A Rotary Spacer System for Energy-Efficient Membrane Fouling Control in Oil/Water Emulsion Filtration

Abstract

:1. Introduction

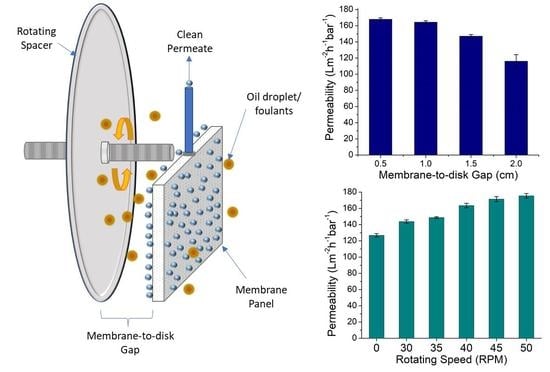

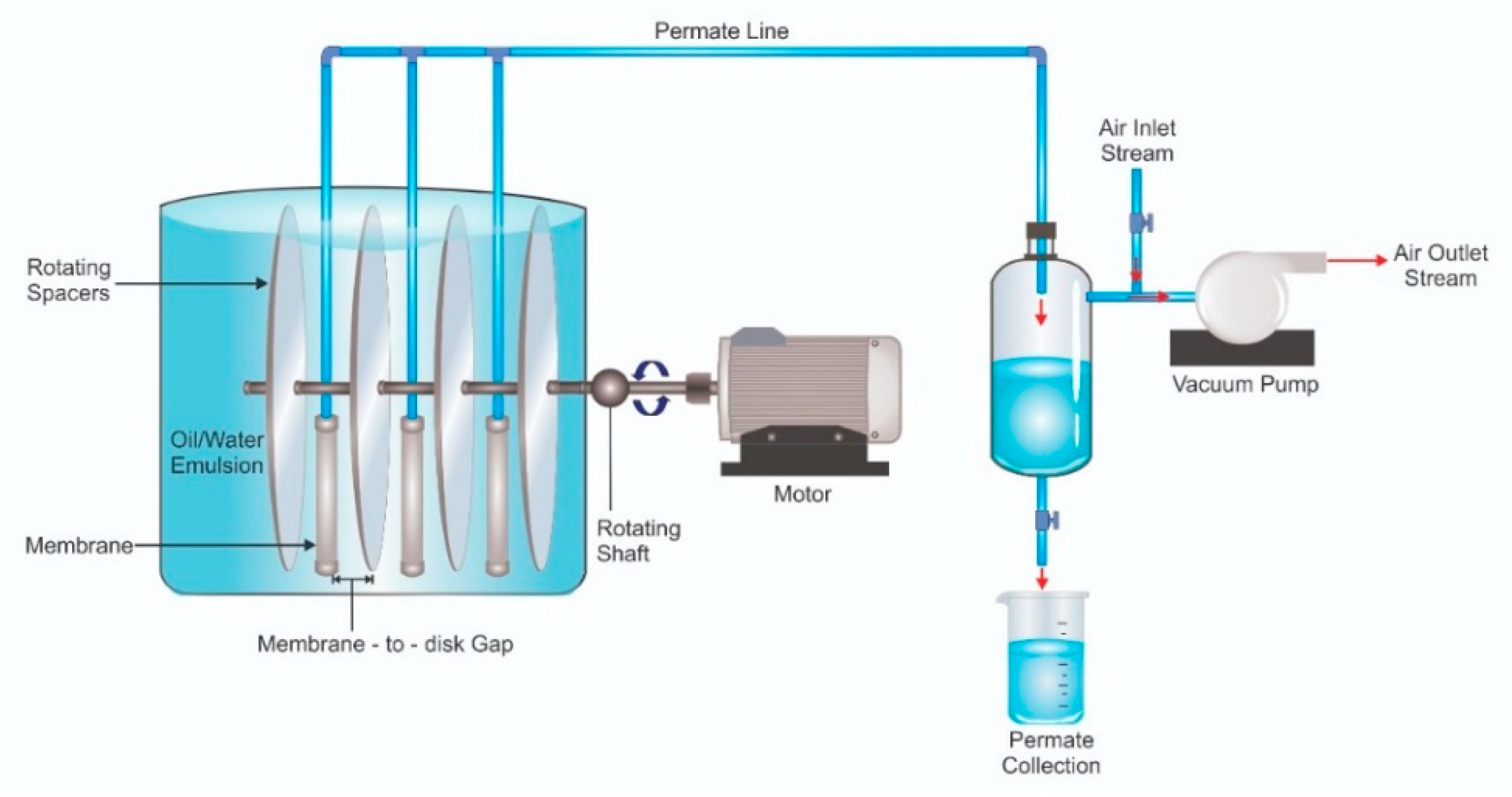

2. Materials and Methods

2.1. Membrane Preparation and Characterization

