Flavonoid-Enriched Plant-Extract-Loaded Emulsion: A Novel Phytocosmetic Sunscreen Formulation with Antioxidant Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Development of o/w Emulsions and Stability Study

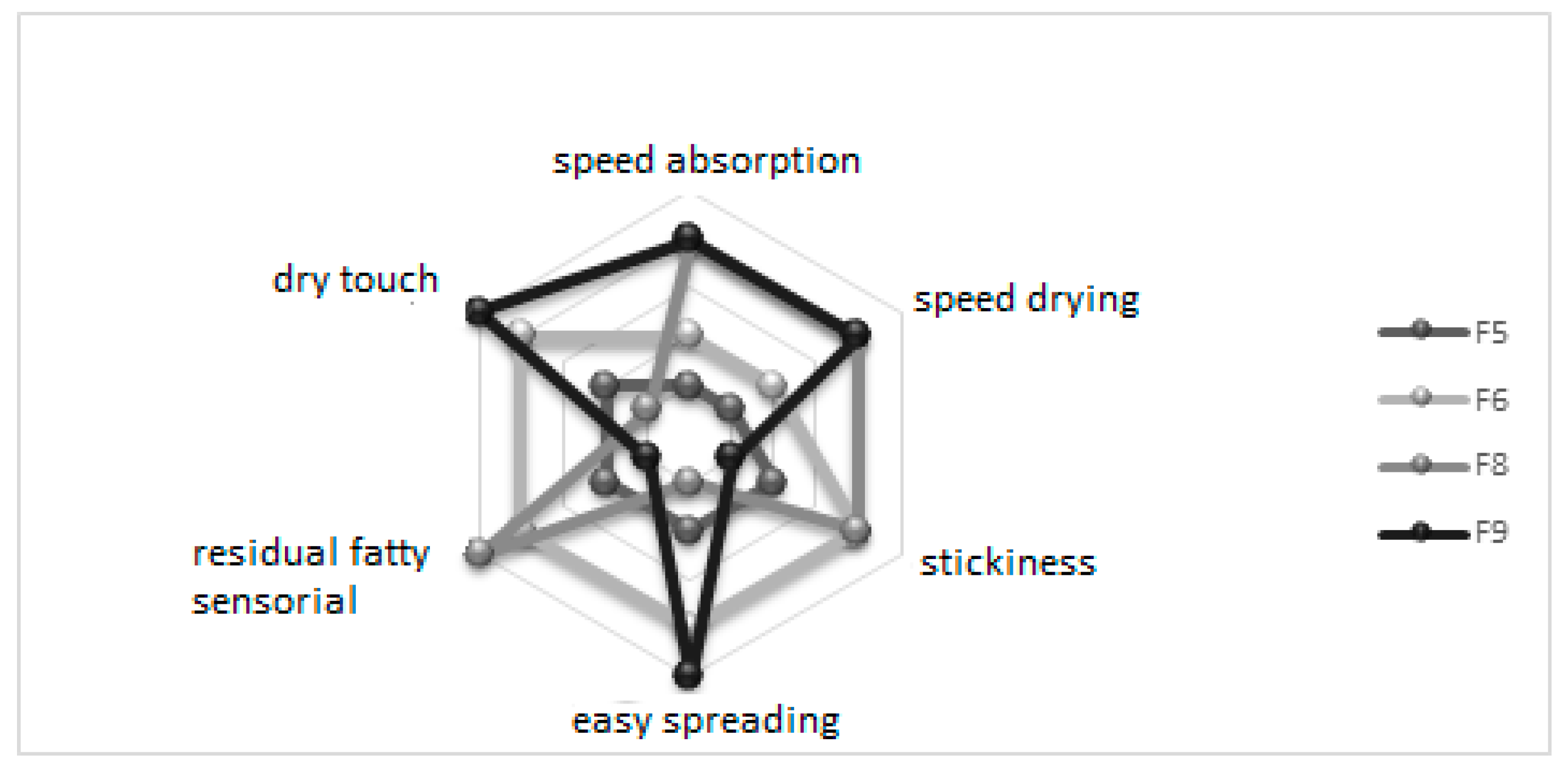

2.3. Sensorial Analysis

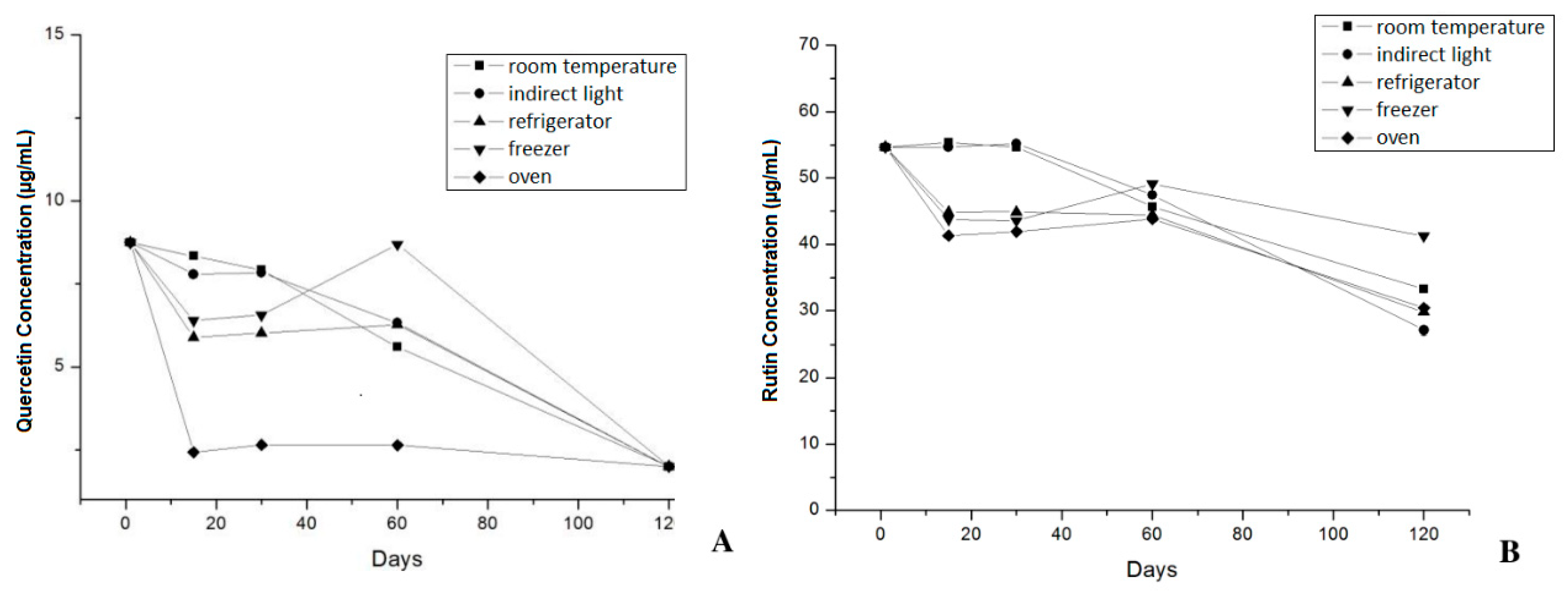

2.4. Production of Phytocosmetic and Stability Study

2.5. Zeta Potential

2.6. Droplet Size Distribution

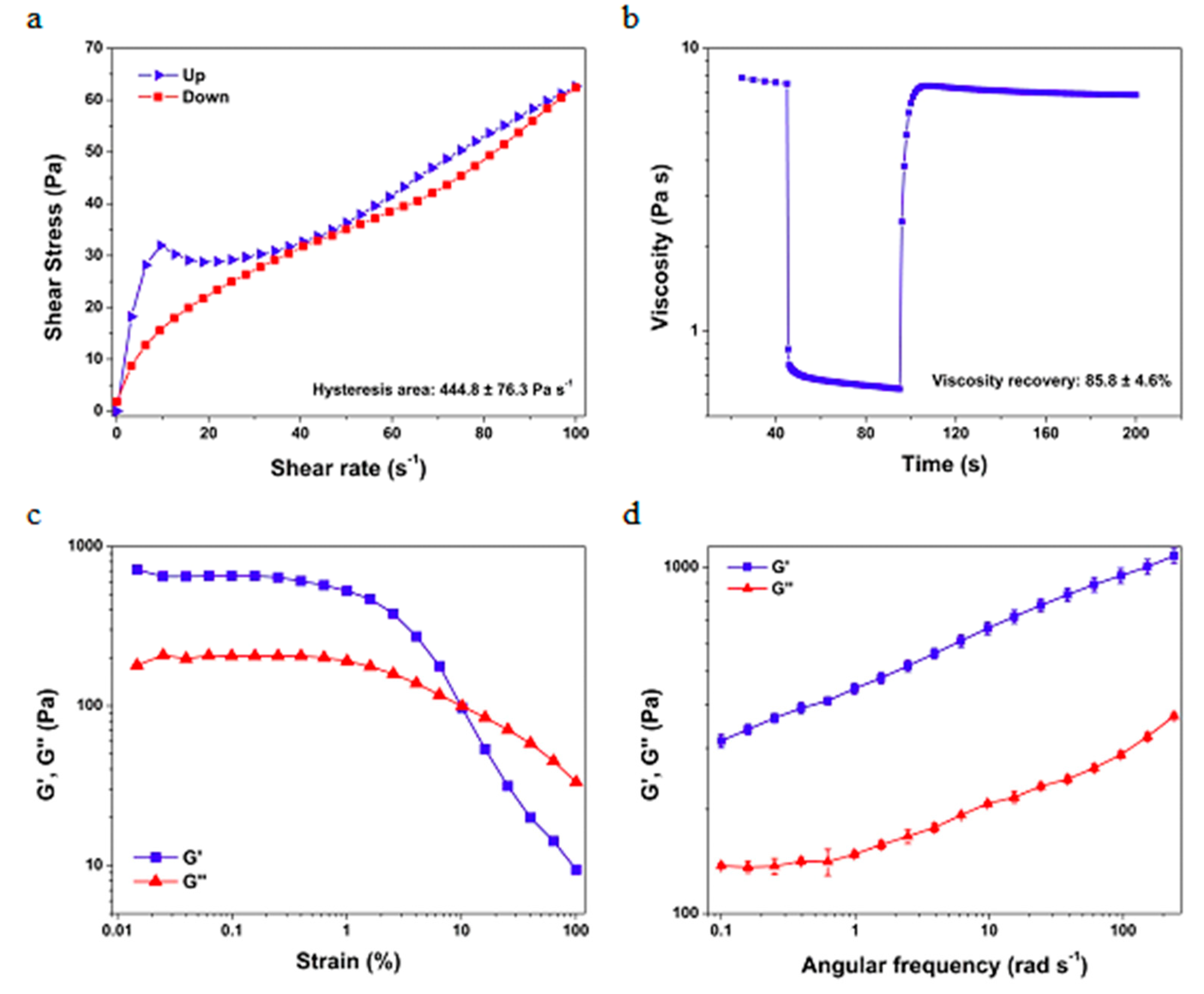

2.7. Mechanical Analysis

2.8. Thermal Analysis

