Partial Removal of Sugar from Apple Juice by Nanofiltration and Discontinuous Diafiltration

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Feed Solution

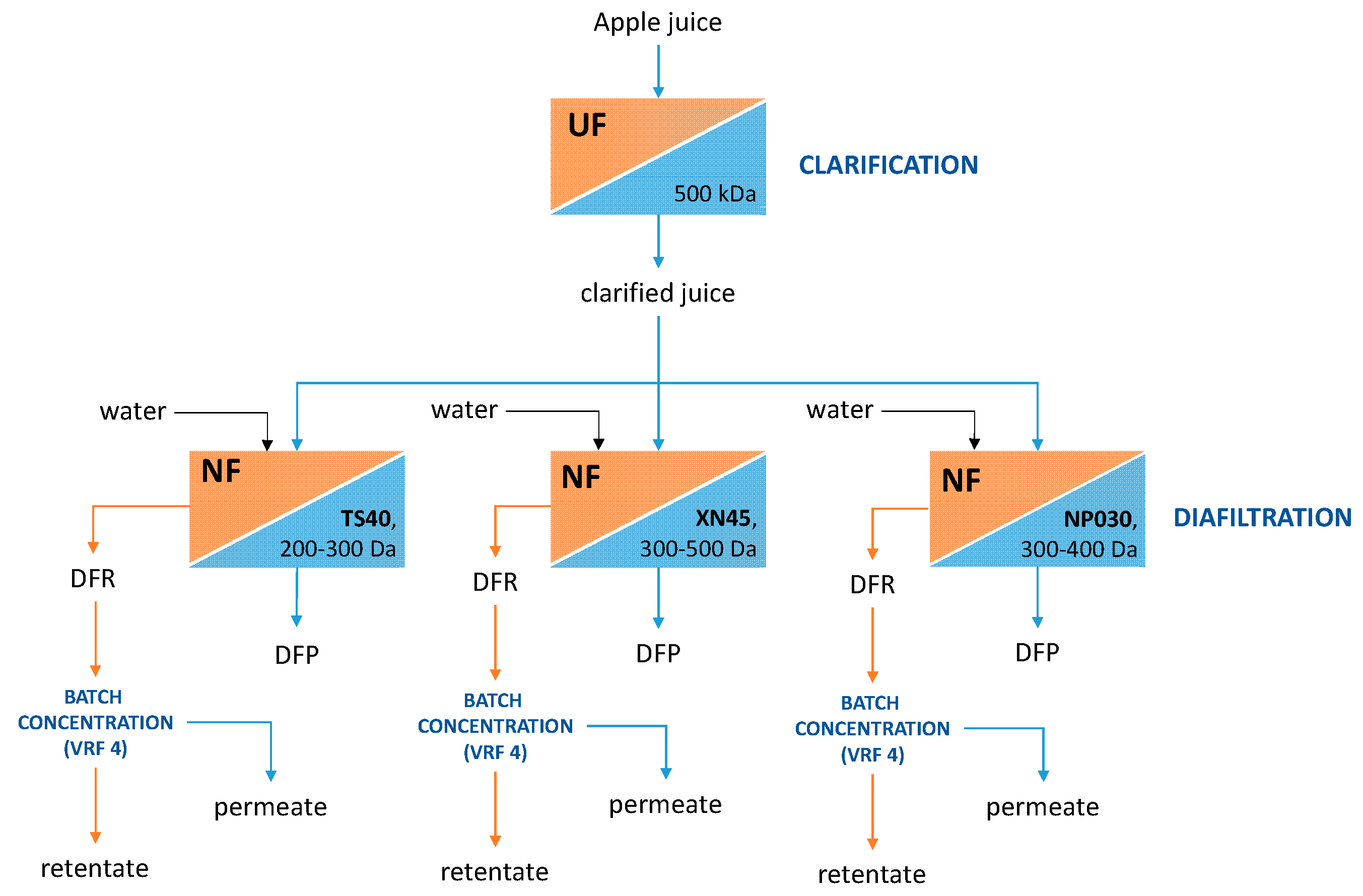

2.3. Diafiltration−Nanofiltration Process: Experimental Set-Up and Procedure

2.4. Performance Parameters

2.5. Analytical Measurements

2.5.1. Total Soluble Solids

2.5.2. Total Phenolic Content

2.5.3. D-Glucose and D-Fructose Quantification

3. Results and Discussion

3.1. Permeate Flux Evaluation

3.2. Recovery Rate of D-Glucose, D-Fructose, and TPC during Discontinuous Diafiltration

3.3. Concentration Factor of D-Glucose, D-Fructose, and TPC during Nanofiltration in Batch Concentration Mode

3.4. Mass Balance and Adsorption of Sugars and TPC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wojdylo, A.; Oszmianski, J.; Laskowski, P. Polyphenolic compounds and antioxidant activity of new and old apple varieties. J. Agric. Food Chem. 2008, 56, 6520–6530. [Google Scholar] [CrossRef] [PubMed]

- Koutsos, A.; Tuohy, K.M.; Lovegrove, J.A. Apples and cardiovascular health—Is the gut microbiota a core consideration? Nutrients 2015, 7, 3959–3998. [Google Scholar] [CrossRef] [PubMed]

- Vallée Marcotte, B.; Verheyde, M.; Pomerleau, S.; Doyen, A.; Couillard, C. Health benefits of apple juice consumption: A review of interventional trials on humans. Nutrients 2022, 14, 821. [Google Scholar] [CrossRef] [PubMed]

- Samborska, K.; Kamińska, P.; Jedlińska, A.; Matwijczuk, A.; Kamińska-Dwórznicka, A. Membrane processing in the sustainable production of low-sugar apple-cranberry cloudy juice. App. Sci. 2018, 8, 1082. [Google Scholar] [CrossRef]

- World Health Organization. Guideline: Sugars Intake for Adults and Children, Geneva. 2015. Available online: https://www.who.int/publications/i/item/9789241549028 (accessed on 28 June 2022).

