Hybrid Thin-Film Materials Combinations for Complementary Integration Circuit Implementation

Abstract

:1. Introduction

2. Materials for Hybrid Inverters

2.1. Two-Dimensional Transition Metal Dichalcogenides Materials

2.2. Metal Oxide Semiconductors

2.3. Organic Semiconductors

2.4. Metal-Halide Perovskite

2.5. Carbon Nanotubes

3. Applications

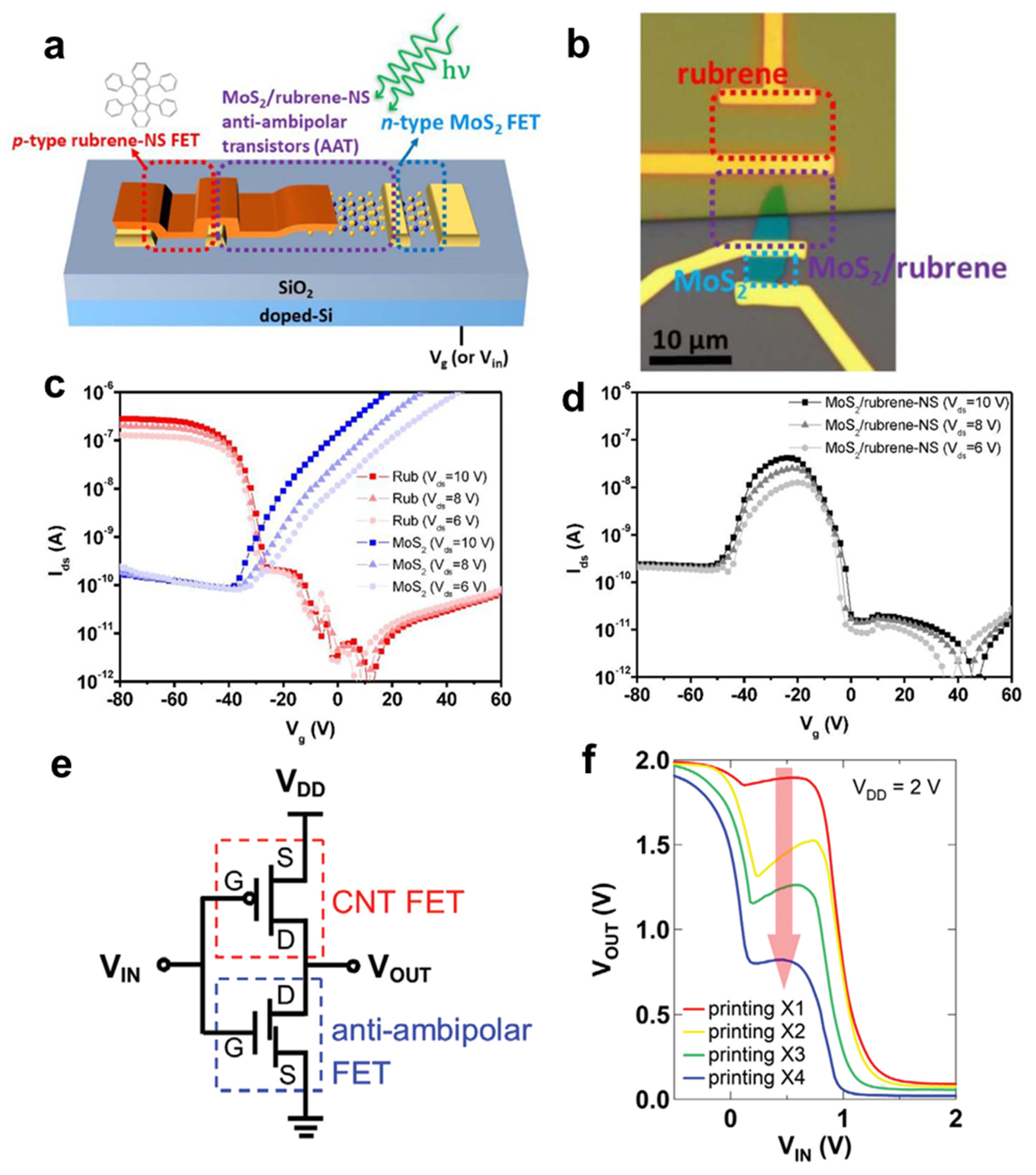

3.1. Multivalued Logics

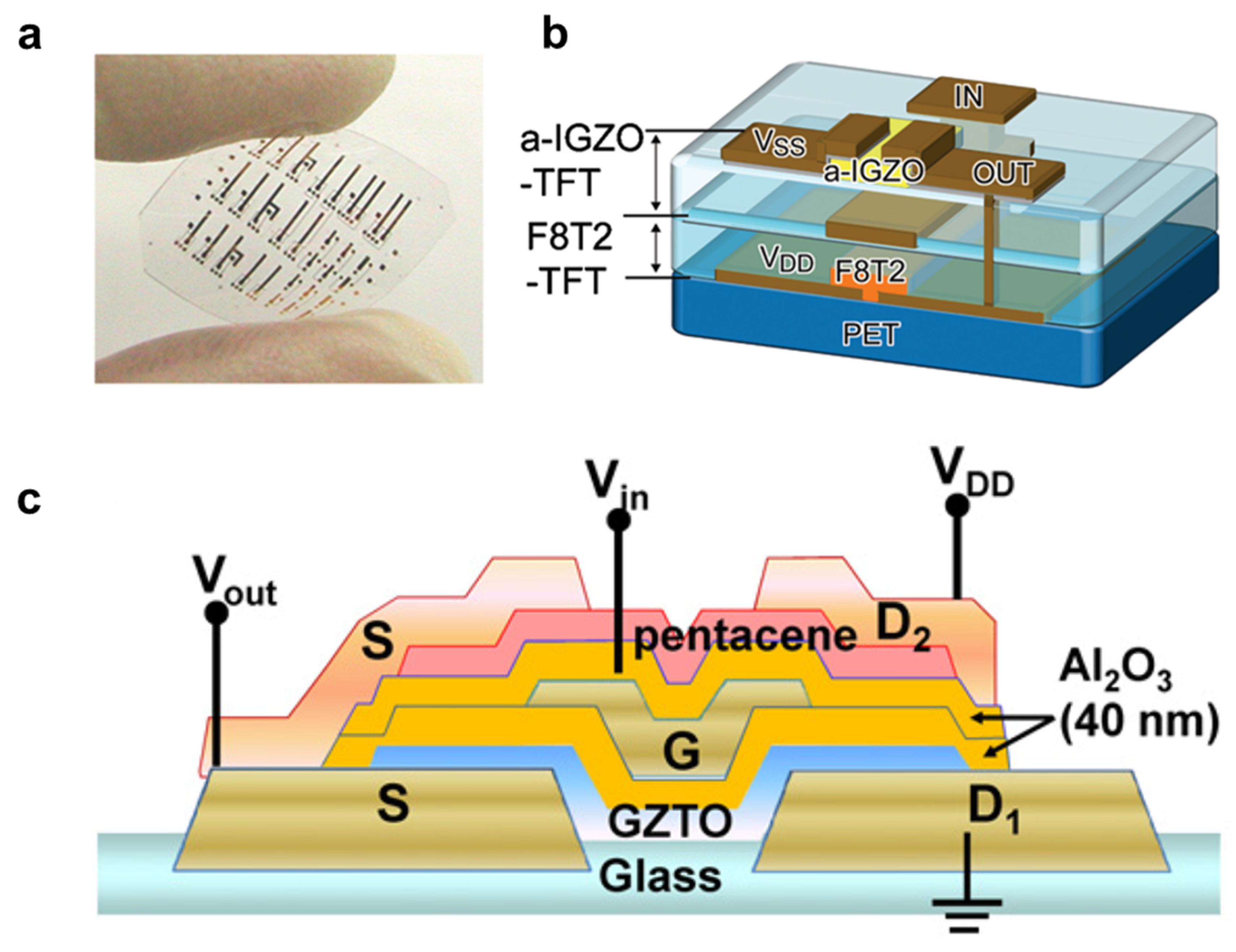

3.2. Vertically Stacked Complementary Inverter

4. Conclusions and Outlook

- (1)

- Two-dimensional materials possess a layered structure based on van der Waals force, which assigns excellent electrical performance, high material stability in the surrounding environment, and great mechanical properties. However, their unique structure is mainly implemented with specific synthesis conditions, confining the compatibility with certain kinds of substrate.

- (2)

- Metal oxide semiconductors are highly promising because of their mild synthesis condition, ease of fabrication for large-scale applications, and great electrical performance. However, most metal oxide semiconductors are an n-type material, and even p-type metal oxide semiconductors show poor charge mobility and a high annealing temperature.

- (3)

- Most organic semiconductors exhibit p-type characteristics, unlike 2D materials and oxide semiconductors, which are very important to fabricate CMOS inverters. Moreover, their simple synthesis process allows them to be fabricated on flexible devices. However, vulnerability to temperature and instability in the surrounding environment still remain a challenge to overcome.

