Environmental Friendly Fabrication of Porous Cement Membranes via Reusable Camphene-Based Freeze-Casting Method

Abstract

:1. Introduction

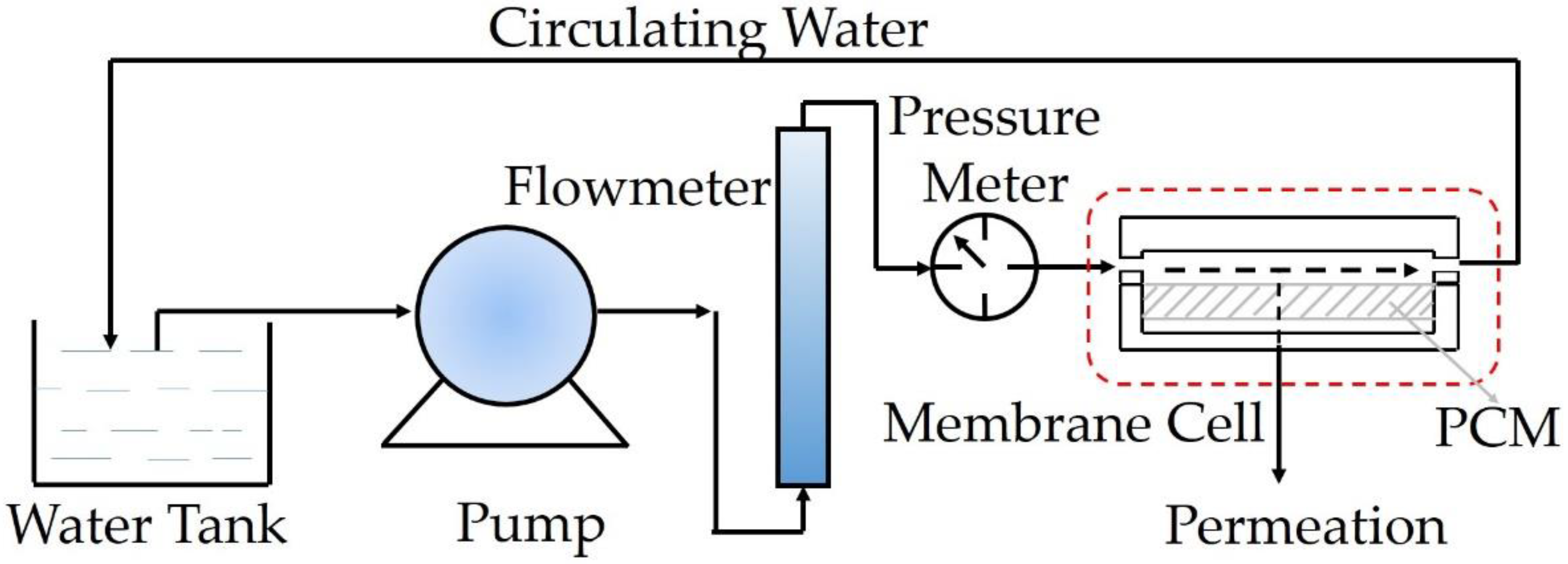

2. Materials and Methods

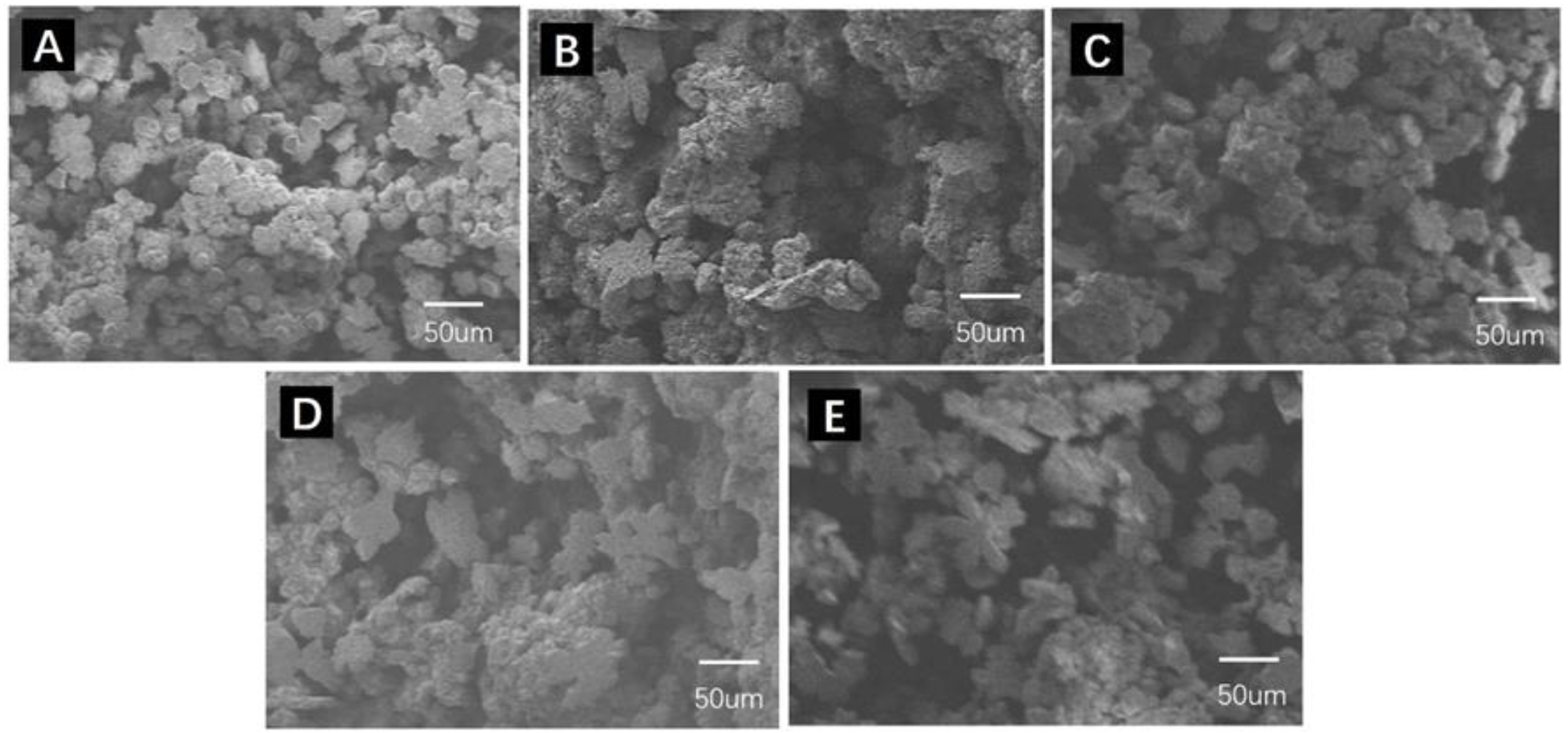

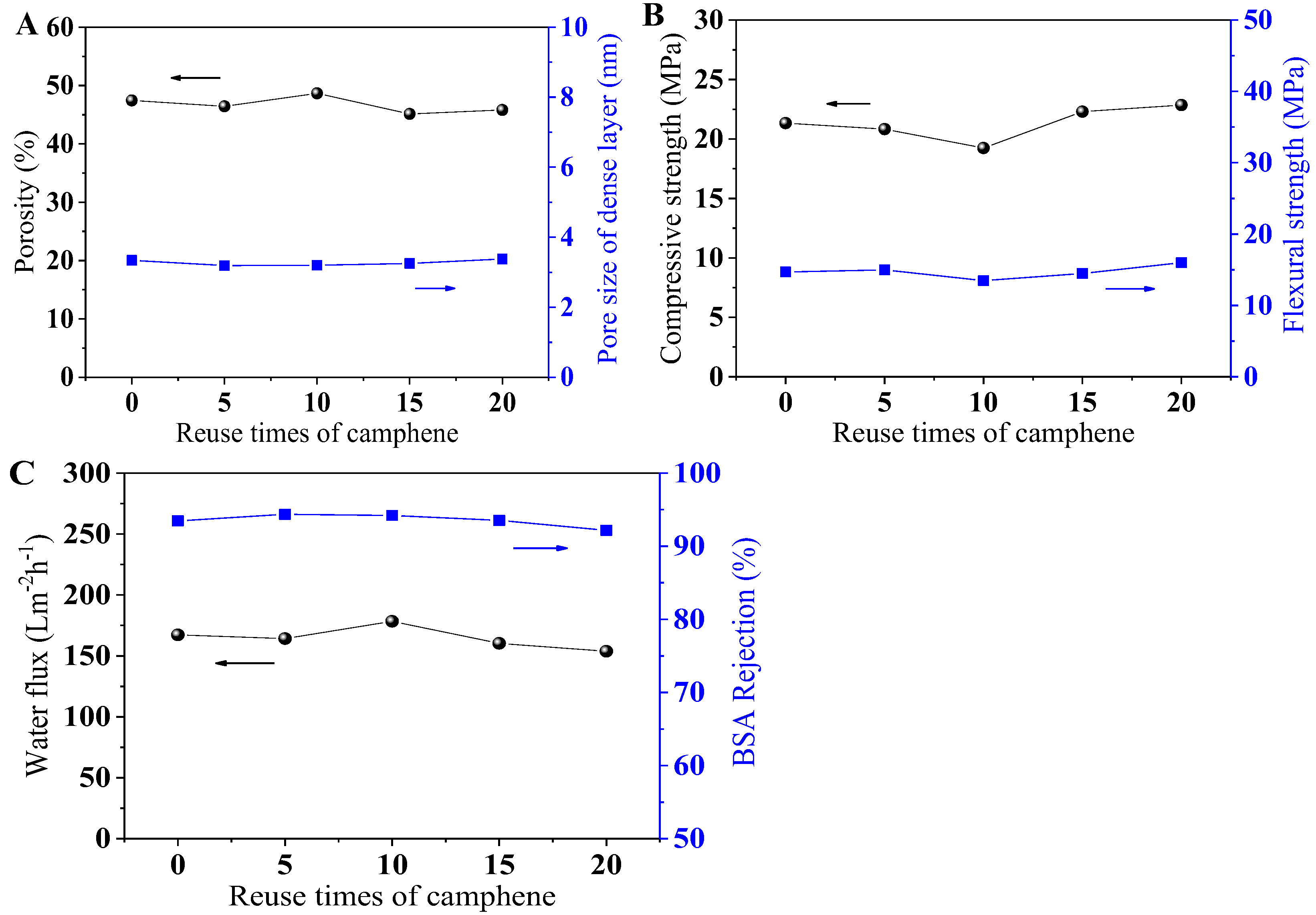

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vergara-Araya, M.; Oeltze, H.; Radeva, J.; Roth, A.G.; Göbbert, C.; Niestroj-Pahl, R.; Dähne, L.; Wiese, J. Operation of Hybrid Membranes for the Removal of Pharmaceuticals and Pollutants from Water and Wastewater. Membranes 2022, 12, 502. [Google Scholar] [CrossRef] [PubMed]

