The Pilot Study of the Influence of Free Ammonia on Membrane Fouling during the Partial Nitrosation of Pig Farm Anaerobic Digestion Liquid

Abstract

:1. Introduction

2. Material and Methods

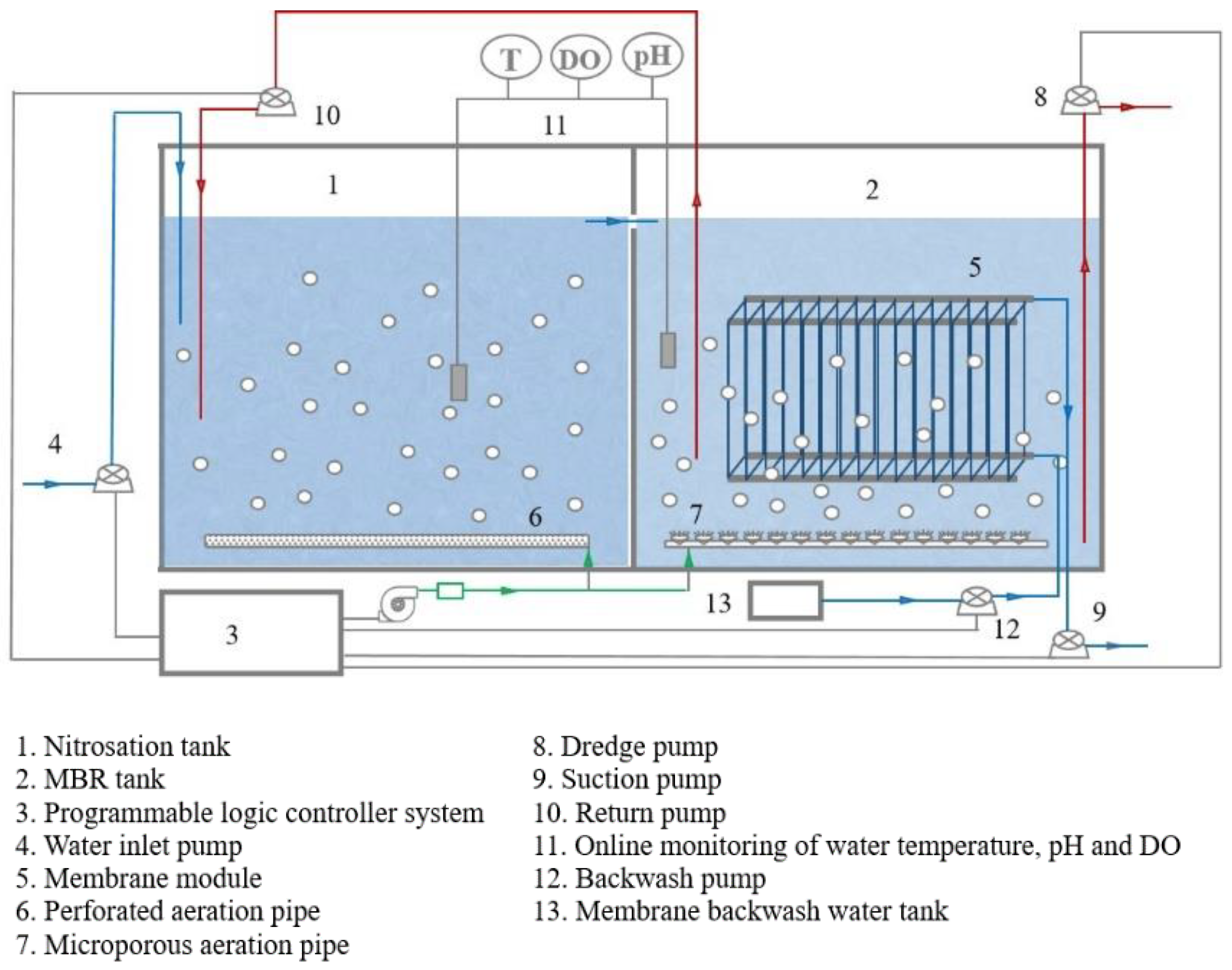

2.1. Equipment of MBR Reactor

2.2. Influent and Inoculum Sludge

2.3. Online Membrane Wash

- (1)

