotranspiration by using indirect methods. Ann. Agron. 2019, 43, 78–91. (in Serbian). [Google Scholar]

- Ertek, A.; Şensoy, S.; Gedik, I.; Küçükyumuk, C. Irrigation scheduling based on pan evaporation values for cucumber (Cucumis sativus L.) grown under field conditions. Agr. Water Manag. 2006, 81, 159–172. [Google Scholar] [CrossRef]

- Pejić, B.; Bajić, I.; Mačkić, K.; Bugarski, D.; Vlajić, S.; Takač, A.; Aksić, M. Irrigation scheduling strategies of pepper based on evaporation and reference evapotranspiration. Acta Agric. Serbica 2021, 26, 69–76. [Google Scholar] [CrossRef]

- Adeogun, E.O. Effect of different irrigation water regime on cucumber yield and water use under sprinkler system. Cont. J. Eng. Sci. 2017, 12, 10–18. [Google Scholar]

- Smajstrla, A.G.; Zazueta, F.S.; Clark, G.A.; Pitts, D.J. Irrigation scheduling with evaporation pans, vol. 254. University of Florida Extension, Institute of Food and Agricultural Sciences. Extention Bulletin. 2000, 254, 11. [Google Scholar]

- Wang, Z.; Zerihum, D.; Feyen, J. General irrigation efficiency for field water management. Agric. Water Manag. 1996, 30, 123–132. [Google Scholar] [CrossRef]

- Doorenbos, J.; Kassam, A.H. Yield Response to Water; FAO Publication No. 33; FAO: Rome, Italy, 1972. [Google Scholar]

- Deng, G.; Du, G.; Yang, Y.; Bao, Y.; Liu, F. Planting density and fertilization evidently influence the fiber yield of hemp (Cannabis sativa L.). Agronomy 2019, 9, 368. [Google Scholar] [CrossRef]

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A review on the current state of knowledge of growing conditions, agronomic soil health practices and utilities of hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef]

- Hall, J.; Bhattarai, S.P.; Midmore, D.J. Effect of industrial hemp (Cannabis sativa L.) planting density on weed suppression, crop growth, physiological responses, and fibre yield in the subtropics. Renew. Bioresour. 2004, 2, 1–7. [Google Scholar]

- Campiglia, E.; Radicetti, E.; Mancinelli, R. Plant density and nitrogen fertilization affect agronomic performance of industrial hemp (Cannabis sativa L.) in Mediterranean environment. Ind. Crop. Prod. 2017, 100, 246–254. [Google Scholar] [CrossRef]

- Deleuran, L.C.; Flengmark, P.K. Yield potential of hemp (Cannabis sativa L.) cultivars in Denmark. J. Ind. Hemp 2005, 10, 19–31. [Google Scholar] [CrossRef]

- Leonte, A.; Robu, T.; Găucă, C.; Pochişcanu, S. Production results obtained at monoecious hemp varieties for fiber after “Secuieni method”. Lucrări Ştiinţific. Ser. Agron. 2015, 58, 83–87. [Google Scholar]

- Bošnjak, Đ. The problems of drought in the Vojvodina province and drought control measures. Ratar. Povrt. 2001, 35, 391–401. [Google Scholar]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2014, Update 2015, International Soil Classification System for Naming Soils And Creating Legends For Soil Maps; World Soil Resources Reports No. 106; FAO: Rome, Italy, 2015. [Google Scholar]

- Tommerup, E.C. The Field Description of the Physical Properties of Soils, First Commission of Commission I–Soil Physics–Of the International Society of Soil Science; International Society of Soil Science: Versailles, France, 1934; pp. 155–158. [Google Scholar]

- Živković, B.; Nejgebauer, V.; Tanasijević, D.; Miljković, N.; Stojković, L.; Drezgić, P. Soils of Vojvodina; Faculty of Agriculture: Novi Sad, Serbia, 1972; pp. 1–684. [Google Scholar]

- Cosentino, S.; Riggi, E.; Testa, G.; Scordia, D.; Copani, V. Evaluation of European developed fibre hemp genotypes (Cannabis sativa L.) in semi-arid Mediterranean environment. Ind. Crop. Prod. 2013, 50, 312–324. [Google Scholar] [CrossRef]

