Quality Characteristics and Clinical Relevance of In-House 3D-Printed Customized Polyetheretherketone (PEEK) Implants for Craniofacial Reconstruction

Abstract

1. Introduction

2. Experimental Section

2.1. PEEK Filament and FFF PEEK 3D Printer

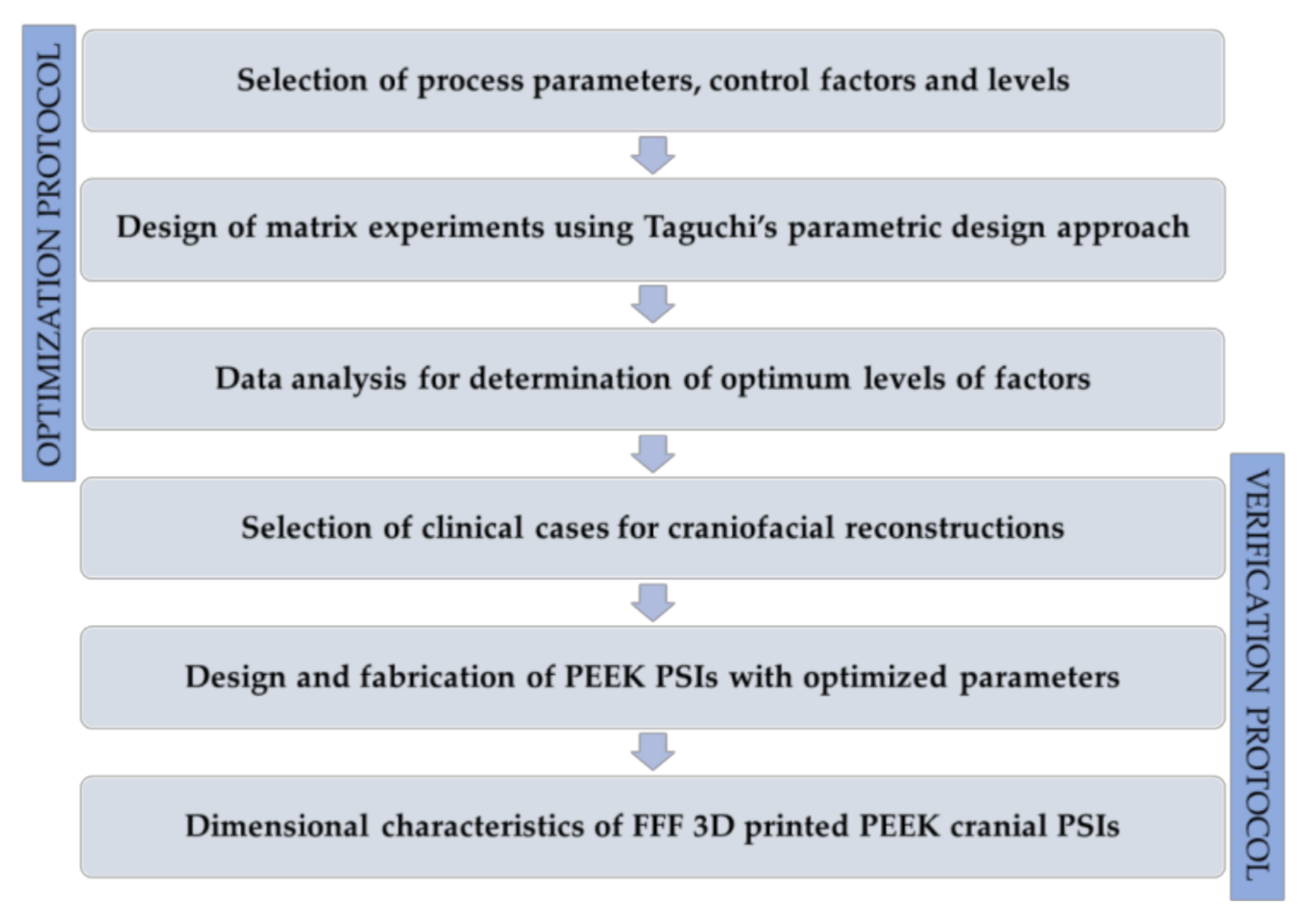

2.2. Optimization Protocol for FFF PEEK 3D Printing Process Parameters

2.2.1. Design of Experiments

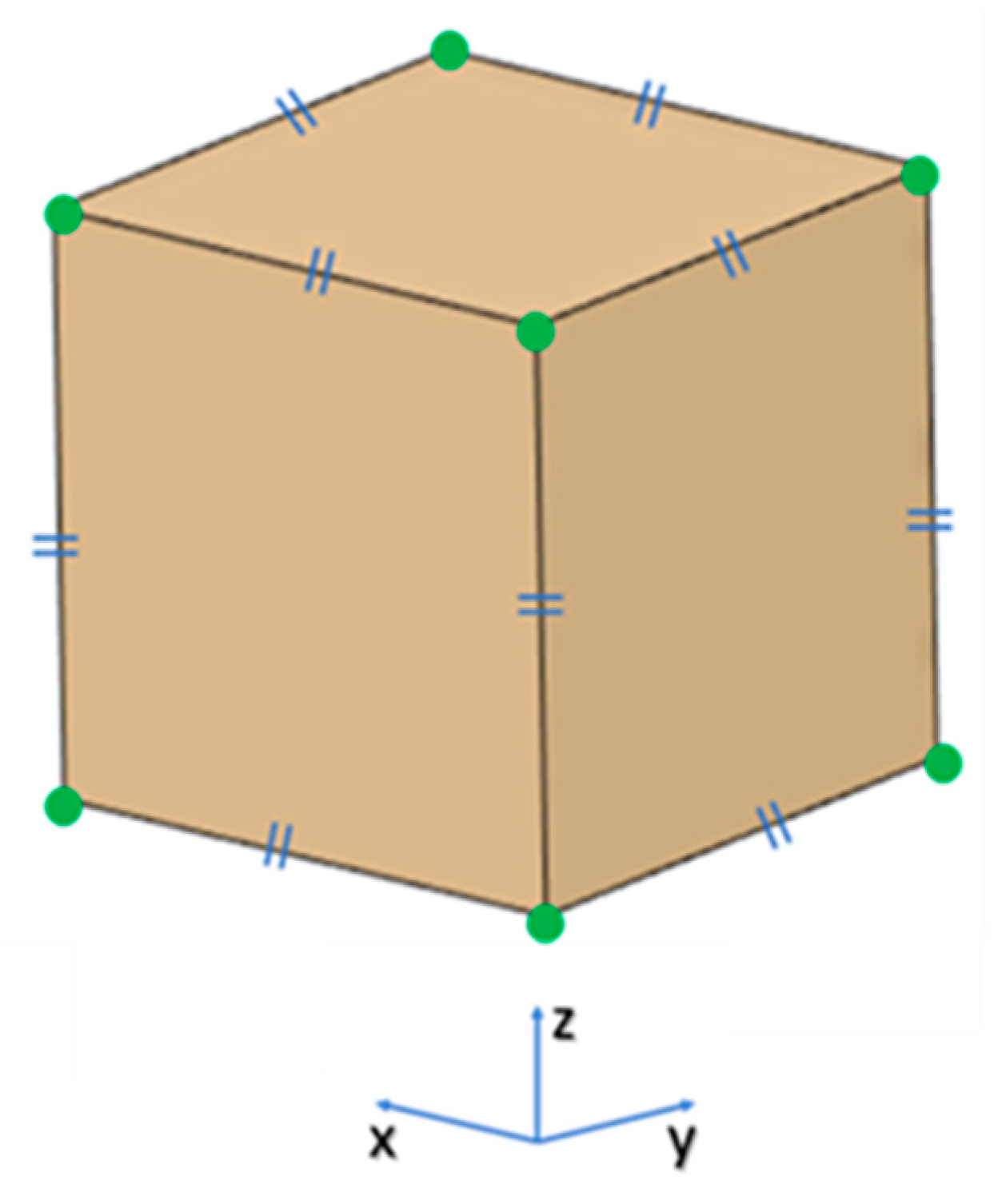

2.2.2. Fabrication of PEEK Test Objects

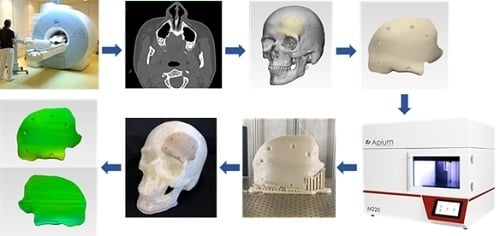

