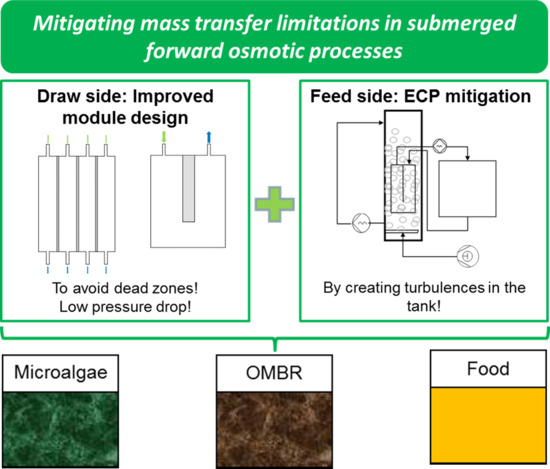

Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations

Abstract

1. Introduction

2. Materials and Methods

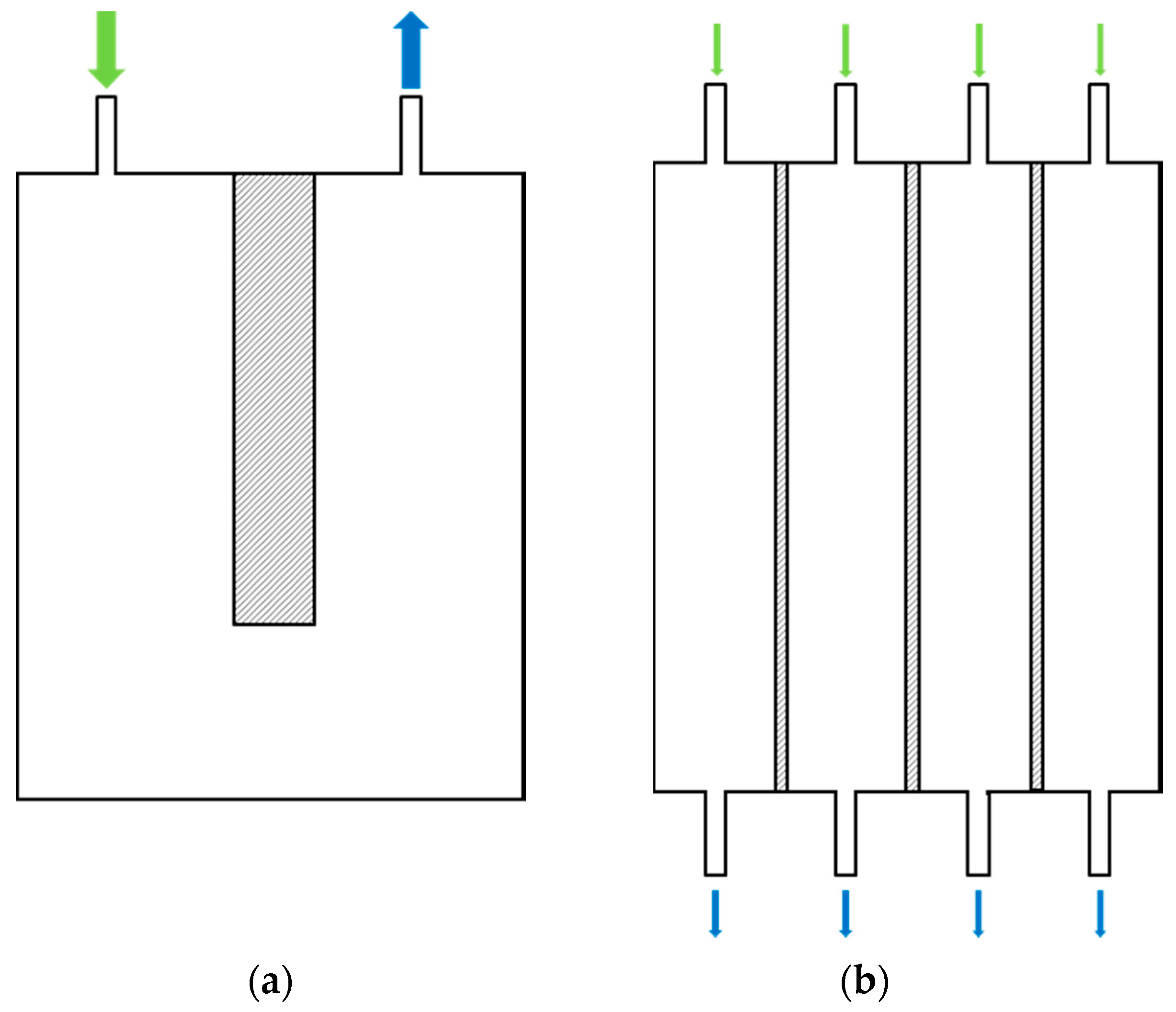

2.1. Membranes and Modules

- U-shape thin-spacer module: U-shape draw channel design with draw channel spacers containing a 0.76-mm-thickness diamond-type polypropylene mesh (Figure 2a).

- Straight large-mesh spacer module: composed of 4 parallel channels containing a 1.2-mm-thickness diamond-type polypropylene mesh spacer (Figure 2b).