- Bredemann, G. Die bestimmung des fasergehaltes bei massenuntersuchungen von hanf, flachs, fasernesseln und anderen bastfaserpfl anzen. Faserforschung 1942, 16, 14–39. [Google Scholar]

- Ivanovska, A.; Maletić, S.; Djokić, V.; Tadić, N.; Kostić, M. Effect of chemical modifications and coating with Cu-based nanoparticles on the electro-physical properties of jute fabrics in a condition of high humidity. Ind. Crop. Prod. 2022, 180, 114792. [Google Scholar] [CrossRef]

- Bos, M.G. Summary of ICID definitions of irrigation efficiency. ICID Bull. 1985, 34, 28–31. [Google Scholar]

- Viets, F.G. Fertilizers and the efficient use of water. Adv. Agron. 1962, 14, 223–264. [Google Scholar]

- Pejić, B.; Maheshwari, B.L.; Šeremešić, S.; Stričević, R.; Pacureanu–Joita, M.; Rajić, M.; Ćupina, B. Water-yield relations of maize (Zea mays L.) in temperate climatic conditions. Maydica 2011, 56, 315–323. [Google Scholar]

- Tsaliki, E.; Kalivas, A.; Jankauskiene, Z.; Irakli, M.; Cook, C.; Grigoriadis, I.; Panoras, I.; Vasilakoglou, I.; Dhima, K. Fibre and seed productivity of industrial hemp (Cannabis sativa L.) varieties under Mediterranean conditions. Agronomy 2021, 11, 171. [Google Scholar] [CrossRef]

- Daničić, M.; Pejić, B.; Mačkić, K.; Lalić, B.; Maksimović, I.; Putnik-Delić, M. The predicted impact of climate change on maize production in Northern Serbia. Maydica 2020, 65, 1–10. [Google Scholar]

- Trochoulias, T.; Johns, G.G. Poor response of macadamia (Macadamia integrifolia Maiden and Betche) to irrigation in a high rainfall area of subtropical Australia. Aust. J. Exp. Agric. 1992, 32, 507–512. [Google Scholar] [CrossRef]

- Zadrożniak, B.; Radwańska, K.; Baranowska, A.; Mystkowska, I. Possibility of industrial hemp cultivation in areas of high nature value. Econ. Reg. Stud. 2017, 10, 114–127. [Google Scholar] [CrossRef][Green Version]

- Bennett, S.J.; Snella, R.; Wright, D. Effect of variety, seed rate and time of cutting on fibre yield of dew-retted hemp. Ind. Crop. Prod. 2006, 24, 79–86. [Google Scholar] [CrossRef]

- Amaducci, S.; Zatta, A.; Pelatti, F.; Venturi, G. Influence of agronomic factors on yield and quality of hemp (Cannabis sativa L.) fiber and implication for an innovative production system. Field Crop. Res. 2008, 107, 161–169. [Google Scholar] [CrossRef]

- Legros, S.; Picault, S.; Cerruti, N. Factors affecting the yield of industrial hemp–experimental results from France. In Hemp: Industrial Production and Uses; Allegret, S., Bouloc, P., Arnaud, L., Eds.; CPi Group Ltd.: Croydon, UK, 2013; pp. 72–97. [Google Scholar]

- Westerhuis, W.; Amaducci, S.; Struik, P.C.; Zatta, A.; Van Dam, J.E.G.; Stomph, T.J. Sowing density and harvest time affect fibre content in hemp (Cannabis sativa L.) through their effects on stem weight. Ann. Appl. Biol. 2009, 155, 225–244. [Google Scholar] [CrossRef]

- Amaducci, S.; Errani, M.; Venturi, G. Response of hemp to plant population and nitrogen fertilization. Ital. J. Agron. 2002, 6, 103–111. [Google Scholar]

- Amaducci, S.; Errani, M.; Venturi, G. Plant population effects on fibre hemp morphology and production. J. Ind. Hemp. 2002, 7, 33–60. [Google Scholar] [CrossRef]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of fibre hemp (Cannabis sativa L.) in Europe. Ind. Crop. Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Kišgeci, J. Praise to Hemp; Nolit: Beograd, Serbia, 1994; pp. 1–192. [Google Scholar]

- Merfield, C.N. Industrial Hemp and Its Potential for New Zealand; A Report for the 1999 Kellogg Rural Leadership Course; Lincoln University: Canterbury, New Zealand, 1999. [Google Scholar]