2.2. Oil-in-Water Emulsion Feed Preparation

2.3. Membrane Panel Assembly and Filtration Set-Up

2.4. Filtration Test

2.5. Estimation of Energy Consumption

2.6. Data Analysis

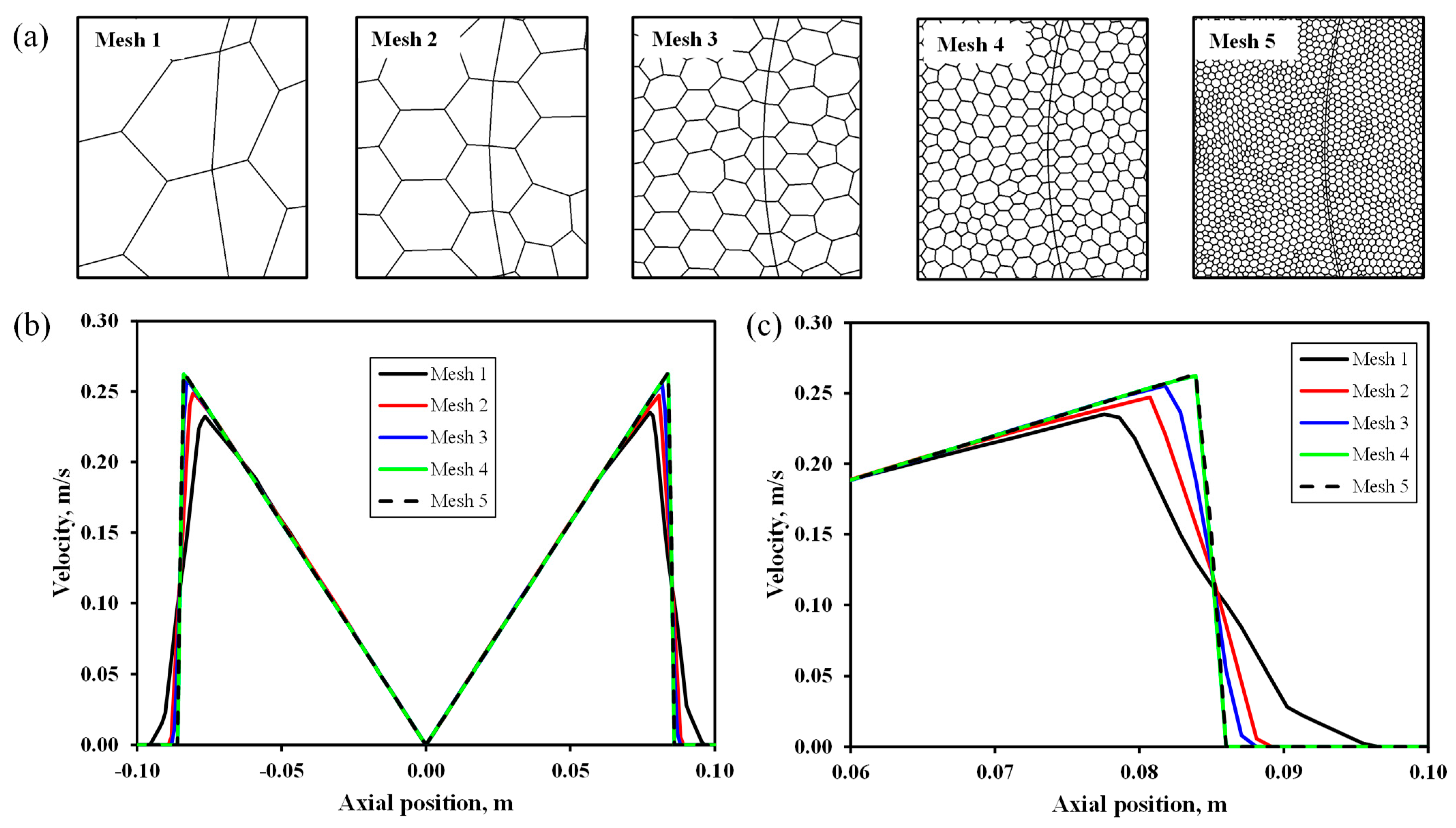

2.7. CFD Simulation

