Formation of Water-Channel by Propylene Glycol into Polymer for Porous Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Membrane Fabrication & Water Pressure Applying Membrane

2.2.2. Water Treatment Equipment

2.2.3. SEM Sampling

2.2.4. FTIR Sampling

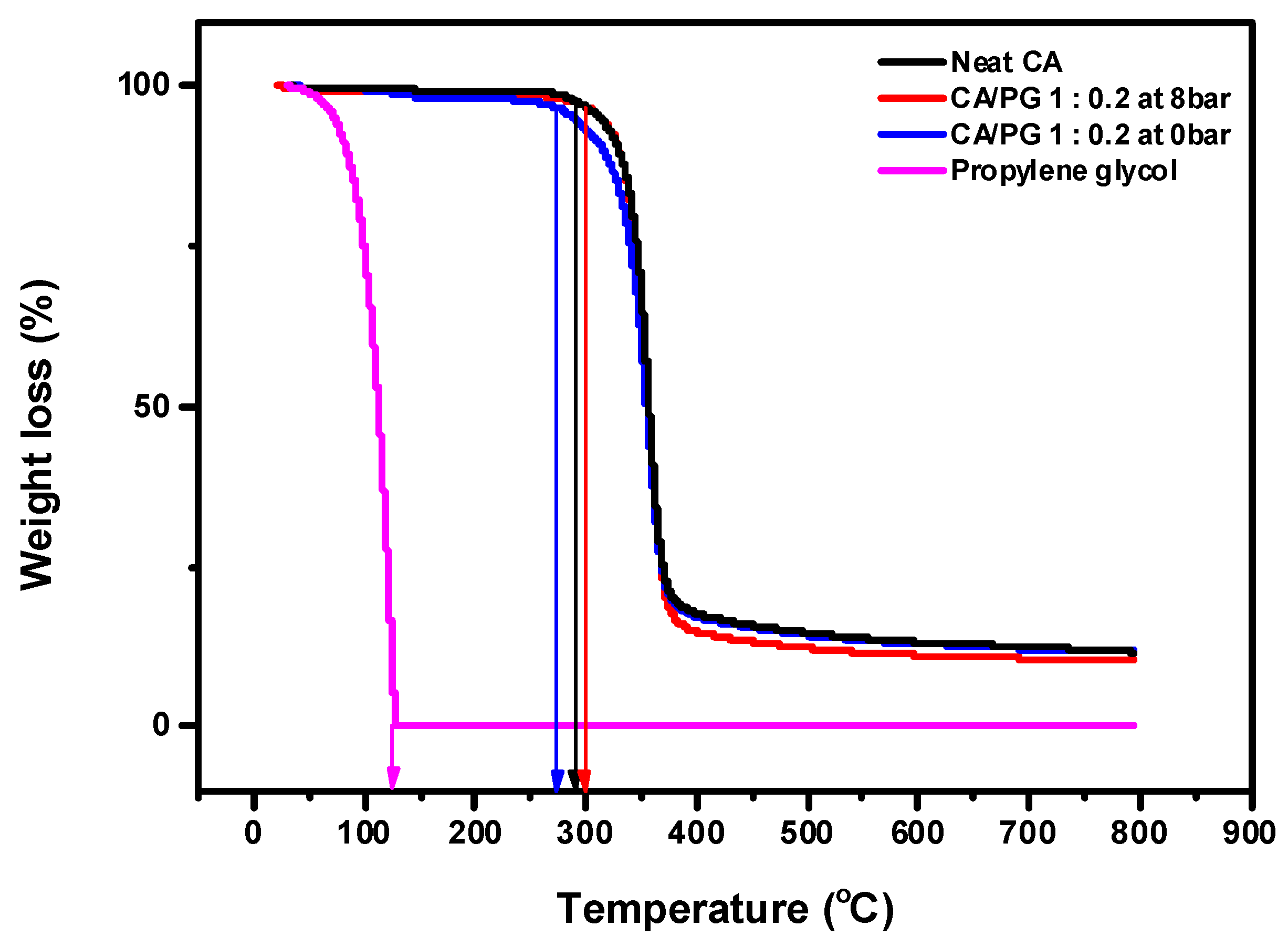

2.2.5. TGA Sampling

3. Results and Discussion

3.1. Scanning Electron Microscope (SEM)

3.2. Fourier Transform Infrared (FTIR)

3.3. TG Analysis

3.4. Porosity of CA/Propylene Glycol

3.5. Water Flux Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, W.; Xia, F.; Zhao, S.; Zhang, M.; Li, W.; Zhang, J. Characterization of liquid–liquid mass transfer performance in a novel pore-array intensified tube-in-tube microchannel. AIChE J. 2020, 66, 16893. [Google Scholar] [CrossRef]

