Recent Progress in Silicon Carbide-Based Membranes for Gas Separation

Abstract

1. Introduction

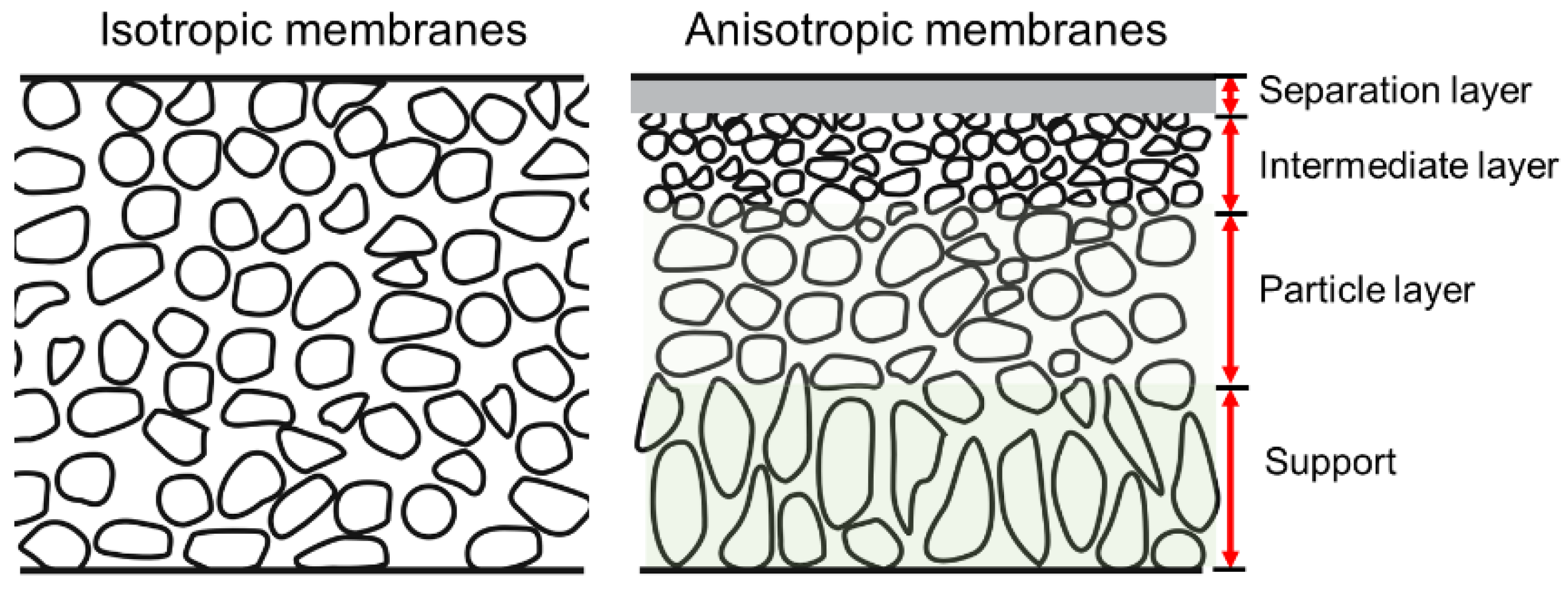

1.1. Membrane-Based Gas Separation

1.2. Inorganic Membranes

1.2.1. Silica Membrane

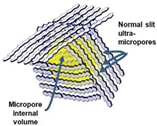

1.2.2. Carbon Molecular Sieve (CMS) Membrane

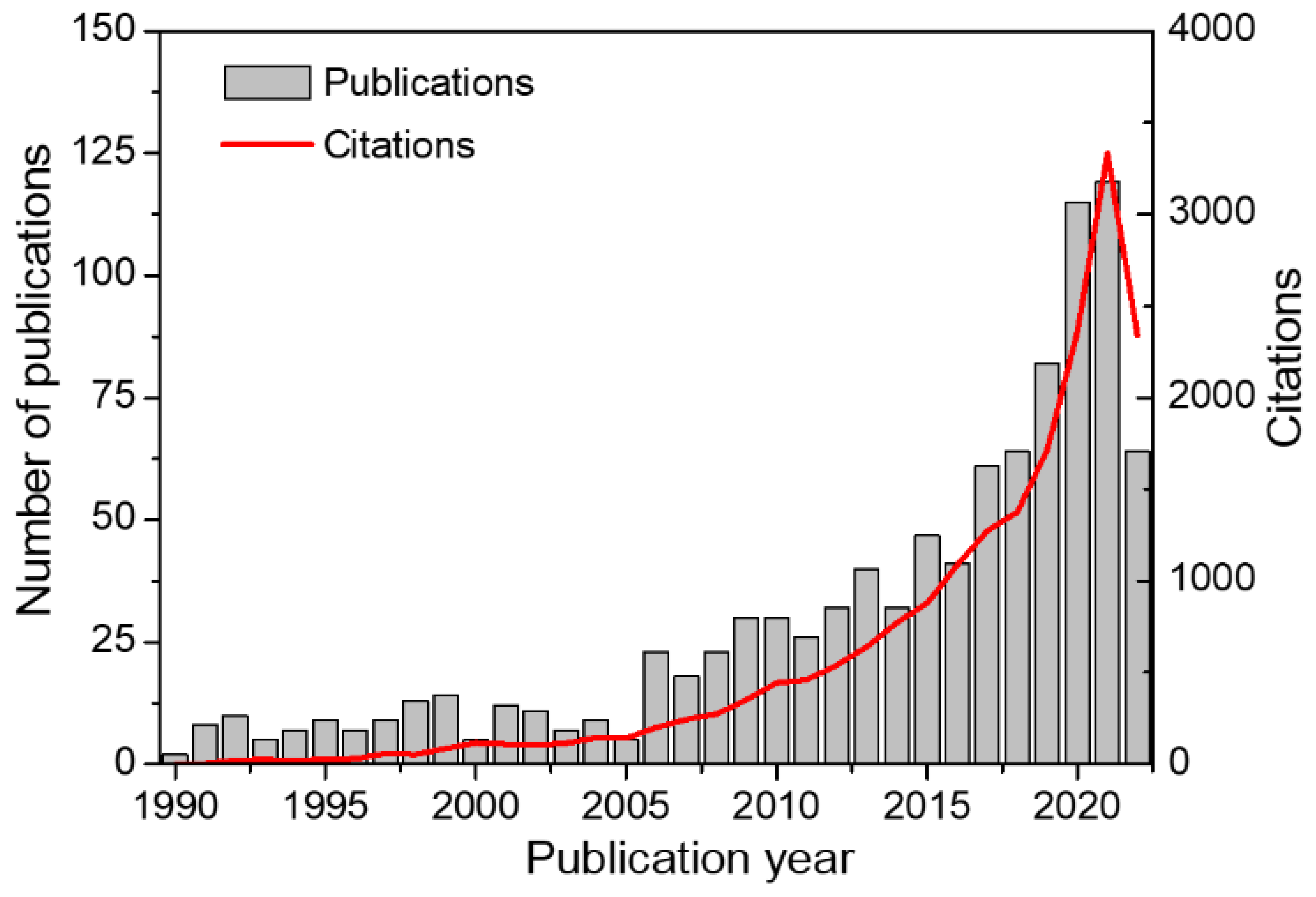

1.2.3. Silicon Carbide Membrane

2. Fabrication of SiC Membranes

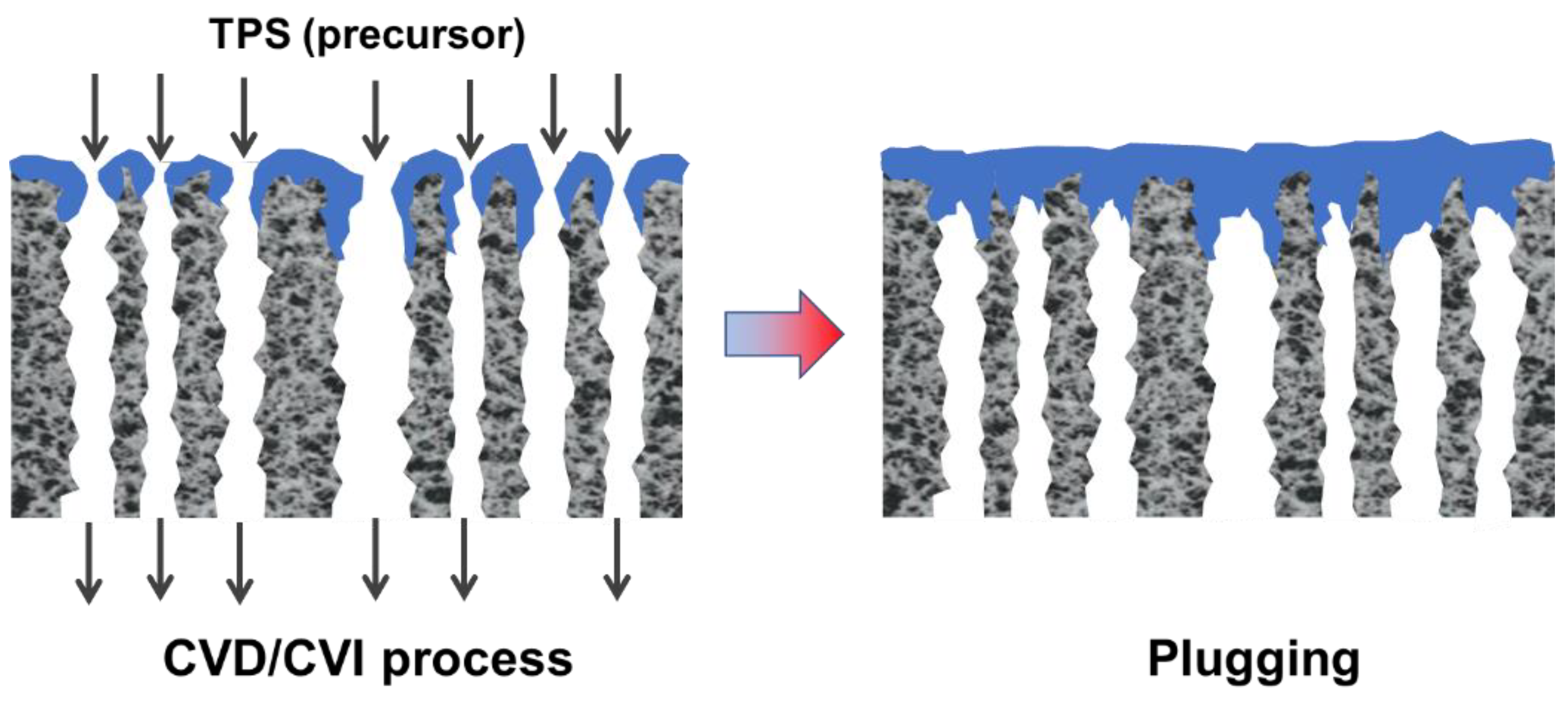

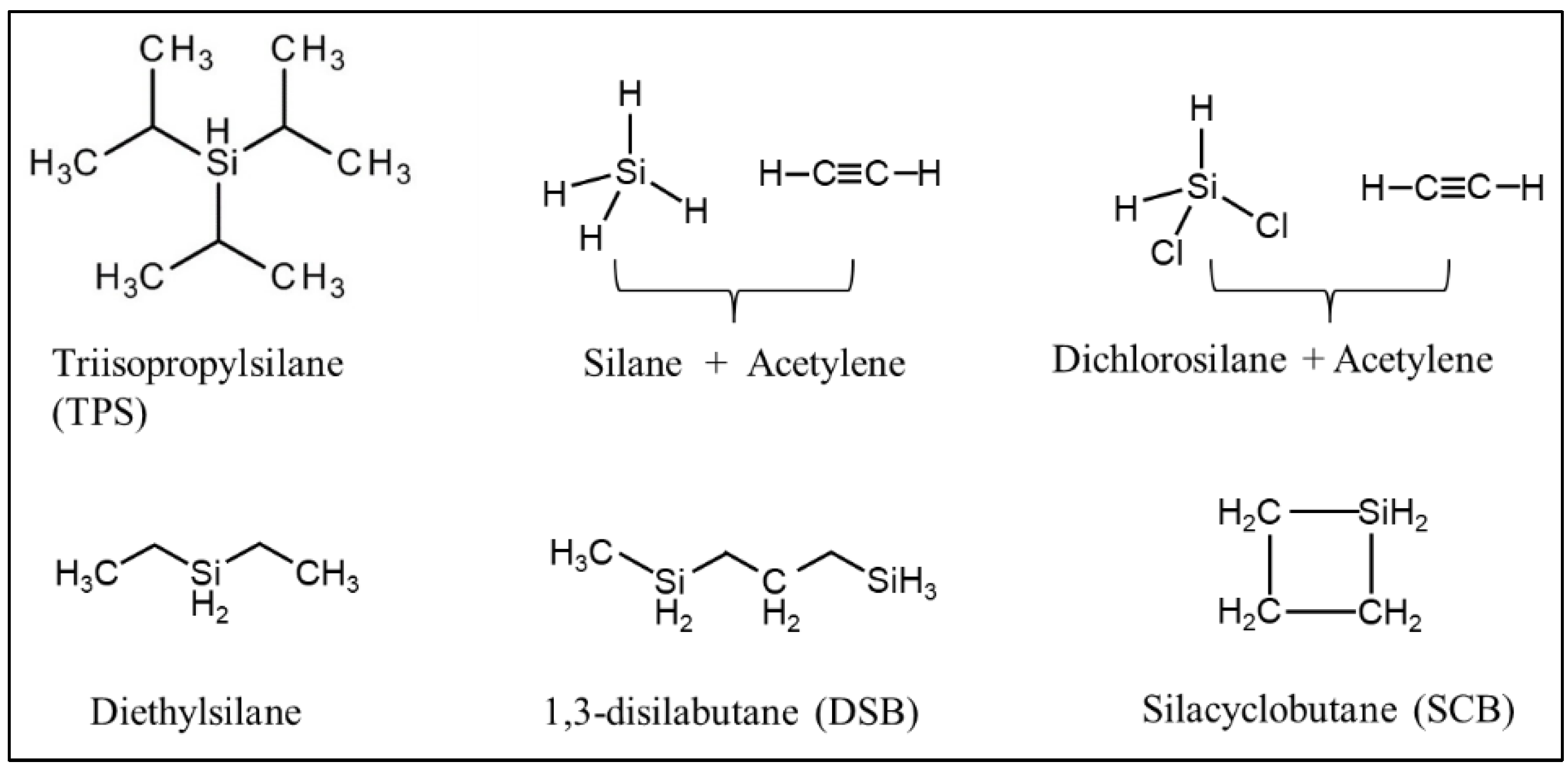

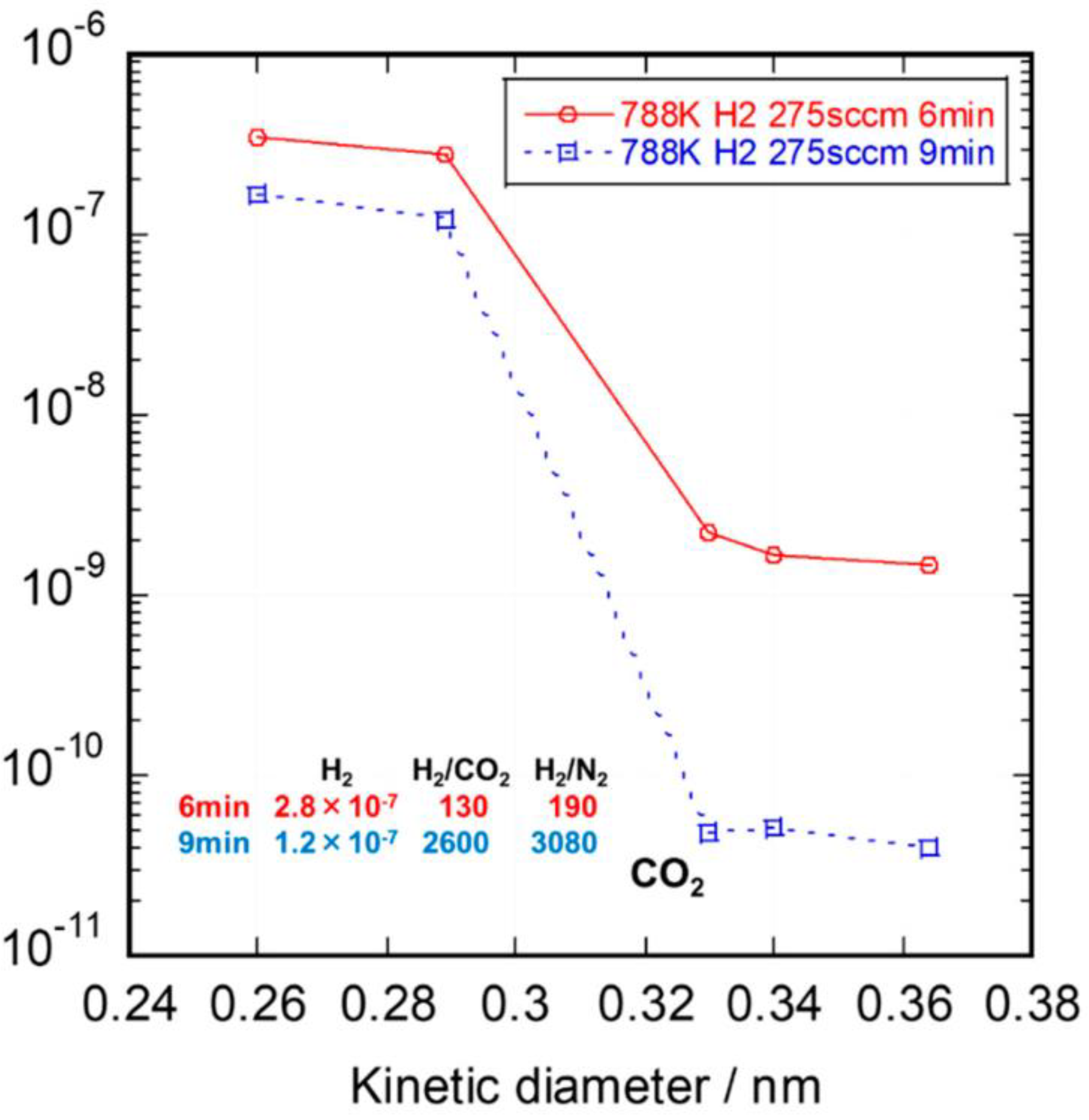

2.1. Chemical Vapor Deposition/Infiltration Route

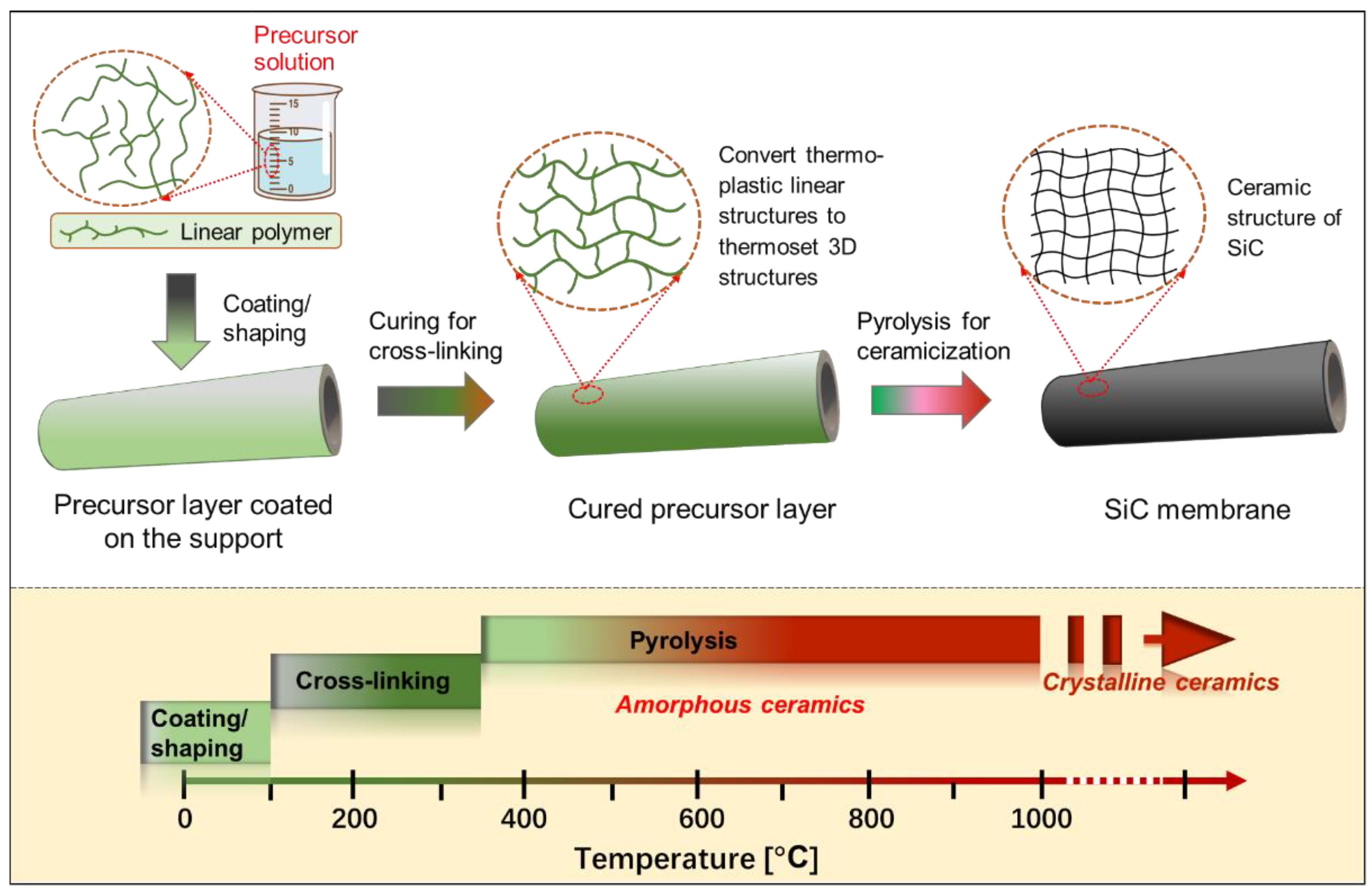

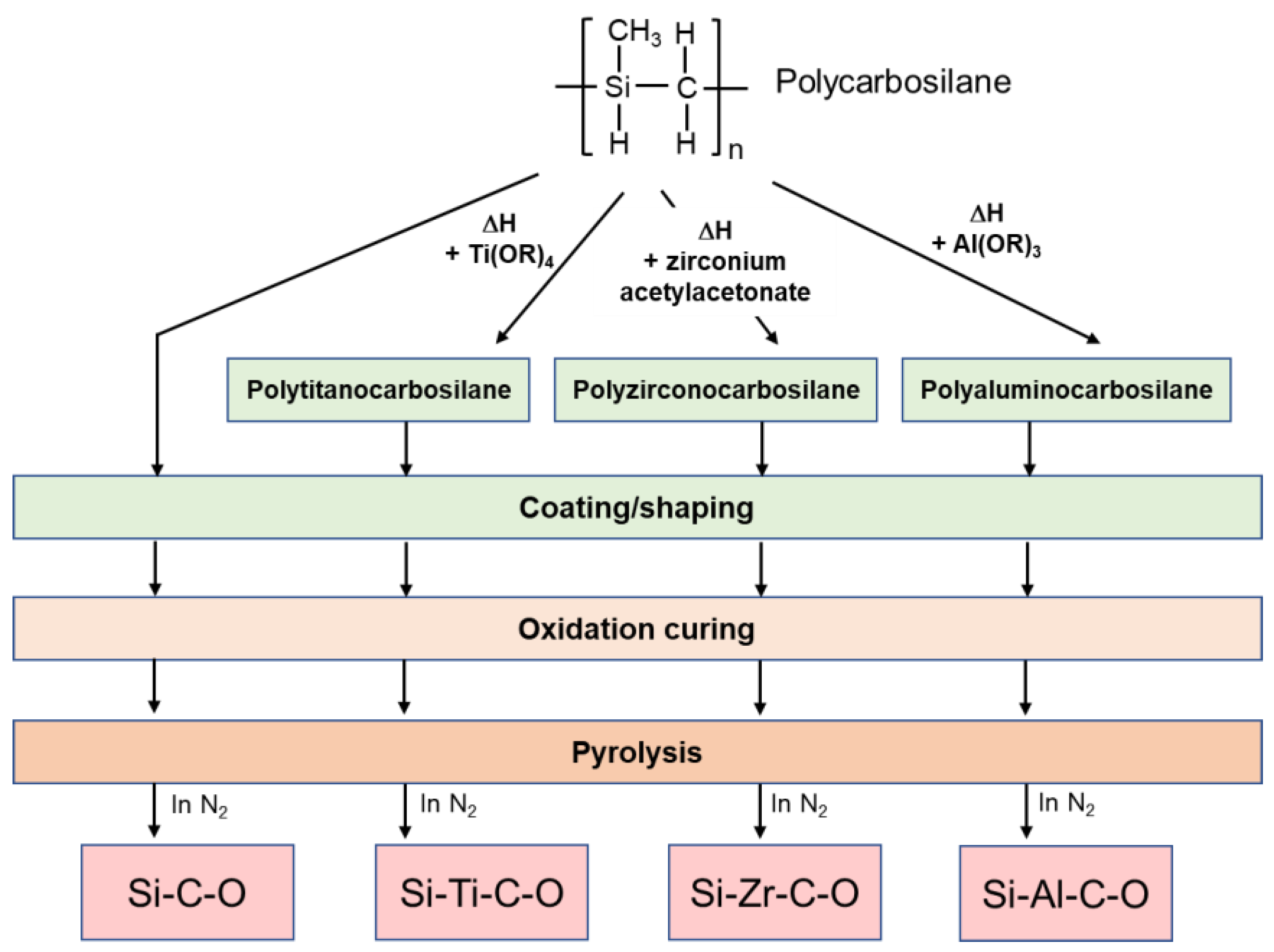

2.2. Pyrolysis of the Polymeric Precursor Route

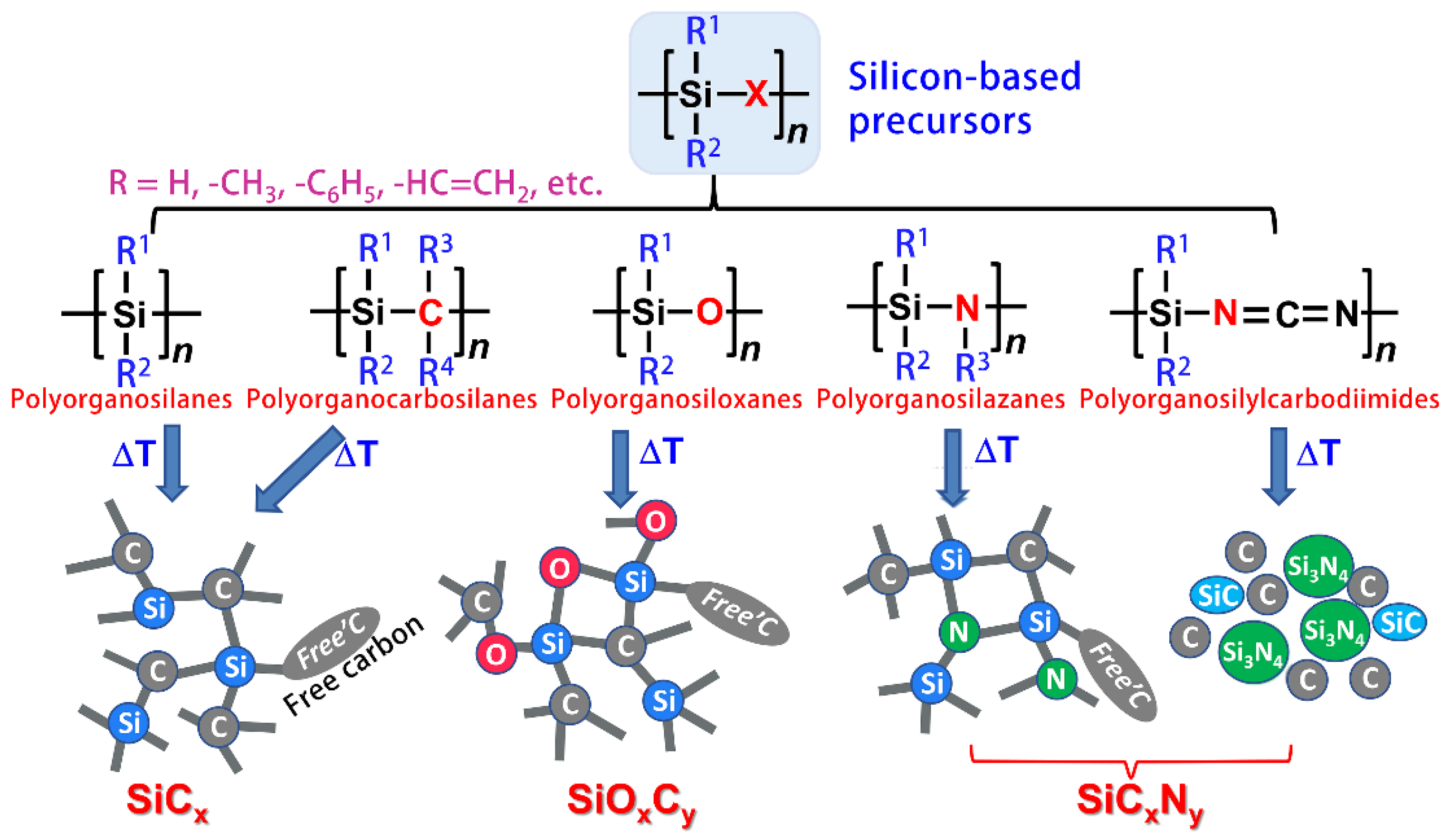

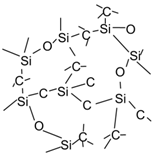

2.2.1. Si-Containing Precursors

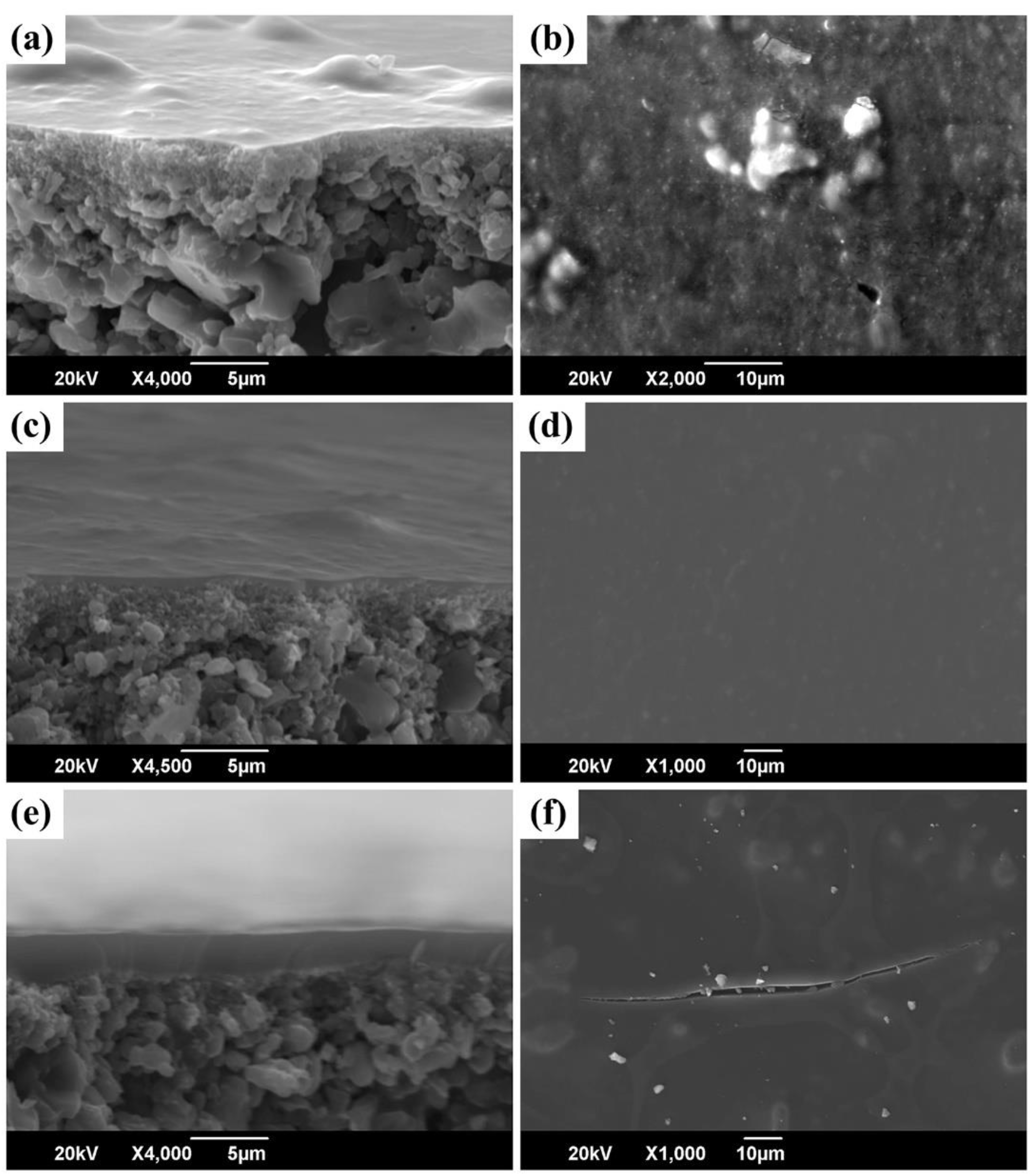

2.2.2. Coating/Shaping

2.2.3. Curing and Pyrolysis Processes

Curing for Cross-Linking

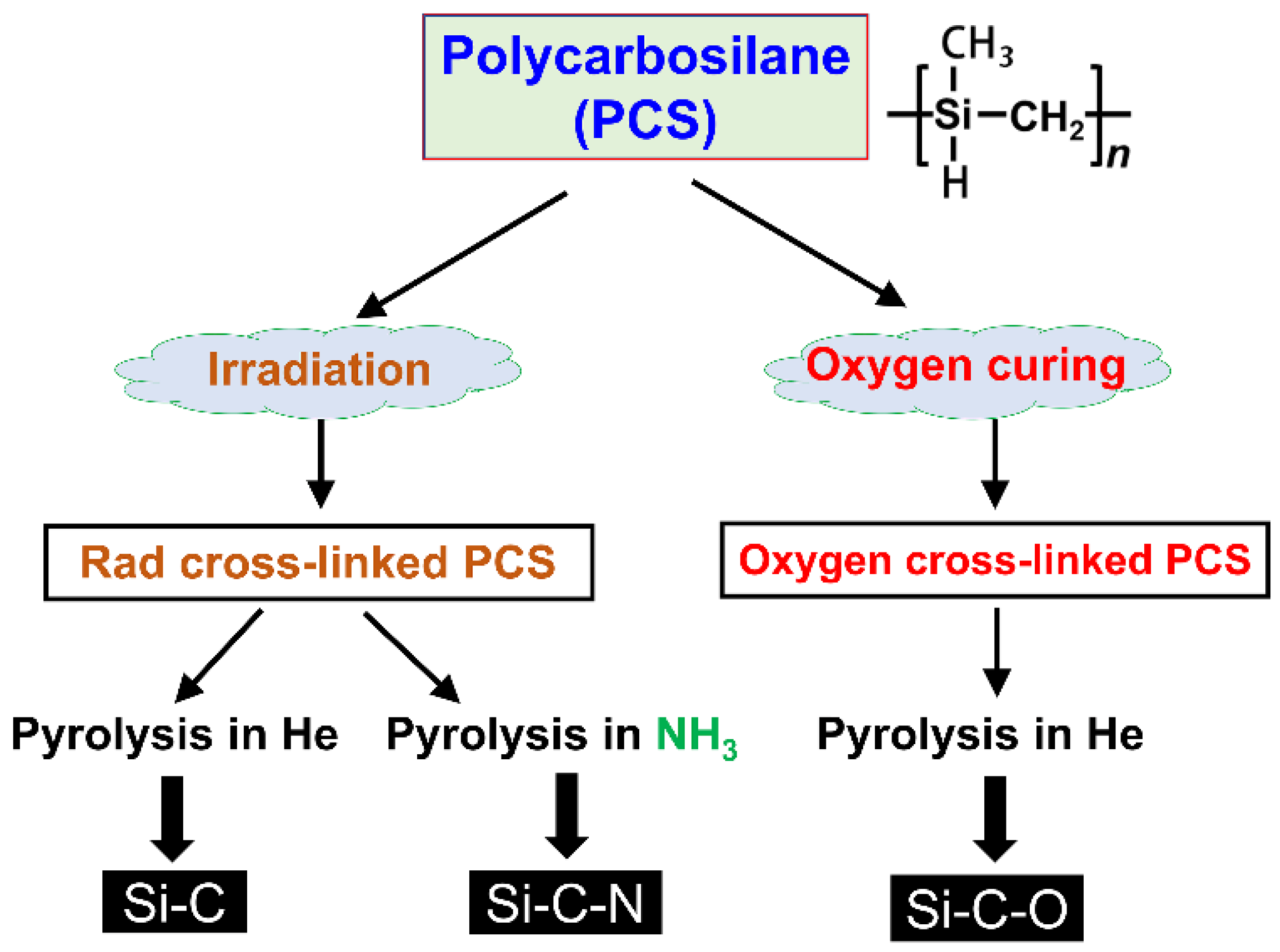

Polycarbosilane (PCS) Precursor

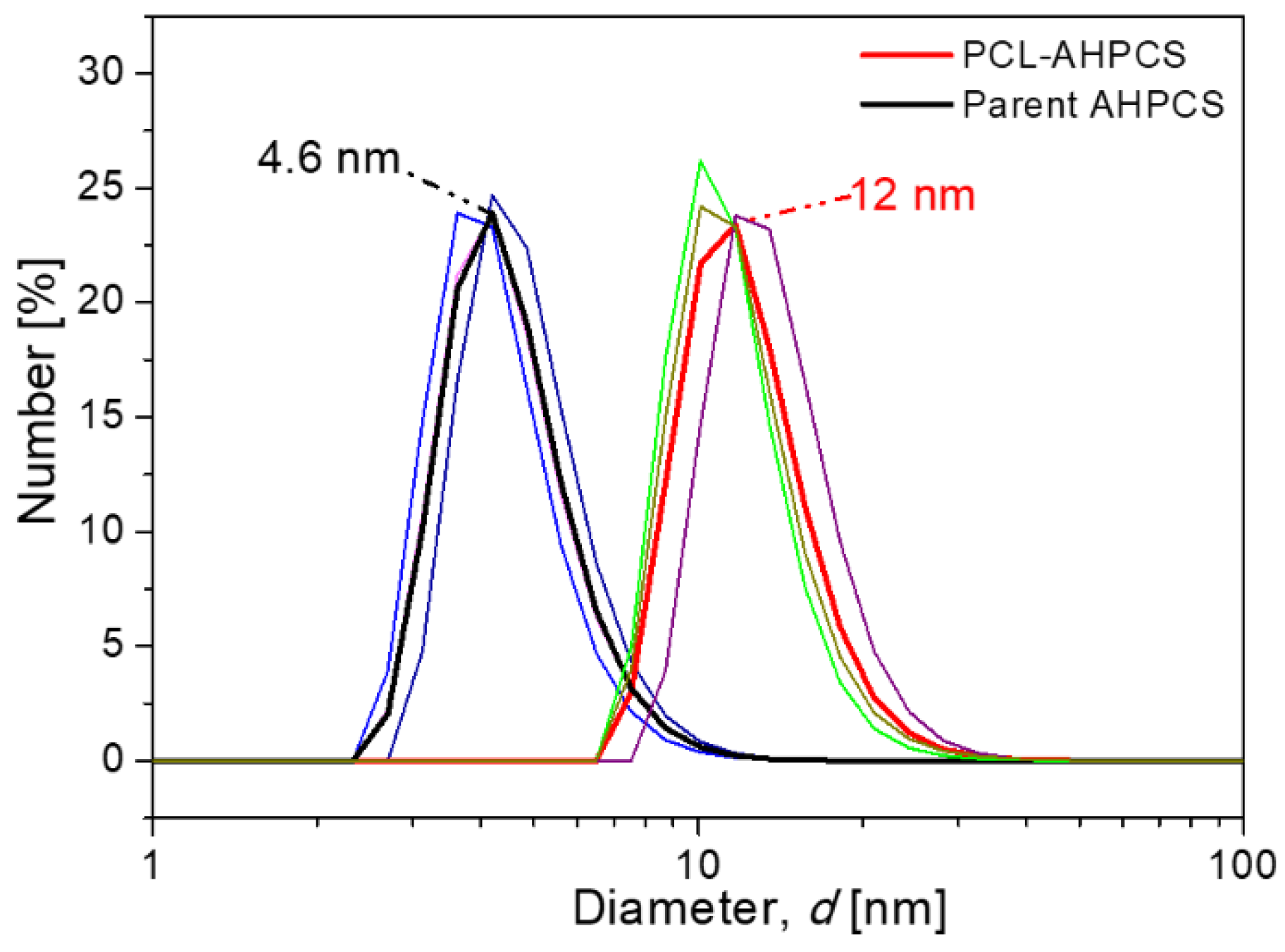

Allyl-Hydridopolycarbosilane (AHPCS) Precursor

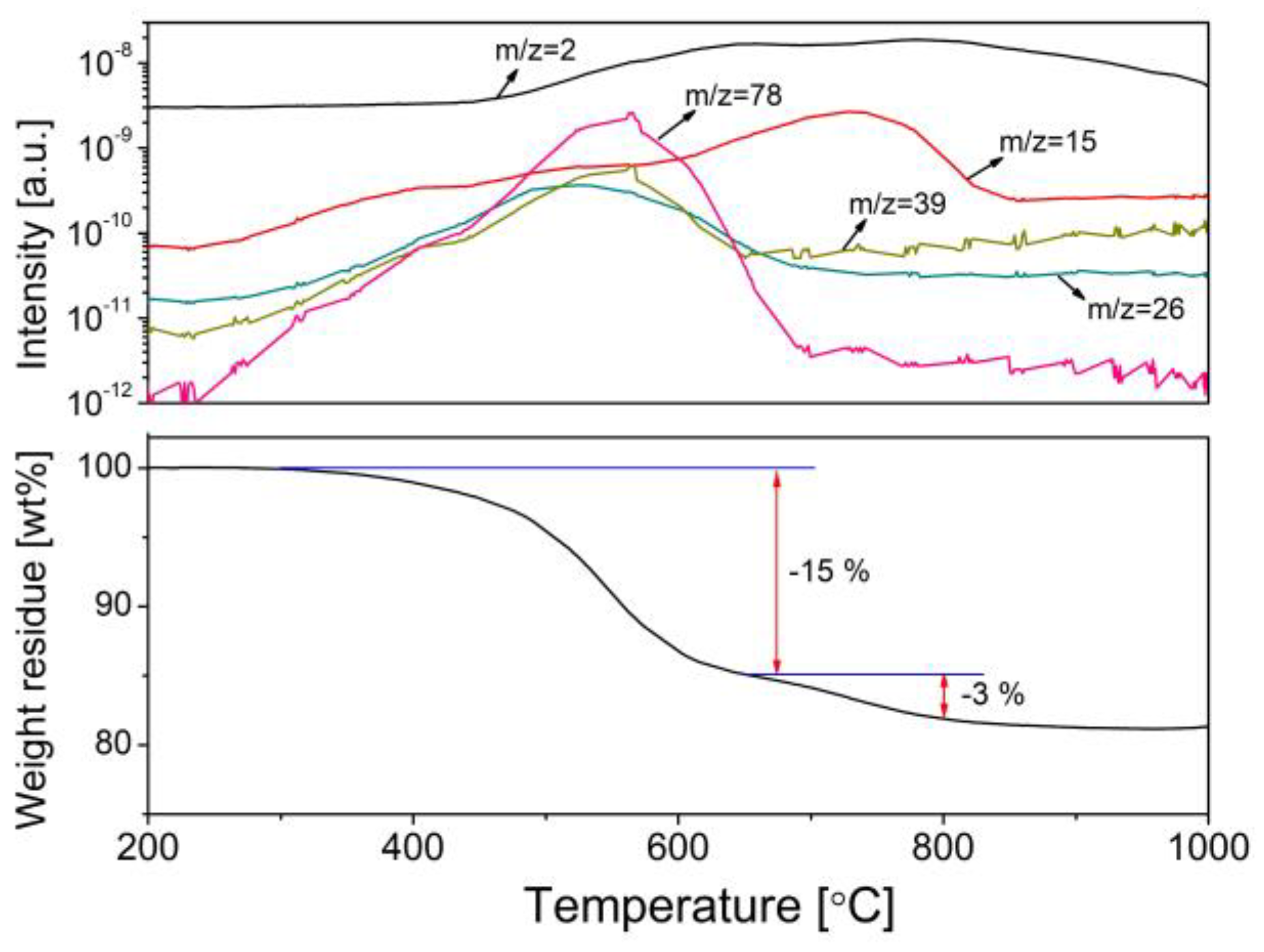

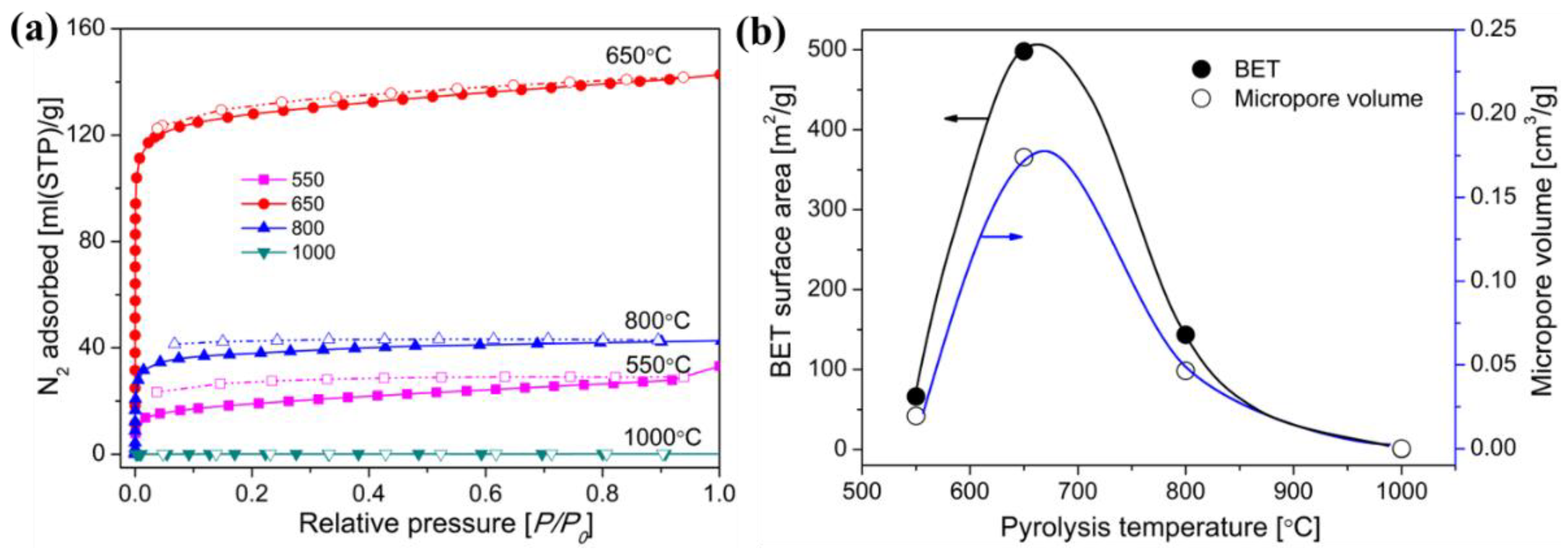

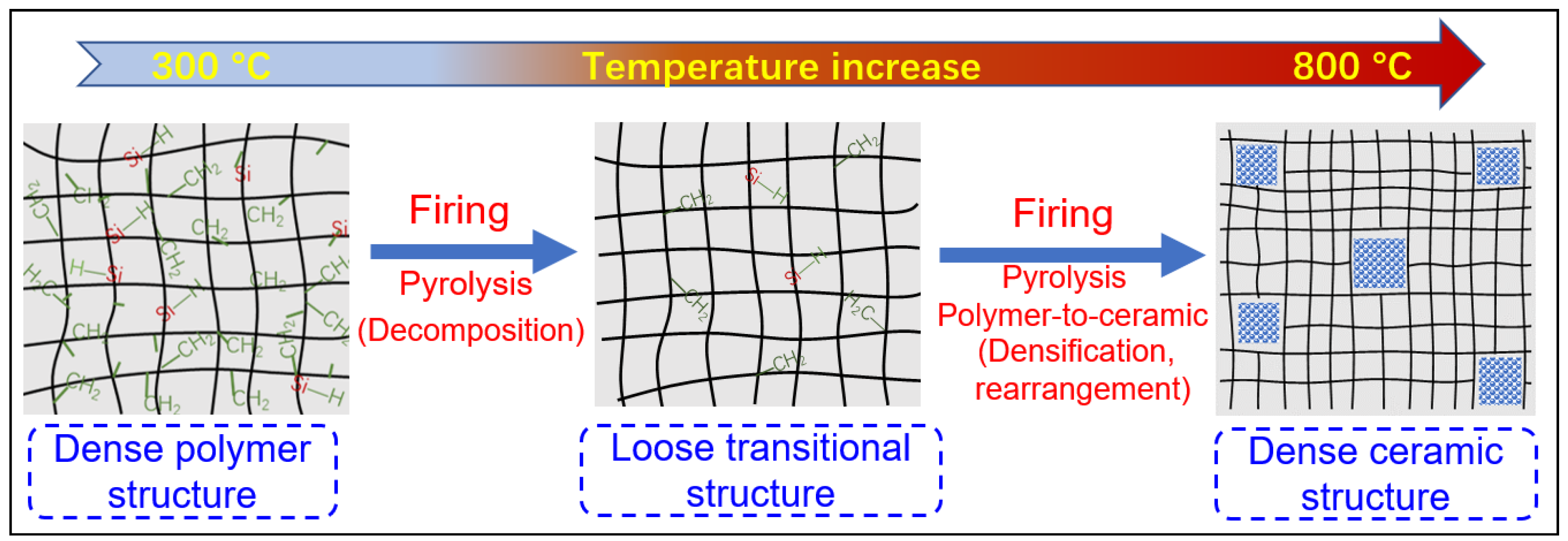

Pyrolysis for Polymer-To-Ceramic Conversion