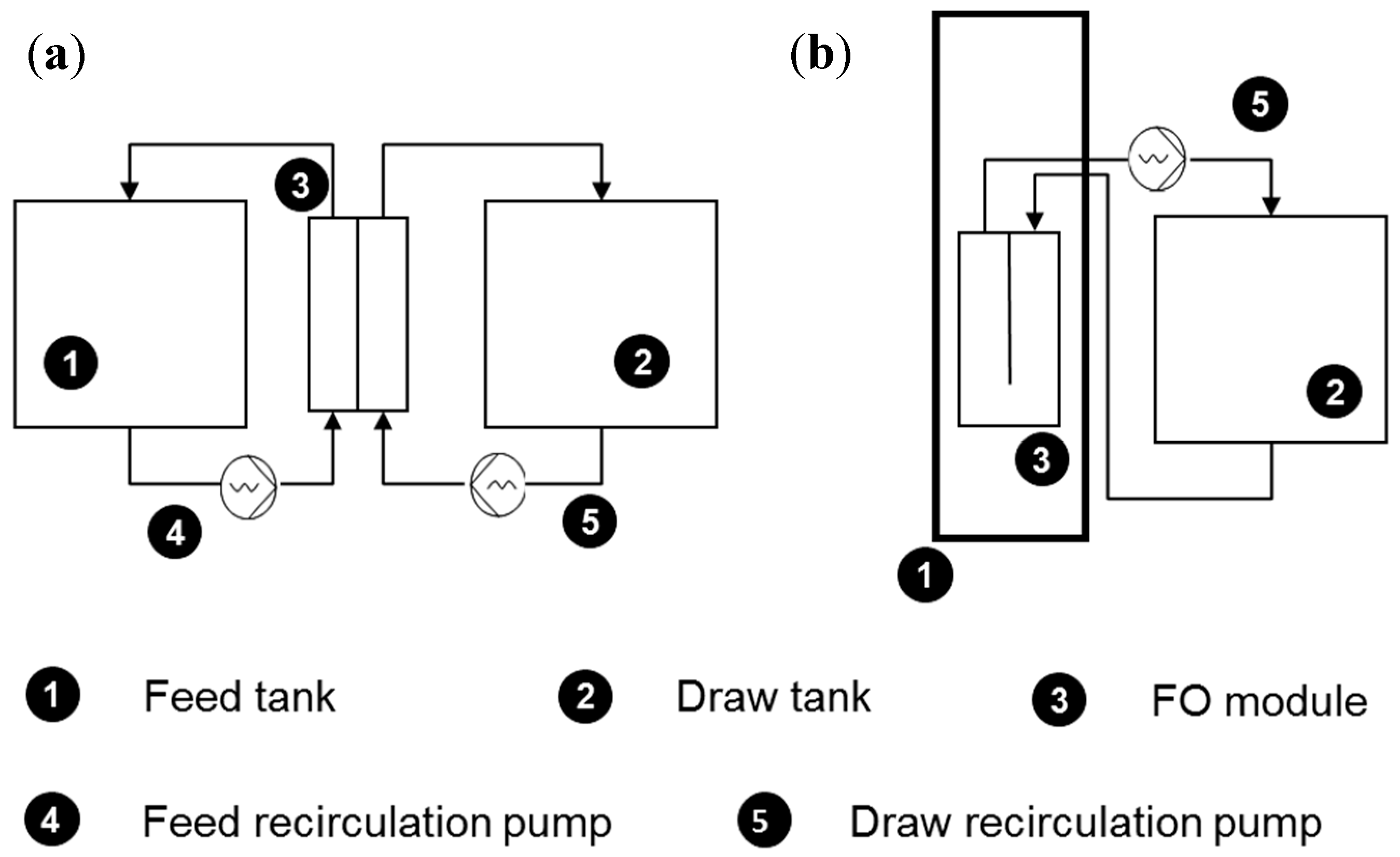

2.2. Cross Flow Cell Setup

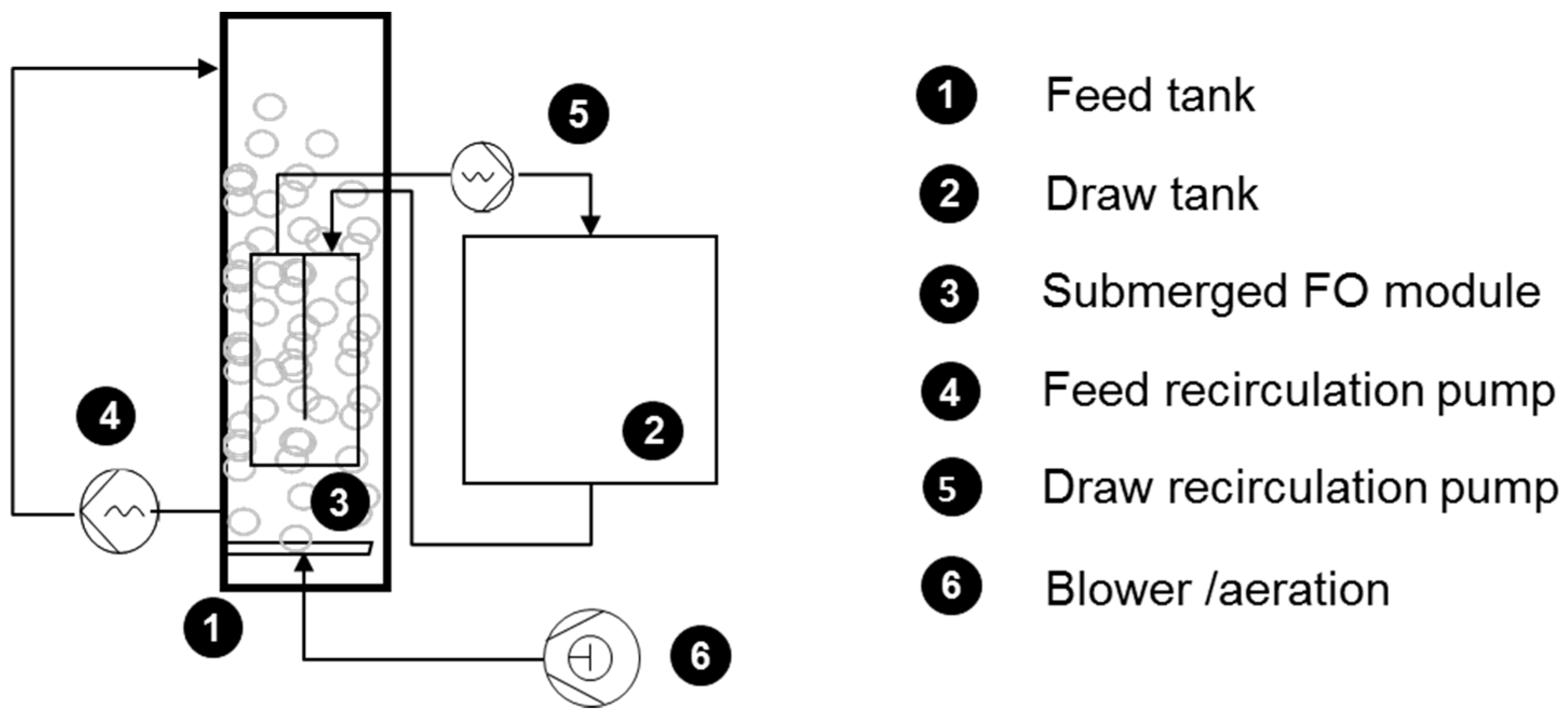

2.3. Submerged Plate Lab Setup

2.4. Submerged Plate Pilot Setup

2.5. Water Flux Modelling

3. Results

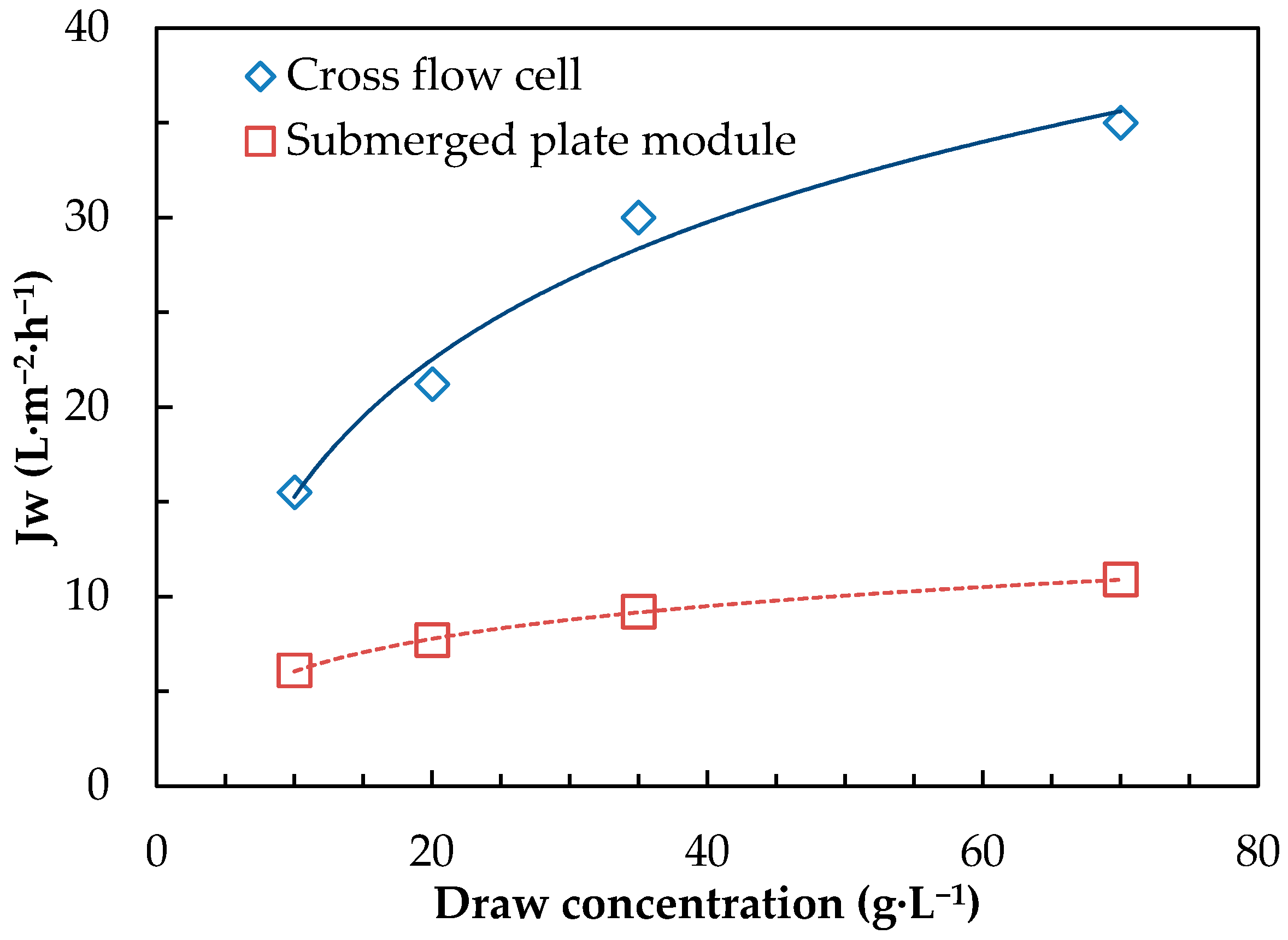

3.1. Initial Test

- positive pressure pumping (feed and draw) for CFC versus negative pressure pumping for submerged plates (draw)

- straight draw channel for CFC versus U-shape design for plates

- different CFV

- optimized feed cross flow channel for CFC versus an unstirred submerged system for plates