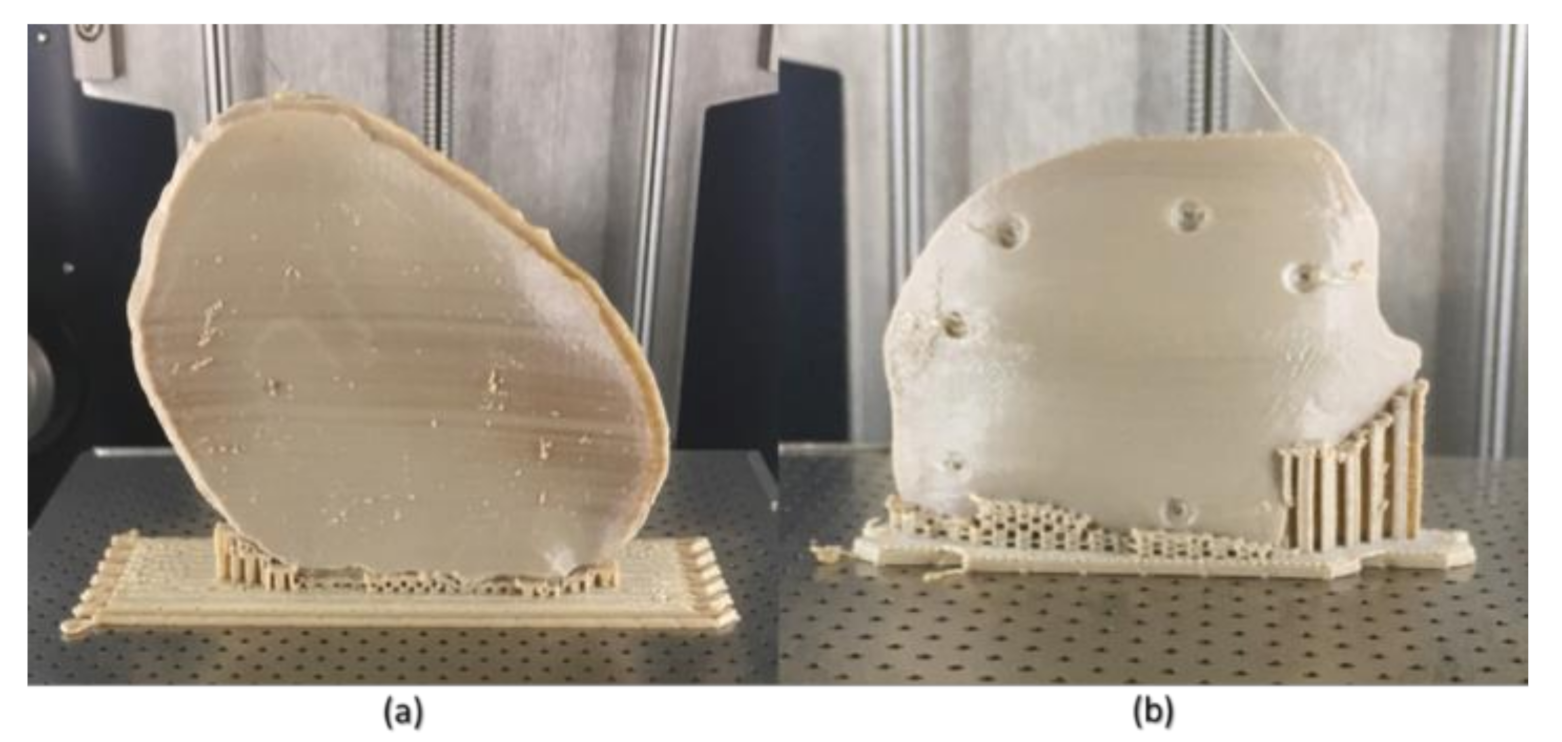

2.3. Verification Protocol for Dimensional Characteristics of FFF 3D Printed PEEK PSIs

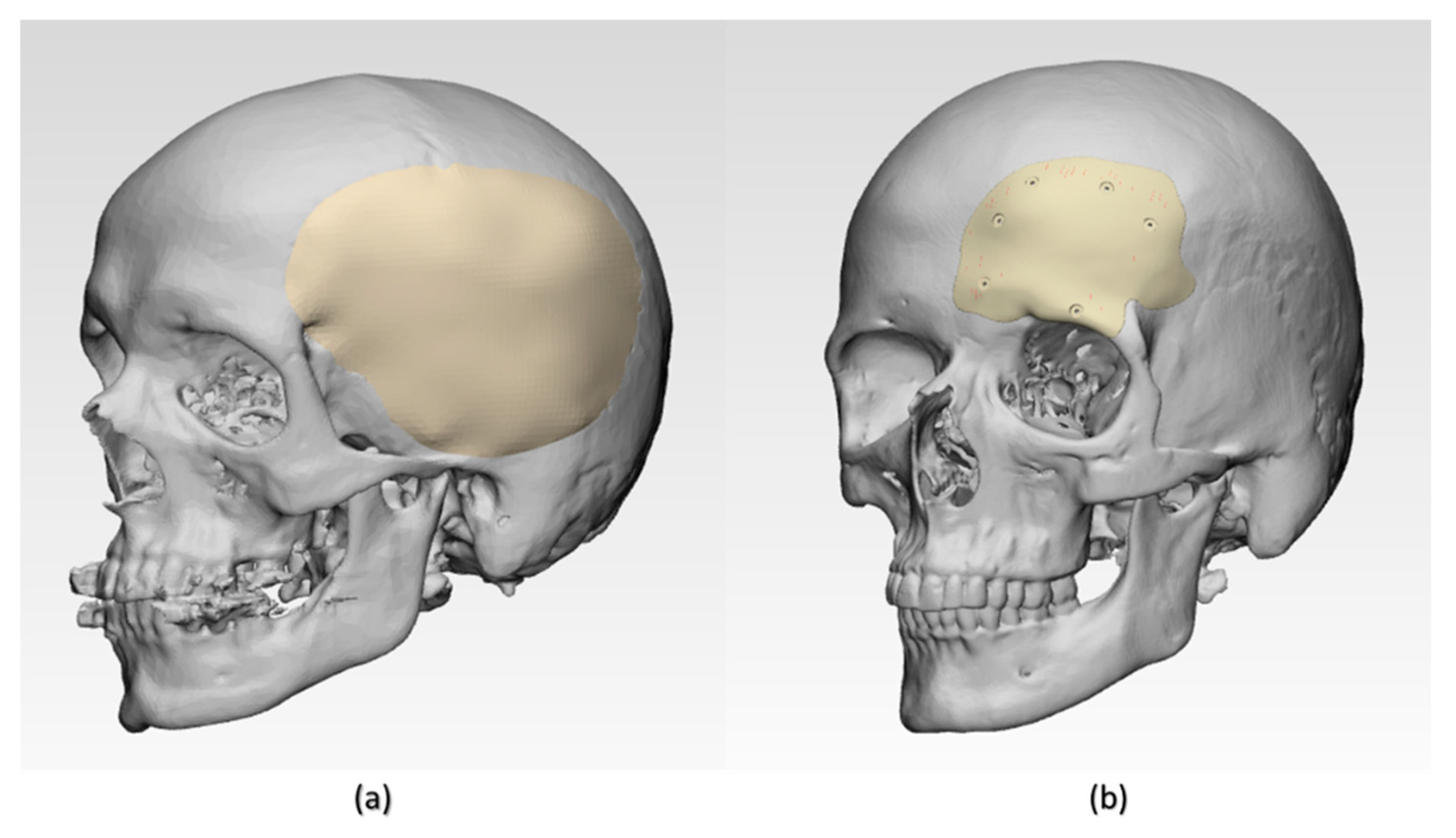

2.3.1. Data Acquisition and Computer-Aided Design (CAD) Modeling of Cranial PSIs

