Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development

Abstract

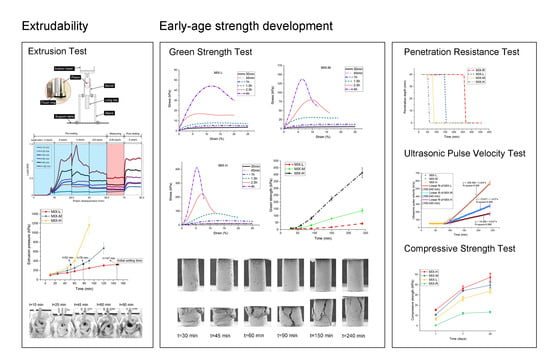

:1. Introduction

2. Materials and Methods

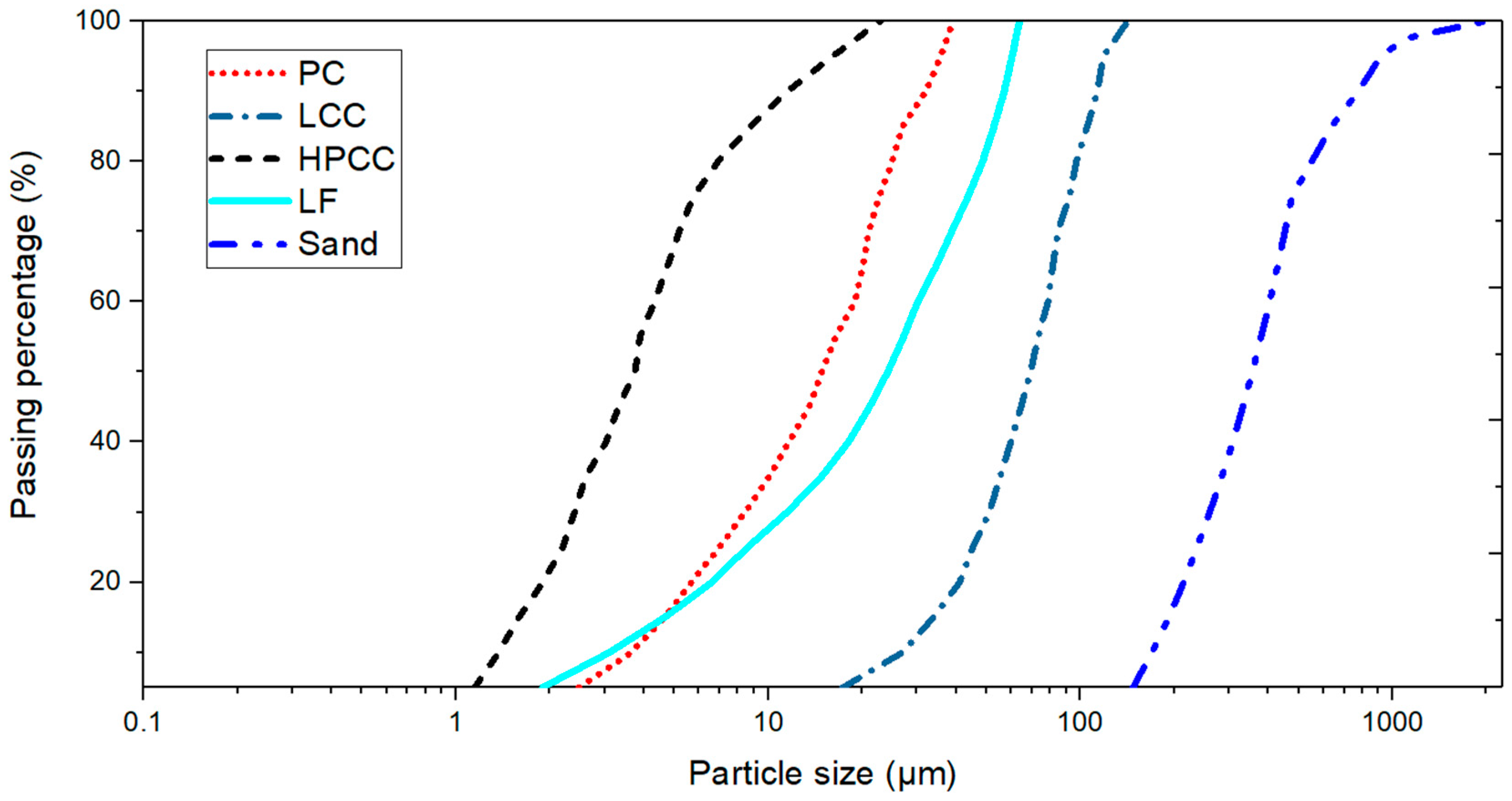

2.1. Raw Materials

2.2. Mix Designs and Preparation of Fresh Materials

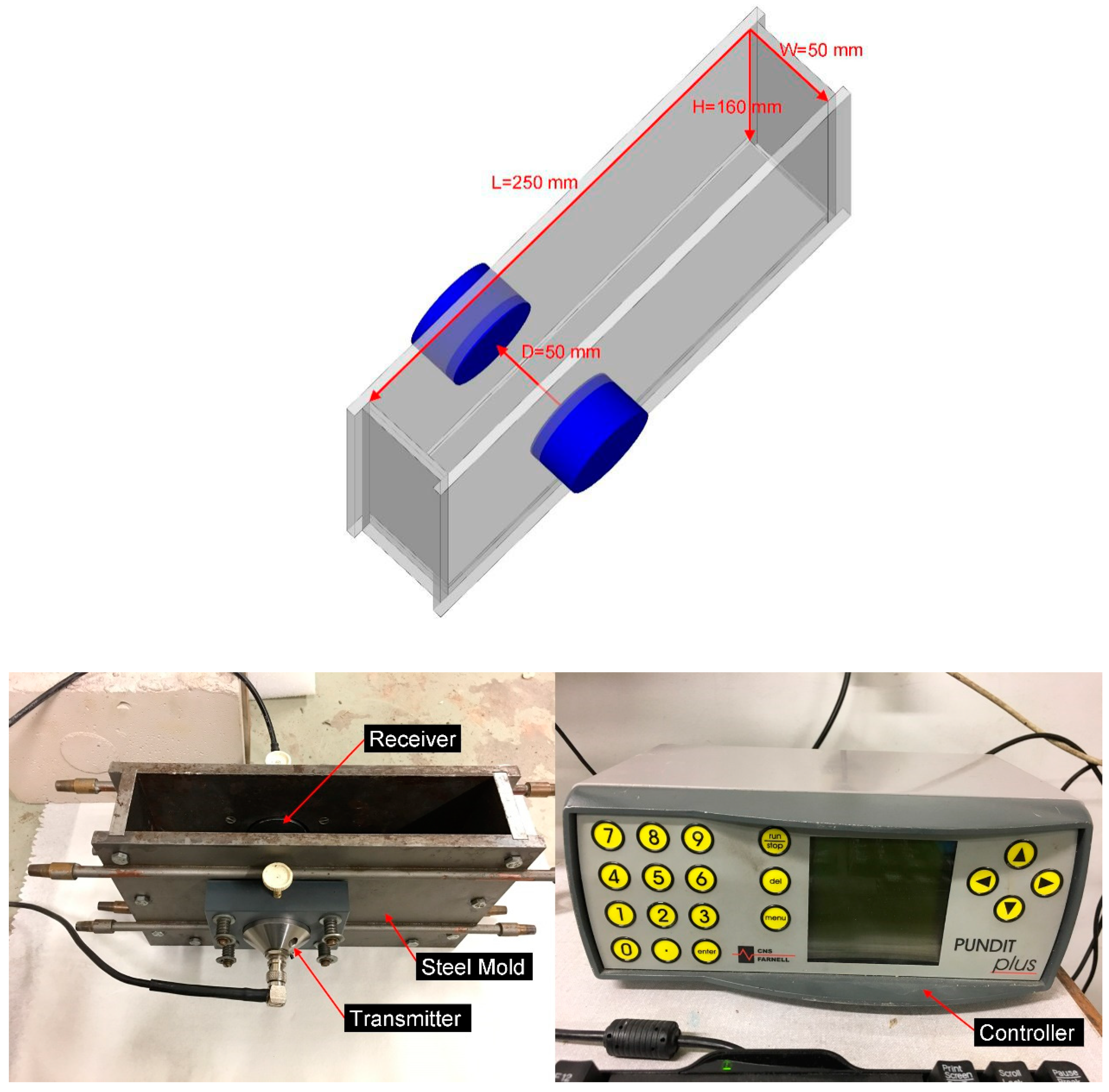

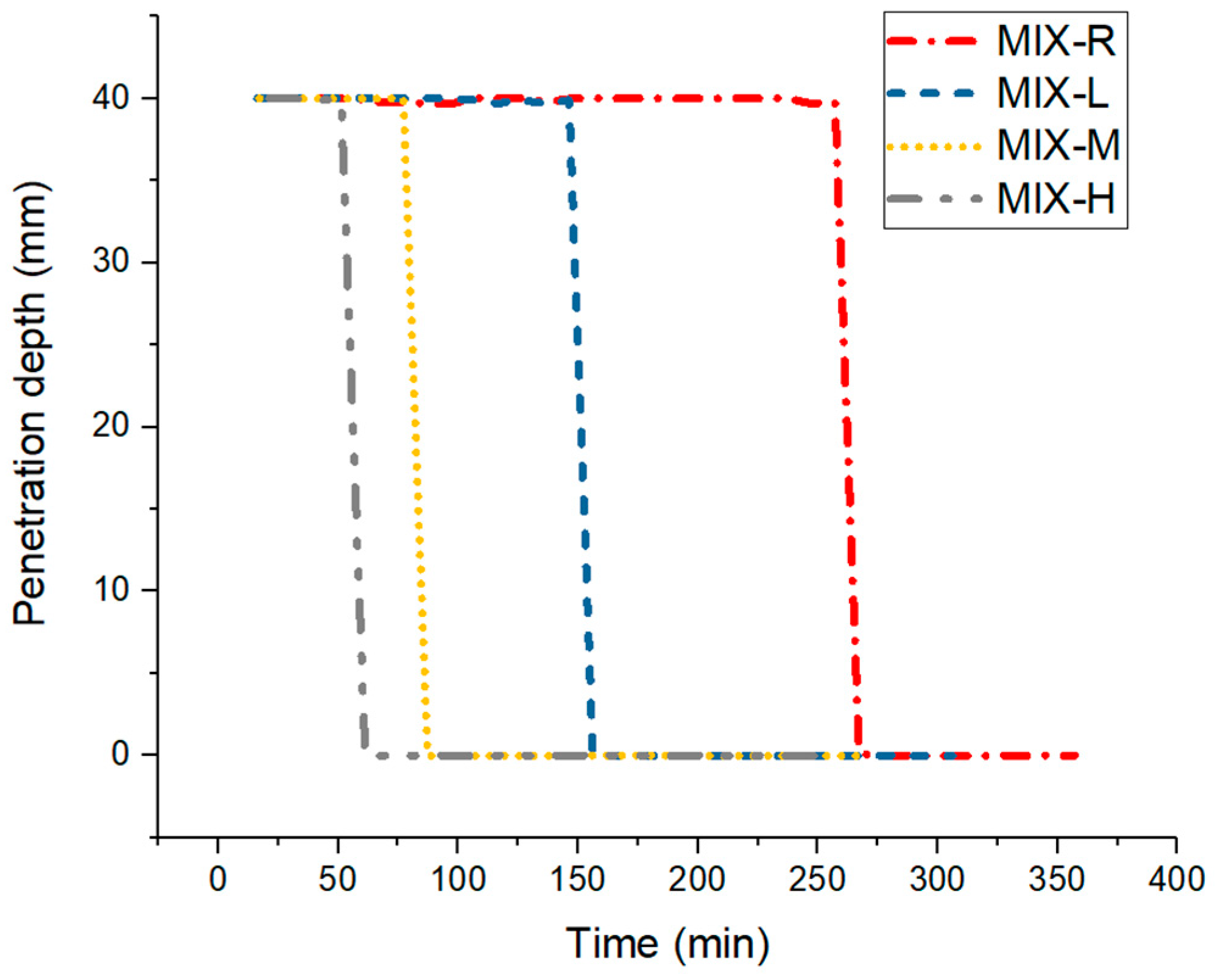

2.3. Penetration Resistance Test

