Decision Support in Horticultural Supply Chains: A Planning Problem Framework for Small and Medium-Sized Enterprises

Abstract

1. Introduction

2. Literature Overview and Research Questions

- Which specific decision problems arise in the value chains of ornamental plants, perennials, and cut flowers and how are they correlated?

- What differences in planning problems can be identified between different positions in the respective supply chain?

- To what extent have these planning problems already been studied, and what research gaps exist?

3. Methodology

3.1. Exploratory Expert Interviews

3.1.1. Data Collection

3.1.2. Data Analysis

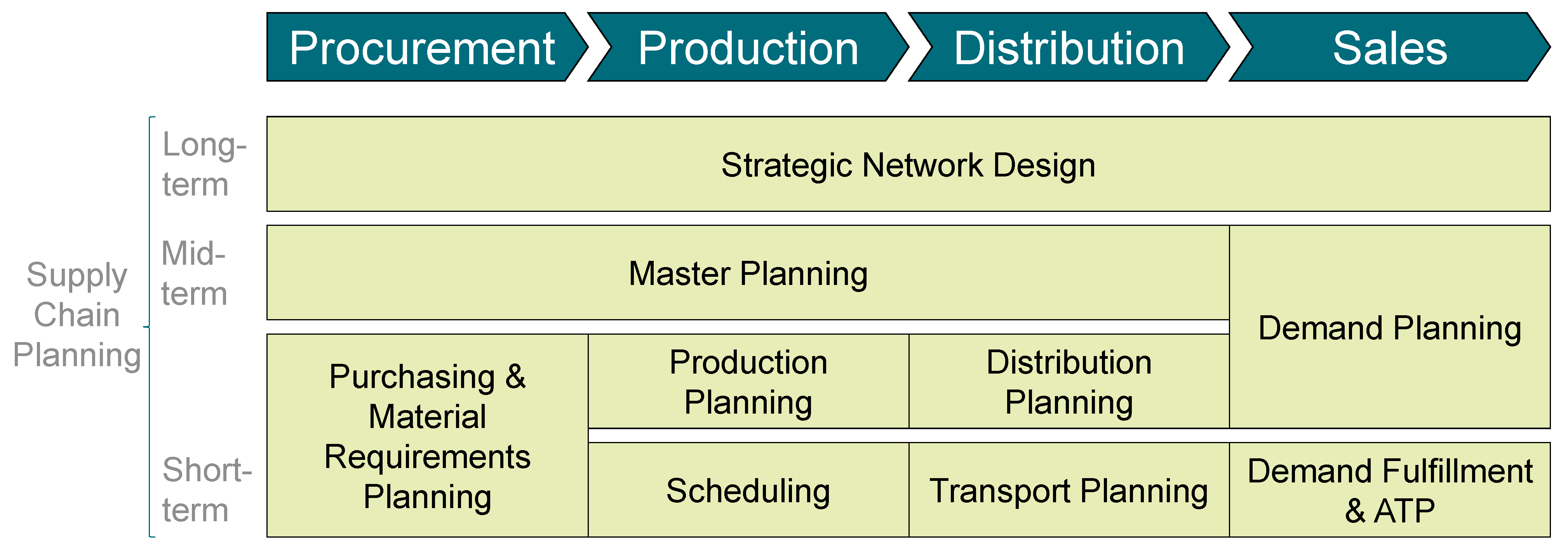

3.2. Supply Chain Planning Framework

3.3. Structured Literature Research

4. Typology of Planning Problems in Horticulture

4.1. Strategic Planning

4.1.1. Strategic Procurement Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.1.2. Strategic Production Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.1.3. Physical Distribution Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.1.4. Strategic Sales Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.2. Tactical Planning

4.2.1. Material/Product Requirement Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.2.2. Production Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.2.3. Distribution Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.2.4. Demand Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.3. Operational Planning

4.3.1. Purchasing

Planning Problems Identified

Pertinent Literature and Gaps

4.3.2. Production Scheduling

Planning Problems Identified

Pertinent Literature and Gaps

4.3.3. Transport Planning

Planning Problems Identified

Pertinent Literature and Gaps

4.3.4. Demand Fulfillment

Planning Problems Identified

Pertinent Literature and Gaps

5. Discussion

6. Conclusions

Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dirksmeyer, W. (Ed.) Status quo und Perspektiven des Deutschen Produktionsgartenbaus; vTI: Braunschweig, Germany, 2009; Volume 330. [Google Scholar]

- Verdouw, C.N.; Beulens, A.J.; van der Vorst, J.G.A.J. Virtualisation of floricultural supply chains: A review from an Internet of Things perspective. Comput. Electron. Agric. 2013, 99, 160–175. [Google Scholar] [CrossRef]

- Zentralverband Gartenbau e.V. Jahresbericht 2020; Mertz, J., Ed.; 2020; pp. 1–64. Available online: https://www.hortigate.de/publikation/86769/ePaper%3A-ZVG-Jahresbericht-2020/ (accessed on 20 October 2022).

