Forward Osmosis Technology and Its Application on Microbial Fuel Cells: A Review

Abstract

:1. Introduction to Forward Osmosis (FO)

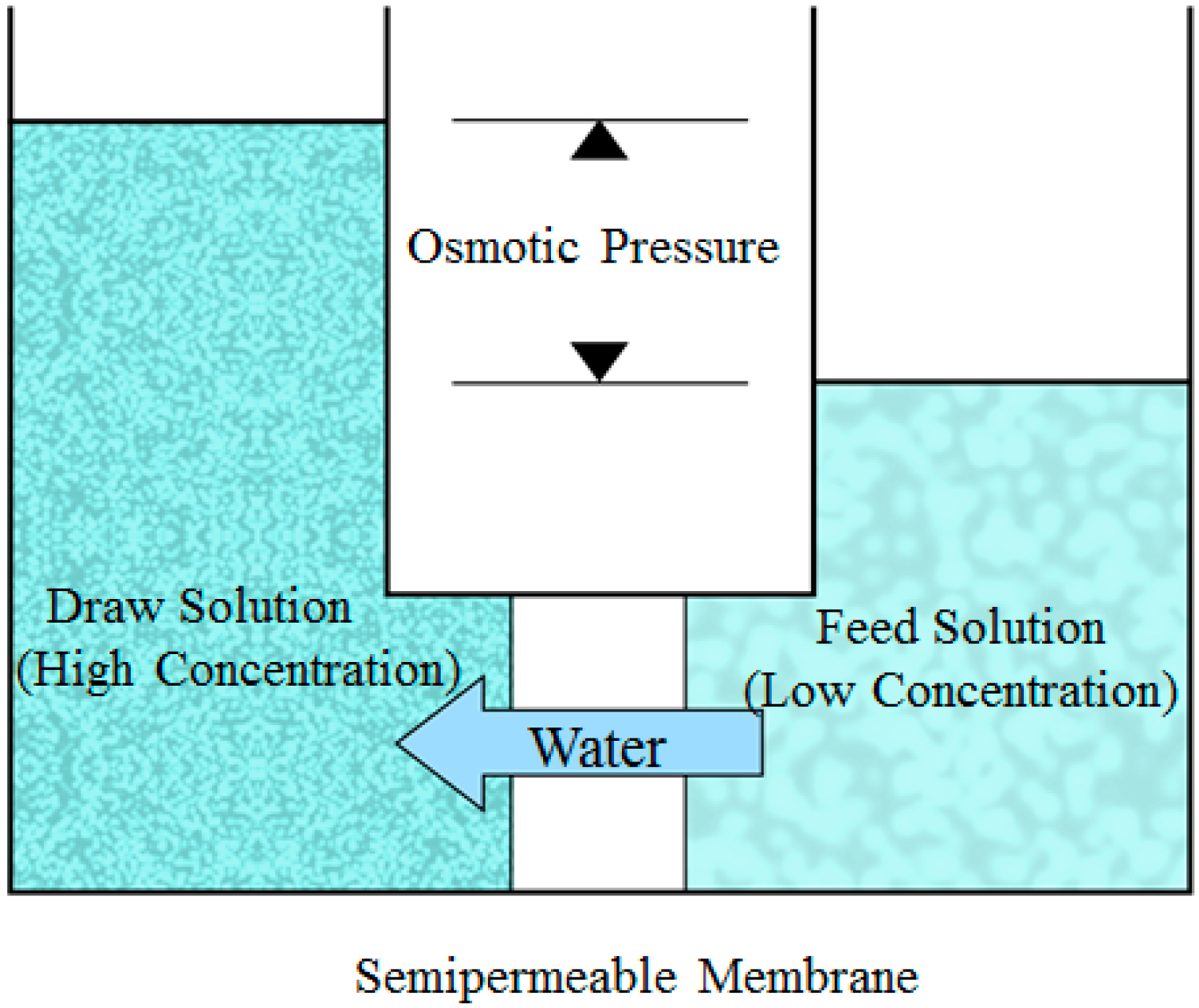

1.1. Principle of Forward Osmosis

1.2. Development of Forward Osmosis(FO)

- ◾

- Low energy consumption

- ◾

- Light membrane pollution and high reversibility

- ◾

- High pollutant retention rate and good effluent quality

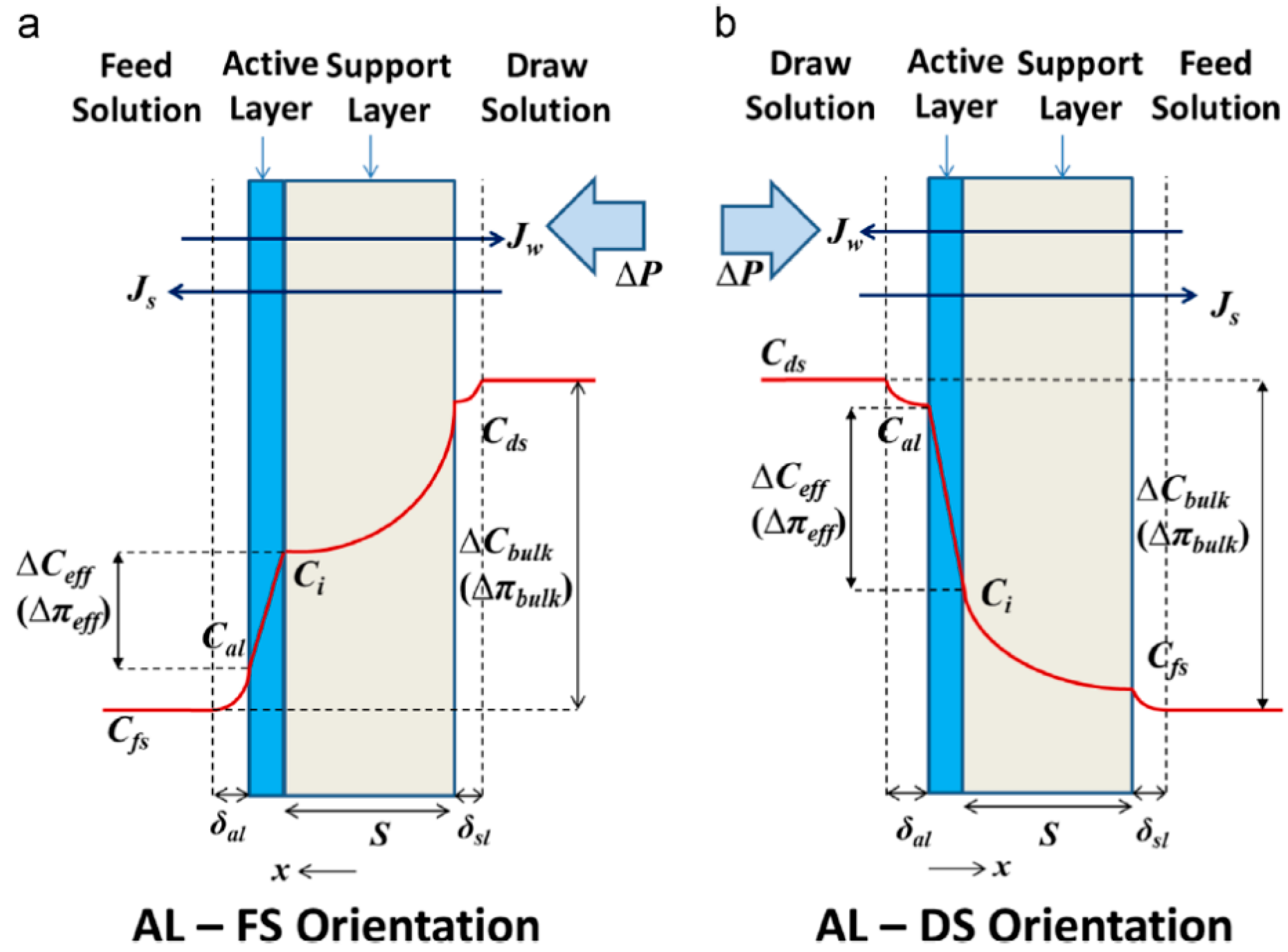

1.3. Concentration Polarization

1.4. Membrane Fouling

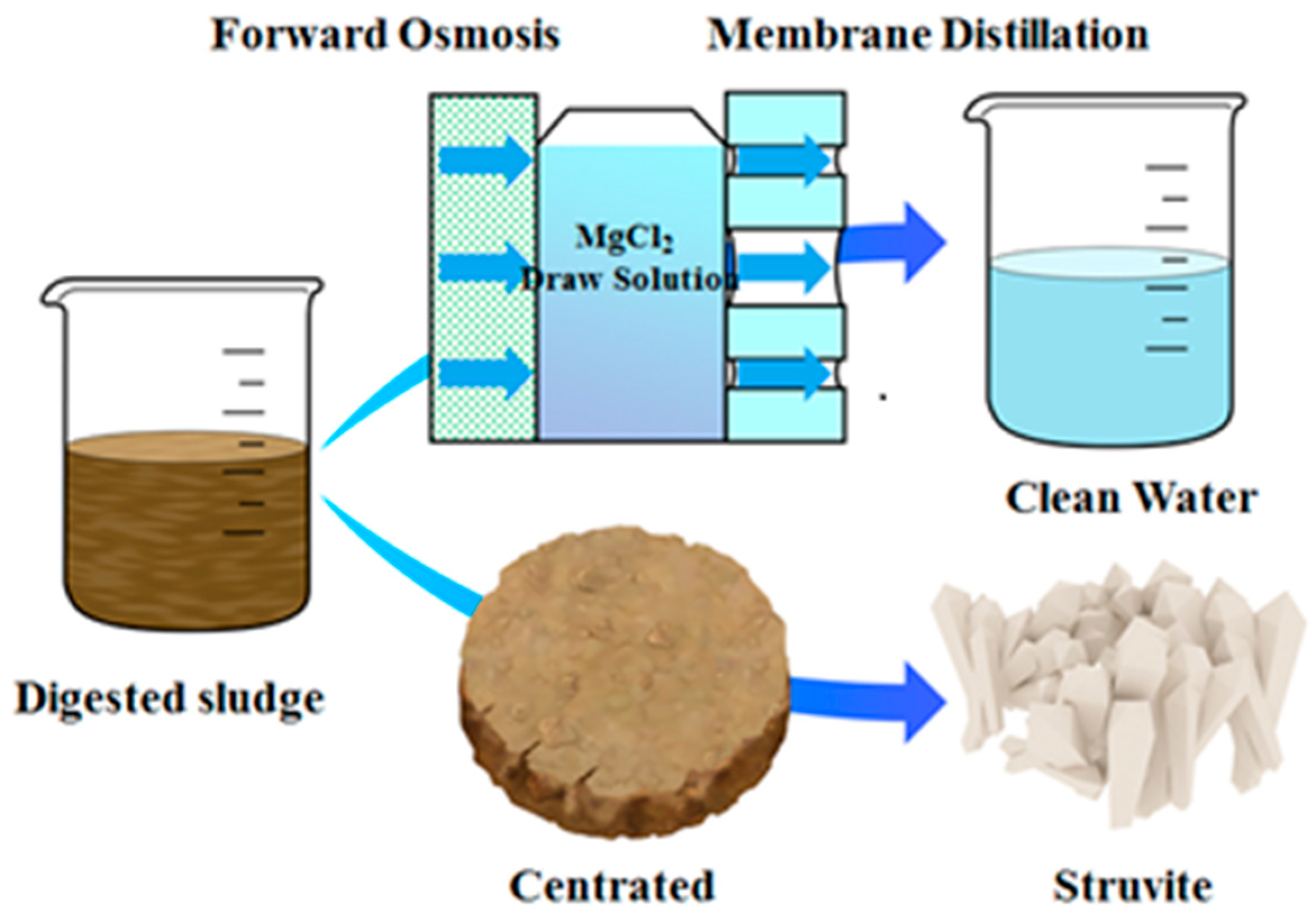

1.5. Application of FO Technology

- ◾

- Water resources regeneration

- ◾

- Recovery of nitrogen and phosphorus nutrients