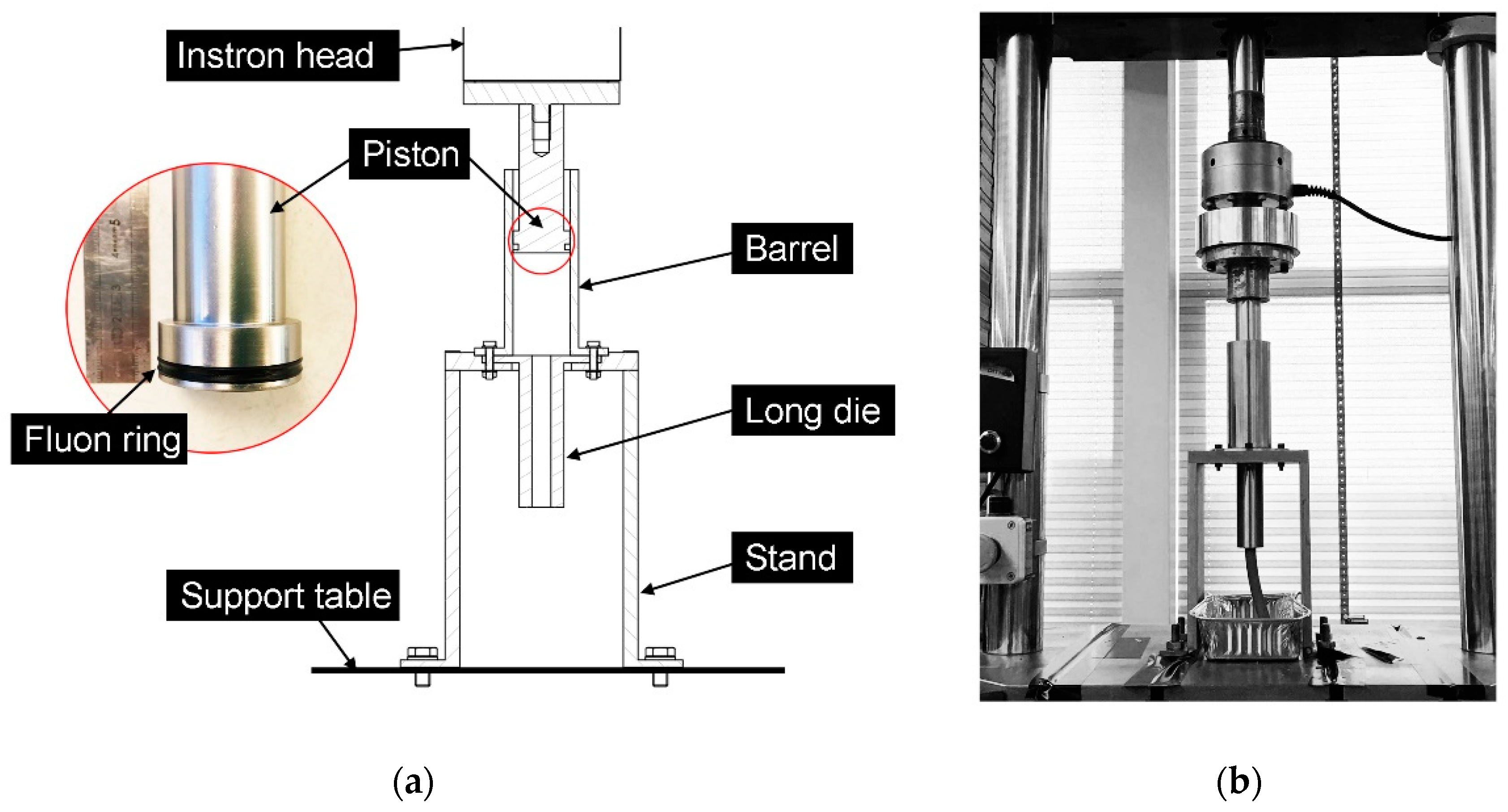

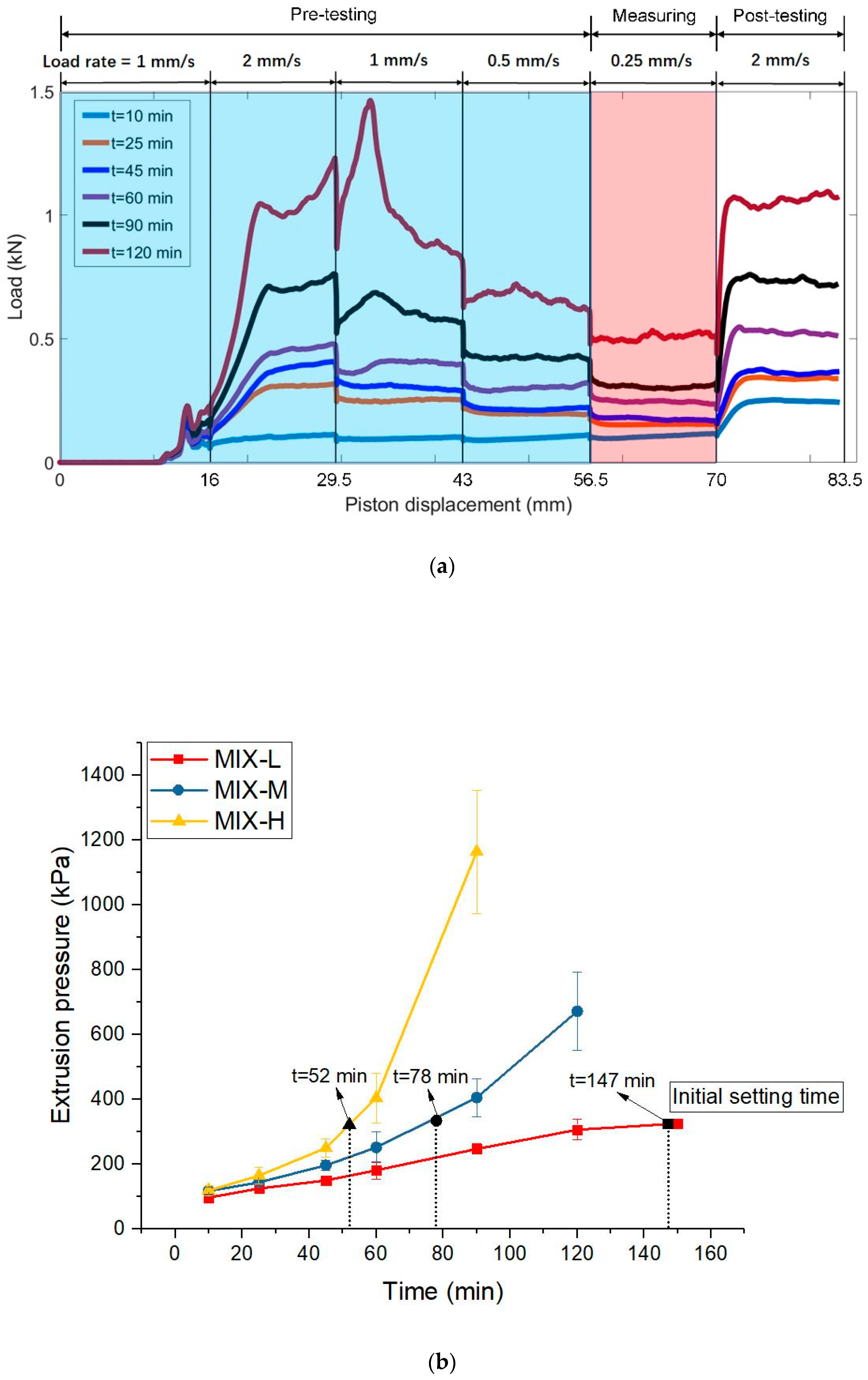

2.4. Extrusion Test

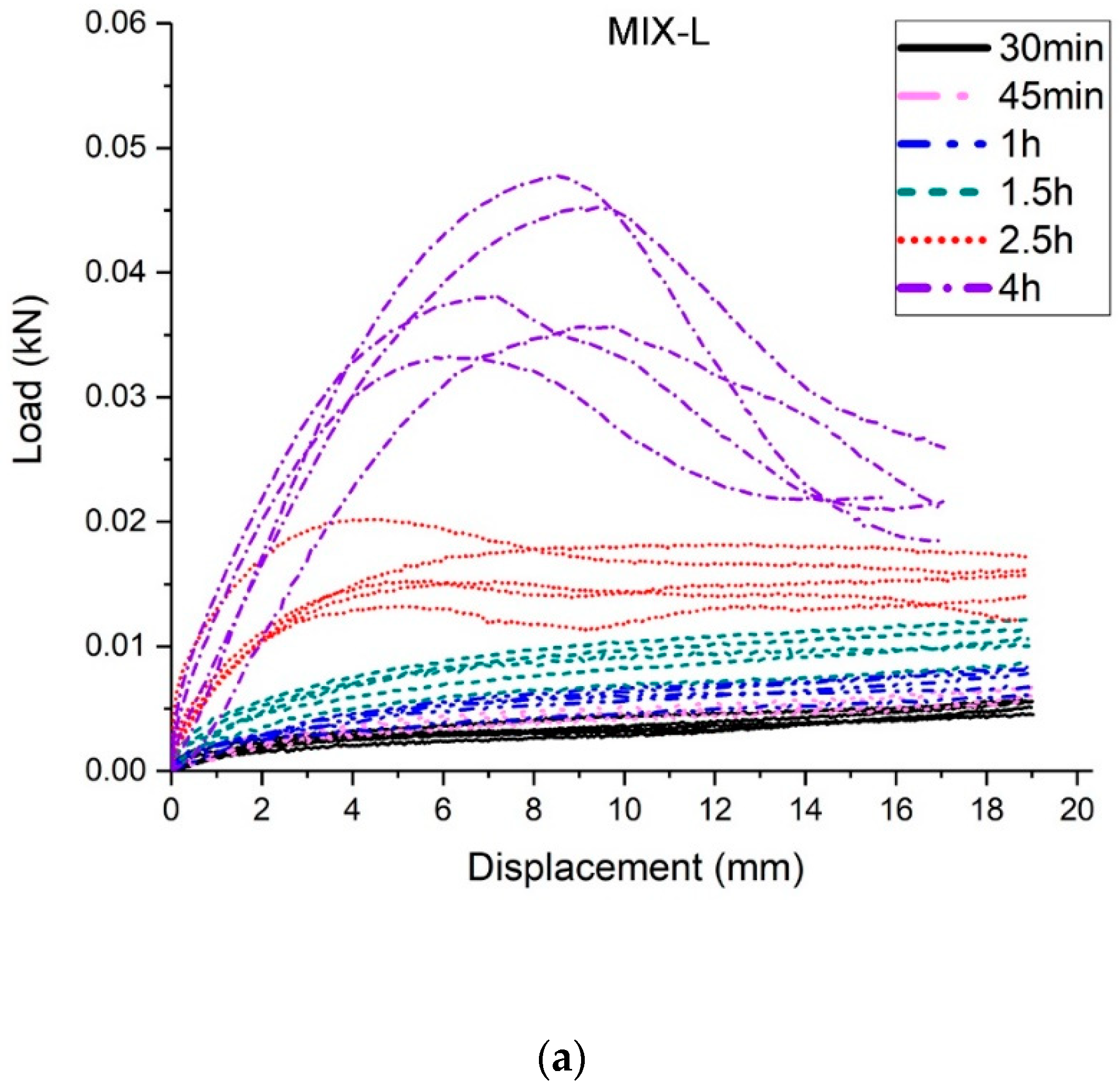

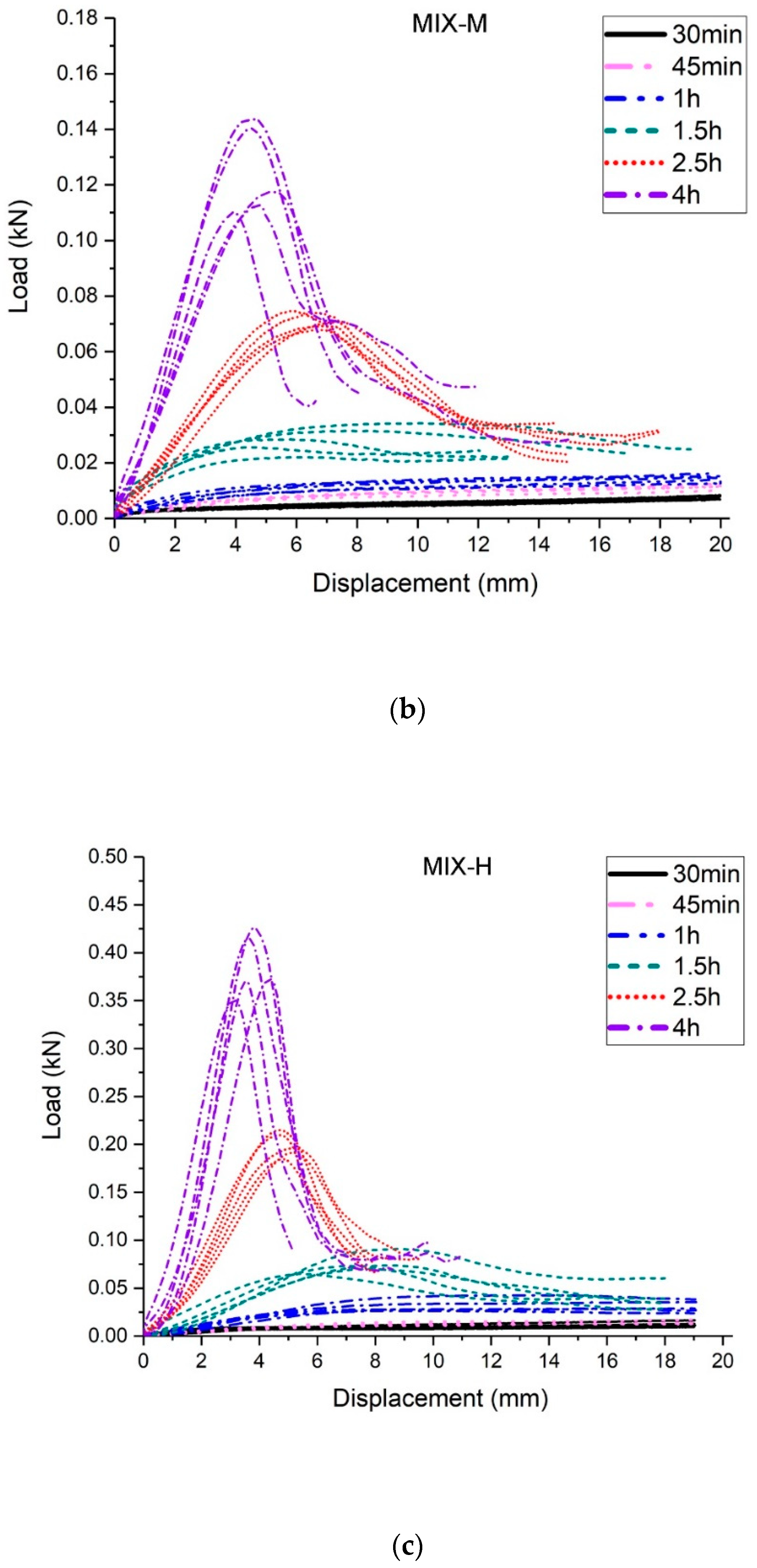

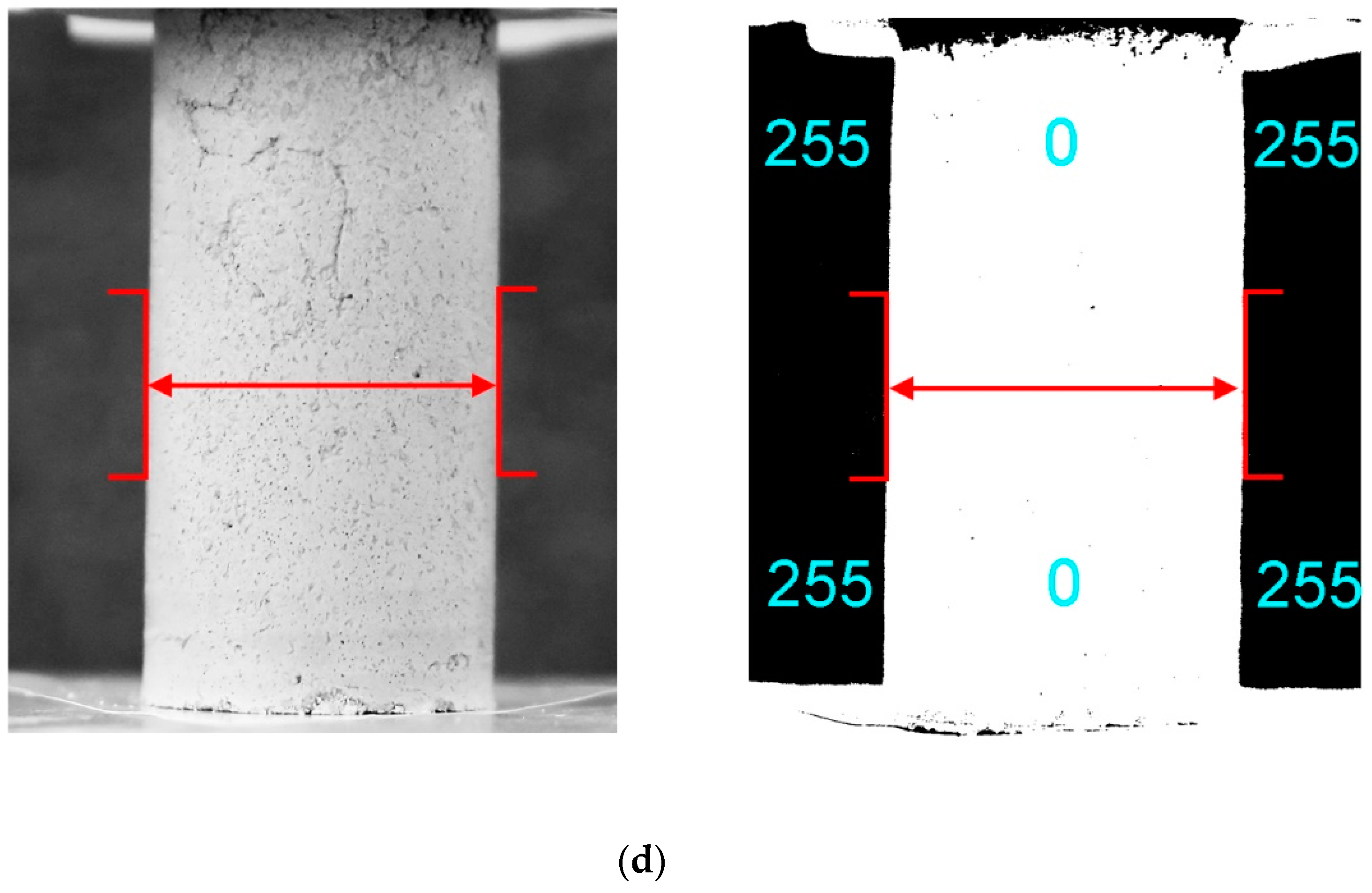

2.5. Green Strength Test

2.6. Ultrasonic Pulse Velocity Test

2.7. Compressive Strength Test

3. Results and Discussion

3.1. Penetration Resistance Test

3.2. Extrusion Test