- Havardi-Burger, N.; Mempel, H.; Bitsch, V. Sustainability Challenges and Innovations in the Value Chain of Flowering Potted Plants for the German Market. Sustainability 2020, 12, 1905. [Google Scholar] [CrossRef]

- De Keizer, M.; van der Vorst, J.G.A.J.; Bloemhof, J.M.; Haijema, R. Floricultural supply chain network design and control: Industry needs and modelling challenges. J. Chain. Netw. Sci. 2015, 15, 61–81. [Google Scholar] [CrossRef]

- Bokelmann, W. Wertschöpfungsketten im Gartenbau. Landbauforsch. Sonderh. 2009, 2009, 115–129. [Google Scholar]

- Mir, S.; Padma, T. Decision support systems for horticulture. Hortic. Compend. 2019, 24010452. [Google Scholar] [CrossRef]

- Havardi-Burger, N.; Mempel, H.; Bitsch, V.; Havardi-Burger, N.; Bitsch, V. Driving forces and characteristics of the value chain of flowering potted plants for the German market. Eur. J. Hortic. Sci. 2020, 85, 267–278. [Google Scholar] [CrossRef]

- Van der Vorst, J.G.A.J.; Bloemhof, J.M.; de Keizer, M. Innovative logistics concepts in the floriculture sector. In System Dynamics and Innovation in Food Networks 2012; International Center for Food Chain and Network, 2012; pp. 241–251. Available online: https://www.researchgate.net/publication/236867355_Innovative_Logistics_Concepts_in_the_Floriculture_Sector (accessed on 20 October 2022).

- Ossevoort, R.; van der Vorst, J.G.A.J.; Verdouw, C.N.; Wenink, E. DAVINC3I: Virtualisation Scenarios for floricultural Trade Network; Weijers, S., Ed.; Vervoerslogistieke Werkdagen, 2012; pp. 81–92. Available online: https://research.wur.nl/en/publications/davinc3i-virtualisation-scenarios-for-floricultural-trade-network (accessed on 20 October 2022).

- Tromp, S.O.; van der Sman, R.G.; Vollebregt, H.M.; Woltering, E.J. On the prediction of the remaining vase life of cut roses. Postharvest Biol. Technol. 2012, 70, 42–50. [Google Scholar] [CrossRef]

- Flynn, B.B.; Sakakibara, S.; Schröder, R.G.; Bates, K.A.; Flynn, E.J. Empirical Research Methods in Operations Management. J. Oper. Manag. 1990, 9, 250–284. [Google Scholar] [CrossRef]

- Trautrims, A.; Grant, D.B.; Cunliffe, A.L.; Wong, C. Using the “documentary method” to analyse qualitative data in logistics research. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 828–842. [Google Scholar] [CrossRef]

- Manuj, I.; Pohlen, T.L. A reviewer’s guide to the grounded theory methodology in logistics and supply chain management research. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 784–803. [Google Scholar] [CrossRef]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Routledge: London, UK; New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Ellram, L.M. The use of the case study method in logistics research. J. Bus. Logist. 1996, 17, 93–138. [Google Scholar]

- Commission of the EC. Commission Recommendation of 6 May 2003 Concerning the Definition of Micro, Small and Medium-Sized Enterprises: 2003/361/EC. 2003. Available online: https://op.europa.eu/en/publication-detail/-/publication/6ca8d655-126b-4a42-ada4-e9058fa4515517 (accessed on 20 October 2022).

- Bell, E.; Bryman, A.; Harley, B. Business Research Methods, 5th ed.; Oxford University Press: Oxford, UK, 2019. [Google Scholar]

- Mayring, P. Qualitative Inhaltsanalyse: Grundlagen und Techniken, 12th ed.; Beltz Pädagogik Beltz: Weinheim, Germany, 2015. [Google Scholar]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Fleischmann, B.; Meyr, H.; Wagner, M. Advanced planning: Structure of advanced planning Systems. In Supply Chain Management and Advanced Planning; Kilger, C., Stadtler, H., Meyr, H., Eds.; Springer Texts in Business and Economics; Springer: Berlin, Germany, 2015; pp. 71–106. [Google Scholar]

- Hübner, A.; Kuhn, H.; Sternbeck, M.G. Demand and supply chain planning in grocery retail: An operations planning framework. Int. J. Retail. Distrib. Manag. 2013, 41, 512–530. [Google Scholar] [CrossRef]

- Nam, S.; Shen, H.; Ryu, C.; Shin, J.G. SCP-Matrix based shipyard APS design: Application to long-term production plan. Int. J. Nav. Archit. Ocean. Eng. 2018, 10, 741–761. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M.; Westhaus, M.; Morana, R. Conducting a literature review: The example of sustainability in supply chains. In Research Methodologies in Supply Chain Management; Kotzab, H., Seuring, S., Müller, M., Reiner, G., Eds.; Physica-Verlag: Heidelberg, Germany, 2005; pp. 91–106. [Google Scholar] [CrossRef]