- World Health Organization. A Healthy Diet Sustainably Produced. 2018. Available online: https://apps.who.int/iris/bitstream/handle/10665/278948/WHO-NMH-NHD-18.12-eng.pdf (accessed on 28 June 2022).

- Bigliardi, B.; Galati, F. Innovation trends in the food industry: The case of functional foods. Trends Food Sci. Technol. 2013, 31, 118–129. [Google Scholar]

- Brglez Mojzer, E.; Knez Hrnčič, M.; Škerget, M.; Knez, Ž.; Bren, U. Polyphenols: Extraction methods, antioxidative action, bioavailability and anticarcinogenic effects. Molecules 2016, 21, 901. [Google Scholar] [CrossRef]

- Conidi, C.; Castro-Muñoz, R.; Cassano, A. Membrane-based operations in the fruit juice processing industry: A review. Beverages 2020, 6, 18. [Google Scholar] [CrossRef]

- Charcosset, C. Classical and recent applications of membrane processes in the food industry. Food Eng. Rev. 2021, 13, 322–343. [Google Scholar] [CrossRef]

- Lazarides, H.N. Food processing technology in a sustainable food supply chain. Procedia Food Sci. 2011, 1, 1918–1923. [Google Scholar] [CrossRef]

- de Moraes, I.V.M.; Rabelo, R.S.; Pereira, J.A.D.; Hubinger, M.D.; Schmidt, F.L. Concentration of hydroalcoholic extracts of graviola (Annona muricata L.) pruning waste by ultra and nanofiltration: Recovery of bioactive compounds and prediction of energy consumption. J. Clean. Prod. 2018, 174, 1412–1421. [Google Scholar] [CrossRef]

- Vieira, G.S.; Moreira, F.K.V.; Matsumoto, R.L.S.; Michelon, M.; Filho, F.M.; Hubinger, M.D. Influence of nanofiltration membrane features on enrichment of jussara ethanolic extract (Euterpe edulis) in anthocyanins. J. Food Eng. 2018, 226, 31–41. [Google Scholar] [CrossRef]