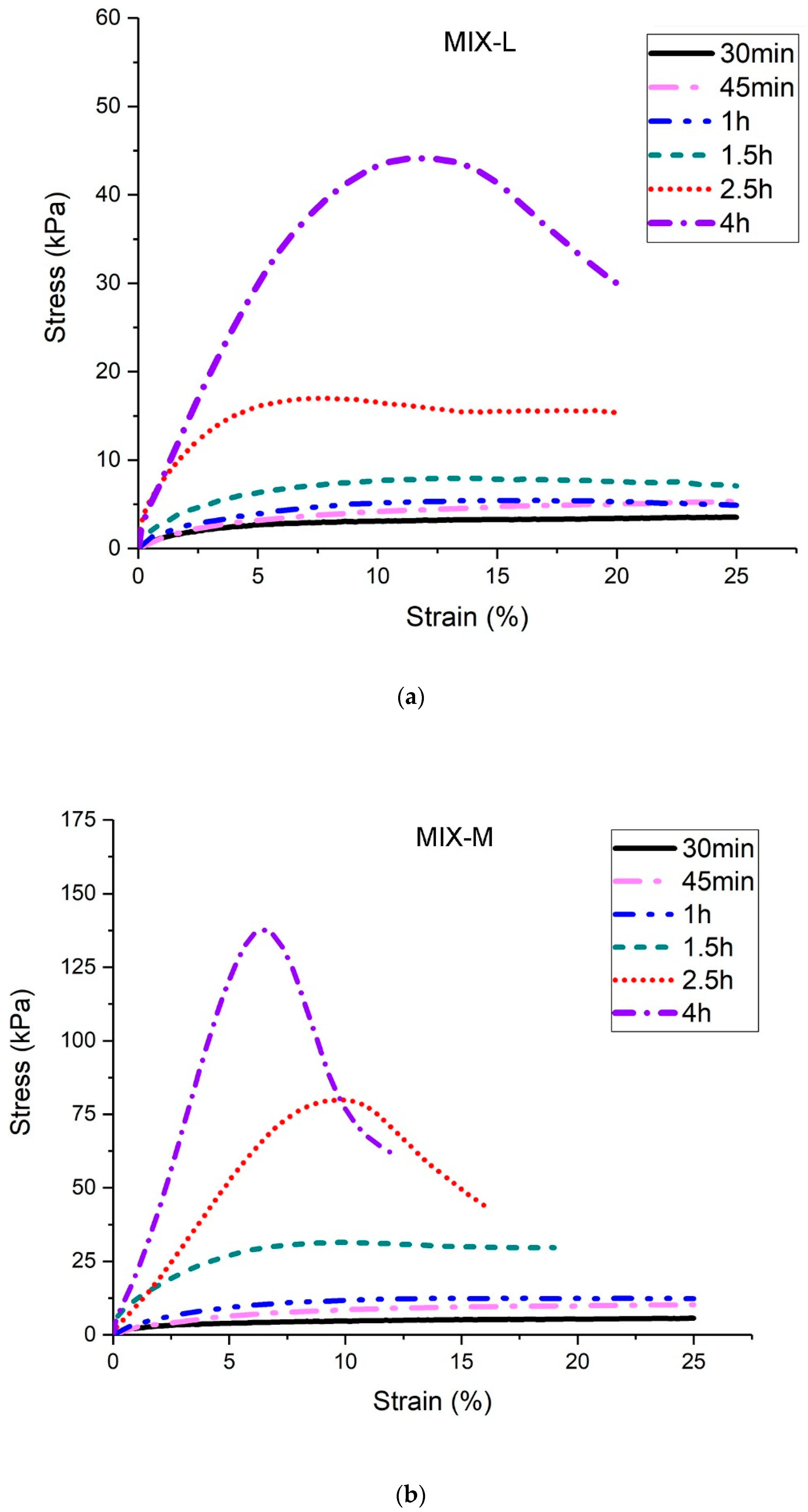

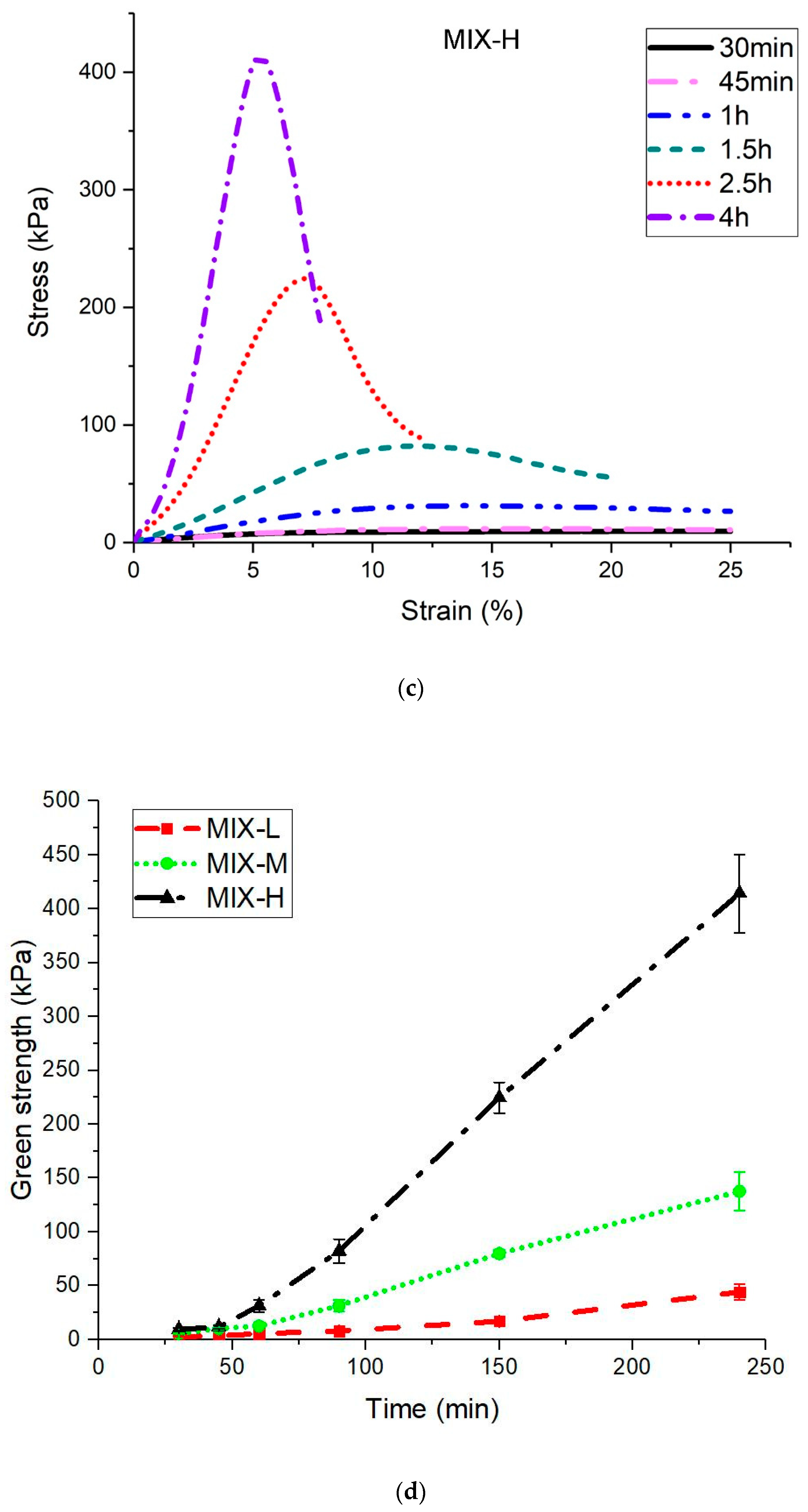

3.3. Green Strength Test

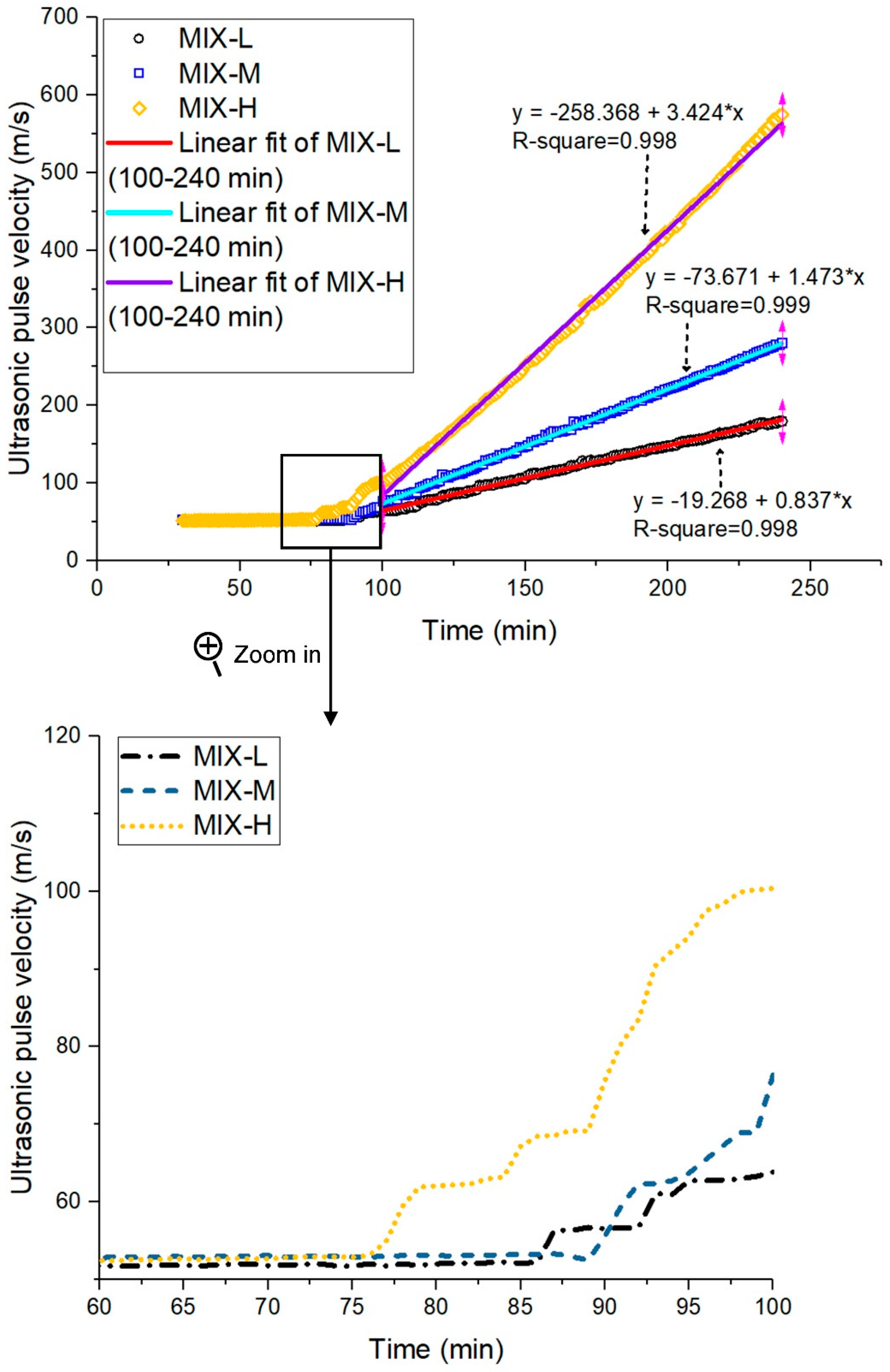

3.4. Ultrasonic Pulse Velocity Test

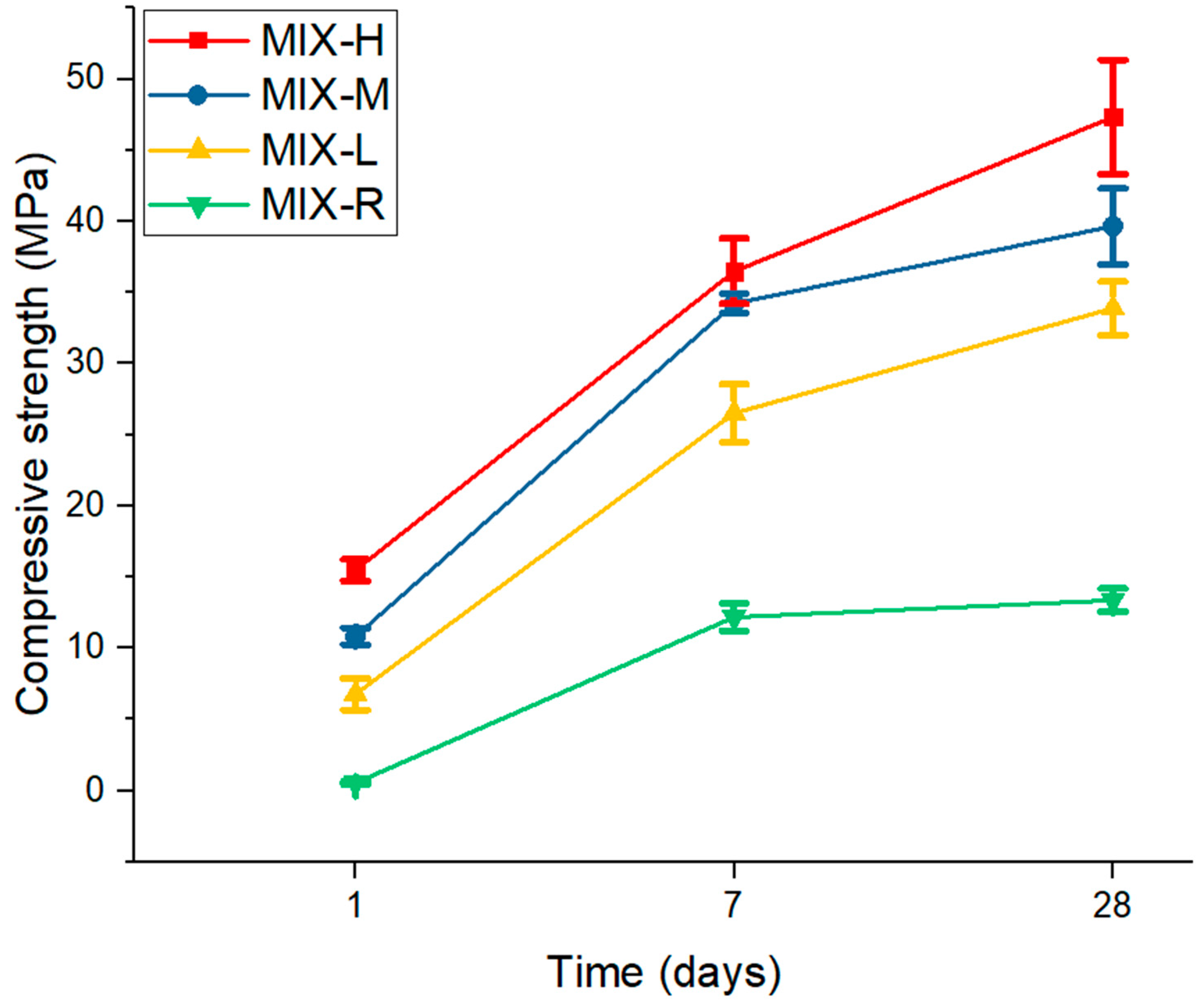

3.5. Compressive Strength at 1, 7 and 28 Days

4. Conclusions

- A lab-scale extrusion test method based on the ram extruder was proposed in this study to efficiently observe the extruded filaments of