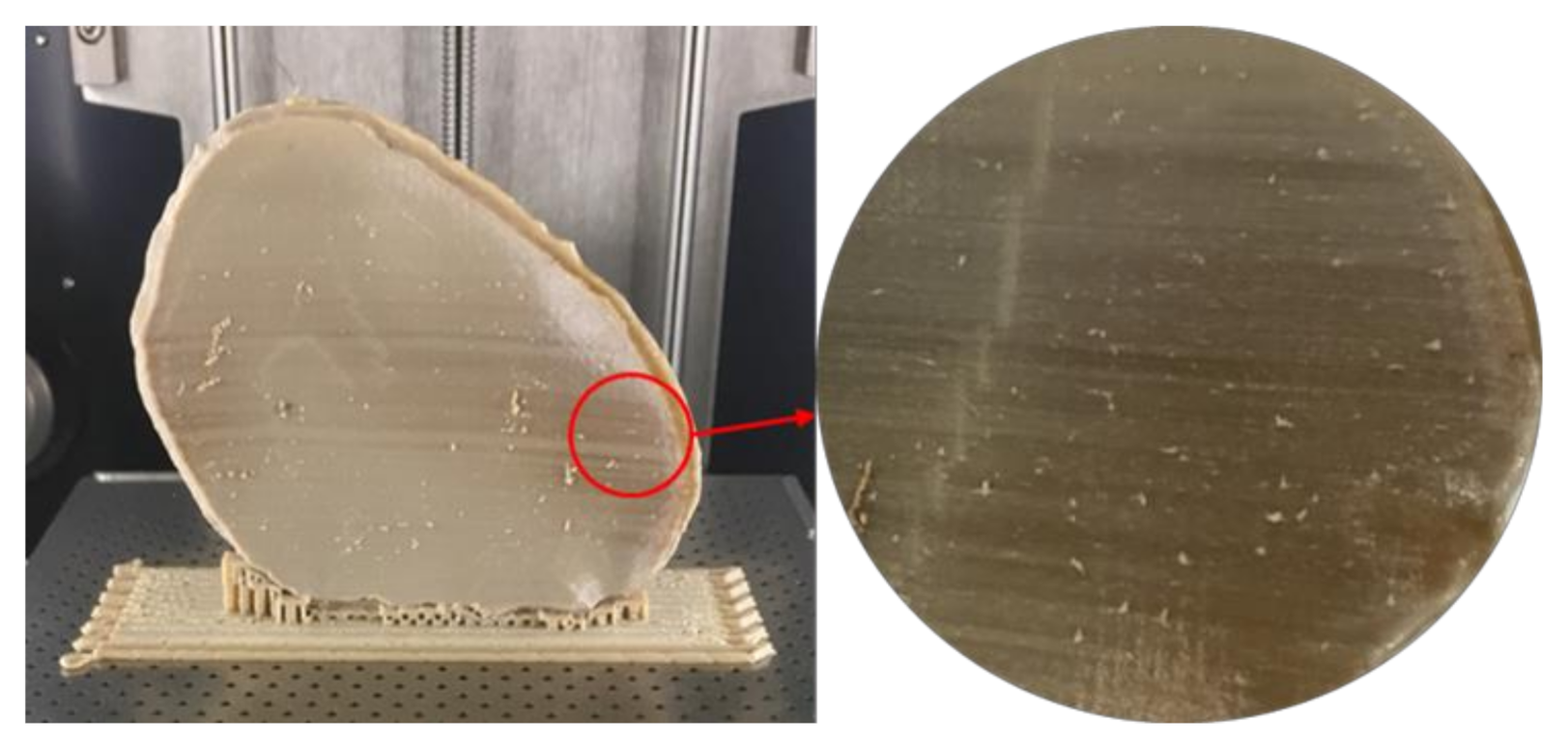

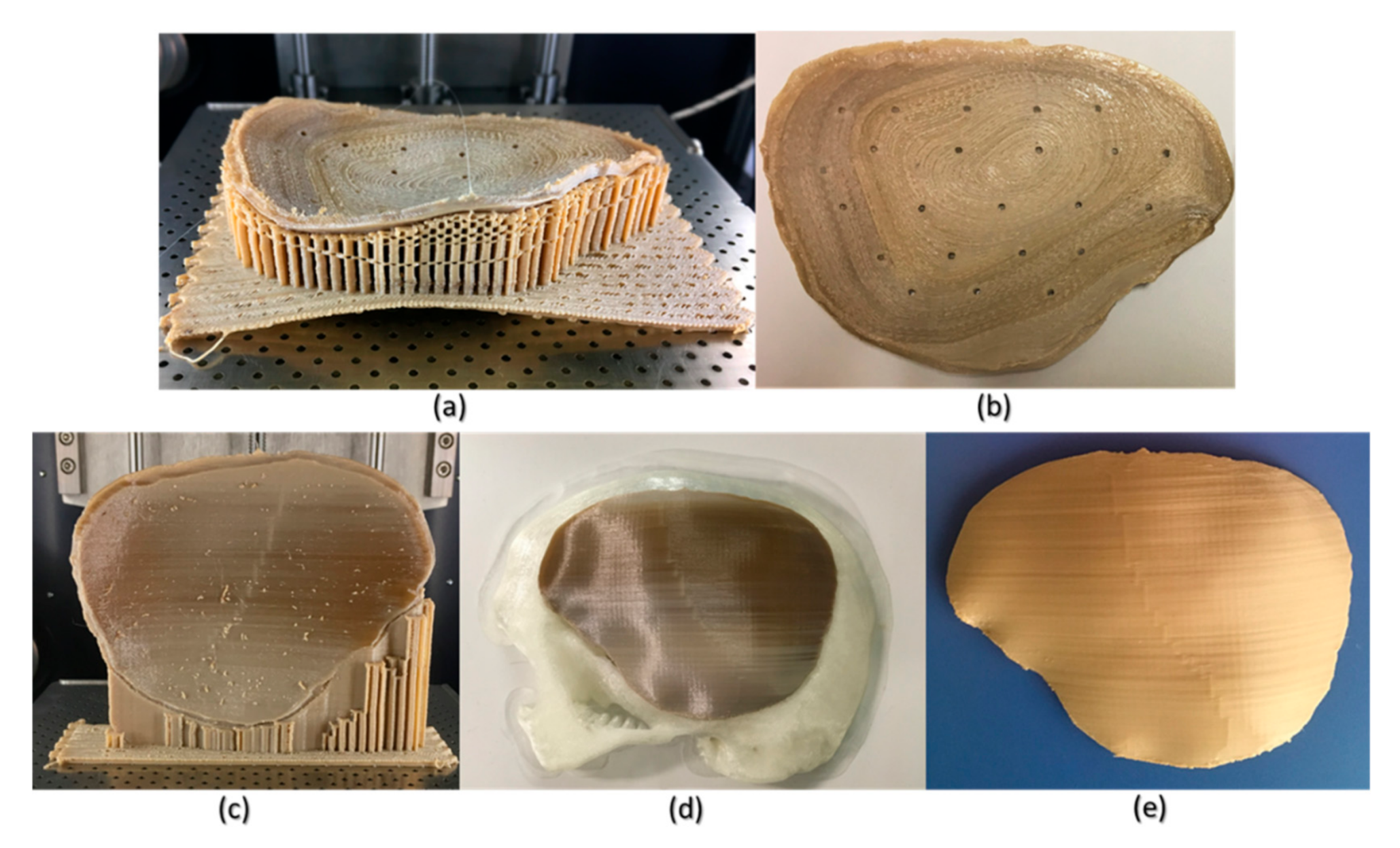

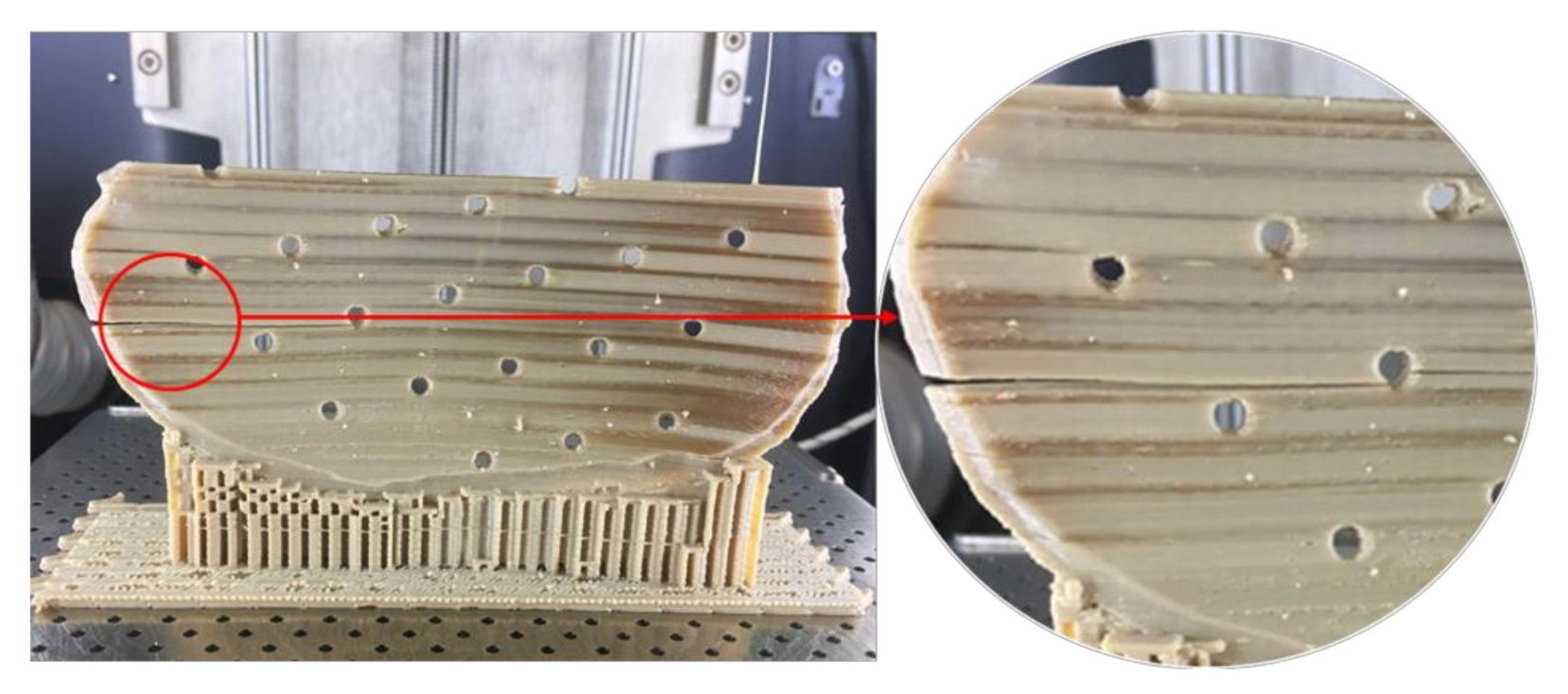

2.3.2. FFF PEEK 3D Printing and Digitization of Cranial PSIs

2.3.3. Registration Protocol of the 3D Surface Meshes

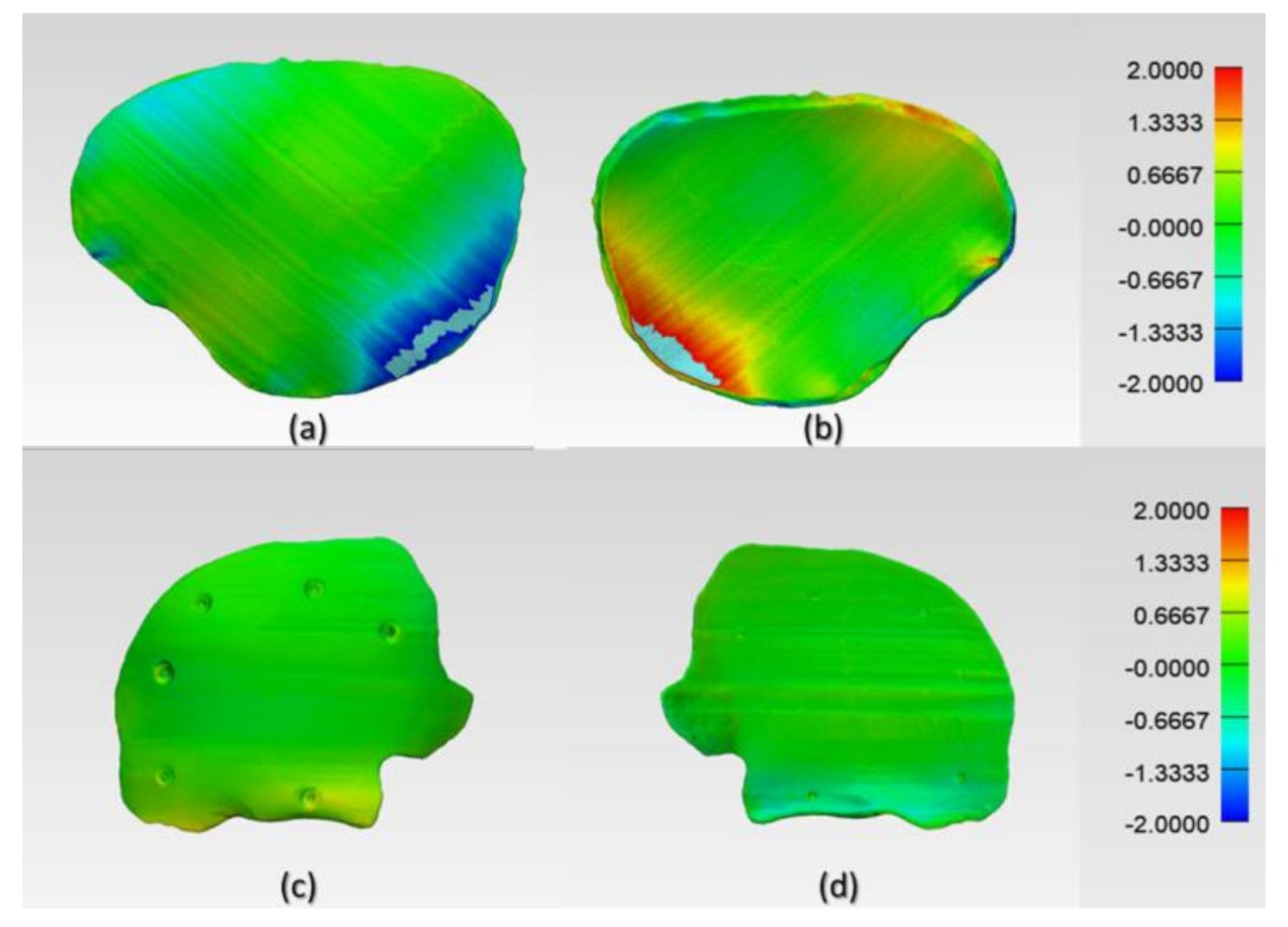