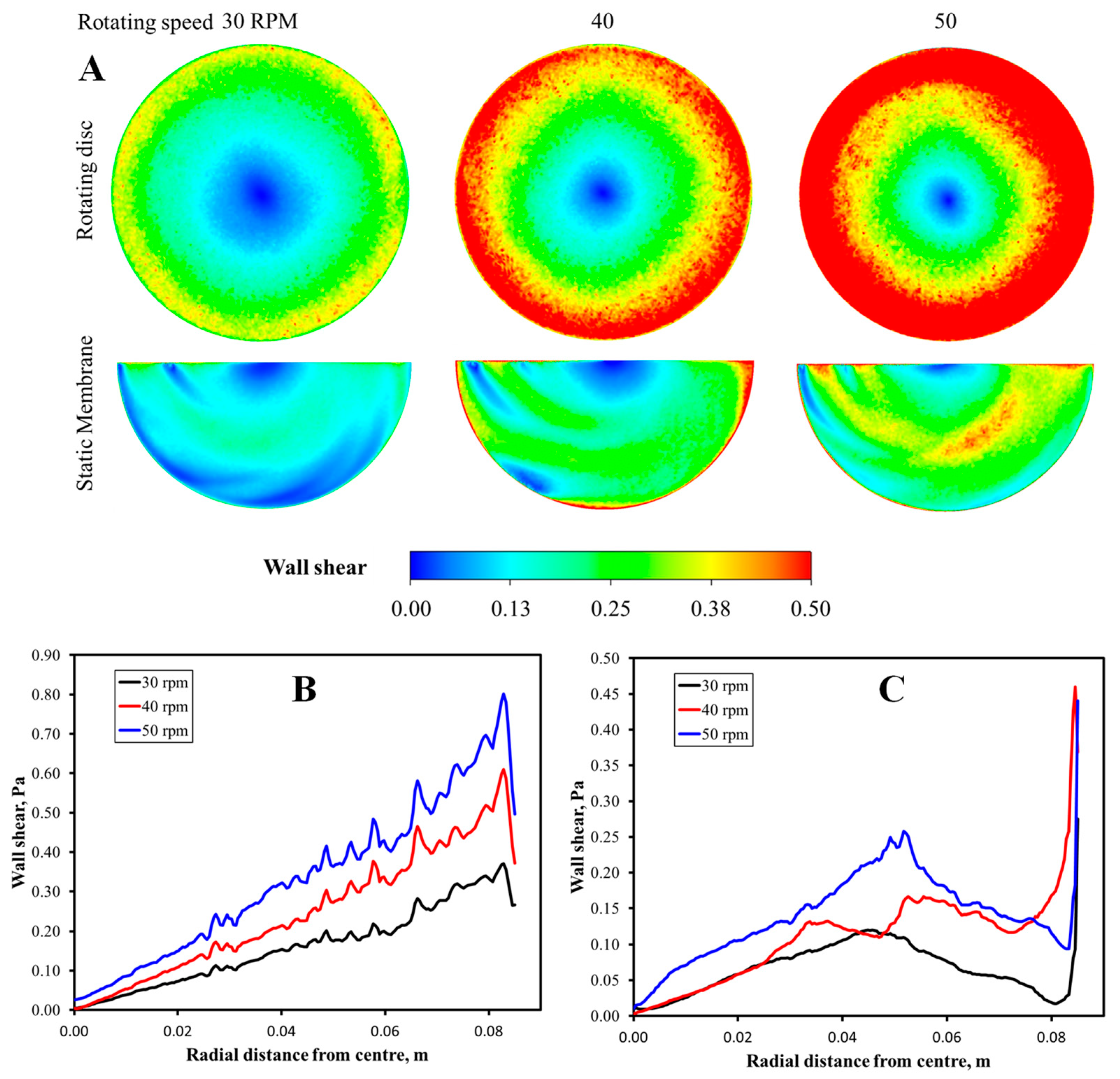

3. Results and Discussion

3.1. Membrane and Feed Properties

3.2. Effect of Rotating Speed

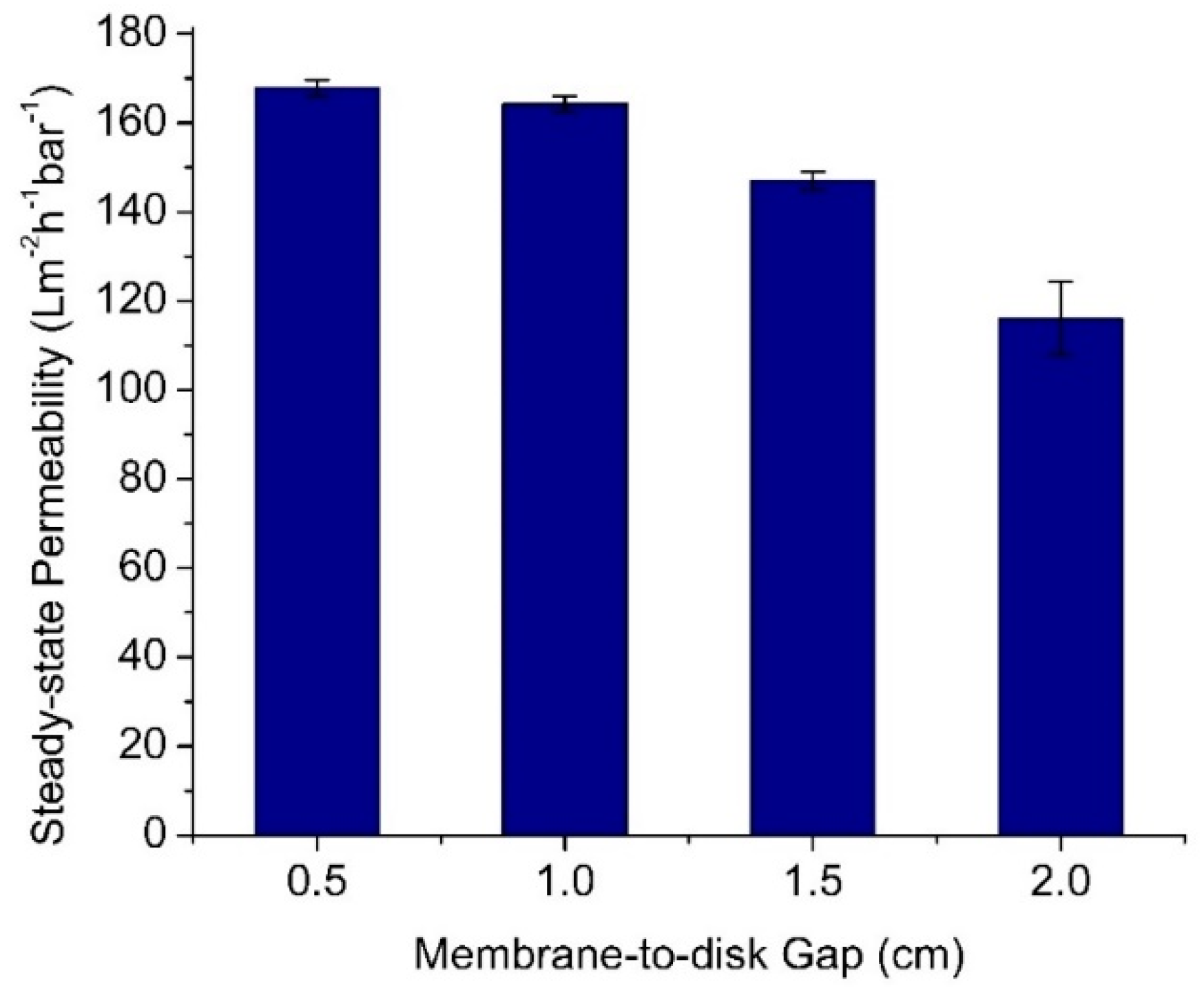

3.3. Effect of Membrane-to-Disk Gap

3.4. Specific Energy Consumption for Fouling Control

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kamali, M.; Suhas, D.; Costa, M.E.; Capela, I.; Aminabhavi, T.M. Sustainability Considerations in Membrane-Based Technologies for Industrial Effluents Treatment. Chem. Eng. J. 2019, 368, 474–494. [Google Scholar] [CrossRef]