3.2. Draw Side Limitations

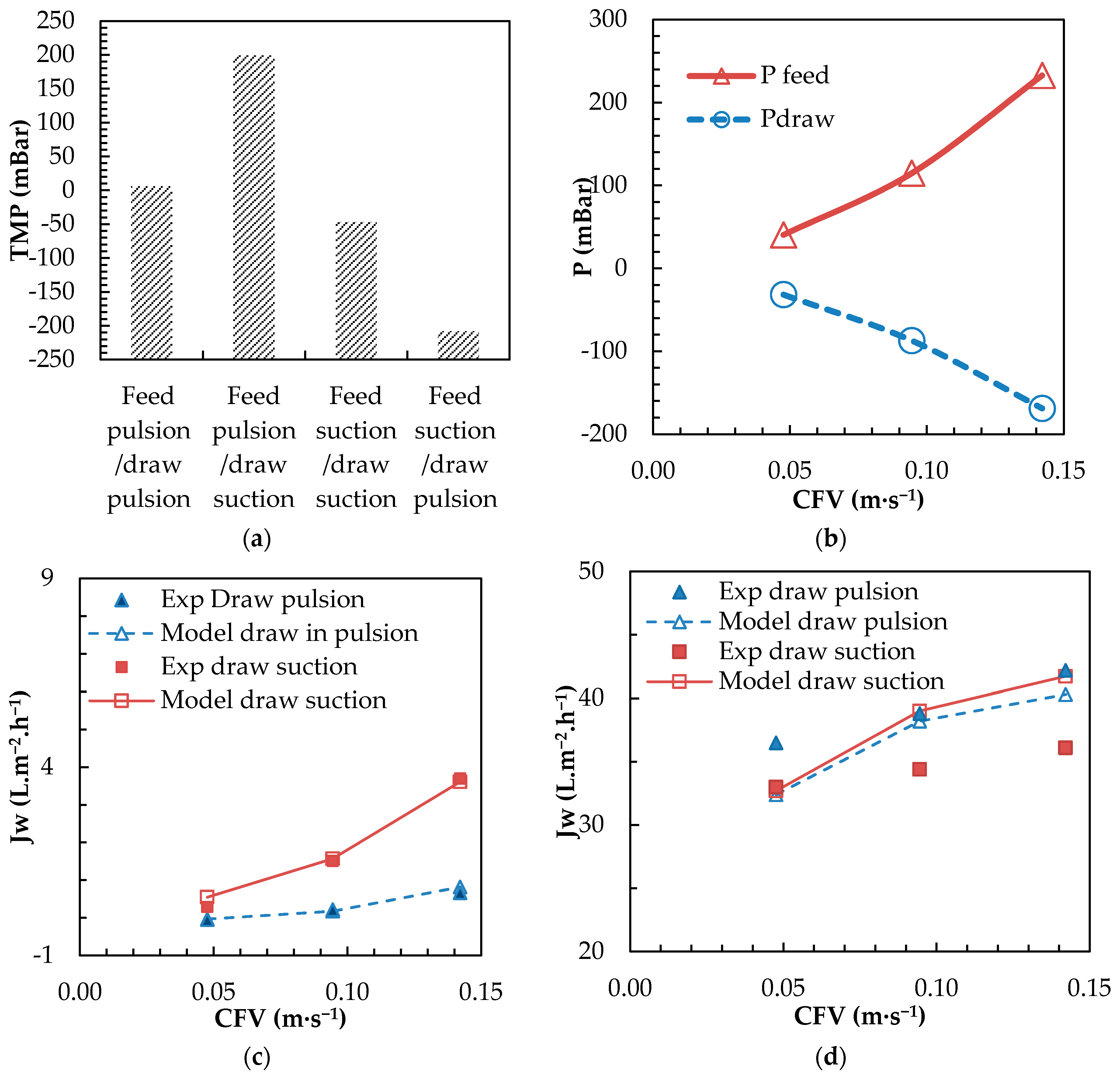

3.2.1. Positive (Pulsion) vs. Negative (Vacuum) Draw Circulation (Using the CFC Setup)

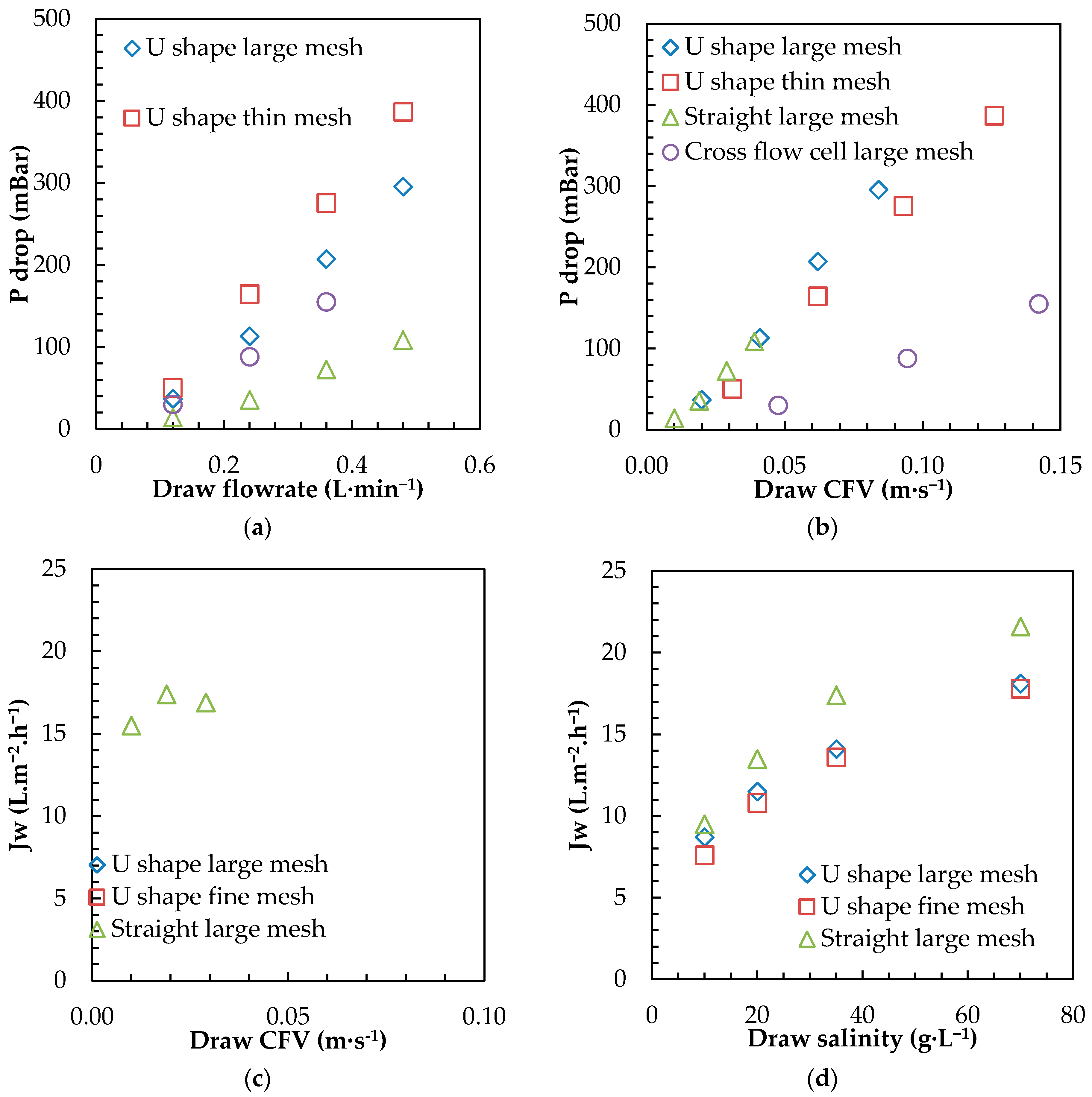

3.2.2. Draw Channel Design (Submerged Plate)

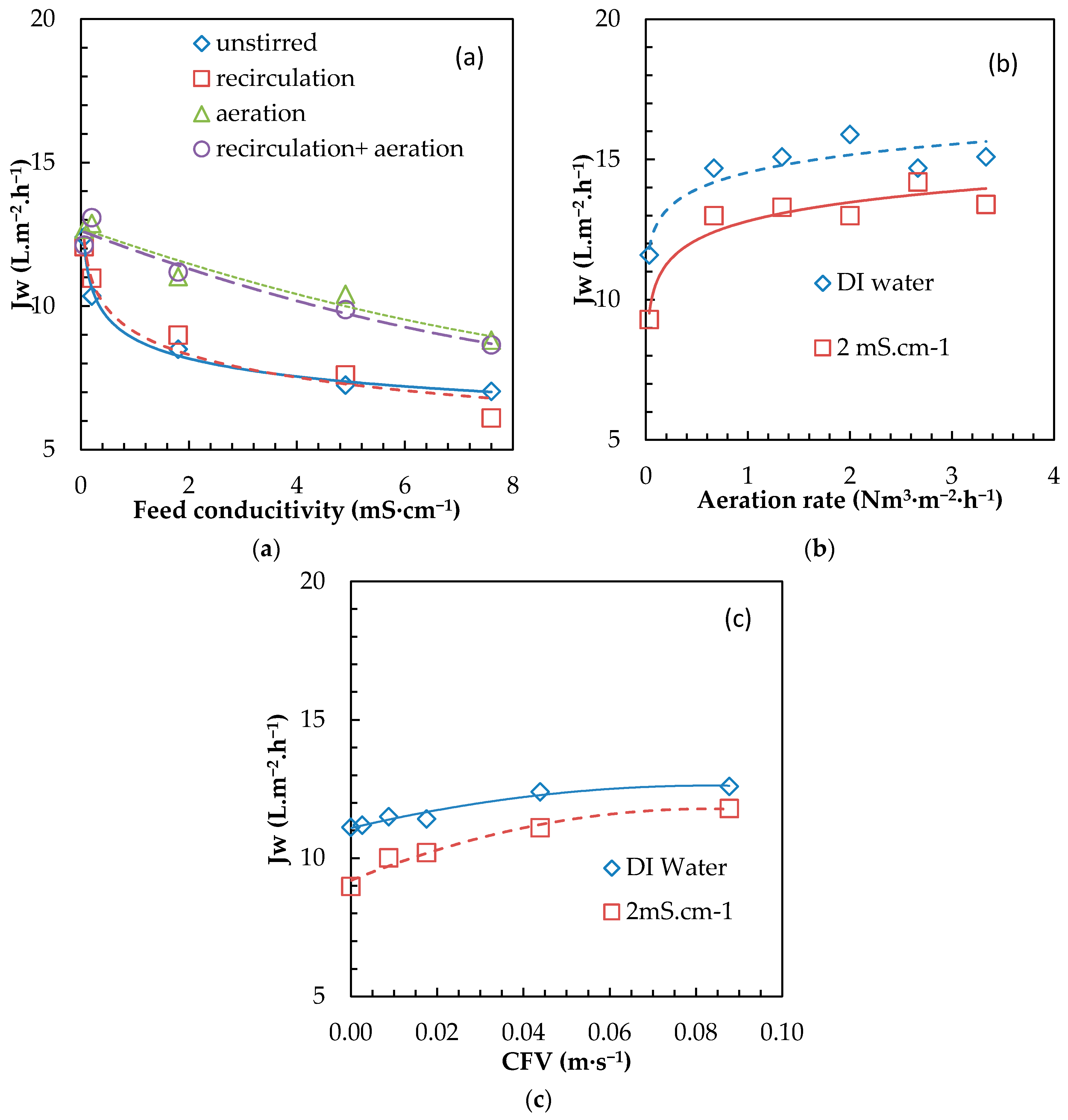

3.3. Feed (Submerged) Side Limitations

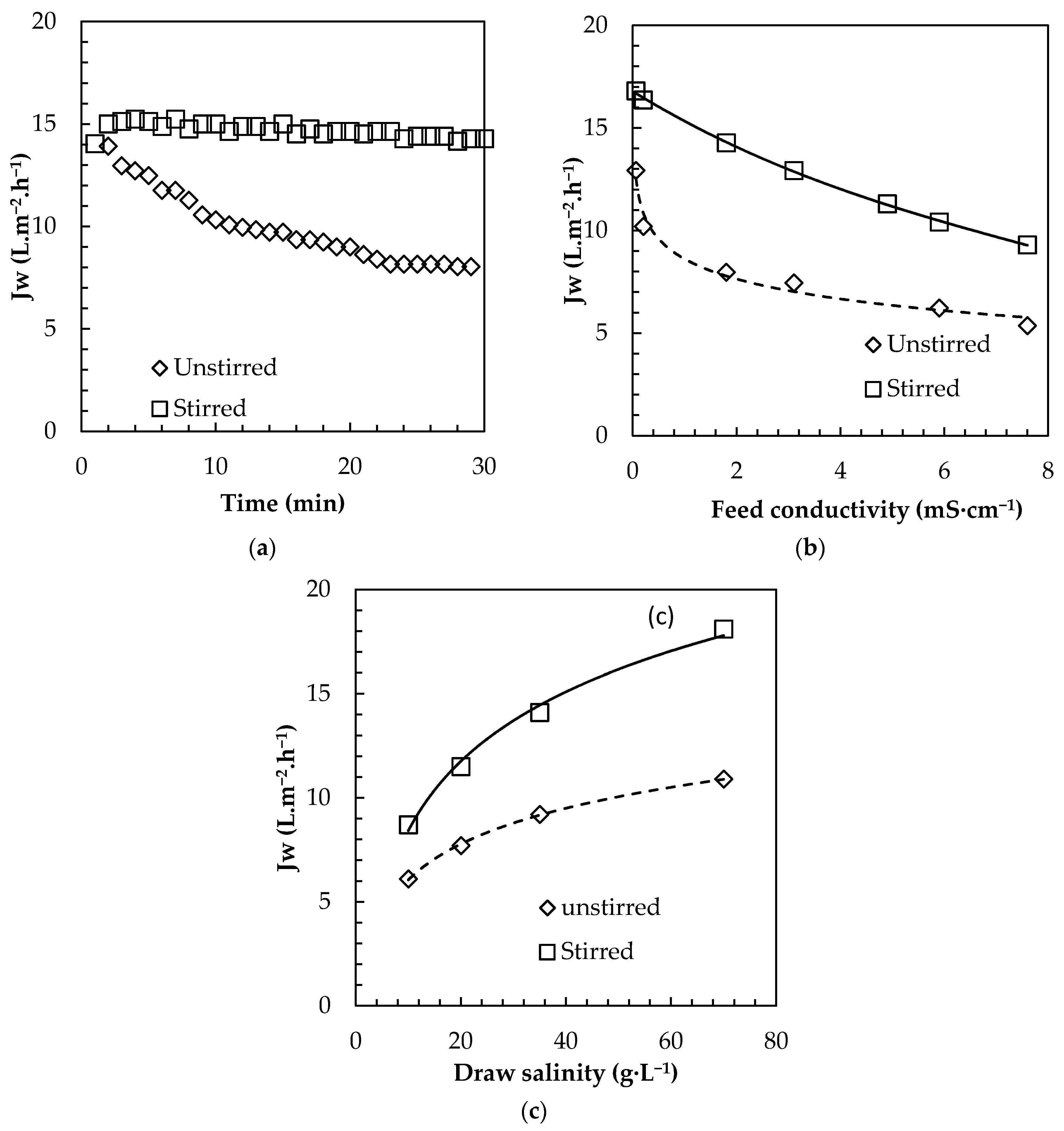

3.3.1. External Concentration Polarization Evidence (Stirred Versus Unstirred Feed Tank)

3.3.2. External Concentration Polarization Mitigation with Air Scouring and Feed Tank Recirculation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Beaudry, E.G.; Herron, J.R.; Peterson, S. Direct Osmosis Concentration of Waste Water: Final Report; Osmotek Inc.: Corvallis, OR, USA, 1999. [Google Scholar]

- York, R.J.; Thiel, R.S.; Beaudry, E.G. Full-Scale Experience of Direct Osmosis Concentration Applied to Leachate Management; S. Margherita di Pala: Cagliari, Italy, 1999. [Google Scholar]

- Cath, T.Y.; Childress, A.E.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Chekli, L.; Phuntsho, S.; Kim, J.E.; Kim, J.; Choi, J.Y.; Choi, J.S.; Kim, S.; Kim, J.H.; Hong, S.; Sohn, J.; et al. A comprehensive review of hybrid forward osmosis systems: Performance, applications and future prospects. J. Membr. Sci. 2016, 497, 430–449. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, R.A.; Comas, J.; Rodriguez, R.I.; Clech, L.P. Efficiently Combining Water Reuse and Desalination through Forward Osmosis-Reverse Osmosis (FO-RO) Hybrids: A Critical Review. Membranes 2016, 6, 37. [Google Scholar] [CrossRef] [PubMed]

