Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application

Abstract

:1. Introduction—Strengthening of Concrete Buildings—Why and How

- Corrosion of the steel reinforcement; it can occur because of carbonation of concrete, the choice of unfavorable materials, insufficient concrete cover, or too wide cracks.

- Insufficient load-bearing capacity; this mostly results from the loads which have steadily increased over the decades and which must be taken into account according to the standard. One example is the increased axle loads of trucks. About 100 years ago, the total weight of commercial vehicles was about 10 tons. Today, gigaliners with total weights of up to 60 tons are under discussion worldwide; however, their traffic-legal approval is the responsibility of national authorities.

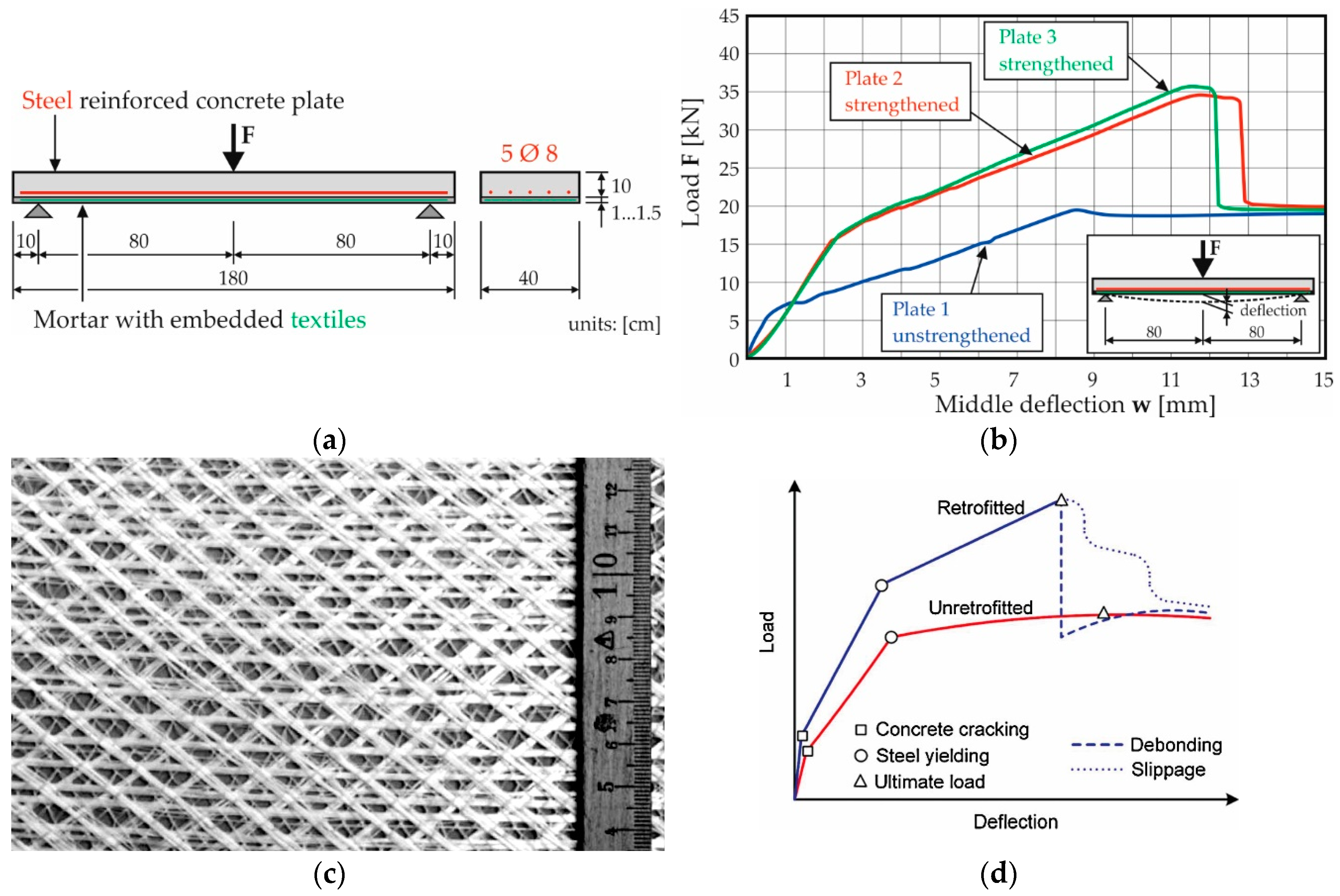

2. Research on Flexural Strengthening with Textile Reinforced Concrete

- Initial cracking at a higher load level,

- Reduction of deflection (at same reference load),

- Increase of the bearable load until failure.

- Similar to RC and steel reinforcement—exceeding the tensile strength of the textile reinforcement; this failure is indicated by increasing crack formation and deflection and is the quasi 𠆌wanted𠆍 failure form; the load-deformation behavior is essentially determined by the mechanical properties of the textile reinforcement (tensile strength, modulus of elasticity).

- Forms of failure due to the transfer of forces from the strengthening layer into the reinforced concrete base body:

- ○

- Failure inside the old concrete (that means the concrete of the structural member to be strengthened fails first, often near the joint between old and new concrete; it is known also from other strengthening methods),

- ○

- Delamination in the joint between old concrete and TRC layer in the end anchorage area or at opening cracks,

- ○

- Delamination or debonding within the TRC layer (usually in the plane of the most stressed textile grid),

- ○

- Extraction of the reinforcement from the matrix (“slippage” of the fibres through the mortar in Figure 1d).

