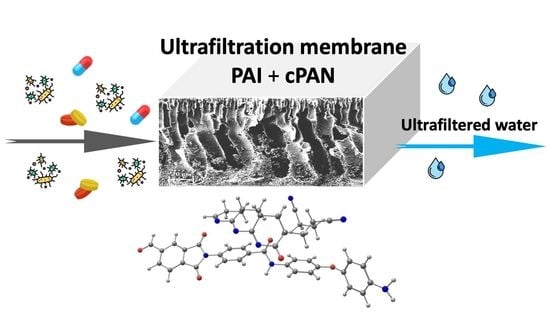

Application of Cyclized Polyacrylonitrile for Ultrafiltration Membrane Fouling Mitigation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Membranes

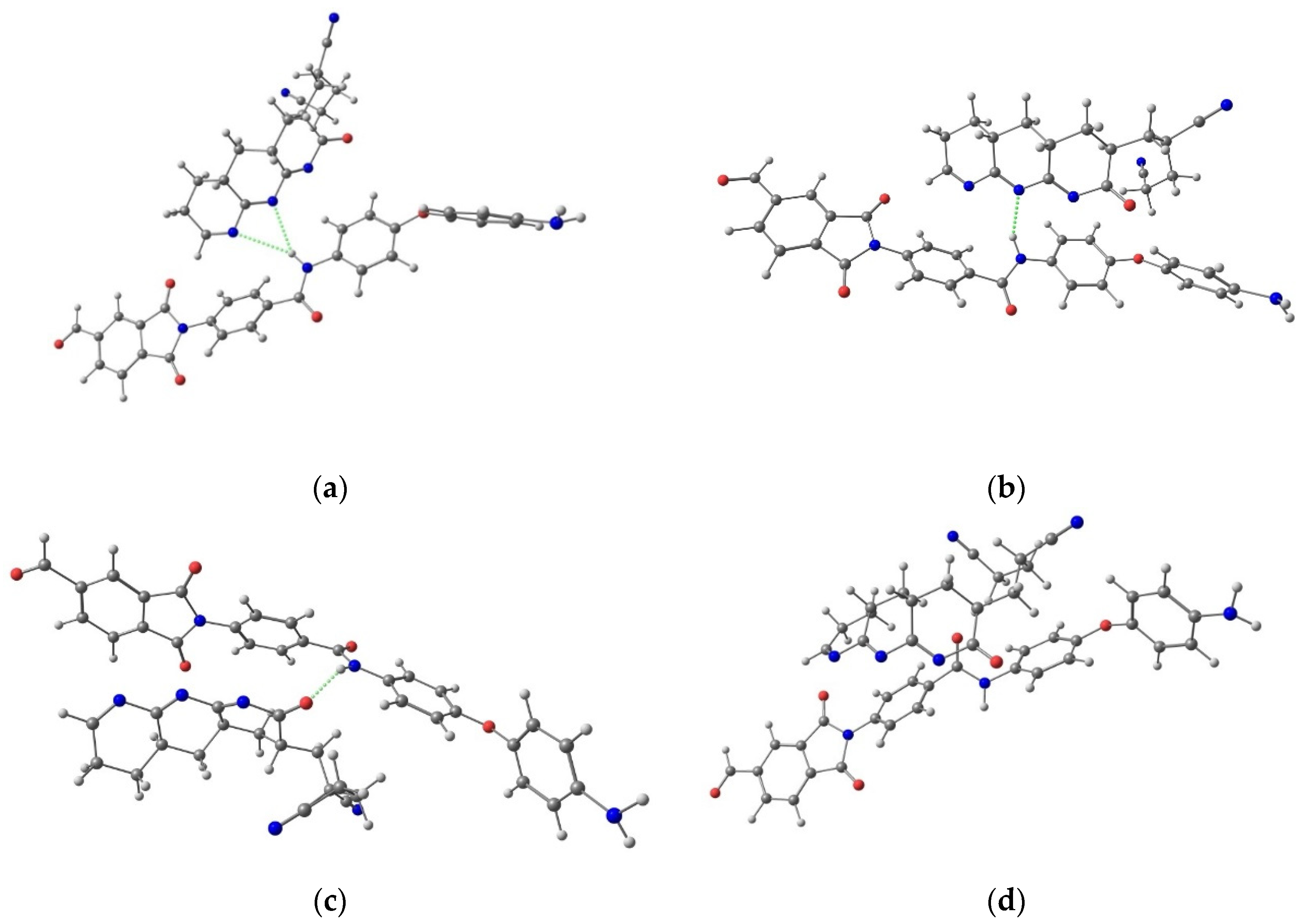

2.3. Computational Details

2.4. Characterization

3. Results and Discussion

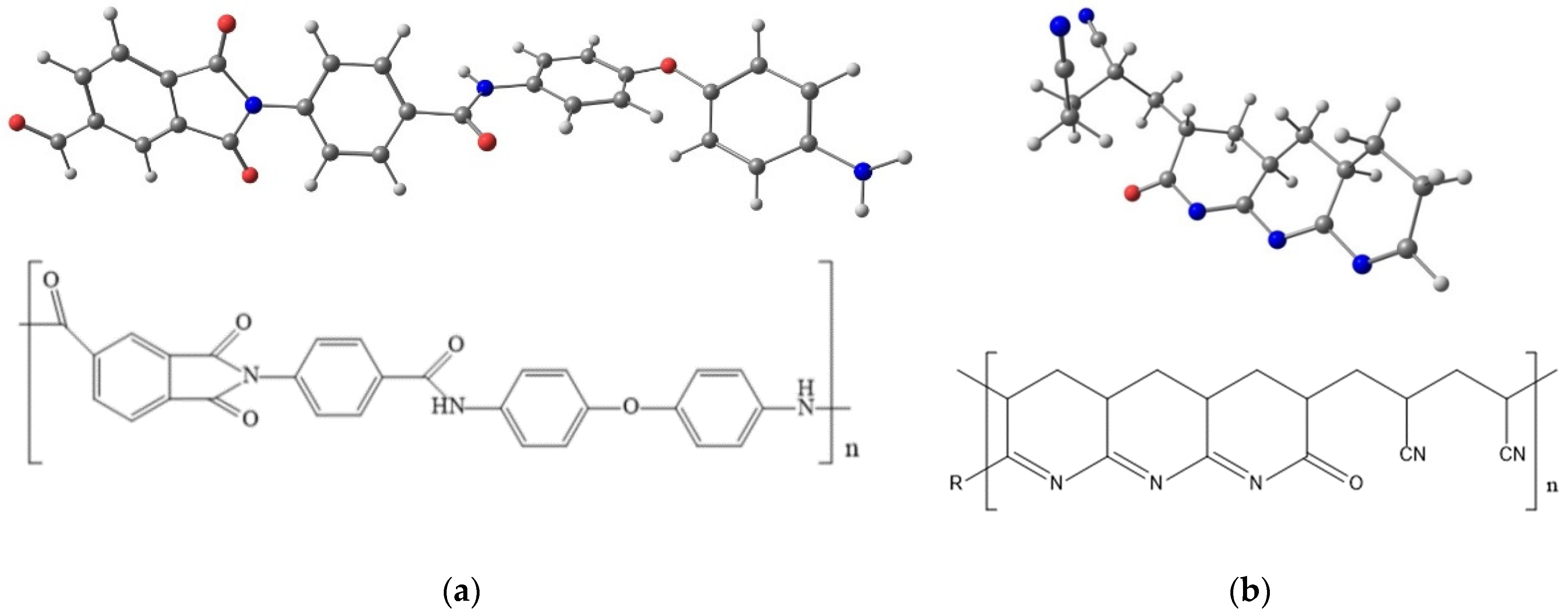

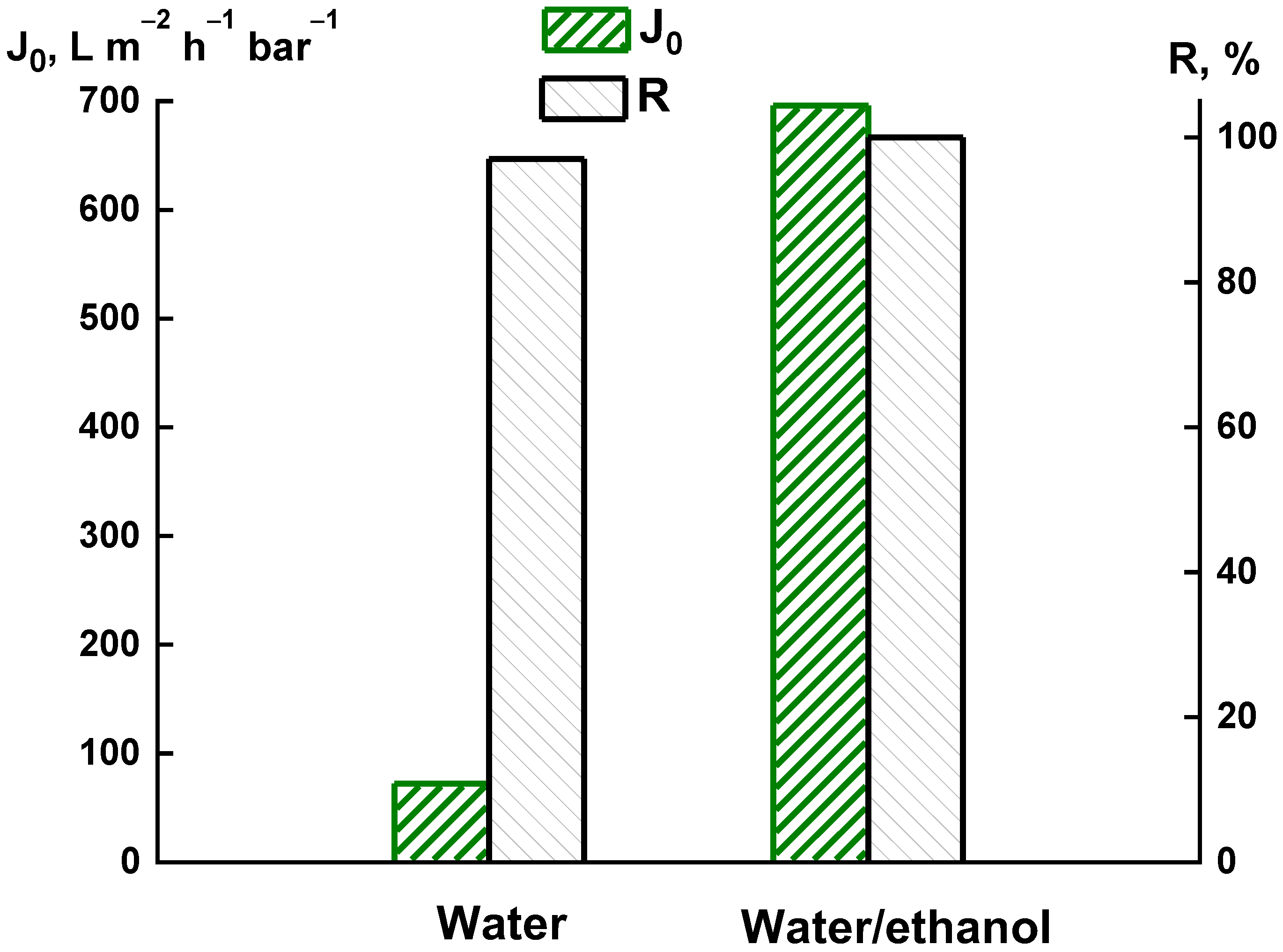

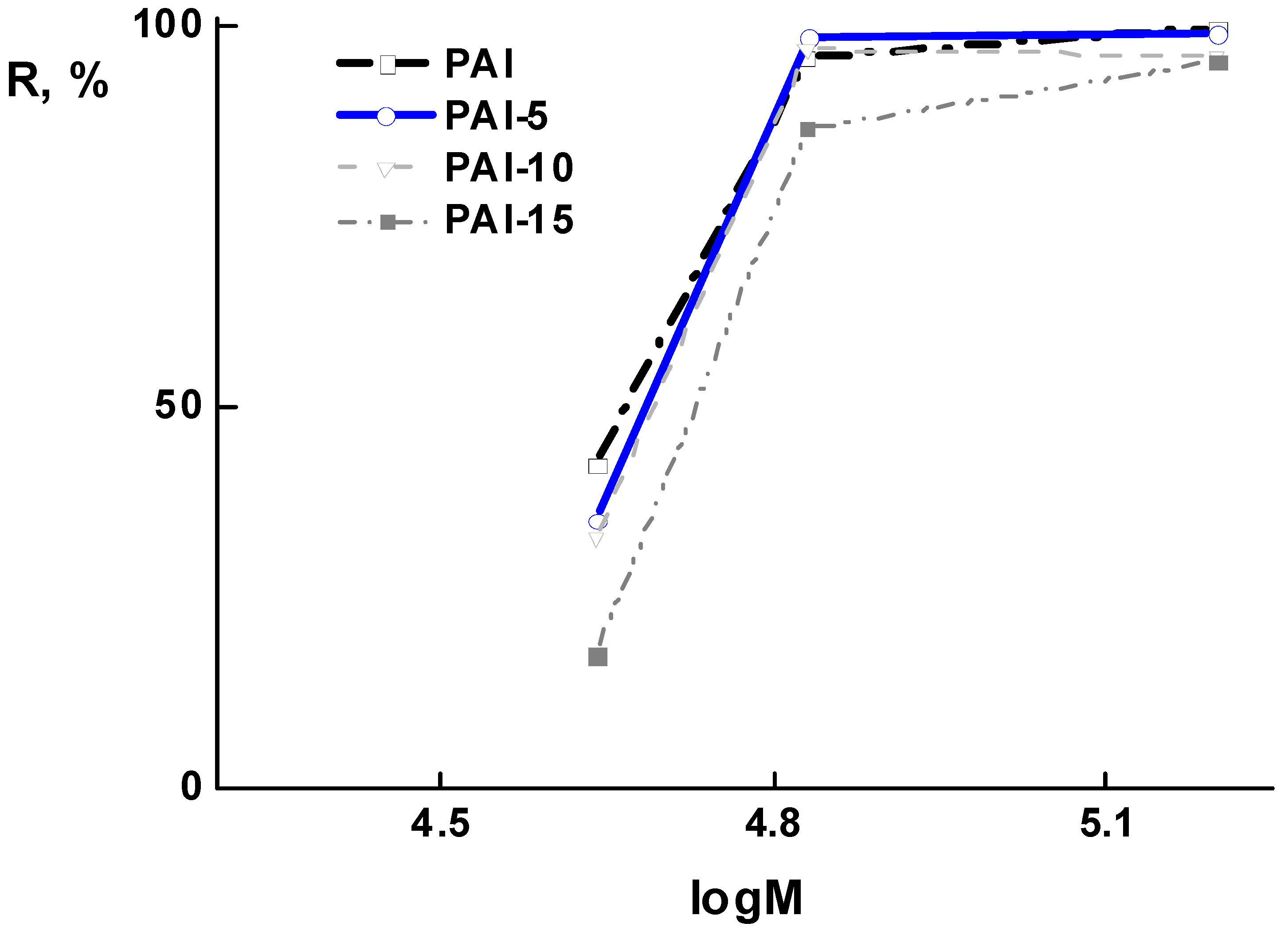

3.1. Transport Properties of Poly(Amide-Imide) (PAI)

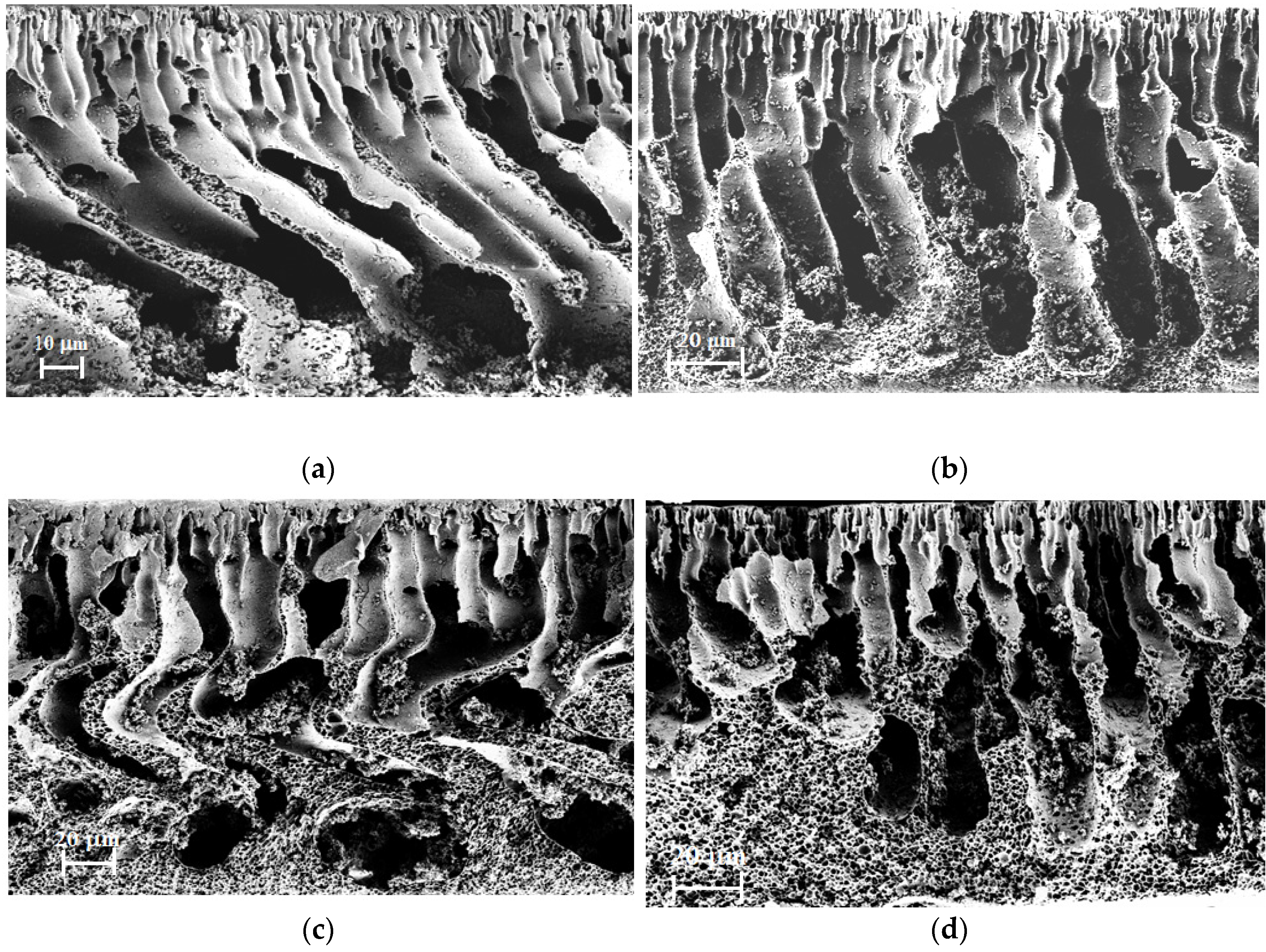

3.2. Membrane Structure and Characterization

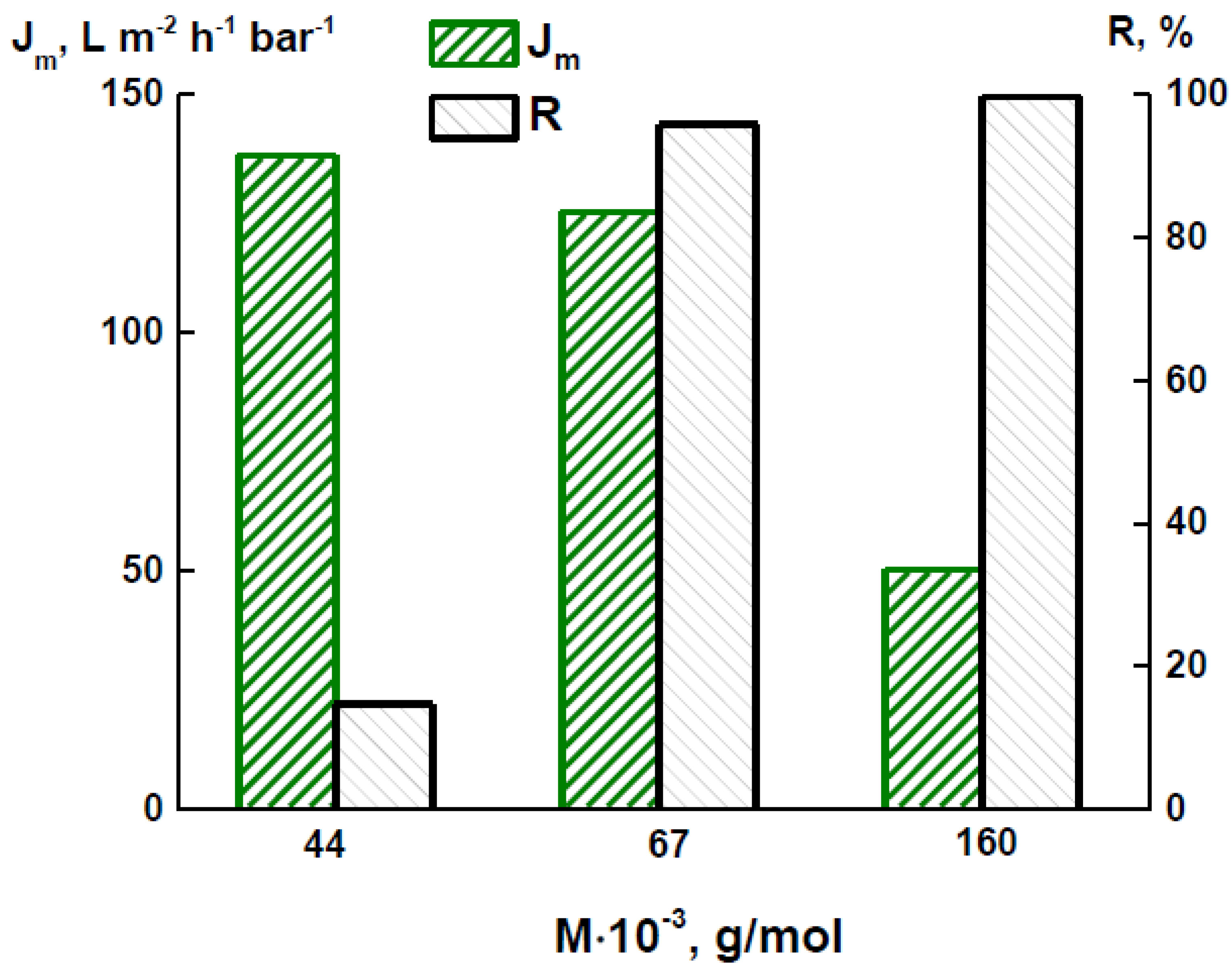

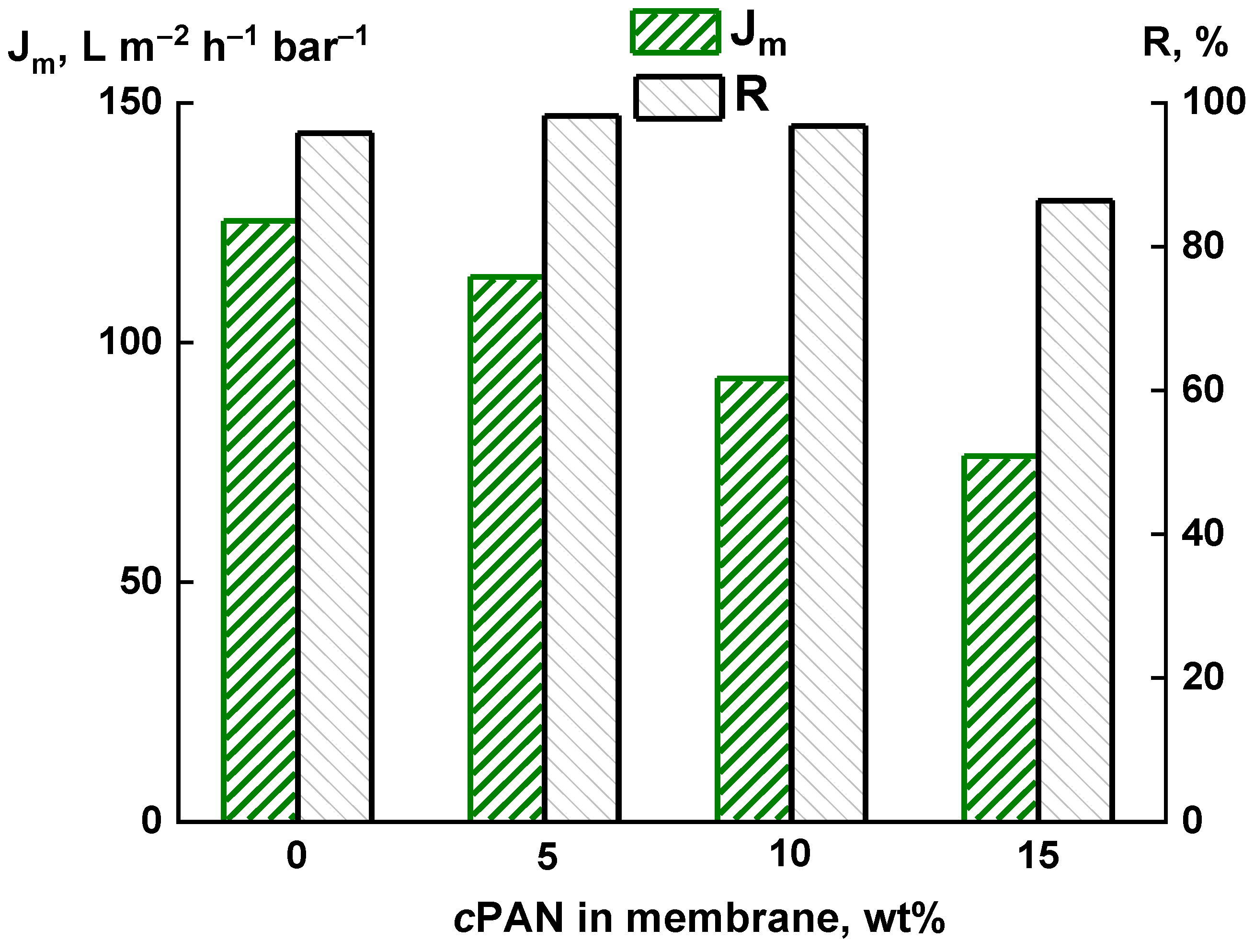

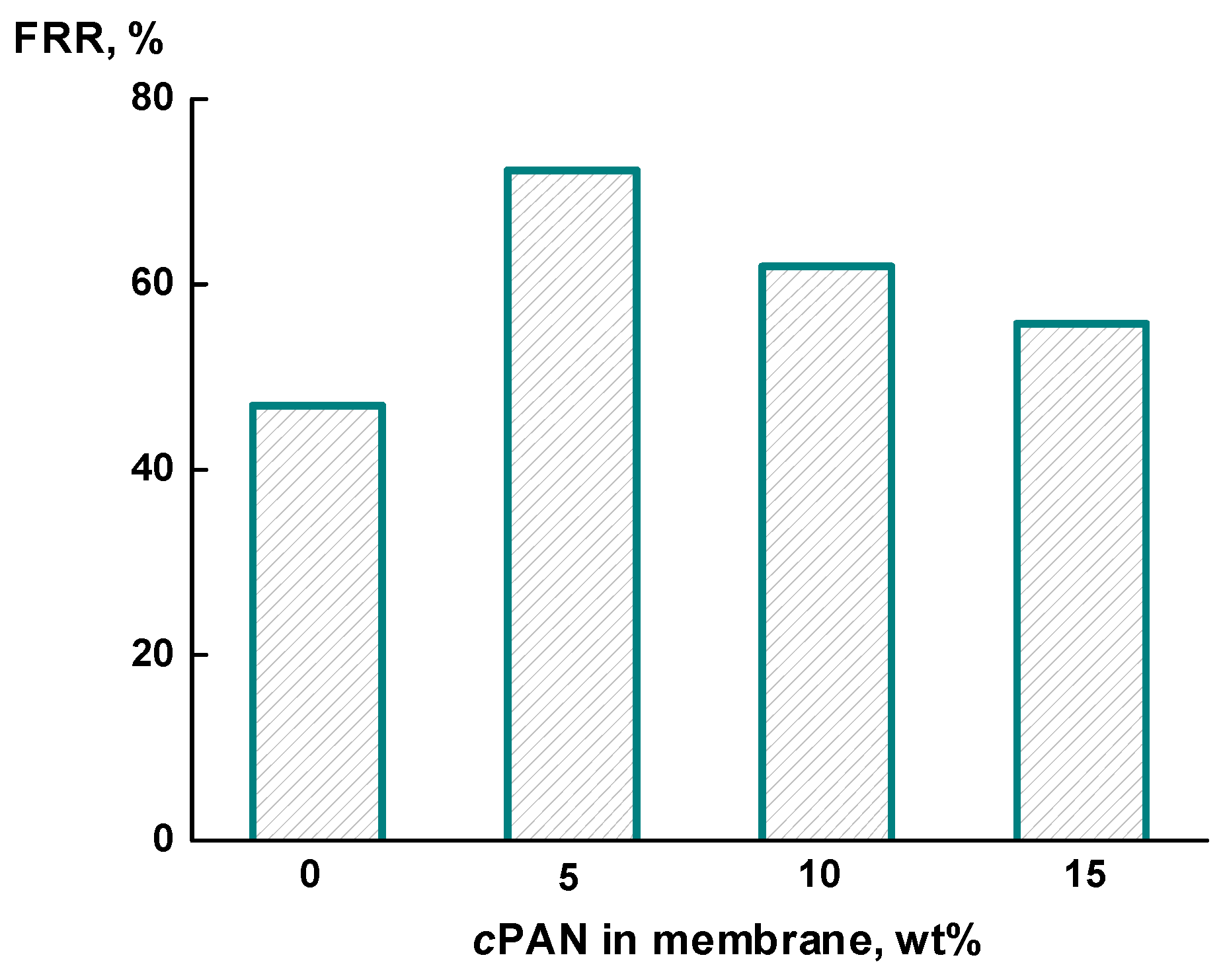

3.3. Transport Properties of the Polymer Composites (PAI/cPAN)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Castro-Muñoz, R.; Galiano, F.; Figoli, A.; Fíla, V.; Drioli, E.; Figoli, A. Matrimid®5218 dense membrane for the separation of azeotropic MeOH-MTBE mixtures by pervaporation. Sep. Purif. Technol. 2018, 199, 27–36. [Google Scholar] [CrossRef]

- Penkova, A.V.; Dmitrenko, M.E.; Ermakov, S.S.; Toikka, A.M.; Roizard, D. Novel green PVA-fullerenol mixed matrix supported membranes for separating water-THF mixtures by pervaporation. Environ. Sci. Pollut. Res. 2018, 25, 20354–20362. [Google Scholar] [CrossRef] [PubMed]

- Kamp, J.; Emonds, S.; Borowec, J.; Restrepo Toro, M.A.; Wessling, M. On the organic solvent free preparation of ultrafiltration and nanofiltration membranes using polyelectrolyte complexation in an all aqueous phase inversion process. J. Membr. Sci. 2021, 618, 118632. [Google Scholar] [CrossRef]

- Dmitrenko, M.E.; Penkova, A.V.; Missyul, A.B.; Kuzminova, A.I.; Markelov, D.A.; Ermakov, S.S.; Roizard, D. Development and investigation of mixed-matrix PVA-fullerenol membranes for acetic acid dehydration by pervaporation. Sep. Purif. Technol. 2017, 187, 285–293. [Google Scholar] [CrossRef]

- Penkova, A.V.; Dmitrenko, M.E.; Sokolova, M.P.; Chen, B.; Plisko, T.V.; Markelov, D.A.; Ermakov, S.S. Impact of fullerene loading on the structure and transport properties of polysulfone mixed-matrix membranes. J. Mater. Sci. 2016, 51, 7652–7659. [Google Scholar] [CrossRef]

- Hube, S.; Eskafi, M.; Hrafnkelsdóttir, K.F.; Bjarnadóttir, B.; Bjarnadóttir, M.A.; Axelsdóttir, S.; Wu, B. Direct membrane filtration for wastewater treatment and resource recovery: A review. Sci. Total Environ. 2020, 710, 136375. [Google Scholar] [CrossRef]