- Chekli, L.; Phuntsho, S.; Shon, H.K.; Vigneswaran, S.; Kandasamy, J.; Chanan, A. A review of draw solutes in forward osmosis process and their use in modern applications. Desalin. Water Treat. 2012, 43, 167–184. [Google Scholar] [CrossRef]

- Qin, J.J.; Lay, W.C.L.; Kekre, K.A. Recent developments and future challenges of forward osmosis for desalination: A review. Desalin. Water Treat. 2012, 39, 123–136. [Google Scholar] [CrossRef]

- Jiao, B.; Cassano, A.; Drioli, E. Recent advances on membrane processes for the concentration of fruit juices: A review. J. Food Eng. 2004, 63, 303–324. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Verliefde, A.R.D.; Roest, K.; Rietveld, L.C.; Cornelissen, E.R. Forward osmosis for application in wastewater treatment: A review. Water Res. 2014, 58, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Coday, B.D.; Yaffe, B.G.M.; Xu, P.; Cath, T.Y. Rejection of trace organic compounds by forward osmosis membranes: A literature review. Environ. Sci. Technol. 2014, 48, 3612–3624. [Google Scholar] [CrossRef]

- She, Q.; Wang, R.; Fane, A.G.; Tang, C.Y. Membrane fouling in osmotically driven membrane processes: A review. J. Membr. Sci. 2016, 499, 201–233. [Google Scholar] [CrossRef]

- Klaysom, C.; Cath, T.Y.; Depuydt, T.; Vankelecom, I.F.J. Forward and pressure retarded osmosis: Potential solutions for global challenges in energy and water supply. Chem. Soc. Rev. 2013, 42, 6959–6989. [Google Scholar] [CrossRef] [PubMed]