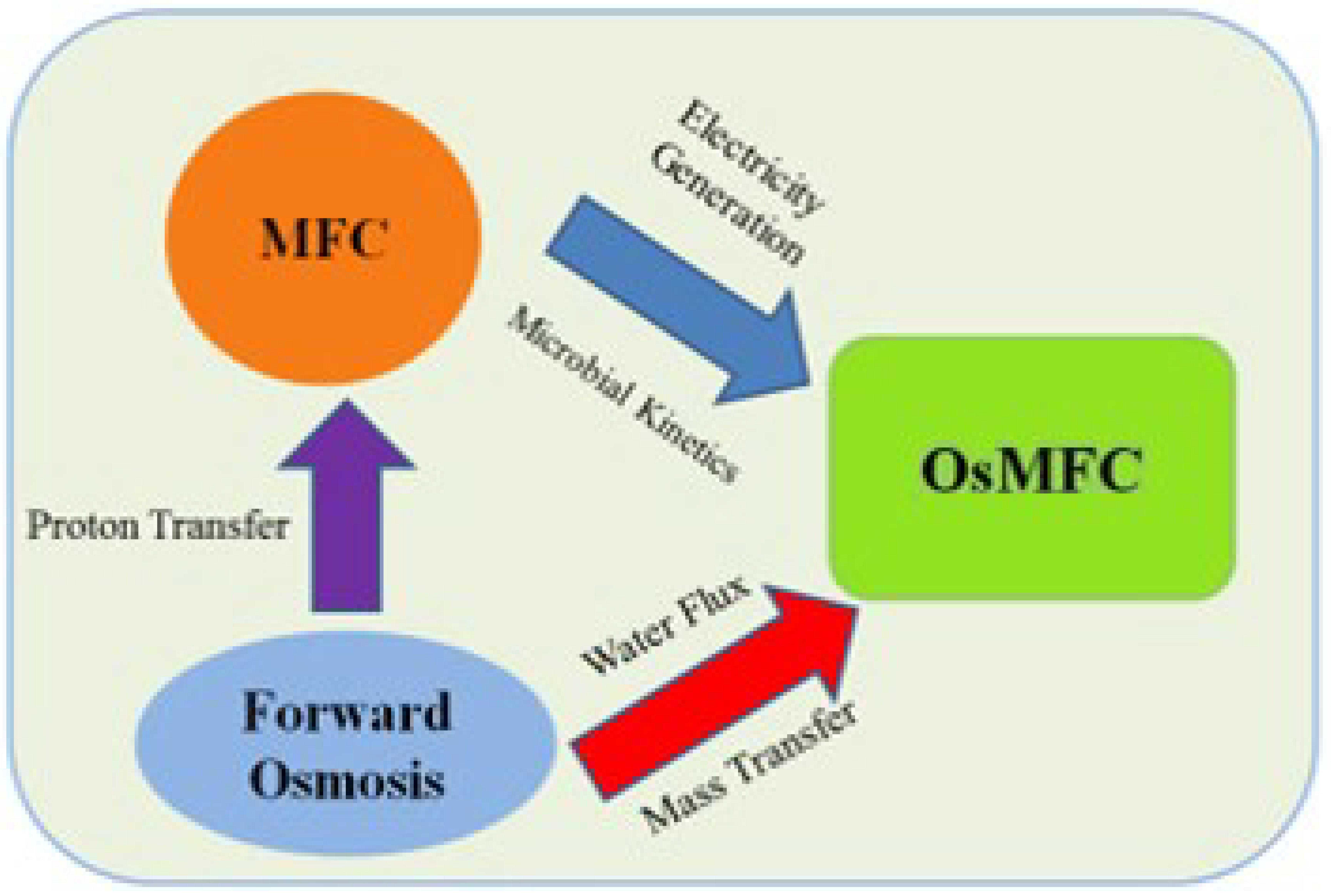

2. FO and Bioelectrochemical System Technology (BES)

2.1. Coupling Advantages of Forward Osmosis Technology and Microbial Fuel Cell Technology

- ◾

- Enhance power generation performance

- ◾

- Recover high-quality water resources

2.2. Development of Forward Osmosis Technology and Microbial Fuel Cell Technology

2.3. Challenges of Forward Osmosis Technology and Microbial Fuel Cell Technology

3. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ashkanani, A.; Almomani, F.; Khraisheh, M.; Bhosale, R.; Tawalbeh, M.; AlJaml, K. Bio-carrier and operating temperature effect on ammonia removal from secondary wastewater effluents using moving bed biofilm reactor (MBBR). Sci. Total Environ. 