- Van der Broek, J.; Smulders, H. Institutional gaps in cross-border regional innovation systems: The horticultural industry in venlo–lower rhine. In The Social Dynamics of Innovation Networks; Rutten, R., Benneworth, P., Irawati, D., Boekema, F., Eds.; Routledge: Abingdon-on-Thames, UK, 2014; pp. 183–202. [Google Scholar] [CrossRef]

- Geerling-Eff, F.; Hoes, A.C.; Dijkshoorn-Dekker, M. Triple helix networks matching knowledge demand and supply in seven Dutch horticulture Greenport regions. Stud. Agric. Econ. 2017, 119, 34–40. [Google Scholar] [CrossRef]

- Matopoulos, A.; Vlachopoulou, M.; Manthou, V.; Manos, B. A conceptual framework for supply chain collaboration: Empirical evidence from the agri–food industry. Supply Chain. Manag. Int. J. 2007, 12, 177–186. [Google Scholar] [CrossRef]

- De Keizer, M.; Haijema, R.; Bloemhof, J.M.; van der Vorst, J.G.A.J. acHybrid optimization and simulation to design a logistics network for distributing perishable products. Comput. Ind. Eng. 2015, 88, 26–38. [Google Scholar] [CrossRef]

- Rijpkema, W.A.; Rossi, R.; van der Vorst, J.G.A.J. Effective sourcing strategies for perishable product supply chains. Int. J. Phys. Distrib. Logist. Manag. 2014, 44, 494–510. [Google Scholar] [CrossRef]

- Yazdani, M.; Pamucar, D.; Chatterjee, P.; Torkayesh, A.E. A multi-tier sustainable food supplier selection model under uncertainty. Oper. Manag. Res. 2021, 15, 116–145. [Google Scholar] [CrossRef]

- Rath, T. Hybride Wissensrepräsentation in einem rechnergestützten Planungs-und Beratungssystem zur Energieversorgung von Gewächshausanlagen. Ber. Ges. Inform. Land Forstund Ernährungswirtschaft 1993, 5, 217–221. [Google Scholar]

- Vanthoor, B.H.; Stigter, J.D.; van Henten, E.J.; Stanghellini, C.; de Visser, P.H.; Hemming, S. A methodology for model-based greenhouse design: Part 5, greenhouse design optimisation for southern-Spanish and Dutch conditions. Biosyst. Eng. 2012, 111, 350–368. [Google Scholar] [CrossRef]

- De Waal, A.; Meingast, A. Applying the high performance organisation framework in the horticulture and greenhouse sector. Meas. Bus. Excell. 2017, 21, 136–151. [Google Scholar] [CrossRef]

- Van der Vorst, J.G.A.J.; Wenink, E.; Bloemhof, J.M.; de Keizer, M. DAVINC3I: Developing Innovative Logistics Concepts for International Floriculture Trade Networks; Weijers, S., Ed.; Vervoerslogistieke Werkdagen, 2011; pp. 225–236. Available online: https://agris.fao.org/agris-search/search.do?recordID=NL2020016733 (accessed on 20 October 2022).

- Cheng, M.; Luo, H.; Zhong, R.Y.; Lan, S.; Huang, G.Q. Cloud-based auction tower for perishable supply chain trading. In Disruptive Innovation in Manufacturing Engineering towards the 4th Industrial Revolution; Bauer, W., Constantinescu, C., Sauer, O., Maropoulos, P., Muelaner, J., Eds.; Fraunhofer Verl.: Stuttgart, Germany, 2014; Volume 25, pp. 329–336. [Google Scholar]

- De Keizer, M.; Akkerman, R.; Grunow, M.; Bloemhof, J.M.; Haijema, R.; van der Vorst, J.G.A.J. Logistics network design for perishable products with heterogeneous quality decay. Eur. J. Oper. Res. 2017, 262, 535–549. [Google Scholar] [CrossRef]

- White, G.; Uva, W.F. Developing a Strategic Marketing Plan for Horticultural Firms. Cornell Univ. Rep. 2000. Available online: https://www.docin.com/p-1379631549.html (accessed on 20 October 2022).

- Engelke, C. Service Differentation and Dimensions of Strategic Orientations in German Retail Horticulture. Ph.D. Thesis, University of Worcester, Worcester, MA, USA, 2020. [Google Scholar]

- Jiao, J.; Zhang, Y.; Wang, Y. A heuristic genetic algorithm for product portfolio planning. Comput. Oper. Res. 2007, 34, 1777–1799. [Google Scholar] [CrossRef]

- Helferich, A.; Herzwurm, G.; Schockert, S. QFD-PPP: Product line portfolio planning using quality function deployment. In Software Product Lines; Hutchison, D., Kanade, T., Kittler, J., Kleinberg, J.M., Mattern, F., Mitchell, J.C., Naor, M., Nierstrasz, O., Pandu Rangan, C., Steffen, B., et al., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2005; Volume 3714, pp. 162–173. [Google Scholar] [CrossRef]