- Pejić, B.; Mačkić, K.; Sikora, V.; Maksimović, L.; Kresović, B.; Gajić, B.; Djalović, I. Water-yield relations of drip irrigated maize in temperate climatic conditions. In Proceedings of the 2nd International and 14th National Congress of Soil Science Society of Serbia, Novi Sad, Serbia, 25–28 September 2017; pp. 258–265. [Google Scholar]

- Howell, A. Enhancing water use efficiency in irrigated agriculture. Agron. J. 2001, 93, 281–289. [Google Scholar] [CrossRef]

- Payero, J.O.; Melvin, S.R.; Irmak, S.; Tarkalson, D. Yield response of corn to deficit irrigation in a semiarid climate. Agric. Water Manag. 2006, 84, 101–112. [Google Scholar] [CrossRef]

- Videnović, Ž.; Stefanović, L.; Simić, M.; Kresović, B. Trends in maize growing practices in Serbia. Herbologia 2007, 8, 85–94. [Google Scholar]

- Bahador, M.; Tadayon, M.R. Investigating of zeolite role in modifying the effect of drought stress in hemp: Antioxidant enzymes and oil content. Ind. Crop. Prod. 2020, 144, 112042. [Google Scholar] [CrossRef]

- Çakir, R. Effect of water stress at different development stages on vegetative and reproductive growth of corn. Field Crop. Res. 2004, 89, 1–16. [Google Scholar] [CrossRef]

| Depth (m) | Textural Status (%) | Field Capacity (33 kPa) (mas.%) | Lento Capillary Moisture (625 kPa) (mas.%) | Wilting Point (1500 kPa) (mas.%) | Soil Bulk Density (g cm−3) | Specific Density (g cm−3) | Total Porosity (vol.%) | Readily Available Water (mm) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Sand | Clay | Silt | ||||||||

| 0.4 | 41 | 34 | 25 | 27.93 | 15.61 | 12.65 | 1.35 | 2.66 | 49.13 | 54.5 |

| Depth (m) | pH | CaCO3 (%) | Humus (%) | N (%) | P2O5 | K2O | |

|---|---|---|---|---|---|---|---|

| KCl | H2O | (mg 100 g−1) | |||||

| 0.4 | 7.28 | 8.17 | 6.01 | 2.9 | 0.19 | 29.77 | 30.43 |

| Elements | From Sowing to 4–5 Pairs of Leaves | From 4–5 Pairs of Leaves to the Appearance of Male Flowers | From the Appearance of Male Flowers to the Harvest | The Entire Season/Average | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 17.IV–22.V | 23.V–26.VI | 27.VI–14.VIII | 17.IV–14.VIII | |||||||||

| I1 | I2 | I3 | I1 | I2 | I3 | I1 | I2 | I3 | I1 | I2 | I3 | |

| Eo (mm) | 177 | 170 | 240 | 588 | ||||||||

| ETm (mm) | 74 | 74 | 74 | 142 | 118 | 94 | 240 | 192 | 144 | 456 | 384 | 312 |

| ETm (%) | 16.3 | 19.3 | 23.8 | 31.1 | 30.7 | 30 | 52.6 | 50.0 | 46.2 | 100 | 100 | 100 |

| Duration (days) | 36 | 35 | 49 | 120 | ||||||||

| ETd (mm) | 2.1 | 2.1 | 2.1 | 4.1 | 3.4 | 2.7 | 4.9 | 3.9 | 2.9 | 3.7 | 3.1 | 2.6 |

| Rainfall (mm) | 58 | 67 | 149 | 274 | ||||||||

| Temp. (°C) | 19.1 | 21.3 | 22.2 | 20.9 | ||||||||

| ∆ ± | −16 | −16 | −16 | −37 | −37 | −27 | −91 | 0 | +5 | |||

| r (mm) | 53 | 53 | 53 | 37 | 37 | 37 | 0 | 0 | 10 | |||

| ETa (mm) | 74 | 74 | 74 | 104 | 104 | 94 | 149 | 149 | 144 | 327 | 327 | 312 |

| d (mm) | 0 | 0 | 0 | 38 | 14 | 0 | 91 | 43 | 0 | 129 | 57 | 0 |

| s (mm) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Irrigation (mm) | 0 | 0 | 0 | 60 | 30 | 30 | 0 | 0 | 0 | |||