- Cleaning agent (0.5% sodium hypochlorite) was placed in the clean water tank, and cleaning dosage was 2 L/m2 membrane surface area;

- (2)

- Suction pump and filtering were stopped and the valve on the suction pump was closed;

- (3)

- The aeration valve of the aeration blower and the membrane module were closed. After 1 min, the backwash pump was opened to inject the backwash liquid at a flow rate of 200 L/h. After injecting the backwash liquid for 10 min, the backwash pump was turned off. Then, after standing for 30 min, the backwash liquid was injected for another 10 min. After all of the backwash liquid was injected, the backwash pump was turned off. The valve on the pipeline was allowed to stand for 90 min;

- (4)

- The membrane module aeration valve was opened, the aeration blower was turned on and aeration continued for 30 min;

- (5)

- The aeration blower and aeration valve were closed, the valve on the suction pump pipeline was opened, the suction pump was opened and the liquid sodium hypochlorite in the membrane module was pumped out;

- (6)

- If the effect of sodium hypochlorite washing was not obvious (indicated by high TMP), 1% citric acid was used to repeat the above steps to perform backwashing again.

2.4. Free Ammonia Impact Experiment on SCOD

2.5. Sampling and Analytical Methods

3. Results and Discussion

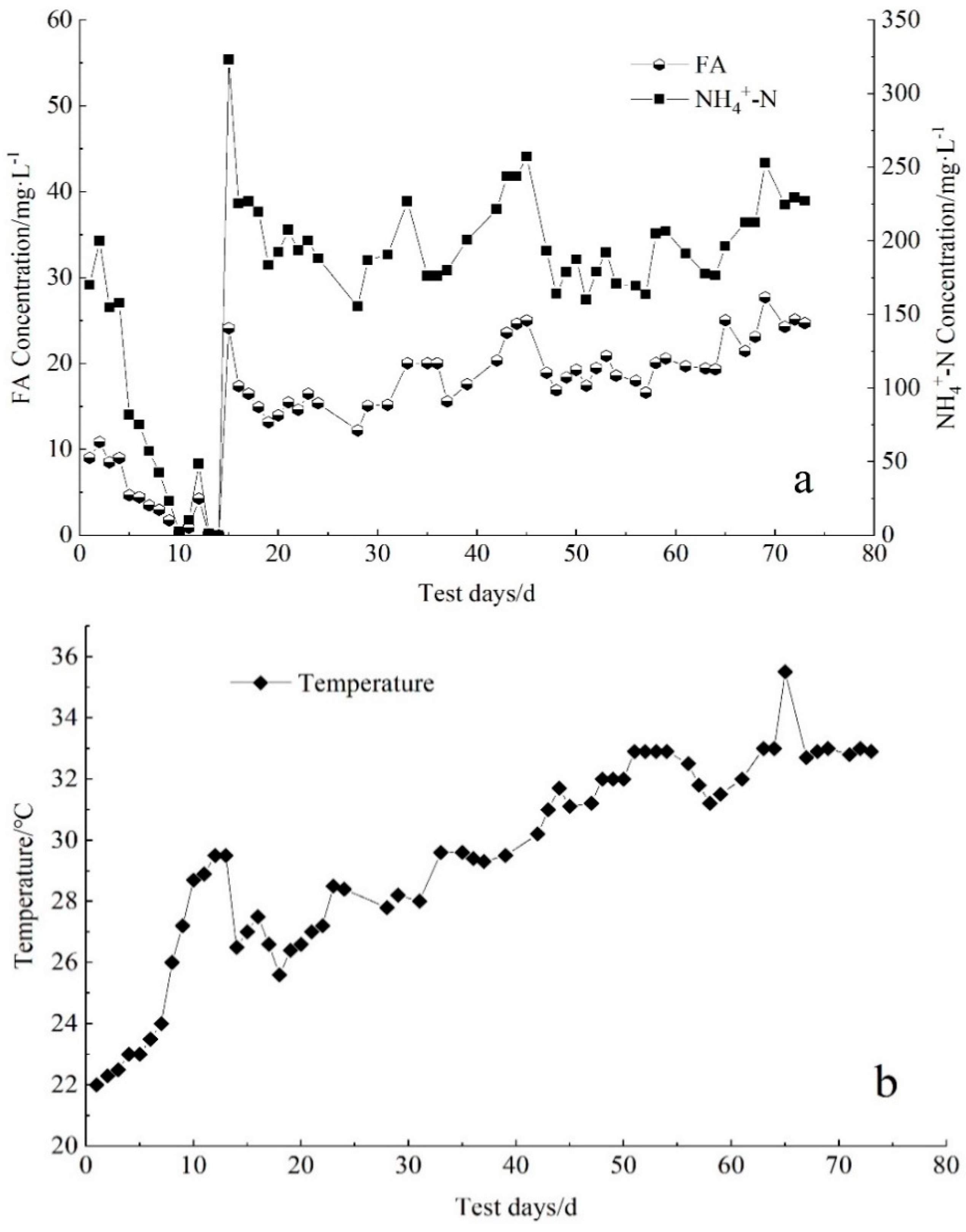

3.1. Reactor Operation Effect and Sludge Characteristics

3.2. Transmembrane Pressure Changes

3.3. Extracellular Polymer (EPS) and Dissolved Microorganism Product (SMP) Changes

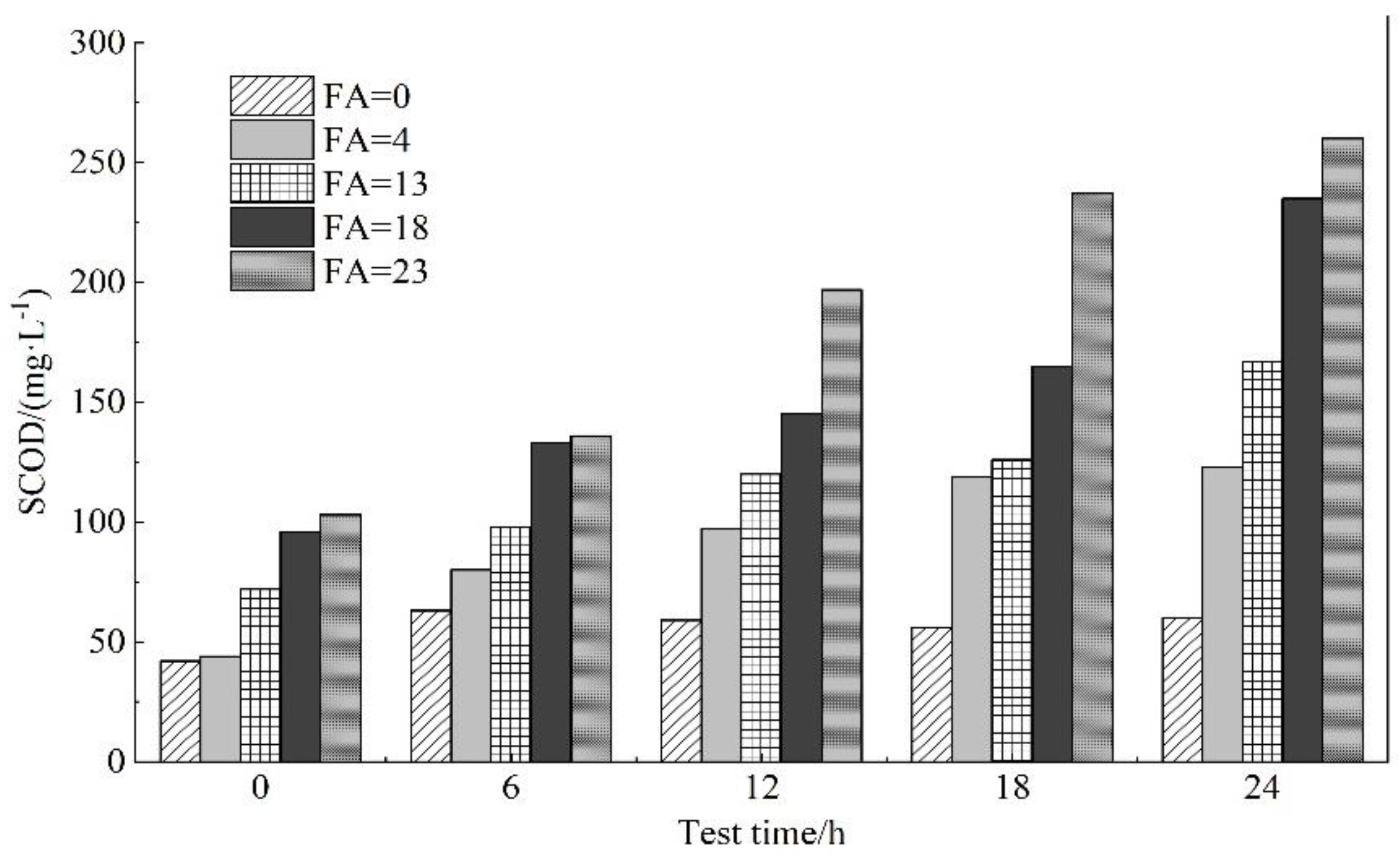

3.4. Changes in SCOD

3.5. The Relationship between FA and EPS, SMP, SCOD, TMP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, G.J.; Chen, C.; Hu, S.; Yuan, Z. Complete Nitrogen Removal from Synthetic Anaerobic Sludge Digestion Liquor through Integrating Anammox and Denitrifying Anaerobic Methane Oxidation in a Membrane Biofilm Reactor. Environ. Sci. Technol. 2017, 51, 819–827. [Google Scholar] [CrossRef] [PubMed]

- Lotti, T.; Cordola, M.; Kleerebezem, R.; Caffaz, S.; Lubello, C.; van Loosdrecht, M. Inhibition effect of swine wastewater heavy metals and antibiotics on anammox activity. Water Sci. Technol. 2012, 66, 1519–1526. [Google Scholar] [CrossRef]