3. SiC Membranes for Gas Separation

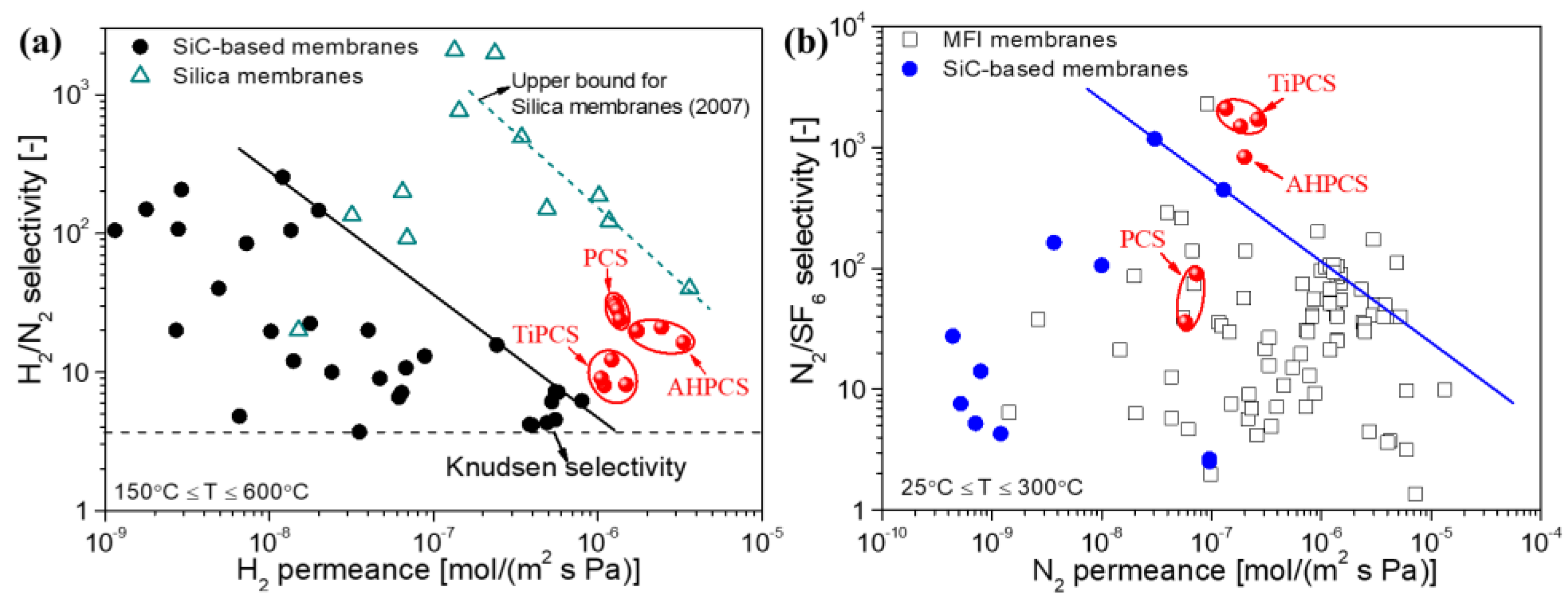

3.1. PCS-Derived SiC Membranes

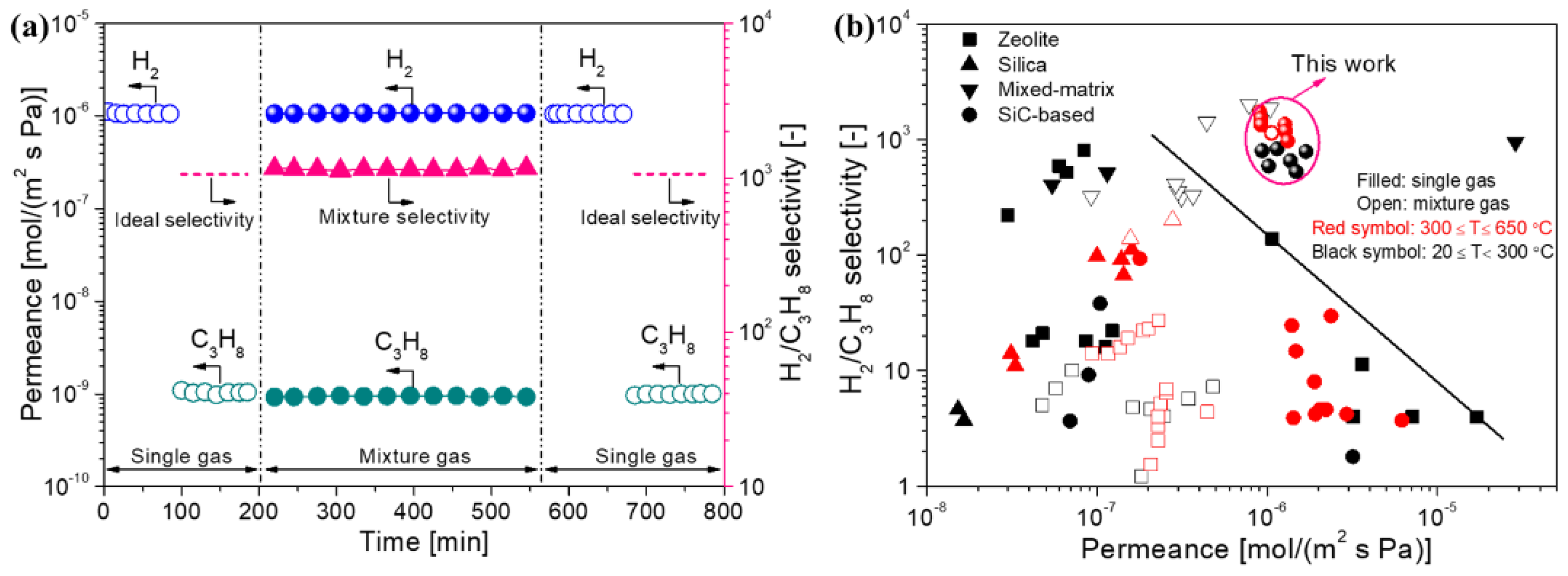

3.2. AHPCS-Derived SiC Membranes

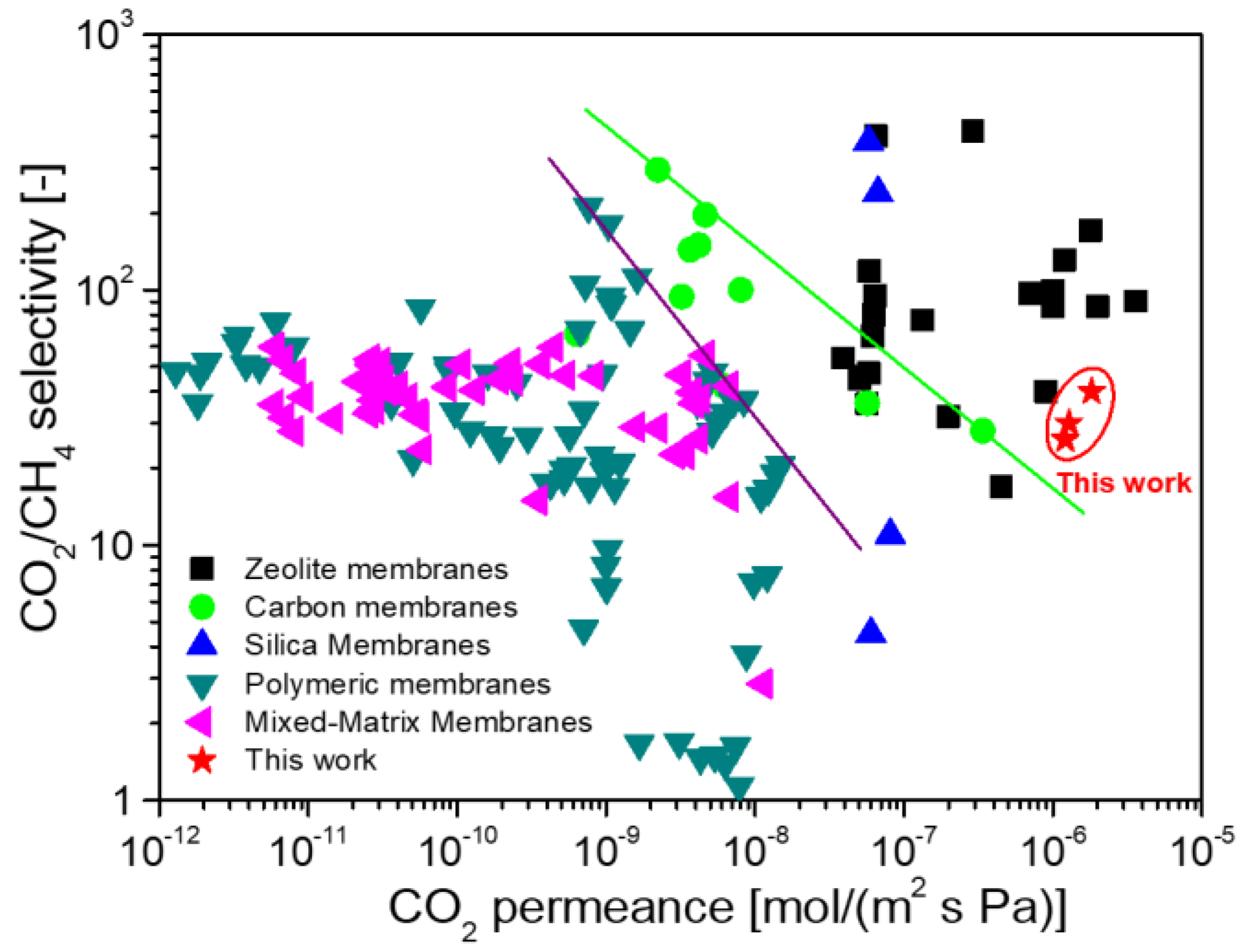

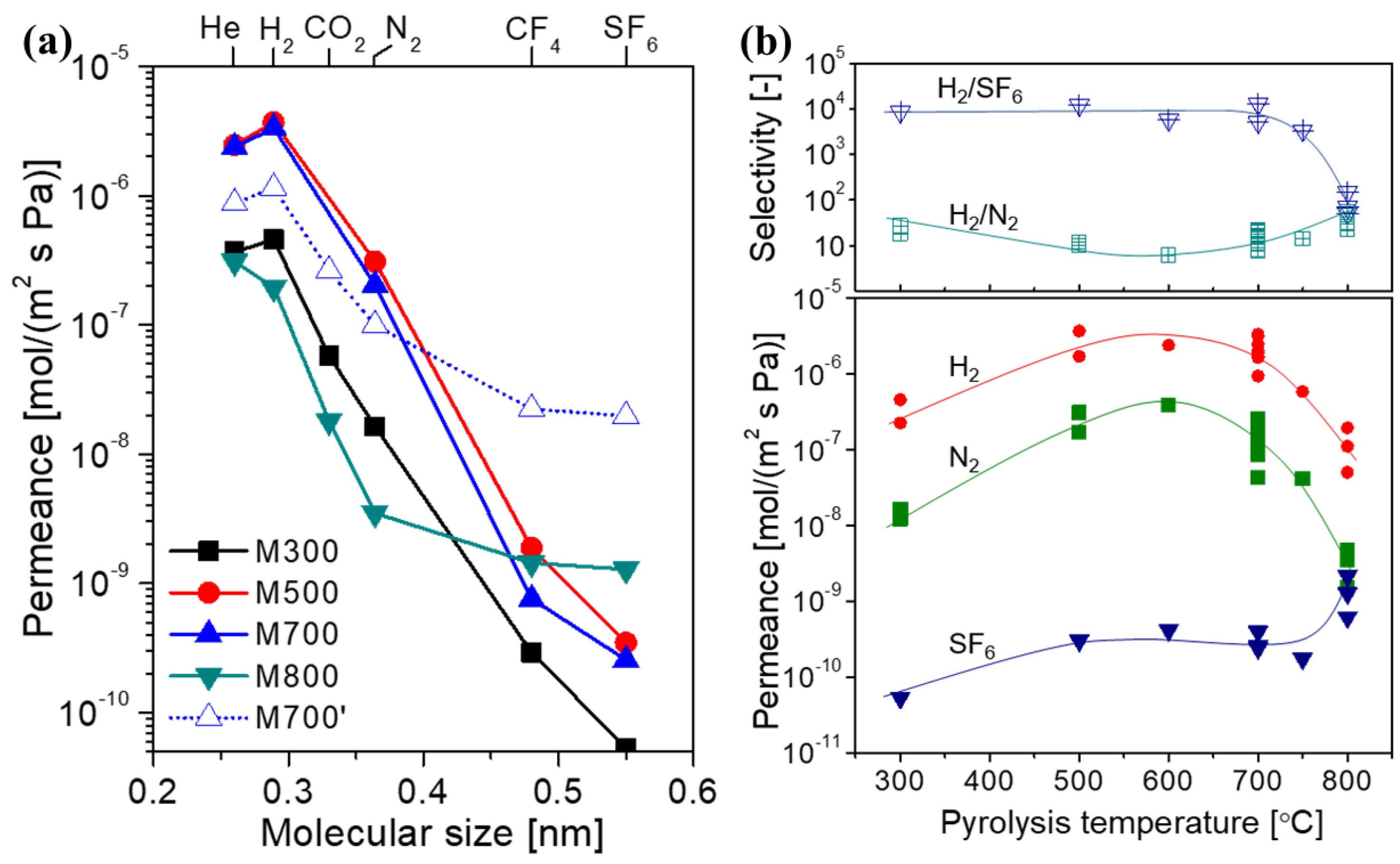

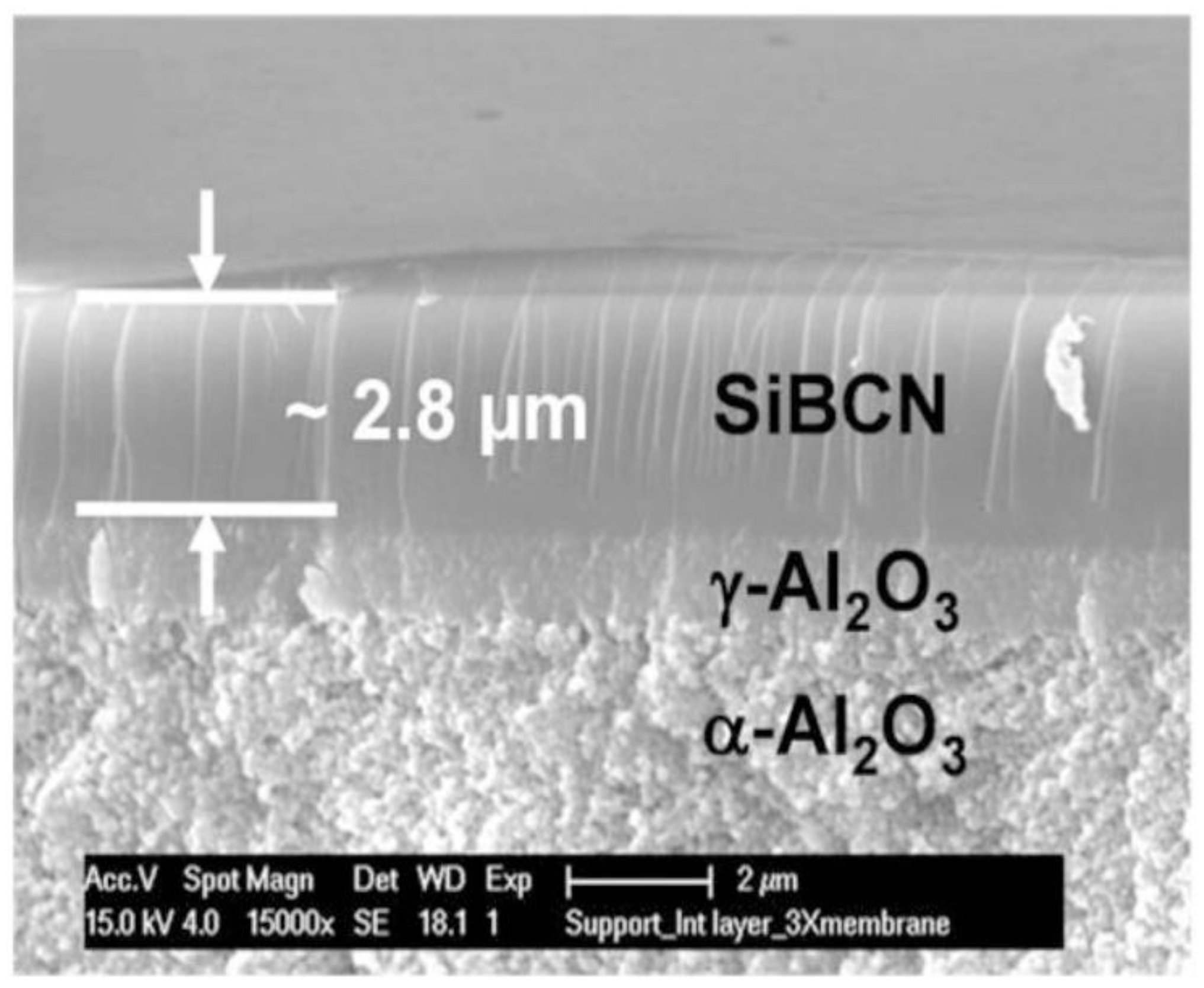

3.3. Other Element-Doped SiC Membranes

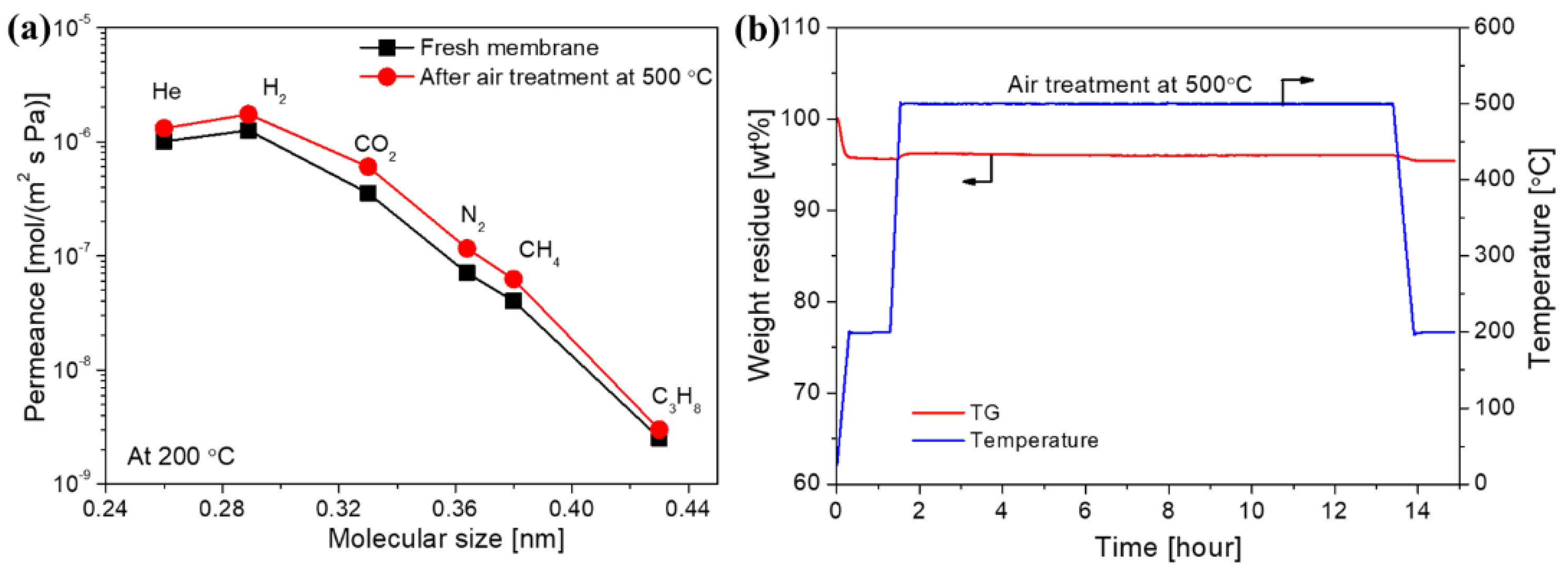

4. Stability under Harsh Conditions

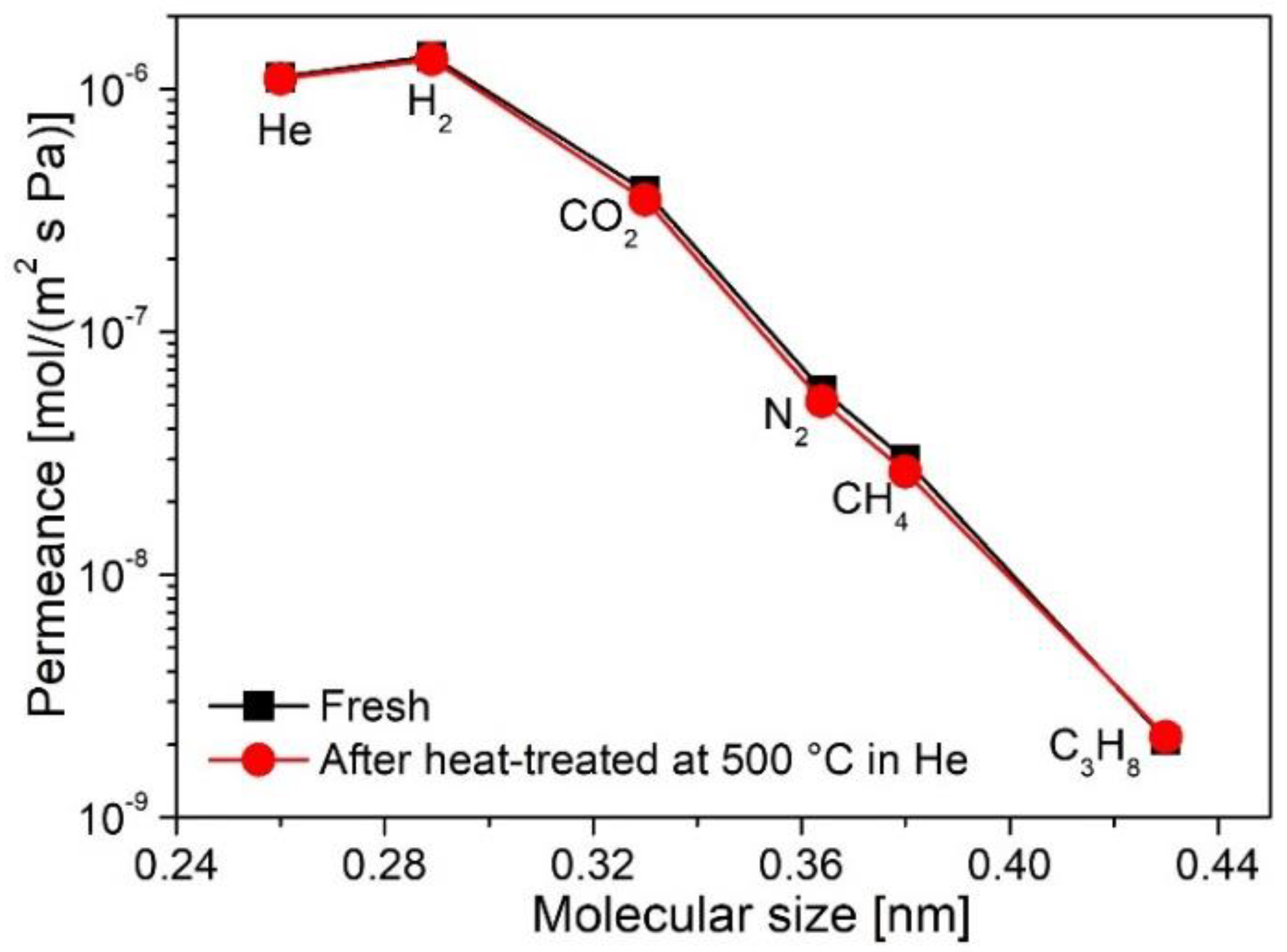

4.1. Thermal Stability and Oxidation Resistance

4.2. Hydrothermal Stability

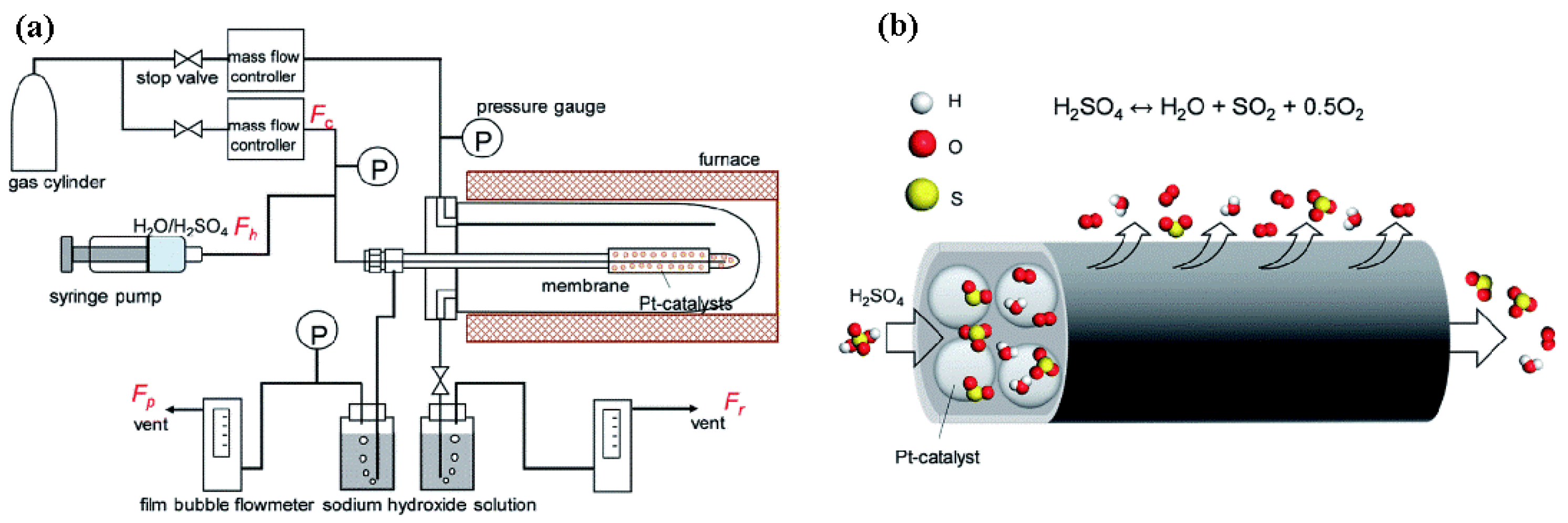

4.3. Chemical Resistance and Membrane Reactors

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Logan, B.E.; Elimelech, M. Membrane-based processes for sustainable power generation using water. Nature 2012, 488, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Sholl, D.S.; Lively, R.P. Seven chemical separations to change the world. Nature 2016, 532, 435–437. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Voutchkov, N. Energy use for membrane seawater desalination—Current status and trends. Desalination 2018, 431, 2–14. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.-S.; Lai, J.-Y. A review of polymeric composite membranes for gas separation and energy production. Prog. Polym. Sci. 2019, 97, 101141. [Google Scholar] [CrossRef]