- Attarde, D.; Jain, M.; Chaudhary, K.; Gupta, S.K. Osmotically driven membrane processes by using a spiral wound module—Modeling, experimentation and numerical parameter estimation. Desalination 2015, 361, 81–94. [Google Scholar] [CrossRef]

- Kim, J.; Blandin, G.; Phuntsho, S.; Verliefde, A.; Clech, L.P.; Shon, H. Practical considerations for operability of an 8″ spiral wound forward osmosis module: Hydrodynamics, fouling behaviour and cleaning strategy. Desalination 2017, 404, 249–258. [Google Scholar] [CrossRef]

- Kim, J.E.; Phuntsho, S.; Lotfi, F.; Shon, H.K. Investigation of pilot-scale 8040 FO membrane module under different operating conditions for brackish water desalination. Desalin. Water Treat. 2015, 53, 2782–2791. [Google Scholar] [CrossRef]

- Kim, Y.C.; Park, S.J. Experimental study of a 4040 spiral-wound forward-osmosis membrane module. Environ. Sci. Technol. 2011, 45, 7737–7745. [Google Scholar] [CrossRef] [PubMed]

- Lian, B.; Blandin, G.; Leslie, G.; Clech, L.P. Impact of module design in forward osmosis and pressure assisted osmosis: An experimental and numerical study. Desalination 2018, 426, 108–117. [Google Scholar] [CrossRef]

- Jim, Y.; Lee, J.H.; Kim, Y.C.; Lee, K.H.; Park, I.S.; Park, S.J. Operation and simulation of pilot-scale forward osmosis desalination with ammonium bicarbonate. Chem. Eng. Res. Des. 2015, 94, 390–395. [Google Scholar]