- Zhu, W.; Jin, L.; Dong, H.; Wang, D.; Zhang, P. Effect of influent substrate ratio on anammox granular sludge: Performance and kinetics. Biodegradation 2017, 28, 437–452. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Peng, Y.; Miao, L.; Cao, T.; Zhang, F.; Wang, S.; Han, J. Continuous-flow combined process of nitritation and ANAMMOX for treatment of landfill leachate. Bioresour. Technol. 2016, 214, 514–519. [Google Scholar] [CrossRef] [PubMed]

- Cui, B.; Yang, Q.; Liu, X.; Huang, S.; Yang, Y.; Liu, Z. The effect of dissolved oxygen concentration on long-term stability of partial nitrification process. J. Environ. Sci. 2020, 90, 346–354. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Kim, M.G.; Nakhla, G.; Andalib, M.; Fang, Y. Partial nitrification-reactor configurations, and operational conditions: Performance analysis. J. Environ. Chem. Eng. 2020, 8, 103984. [Google Scholar] [CrossRef]

- Gonzalez-Martinez, A.; Osorio, F.; Rodriguez-Sanchez, A.; Martinez-Toledo, M.V.; Gonzalez-Lopez, J.; Lotti, T.; van Loosdrecht, M. Bacterial community structure of a lab-scale anammox membrane bioreactor. Biotechnol. Prog. 2015, 31, 186–193. [Google Scholar] [CrossRef]