2019, 693, 133425. [Google Scholar] [CrossRef]

- Hou, H.; Mengting, Z.; Duan, L.; Zhao, Y.; Zhang, Z.; Yao, M.; Zhou, B.; Zhang, H.; Hermanowicz, S.W. Removal performance and biodegradation mechanism of sulfonamides antibiotic contained wastewater by IFAS-MBR bioreactor. J. Mol. Liq. 2022, 367, 120572. [Google Scholar] [CrossRef]

- Sonawane, J.M.; Yadav, A.; Ghosh, P.C.; Adeloju, S.B. Recent advances in the development and utilization of modern anode materials for high performance microbial fuel cells. Biosens. Bioelectron. 2017, 90, 558–576. [Google Scholar] [CrossRef]

- Mohammed, H.; Al-Othman, A.; Nancarrow, P.; Tawalbeh, M.; Assad, M.E.H. Direct hydrocarbon fuel cells: A promising technology for improving energy efficiency. Energy 2019, 172, 207–219. [Google Scholar] [CrossRef]

- Werner, C.M.; Logan, B.E.; Saikaly, P.E.; Amy, G.L. Wastewater treatment, energy recovery and desalination using a forward osmosis membrane in an air-cathode microbial osmotic fuel cell. J. Membr. Sci. 2013, 428, 116–122. [Google Scholar] [CrossRef]

- Coday, B.D.; Heil, D.M.; Xu, P.; Cath, T.Y. Effects of Transmembrane Hydraulic Pressure on Performance of Forward Osmosis Membranes. Environ. Sci. Technol. 2013, 47, 2386–2393. [Google Scholar] [CrossRef] [Green Version]