- (4)

- Strong absorption coefficients and tunable optical bandgaps of MHPs contribute to optoelectrical applications. Specifically, MHP is a good p-type semiconductor, which is highly compatible to fabricate hybrid inverter with an n-type inorganic semiconductor. Nevertheless, the practicality of perovskites for CMOS inverters still needs further improvement for good electrical quality and mass production.

- (5)

- CNT have attracted attention for their printable synthesis method and p-type semiconductor characteristics. However, using CNT is still limited because of their inadequate air stability and limited tunability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nomura, K. Recent progress of oxide-TFT-based inverter technology. J. Inf. Disp. 2021, 23, 211–229. [Google Scholar] [CrossRef]

- Meindl, J.D.; Chen, Q.; Davis, J.A. Limits on silicon nanoelectronics for terascale integration. Science 2001, 293, 2044–2049. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 2003, 300, 1269–1272. [Google Scholar] [CrossRef]

- Fuchigami, H.; Tsumura, A.; Koezuka, H. Polythienylenevinylene thin-film-transistor with high carrier mobility. Appl. Phys. Lett. 1993, 63, 1372–1374. [Google Scholar] [CrossRef]

- Klauk, H.; Gundlach, D.J.; Jackson, T.N. Fast organic thin-film transistor circuits. IEEE Electron Device Lett. 1999, 20, 289–291. [Google Scholar] [CrossRef]

- Zhu, W.N.; Park, S.; Yogeesh, M.N.; McNicholas, K.M.; Bank, S.R.; Akinwande, D. Black phosphorus flexible thin film transistors at gighertz frequencies. Nano Lett. 2016, 16, 2301–2306. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, G.Z.; Wan, J.X.; Guo, T.; Li, L.; Yang, Y.P.; Wu, H.; Liu, C. Transparent and flexible thin-film transistors with high performance prepared at ultralow temperatures by atomic layer deposition. Adv. Electron. Mater. 2019, 5, 1800583. [Google Scholar] [CrossRef]

- Yu, M.; Wan, H.C.; Cai, L.; Miao, J.S.; Zhang, S.M.; Wang, C. Fully printed flexible dual-gate carbon nanotube thin-film transistors with tunable ambipolar characteristics for complementary logic circuits. ACS Nano 2018, 12, 11572–11578. [Google Scholar] [CrossRef]

- Kraft, U.; Zaki, T.; Letzkus, F.; Burghartz, J.N.; Weber, E.; Murmann, B.; Klauk, H. Low-voltage, high-frequency organic transistors and unipolar and complementary ring oscillators on paper. Adv. Electron. Mater. 2019, 5, 1800453. [Google Scholar] [CrossRef]

- Kim, K.-T.; Kang, S.-H.; Nam, S.-J.; Park, C.-Y.; Jo, J.-W.; Heo, J.-S.; Park, S.-K. Skin-compatible amorphous oxide thin-film-transistors with a stress-released elastic architecture. Appl. Sci. 2021, 11, 5501. [Google Scholar] [CrossRef]

- Hong, S.Y.; Lee, Y.H.; Park, H.; Jin, S.W.; Jeong, Y.R.; Yun, J.; You, I.; Zi, G.; Ha, J.S. Stretchable active matrix temperature sensor array of polyaniline nanofibers for electronic skin. Adv. Mater. 2016, 28, 930–935. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.S.; Lee, K.W.; Lee, J.H.; Shin, S.B.; Jo, J.W.; Kim, Y.H.; Kim, M.G.; Park, S.K. Highly-sensitive textile pressure sensors enabled by suspended-type all carbon nanotube fiber transistor architecture. Micromachines 2020, 11, 1103. [Google Scholar] [CrossRef]

- Choi, S.; Jo, W.; Jeon, Y.; Kwon, S.; Kwon, J.H.; Son, Y.H.; Kim, J.; Park, J.H.; Kim, H.; Lee, H.S.; et al. Multi-directionally wrinkle-able textile OLEDs for clothing-type displays. npj Flex. Electron. 2020, 4, 33. [Google Scholar] [CrossRef]

- Yang, A.N.; Li, Y.Z.; Yang, C.X.; Fu, Y.; Wang, N.X.; Li, L.; Yan, F. Fabric organic electrochemical transistors for biosensors. Adv. Mater. 2018, 30, 1800051. [Google Scholar] [CrossRef]

- Choi, M.; Park, Y.J.; Sharma, B.K.; Bae, S.-R.; Kim, S.Y.; Ahn, J.-H. Flexible active-matrix organic light-emitting diode display enabled by MoS2 thin-film transistor. Sci. Adv. 2018, 4, eaas8721. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Heo, S.; Park, K.; Song, M.H.; Kim, J.-Y.; Kyung, G.; Ruoff, R.S.; Park, J.-U.; Bien, F. Research on flexible display at Ulsan National Institute of Science and Technology. npj Flex. Electron. 2017, 1, 9. [Google Scholar] [CrossRef] [Green Version]

- Han, S.Y.; Jeon, K.S.; Cho, B.; Seo, M.S.; Song, J.; Kong, H. Characteristics of a-SiGe:H thin film transistor infrared photosensor for touch sensing displays. IEEE J. Quantum Electron. 2012, 48, 952–959. [Google Scholar] [CrossRef]

- Yun, M.G.; Kim, Y.K.; Ahn, C.H.; Cho, S.W.; Kang, W.J.; Cho, H.K.; Kim, Y.-H. Low voltage-driven oxide phototransistors with fast recovery, high signal-to-noise ratio, and high responsivity fabricated via a simple defect-generating process. Sci. Rep. 2016, 6, 31991. [Google Scholar] [CrossRef]

- Zhuang, X.; Huang, W.; Han, S.; Jiang, Y.; Zheng, H.; Yu, J. Interfacial modifying layer-driven high-performance organic thin-film transistors and their nitrogen dioxide gas sensors. Org. Electron. 2017, 49, 334–339. [Google Scholar] [CrossRef]

- Wang, B.; Thukral, A.; Xie, Z.; Liu, L.; Zhang, X.; Huang, W.; Yu, X.; Yu, C.; Marks, T.J.; Facchetti, A. Flexible and stretchable metal oxide nanofiber networks for multimodal and monolithically integrated wearable electronics. Nat. Commun. 2020, 11, 2405. [Google Scholar] [CrossRef]

- Yang, T.-H.; Chen, T.-Y.; Wu, N.-T.; Chen, Y.-T.; Huang, J.-J. IGZO-TFT biosensors for Epstein–Barr virus protein detection. IEEE Trans. Electron. Devices 2017, 64, 1294–1299. [Google Scholar] [CrossRef]

- Yang, P.; Cai, G.; Wang, X.; Pei, Y. Electrolyte-gated indium oxide thin film transistor based biosensor with low operation voltage. IEEE Trans. Electron. Devices 2019, 66, 3554–3559. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Harada, S.; Yamamoto, D.; Honda, W.; Arie, T.; Akita, S.; Takei, K. Printed multifunctional flexible device with an integrated motion sensor for health care monitoring. Sci. Adv. 2016, 2, e1601473. [Google Scholar] [CrossRef] [Green Version]

- Rao, Z.; Ershad, F.; Almasri, A.; Gonzalez, L.; Wu, X.; Yu, C. Soft electronics for the skin: From health monitors to human–machine interfaces. Adv. Mater. Technol. 2020, 5, 2000233. [Google Scholar] [CrossRef]

- Yoo, H.; On, S.; Lee, S.B.; Cho, K.W.; Kim, J.J. Negative transconductance heterojunction organic transistors and their application to full-swing ternary circuits. Adv. Mater. 2019, 31, 1808265. [Google Scholar] [CrossRef]

- On, S.; Kim, Y.-J.; Lee, H.-K.; Yoo, H. Ambipolar and anti-ambipolar thin-film transistors from edge-on small-molecule heterostructures. Appl. Surf. Sci. 2021, 542, 148616. [Google Scholar] [CrossRef]

- Kim, S.; Hong, S.; Yoo, H. Location-dependent multi-parameter detection behaviors using hetero-interfaced organic anti-ambipolar phototransistors. Sen. Actuator A Phys. 2021, 330, 112888. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, J.Y.; Yin, W.L.; Huang, F.M.; Cui, A.Y.; Zhang, D.X.; Li, W.W.; Hu, Z.G.; Chu, J.H. Annealing time modulated the film microstructures and electrical properties of P-type CuO field effect transistors. Appl. Surf. Sci. 2019, 481, 632–636. [Google Scholar] [CrossRef]

- Lee, S.; Lee, W.; Jang, B.; Kim, T.; Bae, J.; Cho, K.; Kim, S.; Jang, J. Sol-gel processed p-type CuO phototransistor for a near-infrared sensor. IEEE Electron Device Lett. 2018, 39, 47–50. [Google Scholar] [CrossRef]