2.9. Microbiologic Control

2.10. In Vitro Sun Protection Factor (SPF) Evaluation of the Phytocosmetic

2.11. In Vitro Antioxidant Activity Analysis of the Phytocosmetic

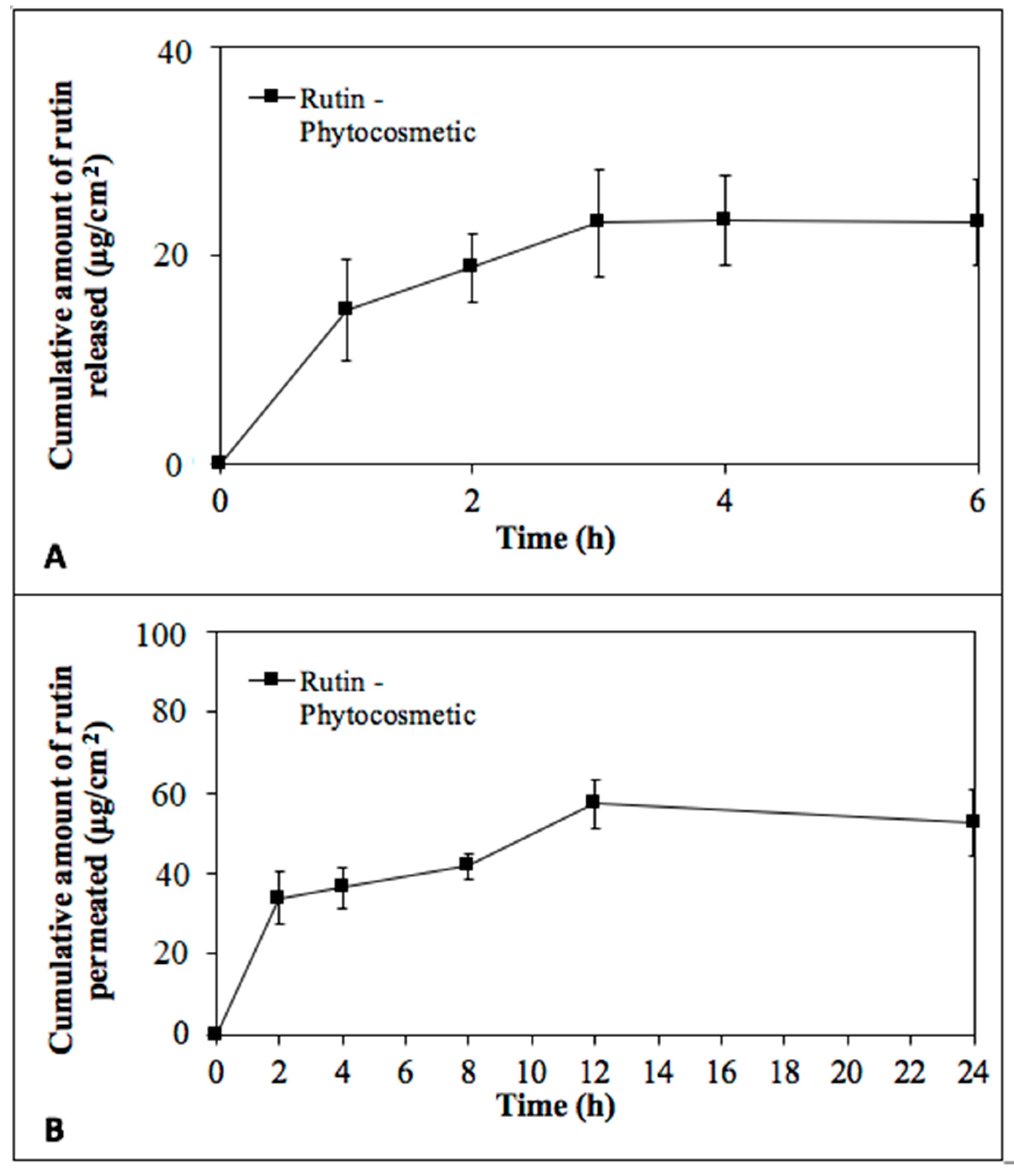

2.12. Skin Permeation

2.13. Photostability Study

2.14. In Vitro Skin Irritation—Reconstructed Human Epidermis

2.15. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baron, E.D.; Kirkland, E.B.; Domingo, D. Advances in photoprotection. Dermatol. Nurs. 2008, 20, 265–272. [Google Scholar] [PubMed]

- Palm, M.D.; O’Donoghue, M.N. Update on photoprotection. Dermatol. Ther. 2007, 20, 360–376. [Google Scholar] [CrossRef] [PubMed]

- Arts, I.C.; Hollman, P.C. Polyphenols and disease risk in epidemiologic studies. Am. J. Clin. Nutr. 2005, 81, 317s–325s. [Google Scholar] [CrossRef] [PubMed]

- Romanhole, R.C.; Ataide, J.A.; Moriel, P.; Mazzola, P.G. Update on ultraviolet A and B radiation generated by the sun and artificial lamps and their effects on skin. Int. J. Cosmet. Sci. 2015, 37, 366–370. [Google Scholar] [CrossRef] [PubMed]