- Ge, Z.; He, Z. Effects of draw solutions and membrane conditions on electricity generation and water flux in osmotic microbial fuel cells. Bioresour. Technol. 2012, 109, 70–76. [Google Scholar] [CrossRef]

- Ge, Z.; Ping, Q.; Xiao, L.; He, Z. Reducing effluent discharge and recovering bioenergy in an osmotic microbial fuel cell treating domestic wastewater. Desalination 2013, 312, 52–59. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, L.; Liu, X.; Song, Y. Study on the Changes in the Microcosmic Environment in Forward Osmosis Membranes to Reduce Membrane Resistance. Membranes 2022, 12, 1203. [Google Scholar] [CrossRef]

- Johnson, D.J.; Suwaileh, W.A.; Mohammed, A.W.; Hilal, N. Osmotic’s potential: An overview of draw solutes for forward osmosis. Desalination 2018, 434, 100–120. [Google Scholar] [CrossRef]

- Korenak, J.; Basu, S.; Balakrishnan, M.; Hélix-Nielsen, C.; Petrinic, I. Forward Osmosis in Wastewater Treatment Processes. Acta Chim. Slov. 2017, 64, 83–94. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Zhang, J.; Chang, V.W.; She, Q.; Tang, C.Y. Removal of cytostatic drugs from wastewater by an anaerobic osmotic membrane bioreactor. Chem. Eng. J. 2018, 339, 153–161. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Adhami, A.; Darvari, S.; Zirepour, A.; Oh, S.-E. Microbial fuel cell as new technology for bioelectricity generation: A review. Alex. Eng. J. 2015, 54, 745–756. [Google Scholar] [CrossRef] [Green Version]

- Yokozeki, A. Osmotic pressures studied using a simple equation-of-state and its applications. Appl. Energy 2006, 83, 15–41. [Google Scholar] [CrossRef]

- Yang, Y.; Qin, M.; Yang, X.; He, Z. Sustainable operation of osmotic microbial fuel cells through effective reproduction of polyelectrolyte draw solutes facilitated by cathodic pH increase. J. Clean. Prod. 2017, 168, 1143–1149. [Google Scholar] [CrossRef]

- Liu, C.; Lei, X.; Wang, L.; Jia, J.; Liang, X.; Zhao, X.; Zhu, H. Investigation on the removal performances of heavy metal ions with the layer-by-layer assembled forward osmosis membranes. Chem. Eng. J. 2017, 327, 60–70. [Google Scholar] [CrossRef]

- Logan, B.E.; Regan, J.M. Electricity-producing bacterial communities in microbial fuel cells. Trends Microbiol. 2006, 14, 512–518. [Google Scholar] [CrossRef]

- Qin, M.; Hynes, E.A.; Abu-Reesh, I.M.; He, Z. Ammonium removal from synthetic wastewater promoted by current generation and water flux in an osmotic microbial fuel cell. J. Clean. Prod. 2017, 149, 856–862. [Google Scholar] [CrossRef] [Green Version]

- Tian, E.; Liu, Y.; Yin, F.; Lu, S.; Zheng, L.; Wang, X.; Wang, Z.; Liu, H. Facilitating proton transport by endowing forward osmosis membrane with proton conductive sites in osmotic microbial fuel cell. Chem. Eng. J. 2023, 451, 138767. [Google Scholar] [CrossRef]

- Rozendal, R.A.; Hamelers, H.V.M.; Buisman, C.J.N. Effects of Membrane Cation Transport on pH and Microbial Fuel Cell Performance. Environ. Sci. Technol. 2006, 40, 5206–5211. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, L.; Liu, X.; Song, Y. Influence of Membrane Fouling and Reverse Salt Flux on Membrane Impedance of Forward Osmosis Microbial Fuel Cell. Membranes 2022, 12, 1165. [Google Scholar] [CrossRef] [PubMed]

- Park, K.; Jang, Y.H.; Chang, J.W.; Yang, D.R. Membrane transport behavior characterization method with constant water flux in pressure-assisted forward osmosis. Desalination 2021, 498, 114738. [Google Scholar] [CrossRef]

- Pramanik, B.K.; Shu, L.; Jegatheesan, V. A review of the management and treatment of brine solutions. Environ. Sci. Water Res. Technol. 2017, 3, 625–658. [Google Scholar] [CrossRef]

- Zhu, M.T.; Tonni, A.; Duan, L.; Song, Y.H.; Hermanowicz, S.W.; Mohd, H. Advances in BiOX-based ternary photocatalysts for water technology and energy storage applications: Research trends, challenges, solutions, and way forward. Rev. Environ. Sci. Bio. 2022, 21, 331–370. [Google Scholar]