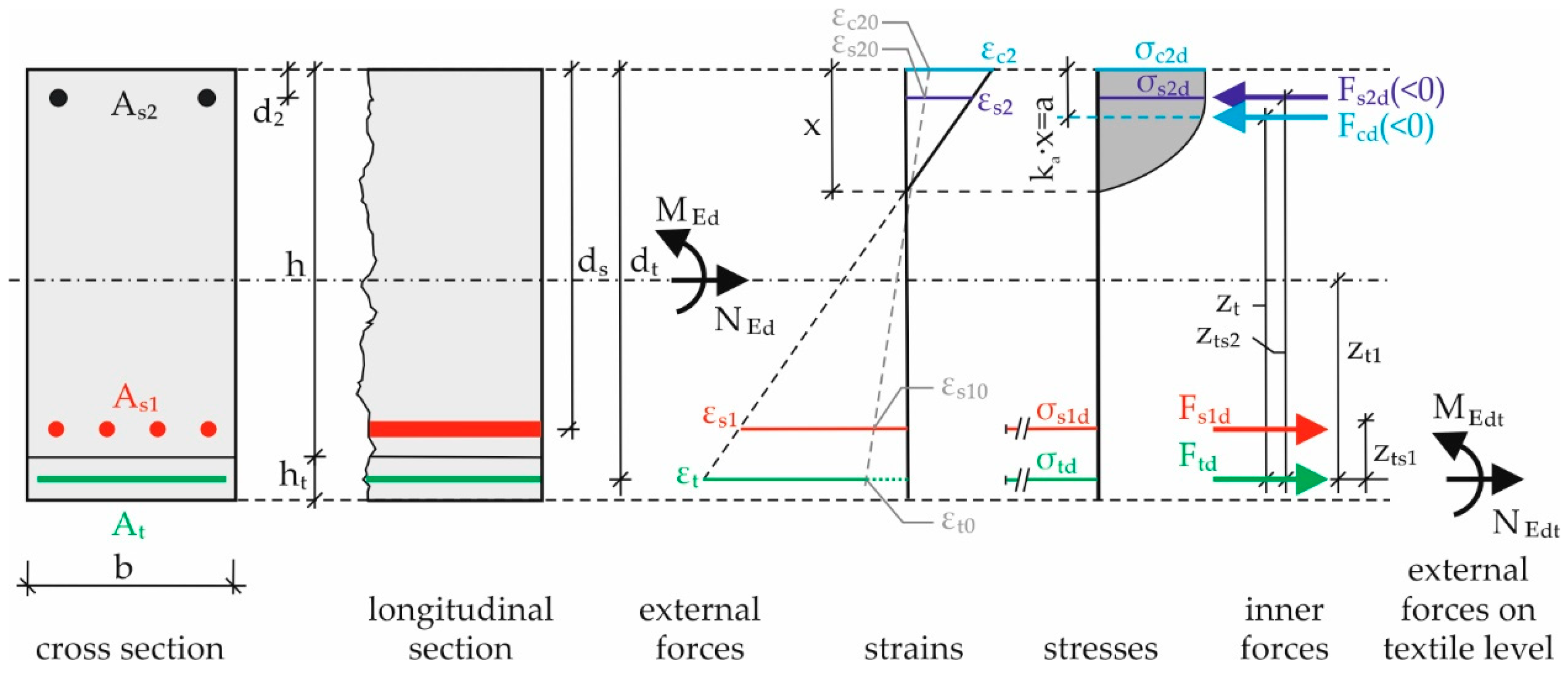

3. Design Concept for Flexural Strengthening of Reinforced Concrete (RC) Components with Textile Reinforced Concrete (TRC)

3.1. General Information

- Cross sections remain plane (Bernoulli hypothesis).

- Strain compatibility between reinforcement and concrete is assumed.

- The concrete’s tensile strength is ignored; all tensile forces are taken up by steel and textile reinforcements.

- Rigid bond between steel, concrete, and textile reinforcement may be assumed.

- The design is carried out at the ultimate limit state (ULS), i.e. at least one material (concrete, reinforcing steel, or textile reinforcement) reaches the ultimate strain.