- Ginnis, M.R.L.; Hancock, N.T.; Slepowron, N.M.S.; Gurgan, M.G.D. Pilot demonstration of the NH3/CO2 forward osmosis desalination process on high salinity brines. Desalination 2013, 312, 67–74. [Google Scholar]

- Spier, M.R.; Vandenberghe, L.P.D.S.; Medeiros, A.B.P.; Soccol, C.R. Application of different types of bioreactors in bioprocesses. In Bioreactors: Design, Properties and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2011; pp. 53–87. [Google Scholar]

- Larretche, L.M.; Jin, X. Microalgae (Scenedesmus obliquus) dewatering using forward osmosis membrane: Influence of draw solution chemistry. Algal Res. 2016, 15, 1–8. [Google Scholar] [CrossRef]

- Larretche, L.M.; Jin, X. Microalgal biomass dewatering using forward osmosis membrane: Influence of microalgae species and carbohydrates composition. Algal Res. 2017, 23, 12–19. [Google Scholar] [CrossRef]

- Buckwalter, P.; Embaye, T.; Gormly, S.; Trent, J.D. Dewatering microalgae by forward osmosis. Desalination 2013, 312, 19–22. [Google Scholar] [CrossRef]

- Petrotos, K.B.; Lazarides, H.N. Osmotic concentration of liquid foods. J. Food Eng. 2001, 49, 201–206. [Google Scholar] [CrossRef]

- Anna, S.V.; Marczak, L.D.F.; Tessaro, I.C. Membrane concentration of liquid foods by forward osmosis: Process and quality view. J. Food Eng. 2012, 111, 483–489. [Google Scholar]

- Blandin, G.; Comas, J.; Roda, R.I. Potential and Challenges of Osmotic Membrane Bioreactor (OMBR) for (Potable) Water Reuse: A Pilot Scale Study. In Frontiers International Conference on Wastewater Treatment and Modelling; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Blandin, G.; Clech, L.P.; Cornelissen, E.R.; Verliefde, A.; Comas, J.; Roda, R.I. Can osmotic membrane bioreactor be a realistic solution for water reuse? NPJ Clean Water 2018, in press. [Google Scholar] [CrossRef]

- Cornelissen, E.R.; Harmsen, D.; Beerendork, E.F.; Qin, J.J.; Oo, H.; Korte, K.F.D.; Kappelhof, J.W.M.N. The innovative osmotic membrane bioreactor (OMBR) for reuse of wastewater. Water Sci. Technol. 2011, 63, 1557–1565. [Google Scholar] [CrossRef] [PubMed]

- Holloway, R.W.; Achilli, A.; Cath, T.Y. The osmotic membrane bioreactor: A critical review. Environ. Sci. Water Res. Technol. 2015, 1, 581–605. [Google Scholar] [CrossRef]

- Facundo, L.M.J.; Cabezas, S.J.L.; Roca, M.J.A.; Vela, V.M.C.; Piá, B.A.; Hernández, D.S. A study of the osmotic membrane bioreactor process using a sodium chloride solution and an industrial effluent as draw solutions. Chem. Eng. J. 2017, 322, 603–610. [Google Scholar] [CrossRef]

- Luo, W.; Hai, F.I.; Kang, J.; Price, W.E.; Nghiem, L.D.; Elimelech, M. The role of forward osmosis and microfiltration in an integrated osmotic-microfiltration membrane bioreactor system. Chemosphere 2015, 136, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Hai, F.I.; Price, W.E.; Guo, W.; Ngo, H.H.; Yamamoto, K.; Nghiem, L.D. High retention membrane bioreactors: Challenges and opportunities. Bioresour. Technol. 2014, 167, 539–546. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Phan, H.V.; Xie, M.; Hai, F.I.; Price, W.E.; Elimelech, M.; Nghiem, L.D. Osmotic versus conventional membrane bioreactors integrated with reverse osmosis for water reuse: Biological stability, membrane fouling, and contaminant removal. Water Res. 2017, 109, 122–134. [Google Scholar] [CrossRef] [PubMed]

- Judd, S. The MBR Book: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment; Elsevier: New York, NY, USA, 2010. [Google Scholar]

- Zhao, F.; Chu, H.; Tan, X.; Zhang, Y.; Yang, L.; Zhou, X.; Zhao, J. Comparison of axial vibration membrane and submerged aeration membrane in microalgae harvesting. Bioresour. Technol. 2016, 208, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhang, M.; Wang, A.; Lin, H.; Hong, H.; Lu, X. Osmotic pressure effect on membrane fouling in a submerged anaerobic membrane bioreactor and its experimental verification. Bioresour. Technol. 2012, 125, 97–101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Cui, Z.; Field, R.W. Effect of bubble size and frequency on mass transfer in flat sheet MBR. J. Membr. Sci. 2009, 332, 30–37. [Google Scholar] [CrossRef]

- Martin, I.; Pidou, M.; Soares, A.; Judd, S.; Jefferson, B. Modelling the energy demands of aerobic and anaerobic membrane bioreactors for wastewater treatment. Environ. Technol. 2011, 32, 921–932. [Google Scholar] [CrossRef] [PubMed]

- Aslan, M.; Saatçi, Y.; Hanay, Ö.; Hasar, H. Effect of biogas sparging with different membrane modules on membrane fouling in anaerobic submerged membrane bioreactor (AnSMBR). Environ. Sci. Pollut. Res. 2014, 21, 3285–3293. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Brannock, M.; Leslie, G. Membrane bioreactors: Overview of the effects of module geometry on mixing energy. Asia-Pac. J. Chem. Eng. 2009, 4, 322–333. [Google Scholar] [CrossRef]

- Buer, T.; Cumin, J. MBR module design and operation. Desalination 2010, 250, 1073–1077. [Google Scholar] [CrossRef]

- Ferrero, G.; Rodríguez-Roda, I.; Comas, J. Automatic control systems for submerged membrane bioreactors: A state-of-the-art review. Water Res. 2012, 46, 3421–3433. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.H.; Ng, H.Y. Revised external and internal concentration polarization models to improve flux prediction in forward osmosis process. Desalination 2013, 309, 125–140. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.R.D.; Tang, C.Y.; Clech, L.P. Opportunities to reach economic sustainability in forward osmosis–reverse osmosis hybrids for seawater desalination. Desalination 2015, 363, 26–36. [Google Scholar] [CrossRef]

- Desormeaux, E. Porifera Commercialization Landscapre for Foward Osmosis. Available online: www.desaltech2015.com/assets/presenters/Desormeaux_Erik.pdf (accessed on 1 August 2015).