the fresh mixture and quantify the required extrusion pressures at different ages. Mixtures MIX-L, MIX-M, and MIX-H showed good shape stability at the ages before their initial setting time. The extrusion pressures and the growth rate of pressure with time were significantly increased by increasing the MK content in calcined clay. Thus, using a higher grade of calcined clay may increase the extrusion shear strength of fresh mixtures which may bring difficulties for extruding and reduce the printability window/open time.

- According to all results found during this study, increasing the MK dosage in calcined clay could significantly accelerate the initial cement hydration. Consequently, higher mechanical performance in the early stages (green strength) were achieved. Moreover, the buildability and structural build-up behavior of mix designs for 3DCP could be enhanced by using higher grades of calcined clay.

- Compared with mixture MIX-R, mix designs with calcined clay showed shorter initial setting time and higher compressive strength at 1, 7, and 28 days.

- Increasing the content of MK in calcined clay could significantly reduce the initial setting time and increase the compressive strength at 1, 7, and 28 days.

- Within the first 4h, the filler effect of the calcined clay may play a dominant role to promote the phase change of flocculation, nucleation and structuration of cement particles from the microstructure view. Increasing the percentage of MK in calcined clay could increase the content of very small particles in the binder system, which may enhance nucleation and facilitate the microstructure development.