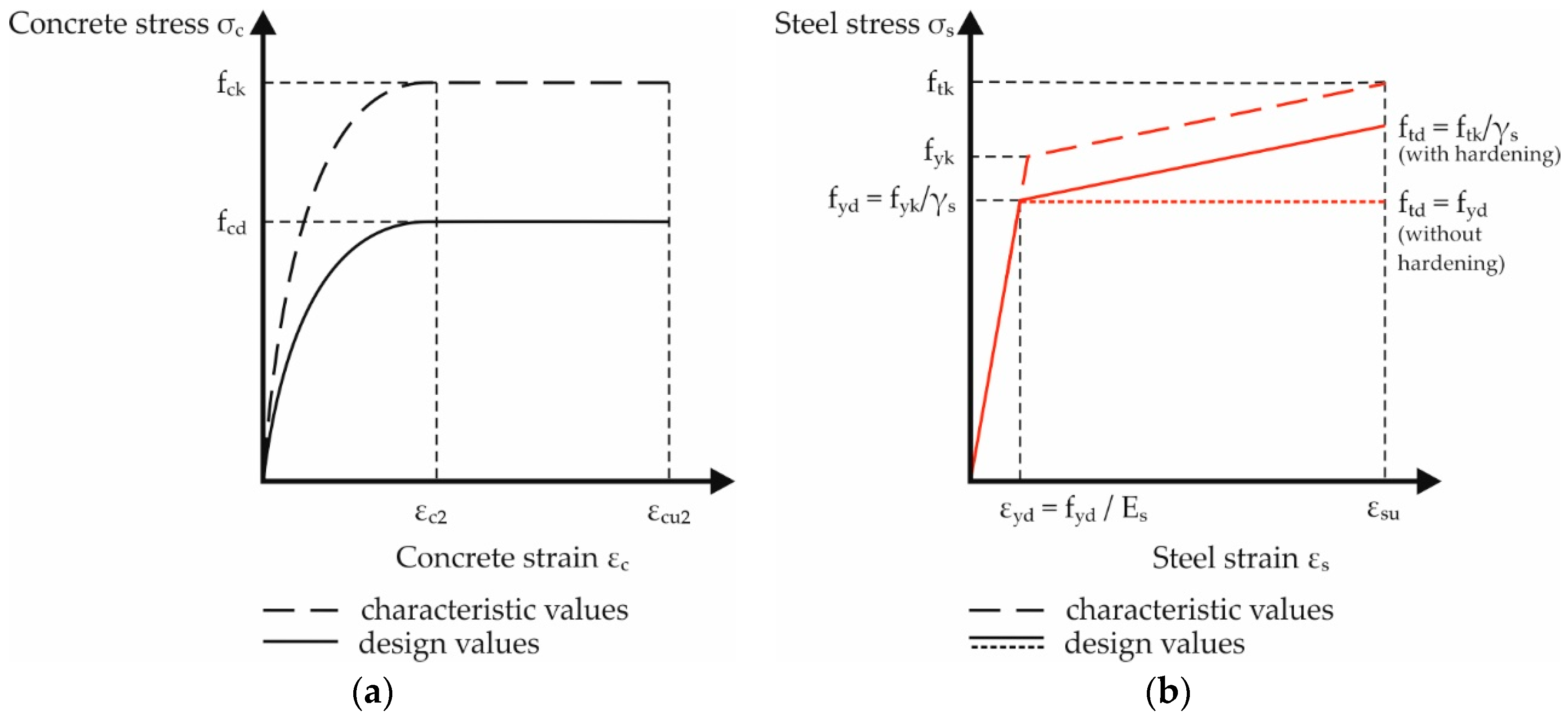

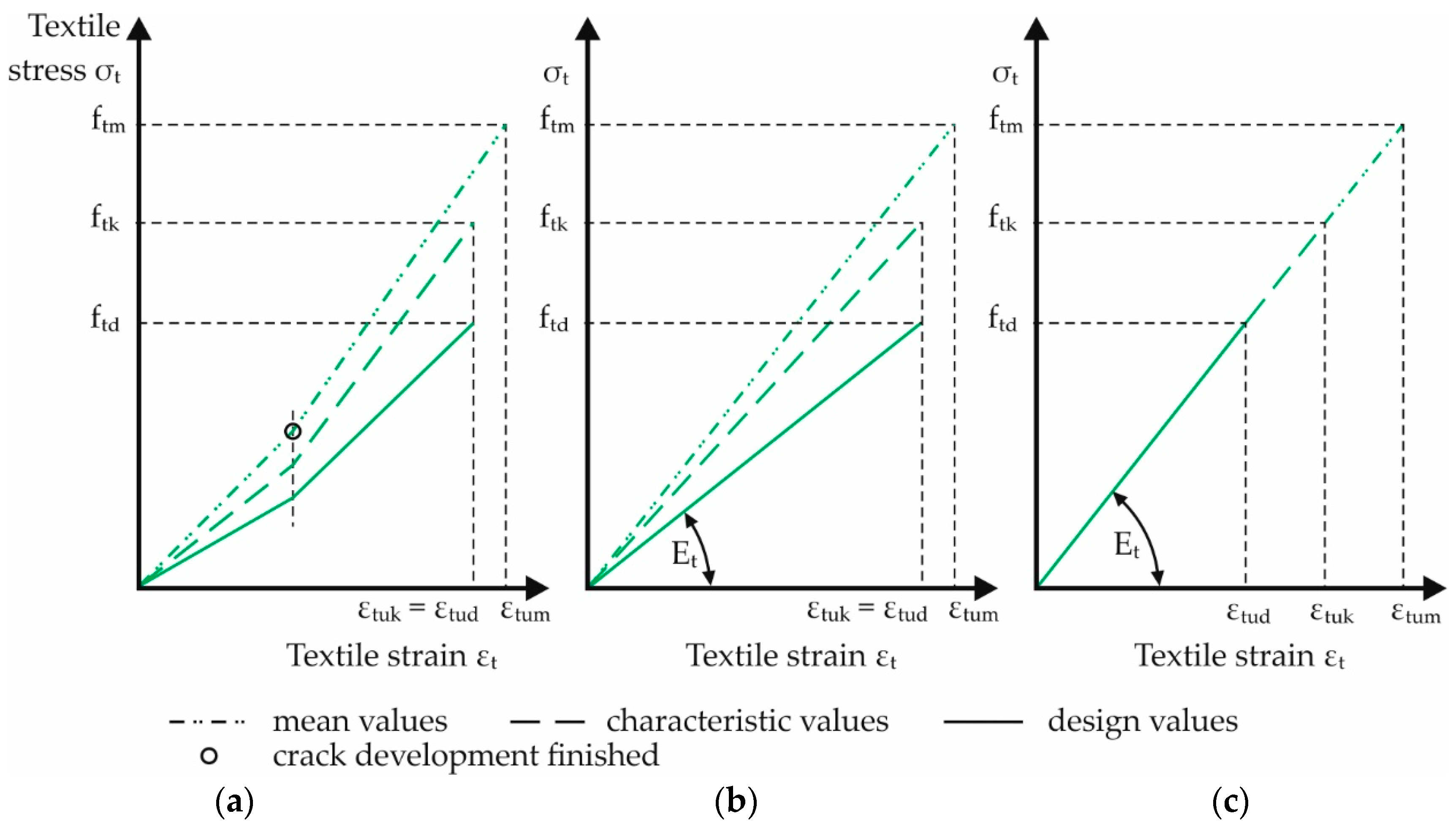

3.2. Material Models

3.3. Calculation Model

3.3.1. Iteration Process

3.3.2. Design Tables for Calculation

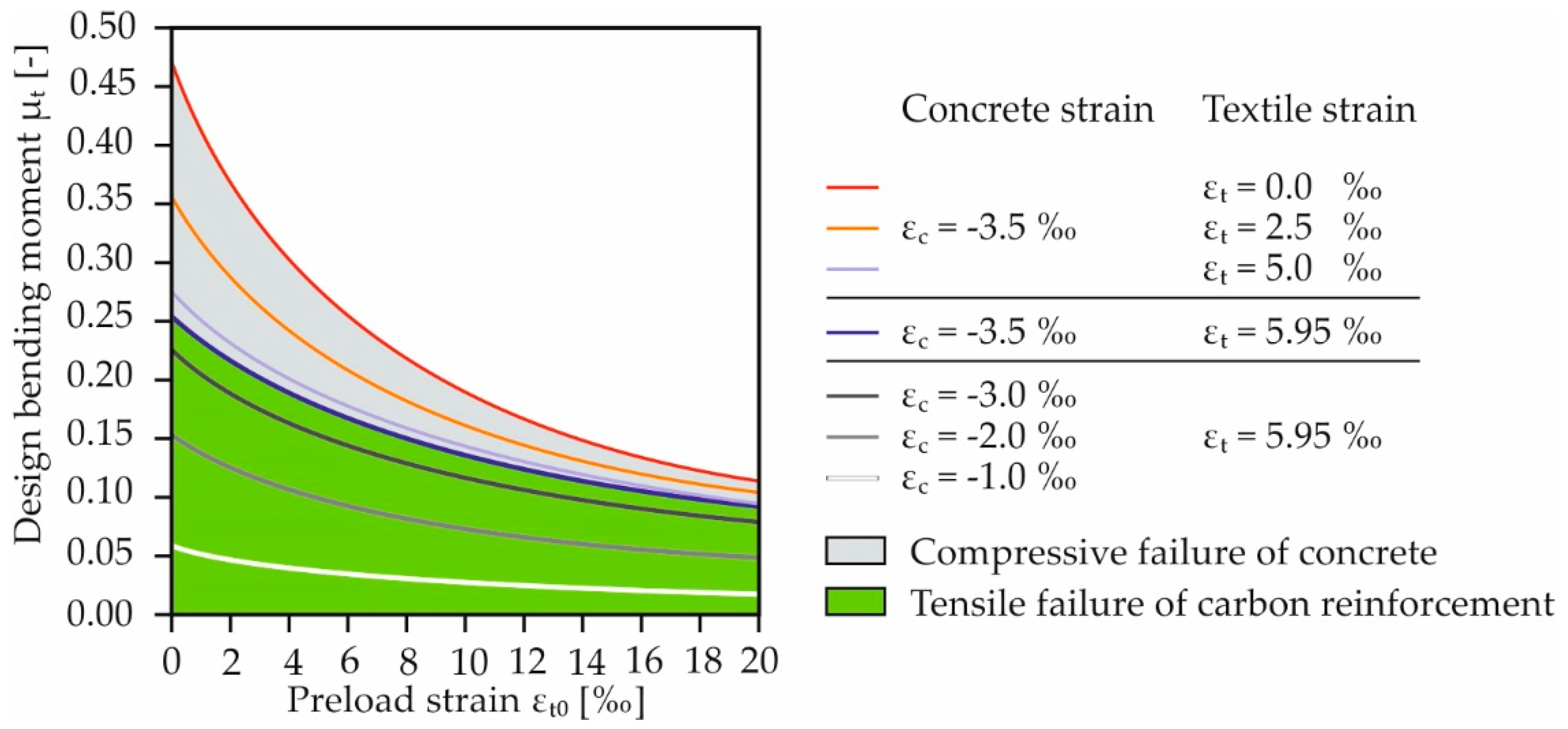

3.3.3. Consideration of a Preload εt0

3.4. Special Aspects to be Taken into Account When Applying the Design Proposal

3.4.1. Influence of the Used Stress–Strain Relationship for the Textile Reinforcement

3.4.2. Partial Safety Factor for Carbon Textiles

4. Practical Applications

5. Outlook on Current Research and Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Béguin, G.H. Various Schemes for Strengthening Concrete Structures. Pract. Period. Struct. Des. Constr. 2018, 23. [Google Scholar] [CrossRef]

- Teichert, P. Die Geschichte des Spritzbetons. Schweizer Ingenieur Architekt 1979, 97, 949–960. [Google Scholar] [CrossRef]

- ACI (Ed.) ACI 506R-05. 2005—Guide to Shotcrete; ACI Commitee Report; ACI: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Jesse, F.; Kaplan, F. Verfahren für Biegeverstärkungen an Stahlbetonbauteilen. Bautechnik 2011, 88, 433–442. [Google Scholar] [CrossRef]

- Bernard, E.S. (Ed.) Shotcrete: Elements of a System. In Proceedings of the Third International Conference on Engineering Developments in Shotcrete, Queenstown, New Zealand, 15–17 March 2010; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Swamy, R.; Jones, R.; Bloxham, J. Structural behavior of reinforced concrete beams strengthened by epoxy-bonded steel plates. Struct. Eng. 1987, 65A, 59–68. [Google Scholar]

- Chen, J.F.; Teng, J.G. Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Oehlers, D.J.; Seracino, R. Design of FRP and Steel Plated RC Structures—Retrofitting Beams and Slabs for Strength, Stiffness and Ductility; Elsevier: Oxford, UK, 2004. [Google Scholar]