- Blandin, G.; Gautier, C.; Sauchelli Toran, M.; Monclús, H.; Rodriguez-Roda, I.; Comas, J. Retrofitting membrane bioreactor (MBR) into osmotic membrane bioreactor (OMBR): A pilot scale study. Chem. Eng. J. 2018. [Google Scholar] [CrossRef]

- Nicoll, P.G. Forward osmosis—A brief introduction. In Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse, Tianjin, China, 21–25 October 2013. [Google Scholar]

- Blandin, G.; Vervoort, H.; D’Haese, A.; Schoutteten, K.; Bussche, J.V.; Vanhaecke, L.; Myat, D.T.; Le-Clech, P.; Verliefde, A.R.D. Impact of hydraulic pressure on membrane deformation and trace organic contaminants rejection in pressure assisted osmosis (PAO). Process Saf. Environ. Protect. 2016, 102, 316–327. [Google Scholar] [CrossRef]

- Blandin, G.; Vervoort, H.; Clech, L.P.; Verliefde, A.R.D. Fouling and cleaning of high permeability forward osmosis membranes. J. Water Process Eng. 2016, 9, 161–169. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.D.; Tang, C.Y.Y.; Childress, A.E.; Le-Clech, P. Validation of assisted forward osmosis (AFO) process: Impact of hydraulic pressure. J. Membr. Sci. 2013, 447, 1–11. [Google Scholar] [CrossRef]

- Tiraferri, A.; Yip, N.Y.; Straub, A.P.; Romero-Vargas Castrillon, S.; Elimelech, M. A method for the simultaneous determination of transport and structural parameters of forward osmosis membranes. J. Membr. Sci. 2013, 444, 523–538. [Google Scholar] [CrossRef]

- Chun, Y.; Qing, L.; Sun, G.; Bilad, M.R.; Fane, A.G.; Chong, T.H. Prototype aquaporin-based forward osmosis membrane: Filtration properties and fouling resistance. Desalination 2018, 445, 75–84. [Google Scholar] [CrossRef]

- Nguyen, T.P.N.; Jun, B.-M.; Lee, J.H.; Kwon, Y.-N. Comparison of integrally asymmetric and thin film composite structures for a desirable fashion of forward osmosis membranes. J. Membr. Sci. 2015, 495, 457–470. [Google Scholar] [CrossRef]

- Sauchelli, M.; Pellegrino, G.; D'Haese, A.; Roda, R.I.; Gernjak, W. Transport of trace organic compounds through novel forward osmosis membranes: Role of membrane properties and the draw solution. Water Res. 2018, 141, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Lutchmiah, K.; Cornelissen, E.; Harmsen, D.; Wols, B.; Verliefde, A.; Post, J. Pressure assisted osmosis (PAO) to enhance forward osmosis (FO) performance. Presented at the 3rd Osmosis Membrane Summit, Barcelona, Spain, 26–27April 2012. [Google Scholar]

- Karabelas, A.J.; Koutsou, C.P.; Sioutopoulos, D.C. Comprehensive performance assessment of spacers in spiral-wound membrane modules accounting for compressibility effects. J. Membr. Sci. 2017. [Google Scholar] [CrossRef]

- Desormeaux, E. Porifera: Creating a World with Less Waste, Water Reuse Instead of Discarded, Concentrated Products. Available online: Erik-desormeaux.squarespace.com/s/Porifera-Technology-Overview-March2017.pdf (accessed on 1 March 2017).

- Cath, T.Y.; Elimelech, M.; McCutcheon, J.R.; McGinnis, R.L.; Achilli, A.; Anastasio, D.; Brady, A.R.; Childress, A.E.; Farr, I.V.; Hancock, N.T.; et al. Standard Methodology for Evaluating Membrane Performance in Osmotically Driven Membrane Processes. Desalination 2013, 312, 31–38. [Google Scholar] [CrossRef]

- Le-Clech, P.; Jefferson, B.; Judd, S. Impact of aeration, solids concentration and membrane characteristics on the hydraulic performance of a membrane bioreactor. J. Membr. Sci. 2003, 218, 117–129. [Google Scholar] [CrossRef]

- Sofia, A.; Ng, W.J.; Ong, S.L. Engineering design approaches for minimum fouling in submerged MBR. Desalination 2004, 160, 67–74. [Google Scholar] [CrossRef]

- Kola, A.; Ye, Y.; Clech, L.P.; Chen, V. Transverse vibration as novel membrane fouling mitigation strategy in anaerobic membrane bioreactor applications. J. Membr. Sci. 2014, 455, 320–329. [Google Scholar] [CrossRef]

| Pump Flow Rate | L·min−1 | 0.12 | 0.24 | 0.36 | 0.48 |

|---|---|---|---|---|---|

| CFC (feed and draw) | m·s−1 | 0.05 | 0.09 | 0.14 | / |

| U shape large mesh | m·s−1 | 0.02 | 0.04 | 0.06 | 0.08 |

| U shape fine mesh | m·s−1 | 0.031 | 0.062 | 0.093 | 0.126 |

| Straight large mesh | m·s−1 | 0.01 | 0.019 | 0.029 | 0.039 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blandin, G.; Rodriguez-Roda, I.; Comas, J. Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations. Membranes 2018, 8, 72. https://doi.org/10.3390/membranes8030072

Blandin G, Rodriguez-Roda I, Comas J. Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations. Membranes. 2018; 8(3):72. https://doi.org/10.3390/membranes8030072

Chicago/Turabian StyleBlandin, Gaetan, Ignasi Rodriguez-Roda, and Joaquim Comas. 2018. "Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations" Membranes 8, no. 3: 72. https://doi.org/10.3390/membranes8030072

APA StyleBlandin, G., Rodriguez-Roda, I., & Comas, J. (2018). Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations. Membranes, 8(3), 72. https://doi.org/10.3390/membranes8030072