- Amar, S.K.; Goyal, S.; Dubey, D.; Srivastav, A.K.; Chopra, D.; Singh, J.; Shankar, J.; Chaturvedi, R.K.; Ray, R.S. Benzophenone 1 induced photogenotoxicity and apoptosis via release of cytochrome c and Smac/DIABLO at environmental UV radiation. Toxicol. Lett. 2015, 239, 182–193. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, L.; Picard, C.; Savary, G.; Grisel, M. Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: Relationships between both data. Colloids Surf. A Physicochem. Eng. Asp. 2013, 421, 150–163. [Google Scholar] [CrossRef]

- Ramos, S.; Homem, V.; Alves, A.; Santos, L. A review of organic UV-filters in wastewater treatment plants. Environ. Int. 2016, 86, 24–44. [Google Scholar] [CrossRef] [PubMed]

- Sambandan, D.R.; Ratner, D. Sunscreens: An overview and update. J. Am. Acad. Dermatol. 2011, 64, 748–758. [Google Scholar] [CrossRef] [PubMed]

- Wong, T.; Orton, D. Sunscreen allergy and its investigation. Clin. Dermatol. 2011, 29, 306–310. [Google Scholar] [CrossRef]

- Ruszkiewicz, J.A.; Pinkas, A.; Ferrer, B.; Peres, T.V.; Tsatsakis, A.; Aschner, M. Neurotoxic effect of active ingredients in sunscreen products, a contemporary review. Toxicol. Rep. 2017, 4, 245–259. [Google Scholar] [CrossRef]

- Cefali, L.; Ataide, J.; Moriel, P.; Foglio, M.; Mazzola, P. Plant-based active photoprotectants for sunscreens. Int. J. Cosmet. Sci. 2016, 38, 346–353. [Google Scholar] [CrossRef] [PubMed]

- De Cooman, L.; Everaert, E.; de Keukeleire, D. Quantitative analysis of hop acids, essential oils and flavonoids as a clue to the identification of hop varieties. Phytochem. Anal. 1998, 9, 145–150. [Google Scholar] [CrossRef]

- Tohge, T.; de Souza, L.P.; Fernie, A.R. Current understanding of the pathways of flavonoid biosynthesis in model and crop plants. J. Exp. Bot. 2017, 68, 4013–4028. [Google Scholar] [CrossRef] [PubMed]

- AMacedo, S.; Quelhas, S.; Silva, A.M.; Souto, E.B. Nanoemulsions for delivery of flavonoids: Formulation and in vitro release of rutin as model drug. Pharm. Dev. Technol. 2014, 19, 677–680. [Google Scholar] [CrossRef] [PubMed]

- Santos, I.S.; Ponte, B.M.; Boonme, P.; Silva, A.M.; Souto, E.B. Nanoencapsulation of polyphenols for protective effect against colon-rectal cancer. Biotechnol. Adv. 2013, 31, 514–523. [Google Scholar] [CrossRef] [PubMed]

- Corrêa, N.M.; Júnior, F.B.C.; Ignácio, R.F.; Leonardi, G.R. Avaliação do comportamento reológico de diferentes géis hidrofílicos. Rev. Bras. Ciênc. Farm. 2005, 41, 73–78. [Google Scholar]

- Barry, B.W. Rheology of Dermatological Vehicles; Marcel Dekker: New York, NY, USA, 1993. [Google Scholar]

- Ribeiro, H.; Morais, J.; Eccleston, G. Structure and rheology of semisolid o/w creams containing cetyl alcohol/non-ionic surfactant mixed emulsifier and different polymers. Int. J. Cosmet. Sci. 2004, 26, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Montenegro, L.; Puglisi, G. Evaluation of sunscreen safety by in vitro skin permeation studies: Effects of vehicle composition. Die Pharm. Int. J. Pharm. Sci. 2013, 68, 34–40. [Google Scholar]

- Huong, S.P.; Rocher, E.; Fourneron, J.-D.; Charles, L.; Monnier, V.; Bun, H.; Andrieu, V. Photoreactivity of the sunscreen butylmethoxydibenzoylmethane (DBM) under various experimental conditions. J. Photochem. Photobiol. A Chem. 2008, 196, 106–112. [Google Scholar] [CrossRef]

- Romanhole, R.C.; Ataide, J.A.; Cefali, L.C.; Moriel, P.; Mazzola, P.G. Photostability study of commercial sunscreens submitted to artificial UV irradiation and/or fluorescent radiation. J. Photochem. Photobiol. B Biol. 2016, 162, 45–49. [Google Scholar] [CrossRef]

- Idson, B. Stability Testing of Emulsions-Part I. Drug Cosmet. Ind. 1993, 152, 27. [Google Scholar]

- MacFie, H.J.H.; Thomson, D.M.H. Preference mapping and multidimensional scaling. In Sensory Analysis of Foods; Piggott, J.R, Ed.; Elsevier: New York, NY, USA, 1988. [Google Scholar]

- Almeida, I.; Gaio, A.; Bahia, M. Hedonic and descriptive skinfeel analysis of two oleogels: Comparison with other topical formulations. J. Sens. Stud. 2008, 23, 92–113. [Google Scholar] [CrossRef]

- Isaac, V.L.B.; Chiari, B.G.; Magnani, C.; Corrêa, M.A. Análise sensorial como ferramenta útil no desenvolvimento de cosméticos. Rev. Ciênc. Farm. Básica Apl. 2013, 33, 479–488. [Google Scholar]

- Dutcosky, S.D. Análise Sensorial de Alimentos, 2nd ed.; e-Tec Brasil: Curitiba, Brzil, 2007. [Google Scholar]

- EMEA. Guideline on Stability Testing: Stability Testing of New Drug Substances and Products; EMEA: Scherpenzeel, The Netherlands, 2008. [Google Scholar]