- DAfStb [German Association for Steel Reinforced Concrete] (Ed.) Verstärken von Betonbauteilen mit Geklebter Bewehrung—Parts 1–4; Technical Rule of DAfStb; Beuth: Berlin, Germany, March 2012. [Google Scholar]

- fib (Ed.) Externally Bonded FRP Reinforcement for RC Structures; fib Bulletin No. 14; Technical Report; fib: Lausanne, Switzerland, 2001. [Google Scholar]

- fib (Ed.) Retrofitting of Concrete Structures by Externally Bonded FRPs, with Emphasis on Seismic Applications; fib Bulletin No. 35; Technical Report; fib: Lausanne, Switzerland, 2006. [Google Scholar]

- Hollaway, L.C.; Leeming, M. (Eds.) Strengthening of Reinforced Concrete Structures—Using Externally-Bonded Frp Composites in Structural and Civil Engineering; Woodhead Publ.: Cambridge, UK, 1999. [Google Scholar]

- Bleibler, A.; Schümperli, E.; Steiner, W. Flat Strip Lamella for Reinforcing Building Components and Method for Their Production. U.S. Patent No. 6,511,727, 28 January 2003. [Google Scholar]

- Rasheed, H.A. Strengthening Design of Reinforced Concrete with FRP; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Design Procedures for the Use of Composites in Strengthening of Reinforced Concrete Structures—State-of-the-Art Report of the RILEM Technical Committee 234-DUC 2016; Pellegrino, C.; Sena-Cruz, J. (Eds.) Springer: Dordrecht, The Netherlands, 2016; ISBN 978-94-017-7335-5. [Google Scholar]

- ACI Committee 440 (Ed.) 440.2R-17: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI Committee: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Jansze, W. Strengthening of Reinforced Concrete Members in Bending by Externally Bonded Steel Plates—Design for Beam Shear and Plate Anchorage. Ph.D. Thesis, Delft University, Delft, The Netherlands, 1997. Available online: http://resolver.tudelft.nl/uuid:ca3ae758-5c6d-4da9-8866-26340c49c9e6 (accessed on 12 January 2019).

- Pelke, E.; Schölch, U. Strengthening the major bridges on the A45 motorway: Recalculation—Immediate measures—Reinforcement concepts. In Taller, Longer, Lighter, Proceedings of the IABSE-IASS Symposium & The 35th Annual Symposium of IABSE & The 52nd Annual Symposium of IASS and Incorporating the 6th International Conference on Space Structures, London, UK, 20–23 September 2011; Hemming Group: London, UK, 2011; book of abstracts: p. 443, full paper 0679 on CD. [Google Scholar]

- Scheerer, S.; Schladitz, F.; Curbach, M. Textile reinforced Concrete—From the idea to a high performance material. In Proceedings of the FERRO-11 & 3rd ICTRC (PRO 98), Aachen, Germany, 7–10 June 2015; Brameshuber, W., Ed.; S.A.R.L. Rilem Publ.: Bagneux, France, 2015; pp. 15–33. [Google Scholar]

- Triantafillou, T.C. (Ed.) Textile Fibre Composites in Civil Engineering; Woodhead Publ./Elsevier: Cambridge, UK, 2016. [Google Scholar]

- Peled, A.; Bentur, A.; Mobasher, B. Textile Reinforced Concrete; Series: Modern Concrete Technology No 19; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23. [Google Scholar] [CrossRef]

- Carloni, C.; Bournas, D.A.; Carozzi, F.G.; D’Antino, T.; Fava, G.; Focacci, F.; Giacomin, G.; Mantegazza, G.; Pellegrino, C.; Perinelli, C.; et al. Fiber Reinforced Composites with Cementitious (Inorganic) Matrix. In Design Procedures for the Use of Composites in Strengthening of Reinforced Concrete Structures – State-of-the-Art Report of the RILEM Technical Committee 234-DUC 2016; Pellegrino, C., Sena-Cruz, J., Eds.; Springer: Dordrecht, The Netherlands, 2016; Chapter 9; pp. 349–392. ISBN 978-94-017-7335-5. [Google Scholar]

- Jesse, F.; Curbach, M. Verstärken mit Textilbeton. In BetonKalender 2010; Bergmeister, K., Fingerloos, F., Wörner, H.D., Eds.; Ernst & Sohn: Berlin, Germany, 2010; Chapter VII; pp. 457–565. [Google Scholar]

- DIBt. Verfahren zur Verstärkung von Stahlbeton mit TUDALIT (Textilbewehrter Beton), 1st ed.; Approval no. Z-31.10-182; DIBt: Berlin, Germany, 2014; update 2016. [Google Scholar]

- Scheerer, S.; Schütze, E.; Curbach, M. Strengthening and Repair with Carbon Concrete Composites—The First General Building Approval in Germany. In Proceedings of the SHCC4—International Conference on Strain-Hardening Cement-Based Composites, Dresden, Germany, 18–20 September 2017; Mechtcherine, V., Slowik, V., Kabele, P., Eds.; Springer: Dordrecht, The Netherlands, 2018; pp. 743–751. [Google Scholar]

- ACI 549.4R. Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures; Reported by ACI Committee 549; ACI: Farmington Hills, MI, USA, 2013. [Google Scholar]

- Peled, A.; Bentur, A.; Yankelevsky, D. Woven fabric reinforcement of cement matrix. Adv. Cement Based Mater. 1991, 1, 216–223. [Google Scholar] [CrossRef]

- Hayashi, R.; Yamada, K.; Inaba, S.; Tsubouchi, S. Tensile properties of carbon fiber mesh reinforced mortar with various wavings. Proc. Jpn. Concr. Inst. 1990, 12, 1043–1048. [Google Scholar]