- Bae, J.H.; Lee, J.H.; Park, S.P.; Jung, T.S.; Kim, H.J.; Kim, D.; Lee, S.W.; Park, K.S.; Yoon, S.; Kang, I.; et al. Gallium doping effects for improving switching performance of p-type copper(I) oxide thin-film transistors. ACS Appl. Mater. Inter. 2020, 12, 38350–38356. [Google Scholar] [CrossRef]

- Cardenas, J.A.; Catenacci, M.J.; Andrews, J.B.; Williams, N.X.; Wiley, B.J.; Franklin, A.D. In-place printing of carbon nanotube transistors at low temperature. ACS Appl. Nano Mater. 2018, 1, 1863–1869. [Google Scholar] [CrossRef]

- Liang, Y.Q.; Xiao, M.M.; Wu, D.; Lin, Y.X.; Liu, L.J.; He, J.P.; Zhang, G.J.; Peng, L.M.; Zhang, Z.Y. Wafer-scale uniform carbon nanotube transistors for ultrasensitive and label-free detection of disease biomarkers. ACS Nano 2020, 14, 8866–8874. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Jang, S.; Prabhumirashi, P.L.; Geier, M.L.; Hersam, M.C.; Dodabalapur, A. Low voltage, high performance inkjet printed carbon nanotube transistors with solution processed ZrO2 gate insulator. Appl. Phys. Lett. 2013, 103, 082119. [Google Scholar] [CrossRef]

- Kim, B.; Geier, M.L.; Hersam, M.C.; Dodabalapur, A. Inkjet printed circuits based on ambipolar and p-type carbon nanotube thin-film transistors. Sci. Rep. 2017, 7, 39627. [Google Scholar] [CrossRef]

- Lin, Y.H.; Pattanasattayavong, P.; Anthopoulos, T.D. Metal-halide perovskite transistors for printed electronics: Challenges and opportunities. Adv. Mater. 2017, 29, 1702838. [Google Scholar] [CrossRef]

- Zhu, H.H.; Liu, A.; Noh, Y.Y. Perovskite transistors clean up their act. Nat. Electron. 2020, 3, 662–663. [Google Scholar] [CrossRef]

- Yu, W.L.; Li, F.; Yu, L.Y.; Niazi, M.R.; Zou, Y.T.; Corzo, D.; Basu, A.; Ma, C.; Dey, S.; Tietze, M.L.; et al. Single crystal hybrid perovskite field-effect transistors. Nat. Commun. 2018, 9, 5354. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, J.Y.; Ge, C.; Riahi, H.; Guo, E.J.; He, M.; Wang, C.; Yang, G.Z.; Jin, K.J. Dual-gated MoS2 transistors for synaptic and programmable logic functions. Adv. Electron. Mater. 2020, 6, 1901408. [Google Scholar] [CrossRef]

- Lee, D.H.; Yun, H.J.; Hong, S.; Yoo, H. Ambipolar conduction and multicolor photosensing behaviors from poly(9,9-di-n-octylfluorenyl-2,7-diyl)-molybdenum disulfide heterointerfaces. Surf. Interfaces 2021, 27, 101448. [Google Scholar] [CrossRef]

- Hong, S.; Choi, S.H.; Park, J.; Yoo, H.; Oh, J.Y.; Hwang, E.; Yoon, D.H.; Kim, S. Sensory adaptation and neuromorphic phototransistors based on CsPb(Br1–xIx)3 perovskite and MoS2 hybrid structure. ACS Nano 2020, 14, 9796–9806. [Google Scholar] [CrossRef]

- Seo, J.; Yoo, H. Remote doping effects of indium–gallium–zinc oxide thin-film transistors by silane-based self-assembled monolayers. Micromachines 2021, 12, 481. [Google Scholar] [CrossRef]

- Stallings, K.; Smith, J.; Chen, Y.; Zeng, L.; Wang, B.; Di Carlo, G.; Bedzyk, M.J.; Facchetti, A.; Marks, T.J. Self-assembled nanodielectrics for solution-processed top-gate amorphous IGZO thin-film transistors. ACS Appl. Mater. Inter. 2021, 13, 15399–15408. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.-L.; Young, S.-J.; Ji, L.-W.; Yan, S.-P. Fabrication and characterization of a-IGZO thin-film transistors with and without passivation layers. ECS J. Solid State Sci. Technol. 2021, 10, 027002. [Google Scholar] [CrossRef]

- Park, H.; Yoo, H.; Lee, C.; Kim, J.J.; Im, S.G. Multi-stage organic logic circuits using via-hole-less metal interconnects. IEEE Electron Device Lett. 2020, 41, 1685–1687. [Google Scholar] [CrossRef]

- Liu, M.; Wang, H.; Tong, Y.; Zhao, X.; Tang, Q.; Liu, Y. Ultrathin free-substrate n-type PTCDI-C13 transistors with bilayer polymer dielectrics. IEEE Electron Device Lett. 2018, 39, 1183–1186. [Google Scholar] [CrossRef]

- Jeong, Y.J.; An, T.K.; Yun, D.-J.; Kim, L.H.; Park, S.; Kim, Y.; Nam, S.; Lee, K.H.; Kim, S.H.; Jang, J.; et al. Photo-patternable ZnO thin films based on cross-linked zinc acrylate for organic/inorganic hybrid complementary inverters. ACS Appl. Mater. Interfaces 2016, 8, 5499–5508. [Google Scholar] [CrossRef]

- Jeong, D.Y.; Chang, Y.; Yoon, W.G.; Do, Y.; Jang, J. Low-temperature polysilicon oxide thin-film transistors with coplanar structure using six photomask steps demonstrating high inverter gain of 264 V V−1. Adv. Eng. Mater. 2020, 22, 1901497. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Y.; Wang, J.; Chen, Y.; Wang, L.; Wang, G.; Dong, J.; Jiang, C. MoS2/pentacene hybrid complementary inverter based photodetector with amplified voltage–output. Nanotechnology 2020, 32, 015203. [Google Scholar] [CrossRef]

- Niu, Y.; Gonzalez-Abad, S.; Frisenda, R.; Marauhn, P.; Drüppel, M.; Gant, P.; Schmidt, R.; Taghavi, N.S.; Barcons, D.; Molina-Mendoza, A.J.; et al. Thickness-dependent differential reflectance spectra of monolayer and few-layer MoS2, MoSe2, WS2 and WSe2. Nanomaterials 2018, 8, 725. [Google Scholar] [CrossRef] [Green Version]

- Tosun, M.; Fu, D.; Desai, S.B.; Ko, C.; Seuk Kang, J.; Lien, D.-H.; Najmzadeh, M.; Tongay, S.; Wu, J.; Javey, A. MoS2 heterojunctions by thickness modulation. Sci. Rep. 2015, 5, 10990. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Sharma, A.; Zhu, Y.; Zhang, Y.; Wang, B.; Dong, M.; Nguyen, H.; Wang, Z.; Wen, B.; Cao, Y.; et al. Efficient and layer-dependent exciton pumping across atomically thin organic–inorganic type-I heterostructures. Adv. Mater. 2018, 30, 1803986. [Google Scholar] [CrossRef]

- Ovchinnikov, D.; Allain, A.; Huang, Y.-S.; Dumcenco, D.; Kis, A. Electrical transport properties of single-layer WS2. ACS Nano 2014, 8, 8174–8181. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, C.; Shaw, J.C.; Cheng, R.; Chen, Y.; Huang, X.; Liu, Y.; Weiss, N.O.; Lin, Z.; Huang, Y.; et al. Large area growth and electrical properties of p-type WSe2 atomic layers. Nano Lett. 2015, 15, 709–713. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Jeong, J.; Lee, S.; Jeong, S.; Roh, Y. Analysis of asymmetrical hysteresis phenomena observed in TMD-based field effect transistors. AIP Adv. 2018, 8, 095114. [Google Scholar] [CrossRef] [Green Version]

- George, A.; Neumann, C.; Kaiser, D.; Mupparapu, R.; Lehnert, T.; Hübner, U.; Tang, Z.; Winter, A.; Kaiser, U.; Staude, I.; et al. Controlled growth of transition metal dichalcogenide monolayers using Knudsen-type effusion cells for the precursors. J. Phys. Mater. 2019, 2, 016001. [Google Scholar] [CrossRef]

- Li, H.; Wu, J.; Yin, Z.; Zhang, H. Preparation and applications of mechanically exfoliated single-layer and multilayer MoS2 and WSe2 nanosheets. Acc. Chem. Res. 2014, 47, 1067–1075. [Google Scholar] [CrossRef]

- Li, H.-M.; Lee, D.-Y.; Choi, M.S.; Qu, D.; Liu, X.; Ra, C.-H.; Yoo, W.J. Metal-semiconductor barrier modulation for high photoresponse in transition metal dichalcogenide field effect transistors. Sci. Rep. 2014, 4, 4041. [Google Scholar] [CrossRef] [PubMed]