2.3.4. Dimensional Accuracy Assessment of FFF 3D Printed PEEK Cranial PSIs

2.4. Statistical Analysis

3. Results

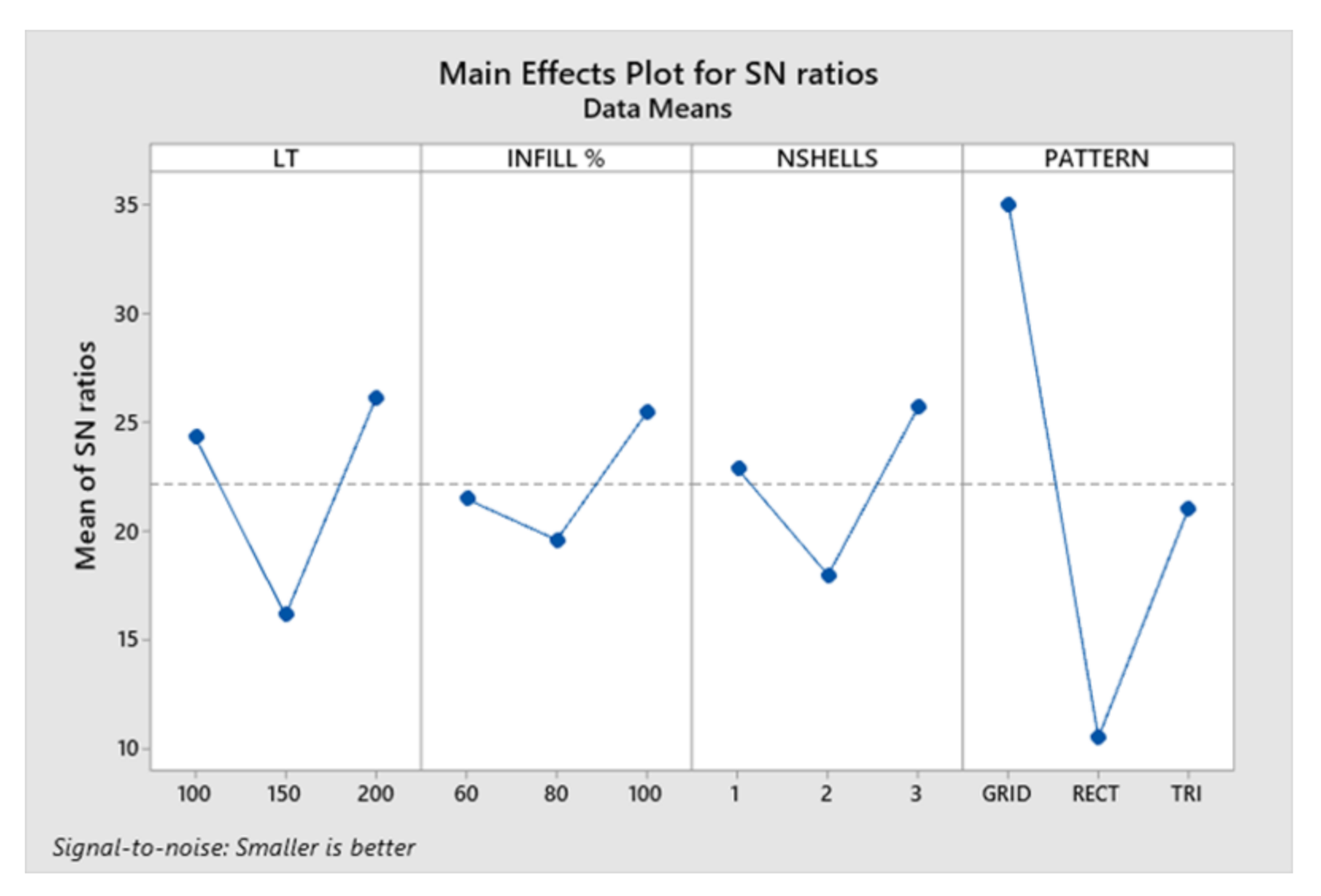

3.1. Optimized Nonthermal Printing Process Parameters

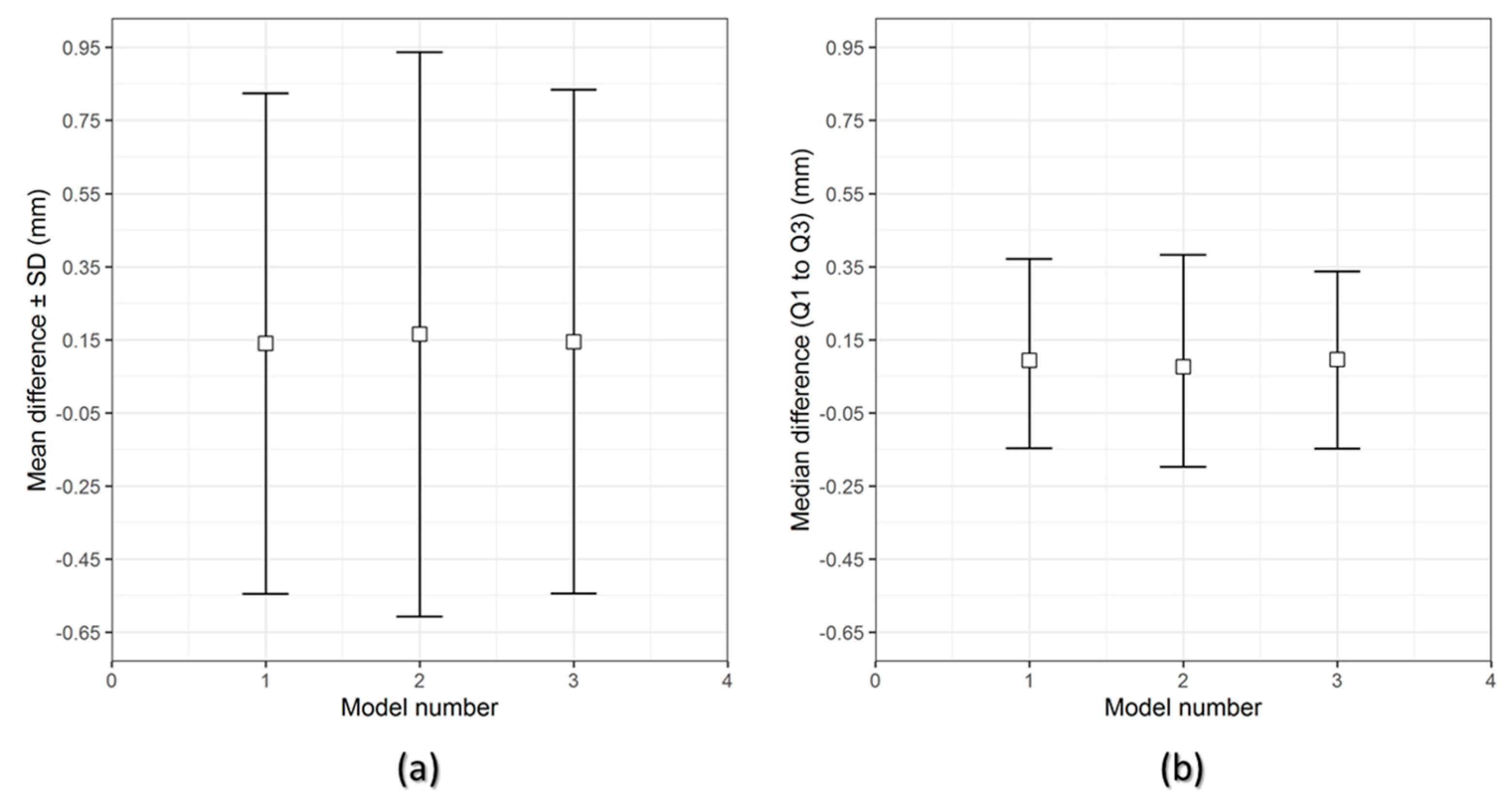