- Van Der Bruggen, B.; Vandecasteele, C.; Van Gestel, T.; Doyen, W.; Leysen, R. A Review of Pressure-Driven Membrane Processes in Wastewater Treatment and Drinking Water Production. Environ. Prog. 2003, 22, 46–56. [Google Scholar] [CrossRef]

- Fulazzaky, M.; Setiadi, T.; Fulazzaky, M.A. An Evaluation of the Oilfield-Produced Water Treatment by the Membrane Bioreactor. J. Environ. Chem. Eng. 2020, 8, 104417. [Google Scholar] [CrossRef]

- Guo, W.; Ngo, H.-H.; Li, J. A Mini-Review on Membrane Fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Mat Nawi, N.I.; Chean, H.M.; Shamsuddin, N.; Bilad, M.R.; Narkkun, T.; Faungnawakij, K.; Khan, A.L. Development of Hydrophilic PVDF Membrane Using Vapour Induced Phase Separation Method for Produced Water Treatment. Membranes 2020, 10, 121. [Google Scholar] [CrossRef]

- Rana, D.; Matsuura, T. Surface Modifications for Antifouling Membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Mohamad Annuar, A.; Mat Nawi, N.I.; Bilad, M.R.; Jaafar, J.; Marbelia, L.; Nandianto, A.B.D. Improved Bubbling for Membrane Fouling Control in Filtration of Palm Oil Mill Effluent Anaerobic Digester Sludge. J. Water Process Eng. 2020, 36, 101350. [Google Scholar] [CrossRef]

- Sutzkover-Gutman, I.; Hasson, D. Feed Water Pretreatment for Desalination Plants. Desalination 2010, 264, 289–296. [Google Scholar] [CrossRef]

- Kim, E.-S.; Liu, Y.; Gamal El-Din, M. The Effects of Pretreatment on Nanofiltration and Reverse Osmosis Membrane Filtration for Desalination of Oil Sands Process-Affected Water. Sep. Purif. Technol. 2011, 81, 418–428. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Klaysom, C.; Jaafar, J.; Khan, A.L. An Integrated Rotating Biological Contactor and Membrane Separation Process for Domestic Wastewater Treatment. Alex. Eng. J. 2020, 59, 4257–4265. [Google Scholar] [CrossRef]

- Serra, C.A.; Wiesner, M.R.; Laîné, J.-M. Rotating Membrane Disk Filters: Design Evaluation Using Computational Fluid Dynamics. Chem. Eng. J. 1999, 72, 1–17. [Google Scholar] [CrossRef]

- Brou, A.; Ding, L.; Boulnois, P.; Jaffrin, M.Y. Dynamic Microfiltration of Yeast Suspensions Using Rotating Disks Equipped with Vanes. J. Membr. Sci. 2002, 197, 269–282. [Google Scholar] [CrossRef]

- Bilad, M.R.; Discart, V.; Vandamme, D.; Foubert, I.; Muylaert, K.; Vankelecom, I.F.J. Harvesting Microalgal Biomass Using a Magnetically Induced Membrane Vibration (MMV) System: Filtration Performance and Energy Consumption. Bioresour. Technol. 2013, 138, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.Z.; Mao, Z.; Zhang, Y.; Tan, W.S.; Chong, T.H.; Wu, B.; Chew, J.W. Enhancing Fouling Mitigation of Submerged Flat-Sheet Membranes by Vibrating 3D-Spacers. Sep. Purif. Technol. 2019, 215, 70–80. [Google Scholar] [CrossRef]

- Fillaudeau, L.; Boissier, B.; Moreau, A.; Blanpain-avet, P.; Ermolaev, S.; Jitariouk, N.; Gourdon, A. Investigation of Rotating and Vibrating Filtration for Clarification of Rough Beer. J. Food Eng. 2007, 80, 206–217. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Ban, Z.H.; Ooi, B.S. A Three-Dimensional Unsteady Hydrodynamic Profile of a Reciprocating Membrane Channel. J. Membr. Sci. 2010, 365, 426–437. [Google Scholar] [CrossRef]

- Ho, J.; Smith, S.; Kim, G.D.; Roh, H.K. Performance Evaluation of a Novel Reciprocation Membrane Bioreactor (RMBR) for Enhanced Nutrient Removal in Wastewater Treatment: A Comparative Study. Water Sci. Technol. 2015, 72, 917–927. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic Shear-Enhanced Membrane Filtration: A Review of Rotating Disks, Rotating Membranes and Vibrating Systems. J. Membr. Sci. 2008, 324, 7–25. [Google Scholar] [CrossRef]