| Elements | From Sowing to 4–5 Pairs of Leaves | From 4–5 Pairs of Leaves to the Appearance of Male Flowers | From the Appearance of Male Flowers to the Harvest | The Entire Season/Average | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 24.IV–12.VI | 13.VI–4.VII | 5.VII–12.VIII | 24.IV–12.VIII | |||||||||

| I1 | I2 | I3 | I1 | I2 | I3 | I1 | I2 | I3 | I1 | I2 | I3 | |

| Eo (mm) | 186 | 112 | 240 | 538 | ||||||||

| ETm (mm) | 168 | 157 | 147 | 112 | 89 | 67 | 240 | 192 | 118 | 520 | 438 | 332 |

| ETm (%) | 32.3 | 35.8 | 44.3 | 21.5 | 20.3 | 20.2 | 46.2 | 43.8 | 35.5 | 100 | 100 | 100 |

| Duration (days) | 50 | 22 | 39 | 111 | ||||||||

| ETd (mm) | 3.4 | 3.1 | 2.9 | 5.1 | 4.0 | 3.0 | 6.2 | 4.9 | 3.0 | 4.7 | 3.9 | 3.0 |

| Rainfall (mm) | 146 | 80 | 69 | 295 | ||||||||

| Temp. (°C) | 16.3 | 24.0 | 22.4 | 20.9 | ||||||||

| ∆ ± | −22 | −11 | −1 | −19 | −9 | 13 | 0 | −21 | −49 | |||

| r (mm) | 41 | 41 | 41 | 19 | 30 | 40 | 0 | 21 | 53 | |||

| ETa (mm) | 168 | 157 | 147 | 99 | 89 | 67 | 69 | 90 | 118 | 336 | 336 | 332 |

| d (mm) | 0 | 0 | 0 | 13 | 0 | 0 | 171 | 102 | 0 | 184 | 102 | 0 |

| s (mm) | 0 | 0 | 0 | 0 | 0 | 13 | 0 | 0 | 4 | 0 | 0 | 17 |

| Irrigation (mm) | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 70 | 70 | |||

| Biomass Yield (t ha−1) | Green Stem Yield (t ha−1) | Dry Stem Yield (t ha−1) | Plant Height (m) | Bark Yield (t ha−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | |||