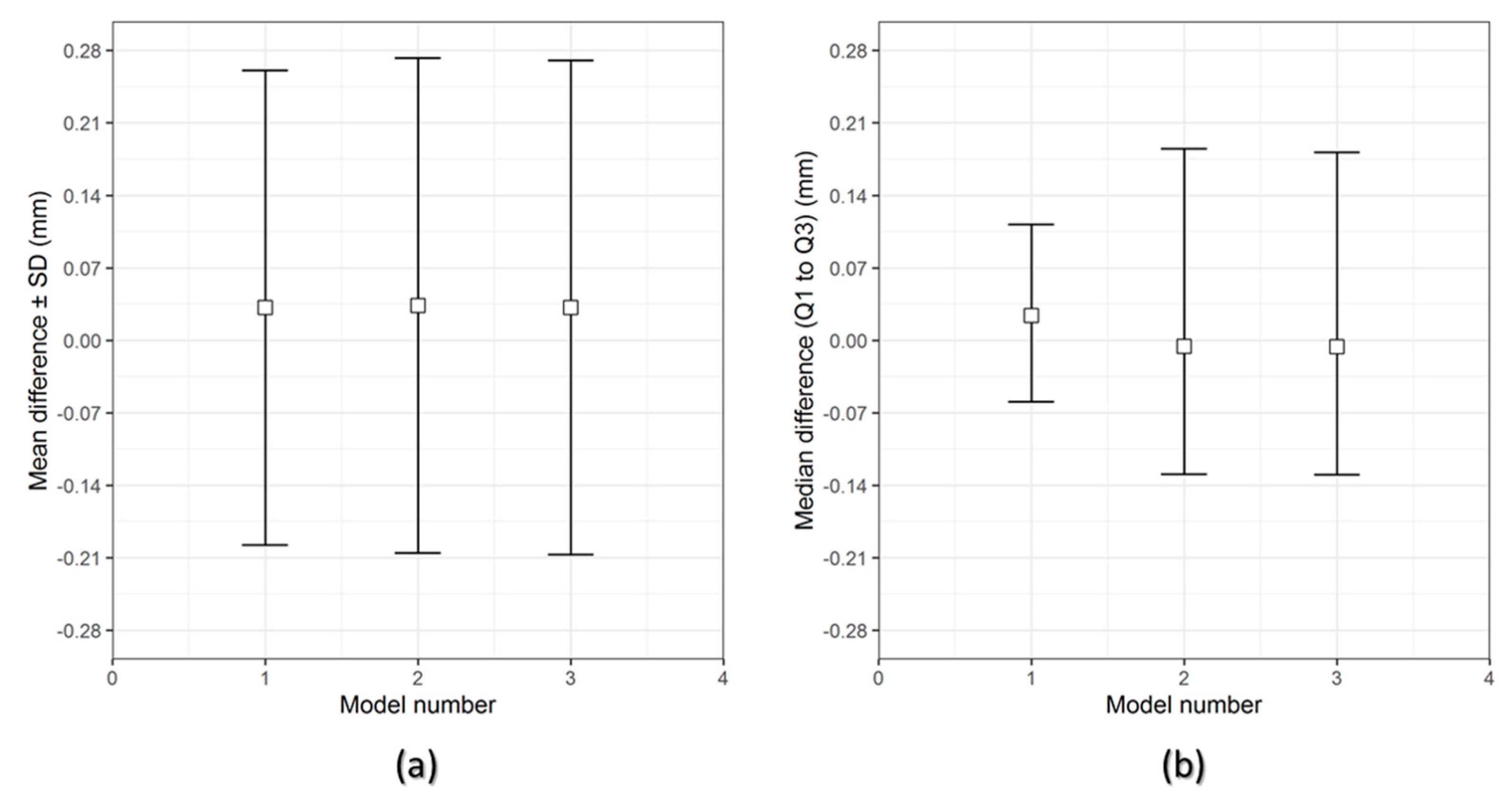

3.2. Deviation Analysis and Dimensional Accuracy Assessment of FFF 3D Printed PEEK Cranial PSIs

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| AAMI | Association for the Advancement of Medical Instrumentation |