- Jaffrin, M.Y.; Ding, L. A Review of Applications of Rotating and Vibrating Membranes Systems: Advantages and Drawbacks. J. Membr. Sep. Technol. 2015, 4, 134. [Google Scholar] [CrossRef]

- Bouzerar, R. Local Permeate Flux–Shear–Pressure Relationships in a Rotating Disk Microfiltration Module: Implications for Global Performance. J. Membr. Sci. 2000, 170, 127–141. [Google Scholar] [CrossRef]

- Jaffrin, M.Y.; Ding, L.-H.; Akoum, O.; Brou, A. A Hydrodynamic Comparison between Rotating Disk and Vibratory Dynamic Filtration Systems. J. Membr. Sci. 2004, 242, 155–167. [Google Scholar] [CrossRef]

- Hapońska, M.; Clavero, E.; Salvadó, J.; Torras, C. Application of ABS Membranes in Dynamic Filtration for Chlorella Sorokiniana Dewatering. Biomass Bioenergy 2017, 111, 224–231. [Google Scholar] [CrossRef]

- Ríos, S.D.; Salvadó, J.; Farriol, X.; Torras, C. Antifouling Microfiltration Strategies to Harvest Microalgae for Biofuel. Bioresour. Technol. 2012, 119, 406–418. [Google Scholar] [CrossRef] [PubMed]

- Frappart, M.; Massé, A.; Jaffrin, M.Y.; Pruvost, J.; Jaouen, P. Influence of Hydrodynamics in Tangential and Dynamic Ultrafiltration Systems for Microalgae Separation. Desalination 2011, 265, 279–283. [Google Scholar] [CrossRef]

- Sarkar, P.; Ghosh, S.; Dutta, S.; Sen, D.; Bhattacharjee, C. Effect of Different Operating Parameters on the Recovery of Proteins from Casein Whey Using a Rotating Disc Membrane Ultrafiltration Cell. Desalination 2009, 249, 5–11. [Google Scholar] [CrossRef]

- Xie, X.; Le Men, C.; Dietrich, N.; Schmitz, P.; Fillaudeau, L. Local Hydrodynamic Investigation by PIV and CFD within a Dynamic Filtration Unit under Laminar Flow. Sep. Purif. Technol. 2018, 198, 38–51. [Google Scholar] [CrossRef]

- Xie, X.; Andre, C.; Dietrich, N.; Schmitz, P.; Fillaudeau, L. Flow Investigation in an Innovating Dynamic Filtration Module Using Tracing Methods. Sep. Purif. Technol. 2019, 227, 115656. [Google Scholar] [CrossRef]

- Miao, R.; Qiu, K.; Wang, B.; Wei, X.; Zuo, J.; Ma, B. Enhanced Ultrafiltration Membrane Fouling Alleviation by Module Rotation with Fe-Based Flocs. J. Environ. Chem. Eng. 2021, 9, 105811. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, Y.; Mao, Z.; Tan, W.S.; Tan, Y.Z.; Chew, J.W.; Chong, T.H.; Fane, A.G. Spacer Vibration for Fouling Control of Submerged Flat Sheet Membranes. Sep. Purif. Technol. 2019, 210, 719–728. [Google Scholar] [CrossRef]

- Rahmawati, R.; Bilad, M.R.; Nawi, N.I.M.; Wibisono, Y.; Suhaimi, H.; Shamsuddin, N.; Arahman, N. Engineered Spacers for Fouling Mitigation in Pressure Driven Membrane Processes: Progress and Projection. J. Environ. Chem. Eng. 2021, 9, 106285. [Google Scholar] [CrossRef]

- Choi, Y.; Oh, H.; Lee, S.; Choi, Y.; Hwang, T.-M.; Jeon, J.; Choung, Y.-K. Removal of Taste and Odor Model Compounds (2-MIB and Geosmin) with the NF Membrane. Desalin. Water Treat. 2010, 15, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Bilad, M.R.; Guillen-Burrieza, E.; Mavukkandy, M.O.; Al Marzooqi, F.A.; Arafat, H.A. Shrinkage, Defect and Membrane Distillation Performance of Composite PVDF Membranes. Desalination 2015, 376, 62–72. [Google Scholar] [CrossRef]