- Arboleda Meija, J.A.; Parpinello, G.P.; Versari, A.; Conidi, C.; Cassano, A. Microwave-assisted extraction and membrane-based separation of biophenols from red wine lees. Food Bioprod. Process. 2019, 117, 74–83. [Google Scholar] [CrossRef]

- Arboleda Meija, J.A.; Ricci, A.; Figueiredo, A.S.; Versari, A.; Cassano, A.; de Pinho, M.N.; Parpinello, G.P. Membrane-based operations for the fractionation of polyphenols and polysaccharides from winery sludges. Food Bioprocess. Technol. 2022, 15, 933–948. [Google Scholar]

- Tylkowski, B.; Trusheva, B.; Bankova, V.; Giamberini, M.; Peev, G.; Nikolova, A. Extraction of biologically active compounds from propolis and concentration of extract by nanofiltration. J. Membr. Sci. 2010, 348, 124–130. [Google Scholar] [CrossRef]

- Cissé, M.; Vaillant, F.; Pallet, D.; Dornier, M. Selecting ultrafiltration and nanofiltration membranes to concentrate anthocyanins from roselle extract (Hibiscus sabdariffa L.). Food Res. Int. 2011, 44, 2607–2614. [Google Scholar] [CrossRef]

- Tundis, R.; Loizzo, M.R.; Bonesi, M.; Sicari, V.; Ursino, C.; Manfredi, I.; Conidi, C.; Figoli, A.; Cassano, A. Concentration of bioactive compounds from elderberry (Sambucus nigra L.) juice by nanofiltration membranes. Plant Food Hum. Nutr. 2018, 73, 336–343. [Google Scholar] [CrossRef]

- Conidi, C.; Cassano, A.; Caiazzo, F.; Drioli, E. Separation and purification of phenolic compounds from pomegranate juice by ultrafiltration and nanofiltration membranes. J. Food Eng. 2017, 195, 1–13. [Google Scholar] [CrossRef]

- Conidi, C.; Cassano, A.; Drioli, E. A membrane-based study for the recovery of polyphenols from bergamot juice. J. Membr. Sci. 2011, 375, 182–190. [Google Scholar] [CrossRef]

- Gaglianò, M.; Conidi, C.; Bartella, L.; Salvino, R.A.; di Donna, L.; Cassano, A.; de Luca, G. An integrated approach based on NMR and HPLC–UV-ESI–MS/MS to characterize apple juices and their nanofiltration (NF) bioactive extracts. Food Bioprocess Technol. 2021, 14, 2273–2285. [Google Scholar] [CrossRef]

- Pruksasri, S.; Lanner, B.; Novalin, S. Nanofiltration as a potential process for the reduction of sugar in apple juices on an industrial scale. LWT 2020, 133, 110118. [Google Scholar] [CrossRef]

- Conidi, C.; Cassano, A.; Drioli, E. Membrane diafiltration for enhanced purification of biologically active compounds from goji berries extracts. Sep. Purif. Technol. 2022, 282, 119991. [Google Scholar] [CrossRef]

- Doran, P.M. Unit Operations. In Bioprocess Engineering Principles; Doran, P.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 445–595. [Google Scholar]

- Loewe, D.; Dieken, H.; Grein, T.A.; Salzig, D.; Czermak, P. A combined ultrafiltration/diafiltration process for the purification of oncolytic measles virus. Membranes 2022, 12, 105. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, L. Diafiltration: A Fast, Efficient Method for Desalting or Buffer Exchange of Biological Samples. Pall Scientific & Technical Report; Pall Life Sciences: Ann Arbor, MI, USA, 2003. [Google Scholar]

- Khunnonkwao, P.; Jantama, K.; Kanchanatawee, S.; Galier, S.; Roux-de Balmann, H. A two steps membrane process for the recovery of succinic acid from fermentation broth. Sep. Purif. Technol. 2018, 207, 451–460. [Google Scholar] [CrossRef]

- Zhou, H.; Ni, J.; Huang, W.; Zhang, J. Separation of hyaluronic acid from fermentation broth by tangential flow microfiltration and ultrafiltration. Sep. Purif. Technol. 2006, 52, 29–38. [Google Scholar] [CrossRef]