- Mohamed, M.H.; Bilisik, A.K. Multi-Layer Three-Dimensional Fabric and Method of Producing. U.S. Patent No. 5,465,760, 14 November 1995. [Google Scholar]

- Curbach, M.; Fuchs, H.; Hegger, J.; Noisternig, J.F.; Offermann, P.; Reinhardt, H.-W.; Sasse, H.R.; Schorn, H.; Wörner, H.-D.; Wulfhorst, B.; et al. Sachstandbericht zum Einsatz von Textilien im Massivbau; Publication series of DAfStb [German Association for Steel Reinforced Concrete]; Beuth: Berlin, Germany, 1998. [Google Scholar]

- Proske, D. textilbewehrter Beton als Verstärkung von Platten. In Proceedings of the 34th DAfStb-Forschungskolloquium 1997, Dresden, Germany, 9–10 October 1997; Institut für Tragwerke und Baustoffe of TU Dresden: Dresden, Germany, 1997; pp. 51–58. [Google Scholar]

- DIN 1048. Prüfverfahren für Beton; Beuth: Berlin, Germany, June 1979. [Google Scholar]

- DIN EN 206. Beton—Festlegung, Eigenschaften, Herstellung und Konformität; Deutsche Fassung EN 206:2013+A1:2016; Beuth: Berlin, Germany, January 2017. [Google Scholar]

- Weiland, S. Interaktion von Betonstahl und textiler Bewehrung bei der Biegeverstärkung mit textilbewehrtem Beton. Ph.D. Thesis, TU Dresden, Dresden, Germany, 2009. Available online: http://nbn-resolving.de/urn:nbn:de:bsz:14-qucosa-37944 (accessed on 12 January 2019).

- Koutas, L.N.; Bournas, D.A. Flexural Strengthening of Two-Way RC Slabs with Textile-Reinforced Mortar: Experimental Investigation and Design Equations. J. Compos. Constr. 2017, 21, 04016065. [Google Scholar] [CrossRef]

- Bisby, L.A.; Stratford, T.J.; Hart, C.; Farren, S. Fire performance of well-anchored TRM, FRCM and FRP flexural strengthening systems. In Advanced Composites in Construction, Proceedings of the ACIC 2013, Belfast, UK, 10–12 September 2013; Whysell, C.J., Taylor, S.E., Eds.; Network Group for Composites in Construction: Belfast, UK, 2013; 12p. [Google Scholar]

- Tsesarsky, M.; Katz, A.; Peled, A.; Sadot, O. Textile Reinforced Cementitious Composites for Retrofit and Strengthening of Concrete Structures under Impact Loading. Mater. Struct. 2015, 48, 471–484. [Google Scholar] [CrossRef]

- Beckmann, B.; Hummeltenberg, A.; Weber, T.; Curbach, M. Strain Behaviour of Concrete Slabs under Impact Load. Struct. Eng. Int. 2012, 22, 562–568. [Google Scholar] [CrossRef]

- Ortlepp, R. Untersuchungen zur Verbundverankerung textilbewehrter Feinbetonverstärkungsschichten für Betonbauteile. Ph.D. Thesis, TU Dresden, Dresden, Germany, 2007. Available online: http://nbn-resolving.de/urn:nbn:de:swb:14-1187166738380-68700 (accessed on 12 January 2019).

- EN 1992-1-1. Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2004. [Google Scholar]

- Müller, E.; Scheerer, S.; Curbach, M. Strengthening of existing concrete structures: Design models. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing/Elsevier: Amsterdam, The Netherlands, 2016; Chapter 14; pp. 323–359. ISBN 978-1-78242-446-8. [Google Scholar]

- Bösche, A. Möglichkeiten zur Steigerung der Biegetragfähigkeit von Beton-und Stahlbetonbauteilen durch den Einsatz textiler Bewehrungen—Ansatz für ein Bemessungsmodell. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2007. [Google Scholar]

- Frenzel, M.; Curbach, M. Bemessungsmodell zur Berechnung der Tragfähigkeit von biegeverstärkten Stahlbetonplatten. In Textilbeton Theorie und Praxis, Proceedings of the 6th Koll. zu textilbewehrten Tragwerken (CTRS6), Berlin, Germany, 19–20 September 2011; Curbach, M., Ortlepp, R., Eds.; Institut für Massivbau der TU Dresden: Dresden, Germany, 2011; pp. 381–399. Available online: http://nbn-resolving.de/urn:nbn:de:bsz:14-qucosa-78041 (accessed on 12 January 2019).

- Curbach, M.; Lorenz, E.; Schladitz, F.; Schütze, E.; Weiland, S. Gesamtbericht der experimentellen Untersuchungen zur allgemeinen bauaufsichtlichen Zulassung für ein Verfahren zur Verstärkung von Stahlbeton mit TUDALIT (Textilbewehrter Beton); Unpublished Report for Deutsches Institut für Bautechnik (DIBt); Institut für Massivbau, TU Dresden: Dresden, Germany, 2014. [Google Scholar]

- Frenzel, M. Bemessung textilbetonverstärkter Stahlbetonbauteile unter Biegebeanspruchung. Beton- Stahlbetonbau Spezial 2015, 110, 54–68. [Google Scholar] [CrossRef]

- Curbach, M.; Schladitz, F.; Zobel, R.; Weselek, J. Eine Vision wird Realität: Der Betonbau der Zukunft ist nachhaltig, leicht, flexibel und formbar—Dank Carbon. Der Prüfingenieur 2017, 51, 20–35. Available online: https://bvpi.de/bvpi/de/aktuelles/abonnement-der-pruefingenieur.php (accessed on 22 January 2019).