- Otaru, A.J.; Morvan, H.P.; Kennedy, A.R. Air flow measurement across negatively infiltration processed porous aluminum structures. AIChE J. 2019, 65, 1355. [Google Scholar] [CrossRef] [Green Version]

- Friedmann, D.; Hakki, A.; Kim, H.; Choi, W.; Bahnemann, D. Heterogeneous photocatalytic organic synthesis: State-of-the-art and future perspectives. Green Chem. 2016, 18, 5391–5411. [Google Scholar] [CrossRef] [Green Version]

- Luna-Galiano, Y.; Leiva, C.; Arenas, C.; Femandez-Pereira, C. Fly ash based geopolymetric foams using silica fume as pore generation agent. Physical, mechanical and acoustic properties. J. Non Cryst. Solids 2018, 15, 196–204. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Thiruvengadam, P.; Ming, W.; Qiu, F.; Yu, K.; Liu, P.; Su, Y.; Zhang, F. Ionized aromatization approach to charged porous polymers as exceptional absorbents. Polym. Chem. 2019, 10, 2792–2800. [Google Scholar] [CrossRef]

- Martin, B.D.; Parsons, S.A.; Jefferson, B. Removal and recovery of phosphate from municipal wastewaters using a polymeric anion exchanger bound with hydrated ferric oxide nanoparticles. Water Sci. Technol. 2009, 60, 2637–2645. [Google Scholar] [CrossRef] [PubMed]

- Uragami, T. Structural Design of Polymer Membranes for Concentration of Bio-ethanol. Polym. J. 2008, 40, 485–494. [Google Scholar] [CrossRef] [Green Version]

- Han, T.Y.; Dzakpasu, C.B.; Kim, D.H.; Kim, S.W.; Jeong, Y.C.; Ryou, M.H.; Lee, Y.M. Thin and porous polymer membrane-based electrochromic device. J. Mater. Chem. C 2019, 7, 1042. [Google Scholar] [CrossRef]

- Hata, H.; Nishihara, Y.; Nishiyama, M.; Sowa, Y.; Kawagishi, I.; Kitao, A. High pressure inhibits signaling protein binding to the flagellar motor and bacterial chemotaxis through enhanced hydration. Sci. Rep. 2020, 10, 2351. [Google Scholar]

- Lesov, I.; Tcholakova, S.; Denkov, N. Drying of particle-loaded foams for production of porous materials: Mechanism and theoretical modeling. RSC Adv. 2013, 4, 811–823. [Google Scholar] [CrossRef]

- Huang, K.; Dai, L.; Fan, Y. Characterization of noise reduction capabilities of porous materials under various vacuum conditions. Appl. Acoust. 2019, 161, 107155. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Li, L.; Zhang, S. Separation of olefin/paraffin by electrodialysis. Sep. Purif. Technol. 2019, 218, 20–24. [Google Scholar] [CrossRef]

- Chu, Y.-H.; Yancey, D.; Xu, L.; Martinez, M.; Brayden, M.; Koros, W. Iron-containing carbon molecular sieve membranes for advanced olefin/paraffin separations. J. Membr. Sci. 2018, 548, 609–620. [Google Scholar] [CrossRef]

- Zhang, W.; Qiu, J.; Yin, X.; Wang, D. A novel heat pope assisted separation type battery thermal management system based on phase change material. Appl. Therm. Eng. 2020, 165, 114571. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, F.; Yang, L.; Bi, S.; Wu, D.; Yao, Y.; Wagner, M.; Graf, R.; Hansen, M.R.; Zhuang, X.; et al. Anionic porous polymers with tunable structures and catalytic properties. J. Mater. Chem. A 2016, 4, 15162–15168. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.G.; Hwang, J.; Kang, S.W. Control of nanoporous polymer matrix by an ionic liquid and water pressure for applications to water-treatment and separator. Chem. Eng. J. 2016, 284, 37–40. [Google Scholar] [CrossRef]

- Huang, K.; Rowe, P.; Chi, C.; Sreepal, V.; Bohn, T.; Zhou, K.G.; Su, Y.; Prestat, E.; Balakrishna, P.; Cherian, C.T.; et al. Cation-controlled wetting properties of vermiculite membranes and its promise for fouling resistant oil-water separation. Nat. Commun. 2020, 11, 1097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, W.G.; Kang, S.W. Control of Pore in Cellulose Acetate containing Mg salt by Water Pressure Treatment for Applications to Separators. J. Ind. Eng. Chem. 2019, 25, 103–106. [Google Scholar] [CrossRef]