- Liu, C.; Greer, D.W.; O’Leary, B.W. Advanced Materials and Membranes for Gas Separations: The UOP Approach. Nanotechnol. Deliv. Promise 2016, 2, 119–135. [Google Scholar] [CrossRef]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane Gas Separation: A Review/State of the Art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Valappil, R.S.K.; Ghasem, N.; Al-Marzouqi, M. Current and future trends in polymer membrane-based gas separation technology: A comprehensive review. J. Ind. Eng. Chem. 2021, 98, 103–129. [Google Scholar] [CrossRef]

- Abdallah, H. A Review on Catalytic Membranes Production and Applications. Bull. Chem. React. Eng. Catal. 2017, 12, 136–156. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- Awasthi, K.; Choudhury, S.; Komber, H.; Simon, F.; Formanek, P.; Sharma, A.; Stamm, M. Functionalization of track-etched poly (ethylene terephthalate) membranes as a selective filter for hydrogen purification. Int. J. Hydrogen Energy 2014, 39, 9356–9365. [Google Scholar] [CrossRef]

- Qiu, W.; Leisen, J.E.; Liu, Z.; Quan, W.; Koros, W.J. Key Features of Polyimide-Derived Carbon Molecular Sieves. Angew. Chem. Int. Ed. 2021, 60, 22322–22331. [Google Scholar] [CrossRef] [PubMed]

- Tsuru, T. Silica-Based Membranes with Molecular-Net-Sieving Properties: Development and Applications. J. Chem. Eng. Jpn. 2018, 51, 713–725. [Google Scholar] [CrossRef]