- DIN EN 1992-1-1. Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spannbetontragwerken—Teil 1-1: Allgemeine Bemessungsregeln und Regeln für den Hochbau; Deutsche Fassung EN 1992-1-1:2004 + AC:2010; Beuth: Berlin, Germany, January 2011. [Google Scholar]

- DIN EN 1992-1-1/NA. Nationaler Anhang—National festgelegte Parameter—Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spannbetontragwerken - Teil 1-1: Allgemeine Bemessungsregeln und Regeln für den Hochbau; Beuth: Berlin, Germany, January 2011. [Google Scholar]

- Schütze, E.; Bielak, J.; Scheerer, S.; Hegger, J.; Curbach, M. Einaxialer Zugversuch für Carbonbeton mit textiler Bewehrung | Uniaxial tensile test for carbon reinforced concrete with textile reinforcement. Beton- Stahlbetonbau 2018, 113, 33–47. [Google Scholar] [CrossRef]

- Beckmann, B.; Frenzel, M.; Lorenz, E.; Schladitz, F.; Rempel, S. Biegetragverhalten von textilbetonverstärkten Platten. Beton- Stahlbetonbau Spezial 2015, 110, 47–53. [Google Scholar] [CrossRef]

- Rempel, S.; Ricker, M. Ermittlung der Materialkennwerte der Bewehrung für die Bemessung von textilbewehrten Bauteilen. Bauingenieur 2017, 92, 280–288. [Google Scholar]

- Just, M. Zur Sicherheit von Textilbeton. Beton- Stahlbetonbau Spezial 2015, 110, 42–46. [Google Scholar] [CrossRef]

- DIN EN 1990. Eurocode: Grundlagen der Tragwerksplanung; Deutsche Fassung EN 1990:2002 + A1:2005 + A1:2005/AC:2010; Beuth: Berlin, Germany, December 2010. [Google Scholar]

- Weselek, J.; Häussler-Combe, U. Calibrating safety factors for Carbon Concrete. Beton- Stahlbetonbau Spezial 2018, 113, 14–21. [Google Scholar] [CrossRef]

- Homepage of C3 Project. Available online: https://www.bauen-neu-denken.de/ (accessed on 25 January 2019).

- Triantafillou, T.C. Strengthening of existing concrete structures: Concepts and structural behavior. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing/Elsevier: Amsterdam, The Netherlands, 2016; Chapter 13; pp. 303–322. ISBN 978-1-78242-446-8. [Google Scholar]

- Bournas, D. Strengthening of existing structures: Selected case studies. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing/Elsevier: Amsterdam, The Netherlands, 2016; Chapter 17; pp. 389–411. ISBN 978-1-78242-446-8. [Google Scholar]

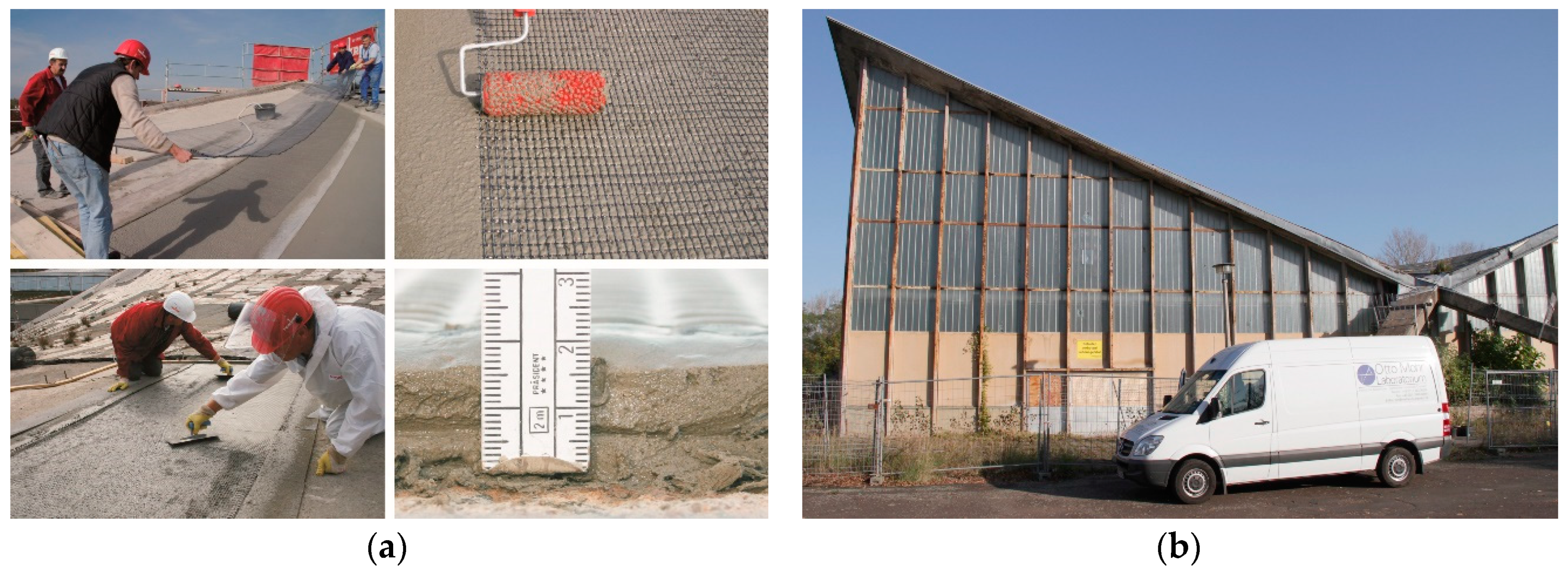

- Erhard, E.; Weiland, S.; Lorenz, E.; Schladitz, F.; Beckmann, B.; Curbach, M. Anwendungsbeispiele für Textilbetonverstärkung—Instandsetzung und Verstärkung bestehender Tragwerke mit Textilbeton. Beton- Stahlbetonbau Spezial 2015, 110, 74–82. [Google Scholar] [CrossRef]