- Van der Bruggen, B. Microfiltration, ultrafiltration, nanofiltration, reverse osmosis, and forward osmosis. In Fundamental Modelling of Membrane Systems, Membrane and Process Performance; Luis, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 25–70. ISBN 978-0-12-813483-2. [Google Scholar]

- Qu, F.; Liang, H.; Zhou, J.; Nan, J.; Shao, S.; Zhang, J.; Li, G. Ultrafiltration membrane fouling caused by extracellular organic matter (EOM) from microcystis aeruginosa: Effects of membrane pore size and surface hydrophobicity. J. Membr. Sci. 2014, 449, 58–66. [Google Scholar] [CrossRef]

- Al Aani, S.; Mustafa, T.N.; Hilal, N. Ultrafiltration membranes for wastewater and water process engineering: A comprehensive statistical review over the past decade. J. Water Process Eng. 2020, 35, 101241. [Google Scholar] [CrossRef]

- Field, R.W.; Wu, J.J. Permeate Flux in Ultrafiltration Processes—Understandings and Misunderstandings. Membranes 2022, 12, 187. [Google Scholar] [CrossRef]

- Cherkasov, A.N.; Tsareva, S.V.; Polotsky, A.E. Selective properties of ultrafiltration membranes from the standpoint of concentration polarization and adsorption phenomena. J. Membr. Sci. 1995, 104, 157–164. [Google Scholar] [CrossRef]

- Susanto, H.; Ulbricht, M. High-performance thin-layer hydrogel composite membranes for ultrafiltration of natural organic matter. Water Res. 2008, 42, 2827–2835. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q.; Su, Y.; Zhu, S.; Li, C.; Zhao, Y.; Jiang, Z. A facile method for synthesis of pegylated polyethersulfone and its application in fabrication of antifouling ultrafiltration membrane. J. Membr. Sci. 2007, 303, 204–212. [Google Scholar] [CrossRef]

- Olimattel, K.; Church, J.; Lee, W.H.; Chumbimuni-Torres, K.Y.; Zhai, L.; Anwar Sadmani, A.H.M. Enhanced Fouling Resistance and Antimicrobial Property of Ultrafiltration Membranes Via Polyelectrolyte-Assisted Silver Phosphate Nanoparticle Immobilization. Membranes 2020, 10, 293. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Yin, J.; Tang, H.; Zhang, Z.; Liu, D.; Liu, S.; Xu, Z.; Li, N. Improved permeability and antifouling performance of Tröger’s base polymer-based ultrafiltration membrane via zwitterionization. J. Membr. Sci. 2022, 646, 120251. [Google Scholar] [CrossRef]

- Said, N.; Khoo, Y.S.; Lau, W.J.; Gürsoy, M.; Karaman, M.; Ting, T.M.; Abouzari-Lotf, E.; Ismail, A.F. Rapid surface modification of ultrafiltration membranes for enhanced antifouling properties. Membranes 2020, 10, 401. [Google Scholar] [CrossRef]