- Ren, X.; Tsuru, T. Organosilica-Based Membranes in Gas and Liquid-Phase Separation. Membranes 2019, 9, 107. [Google Scholar] [CrossRef] [PubMed]

- Ishii, K.; Shibata, A.; Takeuchi, T.; Yoshiura, J.; Urabe, T.; Kameda, Y.; Nomura, M. Development of Silica Membranes to Improve Dehydration Reactions. J. Jpn. Pet. Inst. 2019, 62, 211–219. [Google Scholar] [CrossRef]

- Asaeda, M.; Yamasaki, S. Separation of inorganic/organic gas mixtures by porous silica membranes. Sep. Purif. Technol. 2001, 25, 151–159. [Google Scholar] [CrossRef]

- Gu, Y.; Hacarlioglu, P.; Oyama, S.T. Hydrothermally stable silica–alumina composite membranes for hydrogen separation. J. Membr. Sci. 2008, 310, 28–37. [Google Scholar] [CrossRef]

- De Vos, R.M.; Maier, W.F.; Verweij, H. Hydrophobic silica membranes for gas separation. J. Membr. Sci. 1999, 158, 277–288. [Google Scholar] [CrossRef]

- Kayvani Fard, A.; McKay, G.; Buekenhoudt, A.; Al Sulaiti, H.; Motmans, F.; Khraisheh, M.; Atieh, M. Inorganic Membranes: Preparation and Application for Water Treatment and Desalination. Materials 2018, 11, 74. [Google Scholar] [CrossRef]

- Li, L.; Xu, R.; Song, C.; Zhang, B.; Liu, Q.; Wang, T. A Review on the Progress in Nanoparticle/C Hybrid CMS Membranes for Gas Separation. Membranes 2018, 8, 134. [Google Scholar] [CrossRef]