- Huang, X.W.; Urata, K.; Wei, Q.Y.; Yamashita, Y.; Hama, T.; Kawagoshi, Y. Fast start-up of partial nitritation as pre-treatment for anammox in membrane bioreactor. Biochem. Eng. J. 2016, 105, 371–378. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, H.M.; Yang, F.L.; Liu, S.; Fu, Z.; Chen, H. Start-up of the Anammox process from the conventional activated sludge in a membrane bioreactor. Bioresour. Technol. 2009, 100, 2501. [Google Scholar] [CrossRef]

- Yao, Y.A.; Zhen, Z.; Jie, J.A.; Wang, K.; Yu, S.; Qiang, J.; Ming, Q.; An, Y.; Ye, J.; Wu, D. Partial nitrification performance and microbial community evolution in the membrane bioreactor for saline stream treatment. Bioresour. Technol. 2020, 320, 124419. [Google Scholar]

- Yu, T.; Gao, D.W.; Yuan, F.; Wu, W.-M.; Ren, N.-Q. Impact of reactor configuration on anammox process start-up: MBR versus SBR. Bioresour. Technol. 2012, 104, 73–80. [Google Scholar]

- Shen, L.; Yao, Y.; Meng, F. Reactor performance and microbial ecology of a nitritation membrane bioreactor. J. Membr. Sci. 2014, 462, 139–146. [Google Scholar] [CrossRef]

- Quan, F.; Yu, A.; Chu, L.; Xing, X.-H. Performance study of the reduction of excess sludge and simultaneous removal of organic carbon and nitrogen by a combination of fluidized- and fixed-bed bioreactors with different structured macroporous carriers. Biochem. Eng. J. 2008, 39, 344–352. [Google Scholar]

- Rozzi, A.; Malpei, F.; Bianchi, R.; Mattioli, D. Pilot-scale membrane bioreactor and reverse osmosis studies for direct reuse of secondary textile effluents. Water Sci. Technol. 2000, 41, 189–195. [Google Scholar] [CrossRef]

- Dereli, R.K.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Jeison, D.; van der Zee, F.; van Lier, J.B. Potentials of anaerobic membrane bioreactors to overcome treatment limitations induced by industrial wastewaters. Bioresour. Technol. 2012, 122, 160–170. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Zhao, D.; Yan, L.; Ji, Y.; Chen, B.J.; Gao, P.; Zhang, H.; Li, S.M. Rapid Start-up of Anammox in a Membrane Bioreactor and Characteristics of Membrane Fouling Behaviors. China Water Wastewater 2019, 35, 7–13. [Google Scholar]

- Le-Clech, P.; Chen, V.; Fane, T. Fouling in membrane bioreactors used in wastewater treatment. J. Membr. Sci. 2006, 284, 17–53. [Google Scholar] [CrossRef]

- Zhu, T.; Xie, Y.H.; Jiang, J.; Wang, Y.T.; Zhang, H.J.; Nozaki, T. Comparative study of polyvinylidene fluoride and PES flat membranes in submerged MBRs to treat domestic wastewater. Water Sci. Technol. 2009, 59, 399. [Google Scholar] [CrossRef]

- Gabarró, J.; Ganigué, R.; Gich, F.; Ruscalleda, M.; Balaguer, M.D.; Colprim, J. Effect of temperature on AOB activity of a partial nitritation SBR treating landfill leachate with extremely high nitrogen concentration. Bioresour. Technol. 2012, 126, 283–289. [Google Scholar] [CrossRef]

- Zhang, C.; Qin, Y.; Xu, Q.; Liu, X.; Liu, Y.; Ni, B.-J.; Yang, Q.; Wang, D.; Li, X.; Wang, Q. Free Ammonia-Based Pretreatment Promotes Short-Chain Fatty Acid Production from Waste Activated Sludge. ACS Sustain. Chem. Eng. 2018, 6, 9120–9129. [Google Scholar] [CrossRef]