- George, A.; Fistul, M.V.; Gruenewald, M.; Kaiser, D.; Lehnert, T.; Mupparapu, R.; Neumann, C.; Hübner, U.; Schaal, M.; Masurkar, N.; et al. Giant persistent photoconductivity in monolayer MoS2 field-effect transistors. npj 2D Mater. 2021, 5, 15. [Google Scholar] [CrossRef]

- Daus, A.; Vaziri, S.; Chen, V.; Köroğlu, Ç.; Grady, R.W.; Bailey, C.S.; Lee, H.R.; Schauble, K.; Brenner, K.; Pop, E. High-performance flexible nanoscale transistors based on transition metal dichalcogenides. Nat. Electron. 2021, 4, 495–501. [Google Scholar] [CrossRef]

- Shen, T.; Penumatcha, A.V.; Appenzeller, J. Strain engineering for transition metal dichalcogenides based field effect transistors. ACS Nano 2016, 10, 4712–4718. [Google Scholar] [CrossRef]

- Choi, H.J.; Jung, Y.S.; Lee, S.M.; Kang, S.; Seo, D.; Kim, H.; Choi, H.-J.; Lee, G.-H.; Cho, Y.S. Large-scale self-limiting synthesis of monolayer MoS2 via proximity evaporation from Mo films. Cryst. Growth Des. 2020, 20, 2698–2705. [Google Scholar] [CrossRef]

- Yu, H.; Liao, M.; Zhao, W.; Liu, G.; Zhou, X.J.; Wei, Z.; Xu, X.; Liu, K.; Hu, Z.; Deng, K.; et al. Wafer-scale growth and transfer of highly-oriented monolayer MoS2 continuous films. ACS Nano 2017, 11, 12001–12007. [Google Scholar] [CrossRef]

- Lee, H.S.; Shin, J.M.; Jeon, P.J.; Lee, J.; Kim, J.S.; Hwang, H.C.; Park, E.; Yoon, W.; Ju, S.-Y.; Im, S. Few-layer MoS2—Organic thin-film hybrid complementary inverter pixel fabricated on a glass substrate. Small 2015, 11, 2132–2138. [Google Scholar] [CrossRef] [PubMed]

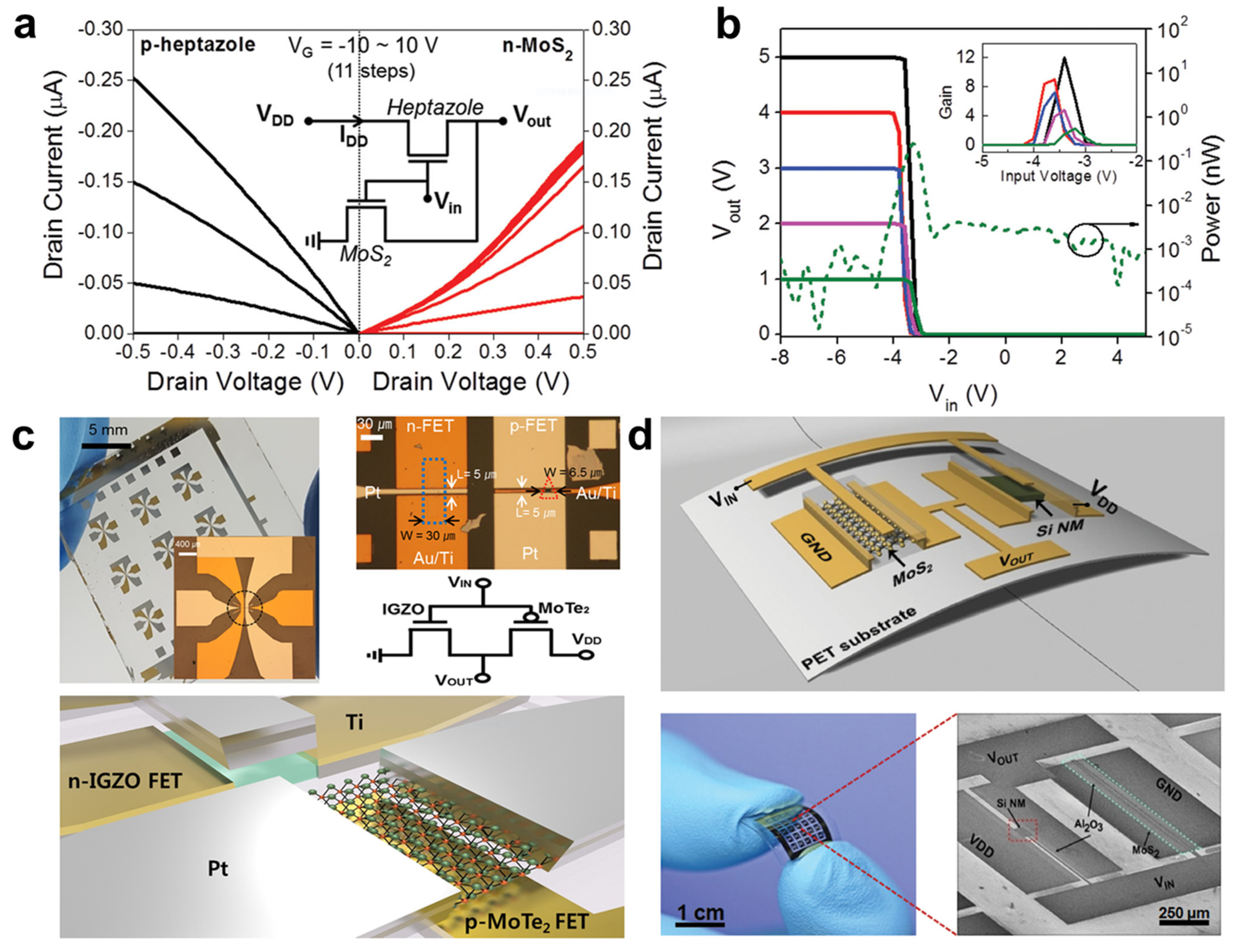

- Lee, H.S.; Choi, K.; Kim, J.S.; Yu, S.; Ko, K.R.; Im, S. Coupling two-dimensional MoTe2 and InGaZnO thin-film materials for hybrid PN junction and CMOS inverters. ACS Appl. Mater. Inter. 2017, 9, 15592–15598. [Google Scholar] [CrossRef] [PubMed]

- Das, T.; Chen, X.; Jang, H.; Oh, I.-K.; Kim, H.; Ahn, J.-H. Highly flexible hybrid CMOS inverter based on Si nanomembrane and molybdenum disulfide. Small 2016, 12, 5720–5727. [Google Scholar] [CrossRef]

- Allain, A.; Kang, J.; Banerjee, K.; Kis, A. Electrical contacts to two-dimensional semiconductors. Nat. Mater. 2015, 14, 1195–1205. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Zhao, S.; Li, F.; Wang, C.; Ge, Y.; Wang, H.; Wang, S.; Zhang, H. Interface engineering of two-dimensional transition metal dichalcogenides towards next-generation electronic devices: Recent advances and challenges. Nanoscale Horiz. 2020, 5, 787–807. [Google Scholar] [CrossRef] [PubMed]

- Velický, M.; Toth, P.S. From two-dimensional materials to their heterostructures: An electrochemist’s perspective. Appl. Mater. Today 2017, 8, 68–103. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Yao, J.; Wu, X.; Zhang, S.; Xing, B.; Niu, X.; Yan, X.; Yu, Y.; Liu, Y.; Wang, Y. P-type doping in large-area monolayer MoS2 by chemical vapor deposition. ACS Appl. Mater. Interfaces 2020, 12, 6276–6282. [Google Scholar] [CrossRef]

- Jin, Y.; Keum, D.H.; An, S.-J.; Kim, J.; Lee, H.S.; Lee, Y.H. A Van Der Waals Homojunction: Ideal p–n diode behavior in MoSe2. Adv. Mater. 2015, 27, 5534–5540. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Xiao, X.; Zhang, K.; Guo, N.; Jia, Y.; Zhou, S.; Wu, Y.; Li, Q.; Xiao, L. Conversion of multi-layered MoTe2 transistor between P-type and N-type and their use in inverter. Nanoscale Res. Lett. 2018, 13, 291. [Google Scholar] [CrossRef] [Green Version]

- Shao, S.; Liang, K.; Li, X.; Zhang, J.; Liu, C.; Cui, Z.; Zhao, J. Large-area (64 × 64 array) inkjet-printed high-performance metal oxide bilayer heterojunction thin film transistors and n-metal-oxide-semiconductor (NMOS) inverters. J. Mater. Sci. Technol. 2021, 81, 26–35. [Google Scholar] [CrossRef]