- Yao, M.; Duan, L.; Song, Y.; Hermanowicz, S.W. Degradation mechanism of Ibuprofen via a forward osmosis membrane bioreactor. Bioresour. Technol. 2020, 321, 124448. [Google Scholar] [CrossRef] [PubMed]

- Shantaram, A.; Beyenal, H.; Veluchamy, R.R.A.; Lewandowski, Z. Wireless Sensors Powered by Microbial Fuel Cells. Environ. Sci. Technol. 2005, 39, 5037–5042. [Google Scholar] [CrossRef]

- Shizas, I.; Bagley, D. Experimental Determination of Energy Content of Unknown Organics in Municipal Wastewater Streams. J. Energy Eng. 2004, 130, 45–53. [Google Scholar] [CrossRef]

- Qin, M.; Abu-Reesh, I.M.; He, Z. Effects of current generation and electrolyte pH on reverse salt flux across thin film composite membrane in osmotic microbial fuel cells. Water Res. 2016, 105, 583–590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Y.; Song, Y.; Duan, L. Study on the Effect of Water Flux in Osmotic Microbial Fuel Cells on Membrane Water Content and Resistance. Water 2022, 14, 848. [Google Scholar] [CrossRef]

- Linares, R.V.; Li, Z.; Sarp, S.; Bucs, S.; Amy, G.; Vrouwenvelder, J. Forward osmosis niches in seawater desalination and wastewater reuse. Water Res. 2014, 66, 122–139. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, L. Research on Measuring Pure Membrane Electrical Resistance under the Effects of Salinity Gradients and Diffusion Boundary Layer and Double Layer Resistances. Membranes 2022, 12, 816. [Google Scholar] [CrossRef] [PubMed]

- Tiraferri, A. New Facility for Membrane Fouling Investigations under Customizable Hydrodynamics: Validation and Preliminary Experiments with Pulsating Cross-Flow. Membranes 2022, 12(3), 334. [Google Scholar] [CrossRef]

- Yu, Y.; Lee, S.; Maeng, S.K. Forward osmosis membrane fouling and cleaning for wastewater reuse. J. Water Reuse Desalination 2016, 7, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Titorova, V.; Mareev, S.; Gorobchenko, A.; Gil, V.; Nikonenko, V.; Sabbatovskii, K.; Pismenskaya, N. Effect of current-induced coion transfer on the shape of chronopotentiograms of cation-exchange membranes. J. Membr. Sci. 2021, 624, 119036. [Google Scholar] [CrossRef]

- Faucher, M.; Thibodeau, J.; Ciftci, O.N.; Gaaloul, S.; Bazinet, L. Phospholipid recovery from sweet whey by combination of electrodialytic processes and understanding of specific mechanisms involved. Chem. Eng. J. 2022, 448, 137165. [Google Scholar] [CrossRef]

- Wang, Z.; He, P.; Zhang, H.; Zhang, N.; Lü, F. Desalination, nutrients recovery, or products extraction: Is electrodialysis an effective way to achieve high-value utilization of liquid digestate? Chem. Eng. J. 2022, 446, 136996. [Google Scholar] [CrossRef]

- Rajesh, K.S.; Kumar, K.P.; Vivekanand, V.; Pareek, N.; Khasim, B.; Sanjukta, S. Microbial fuel cells for waste nutrients minimization:Recent process technologies and inputs of electrochemical active microbial system. Microbiol Res. 2022, 265, 127216. [Google Scholar] [CrossRef]

- Aguero, R.; Bringas, E.; Román, M.S.; Ortiz, I.; Ibañez, R. Membrane Processes for Whey Proteins Separation and Purification. A Review. Curr. Org. Chem. 2017, 21, 1740–1752. [Google Scholar] [CrossRef]

- Mitko, K.; Turek, M.; Jaroszek, H.; Bernacka, E.; Sambor, M.; Skóra, P.; Dydo, P. Pilot studies on circular economy solution for the coal mining sector. Water Resour. Ind. 2021, 26, 100161. [Google Scholar] [CrossRef]

- Zhao, D.; Lee, L.Y.; Ong, S.L.; Chowdhury, P.; Siah, K.B.; Ng, H.Y. Electrodialysis reversal for industrial reverse osmosis brine treatment. Sep. Purif. Technol. 2018, 213, 339–347. [Google Scholar] [CrossRef]

- Sharifi, M.; Pothu, R.; Boddula, R.; Bardajee, G.R. Trends of biofuel cells for smart biomedical devices. Int. J. Hydrogen Energ. 2021, 46, 3220. [Google Scholar] [CrossRef]