| AM | Additive manufacturing |

| ANOVA | Analysis of variance |

| ASTM | American Society for Testing and Materials |

| CAD | Computer-aided design |

| CAM | Computer-aided manufacturing |

| CD | Change in the dimensions |

| CT | Computed Tomography |

| DICOM | Digital Imaging and Communications in Medicine |

| DOE | Design of experiments |

| EOS | Electro-Optical Systems |

| FFF | Fused filament fabrication |

| ICP | Iterative closest point |

| INFILL % | Infill rate |

| ISO | International Organization for Standardization |

| IQR | Interquartile range |

| LT | Layer thickness |

| MIMICS | Materialise Interactive Medical Image Control System |

| MSD | Mean square deviation |

| NSHELLS | Number of shells |

| PATTERN | Infill pattern |

| PEEK | Polyetheretherketone |

| POC | Point-of-care |

| PSIs | Patient-specific implants |

| RMS | Root mean square |

| SD | Standard deviation |

| SLS | Selective laser sintering |

| S/N | Signal-to-noise |

| STL | Standard Tessellation Language |

References

- Alkhaibary, A.; Alharbi, A.; Alnefaie, N.; Aloraidi, A.; Khairy, S. Cranioplasty: A Comprehensive Review of the History, Materials, Surgical Aspects, and Complications. World Neurosurg. 2020, 139, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.M.; Jung, H.; Skirboll, S. Materials used in cranioplasty: A history and analysis. Neurosurg. Focus 2014, 36, 19. [Google Scholar] [CrossRef] [PubMed]

- Msallem, B.; Beiglboeck, F.; Honigmann, P.; Jaquiéry, C.; Thieringer, F. Craniofacial reconstruction by a cost-efficient template-based process using 3D printing. Plast. Reconstr. Surg. Glob. Open 2017, 5, 1582. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Rodriguez, E.; Cebrián, J.L.; Nieto, M.J.; Del Castillo, J.L.; Hernández-Godoy, J.; Burgueño, M. Polyetheretherketone custom-made implants for craniofacial defects: Report of 14 cases and review of the literature. J. Craniomaxillofac. Surg. 2015, 43, 1232–1238. [Google Scholar] [CrossRef]

- Punchak, M.; Chung, L.K.; Lagman, C.; Bui, T.T.; Lazareff, J.; Rezzadeh, K.; Jarrahy, R.; Yang, I. Outcomes following polyetheretherketone (PEEK) cranioplasty: Systematic review and meta-analysis. J. Clin. Neurosci. 2017, 41, 30–35. [Google Scholar] [CrossRef]

- Scolozzi, P.; Martinez, A.; Jaques, B. Complex orbito-fronto-temporal reconstruction using computer-designed PEEK implant. J. Craniofac. Surg. 2007, 18, 224–228. [Google Scholar] [CrossRef]

- Alasseri, N.; Alasraj, A. Patient-specific implants for maxillofacial defects: Challenges and solutions. Maxillofac. Plast. Reconstr. Surg. 2020, 42, 15. [Google Scholar] [CrossRef]

- Feng, X.; Yu, H.; Liu, H.; Yu, X.; Feng, Z.; Bai, S.; Zhao, Y. Three-Dimensionally-Printed Polyether-Ether-Ketone Implant with a Cross-Linked Structure and Acid-Etched Microporous Surface Promotes Integration with Soft Tissue. Int. J. Mol. Sci. 2019, 20, 3811. [Google Scholar] [CrossRef]

- Thieringer, F.M.; Sharma, N.; Mootien, A.; Schumacher, R.; Honigmann, P. Patient Specific Implants from a 3D Printer—An Innovative Manufacturing Process for Custom PEEK Implants in Cranio-Maxillofacial Surgery. In Industrializing Additive Manufacturing, Proceedings of the Additive Manufacturing in Products and Applications—AMPA 2017, Zurich, Switzerland, 13–15 September 2017; Meboldt, M., Klahn, C., Eds.; Springer: Cham, Switzerland, 2018; pp. 308–315. [Google Scholar] [CrossRef]

- Schmidt, M.; Pohle, D.; Rechtenwald, T. Selective Laser Sintering of PEEK. Cirp Ann. 2007, 56, 205–208. [Google Scholar] [CrossRef]

- Ghita, O.R.; James, E.; Trimble, R.; Evans, K.E. Physico-chemical behaviour of Poly (Ether Ketone) (PEK) in High Temperature Laser Sintering (HT-LS). J. Mater. Process. Technol. 2014, 214, 969–978. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.E.; Ghita, O.R. Predicting processing parameters in high temperature laser sintering (HT-LS) from powder properties. Mater. Des. 2016, 105, 301–314. [Google Scholar] [CrossRef]

- Wang, Y.; Müller, W.D.; Rumjahn, A.; Schwitalla, A. Parameters Influencing the Outcome of Additive Manufacturing of Tiny Medical Devices Based on PEEK. Materials 2020, 13, 466. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M. Synthesis and Processing of PEEK for Surgical Implants; Elsevier Inc.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical Properties of Additively Manufactured PEEK Components Using Fused Filament Fabrication. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition. Advanced Manufacturing, Houston, TX, USA, 13–19 November 2015. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Ramakrishna, S. 3D printing of polyether-ether-ketone for biomedical applications. Eur. Polym. J. 2019, 114, 234–248. [Google Scholar] [CrossRef]

- Honigmann, P.; Sharma, N.; Okolo, B.; Popp, U.; Msallem, B.; Thieringer, F.M. Patient-Specific Surgical Implants Made of 3D Printed PEEK: Material, Technology, and Scope of Surgical Application. Biomed. Res. Int. 2018, 2018, 4520636. [Google Scholar] [CrossRef]

- Davis, R.; John, P. Application of Taguchi-Based Design of Experiments for Industrial Chemical Processes. Statistical Approaches with Emphasis on Design of Experiments Applied to Chemical Processes; Silva, V., Ed.; IntechOpen: London, UK, 2018; p. 137. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical Properties Optimization of Poly-Ether-Ether-Ketone via Fused Deposition Modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef]

- Petropolis, C.; Kozan, D.; Sigurdson, L. Accuracy of medical models made by consumer-grade fused deposition modelling printers. Plast. Surg. (Oakv) 2015, 23, 91–94. [Google Scholar] [CrossRef]

- Poukens, J.; Laeven, P.; Beerens, M.; Nijenhuis, G.; Sloten, J.V.; Stoelinga, P.; Kessler, P. A classification of cranial implants based on the degree of difficulty in computer design and manufacture. Int. J. Med. Robot. 2008, 4, 46–50. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, W.; Chen, J.; Yu, J.; Zhang, J.; Chen, J. The application of polyetheretherketone (PEEK) implants in cranioplasty. Brain Res. Bull. 2019, 153, 143–149. [Google Scholar] [CrossRef]