- Ni, B.J.; Rittmann, B.E.; Yu, H.Q. Soluble microbial products and their implications in mixed culture biotechnology. Trends Biotechnol. 2011, 29, 454–463. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wu, Z.; Tang, S. Extracellular polymeric substances (EPS) properties and their effects on membrane fouling in a submerged membrane bioreactor. Water Res. 2009, 43, 2504–2512. [Google Scholar] [CrossRef]

- Li, Z.P.; Tian, Y.; Ding, Y.; Chen, L.; Wang, H. Fouling potential evaluation of soluble microbial products (SMP) with different membrane surfaces in a hybrid membrane bioreactor using worm reactor for sludge reduction. Bioresour. Technol. 2013, 140, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Tsep Administration. The Water and Wastewater Monitoring Analysis Method Editorial Board. Water and Wastewater Monitoring Analysis Method; Environmental Science Press: Beijing, China, 2002. [Google Scholar]

- Zheng, Z.M.; Li, J.; Ma, J.; Du, J.; Wang, F.; Bian, W.; Zhang, Y.; Zhao, B. Inhibition factors and Kinetic model for ammonium inhibition on the anammox process of the SNAD biofilm. J. Environ. Sci. 2017, 53, 60–67. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Bian, H.X.; Sui, Q.W.; Zheng, R.; Dong, H.M.; Hao, Z.P.; Xue, P.Y.; Song, M.; Zhu, Z.P. Quick start-up test of partial nitrosation of pig farm anaerobic digestion liquid in pilot membrane bioreactor. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 223–230. [Google Scholar]

- Zhu, L.; Liu, J.X. Landfill leachate treatment with a novel process: Anaerobic ammonium oxidation (Anammox) combined with soil infiltration system. J. Hazard. Mater. 2007, 151, 202–212. [Google Scholar]

- Zhang, Y.; Shi, Z.; Chen, M.; Dong, X.; Zhou, J. Evaluation of simultaneous nitrification and denitrification under controlled conditions by an aerobic denitrifier culture. Bioresour. Technol. 2015, 175, 602–605. [Google Scholar] [CrossRef]

- Li, X.; Tao, R.J.; Tian, M.J.; Yuan, Y.; Huang, Y.; Li, B.-L. Recovery and dormancy of nitrogen removal characteristics in the pilot-scale denitrification-partial nitrification-Anammox process for landfill leachate treatment. J. Environ. Manag. 2021, 300, 113711. [Google Scholar] [CrossRef]

- Song, J.C.; Shang, X.P.; Tao, X.P.; Dong, H.M.; Wang, J.; Guo, J.P. Pilot study on the effects of flocculation pretreatment on membrane fouling of membrane bioreactor treating wastewater from dairy cattle farms. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 34–41. [Google Scholar]

- Sun, L.; Li, X.; Zhang, G.; Chen, J.; Xu, Z.; Li, G. The substitution of sand filtration by immersed-UF for surface water treatment: Pilot-scale studies. Water Sci. Technol. 2009, 60, 2337. [Google Scholar]

- Gao, D.; Fu, Y.; Ren, N. Tracing biofouling to the structure of the microbial community and its metabolic products: A study of the three-stage MBR process. Water Res. 2013, 47, 6680–6690. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Ahn, W.Y.; Lee, C.H. Comparison of the filtration characteristics between attached and suspended growth microorganisms in submerged membrane bioreactor. Water Res. 2001, 35, 2435–2445. [Google Scholar] [CrossRef]

- Anthonisen, A.C.; Loehr, R.C.; Prakasam, T.B.S.; Srinath, E.G. Inhibition of Nitrification by Ammonia and Nitrous-Acid. J. Water Pollut. Control. Fed. 1976, 48, 835–852. [Google Scholar] [PubMed]

- Cai, W.W.; Liu, Y. Oxidative stress induced membrane biofouling and its implications to on-line chemical cleaning in MBR. Chem. Eng. J. 2018, 334, 1917–1926. [Google Scholar] [CrossRef]

- Han, X.; Wang, Z.; Wang, X.; Zheng, X.; Ma, J.; Wu, Z. Microbial responses to membrane cleaning using sodium hypochlorite in membrane bioreactors: Cell integrity, key enzymes and intracellular reactive oxygen species. Water Res. 2016, 88, 293–300. [Google Scholar] [CrossRef]