- Peyravi, M.; Rahimpour, A.; Jahanshahi, M.; Javadi, A.; Shockravi, A. Tailoring the surface properties of PES ultrafiltration membranes to reduce the fouling resistance using synthesized hydrophilic copolymer. Micropor. Mesopor. Mater. 2012, 160, 114–125. [Google Scholar] [CrossRef]

- Susanti, R.F.; Han, Y.S.; Kim, J.; Lee, Y.H.; Carbonell, R.G. A new strategy for ultralow biofouling membranes: Uniform and ultrathin hydrophilic coatings using liquid carbon dioxide. J. Membr. Sci. 2013, 440, 88–97. [Google Scholar] [CrossRef]

- Purnawan, I.; Angputra, D.; Debora, S.C.; Karamah, E.F.; Febriasari, A.; Kartohardjono, S. Polyvinylidene Fluoride Membrane with a Polyvinylpyrrolidone Additive for Tofu Industrial Wastewater Treatment in Combination with the Coagulation-Flocculation Process. Membranes 2021, 11, 948. [Google Scholar] [CrossRef]

- Polotskaya, G.A.; Pulyalina, A.Y.; Rostovtseva, V.A.; Toikka, A.M.; Saprykina, N.N.; Vinogradova, L.V. Effect of polystyrene stars with fullerene C60 cores on structure and transport properties of polyphenylene oxide membrane. Polym. Int. 2016, 65, 407–414. [Google Scholar] [CrossRef]

- Li, D.; Gao, C.; Wang, X.; Wu, G.; Yin, J.; Huang, Y.; Sun, X. Zwitterionic Polysulfone Copolymer/Polysulfone Blended Ultrafiltration Membranes with Excellent Thermostability and Antifouling Properties. Membranes 2021, 11, 932. [Google Scholar] [CrossRef]

- Bildyukevich, A.; Plisko, T.; Shustikov, A.; Dzyazko, Y.; Rozhdestvenska, L.; Pratsenko, S. Effect of the solvent nature on the structure and performance of poly(amide-imide) ultrafiltration membranes. J. Mater. Sci. 2020, 55, 9638–9654. [Google Scholar] [CrossRef]

- Kosuri, M.R.; Koros, W.J. Defect-free asymmetric hollow fiber membranes from Torlon®, a polyamide-imide polymer, for high-pressure CO2 separations. J. Membr. Sci. 2008, 320, 65–72. [Google Scholar] [CrossRef]

- Pulyalina, A.; Rostovtseva, V.; Minich, I.; Silyukov, O.; Toikka, M.; Saprykina, N.; Polotskaya, G. Specific Structure and Properties of Composite Membranes Based on the Torlon® (Polyamide-imide)/Layered Perovskite Oxide. Symmetry 2020, 12, 1142. [Google Scholar] [CrossRef]

- Dmitrenko, M.E.; Penkova, A.V.; Atta, R.R.; Zolotarev, A.A.; Plisko, T.V.; Mazur, A.S.; Solovyev, N.D.; Ermakov, S.S. The development and study of novel membrane materials based on polyphenylene isophthalamide-Pluronic F127 composite. Mater. Des. 2019, 165, 107596. [Google Scholar] [CrossRef]

- Dmitrenko, M.E.; Penkova, A.V.; Kuzminova, A.I.; Atta, R.R.; Zolotarev, A.A.; Mazur, A.S.; Vezo, O.S.; Lahderanta, E.; Markelov, D.A.; Ermakov, S.S. Development and investigation of novel polyphenylene isophthalamide pervaporation membranes modified with various fullerene derivatives. Sep. Purif. Technol. 2019, 226, 241–251. [Google Scholar] [CrossRef]

- Polotskaya, G.A.; Kuznetsov, Y.P.; Romashkova, K.A.; Bleha, M.; Shauer, J.; Urban, J. Composite polyamideimide–poly(2,6-dimethyl-1,4-phenylene oxide) membrane for gas separation. Polym. Sci. 1992, 34, 908–911. [Google Scholar]

- Sukhanova, T.Y.; Kuznetsov, Y.P.; Kruchinina, Y.V.; Lukashova, N.V.; Sidorovich, A.V.; Gusinskaya, V.A.; Peltsbauer, Z. Morphology of asymmetrical membranes of aromatic polyamidoimides and evaluation of their transport and selective properties for a number of gasses. Polym. Sci. 1989, 31, 2741–2748. [Google Scholar] [CrossRef]

- Sapegin, D.; Gubanova, G.; Popova, E.; Kononova, S. Increasing the performance of asymmetric pervaporation membranes for the separation of methanol/methyl-tert-butyl ether mixtures by the introduction of sulfonated polyimide into the poly(amide-imide) matrix. J. Appl. Polym. Sci. 2021, 138, 49982–49993. [Google Scholar] [CrossRef]

- Cherkasov, A.N.; Polotsky, A.E. Resolving power of ultrafiltration. J. Membr. Sci. 1996, 110, 79–82. [Google Scholar] [CrossRef]

- Plisko, T.V.; Bildyukevich, A.V.; Burts, K.S.; Hliavitskaya, T.A.; Penkova, A.V.; Ermakov, S.S.; Ulbricht, M. Modification of Polysulfone Ultrafiltration Membranes via Addition of Anionic Polyelectrolyte Based on Acrylamide and Sodium Acrylate to the Coagulation Bath to Improve Antifouling Performance in Water Treatment. Membranes 2020, 10, 264. [Google Scholar] [CrossRef]

- Polotskaya, G.A.; Kuznetsov, Y.P.; Ulianova, N.N.; Belonovskaya, G.P.; Baranovskaya, I.A. Processes determining the molecular weight parameters of anionic polyacrylonitrile. Acta Polym. 1986, 37, 83–86. [Google Scholar] [CrossRef]