- Pereira, D.G.; Afonso, A.; Medeiros, F.M. Overview of Friedman’s Test and Post-Hoc Analysis. Commun. Stat.-Simul. Comput. 2015, 44, 2636–2653. [Google Scholar] [CrossRef]

- Ahmad, T.; Guria, C.; Mandal, A. A Review of Oily Wastewater Treatment Using Ultrafiltration Membrane: A Parametric Study to Enhance the Membrane Performance. J. Water Process Eng. 2020, 36, 101289. [Google Scholar] [CrossRef]

- Mat Nawi, N.I.; Abd Halim, N.S.; Lee, L.C.; Wirzal, M.D.H.; Bilad, M.R.; Nordin, N.A.H.; Putra, Z.A. Improved Nylon 6,6 Nanofiber Membrane in A Tilted Panel Filtration System for Fouling Control in Microalgae Harvesting. Polymers 2020, 12, 252. [Google Scholar] [CrossRef] [Green Version]

- Razak, N.N.A.N.; Rahmawati, R.; Bilad, M.R.; Pratiwi, A.E.; Elma, M.; Nawi, N.I.M.; Jaafar, J.; Lam, M.K. Finned Spacer for Enhancing the Impact of Air Bubbles for Membrane Fouling Control in Chlorella Vulgaris Filtration. Bioresour. Technol. Rep. 2020, 11, 100429. [Google Scholar] [CrossRef]

- Salama, A. Modeling of Flux Decline Behavior during the Filtration of Oily-Water Systems Using Porous Membranes: Effect of Pinning of Nonpermeating Oil Droplets. Sep. Purif. Technol. 2018, 207, 240–254. [Google Scholar] [CrossRef]

- Salama, A.; Ibrahim, H.; Adhikari, K.; Ismail, M. Investigation of the Onset of Dislodgment of a Nonpermeating Oil Droplet at a Membrane Surface: Standard Models and a New Force Balance Model. Colloids Surf. Physicochem. Eng. Asp. 2018, 556, 11–22. [Google Scholar] [CrossRef]

- Kim, J.; Shin, J.; Kim, H.; Lee, J.-Y.; Yoon, M.; Won, S.; Lee, B.-C.; Song, K.G. Membrane Fouling Control Using a Rotary Disk in a Submerged Anaerobic Membrane Sponge Bioreactor. Bioresour. Technol. 2014, 172, 321–327. [Google Scholar] [CrossRef]

- Hwang, K.-J.; Wang, S.-Y.; Iritani, E.; Katagiri, N. Fine Particle Removal from Seawater by Using Cross-Flow and Rotating-Disk Dynamic Filtration. J. Taiwan Inst. Chem. Eng. 2016, 62, 45–53. [Google Scholar] [CrossRef]

- Engler, J.A. Investigation of Membrane Filtration in a Rotating Disk Geometry: Use of Computational Fluid Dynamics and Laboratory Evaluation. Master’s Thesis, Rice University, Houston, TX, USA, 1997. [Google Scholar]

- Bendick, J.; Reed, B.; Morrow, P.; Carole, T. Using a High Shear Rotary Membrane System to Treat Shipboard Wastewaters: Experimental Disc Diameter, Rotation and Flux Relationships. J. Membr. Sci. 2014, 462, 178–184. [Google Scholar] [CrossRef]

- Niu, Z.; Guo, H.; Zhou, Y.; Xia, S. Unraveling Membrane Fouling in Anoxic/Oxic Membrane Bioreactors Treating Anaerobically Digested Piggery Wastewater. J. Environ. Chem. Eng. 2021, 9, 104985. [Google Scholar] [CrossRef]

- Pinilla, A.; Berrio, J.C.; Guerrero, E.; Valdés, J.P.; Becerra, D.; Pico, P.; Vargas, L.; Madsen, S.; Bentzen, T.R.; Ratkovich, N. CFD Modelling of the Hydrodynamics in a Filtration Unit with Rotating Membranes. J. Water Process Eng. 2020, 36, 101368. [Google Scholar] [CrossRef]