- O’eilly, E.B.; Barnett, S.; Madden, C.; Welch, B.; Mickey, B.; Rozen, S. Computed-tomography modeled polyether ether ketone (PEEK) implants in revision cranioplasty. J. Plast. Reconstr. Aesthet. Surg. 2015, 68, 329–338. [Google Scholar] [CrossRef]

- Thien, A.; King, N.K.; Ang, B.T.; Wang, E.; Ng, I. Comparison of polyetheretherketone and titanium cranioplasty after decompressive craniectomy. World Neurosurg. 2015, 83, 176–180. [Google Scholar] [CrossRef]

- Valentan, B.; Kadivnik, Z.; Brajlih, T.; Anderson, A.; Igor, D. Processing poly (ether etherKetone) on a 3d printer for thermoplastic modeling. Mater. Technol. 2013, 47, 715–721. [Google Scholar]

- Han, X.; Sharma, N.; Xu, Z.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Thieringer, F.M.; Spintzyk, S. An In Vitro Study of Osteoblast Response on Fused-Filament Fabrication 3D Printed PEEK for Dental and Cranio-Maxillofacial Implants. J. Clin. Med. 2019, 8, 771. [Google Scholar] [CrossRef] [PubMed]

- Chamo, D.; Msallem, B.; Sharma, N.; Aghlmandi, S.; Kunz, C.; Thieringer, F.M. Accuracy Assessment of Molded, Patient-Specific Polymethylmethacrylate Craniofacial Implants Compared to Their 3D Printed Originals. J. Clin. Med. 2020, 9, 832. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Jin, L.; Ball, J.; Bremner, T.; Sue, H.J. Crystallization behavior and morphological characterization of poly (ether ether ketone). Polymer 2014, 55, 5255–5265. [Google Scholar] [CrossRef]

- Conrad, T.L.; Jaekel, D.J.; Kurtz, S.M.; Roeder, R.K. Effects of the mold temperature on the mechanical properties and crystallinity of hydroxyapatite whisker-reinforced polyetheretherketone scaffolds. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 576–583. [Google Scholar] [CrossRef]

- Das, A.; Chatham, C.A.; Fallon, J.J.; Zawaski, C.E.; Gilmer, E.L.; Williams, C.B.; Bortner, M.J. Current understanding and challenges in high temperature additive manufacturing of engineering thermoplastic polymers. Addit. Manuf. 2020, 34, 101218. [Google Scholar] [CrossRef]

- Basgul, C.; Yu, T.; MacDonald, D.W.; Siskey, R.; Marcolongo, M.; Kurtz, S.M. Does annealing improve the interlayer adhesion and structural integrity of FFF 3D printed PEEK lumbar spinal cages? J. Mech. Behav. Biomed. Mater. 2020, 102, 103455. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Lethaus, B.; Poort ter Laak, M.; Laeven, P.; Beerens, M.; Koper, D.; Poukens, J.; Kessler, P. A treatment algorithm for patients with large skull bone defects and first results. J. Craniomaxillofac. Surg. 2011, 39, 435–440. [Google Scholar] [CrossRef] [PubMed]

- Christensen, A.; Rybicki, F.J. Maintaining safety and efficacy for 3D printing in medicine. 3D Print. Med. 2017, 3, 1. [Google Scholar] [CrossRef] [PubMed]

- Graham, J.; Peck, J. FDA Regulation of PEEK Implants PEEK Biomaterials Handbook, 2nd ed.; William Andrew Publishing, Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 431–445. [Google Scholar]

- Sharma, N.; Cao, S.; Msallem, B.; Kunz, C.; Brantner, P.; Honigmann, P.; Thieringer, F.M. Effects of Steam Sterilization on 3D Printed Biocompatible Resin Materials for Surgical Guides—An Accuracy Assessment Study. J. Clin. Med. 2020, 9, 1506. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Specifications |

|---|---|

| Number of extruders | 1 |

| Nozzle diameter | 0.4 mm |

| Build platform | 130 mm × 130 mm × 120 mm |

| Print head temperature | Up to 540 °C |

| Controlled airflow temperature | Up to 200 °C |

| Print bed material | 316L stainless steel |

| Machine operation software | Apium control software |

| Process Parameter | Symbol | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| Layer thickness | A | μm | 100 | 150 | 200 |

| Infill rate | B | % | 60 | 80 | 100 |

| Number of shells | C | – | 1 | 2 | 3 |

| Infill pattern | D | – | Grid | Rectilinear | Triangular |

| Experiment Number | Control Factors | |||

|---|---|---|---|---|

| Layer Thickness | Infill Rate | Number of Shells | Infill Pattern | |

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

| Parameters | Symbol | Level 1 | Level 2 | Level 3 | Rank |

|---|---|---|---|---|---|

| Layer thickness | A | 24.29 | 16.10 | 26.10 | 2 |

| Infill rate | B | 21.46 | 19.57 | 25.46 | 4 |

| Number of shells | C | 22.84 | 17.95 | 25.69 | 3 |

| Infill pattern | D | 35.04 | 10.48 | 20.97 | 1 |

| Group 1 | RMS (mm) | Group 2 | RMS (mm) |

|---|---|---|---|

| PSI 01 | 0.699 | PSI 01 | 0.232 |

| PSI 02 | 0.790 | PSI 02 | 0.241 |

| PSI 03 | 0.704 | PSI 03 | 0.241 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, N.; Aghlmandi, S.; Cao, S.; Kunz, C.; Honigmann, P.; Thieringer, F.M. Quality Characteristics and Clinical Relevance of In-House 3D-Printed Customized Polyetheretherketone (PEEK) Implants for Craniofacial Reconstruction. J. Clin. Med. 2020, 9, 2818. https://doi.org/10.3390/jcm9092818

Sharma N, Aghlmandi S, Cao S, Kunz C, Honigmann P, Thieringer FM. Quality Characteristics and Clinical Relevance of In-House 3D-Printed Customized Polyetheretherketone (PEEK) Implants for Craniofacial Reconstruction. Journal of Clinical Medicine. 2020; 9(9):2818. https://doi.org/10.3390/jcm9092818

Chicago/Turabian StyleSharma, Neha, Soheila Aghlmandi, Shuaishuai Cao, Christoph Kunz, Philipp Honigmann, and Florian M. Thieringer. 2020. "Quality Characteristics and Clinical Relevance of In-House 3D-Printed Customized Polyetheretherketone (PEEK) Implants for Craniofacial Reconstruction" Journal of Clinical Medicine 9, no. 9: 2818. https://doi.org/10.3390/jcm9092818

APA StyleSharma, N., Aghlmandi, S., Cao, S., Kunz, C., Honigmann, P., & Thieringer, F. M. (2020). Quality Characteristics and Clinical Relevance of In-House 3D-Printed Customized Polyetheretherketone (PEEK) Implants for Craniofacial Reconstruction. Journal of Clinical Medicine, 9(9), 2818. https://doi.org/10.3390/jcm9092818