- Ruminskaya, I.G.; Romanova, E.P.; Agranova, S.A.; Polotskaya, G.A.; Frenkel, S.Y. Influence of Synthesis Method on Kinetics of Conformational Transformations in Polyacrylonitrile Solutions. Vysokomol. Soed. 1991, 33, 195–198. [Google Scholar]

- Sazanov, Y.N. Polyacrylonitrile. White and Black Pearls; Polytechnic University: St. Petersburg, Russia, 2017; 302p, ISBN 978-5-7422-5584-0. (In Russian) [Google Scholar]

- Polotskaya, G.A.; Meleshko, T.K.; Novoselova, A.V.; Gofman, I.V.; Polotsky, A.E. New approach to ultrafiltration polyimide membrane formation with involvement of modified polyacrylonitrile. Pet. Chem. 2012, 53, 527–532. [Google Scholar] [CrossRef]

- Gusinskaya, V.; Koton, M.; Batrakova, T.; Romashkova, K. Poly(amido)imides based on symmetrical and asymmetrical imido acid dichlorides. Polym. Sci. 1976, 18, 3062–3068. [Google Scholar]

- Novoselova, A.V.; Zgonnik, V.N.; Spirina, T.P.; Lyubimova, G.V.; Orlova, G.A.; Shulagina, N.N. Cyclization of poly(acrylonitrile) under the influence of anionic initiators. Polym. Sci. 1993, 35, 510. [Google Scholar]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Mennucci, B.; Petersson, G.A.; et al. Gaussian 09, Revision C.01; Gaussian, Inc.: Wallingford, CT, USA, 2010. [Google Scholar]

- Baek, Y.; Kang, J.; Theato, P.; Yoon, J. Measuring hydrophilicity of RO membranes by contact angles via sessile drop and captive bubble method: A comparative study. Desalination 2012, 303, 23–28. [Google Scholar] [CrossRef]

- Polotskaya, G.A.; Meleshko, T.K.; Gofman, I.V.; Polotsky, A.E.; Cherkasov, A.N. Polyimide ultrafiltration membranes with high thermal stability and chemical durability. Sep. Sci. Technol. 2009, 44, 3814–3831. [Google Scholar] [CrossRef]

- Cherkasov, A.N. A rapid analysis of ultrafiltration membrane structure. Sep. Sci. Tech. 2005, 40, 2775–2801. [Google Scholar] [CrossRef]

- Mulder, M. Membrane Preparation | Phase Inversion Membranes. In Encyclopedia of Separation Science; Wilson, I.D., Ed.; Academic Press: New York, NY, USA, 2000; p. 3331. ISBN 978-0-12-226770-3. [Google Scholar]

- Russo, F.; Castro-Muñoz, R.; Galiano, F.; Figoli, A. Unprecedented preparation of porous Matrimid 5218 membranes. J. Membr. Sci. 2019, 585, 166–174. [Google Scholar] [CrossRef]

- Wu, L.; Sun, J.; Wang, Q. Poly(vinylidene fluoride)/polyethersulfone blend membranes: Effects of solvent sort, polyethersulfone and polyvinylpyrrolidone concentration on their properties and morphology. J. Membr. Sci. 2006, 285, 290–298. [Google Scholar] [CrossRef]

- Yusoff, I.I.; Rohani, R.; Zaman, N.K.; Junaidi, M.U.M.; Mohammad, A.W.; Zainal, Z. Durable pressure filtration membranes based on polyaniline-polyimide P84 blends. Polym. Eng. Sci. 2019, 5, E82–E92. [Google Scholar] [CrossRef]

| Protein | M 10−3, g/mol | rS, Ǻ |

|---|---|---|

| Ovalbumin | 44.0 | 28.6 |

| Bovine serum albumin | 67.0 | 34.0 |

| γ-globulin | 160.0 | 46.5 |

| Property | Unit | Value |

|---|---|---|

| Molecular weight | g·mol−1 | 60,000 |

| Density | g·cm−3 | 1.50 |

| Glass transition temperature | °C | 230 |

| Break stress | MPa | 125 |

| Ultimate deformation | % | 53 |

| Supramolecular Association Process | ΔH | ΔG |

|---|---|---|

| PAI + cPAN → A | −8.0 | 3.0 |

| PAI + cPAN → B | −8.3 | 5.7 |

| PAI + cPAN → C | −10.5 | 2.6 |

| PAI + cPAN → D | −16.4 | −0.9 |

| Liquid | Contact Angle, ° | |||

|---|---|---|---|---|

| PAI-0 | PAI-5 | PAI-10 | PAI-15 | |

| Water | 56.0 | 35.6 | 33.3 | 32.6 |

| Ethylene glycol | 33.5 | 29.5 | 28.3 | 24.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pulyalina, A.; Tian, N.; Senchukova, A.; Faykov, I.; Ryabikova, M.; Novikov, A.; Saprykina, N.; Polotskaya, G. Application of Cyclized Polyacrylonitrile for Ultrafiltration Membrane Fouling Mitigation. Membranes 2022, 12, 489. https://doi.org/10.3390/membranes12050489

Pulyalina A, Tian N, Senchukova A, Faykov I, Ryabikova M, Novikov A, Saprykina N, Polotskaya G. Application of Cyclized Polyacrylonitrile for Ultrafiltration Membrane Fouling Mitigation. Membranes. 2022; 12(5):489. https://doi.org/10.3390/membranes12050489

Chicago/Turabian StylePulyalina, Alexandra, Nadezhda Tian, Anna Senchukova, Ilya Faykov, Maria Ryabikova, Alexander Novikov, Natalia Saprykina, and Galina Polotskaya. 2022. "Application of Cyclized Polyacrylonitrile for Ultrafiltration Membrane Fouling Mitigation" Membranes 12, no. 5: 489. https://doi.org/10.3390/membranes12050489

APA StylePulyalina, A., Tian, N., Senchukova, A., Faykov, I., Ryabikova, M., Novikov, A., Saprykina, N., & Polotskaya, G. (2022). Application of Cyclized Polyacrylonitrile for Ultrafiltration Membrane Fouling Mitigation. Membranes, 12(5), 489. https://doi.org/10.3390/membranes12050489