| Irrigation regimes | ||||||||||||

| I1 | 49.4 | 40.7 | 37.5 | 30.8 | 14.5 | 11.6 | 3.1 | 2.4 | 5.4 | 4.7 | ||

| I2 | 54.2 | 28.6 | 42.9 | 21.9 | 17.0 | 8.6 | 3.1 | 1.9 | 6.2 | 3.5 | ||

| I3 | 56.7 | 30.9 | 45.2 | 23.4 | 18.0 | 9.6 | 3.0 | 2.2 | 6.6 | 3.7 | ||

| I0 | 53.6 | 28.1 | 42.2 | 22.1 | 16.7 | 8.6 | 3.0 | 1.9 | 6.0 | 3.4 | ||

| LSD | 4.71 | 2.63 | 3.41 | 2.3 | 1.52 | 1.1 | 0.31 | 0.17 | 0.74 | 0.51 | ||

| Topping treatment | ||||||||||||

| T | 44.9 | 29.3 | 34.8 | 22.1 | 12.7 | 8.5 | 2.8 | 2.0 | 4.5 | 3.4 | ||

| NT | 62.0 | 34.8 | 49.1 | 27.0 | 20.4 | 10.8 | 3.3 | 2.3 | 7.5 | 4.3 | ||

| LSD | 3.33 | 1.9 | 2.41 | 1.3 | 1.07 | 0.7 | 0.22 | 0.12 | 0.53 | 0.36 | ||

| Interrow spacing | ||||||||||||

| RS1 | 55.1 | 32.5 | 43.9 | 25.0 | 16.9 | 9.7 | 3.0 | 2.0 | 6.0 | 3.8 | ||

| RS2 | 51.9 | 31.6 | 40.0 | 24.1 | 16.2 | 9.5 | 3.1 | 2.2 | 6.0 | 3.8 | ||

| LSD | 3.33 | 1.9 | 2.41 | 1.6 | 1.07 | 0.7 | 0.22 | 0.12 | 0.53 | 0.36 | ||

| Irrigation regime x Topping treatment x Interrow spacing | ||||||||||||

| I1 | T | 12.5 | 45.5 | 43.2 | 35.1 | 32.1 | 12.4 | 11.8 | 2.8 | 2.3 | 4.3 | 5.1 |

| 25.0 | 33.2 | 36.8 | 22.9 | 27.4 | 7.5 | 9.7 | 3.4 | 2.4 | 2.9 | 3.9 | ||

| NT | 12.5 | 55.2 | 46.4 | 43.5 | 36.3 | 17.0 | 14.1 | 3.1 | 2.5 | 6.6 | 5.7 | |

| 25.0 | 63.7 | 36.3 | 48.4 | 27.6 | 21.3 | 10.8 | 3.3 | 2.4 | 7.7 | 4.3 | ||

| I2 | T | 12.5 | 52.3 | 22.4 | 40.8 | 16.8 | 14.4 | 6.8 | 2.5 | 1.6 | 5.0 | 2.7 |

| 25.0 | 42.1 | 21.2 | 33.1 | 16.0 | 12.3 | 6.3 | 2.8 | 1.8 | 4.6 | 2.4 | ||

| NT | 12.5 | 62.0 | 36.4 | 51.0 | 29.1 | 21.1 | 11.1 | 3.5 | 2.0 | 7.7 | 4.5 | |

| 25.0 | 60.4 | 34.4 | 46.6 | 25.6 | 20.2 | 10.4 | 3.5 | 2.3 | 7.4 | 4.3 | ||

| I3 | T | 12.5 | 42.7 | 30.8 | 33.3 | 23.1 | 12.5 | 9.0 | 2.6 | 2.1 | 4.3 | 3.5 |

| 25.0 | 42.0 | 30.7 | 32.7 | 22.9 | 12.1 | 9.5 | 2.8 | 2.0 | 4.6 | 3.8 | ||

| NT | 12.5 | 78.4 | 34.3 | 63.8 | 26.5 | 26.2 | 10.3 | 3.3 | 2.4 | 9.3 | 3.9 | |

| 25.0 | 63.6 | 28.0 | 50.9 | 21.1 | 21.0 | 9.4 | 3.5 | 2.4 | 8.1 | 3.9 | ||

| I0 | T | 12.5 | 47.9 | 21.6 | 38.6 | 16.2 | 13.9 | 6.3 | 2.8 | 1.5 | 4.7 | 2.3 |

| 25.0 | 53.7 | 28.0 | 41.9 | 22.3 | 16.6 | 8.3 | 2.8 | 2.1 | 5.8 | 3.3 | ||

| NT | 12.5 | 56.5 | 25.1 | 44.9 | 20.2 | 17.6 | 8.2 | 3.5 | 1.9 | 6.4 | 3.2 | |

| 25.0 | 56.1 | 37.9 | 43.6 | 29.8 | 18.6 | 11.7 | 3.0 | 2.4 | 6.9 | 4.8 | ||

| LSD | 9.41 | 5.27 | 6.81 | 4.57 | 3.03 | 2.14 | 0.61 | 0.35 | 1.48 | 1.02 | ||

| α-Cellulose (%) | Lignin (%) | |||||

|---|---|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | |||

| Irrigation regimes | ||||||

| I1 | 77.5 | 70.1 | 2.4 | 7.1 | ||

| I2 | 76.8 | 69.9 | 3.5 | 7.3 | ||

| I3 | 77.4 | 69.8 | 3.4 | 7.2 | ||

| Io | 77.7 | 70.2 | 3.4 | 6.5 | ||

| LSD | 2.65 | 2.25 | 0.76 | 0.89 | ||

| Topping treatment | ||||||

| T | 76.5 | 70.0 | 3.3 | 7.0 | ||

| NT | 78.2 | 70.5 | 3.1 | 7.1 | ||

| LSD | 1.88 | 1.59 | 0.54 | 0.63 | ||

| Interrow spacing | ||||||

| RS1 | 77.6 | 70.0 | 3.1 | 7.1 | ||