- ISO. Guidelines for the Characterization of Dispersion Stability; International Organization of Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Colipa Project Team IV. Method for the In Vitro Determination of UVA Protection Provided by Sunscreen Products; Colipa: Brussels, Belgium, 2006. [Google Scholar]

- Badolato, G.; Aguilar, F.; Schuchmann, H.; Sobisch, T.; Lerche, D. Evaluation of long term stability of model emulsions by multisample analytical centrifugation. In Surface and Interfacial Forces–From Fundamentals to Applications; Springer: Berlin, Germany, 2008; pp. 66–73. [Google Scholar]

- Roland, I.; Piel, G.; Delattre, L.; Evrard, B. Systematic characterization of oil-in-water emulsions for formulation design. Int. J. Pharm. 2003, 263, 85–94. [Google Scholar] [CrossRef]

- Hejjaji, E.M.; Smith, A.M.; Morris, G.A. Designing chitosan-tripolyphosphate microparticles with desired size for specific pharmaceutical or forensic applications. Int. J. Biol. Macromol. 2017, 95, 564–573. [Google Scholar] [CrossRef] [PubMed]

- Savary, G.; Grisel, M.; Picard, C. Impact of emollients on the spreading properties of cosmetic products: A combined sensory and instrumental characterization. Colloids Surf. B Biointerfaces 2013, 102, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Estanqueiro, M.; Conceição, J.; Amaral, M.H.; Santos, D.; Silva, J.B.; Lobo, J.M.S. Characterization and stability studies of emulsion systems containing pumice. Braz. J. Pharm. Sci. 2014, 50, 361–369. [Google Scholar] [CrossRef]

- Isaac, V.L.B.; Cefali, L.; Chiari, B.; Almeida, M.; Ribeiro, H.; Correa, M.A. Effect of various thickening agents on the rheological properties of oil-in-water emulsions containing nonionic emulsifier. J. Dispers. Sci. Technol. 2013, 34, 880–885. [Google Scholar] [CrossRef]

- Cefali, L.C.; Souza-Moreira, T.M.; Corrêa, M.A.; Salgado, H.R.N.; Isaac, V.L.B. Development and evaluation of an emulsion containing lycopene for combating acceleration of skin aging. Braz. J. Pharm. Sci. 2015, 51, 579–590. [Google Scholar] [CrossRef]

- Dávila, J.L.; d’Ávila, M.A. Laponite as a rheology modifier of alginate solutions: Physical gelation and aging evolution. Carbohydr. Polym. 2017, 157, 1–8. [Google Scholar] [CrossRef]

- ISO. Cosmetics—Microbiology—Microbiological Limits; International Organization of Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- USP. The United States Pharmacopeial Convention; USP: Rockville, MD, USA, 2013. [Google Scholar]

- Mansur, M.C.P.; Leitão, S.G.; Cerqueira-Coutinho, C.; Vermelho, A.B.; Silva, R.S.; Presgrave, O.A.; Leitão, Á.A.; Leitão, G.G.; Ricci-Júnior, E.; Santos, E.P. In Vitro and in vivo evaluation of efficacy and safety of photoprotective formulations containing antioxidant extracts. Rev. Bras. Farm. 2016, 26, 251–258. [Google Scholar] [CrossRef]

- Severino, P.; Moraes, L.F.; Zanchetta, B.; Souto, E.B.; Santana, M.H. Elastic liposomes containing benzophenone-3 for sun protection factor enhancement. Pharm. Dev. Technol. 2012, 17, 661–665. [Google Scholar] [CrossRef] [PubMed]

- Sayre, R.M.; Agin, P.P.; LeVee, G.J.; Marlowe, E. A comparison of in vivo and in vitro testing of sunscreening formulas. Photochem. Photobiol. 1979, 29, 559–566. [Google Scholar] [CrossRef] [PubMed]

- ISO. Determination of Sunscreen UVA Photoprotection In Vitro; International Organization of Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Socorro, M.R.M.d.; Alves, R.E.; de Brito, E.S.; Pérez-Jiménez, J.; Saura-Calixto, F.; Mancini-Filho, J. Bioactive compounds and antioxidant capacities of 18 non-traditional tropical fruits from Brazil. Food Chem. 2010, 121, 996–1002. [Google Scholar]

- Seal, T. Quantitative HPLC analysis of phenolic acids, flavonoids and ascorbic acid in four different solvent extracts of two wild edible leaves, Sonchus arvensis and Oenanthe linearis of North-Eastern region in India. J. Appl. Pharm. Sci. 2016, 6, 10. [Google Scholar] [CrossRef]

- JAlencastre, B.; Bentley, M.V.L.B.; Garcia, F.S.; Moragas, M.d.; Viladot, J.L.; Marchetti, J.M. A study of the characteristics and in vitro permeation properties of CMC/chitosan microparticles as a skin delivery system for vitamin E. Revista Brasileira de Ciências Farmacêuticas 2006, 42, 69–76. [Google Scholar] [CrossRef]

- OECD. Test Guideline No. 439. In Vitro Skin Irritation: Reconstructed Human Epidermis Test Method. Available online: https://www.oecd-ilibrary.org/docserver/9789264242845-en.pdf?expires=1570612196&id=id&accname=guest&checksum=7598839FA6F86688026A68D7259A6694 (accessed on 18 June 2019).