- Al-Abbasi, O.; Bin Shams, M. Dynamic CFD Modelling of an Industrial-Scale Dead-End Ultrafiltration System: Full Cycle and Complete Blockage. J. Water Process Eng. 2021, 40, 101887. [Google Scholar] [CrossRef]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane Bioreactors—A Review on Recent Developments in Energy Reduction, Fouling Control, Novel Configurations, LCA and Market Prospects. J. Membr. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Sosa, D.; Helmreich, B.; Netter, T.; Paris, S.; Bischof, F.; Horn, H. Anaerobic Submerged Membrane Bioreactor (AnSMBR) for Municipal Wastewater Treatment under Mesophilic and Psychrophilic Temperature Conditions. Bioresour. Technol. 2011, 102, 10377–10385. [Google Scholar] [CrossRef]

- Martin, I.; Pidou, M.; Soares, A.; Judd, S.; Jefferson, B. Modelling the Energy Demands of Aerobic and Anaerobic Membrane Bioreactors for Wastewater Treatment. Environ. Technol. 2011, 32, 921–932. [Google Scholar] [CrossRef]

- Shin, C.; Bae, J. Current Status of the Pilot-Scale Anaerobic Membrane Bioreactor Treatments of Domestic Wastewaters: A Critical Review. Bioresour. Technol. 2018, 247, 1038–1046. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Suleman, H.; Hadi Nordin, N.A.; Jaafar, J.; Dzarfan Othman, M.H.; Elma, M. An Energy-Efficient Membrane Rotating Biological Contactor for Wastewater Treatment. J. Clean. Prod. 2021, 282, 124544. [Google Scholar] [CrossRef]

- Lu, Q.; Li, N. Preparation of Hydrophilic Polyvinylidene Fluoride/Polyvinyl Alcohol Ultrafiltration Membrane via Polymer/Non-Solvent Co-Induced Phase Separation Method towards Enhance Anti-Fouling Performance. J. Environ. Chem. Eng. 2021, 9, 106431. [Google Scholar] [CrossRef]

- Nemade, P.R.; Ganjare, A.V.; Ramesh, K.; Rakte, D.M.; Vaishnavi, P.S.V.; Thapa, G. Low Fouling Sulphonated Carbon Soot-Polysulphone Membranes for Rapid Dehydration of Stabilized Oil-Water Emulsions. J. Water Process Eng. 2020, 38, 101590. [Google Scholar] [CrossRef]

| Mesh | Size (mm) | No. of Cells | |

|---|---|---|---|

| Tetrahedral | Polyhedral | ||

| 1 | 20.0 | 403,411 | 74,510 |

| 2 | 10.0 | 408,215 | 76,023 |

| 3 | 5.0 | 456,440 | 86,953 |

| 4 | 2.5 | 780,897 | 152,042 |

| 5 | 1.0 | 4,127,764 | 779,710 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mat Nawi, N.I.; Mohd Lazis, A.; Rahma, A.; Elma, M.; Bilad, M.R.; Md Nordin, N.A.H.; Wirzal, M.D.H.; Shamsuddin, N.; Suhaimi, H.; Yusof, N. A Rotary Spacer System for Energy-Efficient Membrane Fouling Control in Oil/Water Emulsion Filtration. Membranes 2022, 12, 554. https://doi.org/10.3390/membranes12060554

Mat Nawi NI, Mohd Lazis A, Rahma A, Elma M, Bilad MR, Md Nordin NAH, Wirzal MDH, Shamsuddin N, Suhaimi H, Yusof N. A Rotary Spacer System for Energy-Efficient Membrane Fouling Control in Oil/Water Emulsion Filtration. Membranes. 2022; 12(6):554. https://doi.org/10.3390/membranes12060554

Chicago/Turabian StyleMat Nawi, Normi Izati, Afiq Mohd Lazis, Aulia Rahma, Muthia Elma, Muhammad Roil Bilad, Nik Abdul Hadi Md Nordin, Mohd Dzul Hakim Wirzal, Norazanita Shamsuddin, Hazwani Suhaimi, and Norhaniza Yusof. 2022. "A Rotary Spacer System for Energy-Efficient Membrane Fouling Control in Oil/Water Emulsion Filtration" Membranes 12, no. 6: 554. https://doi.org/10.3390/membranes12060554

APA StyleMat Nawi, N. I., Mohd Lazis, A., Rahma, A., Elma, M., Bilad, M. R., Md Nordin, N. A. H., Wirzal, M. D. H., Shamsuddin, N., Suhaimi, H., & Yusof, N. (2022). A Rotary Spacer System for Energy-Efficient Membrane Fouling Control in Oil/Water Emulsion Filtration. Membranes, 12(6), 554. https://doi.org/10.3390/membranes12060554