- Naga, N.; Fujioka, S.; Inose, D.; Ahmed, K.; Nageh, H.; Nakano, T. Synthesis and properties of porous polymer synthesized by Michael addition reactions of multi-functional acrylate, diamine, and dithiol compounds. RSC Adv. 2020, 10, 60. [Google Scholar] [CrossRef] [Green Version]

- Xu, R.; Sun, Y.; Wang, Y.; Huang, J.; Zhang, Q. Two-dimensional vermiculite separator for lithium sulfur batteries. Chin. Chem. Lett. 2017, 28, 2235–2238. [Google Scholar] [CrossRef]

- Raso, R.; Tovar, M.; Lasobras, J.; Herguido, J.; Kumakiri, I.; Araki, S.; Menéndez, M. Zeolite membranes: Comparison in the separation of H2O/H2/CO2 mixtures and test of a reactor for CO2 hydrogenation to methanol. Catal. Today 2020, 364, 270–275. [Google Scholar] [CrossRef]

- Sun, Q.; Dai, Z.; Meng, X.; Xiao, F.-S. Porous polymer catalysts with hierarchical structures. Chem. Soc. Rev. 2015, 44, 6018–6034. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Guan, J.-J.; Chen, W.; Ke, Q.-F.; Zhang, C.-Q.; Guo, Y.-P. Fabrication of hydroxyapatite/chitosan porous materials for Pb(ii) removal from aqueous solution. RSC Adv. 2015, 5, 25462–25470. [Google Scholar] [CrossRef]

- Oh, Y.T.; Lee, S.H.; Elimelech, M. Effect of hydraulic pressure and membrane orientation on water flux and reverse solute flux in pressure assisted osmosis. J. Membr. Sci. 2014, 465, 159–166. [Google Scholar] [CrossRef]

- Tow, E.W.; Lienhard, J.H.V. Unpacking compaction: Effect of hydraulic pressure on alginate fouling. J. Membr. Sci. 2017, 544, 221–233. [Google Scholar] [CrossRef]

- Kim, H.Y.; Cho, Y.; Kang, S.W. Porous cellulose acetate membranes prepared by water pressure-assisted process for water-treatment. J. Ind. Eng. Chem. 2019, 78, 421–424. [Google Scholar] [CrossRef]

- Lee, W.G.; Kim, D.H.; Jeon, W.C.; Kwak, S.K.; Kang, S.J.; Kang, S.W. Facile control of nanoporosity in Cellulose Acetate using Nickel(II) nitrate additive and water pressure treatment for highly efficient battery gel separators. Sci. Rep. 2017, 7, 1287. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, W.G.; Kang, S.W. Eco-friendly process for facile pore control in thermally stable cellulose acetate utilizing zinc(II) nitrate for water-treatment. J. Ind. Eng. Chem. 2019, 81, 88–92. [Google Scholar] [CrossRef]

- Hong, S.H.; Cho, Y.; Kang, S.W. Highly porous and thermally stable cellulose acetate to utilize hydrated glycerin. J. Ind. Eng. Chem. 2020, 91, 79–84. [Google Scholar] [CrossRef]

- Lipiec, J.; Hajnos, M.; Świeboda, R. Estimating effects of compaction on pore size distribution of soil aggregates by mercury porosimeter. Geoderma 2012, 179–180, 20–27. [Google Scholar] [CrossRef]

| Material | Parameter | Value |

|---|---|---|

| Bulk density | 0.13 g/mL | |

| Water-pressure-treated CA with propylene glycol | Average pore diameter | 300 nm |

| Porosity | 69.7% |

| Additive | Glycerin | Propylene Glycol |

|---|---|---|

| Bulk density | 0.14 g/mL | 0.13 g/mL |

| Average pore diameter | 630 nm | 300 nm |

| Porosity | 78.3% | 69.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.H.; Cho, Y.; Kang, S.W. Formation of Water-Channel by Propylene Glycol into Polymer for Porous Materials. Membranes 2021, 11, 881. https://doi.org/10.3390/membranes11110881

Hong SH, Cho Y, Kang SW. Formation of Water-Channel by Propylene Glycol into Polymer for Porous Materials. Membranes. 2021; 11(11):881. https://doi.org/10.3390/membranes11110881

Chicago/Turabian StyleHong, Seong Ho, Younghyun Cho, and Sang Wook Kang. 2021. "Formation of Water-Channel by Propylene Glycol into Polymer for Porous Materials" Membranes 11, no. 11: 881. https://doi.org/10.3390/membranes11110881

APA StyleHong, S. H., Cho, Y., & Kang, S. W. (2021). Formation of Water-Channel by Propylene Glycol into Polymer for Porous Materials. Membranes, 11(11), 881. https://doi.org/10.3390/membranes11110881