- Pimentel-Moral, S.; Teixeira, M.C.; Fernandes, A.R.; Arraez-Roman, D.; Martinez-Ferez, A.; Segura-Carretero, A.; Souto, E.B. Lipid nanocarriers for the loading of polyphenols—A comprehensive review. Adv. Colloid Interface Sci. 2018, 260, 85–94. [Google Scholar] [CrossRef]

- Clares, B.; Calpena, A.C.; Parra, A.; Abrego, G.; Alvarado, H.; Fangueiro, J.F.; Souto, E.B. Nanoemulsions (NEs), liposomes (LPs) and solid lipid nanoparticles (SLNs) for retinyl palmitate: Effect on skin permeation. Int. J. Pharm. 2014, 473, 591–598. [Google Scholar] [CrossRef]

- Teixeira, M.C.; Severino, P.; Andreani, T.; Boonme, P.; Santini, A.; Silva, A.M.; Souto, E.B. d-alpha-tocopherol nanoemulsions: Size properties, rheological behavior, surface tension, osmolarity and cytotoxicity. Saudi Pharm. J. 2017, 25, 231–235. [Google Scholar] [CrossRef]

- Severino, P.; Fangueiro, J.F.; Ferreira, S.V.; Basso, R.; Chaud, M.V.; Santana, M.H.; Rosmaninho, A.; Souto, E.B. Nanoemulsions and nanoparticles for non-melanoma skin cancer: Effects of lipid materials. Clin. Transl. Oncol. 2013, 15, 417–424. [Google Scholar] [CrossRef]

- ECOCERT. Organismo de Inspeção e Certificação. Ecocert Brasil. Available online: http://www.brazil.ecocert.com/politicas-e-diretrizes-ecocert (accessed on 1 June 2017).

- Carbone, C.; Teixeira, M.D.C.; Sousa, M.D.C.; Martins-Gomes, C.; Silva, A.M.; Souto, E.M.B.; Musumeci, T. Clotrimazole-Loaded Mediterranean Essential Oils NLC: A Synergic Treatment of Candida Skin Infections. Pharmaceutics 2019, 11, 231. [Google Scholar] [CrossRef] [PubMed]

- Zielinska, A.; Martins-Gomes, C.; Ferreira, N.R.; Silva, A.M.; Nowak, I.; Souto, E.B. Anti-inflammatory and anti-cancer activity of citral: Optimization of citral-loaded solid lipid nanoparticles (SLN) using experimental factorial design and LUMiSizer(R). Int. J. Pharm. 2018, 553, 428–440. [Google Scholar] [CrossRef] [PubMed]

- Shimojo, A.A.M.; Fernandes, A.R.V.; Ferreira, N.R.E.; Sanchez-Lopez, E.; Santana, M.H.A.; Souto, E.B. Evaluation of the Influence of Process Parameters on the Properties of Resveratrol-Loaded NLC Using 2(2) Full Factorial Design. Antioxidants 2019, 8, 272. [Google Scholar] [CrossRef] [PubMed]

- Meilgaard, M.C.; Carr, B.T.; V, G. Civille, Sensory Evaluation Techniques; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Muñoz, A.M.; Civille, V.G.; Carr, T.B. Sensory Evaluation in Quality Control; Van Nostrand Reinhold: New York, NY, USA, 1993. [Google Scholar]

- Silva, T.M.D.; Migliato, K.F.; Salgado, H.R.N.; Rangel, V.L.B.I. Quality comparison of W/O and O/W photo-protection creams. Cosmet. Toilet. 2004, 119, 41–46. [Google Scholar]

- Isaac, V.L.B.; Cefali, L.C.; Chiari, B.G.; Oliveira, C.C.L.G.; Salgado, H.R.N.; Correa, M.A. Protocolo para ensaios físico-químicos de estabilidade de fitocosméticos. Revista de Ciências Farmacêuticas Básica e Aplicada 2008, 28, 81. [Google Scholar]

- Liapis, A.I.; Bruttini, R. Freeze drying. In Handbook of Industrial Drying; Mujumdar, A., Ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 257–271. [Google Scholar]

- Figueiredo, S.A.; Vilela, F.M.P.; da Silva, C.A.; Cunha, T.M.; Santos, M.H.D.; Fonseca, M.J.V. In Vitro and in vivo photoprotective/photochemopreventive potential of Garcinia brasiliensis epicarp extract. J. Photochem. Photobiol. B Biol. 2014, 131, 65–73. [Google Scholar] [CrossRef]

- Hubinger, S.Z.; Cefali, L.C.; Vellosa, J.C.; Salgado, H.R.N.; Isaac, V.L.B.; Moreira, R.R.D. Dimorphandra mollis: An alternative as a source of flavonoids with antioxidant action. Lat. Am. J. Pharm. 2010, 29, 271–274. [Google Scholar]

- Veberic, R.; Jakopic, J.; Stampar, F.; Schmitzer, V. European elderberry (Sambucus nigra L.) rich in sugars, organic acids, anthocyanins and selected polyphenols. Food Chem. 2009, 114, 511–515. [Google Scholar] [CrossRef]

- Grinberg, L.N.; Rachmilewitz, E.A.; Newmark, H. Protective effects of rutin against hemoglobin oxidation. Biochem. Pharmacol. 1994, 48, 643–649. [Google Scholar] [CrossRef]

- Jeong, Y.I.; Cho, C.S.; Kim, S.H.; Ko, K.S.; Kim, S.I.; Shim, Y.H.; Nah, J.W. Preparation of poly (DL-lactide-co-glycolide) nanoparticles without surfactant. J. Appl. Polym. Sci. 2001, 80, 2228–2236. [Google Scholar] [CrossRef]

- Wiącek, A.E.; Chibowski, E. Zeta potential and droplet size of n-tetradecane/ethanol (protein) emulsions. Colloids Surf. B Biointerfaces 2002, 25, 55–67. [Google Scholar] [CrossRef]