- Li, J.; Song, E.; Chiang, C.-H.; Yu, K.J.; Koo, J.; Du, H.; Zhong, Y.; Hill, M.; Wang, C.; Zhang, J.; et al. Conductively coupled flexible silicon electronic systems for chronic neural electrophysiology. Proc. Natl. Acad. Sci. USA 2018, 115, E9542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Sim, K.; Rao, Z.; Zou, Z.; Ershad, F.; Lei, J.; Thukral, A.; Chen, J.; Huang, Q.-A.; Xiao, J.; Yu, C. Metal oxide semiconductor nanomembrane–based soft unnoticeable multifunctional electronics for wearable human-machine interfaces. Sci. Adv. 2019, 5, eaav9653. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.-S.; Jeon, J.-Y.; Kang, B.-C.; Lee, W.; Kim, Y.-H.; Ha, T.-J. Wearable 1 V operating thin-film transistors with solution-processed metal-oxide semiconductor and dielectric films fabricated by deep ultra-violet photo annealing at low temperature. Sci. Rep. 2019, 9, 8416. [Google Scholar] [CrossRef]

- Kawazoe, H.; Yasukawa, M.; Hyodo, H.; Kurita, M.; Yanagi, H.; Hosono, H. P-type electrical conduction in transparent thin films of CuAlO2. Nature 1997, 389, 939–942. [Google Scholar] [CrossRef]

- Wang, Z.; Nayak, P.K.; Caraveo-Frescas, J.A.; Alshareef, H.N. Recent developments in p-type oxide semiconductor materials and devices. Adv. Mater. 2016, 28, 3831–3892. [Google Scholar] [CrossRef] [Green Version]

- Hosono, H.; Ueda, K. Transparent conductive oxides. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1391–1404. [Google Scholar]

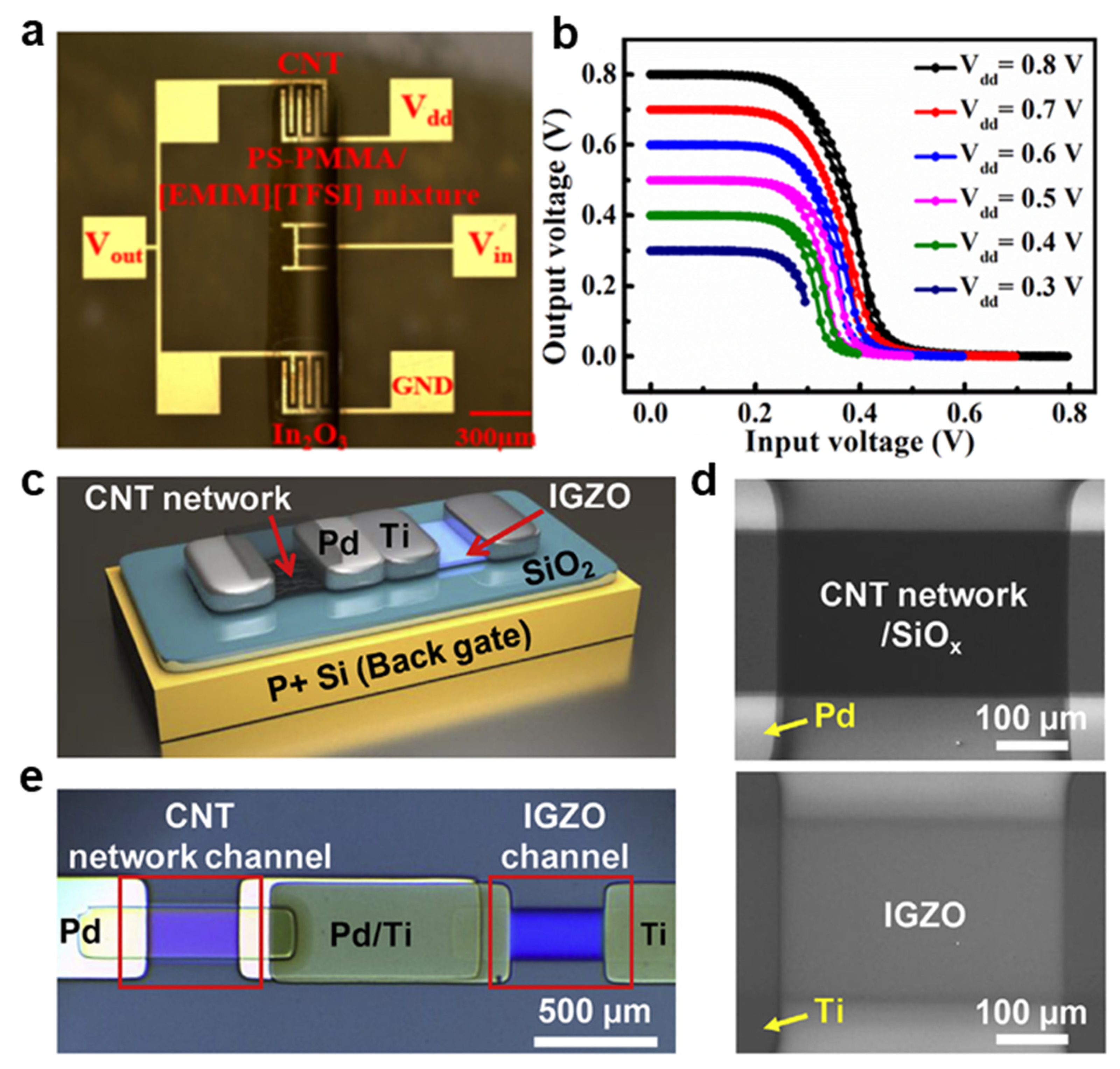

- Luo, M.; Xie, H.; Wei, M.; Liang, K.; Shao, S.; Zhao, J.; Gao, T.; Mo, L.; Chen, Y.; Chen, S.; et al. High-performance partially printed hybrid CMOS inverters based on indium-zinc-oxide and chirality enriched carbon nanotube thin-film transistors. Adv. Electron. Mater. 2019, 5, 1900034. [Google Scholar] [CrossRef]

- Caraveo-Frescas, J.A.; Nayak, P.K.; Al-Jawhari, H.A.; Granato, D.B.; Schwingenschlögl, U.; Alshareef, H.N. Record mobility in transparent p-type tin monoxide films and devices by phase Engineering. ACS Nano 2013, 7, 5160–5167. [Google Scholar] [CrossRef]

- Liu, A.; Zhu, H.; Guo, Z.; Meng, Y.; Liu, G.; Fortunato, E.; Martins, R.; Shan, F. Solution combustion synthesis: Low-temperature processing for p-type Cu:NiO thin films for transparent electronics. Adv. Mater. 2017, 29, 1701599. [Google Scholar] [CrossRef]

- Honda, W.; Harada, S.; Ishida, S.; Arie, T.; Akita, S.; Takei, K. High-performance, mechanically flexible, and vertically integrated 3D carbon nanotube and InGaZnO complementary circuits with a temperature sensor. Adv. Mater. 2015, 27, 4674–4680. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Lee, H.S.; Yu, S.; Park, J.H.; Bae, H.; Im, S. Tungsten dichalcogenide nanoflake/InGaZnO thin-film heterojunction for photodetector, inverter, and AC rectifier circuits. Adv. Electron. Mater. 2020, 6, 2000026. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Z.; Chen, S.-C.; Dai, S.; Huang, J.; Zheng, Q. Binary polymer composite dielectrics for flexible low-voltage organic field-effect transistors. Org. Electron. 2018, 53, 205–212. [Google Scholar] [CrossRef]

- Sekitani, T.; Nakajima, H.; Maeda, H.; Fukushima, T.; Aida, T.; Hata, K.; Someya, T. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 2009, 8, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Kim, Z.-S.; Lim, S.C.; Kim, S.H.; Yang, Y.S.; Hwang, D.-H. Biotin-functionalized semiconducting polymer in an organic field effect transistor and application as a biosensor. Sensors 2012, 12, 11238–11248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Gong, Q.; Miao, Q. Structured and functionalized organic semiconductors for chemical and biological sensors based on organic field effect transistors. Mater. Chem. Front. 2020, 4, 3505–3520. [Google Scholar] [CrossRef]

- Yu, X.; Zhou, N.; Han, S.; Lin, H.; Buchholz, D.B.; Yu, J.; Chang, R.P.H.; Marks, T.J.; Facchetti, A. Flexible spray-coated TIPS-pentacene organic thin-film transistors as ammonia gas sensors. J. Mater. Chem. C 2013, 1, 6532–6535. [Google Scholar] [CrossRef]

- Oh, G.; Kim, J.-S.; Jeon, J.H.; Won, E.; Son, J.W.; Lee, D.H.; Kim, C.K.; Jang, J.; Lee, T.; Park, B.H. Graphene/pentacene barristor with Ion-gel gate dielectric: Flexible ambipolar transistor with high mobility and on/off ratio. ACS Nano 2015, 9, 7515–7522. [Google Scholar] [CrossRef]

- Tan, L.; Guo, Y.; Zhang, G.; Yang, Y.; Zhang, D.; Yu, G.; Xu, W.; Liu, Y. New air-stable solution-processed organic n-type semiconductors based on sulfur-rich core-expanded naphthalene diimides. J. Mater. Chem. 2011, 21, 18042–18048. [Google Scholar] [CrossRef]