- Mountoumnjou, O.; Szymczyk, A.; Lyonga Mbambyah, E.E.; Njoya, D.; Elimbi, A. New Low-Cost Ceramic Microfiltration Membranes for Bacteria Removal. Membranes 2022, 12, 490. [Google Scholar] [CrossRef] [PubMed]

- Sun, R.; Jin, Y. Pilot Scale Application of a Ceramic Membrane Bioreactor for Treating High-Salinity Oil Production Wastewater. Membranes 2022, 12, 473. [Google Scholar] [CrossRef] [PubMed]

- Baig, U.; Waheed, A.; Abussaud, B.; Aljundi, I. A Simple Approach to Fabricate Composite Ceramic Membranes Decorated with Functionalized Carbide-Derived Carbon for Oily Wastewater Treatment. Membranes 2022, 12, 394. [Google Scholar] [CrossRef]

- Badwal, S.P.S.; Ciacchi, F.T. Ceramic membrane technologies for oxygen separation. Adv. Mater. 2001, 13, 993–996. [Google Scholar] [CrossRef]

- Lee, S.; Cho, J. Comparison of ceramic and polymeric membranes for natural organic matter (NOM) removal. Desalination 2004, 160, 223–232. [Google Scholar] [CrossRef]

- Dong, S.; Zhu, W.; Gao, X.; Wang, Z.; Wang, L.; Wang, X.; Gao, C. Preparation of tubular hierarchically porous silicate cement compacts via a tert-butyl alcohol (TBA)-based freeze casting method. Chem. Eng. J. 2016, 295, 530–541. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Cuiming, W.; Tongwen, X.; Weihua, Y. Fundamental studies of a new hybrid (inorganic–organic) positively charged membrane: Membrane preparation and characterizations. J. Membr. Sci. 2003, 216, 269–278. [Google Scholar] [CrossRef]