- Hübner, A.H.; Kuhn, H. Retail category management: State-of-the-art review of quantitative research and software applications in assortment and shelf space management. Omega 2012, 40, 199–209. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Beulens, A.J.; Trienekens, J.H.; van der Vorst, J.G.A.J. A framework for modelling business processes in demand-driven supply chains. Prod. Plan. Control. 2011, 22, 365–388. [Google Scholar] [CrossRef]

- McIvor, R.T.; Humphreys, P.K. A case–based reasoning approach to the make or buy decision. Integr. Manuf. Syst. 2000, 11, 295–310. [Google Scholar] [CrossRef]

- Van de Water, H.; van Peet, H.P. A decision support model based on the Analytic Hierarchy Process for the Make or Buy decision in manufacturing. J. Purch. Supply Manag. 2006, 12, 258–271. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Robbemond, R.M.; Wolfert, J. ERP in agriculture: Lessons learned from the Dutch horticulture. Comput. Electron. Agric. 2015, 114, 125–133. [Google Scholar] [CrossRef]

- Faraudo Pijuan, C. EOQ: Optimizing Price and Order Quantity for Growing Items with Imperfect Quality and Carbon Restrictions. Ph.D. Thesis, TecnoCampus, Escola Superior de Ciències Socials i de l’Empresa del (ESCSET), 2021. Available online: https://repositori.tecnocampus.cat/handle/20.500.12367/1798 (accessed on 20 October 2022).

- Van der Vorst, J.G.A.J.; van Kooten, O.; Luning, P.A. Towards a Diagnostic Instrument to Identify Improvement Opportunities for Quality Controlled Logistics in Agrifood Supply Chain Networks. Int. J. Food Syst. Dyn. 2011, 2, 94–105. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Beulens, A.J.; van der Vorst, J.G.A.J. Virtual logistic networks in dutch horticulture. In Proceedings of the 4th Production and Operations Management World Conference, Amsterdam, The Netherlands, 1–4 July 2012; POMS, JOMSA, Eds.; European Operations Management Association: Brussels, Belgium, 2012; pp. 1–10. [Google Scholar]

- Rosset, P.; Cornu, M.; Noël, V.; Morelli, E.; Poumeyrol, G. Time-temperature profiles of chilled ready-to-eat foods in school catering and probabilistic analysis of Listeria monocytogenes growth. Int. J. Food Microbiol. 2004, 96, 49–59. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Rijgersberg, H.; Tromp, S.O.; Jacxsens, L.; Uyttendaele, M. Modeling logistic performance in quantitative microbial risk assessment. Risk Anal. Off. Publ. Soc. Risk Anal. 2010, 30, 20–31. [Google Scholar] [CrossRef]

- Annevelink, I.E. The IMAG production planning system (IPP) for glasshouse floriculture in its introduction phase. Acta Hortic. 1989, 1989, 37–46. [Google Scholar] [CrossRef]

- Annevelink, I.E. Operational planning in horticulture: Optimal space allocation in pot-plant nurseries using heuristic techniques. J. Agric. Eng. Res. 1992, 51, 167–177. [Google Scholar] [CrossRef]

- Darby-Dowman, K.; Barker, S.; Audsley, E.; Parsons, D. A two-stage stochastic programming with recourse model for determining robust planting plans in horticulture. J. Oper. Res. Soc. 2000, 51, 83–89. [Google Scholar] [CrossRef]

- Jans, R.; Degraeve, Z. Modeling industrial lot sizing problems: A review. Int. J. Prod. Res. 2008, 46, 1619–1643. [Google Scholar] [CrossRef]

- Pauls-Worm, K.G.J.; Hendrix, E.M.T.; Haijema, R.; van der Vorst, J.G.A.J. An MILP approximation for ordering perishable products with non-stationary demand and service level constraints. Int. J. Prod. Econ. 2014, 157, 133–146. [Google Scholar] [CrossRef]

- Guzman, E.; Andres, B.; Poler, R. Models and algorithms for production planning, scheduling and sequencing problems: A holistic framework and a systematic review. J. Ind. Inf. Integr. 2021, 27, 100287. [Google Scholar] [CrossRef]

- De Keizer, M.; Groot, J.J.; Bloemhof, J.M.; van der Vorst, J.G.A.J. Logistics orchestration scenarios in a potted plant supply chain network. Int. J. Logist. Res. Appl. 2014, 17, 156–177. [Google Scholar] [CrossRef]

- Ossevoort, R.; de Keizer, M.; van der Vorst, J.G.A.J.; Wenink, E. DAVINC3I: Moving towards Responsive Hub Network Designs; Weijers, S., Ed.; Vervoerslogistieke Werkdagen, 2013; pp. 139–151. Available online: https://www.researchgate.net/publication/283418508_DAVINC3I_moving_towards_responsive_hub_network_designs (accessed on 20 October 2022).