- Overall, it is essential to find the balance between extrudability and early-age strength to apply the discussed mix designs in 3DCP. Results of this research showed that the MK content of calcined clay plays a key role in the performance of printable cementitious mortars.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Chen, Y.; Veer, F.; Copuroglu, O. A Critical Review of 3D Concrete Printing as a Low CO2 Concrete Approach. Heron 2017, 62, 167–194. [Google Scholar]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T.; Kwan, A.H.K.; Wu, S.K. Substituting local data for overseas life cycle inventories—A case study of concrete products in Hong Kong. J. Clean. Prod. 2015, 87, 414–422. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.; Unluer, C.; Jen, M. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part B 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Material properties of 3D printable high-volume slag cement. In Proceedings of the First International Conference on 3D Construction Printing (3DcP) in Conjunction with the 6th International Conference on Innovative Production and Construction (IPC 2018), Melbourne, Australia, 26–28 November 2018. [Google Scholar]

- Bentz, D.P.; Jones, S.Z.; Bentz, I.R.; Peltz, M.A. Towards the formulation of robust and sustainable cementitious binders for 3-D additive construction by extrusion. Constr. Build. Mater. 2018, 175, 215–224. [Google Scholar] [CrossRef]

- Glavind, M. Sustainability of Cement, Concrete and Cement Replacement Materials in Construction; Woodhead Publishing Limited: Cambridge, UK, 2009; ISBN 978-1-84569-349-7. [Google Scholar]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Snellings, R. Assessing, Understanding and Unlocking Supplementary Cementitious Materials. Rilem Tech. Lett. 2016, 1, 50–55. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Chen, Y.; Veer, F.; Copuroglu, O.; Schlangen, E. Feasibility of Using Low CO2 Concrete Alternatives in Extrusion-Based 3D Concrete Printing. In Proceedings of the RILEM International Conference on Concrete and Digital Fabrication, Zurich, Switzerland, 10–12 September 2018; pp. 269–276. [Google Scholar]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljković, M.; Zuo, Y.; Ye, G. A Review on the Durability of Alkali-Activated Fly Ash/Slag Systems: Advances, Issues, and Perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Alujas Diaz, A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Nerella, V.N.; Beigh, M.A.B.; Fataei, S.; Mechtcherine, V. Strain-based approach for measuring structural build-up of cement pastes in the context of digital construction. Cem. Concr. Res. 2018, 115, 530–544. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Z.; Fan, M.; Chen, H. Rheology of semi-solid fresh cement pastes and mortars in orifice extrusion. Cem. Concr. Compos. 2013, 37, 304–311. [Google Scholar] [CrossRef]

- Perrot, A.; Mélinge, Y.; Rangeard, D.; Micaelli, F.; Estellé, P.; Lanos, C. Use of ram extruder as a combined rheo-tribometer to study the behaviour of high yield stress fluids at low strain rate. Rheol. Acta 2012, 51, 743–754. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Voigt, T.; Malonn, T.; Shah, S.P. Green and early age compressive strength of extruded cement mortar monitored with compression tests and ultrasonic techniques. Cem. Concr. Res. 2006, 36, 858–867. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Correlation between destructive compression tests and non-destructive ultrasonic measurements on early age 3D printed concrete. Constr. Build. Mater. 2018, 181, 447–454. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical deformation of metakaolin based geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- NEN-EN 196-2 Method of Testing Cement—Part 2: Chemical Analysis of Cement; NEN: Delft, The Netherlands, 2013.

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Rodrıguez, C.R.; Ahmed, Z.Y.; Bos, D.H.; Xu, Y.; Salet, T.A.M.; Copuroglu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2017, 12, 1–19. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- NEN-EN 196-3—Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness; NEN: Delft, The Netherlands, 2017.

- NEN-EN 12504-4:2005—Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity; NEN: Delft, The Netherlands, 2005.

- NEN-EN 196-1—Methods of Testing Cement—Part 1: Determination of Strength; NEN: Delft, The Netherlands, 2016.

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Panda, B.; Hui, L.J.; Tan, M.J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. Part B Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

| Oxide (wt. %) | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | TiO2 | ZrO2 | Other | Total |

|---|---|---|---|---|---|---|---|---|---|

| PC | 17.4 | 4.1 | 68.7 | 2.8 | 0.6 | 0.3 | 0 | 6.1 | 100.0 |

| LF | 0.2 | 0 | 39.6 | 0.1 | 0 | 0 | 0 | 60.1 | 100.0 |

| LCC | 55.1 | 38.4 | 0.6 | 2.6 | 0.2 | 1.1 | 0.1 | 1.9 | 100.0 |

| HPCC | 47.3 | 50.6 | 0 | 0.5 | 0.2 | 1.3 | 0 | 0.1 | 100.0 |

| Components (wt. %) | I.R. | Reactive Content | Reactive SiO2 | Reactive Al2O3 | Other Reactive Phases |

|---|---|---|---|---|---|

| LCC | 51.2 | 48.8 | 12.3 | 32.0 | 4.5 |

| HPCC | 24.9 | 75.1 | 34.6 | 39.9 | 0.6 |

| Type | PC | Calcined Clay | LF | Sand | Water | PCE | VMA | |

|---|---|---|---|---|---|---|---|---|

| (kg/m3) | LCC (kg/m3) | HPCC (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | |

| MIX-R | 331 | 0 | 0 | 497 | 1242 | 248 | 17 | 2 |

| MIX-L | 331 | 331 | 0 | 166 | 1242 | 248 | 17 | 2 |

| MIX-M | 331 | 248 | 83 | 166 | 1242 | 248 | 17 | 2 |

| MIX-H | 331 | 166 | 165 | 166 | 1242 | 248 | 17 | 2 |

| Time (min:s) | Steps Followed |

|---|---|

| -4:00 | Homogenizing dry components, mixing with the low speed by a planetary mixer (HOBART). |

| 0:00 | While mixing with the low speed, add the blended liquid (water and superplasticizer). |

| 4:00 | Pause, scraping the walls and blade (A dough-like mixture is generated). |

| 4:30 | Mixing with the high speed. (until the dough-like material adhere to the walls of the bowl). |

| 8:00 | Stop, start to fill molds or do other tests |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Li, Z.; Chaves Figueiredo, S.; Çopuroğlu, O.; Veer, F.; Schlangen, E. Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Appl. Sci. 2019, 9, 1809. https://doi.org/10.3390/app9091809

Chen Y, Li Z, Chaves Figueiredo S, Çopuroğlu O, Veer F, Schlangen E. Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Applied Sciences. 2019; 9(9):1809. https://doi.org/10.3390/app9091809

Chicago/Turabian StyleChen, Yu, Zhenming Li, Stefan Chaves Figueiredo, Oğuzhan Çopuroğlu, Fred Veer, and Erik Schlangen. 2019. "Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development" Applied Sciences 9, no. 9: 1809. https://doi.org/10.3390/app9091809

APA StyleChen, Y., Li, Z., Chaves Figueiredo, S., Çopuroğlu, O., Veer, F., & Schlangen, E. (2019). Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Applied Sciences, 9(9), 1809. https://doi.org/10.3390/app9091809