- Zanatta, C.; Arnal, M.M.; Urgatondo, V.; Rocha-Filho, P.; Martínez-Hidalgo, M.V. Photoprotective potential of emulsions formulated with Buriti oil (Mauritia flexuosa) and Vitamin E against UV irradiation on human keratinocytes and fibroblasts cell lines. Food Chem. Toxicol. 2010, 48, 70–75. [Google Scholar] [CrossRef] [PubMed]

- Tai, A.; Bianchini, R.; Jachowicz, J. Texture analysis of cosmetic/pharmaceutical raw materials and formulations. Int. J. Cosmet. Sci. 2014, 36, 291–304. [Google Scholar] [CrossRef] [PubMed]

- Casimiro, M.H.; Leal, J.P.; Gil, M.H.; Castro, C. Análise calorimétrica aplicada a polímeros biológicos. Parte I: Fundamentos teóricos. Boletim da Sociedade Portuguesa de Química 2005, 98, 29–36. [Google Scholar]

- Daneluti, A.L.M.; Velasco, M.V.R.; Baby, A.R.; Matos, J.d.R. Thermal behavior and free-radical-scavenging activity of phytic acid alone and incorporated in cosmetic emulsions. Cosmetics 2015, 2, 248–258. [Google Scholar] [CrossRef]

- Schnitzler, E.; Carvalho, M.A.D.S.F.; Stadler, C.C.; Volpato, A.M.; Ionashiro, M. Aplicação da calorimetria exploratória diferencial (dsc) na caracterização térmica do acetato de dexametazona, excipientes e do creme de dexametazona. Eclética Química 2001, 26, 1–18. [Google Scholar] [CrossRef]

- De Flora, S.; Ferguson, L.R. Overview of mechanisms of cancer chemopreventive agents. Mutat. Res. Fundam. Mol. Mech. Mutagen. 2005, 591, 8–15. [Google Scholar] [CrossRef]

- Food and Drug Administration. Sunscreen Drug Products for Over-the-Counter Human Use; Food and Drug Administration: Silver Spring, MD, USA, 2019. [Google Scholar]

- Seok, H.K.; Kwak, J.Y.; Choi, G.W.; An, S.M.; Kwak, J.H.; Seo, H.H.; Suh, H.J.; Boo, Y.C. Scutellaria radix Extract as a Natural UV Protectant for Human Skin. Phytother. Res. 2016, 30, 374–379. [Google Scholar] [CrossRef]

- Chuang, S.-Y.; Lin, Y.-K.; Lin, C.-F.; Wang, P.-W.; Chen, E.-L.; Fang, J.-Y. Elucidating the skin delivery of aglycone and glycoside flavonoids: How the structures affect cutaneous absorption. Nutrients 2017, 9, 1304. [Google Scholar] [CrossRef]

- Isaac, V.L.B.; Chiari, B.G.; Miglioli, K.; Moreira, R.; Oliveira, J.R.S.; Salgado, H.; Relkin, P.; Correa, M.A.; Salgado, A.; Ribeiro, H.M. Development of a topical formulation containing S. lutea extract: Stability, in vitro studies and cutaneous permeation. J. Appl. Pharm. Sci. 2012, 8, 174–179. [Google Scholar] [CrossRef]

- Gaspar, L.; Campos, P.M. Rheological behavior and the SPF of sunscreens. Int. J. Pharm. 2003, 250, 35–44. [Google Scholar] [CrossRef]

- Mayer, L.; Wadsley, J.; Quinn, T.; Stadel, J. Gravitational instability in binary protoplanetary discs: New constraints on giant planet formation. Mon. Not. R. Astron. Soc. 2005, 363, 641–648. [Google Scholar] [CrossRef]

- Perugini, D.; Poli, G.; Gatta, G. Analysis and simulation of magma mixing processes in 3D. Lithos 2002, 65, 313–330. [Google Scholar] [CrossRef]

- Antoniou, C.; Kosmadaki, M.G.; Stratigos, A.J.; Katsambas, A.D. Sunscreens—What’s important to know. J. Eur. Acad. Dermatol. Venereol. 2008, 22, 1110–1119. [Google Scholar] [CrossRef] [PubMed]

- Herzog, B.; Wehrle, M.; Quass, K. Photostability of UV absorber systems in sunscreens. Photochem. Photobiol. 2009, 85, 869–878. [Google Scholar] [CrossRef] [PubMed]

- Hojerová, J.; Medovcíková, A.; Mikula, M. Photoprotective efficacy and photostability of fifteen sunscreen products having the same label SPF subjected to natural sunlight. Int. J. Pharm. 2011, 408, 27–38. [Google Scholar] [CrossRef] [PubMed]

- Jarzycka, A.; Lewińska, A.; Gancarz, R.; Wilk, K.A. Assessment of extracts of Helichrysum arenarium, Crataegus monogyna, Sambucus nigra in photoprotective UVA and UVB; photostability in cosmetic emulsions. J. Photochem. Photobiol. B Biol. 2013, 128, 50–57. [Google Scholar] [CrossRef] [PubMed]

- Choquenet, B.; Couteau, C.; Paparis, E.; Coiffard, L.J. Quercetin and rutin as potential sunscreen agents: Determination of efficacy by an in vitro method. J. Nat. Prod. 2008, 71, 1117–1118. [Google Scholar] [CrossRef]

- De Alencar Filho, J.E.M.T.; Sampaio, P.A.; Pereira, E.C.V.; de Oliveira Junior, R.G.; Silva, F.I.S.; da Silva Almeida, J.R.G.; Rolim, L.A.U.; Nunes, X.P.; da Cruz Araujo, E.C. Flavonoids as photoprotective agents: A systematic review. J. Med. Plants Res. 2016, 10, 848–864. [Google Scholar]