- Cai, C.J.; Wu, C.F.; Yang, H.; Chen, T.S.; Sun, H.W. Effect of free ammonia on nitrogen removal and extracellular polymeric substances in the suspended activated sludge system. J. Civ. Environ. Eng. 2021, 43, 184–192. [Google Scholar]

- Raunkj, R.K.; Hvitved-Jacobsen, T.; Nielsen, P.H. Measurement of pools of protein, carbohydrate and lipid in domestic wastewater. Water Res. 1994, 28, 251–262. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, Z.; Zhen, Z.; Yu, G.; Gu, G. Sludge rheological and physiological characteristics in a pilot-scale submerged membrane bioreactor. Desalination 2007, 212, 152–164. [Google Scholar] [CrossRef]

- Fan, F.; Zhou, H.; Husain, H. Identification of wastewater sludge characteristics to predict critical flux for membrane bioreactor processes. Water Res. 2006, 40, 205–212. [Google Scholar] [CrossRef] [PubMed]

| NH4+-N/mg·L−1 | SCOD a/mg·L−1 | MLSS b/g·L−1 | MLVSS c/g·L−1 | SV30 d/% | pH |

|---|---|---|---|---|---|

| 153–508 | 52.0–178 | 4.73 | 3.49 | 38 | 8.0 |

| Test Days/d | Coverage | Chao | Simpson | Ace |

|---|---|---|---|---|

| 1 | 0.989 | 2559.273 | 0.018 | 2585.432 |

| 39 | 0.986 | 3738.099 | 0.009 | 3819.655 |

| Analysis Project | EPS | SMP | SCOD | TMP | FA | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| rp | p | rp | p | rp | p | rp | p | rp | p | |

| EPS | 1 | 0.863 ** | 0.001 | 0.847 * | 0.002 | 0.967 ** | 0.000 | 0.780 ** | 0.008 | |

| SMP | 0.863 ** | 0.001 | 1 | 0.730 * | 0.017 | 0.856 * | 0.014 | 0.600 | 0.067 | |

| SCOD | 0.847 * | 0.002 | 0.730 * | 0.017 | 1 | 0.827 * | 0.022 | 0.797 ** | 0.006 | |

| TMP | 0.967 ** | 0.000 | 0.856 * | 0.014 | 0.827 * | 0.022 | 1 | 0.538 | 0.213 | |

| FA | 0.780 ** | 0.008 | 0.600 | 0.067 | 0.797 ** | 0.006 | 0.538 | 0.213 | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, H.; Zhu, Z.; Sui, Q.; Wang, S. The Pilot Study of the Influence of Free Ammonia on Membrane Fouling during the Partial Nitrosation of Pig Farm Anaerobic Digestion Liquid. Membranes 2021, 11, 894. https://doi.org/10.3390/membranes11110894

Bian H, Zhu Z, Sui Q, Wang S. The Pilot Study of the Influence of Free Ammonia on Membrane Fouling during the Partial Nitrosation of Pig Farm Anaerobic Digestion Liquid. Membranes. 2021; 11(11):894. https://doi.org/10.3390/membranes11110894

Chicago/Turabian StyleBian, Hanxiao, Zhiping Zhu, Qianwen Sui, and Shunli Wang. 2021. "The Pilot Study of the Influence of Free Ammonia on Membrane Fouling during the Partial Nitrosation of Pig Farm Anaerobic Digestion Liquid" Membranes 11, no. 11: 894. https://doi.org/10.3390/membranes11110894

APA StyleBian, H., Zhu, Z., Sui, Q., & Wang, S. (2021). The Pilot Study of the Influence of Free Ammonia on Membrane Fouling during the Partial Nitrosation of Pig Farm Anaerobic Digestion Liquid. Membranes, 11(11), 894. https://doi.org/10.3390/membranes11110894