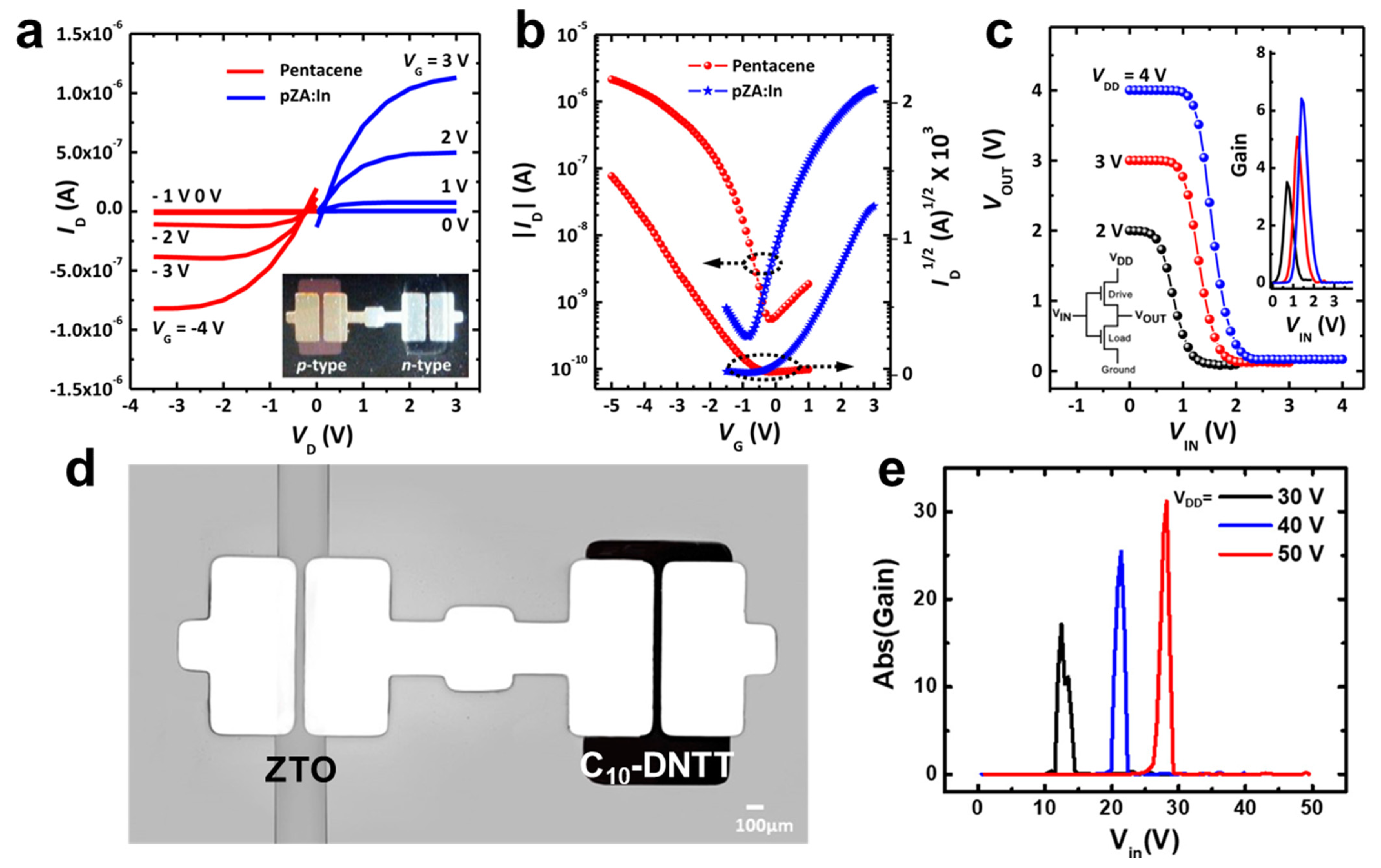

- Ye, H.; Kwon, H.-J.; Tang, X.; Lee, D.Y.; Nam, S.; Kim, S.H. Direct patterned zinc-tin-oxide for solution-processed thin-film transistors and complementary inverter through electrohydrodynamic jet printing. Nanomaterials 2020, 10, 1304. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Liu, B.; Luo, J.; Li, Y.; Zheng, C.; Yao, X.; Fan, L.; Liang, J.; Ding, Y.; Wei, C.; et al. Enhanced light absorption of thin perovskite solar cells using textured substrates. Sol. Energy Mater. Sol. Cells 2017, 168, 214–220. [Google Scholar] [CrossRef]

- Cui, D.; Yang, Z.; Yang, D.; Ren, X.; Liu, Y.; Wei, Q.; Fan, H.; Zeng, J.; Liu, S. Color-tuned perovskite films prepared for efficient solar cell applications. J. Phys. Chem. C 2016, 120, 42–47. [Google Scholar] [CrossRef]

- Hou, X.; Huang, S.; Ou-Yang, W.; Pan, L.; Sun, Z.; Chen, X. Constructing efficient and stable perovskite solar cells via interconnecting perovskite grains. ACS Appl. Mater. Inter. 2017, 9, 35200–35208. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, F.; Xu, B.; Li, Y.; Wang, L.; Zhang, B.; Guo, Y.; Gardner, J.M.; Sun, L.; Kloo, L. Organic salts as p-type dopants for efficient LiTFSI-free perovskite solar cells. ACS Appl. Mater. Inter. 2020, 12, 33751–33758. [Google Scholar] [CrossRef]

- Long, R.; Li, B.; Mi, Q. Selection of contact materials to p-type halide perovskite by electronegativity matching. AIP Adv. 2020, 10, 065224. [Google Scholar] [CrossRef]

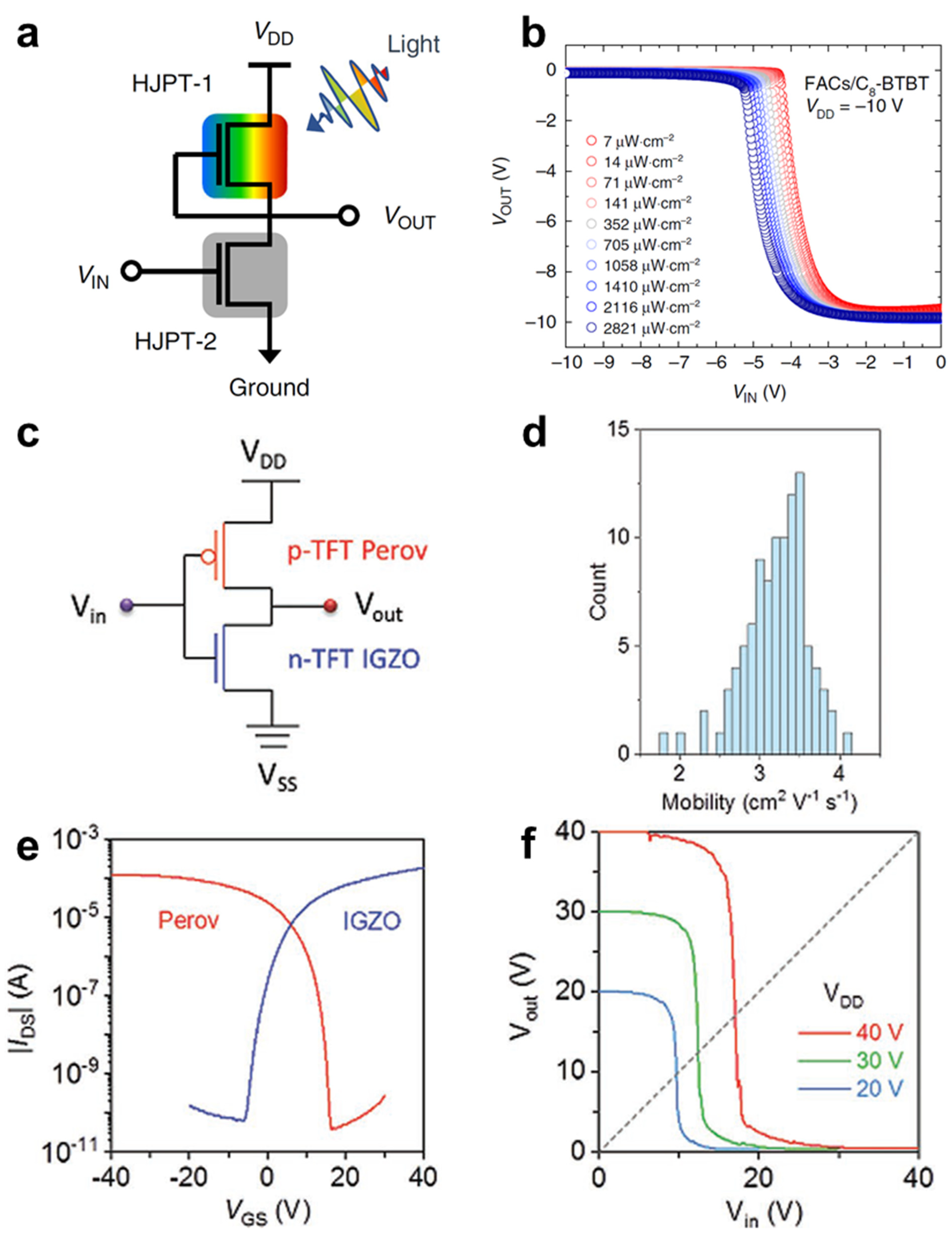

- Lin, Y.-H.; Huang, W.; Pattanasattayavong, P.; Lim, J.; Li, R.; Sakai, N.; Panidi, J.; Hong, M.J.; Ma, C.; Wei, N.; et al. Deciphering photocarrier dynamics for tuneable high-performance perovskite-organic semiconductor heterojunction phototransistors. Nat. Commun. 2019, 10, 4475. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Liu, A.; Shim, K.I.; Hong, J.; Han, J.W.; Noh, Y.-Y. High-performance and reliable lead-free layered-perovskite transistors. Adv. Mater. 2020, 32, 2002717. [Google Scholar] [CrossRef] [PubMed]