- Jiang, Y.; Chen, L.; Fang, Y. Integrated Harvest and Distribution Scheduling with Time Windows of Perishable Agri-Products in One-Belt and One-Road Context. Sustainability 2018, 10, 1570. [Google Scholar] [CrossRef]

- Gaggero, M.; Tonelli, F. A two–step optimization model for the distribution of perishable products. Networks 2021, 78, 69–87. [Google Scholar] [CrossRef]

- Holzapfel, A.; Hübner, A.; Kuhn, H.; Sternbeck, M.G. Delivery pattern and transportation planning in grocery retailing. Eur. J. Oper. Res. 2016, 252, 54–68. [Google Scholar] [CrossRef]

- Frank, M.; Ostermeier, M.; Holzapfel, A.; Hübner, A.; Kuhn, H. Optimizing routing and delivery patterns with multi-compartment vehicles. Eur. J. Oper. Res. 2021, 293, 495–510. [Google Scholar] [CrossRef]

- Haselbeck, F.; Killinger, J.; Menrad, K.; Hannus, T.; Grimm, D.G. Machine Learning Outperforms Classical Forecasting on Horticultural Sales Predictions. Mach. Learn. Appl. 2022, 7, 100239. [Google Scholar] [CrossRef]

- Dellino, G.; Laudadio, T.; Mari, R.; Mastronardi, N.; Meloni, C. A reliable decision support system for fresh food supply chain management. Int. J. Prod. Res. 2018, 56, 1458–1485. [Google Scholar] [CrossRef]

- Ni, W.; Tan, S.K.; Ng, W.J.; Brown, S.D. Moving-Window GPR for Nonlinear Dynamic System Modeling with Dual Updating and Dual Preprocessing. Ind. Eng. Chem. Res. 2012, 51, 6416–6428. [Google Scholar] [CrossRef]

- Matsuyama, K. The multi-period newsboy problem. Eur. J. Oper. Res. 2006, 171, 170–188. [Google Scholar] [CrossRef]

- Khouja, M. The single-period (news-vendor) problem: Literature review and suggestions for future research. Omega 1999, 27, 537–553. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, R.; Vakharia, A.J.; Chen, Y.; Seref, M.M. The newsvendor problem: Review and directions for future research. Eur. J. Oper. Res. 2011, 213, 361–374. [Google Scholar] [CrossRef]

- Goyal, S.K.; Giri, B.C. Recent trends in modeling of deteriorating inventory. Eur. J. Oper. Res. 2001, 134, 1–16. [Google Scholar] [CrossRef]

- Broekmeulen, R.A.; van Donselaar, K.H. A heuristic to manage perishable inventory with batch ordering, positive lead-times, and time-varying demand. Comput. Oper. Res. 2009, 36, 3013–3018. [Google Scholar] [CrossRef]

- Chalabi, Z.S.; Bailey, B.J.; Wilkinson, D.J. A real-time optimal control algorithm for greenhouse heating. Comput. Electron. Agric. 1996, 15, 1–13. [Google Scholar] [CrossRef]

- Magarey, R.D.; Travis, J.W.; Russo, J.M.; Seem, R.C.; Magarey, P.A. Decision Support Systems: Quenching the Thirst. Plant Dis. 2002, 86, 4–14. [Google Scholar] [CrossRef] [PubMed]

- Damos, P.; Karabatakis, S. Real time pest modeling through the World Wide Web: Decision making from theory to praxis. Integr. Prot. Fruit Crop. IOBC-WPRS Bull. 2013, 91, 253–258. [Google Scholar]

- Bergez, J.E.; Garcia, F.; Lapasse, L. A hierarchical partitioning method for optimizing irrigation strategies. Agric. Syst. 2004, 80, 235–253. [Google Scholar] [CrossRef]

- Gurovich, L.A.; Ton, Y.; Vergara, L.M. Irrigation scheduling of avocado using phytomonitoring techniques. Cienc. Inverstig. Agrar. 2006, 33, 117–124. [Google Scholar]

- Gonzalez-Araya, M.C.; Soto-Silva, W.E.; Acosta Espejo, L.G. (Eds.) Harvest Planning in Apple Orchards Using an Optimization Model; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2015; Volume 224. [Google Scholar] [CrossRef]

- Caixeta-Filho, J.V. Orange harvesting scheduling management: A case study. J. Oper. Res. Soc. 2006, 57, 637–642. [Google Scholar] [CrossRef]

- Higgins, A.J.; Laredo, L.A. Improving harvesting and transport planning within a sugar value chain. J. Oper. Res. Soc. 2006, 57, 367–376. [Google Scholar] [CrossRef]

- Ferrer, J.C.; Mac Cawley, A.; Maturana, S.; Toloza, S.; Vera, J. An optimization approach for scheduling wine grape harvest operations. Int. J. Prod. Econ. 2008, 112, 985–999. [Google Scholar] [CrossRef]