- Sweeney, S.F.; Woehrle, G.H.; Hutchison, J.E. Rapid purification and size separation of gold nanoparticles via diafiltration. J. Am. Chem. Soc. 2006, 128, 3190–3197. [Google Scholar] [CrossRef]

- Ambrosi, A.; Motke, M.B.; Souza-Silva, É.A.; Zini, C.A.; McCutcheon, J.R.; Cardozo, N.; Tessaro, I.C. Beer dealcoholization by forward osmosis diafiltration. Innov. Food Sci. Emerg. Technol. 2020, 63, 102371. [Google Scholar] [CrossRef]

- Nisticò, D.M.; Piro, A.; Oliva, D.; Osso, V.; Mazzuca, S.; Fagà, F.A.; Morelli, R.; Conidi, C.; Figoli, A.; Cassano, A. A combination of aqueous extraction and ultrafiltration for the purification of phycocyanin from Arthrospira maxima. Microorganisms 2022, 10, 308. [Google Scholar] [CrossRef]

- Almanasrah, M.; Brazinha, C.; Kallioinen, M.; Duarte, L.C.; Roseiro, L.B.; Bogel-Lukasik, R.; Carvalheiro, F.; Manttari, M.; Crespo, J.G. Nanofiltration and reverse osmosis as a platform for production of natural botanic extracts: The case study of carob by-products. Sep. Purif. Technol. 2015, 149, 389–397. [Google Scholar] [CrossRef][Green Version]

- Wei, D.S.; Hossain, M.; Saleh, Z.S. Separation of polyphenolics and sugar by ultrafiltration: Effects of operating conditions on fouling and diafiltration. Int. J. Nutr. Food Eng. 2007, 1, 115–122. [Google Scholar]

- Barańska, A.; Kot, A.; Samborska, K. Ultrafiltration as a method to obtain sugar reduced cloudy juices—A research on juice’s properties. Zeszyty Problemowe Postępów Nauk Rolniczych 2020, 600, 3–11. [Google Scholar] [CrossRef]

- Zdarta, J.; Thygesen, A.; Holm, M.S.; Meyer, A.S.; Pinelo, M. Direct separation of acetate and furfural from xylose by nanofiltration of birch pretreated liquor: Effect of process conditions and separation mechanism. Sep. Purif. Technol. 2020, 239, 116546. [Google Scholar] [CrossRef]

- Peiris, R.H.; Hallé, C.; Budman, H.; Moresoli, C.; Peldszus, S.; Huck, P.M.; Legge, R.L. Identifying fouling events in a membrane-based drinking water treatment process using principal component analysis of fluorescence excitation-emission matrices. Water Res. 2010, 44, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Boussu, K.; Vandecasteele, C.; van der Bruggen, B. Relation between membrane characteristics and performance in nanofiltration. J. Membr. Sci. 2008, 310, 51–65. [Google Scholar] [CrossRef]

- Mittal, R.; Lamdande, A.G.; Sharma, R.; Raghavarao, K.S.M.S. Membrane processing for purification of R-Phycoerythrin from marine macro-alga, Gelidium pusillum and process integration. Sep. Purif. Technol. 2020, 252, 117470. [Google Scholar] [CrossRef]

- Chen, V.; Li, H.; Li, D.; Tan, S.; Petrus, H.B. Cleaning strategies for membrane fouled with protein mixtures. Desalination 2006, 200, 198–200. [Google Scholar] [CrossRef]

- Sun, X.; Lu, H.; Wang, J. Recovery of citric acid from fermented liquid by bipolar membrane electrodialysis. J. Clean. Prod. 2017, 143, 250–256. [Google Scholar] [CrossRef]

- Conidi, C.; Cassano, A.; Garcia-Castello, E. Valorization of artichoke wastewaters by integrated membrane process. Water Res. 2014, 48, 363–374. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzimol. 1999, 299, 152–178. [Google Scholar]

- Enzytec Liquid D-Glucose. 2017. Available online: https://food.r-biopharm.com/wp-content/uploads/2017/05/E-Liquid_IFU_E8140_Glucose_EN.pdf (accessed on 28 June 2022).