- Scalia, S.; Mezzena, M. Photostabilization effect of quercetin on the UV filter combination, butyl methoxydibenzoylmethane–octyl methoxycinnamate. Photochem. Photobiol. 2010, 86, 273–278. [Google Scholar] [CrossRef]

- Kandarova, H.; Willoughby, J.A.; de Jong, W.H.; Letasiova, S.; Milasova, T.; Bachelor, M.A.; Breyfogle, B.; Handa, Y.; de la Fonteyne, L.; Coleman, K.P. Pre-validation of an in vitro skin irritation test for medical devices using the reconstructed human tissue model EpiDerm™. Toxicol. Vitr. 2018, 50, 407–417. [Google Scholar] [CrossRef] [PubMed]

| Components (INCI NAME) | Concentration (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | |

| Tribehenin | 5.0 | 6.0 | 5.0 | 6.0 | - | - | 8.0 | 8.0 | - |

| Sorbitan stearate and sucrose cocoate | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | - | - | 8.0 |

| Sucrose palmitate glyceryl stearate and glyceryl stearate citrate and sucrose and manna and xanthan gum | 5.0 | 5.0 | 3.0 | 3.0 | 5.0 | 2.0 | 5.0 | 2.0 | 0.5 |

| Caprylic and capric triglyceride | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Hydrolyzed wheat protein and PVP cross-polymer | 3.0 | 3.0 | 5.0 | 5.0 | 3.0 | 2.0 | 3.0 | 2.0 | 2.0 |

| Persea gratissima (Avocado) oil | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Phenoxyethanol | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Glycerin | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Talc | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.5 | 1.5 | 1.5 |

| Aqua | 72.0 | 71.0 | 72.0 | 71.0 | 77.0 | 81.0 | 76.5 | 80.5 | 82.0 |

| Formulations | Rupture Strength (G) | Brittleness (mm) | Adhesiveness (g.s) | Firmness (G) |

|---|---|---|---|---|

| Plain emulsion | 3.62 ± 1.31 | 19.05 ± 0.76 | −50.18 ± 0.63 | 633.26 ± 0.11 |

| Phytocosmetic | 3.07 ± 0.33 | 16.57 ± 2.90 | −43.01 ± 2.53 | 487.08 ± 0.15 |

| Formulations | Enthalpy Variation | |

|---|---|---|

| Stage 1 (°C) | Stage 2 (°C) | |

| Plain emulsion | 51.66 | 120.93 |

| Phytocosmetic | 52.65 | 113.77 |

| Formulation | TM (°C) Stage 1 | Weight Loss (%) | TM (°C) Stage 2 | Weight Loss (%) | TM (°C) Stage 3 | Weight Loss (%) |

|---|---|---|---|---|---|---|

| Plain emulsion | 87.89 | 86.64 | 167.83 | 3.94 | 278.22 | 4.21 |

| Phytocosmetic | 82.76 | 79.87 | 166.97 | 4.53 | 273.20 | 5.82 |

| Samples | Cell Viability (%) ± SD |

|---|---|

| Formulation with extracts | 104.6 ± 7.5 |

| Negative control | 100.0 ± 2.9 |

| Positive control | 1.1 ± 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cefali, L.C.; Ataide, J.A.; Fernandes, A.R.; Sousa, I.M.d.O.; Gonçalves, F.C.d.S.; Eberlin, S.; Dávila, J.L.; Jozala, A.F.; Chaud, M.V.; Sanchez-Lopez, E.; et al. Flavonoid-Enriched Plant-Extract-Loaded Emulsion: A Novel Phytocosmetic Sunscreen Formulation with Antioxidant Properties. Antioxidants 2019, 8, 443. https://doi.org/10.3390/antiox8100443

Cefali LC, Ataide JA, Fernandes AR, Sousa IMdO, Gonçalves FCdS, Eberlin S, Dávila JL, Jozala AF, Chaud MV, Sanchez-Lopez E, et al. Flavonoid-Enriched Plant-Extract-Loaded Emulsion: A Novel Phytocosmetic Sunscreen Formulation with Antioxidant Properties. Antioxidants. 2019; 8(10):443. https://doi.org/10.3390/antiox8100443

Chicago/Turabian StyleCefali, Letícia Caramori, Janaína Artem Ataide, Ana Rita Fernandes, Ilza Maria de Oliveira Sousa, Fernanda Cristina da Silva Gonçalves, Samara Eberlin, José Luis Dávila, Angela Faustino Jozala, Marco Vinicius Chaud, Elena Sanchez-Lopez, and et al. 2019. "Flavonoid-Enriched Plant-Extract-Loaded Emulsion: A Novel Phytocosmetic Sunscreen Formulation with Antioxidant Properties" Antioxidants 8, no. 10: 443. https://doi.org/10.3390/antiox8100443

APA StyleCefali, L. C., Ataide, J. A., Fernandes, A. R., Sousa, I. M. d. O., Gonçalves, F. C. d. S., Eberlin, S., Dávila, J. L., Jozala, A. F., Chaud, M. V., Sanchez-Lopez, E., Marto, J., d’Ávila, M. A., Ribeiro, H. M., Foglio, M. A., Souto, E. B., & Gava Mazzola, P. (2019). Flavonoid-Enriched Plant-Extract-Loaded Emulsion: A Novel Phytocosmetic Sunscreen Formulation with Antioxidant Properties. Antioxidants, 8(10), 443. https://doi.org/10.3390/antiox8100443