- Elia, A.; Conversa, G. A decision support system (GesCoN) for managing fertigation in open field vegetable crops. Part I-methodological approach and description of the software. Front. Plant Sci. 2015, 6, 319. [Google Scholar] [CrossRef]

- Vidal, T.; Crainic, T.G.; Gendreau, M.; Prins, C. Heuristics for multi-attribute vehicle routing problems: A survey and synthesis. Eur. J. Oper. Res. 2013, 231, 1–21. [Google Scholar] [CrossRef]

- Braekers, K.; Ramaekers, K.; van Nieuwenhuyse, I. The vehicle routing problem: State of the art classification and review. Comput. Ind. Eng. 2016, 99, 300–313. [Google Scholar] [CrossRef]

- Gong, W.; Fu, Z. ABC-ACO for perishable food vehicle routing problem with time windows. In Proceedings of the 2010 International Conference on Computational and Information Sciences (ICCIS 2010), Chengdu, China, 17–19 December 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1261–1264. [Google Scholar] [CrossRef]

- Padilla, M.P.B.; Canabal, P.A.N.; Pereira, J.M.L.; Riaño, H.E.H. Vehicle Routing Problem for the Minimization of Perishable Food Damage Considering Road Conditions. Logist. Res. 2018, 2, 1–18. [Google Scholar]

- Wu, D.; Wu, C. Research on the Time-Dependent Split Delivery Green Vehicle Routing Problem for Fresh Agricultural Products with Multiple Time Windows. Agriculture 2022, 12, 793. [Google Scholar] [CrossRef]

- Ginantaka, A. Fuzzy model for distribution route determination of horticultural Products. In Proceedings of the 7th BANGKOK International Conference on “Recent Trends in Engineering and Technology”, Bangkok, Thailand, 3–4 May 2017. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof, J.M.; Haijema, R.; van der Vorst, J.G.A.J. Modeling an Inventory Routing Problem for perishable products with environmental considerations and demand uncertainty. Int. J. Prod. Econ. 2015, 164, 118–133. [Google Scholar] [CrossRef]

- Kuhn, H.; Schubert, D.; Holzapfel, A. Integrated order batching and vehicle routing operations in grocery retail—A General Adaptive Large Neighborhood Search algorithm. Eur. J. Oper. Res. 2021, 294, 1003–1021. [Google Scholar] [CrossRef]

- Widodo, K.H.; Nagasawa, H.; Morizawa, K.; Ota, M. A periodical flowering–harvesting model for delivering agricultural fresh products. Eur. J. Oper. Res. 2006, 170, 24–43. [Google Scholar] [CrossRef]

- Ludwig, S. A stochastic model to evaluate the effect of uncertainty in pot plant production. Acta Hortic. 1991, 295, 223–230. [Google Scholar] [CrossRef]

- Matos, C.; Maciel, V.; Fernandez, C.M.; Lima, T.M.; Gaspar, P.D. Decision support system to assign price rebates of fresh horticultural products based on quality decay. In Computational Management; Patnaik, S., Tajeddini, K., Jain, V., Eds.; Springer International Publishing and Imprint Springer: Cham, Switzerland, 2021; Volume 18, pp. 487–497, Springer eBook Collection. [Google Scholar] [CrossRef]

- Pina, M.; Gaspar, P.; Lima, T. Decision Support System in Dynamic Pricing of Horticultural Products Based on the Quality Decline Due to Bacterial Growth. Appl. Syst. Innov. 2021, 4, 80. [Google Scholar] [CrossRef]

- Verloop, C.M.; Verdouw, C.N.; van der Hoeven, R. Plantform: Horizontal cooperation in realizing integrated information systems for potted plants production. In Proceedings of the 7th EFITA Conference, Wageningen, The Netherlands, 6–8 July 2009. [Google Scholar]

- Akkermans, H.A.; Bogerd, P.; Yücesan, E.; van Wassenhove, L.N. The impact of ERP on supply chain management: Exploratory findings from a European Delphi study. Eur. J. Oper. Res. 2003, 146, 284–301. [Google Scholar] [CrossRef]

- Guzueva, E.R.; Beibalaeva, D.K.; Abubakarov, M.V. Information and management system for farming. In Proceedings of the 1st International Conference ASE-I—2021: Applied Science and Engineering: ASE-I—2021, Melbourne, Australia, 15–19 November 2021; AIP Conference Proceedings. Salamova, A., Dakhaeva, F., Eds.; AIP Publishing: Melville, NY, USA, 2021; Volume 2442. [Google Scholar] [CrossRef]

| Company | Size | Assortment | Description |

|---|---|---|---|

| Com 1 | Medium | Bed and balcony plants, cut flowers | Cash & carry market wholesaler with their own large production and fleet |

| Com 2 | Small | Pot plants, perennials, cut flowers | Producer with their own retail store, wholesale activities and a limited own fleet |

| Com 3 | Medium | Cut flowers | Online retailer for bouquets, also acting as mediator and wholesaler for cooperating retailers |