- Barros, K.S.; Martí-Calatayud, M.C.; Pérez-Herranz, V.; Espinosa, D.C.R. A three-stage chemical cleaning of ion-exchange membranes used in the treatment by electrodialysis of wastewaters generated in brass electroplating industries. Desalination 2020, 492, 114628. [Google Scholar] [CrossRef]

- Mishchuk, N.A. Concentration polarization of interface and non-linear electrokinetic phenomena. Adv. Colloid Interface Sci. 2010, 160, 16–39. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, K.S.; Ramyakrishna, P.; Cesar, P.S.; Orsha, G.; Sudip, M.; Eldon, R.R.; Sruthy, V.N. Removal and recovery of nutrients and value-added products from wastewater: Technological options and practical perspective. Syst. Microbiol. Biomanuf. 2022, 2, 67. [Google Scholar] [CrossRef]

- Karatay, E.; Andersen, M.B.; Wessling, M.; Mani, A. Coupling between Buoyancy Forces and Electroconvective Instability near Ion-Selective Surfaces. Phys. Rev. Lett. 2016, 116, 194501. [Google Scholar] [CrossRef] [Green Version]

- Barakat, M.A.; Schmidt, E. Polymer-enhanced ultrafiltration process for heavy metals removal from industrial wastewater. Desalination 2010, 256, 90–93. [Google Scholar] [CrossRef]

- Verma, B.; Balomajumder, C.; Sabapathy, M.; Gumfekar, S.P. Pressure-Driven Membrane Process: A Review of Advanced Technique for Heavy Metals Remediation. Processes 2021, 9, 752. [Google Scholar] [CrossRef]

- Murthy, Z.; Chaudhari, L.B. Application of nanofiltration for the rejection of nickel ions from aqueous solutions and estimation of membrane transport parameters. J. Hazard. Mater. 2008, 160, 70–77. [Google Scholar] [CrossRef]

- Conidi, C.; Drioli, E.; Cassano, A. Biologically Active Compounds from Goji (Lycium Barbarum L.) Leaves Aqueous Extracts: Purification and Concentration by Membrane Processes. Biomolecules 2020, 10, 935. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Boddula, R.; Pothu, R. Microbial fuel cells: Technologically advanced devices and approach for sustainable/renewable energy development. Energy Convers. Manag. X 2021, 13, 100160. [Google Scholar] [CrossRef]

- Esmaeili, M.; Virtanen, T.; Lahti, J.; Mänttäri, M.; Kallioinen, M. Vanillin as an Antifouling and Hydrophilicity Promoter Agent in Surface Modification of Polyethersulfone Membrane. Membranes 2019, 9, 56. [Google Scholar] [CrossRef] [PubMed]

- Ranieri, G.; Mazzei, R.; Poerio, T.; Bazzarelli, F.; Wu, Z.; Li, K.; Giorno, L. Biorefinery of olive leaves to produce dry oleuropein aglycone: Use of homemade ceramic capillary biocatalytic membranes in a multiphase system. Chem. Eng. Sci. 2018, 185, 149–156. [Google Scholar] [CrossRef] [Green Version]

- Díaz-Villanueva, J.F.; Díaz-Molina, R.; García-González, V. Protein Folding and Mechanisms of Proteostasis. Int. J. Mol. Sci. 2015, 16, 17193–17230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, C.Y.; She, Q.; Lay, W.C.L.; Wang, R.; Fane, A.G. Coupled effects of internal concentration polarization and fouling on flux behavior of forward osmosis membranes during humic acid filtration. J. Membr. Sci. 2010, 354, 123–133. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Rajangam, A.S.; Salameh, T.; Al-Othman, A.; Alkasrawi, M. Characterization of paper mill sludge as a renewable feedstock for sustainable hydrogen and biofuels production. Int. J. Hydrogen Energy 2020, 46, 4761–4775. [Google Scholar] [CrossRef]

- Ferby, M.; Zou, S.; He, Z. Effects of draw solutes on an integrated forward osmosis—Microbial fuel cell system treating a synthetic wastewater. Water Environ. Res. 2022, 94, e10802. [Google Scholar] [CrossRef]

| System | Membrane Type | Anolyte Substrate | Catholyte Solute | Catholyte Concentration | COD Removal (%) | Water Flux (LMH) | Maximum Power Density (W/m3) | References |

|---|---|---|---|---|---|---|---|---|

| OsMFC | CTA (Flat sheet) | Acetate | NaCl | 20–116 g/L | 82.5% | 1.2–2.8 | 28.2 | [18] |