- Jana, S.; Carlos, E.; Panigrahi, S.; Martins, R.; Fortunato, E. Toward stable solution-processed high-mobility p-type thin film transistors based on halide perovskites. ACS Nano 2020, 14, 14790–14797. [Google Scholar] [CrossRef]

- Zschieschang, U.; Kang, M.J.; Takimiya, K.; Sekitani, T.; Someya, T.; Canzler, T.W.; Werner, A.; Blochwitz-Nimoth, J.; Klauk, H. Flexible low-voltage organic thin-film transistors and circuits based on C10-DNTT. J. Mater. Chem. 2012, 22, 4273–4277. [Google Scholar] [CrossRef]

- Zschieschang, U.; Ante, F.; Kälblein, D.; Yamamoto, T.; Takimiya, K.; Kuwabara, H.; Ikeda, M.; Sekitani, T.; Someya, T.; Nimoth, J.B.; et al. Dinaphtho[2,3-b:2′,3′-f]thieno[3,2-b]thiophene (DNTT) thin-film transistors with improved performance and stability. Org. Electron. 2011, 12, 1370–1375. [Google Scholar] [CrossRef]

- Acton, O.; Dubey, M.; Weidner, T.; O’Malley, K.M.; Kim, T.-W.; Ting, G.G.; Hutchins, D.; Baio, J.E.; Lovejoy, T.C.; Gage, A.H.; et al. Simultaneous modification of bottom-contact electrode and dielectric surfaces for organic thin-film transistors through single-component spin-cast monolayers. Adv. Funct. Mater. 2011, 21, 1476–1488. [Google Scholar] [CrossRef]

- Huang, J.; Somu, S.; Busnaina, A. A molybdenum disulfide/carbon nanotube heterogeneous complementary inverter. Nanotechnology 2012, 23, 335203. [Google Scholar] [CrossRef]

- Xu, Q.; Zhao, J.; Pecunia, V.; Xu, W.; Zhou, C.; Dou, J.; Gu, W.; Lin, J.; Mo, L.; Zhao, Y.; et al. Selective conversion from p-type to n-type of printed bottom-gate carbon nanotube thin-film transistors and application in complementary metal–oxide–semiconductor inverters. ACS Appl. Mater. Inter. 2017, 9, 12750–12758. [Google Scholar] [CrossRef] [PubMed]

- Wei, M.; Robin, M.; Portilla, L.; Ren, Y.; Shao, S.; Bai, L.; Cao, Y.; Pecunia, V.; Cui, Z.; Zhao, J. Air-stable N-type printed carbon nanotube thin film transistors for CMOS logic circuits. Carbon 2020, 163, 145–153. [Google Scholar] [CrossRef]

- Nakashima, Y.; Yamaguchi, R.; Toshimitsu, F.; Matsumoto, M.; Borah, A.; Staykov, A.; Islam, M.S.; Hayami, S.; Fujigaya, T. Air-stable n-type single-walled carbon nanotubes doped with benzimidazole derivatives for thermoelectric conversion and their air-stable mechanism. ACS Appl. Nano Mater. 2019, 2, 4703–4710. [Google Scholar] [CrossRef]

- Li, G.; Li, Q.; Jin, Y.; Zhao, Y.; Xiao, X.; Jiang, K.; Wang, J.; Fan, S. Fabrication of air-stable n-type carbon nanotube thin-film transistors on flexible substrates using bilayer dielectrics. Nanoscale 2015, 7, 17693–17701. [Google Scholar] [CrossRef]

- Luo, M.; Zhu, M.; Wei, M.; Shao, S.; Robin, M.; Wei, C.; Cui, Z.; Zhao, J.; Zhang, Z. Radiation-hard and repairable complementary metal–oxide–semiconductor circuits integrating n-type indium oxide and p-type carbon nanotube field-effect transistors. ACS Appl. Mater. Inter. 2020, 12, 49963–49970. [Google Scholar] [CrossRef]

- Yoon, J.; Jung, H.; Jang, J.T.; Lee, J.; Lee, Y.; Lim, M.; Kim, D.M.; Kim, D.H.; Choi, S.-J. Hybrid complementary inverter based on carbon nanotube and IGZO thin-film transistors with controlled process conditions. J. Alloys Compd. 2018, 762, 456–462. [Google Scholar] [CrossRef]

- Hassan, Y.; Srivastava, P.K.; Singh, B.; Abbas, M.S.; Ali, F.; Yoo, W.J.; Lee, C. Phase-engineered molybdenum telluride/black phosphorus Van der Waals heterojunctions for tunable multivalued logic. ACS Appl. Mater. Inter. 2020, 12, 14119–14124. [Google Scholar] [CrossRef]

- Panigrahi, D.; Hayakawa, R.; Fuchii, K.; Yamada, Y.; Wakayama, Y. Optically controlled ternary logic circuits based on organic antiambipolar transistors. Adv. Electron. Mater. 2021, 7, 2000940. [Google Scholar] [CrossRef]

- Park, C.-J.; Park, H.J.; Kim, J.Y.; Lee, S.-H.; Lee, Y.; Kim, J.; Joo, J. Photo-responsive MoS2/organic-rubrene heterojunction field-effect-transistor: Application to photo-triggered ternary inverter. Semicond. Sci. Technol. 2020, 35, 065020. [Google Scholar] [CrossRef]

- Kim, B. Inkjet-printed ternary inverter circuits with tunable middle logic voltages. Adv. Electron. Mater. 2020, 6, 2000426. [Google Scholar] [CrossRef]

- Jeong, J.W.; Choi, Y.-E.; Kim, W.-S.; Park, J.-H.; Kim, S.; Shin, S.; Lee, K.; Chang, J.; Kim, S.-J.; Kim, K.R. Tunnelling-based ternary metal–oxide–semiconductor technology. Nat. Electron. 2019, 2, 307–312. [Google Scholar] [CrossRef]

- Kwon, J.; Takeda, Y.; Fukuda, K.; Cho, K.; Tokito, S.; Jung, S. Three-dimensional, inkjet-printed organic transistors and integrated circuits with 100% yield, high uniformity, and long-term stability. ACS Nano 2016, 10, 10324–10330. [Google Scholar] [CrossRef] [PubMed]

- Lyu, R.; Lin, H.; Li, P.; Huang, T. A film-profile-engineered 3-D InGaZnO inverter technology with systematically tunable threshold voltage. IEEE Trans. Electron Devices 2016, 63, 3533–3539. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, H.S.; Lee, K.H.; Kim, D.-H.; Kim, H.-R.; Lee, G.-H.; Kim, J.H.; Im, S. Organic/oxide hybrid complementary thin-film transistor inverter in vertical stack for logic, photo-gating, and ferroelectric memory operation. Org. Electron. 2011, 12, 1533–1538. [Google Scholar] [CrossRef]

- Rashid, R.B.; Du, W.; Griggs, S.; Maria, I.P.; McCulloch, I.; Rivnay, J. Ambipolar inverters based on cofacial vertical organic electrochemical transistor pairs for biosignal amplification. Sci. Adv. 2021, 7, eabh1055. [Google Scholar] [CrossRef]

- Yoo, H.; Park, H.; Yoo, S.; On, S.; Seong, H.; Im, S.G.; Kim, J.-J. Highly stacked 3D organic integrated circuits with via-hole-less multilevel metal interconnects. Nat. Commun. 2019, 10, 2424. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Xiao, X.; Li, G.; Jin, Y.; Jiang, K.; Wang, J.; Fan, S. Three-dimensional flexible complementary metal–oxide–semiconductor logic circuits based on two-layer stacks of single-walled carbon nanotube networks. ACS Nano 2016, 10, 2193–2202. [Google Scholar] [CrossRef]

- Nomura, K.; Aoki, T.; Nakamura, K.; Kamiya, T.; Nakanishi, T.; Hasegawa, T.; Kimura, M.; Kawase, T.; Hirano, M.; Hosono, H. Three-dimensionally stacked flexible integrated circuit: Amorphous oxide/polymer hybrid complementary inverter using n-type a-In–Ga–Zn–O and p-type poly-(9,9-dioctylfluorene-co-bithiophene) thin-film transistors. Appl. Phys. Lett. 2010, 96, 263509. [Google Scholar] [CrossRef]