- Liu, S.; Li, K.; Hughes, R. Preparation of porous aluminium oxide (Al2O3) hollow fibre membranes by a combined phase-inversion and sintering method. Ceram. Int. 2003, 29, 875–881. [Google Scholar] [CrossRef]

- Soon, Y.M.; Shin, K.H.; Koh, Y.H.; Lee, J.H.; Kim, H.E. Compressive strength and processing of camphene-based freeze cast calcium phosphate scaffolds with aligned pores. Mater. Lett. 2009, 63, 1548–1550. [Google Scholar] [CrossRef]

- Deville, S. Freeze-casting of porous ceramics: A review of current achievements and issues. Adv. Eng. Mater. 2008, 10, 155–169. [Google Scholar] [CrossRef]

- Abdullayev, A.; Kamm, P.H.; Bekheet, M.F.; Gurlo, A. Fabrication and Characterization of Ice Templated Membrane Supports from Portland Cement. Membranes 2020, 10, 93. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Gao, X.; Ma, Z.; Wang, X.; Gao, C. Ice-templated porous silicate cement with hierarchical porosity. Mater. Lett. 2018, 217, 292–295. [Google Scholar] [CrossRef]

- Dong, S.; Wang, L.; Gao, X.; Zhu, W.; Wang, Z.; Ma, Z.; Gao, C. Freeze casting of novel porous silicate cement supports using tert-butyl alcohol-water binary crystals as template: Microstructure, strength and permeability. J. Membr. Sci. 2017, 541, 143–152. [Google Scholar] [CrossRef]

- Seuba, J.; Deville, S.; Guizard, C.; Stevenson, A.J. Mechanical properties and failure behavior of unidirectional porous ceramics. Sci. Rep. 2016, 6, 24326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Solid Content, wt.% | |||

|---|---|---|---|

| 40 | 50 | 60 | |

| Porosity, % | 65.4 ± 1.4 | 55.3 ± 2.1 | 47.4 ± 2.1 |

| Pore size of dense layer, nm | 3.62 ± 0.09 | 3.52 ± 0.06 | 3.34 ± 0.06 |

| Compressive Strength, MPa | 15.6 ± 0.4 | 18.5 ± 0.5 | 21.3 ± 1.6 |

| Flexural Strength, MPa | 8.6 ± 0.5 | 12.5 ± 0.4 | 14.7 ± 1.1 |

| Water Flux, L·m−2·h−1 | 346.8 ± 5.1 | 228.0 ± 5.7 | 167.3 ± 5.5 |

| BSA Rejection, % | 81.3 ± 1.5 | 89.6 ± 1.8 | 93.5 ± 1.4 |

| PEG 100,000 Rejection, % | 87.4 ± 1.1 | 93.5 ± 0.9 | 97.1 ± 1.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wang, X.; Sun, Z.; Wang, X.; Wang, H.; Gao, C.; Gao, X. Environmental Friendly Fabrication of Porous Cement Membranes via Reusable Camphene-Based Freeze-Casting Method. Membranes 2022, 12, 867. https://doi.org/10.3390/membranes12090867

Wang Z, Wang X, Sun Z, Wang X, Wang H, Gao C, Gao X. Environmental Friendly Fabrication of Porous Cement Membranes via Reusable Camphene-Based Freeze-Casting Method. Membranes. 2022; 12(9):867. https://doi.org/10.3390/membranes12090867

Chicago/Turabian StyleWang, Zhen, Xiaojuan Wang, Zhantong Sun, Xiaofeng Wang, Hongdong Wang, Congjie Gao, and Xueli Gao. 2022. "Environmental Friendly Fabrication of Porous Cement Membranes via Reusable Camphene-Based Freeze-Casting Method" Membranes 12, no. 9: 867. https://doi.org/10.3390/membranes12090867

APA StyleWang, Z., Wang, X., Sun, Z., Wang, X., Wang, H., Gao, C., & Gao, X. (2022). Environmental Friendly Fabrication of Porous Cement Membranes via Reusable Camphene-Based Freeze-Casting Method. Membranes, 12(9), 867. https://doi.org/10.3390/membranes12090867