| Com 4 | Small | Mediterranean perennials | Specialized importing wholesaler with their own fleet |

| Com 5 | Small | Pot plants, perennials, house plants | Retailer relying on close cooperation with a producer at the same location |

| Com 6 | Small | Herbs, pot plants, bulb plants | Specialized producer expanding their operations by establishing a further modern production facility |

| Com 7 | Medium | Grasses, perennials | Specialized producer with their own fleet serving large customers |

| Com 8 | Small | Cut flowers, pot plants | Specialized producer with their own retail store, also serving other retailers or wholesalers |

| Com 9 | Small | Perennials, blooming plants, herbs | Specialized producer mostly serving retailers with an own fleet and wholesale activities |

| Com 10 | Small | Bed and balcony plants, perennials, house plants | Retailer with a small production operation of their own and mainly wholesaler sourcing |

| Planning Area | Literature (Q:Qualitative; M:Model-Based) | Focus and Methodology | Gaps |

|---|---|---|---|

| Strategic Procurement Planning | van der Broek and Smulders [25] (Q) | Cross-border barriers for innovation on the example of international cooperations in horticulture (case study/interviews) | Development of generic supplier selection models reflecting specifics in horticulture |

| Geerling-Eff et al. [26] (Q) | National cooperation between different agents in Dutch horticulture (secondary analysis of publications) | ||

| Matopoulos et al. [27] (Q) | Collaboration in agri-food grower-processor supply chains of small and medium-sized companies (case study/ interviews) | ||

| de Keizer et al. [28] (M) | Logistics network design considering the quality of perishable (horticultural) products (modeling and optimization) | ||

| Rijpkema et al. [29] (M) | Sourcing strategies for international perishable product supply chains considering shelf life decay of perishables (modeling and simulation) | ||

| Yazdani et al. [30] (M) | Multi-tier supplier selection for food supply chains considering uncertainty (modeling) | ||

| Strategic Production Planning | Rath [31] (M) | Energy supply for greenhouse production (modeling) | Consideration of additional relevant factors for horticultural practice |

| Vanthoor et al. [32] (M) | Greenhouse design (modeling and optimization) | ||

| Physical Distribution Planning | van der Vorst et al. [34] (Q) | Dutch horticultural network, sector developments, bottlenecks and improvement potentials (qualitative study) | Investigation of distribution conditions and particularities outside the Netherlands |

| van der Vorst et al. [9] (Q) | Dutch floricultural sector developments, bottlenecks, and opportunities (qualitative study) | ||

| Ossevoort et al. [10] (M) | Logistics hub network for Dutch floricultural logistics (scenario analysis) | ||

| Cheng et al. [35] (M) | Cloud-based auction tower for trading perishable products and information sharing in Dutch horticulture (platform development) | ||

| de Keizer et al. [36] (M) | Network design considering heterogeneous quality decay of perishables and application to the horticultural sector (modeling and optimization) | ||

| Strategic Sales Planning | White and Uva [37] (Q) | Marketing plan development for horticultural companies (guideline development) | Adaptation of generic assortment planning models for horticultural products and their requirements |

| Planning Area | Literature (Q:Qualitative; M:Model-Based) | Focus and Methodology | Gaps |

|---|---|---|---|

| Material/ Product Requirement Planning | Verdouw et al. [45] (Q) | Drivers and barriers of ERP systems in Dutch horticulture (case study/interviews) | Horticultural focus; consideration of quality decay and pre- and re-order distinction |

| Faraudo Pijuan [46] (M) | Economic order quantity and price determination for agricultural and livestock industries (modeling and optimization) | ||

| van der Vorst et al. [47] (Q) | Quality-controlled fresh food distribution and inventory management (qualitative framework) | ||

| Verdouw et al. [48] (Q) | Information distribution in virtual logistic networks in Dutch horticulture (case study) | ||

| Rijpkema et al. [29] (M) | Sourcing strategies for international perishable product supply chains considering shelf life decay (modeling and simulation) | ||

| Tromp et al. [11] (M) | Prediction of remaining vase life of cut roses based on time-temperature sum (modeling) | ||

| Production Planning | Annevelink [51] (M) | Production planning for glasshouse floriculture (modeling and optimization) | Consideration of stochastic demand, service levels, and horticulture-specific production and ordering structure |

| Annevelink [52] (M) | Spacing and allocation plan with dynamic space requirements for floricultural glasshouse production (modeling and optimization) | ||

| Darby-Dowman et al. [53] (M) | Planting and harvest planning considering risk aversion in agriculture (modeling and optimization) | ||

| Distribution Planning | de Keizer et al. [57] (M) | Hub network in a Dutch potted plant supply chain considering logistics costs, working times, and emissions (modeling and simulation) | Investigation of non-auction-dominated markets, considering horticulture specifics |

| Ossevoort et al. [58] (M) | Distribution planning for Dutch horticulture using consolidation effects (modeling and simulation) | ||