- Enzytec Liquid D-Glucose/D-Fructose. 2017. Available online: https://food.r-biopharm.com/wp-content/uploads/2017/07/e-liquid_ifu_e8160_glucose-fructose_en.pdf (accessed on 28 June 2022).

- Laorko, A.; Li, Z.; Tongchitpakdee, S.; Chantachum, S.; Youravong, W. Effect of membrane property and operating conditions on phytochemical properties and permeate flux during clarification of pineapple juice. J. Food Eng. 2010, 100, 514–521. [Google Scholar] [CrossRef]

- Servent, A.; Abreu, F.A.P.; Dhuique-Mayer, C.; Belleville, M.P.; Dornier, M. Concentration and purification by crossflow microfiltration with diafiltration of carotenoids from a by-product of cashew apple juice processing. Innov. Food Sci. Emerg. Technol. 2020, 66, 102519. [Google Scholar] [CrossRef]

- Nguyen, D.T.N.N.; Lameloise, M.L.; Guiga, W.; Lewandowski, R.; Bouix, M.; Fargues, C. Optimization and modeling of diananofiltration process for the detoxification of ligno-cellulosic hydrolysates—Study at pre-industrial scale. J. Membr. Sci. 2016, 512, 111–121. [Google Scholar] [CrossRef]

- Lyu, H.; Fang, Y.; Ren, S.; Chen, K.; Luo, G.; Zhang, S.; Chen, J. Monophenols separation from monosaccharides and acids by two-stage nanofiltration and reverse osmosis in hydrothermal liquefaction hydrolysates. J. Membr. Sci. 2016, 504, 141–152. [Google Scholar] [CrossRef]

- Nicolini, J.V.; Borges, C.P.; Ferraz, H.C. Selective rejection of ions and correlation with surface properties of nanofiltration membranes. Sep. Purif. Technol. 2016, 171, 238–247. [Google Scholar] [CrossRef]

- De Oliveira, R.C.; de Barros, S.T.D. Beer clarification with polysulfone membrane and study on fouling mechanism. Braz. Arch. Biol. Technol. 2011, 54, 1335–1342. [Google Scholar] [CrossRef]

- Suhalim, N.S.; Kasim, N.; Mahmoudi, E.; Shamsudin, I.J.; Mohammad, A.W.; Zuki, F.M.; Jamari, N.L.A. Rejection mechanism of ionic solute removal by nanofiltration membranes: An overview. Nanomaterials 2022, 12, 437. [Google Scholar] [CrossRef]

- Muñoz, P.; Pérez, K.; Cassano, A.; Ruby-Figueroa, R. Recovery of anthocyanins and monosaccharides from grape marc extract by nanofiltration membranes. Molecules 2021, 26, 2003. [Google Scholar] [CrossRef]

- Prudêncio, A.P.A.; Prudêncio, E.S.; Amboni, R.D.M.C.; Murakami, A.N.N.; Maraschin, M.; Petrus, J.C.C.; Ogliari, P.J.; Leite, R.S. Phenolic composition and antioxidant activity of the aqueous extract of bark from residues from mate tree (Ilex paraguariensis St. Hil.) bark harvesting concentrated by nanofiltration. Food Bioprod. Process. 2012, 90, 399–405. [Google Scholar] [CrossRef]

- Cassano, A.; Cabri, W.; Mombelli, G.; Peterlongo, F.; Giorno, L. Recovery of bioactive compounds from artichoke brines by nanofiltration. Food Bioprod. Process. 2016, 98, 257–265. [Google Scholar] [CrossRef]

- Tsuru, T.; Sudoh, T.; Yoshioka, T.; Asaeda, M. Nanofiltration in non-aqueous solutions by porous silica-zirconia membranes. J. Membr. Sci. 2001, 185, 253–261. [Google Scholar] [CrossRef]

- Tonova, K.; Lazarova, M.; Dencheva-Zarkova, M.; Genova, J. Nanofiltration of aquatic weed hydrolysate: Diafiltration versus concentration mode for separating saccharides from phenolics. Chem. Eng. Res. Des. 2022, 182, 360–370. [Google Scholar] [CrossRef]