- Battersby, S.; Smart, S.; Ladewig, B.; Liu, S.; Duke, M.C.; Rudolph, V.; da Costa, J.C.D. Hydrothermal stability of cobalt silica membranes in a water gas shift membrane reactor. Sep. Purif. Technol. 2009, 66, 299–305. [Google Scholar] [CrossRef]

- Rungta, M.; Wenz, G.B.; Zhang, C.; Xu, L.; Qiu, W.; Adams, J.S.; Koros, W.J. Carbon molecular sieve structure development and membrane performance relationships. Carbon 2017, 115, 237–248. [Google Scholar] [CrossRef]

- Pal, N.; Agarwal, M. Advances in materials process and separation mechanism of the membrane towards hydrogen separation. Int. J. Hydrogen Energy 2021, 46, 27062–27087. [Google Scholar] [CrossRef]

- Ngamou, P.H.T.; Ivanova, M.E.; Guillon, O.; Meulenberg, W.A. High-performance carbon molecular sieve membranes for hydrogen purification and pervaporation dehydration of organic solvents. J. Mater. Chem. A 2019, 7, 7082–7091. [Google Scholar] [CrossRef]

- Koros, W.J.; Mahajan, R. Pushing the limits on possibilities for large scale gas separation: Which strategies? J. Membr. Sci. 2000, 175, 181–196. [Google Scholar] [CrossRef]

- Saufi, S.M.; Ismail, A.F. Fabrication of carbon membranes for gas separation––A review. Carbon 2004, 42, 241–259. [Google Scholar] [CrossRef]