| de Keizer et al. [5] (Q) | Control and design of floricultural supply chain networks and market developments (case study/ interviews and literature review) | ||

| Jiang et al. [59] (M) | Distribution scheduling with integrated harvest planning of perishable products and time windows in an agricultural context (modeling and optimization) | ||

| Gaggero and Tonelli [60] (M) | Distribution planning for perishable products considering replenishment cycles, safety stocks, and product volumes (modeling, optimization, and simulation) | ||

| Demand Planning | Haselbeck et al. [63] (M) | Demand forecasting using machine learning for horticulture (modeling and forecasting) | Considering horticulture-specific factors in demand forecasting |

| Dellino et al. [64] (M) | Sales forecasting for perishable products and order plan selection (modeling and forecasting) |

| Planning Area | Literature (Q:Qualitative; M:Model-Based) | Focus and Methodology | Gaps |

|---|---|---|---|

| Purchasing | Matsuyama [66] (M) | Multi-period newsvendor problem for ordering perishables (modeling and optimization) | Horticultural focus and specifics |

| Broekmeulen and van Donselaar [70] (M) | Ordering perishables considering age distributions (modeling and optimization) | ||

| Production Scheduling | Chalabi et al. [71] (M) | Control of greenhouse heating considering weather data, forecasts, and set points (modeling and optimization) | Comprehensive approach combining the heterogeneous requirements of different plants; consideration of further plant treatments and uncertainty |

| Magarey et al. [72] (Q) | Management of plant diseases with decision support systems in an agricultural context (case study) | ||

| Damos and Karabatakis [73] (M) | Web-based integrated pest management in an agricultural context (modeling and forecasting) | ||

| Bergez et al. [74] (M) | Effective water use in irrigated agriculture (modeling, simulation, and optimization) | ||

| Gurovich et al. [75] (M) | Irrigation scheduling strategies based on phytomonitoring techniques (modeling) | ||

| Gonzalez-Araya et al. [76] (M) | Harvest planning and labor distribution for apple orchards (modeling and optimization) | ||

| Caixeta-Filho [77] (M) | Harvest planning of oranges considering chemical, biological, and logistical restrictions (modeling and optimization) | ||

| Higgins and Laredo [78] (M) | Harvesting and transport planning for sugar supply chains (modeling and optimization) | ||

| Ferrer et al. [79] (M) | Scheduling wine grape harvest considering cost and quality objectives (modeling and optimization) | ||

| Elia and Conversa [80] (M) | Real-time irrigation and nitrogen fertilization management (modeling, optimization, and simulation) | ||

| Transport Planning | Gong and Fu [83] (M) | Vehicle routing problem with time windows considering the quality loss of perishable products (modeling and optimization) | Horticultural focus; integrated production and transportation planning considering horticultural specifics |

| Buelvas Padilla et al. [84] (M) | Vehicle routing problem considering perishable food damage caused by road conditions (modeling and optimization) | ||

| Wu and Wu [85] (M) | Vehicle routing problem considering time-dependent split deliveries, time windows, and customer satisfaction (modeling and optimization) | ||

| Ginantaka [86] (M) | Vehicle routing problem for horticultural products considering road conditions and traffic (modeling and optimization) | ||

| Soysal et al. [87] (M) | Inventory routing problem considering perishability and shelf life in food supply chains (modeling and simulation) | ||

| Demand Fulfillment | Widodo et al. [89] (M) | Harvest planning considering plant growth and loss of fresh agricultural products to maximize demand satisfaction (modeling and optimization) | Investigating multiple possibilities for demand control in an ornamental horticultural context |

| Ludwig [90] (M) | Production planning considering the effects of risks on demand fulfillment (modeling and optimization) | ||

| Matos et al. [91] (M) | Discounts of fresh horticultural products based on quality decay (modeling and optimization) | ||

| Pina et al. [92] (M) | Dynamic pricing of horticultural food products considering remaining shelf life (modeling and optimization) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drechsler, M.; Holzapfel, A. Decision Support in Horticultural Supply Chains: A Planning Problem Framework for Small and Medium-Sized Enterprises. Agriculture 2022, 12, 1922. https://doi.org/10.3390/agriculture12111922

Drechsler M, Holzapfel A. Decision Support in Horticultural Supply Chains: A Planning Problem Framework for Small and Medium-Sized Enterprises. Agriculture. 2022; 12(11):1922. https://doi.org/10.3390/agriculture12111922

Chicago/Turabian StyleDrechsler, Marius, and Andreas Holzapfel. 2022. "Decision Support in Horticultural Supply Chains: A Planning Problem Framework for Small and Medium-Sized Enterprises" Agriculture 12, no. 11: 1922. https://doi.org/10.3390/agriculture12111922

APA StyleDrechsler, M., & Holzapfel, A. (2022). Decision Support in Horticultural Supply Chains: A Planning Problem Framework for Small and Medium-Sized Enterprises. Agriculture, 12(11), 1922. https://doi.org/10.3390/agriculture12111922