- Saleh, Z.S.; Stanley, R.; Wibisono, R. Separation and concentration of health compounds by membrane filtration. Int. J. Food Eng. 2006, 2, 4. [Google Scholar] [CrossRef]

- Sotto, A.; Arsuaga, J.M.; van der Bruggen, B. Sorption of phenolic compounds on NF/RO membrane surfaces: Influence on membrane performance. Desalination 2013, 309, 64–73. [Google Scholar] [CrossRef]

- Susanto, H.; Feng, Y.; Ulbricht, M. Fouling behavior of aqueous solutions of polyphenolic compounds during ultrafiltration. J. Food Eng. 2009, 91, 333–340. [Google Scholar] [CrossRef]

- Cassano, A.; de Luca, G.; Conidi, C.; Drioli, E. Effect of polyphenols-membrane interactions on the performance of membrane-based processes. A review. Coord. Chem. Rev. 2017, 351, 45–75. [Google Scholar] [CrossRef]

- Cai, M.; Hou, W.; Li, Z.; Lv, Y.; Sun, P. Understanding nanofiltration fouling of phenolic compounds in model juice solution with two membranes. Food Bioprocess. Technol. 2017, 10, 2123–2131. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Glucose (g/L) | 17.2 ± 1.3 |

| Fructose (g/L) | 43.7 ± 2.4 |

| Total phenolic content (mgGAE/L) | 241.5 ± 8.1 |

| Total soluble solids (°Brix) | 7.0 ± 0.1 |

| pH | 3.78 ± 0.02 |

| Membrane Type | TS40 | XN45 | NP030 |

|---|---|---|---|

| Membrane material | TFC | TFC | PES |

| Configuration | spiral-wound | spiral-wound | spiral-wound |

| Max. operating pressure (bar) | 41 | 41 | 35 |

| Max. operating temperature (°C) | 50 | 50 | 70 |

| pH | 1–12 | 1–12 | 0–14 |

| Membrane surface area (m2) | 0.23 | 0.23 | 0.23 |

| Nominal MWCO (Da) | 200–300 | 300–500 | 300–400 |

| Contact angle (°) | 30 a | 57 b | 80 c |

| Water permeability at 25 °C (kg/m2hbar) | 4.48 d | 6.12 d | 2.99 d |

| Membrane Type | Process | Component | ||

|---|---|---|---|---|

| Glucose | Fructose | TPC | ||

| TS40 | Diafiltration | 94.62 | 93.56 | 97.49 |

| Batch concentration | 68.81 | 68.19 | 81.51 | |

| NP030 | Diafiltration | 95.83 | 99.99 | 90.98 |

| Batch concentration | 59.07 | 59.63 | 54.33 | |

| XN45 | Diafiltration | 100.00 | 99.99 | 99.99 |

| Batch concentration | 63.13 | 72.45 | 58.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaglianò, M.; Conidi, C.; De Luca, G.; Cassano, A. Partial Removal of Sugar from Apple Juice by Nanofiltration and Discontinuous Diafiltration. Membranes 2022, 12, 712. https://doi.org/10.3390/membranes12070712

Gaglianò M, Conidi C, De Luca G, Cassano A. Partial Removal of Sugar from Apple Juice by Nanofiltration and Discontinuous Diafiltration. Membranes. 2022; 12(7):712. https://doi.org/10.3390/membranes12070712

Chicago/Turabian StyleGaglianò, Martina, Carmela Conidi, Giuseppina De Luca, and Alfredo Cassano. 2022. "Partial Removal of Sugar from Apple Juice by Nanofiltration and Discontinuous Diafiltration" Membranes 12, no. 7: 712. https://doi.org/10.3390/membranes12070712

APA StyleGaglianò, M., Conidi, C., De Luca, G., & Cassano, A. (2022). Partial Removal of Sugar from Apple Juice by Nanofiltration and Discontinuous Diafiltration. Membranes, 12(7), 712. https://doi.org/10.3390/membranes12070712