- Hayashi, J.-I.; Yamamoto, M.; Kusakabe, K.; Morooka, S. Effect of Oxidation on Gas Permeation of Carbon Molecular Sieving Membranes Based on BPDA-pp‘ODA Polyimide. Ind. Eng. Chem. Res. 1997, 36, 2134–2140. [Google Scholar] [CrossRef]

- Kriegesmann, J. Processing of Silicon Carbide-Based Ceramics. In Comprehensive Hard Materials; Sarin, V.K., Ed.; Elsevier: Oxford, UK, 2014; pp. 89–175. [Google Scholar] [CrossRef]

- Proust, V.; Bechelany, M.C.; Ghisleni, R.; Beaufort, M.-F.; Miele, P.; Bernard, S. Polymer-derived Si-C-Ti systems: From titanium nanoparticle-filled polycarbosilanes to dense monolithic multi-phase components with high hardness. J. Eur. Ceram. Soc. 2016, 36, 3671–3679. [Google Scholar] [CrossRef]

- Kanezashi, M.; Sazaki, H.; Nagasawa, H.; Yoshioka, T.; Tsuru, T. Preparation and gas permeation properties of thermally stable organosilica membranes derived by hydrosilylation. J. Mater. Chem. A 2013, 2, 672–680. [Google Scholar] [CrossRef]

- Dabir, S.; Deng, W.; Sahimi, M.; Tsotsis, T. Fabrication of silicon carbide membranes on highly permeable supports. J. Membr. Sci. 2017, 537, 239–247. [Google Scholar] [CrossRef]

- Li, Z.; Kusakabe, K.; Morooka, S. Preparation of thermostable amorphous Si-C-O membrane and its application to gas separation at elevated temperature. J. Membr. Sci. 1996, 118, 159–168. [Google Scholar] [CrossRef]