| OsMFC | TFC-1 | Acetate | NaCl | 1 M | 75.5% | 1.82 | 13.6 | [19] |

| OsMFC | TFC-2 | Acetate | CaCl2 | 1 M | 78.3% | 0.56 | 7.3 | [19] |

| OsMFC | TFC-3 | Acetate | PBS buffer | 1 M | 65.6% | 2.42 | 5.5 | [19] |

| OsMFC | TFC-4 | Acetate | Glucose | 1 M | 52.1% | 1.82 | 3.7 | [19] |

| OsMDC | CTA (Hydrowell filter) | Acetate | NaCl | 5–20 g/L | - | 0.29–0.69 | - | [20] |

| OsMFC | CTA + polypyrrole | Glucose | NaCl | 2 M | 89.8% | 1.1 | 27.8 | [21] |

| OsMFC | Chitosan + PAAc | Glucose | NaCl | 35 g/L | 74.8% | 18.4–34.4 | 24.5 | [22] |

| OsMFC | TFC | Glucose | NaCl | 58.5 g/L | 85% | 3.25 | 16.5 | [23] |

| OsMEC | CTA | Acetate | PBS buffer | 24 g/L | - | - | - | [24] |

| MEC-FO | TFC + Disulphonate | Glucose | NH4HCO3 | 0.8 M | 60.6% | 3.0 | [24] | |

| AAFO-MFC | TFC (DS-11-AG) | Acetate | NaCl | 5 M | 71.2% | 2.33–5.62 | 4.38 | [25] |

| MEC-PRO | CTA | Acetate | NaCl | 0.1–2.0 M | 80% | 0.5–1 | [25] | |

| MFC-OMBR | TFC + Polydopamine | Acetate | NaCl | 0.5 | - | 2.0–12 | 11.5 | [26] |

| FO-MDC | CTA | Acetate | NaCl | 35 g/L | 70.6 | 0.64–0.99 | [26] | |

| OsMFC | CTA + Anthraquinone | Primary effluent | NaCl | 1 M | 74.8% | 1.11–1.49 | 4.5 | [27] |

| OsMFC | CTA | Domestic Wastewater | NaCl | 58.5 g/L | 85–90% | 2.93 | 0.48–0.52 | [27] |

| OsMFC | CTA-Double Skinned | Acetate | Oil produced water | - | - | 1.8–4.1 | 3.9 | [28] |

| OsMFC | CTA-Hydrowell filte | Acetate | NaCl | 3 g/L | 65% | 0–0.75 | 0.615 | [28] |

| Items | Anaerobic Digestion Technology | Microbial Fuel Cells Technology | Osmosis Microbial Fuel Cells Technology |

|---|---|---|---|

| Configuration | Upflow Anaerobic Sludge Blanket (UASB) reactor. | Single/Two chamber. | Two chamber. |

| Biocatalyst | A complex “food chain” type microbial consortium catalyzes the process. | The microbial catalysts can be an axenic culture or a mixed culture. | Directly inoculated from other MFC reactors that have been domesticated and matured. |

| Power input | Can application for both high and low concentration COD biomass at temperatures about 30 °C. | Can be utilized rather low strength influents containing glucose, sucrose or acetate at temperatures below 30 °C. | - |

| Power output types |

| Convert energy available in biomass directly to electricity. |

|

| Power output units | The power density obtained is about 400 W/m3 when the technology is applied to treat about 5 to 25 kg of COD per m3 of the reactor per day. | The average power density of MFCs is about 40 W/m3. | Recently, stacked configurations of OsMFCs have reached power densities of 250 W/m3. |

| Advantages |

| Less excess activated sludge; Intensive to operation environment; Widespread application in location with insufficient electrical infrastructures. | In addition to retaining the advantages of MFC, the low membrane resistance enhances the power generation performance of MFC. |

| Disadvantages |

|

| Inhibition of Reverse Salt Flux and Recycling of draw solution. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Duan, L.; Liu, X.; Song, Y. Forward Osmosis Technology and Its Application on Microbial Fuel Cells: A Review. Membranes 2022, 12, 1254. https://doi.org/10.3390/membranes12121254

Zhao Y, Duan L, Liu X, Song Y. Forward Osmosis Technology and Its Application on Microbial Fuel Cells: A Review. Membranes. 2022; 12(12):1254. https://doi.org/10.3390/membranes12121254

Chicago/Turabian StyleZhao, Yang, Liang Duan, Xiang Liu, and Yonghui Song. 2022. "Forward Osmosis Technology and Its Application on Microbial Fuel Cells: A Review" Membranes 12, no. 12: 1254. https://doi.org/10.3390/membranes12121254

APA StyleZhao, Y., Duan, L., Liu, X., & Song, Y. (2022). Forward Osmosis Technology and Its Application on Microbial Fuel Cells: A Review. Membranes, 12(12), 1254. https://doi.org/10.3390/membranes12121254