| RS2 | 77.1 | 70.5 | 3.2 | 7.0 | ||

| LSD | 1.88 | 1.59 | 0.54 | 0.63 | ||

| Irrigation regimen x Topping treatment x Interrow spacing | ||||||

| I1 | T | 12.5 | 76.7 | 70.4 | 2.5 | 6.5 |

| 25.0 | 78.5 | 70.4 | 2.2 | 6.2 | ||

| NT | 12.5 | 76.6 | 71.3 | 2.2 | 7.4 | |

| 25.0 | 78.2 | 71.7 | 2.7 | 8.5 | ||

| I2 | T | 12.5 | 75.1 | 69.8 | 3.2 | 7.6 |

| 25.0 | 76.1 | 70.1 | 4.1 | 7.4 | ||

| NT | 12.5 | 78.2 | 70.1 | 3.5 | 6.9 | |

| 25.0 | 77.6 | 69.7 | 3.1 | 7.1 | ||

| I3 | T | 12.5 | 75.7 | 68.8 | 3.5 | 7.7 |

| 25.0 | 75.5 | 69.4 | 3.9 | 7.3 | ||

| NT | 12.5 | 80.6 | 69.4 | 3.4 | 7.6 | |

| 25.0 | 77.7 | 71.7 | 3.0 | 6.3 | ||

| I0 | T | 12.5 | 79.6 | 69.8 | 3.7 | 6.4 |

| 25.0 | 74.8 | 71.2 | 3.3 | 6.6 | ||

| NT | 12.5 | 78.2 | 70.4 | 3.0 | 6.6 | |

| 25.0 | 78.3 | 69.8 | 3.5 | 6.3 | ||

| LSD | 5.31 | 4.49 | 1.52 | 1.78 | ||

| Year | War. | IWUE (Equation (2)) | IWUE (Equation (3)) | ETWUE (Equation (4)) | ETWUE (Equation (5)) | ETm | ETa | 1 − ETa/ETm | Ym | Ya | 1 − Ya/Ym | Ky |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2018 | I1 | - | 9.0 | - | 1.18 | 456 | - | 5.4 | - | - | - | |

| I2 | 0.67 | 20.7 | 0.28 | 1.61 | 384 | 0.148 | 6.2 | - | 0.032 | 0.22 | ||

| I3 | 2.0 | 22.0 | - | 2.12 | 312 | - | 6.6 | - | - | - | ||

| I0 | - | - | - | 1.92 | - | 312 | - | - | 6.0 | - | - | |

| 2019 | I1 | 1.18 | 4.27 | 0.69 | 0.90 | 520 | - | 0.35 | 4.7 | - | 0.210 | 0.60 |

| I2 | 0.14 | 5.0 | 0.09 | 0.80 | 438 | - | 0.21 | 3.5 | - | - | - | |

| I3 | 0.43 | 5.29 | - | 1.11 | 332 | - | - | 3.7 | - | - | - | |

| I0 | - | - | - | 1.02 | - | 332 | - | - | 3.4 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajić, I.; Pejić, B.; Sikora, V.; Kostić, M.; Ivanovska, A.; Pejić, B.; Vojnov, B. The Effects of Irrigation, Topping, and Interrow Spacing on the Yield and Quality of Hemp (Cannabis sativa L.) Fibers in Temperate Climatic Conditions. Agriculture 2022, 12, 1923. https://doi.org/10.3390/agriculture12111923

Bajić I, Pejić B, Sikora V, Kostić M, Ivanovska A, Pejić B, Vojnov B. The Effects of Irrigation, Topping, and Interrow Spacing on the Yield and Quality of Hemp (Cannabis sativa L.) Fibers in Temperate Climatic Conditions. Agriculture. 2022; 12(11):1923. https://doi.org/10.3390/agriculture12111923

Chicago/Turabian StyleBajić, Ivana, Borivoj Pejić, Vladimir Sikora, Mirjana Kostić, Aleksandra Ivanovska, Biljana Pejić, and Bojan Vojnov. 2022. "The Effects of Irrigation, Topping, and Interrow Spacing on the Yield and Quality of Hemp (Cannabis sativa L.) Fibers in Temperate Climatic Conditions" Agriculture 12, no. 11: 1923. https://doi.org/10.3390/agriculture12111923

APA StyleBajić, I., Pejić, B., Sikora, V., Kostić, M., Ivanovska, A., Pejić, B., & Vojnov, B. (2022). The Effects of Irrigation, Topping, and Interrow Spacing on the Yield and Quality of Hemp (Cannabis sativa L.) Fibers in Temperate Climatic Conditions. Agriculture, 12(11), 1923. https://doi.org/10.3390/agriculture12111923