- Li, Z.; Kusakabe, K.; Morooka, S. Pore Structure and Permeance of Amorphous Si-C-O Membranes with High Durability at Elevated Temperature. Sep. Sci. Technol. 1997, 32, 1233–1254. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Q.; Nagasawa, H.; Kanezashi, M.; Tsuru, T. SiC mesoporous membranes for sulfuric acid decomposition at high temperatures in the iodine–sulfur process. RSC Adv. 2020, 10, 41883–41890. [Google Scholar] [CrossRef] [PubMed]

- Eray, E.; Candelario, V.M.; Boffa, V.; Safafar, H.; Østedgaard-Munck, D.N.; Zahrtmann, N.; Kadrispahic, H.; Jørgensen, M.K. A roadmap for the development and applications of silicon carbide membranes for liquid filtration: Recent advancements, challenges, and perspectives. Chem. Eng. J. 2021, 414, 128826. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Chen, Z.; Liu, Y.; Guo, J.; Zhang, W.; Rao, P.; Li, G. Recent progress in the pore size control of silicon carbide ceramic membranes. Ceram. Int. 2022, 48, 8960–8971. [Google Scholar] [CrossRef]

- Hotza, D.; Di Luccio, M.; Wilhelm, M.; Iwamoto, Y.; Bernard, S.; da Costa, J.C.D. Silicon carbide filters and porous membranes: A review of processing, properties, performance and application. J. Membr. Sci. 2020, 610, 118193. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane Technology and Applications, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Jafari, B.; Rezaei, E.; Abbasi, M.; Hashemifard, S.A.; Sillanpää, M. Application of mullite-zeolite-alumina microfiltration membranes coated by SiO2 nanoparticles for separation of oil-in-water emulsions. J. Eur. Ceram. Soc. 2022, 42, 6005–6014. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A Review on Reverse Osmosis and Nanofiltration Membranes for Water Purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sakai, T. Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter. Computation 2016, 4, 46. [Google Scholar] [CrossRef]

- Xu, C.; Xu, C.; Han, F.; Zhang, F.; Wei, W.; Zhong, Z.; Xing, W. Fabrication of high performance macroporous tubular silicon carbide gas filters by extrusion method. Ceram. Int. 2018, 44, 17792–17799. [Google Scholar] [CrossRef]

- Dong, B.; Min, Z.; Guan, L.; Zheng, X.; Wang, L.; Wang, Q.; Yin, C.; Wang, Y.; Zhang, R.; Wang, F.; et al. Porous mullite-bonded SiC filters prepared by foaming-sol-gel-tape casting for high-efficiency hot flue gas filtration. Sep. Purif. Technol. 2022, 295, 121338. [Google Scholar] [CrossRef]

- Fontão, N.C.; Wilhelm, M.; Rezwan, K. Asymmetric polysiloxane-based SiOC membranes produced via phase inversion tape casting process. Mater. Des. 2020, 198, 109328. [Google Scholar] [CrossRef]

- Gubernat, A.; Zych, Ł.; Wierzba, W. SiC products formed by slip casting method. Int. J. Appl. Ceram. Technol. 2015, 12, 957–966. [Google Scholar] [CrossRef]

- Deng, W.; Yu, X.; Sahimi, M.; Tsotsis, T.T. Highly permeable porous silicon carbide support tubes for the preparation of nanoporous inorganic membranes. J. Membr. Sci. 2014, 451, 192–204. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, W.; Jiang, Q.; Xu, P.; Zhong, Z.; Zhang, F.; Xing, W. Preparation of non-oxide SiC membrane for gas purification by spray coating. J. Membr. Sci. 2017, 540, 381–390. [Google Scholar] [CrossRef]

- Bukhari, S.Z.A.; Ha, J.-H.; Lee, J.; Song, I.-H. Oxidation-bonded SiC membrane for microfiltration. J. Eur. Ceram. Soc. 2018, 38, 1711–1719. [Google Scholar] [CrossRef]

- Liu, J.; Tian, C.; Xiao, H.; Guo, W.; Gao, P.; Liang, J. Effect of B4C on co-sintering of SiC ceramic membrane. Ceram. Int. 2018, 45, 3921–3929. [Google Scholar] [CrossRef]

- Eray, E.; Candelario, V.M.; Boffa, V. Ceramic Processing of Silicon Carbide Membranes with the Aid of Aluminum Nitrate Nonahydrate: Preparation, Characterization, and Performance. Membranes 2021, 11, 714. [Google Scholar] [CrossRef]

- Li, S.; Wei, C.; Zhou, L.; Wang, P.; Xie, Z. Evaporation-condensation derived silicon carbide membrane from silicon carbide particles with different sizes. J. Eur. Ceram. Soc. 2019, 39, 1781–1787. [Google Scholar] [CrossRef]

- König, K.; Boffa, V.; Buchbjerg, B.; Farsi, A.; Christensen, M.L.; Magnacca, G.; Yue, Y. One-step deposition of ultrafiltration SiC membranes on macroporous SiC supports. J. Membr. Sci. 2014, 472, 232–240. [Google Scholar] [CrossRef]

- Elyassi, B.; Sahimi, M.; Tsotsis, T.T. A novel sacrificial interlayer-based method for the preparation of silicon carbide membranes. J. Membr. Sci. 2008, 316, 73–79. [Google Scholar] [CrossRef]

- Wang, Q.; Kawano, Y.; Yu, L.; Nagasawa, H.; Kanezashi, M.; Tsuru, T. Development of high-performance sub-nanoporous SiC-based membranes derived from polytitanocarbosilane. J. Membr. Sci. 2020, 598, 117688. [Google Scholar] [CrossRef]

- Besmann, T.M.; Stinton, D.P.; Lowden, R.A.; Lee, W.Y. Chemical Vapor Deposition (CVD) and Infiltration (CVI). In Carbide, Nitride and Boride Materials Synthesis and Processing; Springer: Dordrecht, The Netherlands, 1997; pp. 547–577. [Google Scholar] [CrossRef]

- Carlsson, J.-O.; Martin, P.M. Chemical vapor deposition. In Handbook of Deposition Technologies for Films and Coatings; Elsevier: Amsterdam, The Netherlands, 2010; pp. 314–363. [Google Scholar]

- Pierson, H.O. Introduction and general considerations. In Handbook of Chemical Vapor Deposition (CVD); William Andrew Inc.: Norwich, NY, USA, 1992; p. 2. [Google Scholar]

- Chen, F.; Mourhatch, R.; Tsotsis, T.T.; Sahimi, M. Experimental studies and computer simulation of the preparation of nanoporous silicon-carbide membranes by chemical-vapor infiltration/chemical-vapor deposition techniques. Chem. Eng. Sci. 2008, 63, 1460–1470. [Google Scholar] [CrossRef]

- Hong, L.-S.; Lai, H.-T. Pore Structure Modification of Alumina Support by SiC− Si3N4 Nanoparticles Prepared by the Particle Precipitation Aided Chemical Vapor Deposition. Ind. Eng. Chem. Res. 1999, 38, 950–957. [Google Scholar] [CrossRef]

- Nagano, T.; Sato, K.; Fujisaki, S.; Saitoh, T.; Iwamoto, Y. Helium-Permselective Amorphous SiC Membrane Modified by Chemical Vapor Infiltration. Soft Mater. 2007, 4, 109–122. [Google Scholar] [CrossRef]

- Takeda, Y.; Shibata, N.; Kubo, Y. SiC coating on porous γ-Al2O3 using alternative-supply CVI method. J. Ceram. Soc. Jpn. 2001, 109, 305–309. [Google Scholar] [CrossRef][Green Version]

- Nagano, T.; Sato, K.; Kawahara, K. Gas Permeation Property of Silicon Carbide Membranes Synthesized by Counter-Diffusion Chemical Vapor Deposition. Membranes 2020, 10, 11. [Google Scholar] [CrossRef]

- Sea, B.-K.; Ando, K.; Kusakabe, K.; Morooka, S. Separation of hydrogen from steam using a SiC-based membrane formed by chemical vapor deposition of triisopropylsilane. J. Membr. Sci. 1998, 146, 73–82. [Google Scholar] [CrossRef]

- Ciora, R.J.; Fayyaz, B.; Liu, P.K.; Suwanmethanond, V.; Mallada, R.; Sahimi, M.; Tsotsis, T.T. Preparation and reactive applications of nanoporous silicon carbide membranes. Chem. Eng. Sci. 2004, 59, 4957–4965. [Google Scholar] [CrossRef]

- Barroso, G.; Li, Q.; Bordia, R.K.; Motz, G. Polymeric and ceramic silicon-based coatings—A review. J. Mater. Chem. A 2019, 7, 1936–1963. [Google Scholar] [CrossRef]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Wang, Q. Development of High-Performance SiC-Based Membranes Derived from Preceramic Precursors and Application to Gas Separation and Pervaporation. Doctoral Dissertation, Hiroshima University, Hiroshima, Japan, 2020. [Google Scholar]

- Ionescu, E.; Mera, G.; Riedel, R. Polymer-Derived Ceramics (PDCs): Materials Design towards Applications at Ultrahigh-Temperatures and in Extreme Environments. In MAX Phases and Ultra-High Temperature Ceramics for Extreme Environments; Low, I.M., Sakka, Y., Hu, C.F., Eds.; IGI Global: Hershey, PA, USA, 2013; pp. 203–245. [Google Scholar] [CrossRef]

- Mera, G.; Gallei, M.; Bernard, S.; Ionescu, E. Ceramic Nanocomposites from Tailor-Made Preceramic Polymers. Nanomaterials 2015, 5, 468–540. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Xu, N.; Liu, Q.; Dong, Q.; Nagasawa, H.; Kanezashi, M.; Zhou, R.; Tsuru, T. Low-temperature cross-linking fabrication of sub-nanoporous SiC-based membranes for application to the pervaporation removal of methanol. J. Membr. Sci. 2022, 662, 121008. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, L.; Nagasawa, H.; Kanezashi, M.; Tsuru, T. Tuning the microstructure of polycarbosilane-derived SiC(O) separation membranes via thermal-oxidative cross-linking. Sep. Purif. Technol. 2020, 248, 117067. [Google Scholar] [CrossRef]

- Wang, Q.; Yokoji, M.; Nagasawa, H.; Yu, L.; Kanezashi, M.; Tsuru, T. Microstructure evolution and enhanced permeation of SiC membranes derived from allylhydridopolycarbosilane. J. Membr. Sci. 2020, 612, 118392. [Google Scholar] [CrossRef]

- Yamamura, T.; Ishikawa, T.; Shibuya, M.; Hisayuki, T.; Okamura, K. Development of a new continuous Si-Ti-C-O fibre using an organometallic polymer precursor. J. Mater. Sci. 1988, 23, 2589–2594. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, L.; Zhan, J.; Zhou, C.; Min, H.; Zheng, Q.; Xia, H. Preparation, cross-linking and ceramization of AHPCS/Cp2ZrCl2 hybrid precursors for SiC/ZrC/C composites. J. Eur. Ceram. Soc. 2012, 32, 1291–1298. [Google Scholar] [CrossRef]

- Gupta, R.K.; Mishra, R.; Tiwari, R.K.; Ranjan, A.; Saxena, A.K. Studies on the Rheological Behavior of Polycarbosilane Part I: Effect of Time, Temperature and Atmosphere. Silicon 2010, 3, 27–35. [Google Scholar] [CrossRef]

- Ichikawa, H. Polymer-derived ceramic fibers. Annu. Rev. Mater. Res. 2016, 46, 335–356. [Google Scholar] [CrossRef]

- Ishikawa, T.; Yamamura, T.; Okamura, K. Production mechanism of polytitanocarbosilane and its conversion of the polymer into inorganic materials. J. Mater. Sci. 1992, 27, 6627–6634. [Google Scholar] [CrossRef]

- Jacobson, N.S.; Kline, S.E. A Thermoanalytical Study of the Conversion of Amorphous Si–Ti–C–O Fibers to SiC. Int. J. Appl. Ceram. Technol. 2012, 9, 816–822. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, E.B.; Kim, S.R.; Suh, M.H.; Choi, D.J.; Kwon, W.T. Hydrogen Separation Characteristics of SiC Nanoporous Membrane at High Temperature. Adv. Mater. Res. 2007, 26, 271–274. [Google Scholar] [CrossRef]

- Li, X.; Pei, X.; Zhong, X.; Mo, G.; He, L.; Huang, Z.; Huang, Q. Highly effective free-radical-catalyzed curing of hyperbranched polycarbosilane for near stoichiometric SiC ceramics. J. Am. Ceram. Soc. 2018, 102, 1041–1048. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, L.; Nagasawa, H.; Kanezashi, M.; Tsuru, T. High-performance molecular-separation ceramic membranes derived from oxidative cross-linked polytitanocarbosilane. J. Am. Ceram. Soc. 2020, 103, 4473–4488. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Cheng, L.; Wang, Y.; Yu, Z.; Huang, M.; Tu, H.; Xia, H. Effect of the polycarbosilane structure on its final ceramic yield. J. Eur. Ceram. Soc. 2008, 28, 887–891. [Google Scholar] [CrossRef]

- Hong, J.; Cho, K.-Y.; Shin, D.-G.; Kim, J.-I.; Riu, D.-H. Iodine diffusion during iodine-vapor curing and its effects on the morphology of polycarbosilane/silicon carbide fibers. J. Appl. Polym. Sci. 2015, 132, 42687. [Google Scholar] [CrossRef]

- Wach, R.A.; Sugimoto, M.; Yoshikawa, M. Formation of Silicone Carbide Membrane by Radiation Curing of Polycarbosilane and Polyvinylsilane and its Gas Separation up to 250 °C. J. Am. Ceram. Soc. 2006, 90, 275–278. [Google Scholar] [CrossRef]

- Takeyama, A.; Sugimoto, M.; Yoshikawa, M. Gas Permeation Property of SiC Membrane Using Curing of Polymer Precursor Film by Electron Beam Irradiation in Helium Atmosphere. Mater. Trans. 2011, 52, 1276–1280. [Google Scholar] [CrossRef]

- Li, Y.-L.; Fan, H.; Su, D.; Fasel, C.; Riedel, R. Synthesis, Structures, and Properties of Bulk Si(O)C Ceramics from Polycarbosilane. J. Am. Ceram. Soc. 2009, 92, 2175–2181. [Google Scholar] [CrossRef]