- Patcharaprakiti, N.; Premrudeepreechacharn, S. Maximum power point tracking using adaptive fuzzy logic control for grid-connected photovoltaic system. In Proceedings of the 2002 IEEE Power Engineering Society Winter Meeting. Conference Proceedings (Cat. No.02CH37309), Columbus, OH, USA, 27–31 January 2002; Volume 371, pp. 372–377. [Google Scholar]

- Lee, J.; Lee, J.; Lee, J.H.; Lee, W.H.; Uhm, M.; Park, B.; Kim, D.M.; Jeong, Y.; Kim, D.H. Complementary silicon nanowire hydrogen Ion sensor with high sensitivity and voltage output. IEEE Electron Device Lett. 2012, 33, 1768–1770. [Google Scholar] [CrossRef]

- Cho, C.H.; Choe, Y.-S.; Oh, J.Y.; Lee, T. Il self-assembled 2D networks of metal oxide nanomaterials enabling sub-ppm level breathalyzers. ACS Sens. 2021, 6, 3195–3203. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Seo, S.G.; Kim, S.Y.; Jin, S.H. Photosensitive complementary inverters composed of n-channel ReS2 and p-channel single-walled carbon nanotube field-effect transistors. Phys. Status Solidi RRL 2020, 14, 2000420. [Google Scholar] [CrossRef]

- Tsai, J.-H.; Niu, J.-S.; Chen, Y.-C.; Huang, X.-Y. Hydrogen sensing characteristics of AlGaInP/InGaAs complementary Co-integrated pseudomorphic doping-channel field-effect transistors. ECS J. Solid State Sci. Technol. 2018, 7, Q191–Q195. [Google Scholar] [CrossRef]

- Rashid, R.B.; Ji, X.; Rivnay, J. Organic electrochemical transistors in bioelectronic circuits. Biosens. Bioelectron. 2021, 190, 113461. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Bang, J.W.; Seo, S. Organic photovoltaic application for new insights into bio-analytic systems. Sci. Adv. Mater. 2016, 8, 47–51. [Google Scholar] [CrossRef]

- Baek, S.; Kwon, J.; Mano, T.; Tokito, S.; Jung, S. A flexible 3D organic preamplifier for a lactate sensor. Macromol. Biosci. 2020, 20, 2000144. [Google Scholar] [CrossRef]

| Materials | Conduction Type | Mobility (cm2/V·s) | Band Gap (eV) | ||

| Multilayers (>10 Layers) | Monolayer | Multilayers (>10 Layers) | Monolayer | ||

| 2H-MoS2 | n-type | 60–200 | >200 | 1.23 | 1.89 |

| 2H-MoSe2 | n-type | 160–260 | 50 | 1.09 | 1.57 |

| 2H-MoTe2 | p-type | 40 | N/A | 0.93 | 1.08 |

| 2H-WS2 | n-type | 20–100 | 0.2 | 1.35 | 1.98 |

| 2H-WSe2 | p-type | 120–150 | 30–180 | 1.20 | 1.66 |

| 1T’-WTe2 | N/A | 6000–44,000 | 20–21,000 | Semimetal/metal | |

| Materials | αInterlayer Distance (Å) | βvdW Gap (Å) | MX2 Sandwich Thickness (Å) | M-X Bond Length (Å) | γM|M Distance (Å) |

| 2H-MoS2 | 6.15 | 2.98 | 3.17 | 2.42 | 3.16 |

| 2H-MoSe2 | 6.47 | 3.24 | 3.23 | 2.49 | 3.29 |

| 2H-MoTe2 | 7.28 | 3.68 | 3.60 | 2.72 | 3.52 |

| 2H-WS2 | 6.16 | 3.02 | 3.14 | 2.40 | 3.15 |

| 2H-WSe2 | 7.00 | 3.76 | 3.24 | 2.49 | 3.29 |

| 1T’-WTe2 | 7.02 | 3.80–3.90 | 3.50–4.00 | 2.71–2.82 | 2.86 |

| Materials | Conduction Type | On/off Current Ratio | Mobility (cm2/V·s) | Subthreshold Swing (V·dec−1) | Threshold Voltage (V) | Ref. |

|---|---|---|---|---|---|---|

| (PEA)2SnI4 | p-type | 3.4 × 106 | 3.51 | 0.8 | 7.3 | [99] |

| MAPbI3 | p-type | 2.5 × 104 | 23.2 | 0.14 | −0.57 | [100] |

| C10-DNTT | p-type | 108 | 4.3 | 68 | −0.4 | [101] |

| DNTT | p-type | 108 | 2.1 | 100 | −1.4 | [102] |

| Pentacene | p-type | 107 | 0.8 | 75 | −0.6 | [103] |

| n-Type Material | p-Type Material | NMOS Mobility (cm2/V·s) | PMOS Mobility (cm2/V·s) | Voltage Gain (V/V) | Noise Margin | Operation Voltage (V) | Power Consumption (nW) | Ref. |

|---|---|---|---|---|---|---|---|---|

| MoS2 | Heptazole | 6 | 0.14 | 12 | N/A | 5 | 1 | [69] |

| IGZO | MoTe2 | 4.2 | 22.4 | 40 | N/A | 5 | 300 | [70] |

| MoS2 | Si NM | N/A | N/A | 16 | α NMT 80% | 5 | 300 | [71] |

| IZO | SWCNT | 3.01 | 3–5 | 45 | β NMH 77% γ NML 83% | 2 | 400 | [80] |

| IGZO | CNT | 4.93 | 2.19 | 45 | N/A | 5 | 0.69 | [83] |

| IGZO | WSe2 | N/A | N/A | 6.5 | N/A | 3 | N/A | [84] |

| pWA:In-ZnO | Pentacene | 0.853 | 0.718 | 6.5 | N/A | 4 | N/A | [46] |

| ZTO | C10-DNTT | 1.35 | N/A | 31.2 | N/A | 50 | N/A | [92] |

| FACs/C8-BTBT | FACs/C8-BTBT | 0.52 | 0.52 | 15 | N/A | −10 | N/A | [98] |

| IGZO | (PEA)2SnI4 | N/A | 3.16 | 30 | NMT 70% | 40 | N/A | [99] |

| In2O3 | CNT | 2.8 | 8.6 | 11.5 | NMH 82% NML 75% | 0.8 | 9700 | [109] |

| IGZO | CNT | 12.9 | 11.7 | 108.3 | N/A | 20 | N/A | [110] |

| GZTO | Pentacene | 1.2 | 0.4 | 52 | N/A | 8 | N/A | [118] |

| IGZO | F8T2 | 3.2 | 1.7 × 10−3 | 67 | NMH 10.4 V NML 18.3 V | 30 | N/A | [122] |

| Materials | Family | Mobility (cm2/V·s) | Conduction Type | Preparation Method | Band Gap (eV) | Material Thickness (nm) | Ref. |

|---|---|---|---|---|---|---|---|

| pentacene | Organic semiconductor | 0.718 | p-type | Organic molecular beam deposition | N/A | 50 | [46] |

| MoS2 | TMD | 6 | n-type | Exfoilation | 1.8 | 2 | [69] |

| MoTe2 | TMD | 22.4 | p-type | Exfoilation | 0.94 | 4 | [70] |

| IGZO | Metal oxide | 4.2 | n-type | DC magnetron sputtering | 2.7 | 50 | [70] |

| IZO | Metal oxide | 3.01 | n-type | Inkjet printing | >3.0 | 23 | [80] |

| SWCNT | Carbon nanotube | 3–5 | p-type | Inkjet printing | 0.67 | 1.17 | [80] |

| (PEA)2SnI4 | Perovskite | 3.16 | p-type | Spin coating | N/A | N/A | [99] |

| F8T2 | Organic semiconductor | 0.0017 | p-type | Inkjet printing | N/A | 50 | [122] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woo, G.; Yoo, H.; Kim, T. Hybrid Thin-Film Materials Combinations for Complementary Integration Circuit Implementation. Membranes 2021, 11, 931. https://doi.org/10.3390/membranes11120931

Woo G, Yoo H, Kim T. Hybrid Thin-Film Materials Combinations for Complementary Integration Circuit Implementation. Membranes. 2021; 11(12):931. https://doi.org/10.3390/membranes11120931

Chicago/Turabian StyleWoo, Gunhoo, Hocheon Yoo, and Taesung Kim. 2021. "Hybrid Thin-Film Materials Combinations for Complementary Integration Circuit Implementation" Membranes 11, no. 12: 931. https://doi.org/10.3390/membranes11120931

APA StyleWoo, G., Yoo, H., & Kim, T. (2021). Hybrid Thin-Film Materials Combinations for Complementary Integration Circuit Implementation. Membranes, 11(12), 931. https://doi.org/10.3390/membranes11120931