- Yajima, S.; Okamura, K.; Hayashi, J.; Omori, M. Synthesis of Continuous Sic Fibers with High Tensile Strength. J. Am. Ceram. Soc. 1976, 59, 324–327. [Google Scholar] [CrossRef]

- Zhong, X.; Pei, X.; Miao, Y.; He, L.; Huang, Q. Accelerating the crosslinking process of hyperbranched polycarbosilane by UV irradiation. J. Eur. Ceram. Soc. 2017, 37, 3263–3270. [Google Scholar] [CrossRef]

- Shibuya, M.; Yamamura, T. Characteristics of a continuous Si-Ti-C-O fibre with low oxygen content using an organometallic polymer precursor. J. Mater. Sci. 1996, 31, 3231–3235. [Google Scholar] [CrossRef]

- Williams, H.M.; Dawson, E.A.; Barnes, P.A.; Rand, B.; Brydson, R.M.D.; Brough, A.R. High temperature ceramics for use in membrane reactors: The development of microporosity during the pyrolysis of polycarbosilanes. J. Mater. Chem. 2002, 12, 3754–3760. [Google Scholar] [CrossRef]

- Anhua, L.; Jianming, C.; Shaonan, D.; Yanbo, Y.; Ling, L.; Fengping, L.; Lifu, C. Processing and characterization of cobalt silicide nanoparticle-containing silicon carbide fibers through a colloidal method and their underlying mechanism. J. Mater. Chem. C 2014, 2, 4980–4988. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Okamura, K. Synthesis of continuous silicon carbide fibre. III- Pyrolysis process of polycarbosilane and structure of the products. J. Mater. Sci. 1983, 18, 3633–3648. [Google Scholar] [CrossRef]

- Makuuchi, K.; Cheng, S. New Application of Radiation Crosslinking. In Radiation Processing of Polymer Materials and its Industrial Applications; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2012; ISBN 978-0-470-58769-0. [Google Scholar]

- Schitco, C.; Bazarjani, M.S.; Riedel, R.; Gurlo, A. NH3-assisted synthesis of microporous silicon oxycarbonitride ceramics from preceramic polymers: A combined N2 and CO2 adsorption and small angle X-ray scattering study. J. Mater. Chem. A 2014, 3, 805–818. [Google Scholar] [CrossRef]

- Maddocks, A.R.; Cassidy, D.J.; Jones, A.S.; Harris, A.T. Synthesis of nanoporous silicon carbide via the preceramic polymer route. Mater. Chem. Phys. 2009, 113, 861–867. [Google Scholar] [CrossRef]

- Lee, L.-L.; Tsai, D.-S. Synthesis and Permeation Properties of Silicon−Carbon-Based Inorganic Membrane for Gas Separation. Ind. Eng. Chem. Res. 2000, 40, 612–616. [Google Scholar] [CrossRef]

- Lee, L.-L.; Tsai, D.-S. A Hydrogen-Permselective Silicon Oxycarbide Membrane Derived from Polydimethylsilane. J. Am. Ceram. Soc. 2004, 82, 2796–2800. [Google Scholar] [CrossRef]

- Chen, C.L.; Tsai, D.S. Permeation properties of microporous membranes prepared via coating of evaporated polydimethylsilane. J. Membr. Sci. 2004, 237, 163–165. [Google Scholar] [CrossRef]

- Yajima, S. Special heat-resisting materials from organometallic polymers. Am. Ceram. Soc. Bull. 1983, 62, 893–903. [Google Scholar]

- Wach, R.A.; Sugimoto, M.; Idesaki, A.; Yoshikawa, M. Molecular sieve SiC-based membrane for hydrogen separation produced by radiation curing of preceramic polymers. Mater. Sci. Eng. B 2007, 140, 81–89. [Google Scholar] [CrossRef]

- Idesaki, A.; Narisawa, M.; Okamura, K.; Sugimoto, M.; Morita, Y.; Seguchi, T.; Itoh, M. Application of electron beam curing for silicon carbide fiber synthesis from blend polymer of polycarbosilane and polyvinylsilane. Radiat. Phys. Chem. 2001, 60, 483–487. [Google Scholar] [CrossRef]

- Suda, H.; Yamauchi, H.; Uchimaru, Y.; Fujiwara, I.; Haraya, K. Preparation and gas permeation properties of silicon carbide-based inorganic membranes for hydrogen separation. Desalination 2006, 193, 252–255. [Google Scholar] [CrossRef]

- Suda, H.; Yamauchi, H.; Uchimaru, Y.; Fujiwara, I.; Haraya, K. Structural Evolution during Conversion of Polycarbosilane Precursor into Silicon Carbide-Based Microporous Membranes. J. Ceram. Soc. Jpn. 2006, 114, 539–544. [Google Scholar] [CrossRef]

- Elyassi, B.; Sahimi, M.; Tsotsis, T.T. Silicon carbide membranes for gas separation applications. J. Membr. Sci. 2007, 288, 290–297. [Google Scholar] [CrossRef]

- Ishikawa, T.; Yamaoka, H.; Harada, Y.; Fujii, T.; Nagasawa, T. A general process for in situ formation of functional surface layers on ceramics. Nature 2002, 416, 64–67. [Google Scholar] [CrossRef]

- Prasad, R.M.; Iwamoto, Y.; Riedel, R.; Gurlo, A. Multilayer Amorphous-Si-B-C-N/γ-Al2O3/α-Al2O3 Membranes for Hydrogen Purification. Adv. Eng. Mater. 2010, 12, 522–528. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, J.; Li, M.; Zhou, Y. Mechanical properties and damage tolerance of Y2SiO5. J. Eur. Ceram. Soc. 2008, 28, 2895–2901. [Google Scholar] [CrossRef]

- Holmstrom, E.; Ghan, S.; Asakawa, H.; Fujita, Y.; Fukuma, T.; Kamimura, S.; Ohno, T.; Foster, A.S. Hydration structure of brookite TiO2 (210). J. Phys. Chem. C 2017, 121, 20790–20801. [Google Scholar] [CrossRef]

- Kanezashi, M.; Murata, M.; Nagasawa, H.; Tsuru, T. Fluorine Doping of Microporous Organosilica Membranes for Pore Size Control and Enhanced Hydrophobic Properties. ACS Omega 2018, 3, 8612–8620. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wu, A.; Zhong, S.; Wang, B.; Zhou, R. Highly (h0h)-oriented silicalite-1 membranes for butane isomer separation. J. Membr. Sci. 2017, 540, 50–59. [Google Scholar] [CrossRef]

- Williams, H.M.; Dawson, E.A.; Barnes, P.A.; Rand, B.; Brydson, R.M. The development and stability of porosity formed during the pyrolysis of polyborodiphenylsiloxane. Microporous Mesoporous Mater. 2007, 99, 261–267. [Google Scholar] [CrossRef]

- Ly, H.Q.; Taylor, R.; Day, R.; Heatley, F. Conversion of polycarbosilane (PCS) to SiC-based ceramic Part II Pyrolysis and characterisation. J. Mater. Sci. 2001, 36, 4045–4057. [Google Scholar] [CrossRef]

- Lipowtz, J.; Freeman, H.; Chen, R.; Prack, E.R. Composition and Structure of Ceramic Fibers Prepared from Polymer Precursors. Adv. Ceram. Mater. 1987, 2, 121–128. [Google Scholar] [CrossRef]

- Kanezashi, M.; Sazaki, H.; Nagasawa, H.; Yoshioka, T.; Tsuru, T. Evaluating the gas permeation properties and hydrothermal stability of organosilica membranes under different hydrosilylation conditions. J. Membr. Sci. 2015, 493, 664–672. [Google Scholar] [CrossRef]

- Duke, M.C.; da Costa, J.C.D.; Do, D.D.; Gray, P.G.; Lu, G.Q. Hydrothermally Robust Molecular Sieve Silica for Wet Gas Separation. Adv. Funct. Mater. 2006, 16, 1215–1220. [Google Scholar] [CrossRef]

- Meng, L.; Kanezashi, M.; Tsuru, T. Catalytic membrane reactors for SO3 decomposition in Iodine–Sulfur thermochemical cycle: A simulation study. Int. J. Hydrogen Energy 2015, 40, 12687–12696. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, P.; Chen, S.; Wang, L.; Xu, J. Modeling and validation of the iodine-sulfur hydrogen production process. AIChE J. 2013, 60, 546–558. [Google Scholar] [CrossRef]

| Membrane Material | Amorphous Structure | Advantages | Disadvantages |

|---|---|---|---|

| Silica (SiO2) |  |

|

|

| Carbon molecular sieve (CMS) or carbon membranes |  [12] [12] |

|

|

| Silicon carbide (SiC) |  |

|

|

| Shape and Pore Size of Supports | Raw Materials of Layers on Supports | Layer Deposition Method | Top Layer Thickness [μm] | Thermal Treatment | Pore Size (Type: MF, UF) | Applications and Other Remarks | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Transition Layer | Top Layer | |||||||

| Disk, 15 μm | na. | α-SiC powder (10 μm), SiC whisker, methylcellulose (MC) 2, CaO 5, ZrO2 5, mullite 5, TL-56NQ 4, water 1 | Spray coating | 125 | 1150–1250 °C, 2 h in air; then 1350–1500 °C, 4 h in Ar | 2.31 μm (MF) |

| [48] |

| Flat tube, 1.8 μm | na. | SiC powder (0.55 μm), IPA 1, PVA 3, PEG 3, Darvan-CN 2, water 1 | Dip-coating | 12–30 | 900–1300 °C, 1 h | 75–155 nm (MF) |

| [49] |

| Flat tube, 34.92 μm | na. | SiC powder (22 µm), B4C 5, PVA 3, TMAOH 2, water | Dip-coating | ~100 | 2200–2250 °C | 9.93 μm (MF) |

| [50] |

| Tube, 15 μm | na. | α-SiC powder (0.4 μm and 0.6 μm), Al(NO3)3·9H2O 5, Optapix CS-76 3, polysaccharide dicarbonic acid polymer 3, water 1 | Dip-coating | 27.3–29.4 | 1600–1900 °C | 0.35 μm (MF) |

| [51] |

| Flat sheet, 5.6–14.1 μm | na. | SiC powders (0.5 µm and 3 µm), PAA 2, CMC 3, water 1 | Dip-coating | 60 | 1900–2000 °C in vacuum | 0.5 μm (1900 °C); 1.4 μm (2000 °C) (MF) |

| [52] |

| Flat disk, <100 μm | Consisting of several SiC layers; pore diameter <300 nm | α-SiC powder (0.4 µm), AHPCS 6, hexane 1, hexane/tetradecane 1 | Dip-coating | 10–19 | 200 °C, 1 h; 400 °C, 1 h; and then 750 °C, 2 h | <50 nm (UF) |

| [53] |

| Tube/na. | SiC powder (0.6 µm), acetone; pore diameter =130 nm | PS 7, toluene 1, AHPCS 6, hexane 1 | Slip-casting + dip-coating | 7 | 200 °C, 1 h, 400 °C, 1 h, and then 750 °C, 2 h in Ar; 450 °C, 2 h in air | Nanoporous SiC membranes |

| [54] |

| Membranes | Precursor | Supports | Deposition Temperature | Ref. |

|---|---|---|---|---|

| SiCN | SiH4/C2H2/NH3 | α-Al2O3; disk | 1050 °C in Ar | [60] |

| SiCO | SiH2Cl2/C2H2/H2 | γ-Al2O3/α-Al2O3; tube | 800–900 °C in H2 | [61,62] |

| SiC | Triisopropylsilane (TPS) | SiC; disk; and tube | 760–800 °C in Ar/He | [59] |

| SiC | Silacyclobutane (SCB) | Ni-γ-Al2O3/α-Al2O3; tube | 515 °C in Ar | [63] |

| SiC | 1,3-disilabutane (DSB); TPS | α-Al2O3; γ-Al2O3/α-Al2O3; tube | TPS: 700–800 °C in He, and annealed at 1000 °C; DSB: 650–750 °C in He | [64,65] |

| Gas Separation | Applications (or Potential Applications) |

|---|---|

| H2/N2 | Ammonia purge gas |

| H2/hydrocarbon | Refinery hydrogen recovery, alkane dehydrogenation |

| H2/H2O, H2/CO2, H2O/CO | H2 production, water–gas shift, thermochemical water splitting |

| He/hydrocarbon | Helium separation |

| He/N2 | Helium recovery |

| O2/SO2, O2/SO3 | O2 separation in H2SO4 decomposition |

| CO2/(hydrocarbon or N2) | Acid gas treatment, greenhouse gas capture |

| H2O/Air | Air dehydration |

| Pyrolysis Temperature [°C] | BET Surface Area * [m2/g] | Micropore Volume # [cm3/g] | ||

|---|---|---|---|---|

| PCS [72] | TiPCS [82] | PCS [72] | TiPCS [82] | |

| 350 | 449 | dense polymer | 0.2164 | dense polymer |

| 550 | 520 | 66 | 0.2326 | 0.02 |

| 650 | 316 | 498 | 0.1304 | 0.174 |

| 750 | 0.754 | 245.7 | 0 | 0.084 |

| 800 | — | 143.1 | — | 0.046 |

| 1000 | — | 0.4 | — | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhou, R.; Tsuru, T. Recent Progress in Silicon Carbide-Based Membranes for Gas Separation. Membranes 2022, 12, 1255. https://doi.org/10.3390/membranes12121255

Wang Q, Zhou R, Tsuru T. Recent Progress in Silicon Carbide-Based Membranes for Gas Separation. Membranes. 2022; 12(12):1255. https://doi.org/10.3390/membranes12121255

Chicago/Turabian StyleWang, Qing, Rongfei Zhou, and Toshinori Tsuru. 2022. "Recent Progress in Silicon Carbide-Based Membranes for Gas Separation" Membranes 12, no. 12: 1255. https://doi.org/10.3390/membranes12121255

APA StyleWang, Q., Zhou, R., & Tsuru, T. (2022). Recent Progress in Silicon Carbide-Based Membranes for Gas Separation. Membranes, 12(12), 1255. https://doi.org/10.3390/membranes12121255