- Scheerer, S.; Chudoba, R.; Garibaldi, M.P.; Curbach, M. Shells made of Textile Reinforced Concrete—Applications in Germany. J. Int. Assoc. Shell Spat. Struct. J. IASS 2017, 58, 79–93. [Google Scholar] [CrossRef]

- Curbach, M.; Hauptenbuchner, B.; Ortlepp, R.; Weiland, S. Textilbewehrter Beton zur Verstärkung eines Hyparschalentragwerks in Schweinfurt. Beton- Stahlbetonbau 2007, 102, 353–361. [Google Scholar] [CrossRef]

- Weiland, S.; Ortlepp, R.; Hauptenbuchner, B.; Curbach, M. Textile Reinforced Concrete for Flexural Strengthening of RC-Structures—Part 2: Application on a Concrete Shell. In Design & Applications of Textile-Reinforced Concrete, Proceedings of the ACI Fall Convention, Fajardo, Puerto Rico, 14–18 October 2007; Aldea, C.-M., Ed.; ACI: Farmington Hills, MI, USA, 2007; SP-251CD—3; pp. 41–58. [Google Scholar]

- Hentschel, M.; Schumann, A.; Ulrich, H.; Jentzsch, S. Sanierung der Hyparschale Magdeburg. Bautechnik 2019, 96, 25–30. [Google Scholar] [CrossRef]

- Feix, J.; Hansl, M. Zur Anwendung von Textilbeton für Verstärkungen im Brückenbau. In Festschrift zum 60. Geburtstag von Univ.-Prof. Dr.-Ing. Manfred Keuser; Berichte aus dem konstruktiven Ingenieurbau 12/4; Gebekken, N., Holzer, S., Keuser, M., Mangerig, I., Petersen, C., Siebert, G., Thienel, K.-Ch., Eds.; Universität der Bundeswehr München: München, Germany, 2012; pp. 289–295. [Google Scholar]

- Al Jamous, A. Instandsetzung der historischen Betonbogenbrücke in Naila. Beton- Stahlbetonbau 2017, 112, 623–628. [Google Scholar] [CrossRef]

- Herbrand, M.; Adam, V.; Classen, M.; Kueres, D.; Hegger, J. Strengthening of Existing Bridge Structures for Shear and Bending with Carbon Textile-Reinforced Mortar. Materials (Basel) 2017, 10, 1099. [Google Scholar] [CrossRef] [PubMed]

- Homepage of the Project C3-V1.2. Available online: https://tu-dresden.de/bu/bauingenieurwesen/imb/forschung/Forschungsfelder/TRC-C3/C3-vorhaben/C3-V1.2?set_language=en (accessed on 25 January 2019).

- Homepage of the Project C3-V2.7. Available online: https://tu-dresden.de/bu/bauingenieurwesen/imb/forschung/Forschungsfelder/TRC-C3/C3-vorhaben/C3-V2.7?set_language=en (accessed on 25 January 2019).

- Homepage of Collaborative Research Centre ‘SFB 528’. Available online: https://tu-dresden.de/bu/bauingenieurwesen/imb/forschung/sfb528?set_language=en (accessed on 25 January 2019).

- Curbach, M.; Ortlepp, R. (Eds.) Sonderforschungsbereich 528—Textile Bewehrungen zur bautechnischen Verstärkung und Instandsetzung—Abschlussbericht (gekürzte Fassung); Research Report; TU Dresden: Dresden, Germany, 2012; Available online: http://nbn-resolving.de/urn:nbn:de:bsz:14-qucosa-86425 (accessed on 10 January 2019).

- Homepage of TUDALIT e.V. Available online: http://tudalit.de/ (accessed on 25 January 2019).

- Special issue of the journal Beton- und Stahlbetonbau. Special issue of the journal Beton- und Stahlbetonbau. Beton- Stahlbetonbau Spezial 2015. 110/S1—Supplement 𠆌Verstärken mit Textilbeton𠆍. Available online: https://onlinelibrary.wiley.com/toc/14371006/110/S1 (accessed on 28 March 2019).

| Symbol | Definition |

|---|---|

| Indices | |

| E | external |

| c | concrete |

| s | steel |

| t | textile |

| d | design value |

| 1 | tensile stress area |

| 2 | compressive stress area |

| 0 | preload condition |

| Forces and Moments | |

| F | force |

| N | normal force |

| M | bending moment |

| Geometrical Values | |

| h | height |

| d | effective depth |

| b | width |

| A | reinforcement area |

| a | distance of compression force to top layer |

| x | neutral axis depth |

| z | inner lever arm |

| ka | coefficient for distance a |

| αR | block coefficient |

| Stresses and Strains | |

| σ | stress |

| ε | strain |

| μt | ωt | ξt = x/dt | ζt = zt/dt | εc2 (‰) | εt (‰) | σt (N/mm2) | |

|---|---|---|---|---|---|---|---|

| 0.01 | 0.0102 | 0.059 | 0.980 | −0.37 | 5.95 | 1291.67 | Rupture of textile reinforcement |

| 0.02 | 0.0206 | 0.084 | 0.972 | −0.54 | 5.95 | 1291.67 | |

| 0.03 | 0.0311 | 0.103 | 0.965 | −0.68 | 5.95 | 1291.67 | |

| 0.04 | 0.0417 | 0.120 | 0.959 | −0.81 | 5.95 | 1291.67 | |

| 0.25 | 0.2947 | 0.366 | 0.848 | −3.43 | 5.95 | 1291.67 | |

| 0.26 | 0.3091 | 0.382 | 0.841 | −3.50 | 5.67 | 1230.68 | Failure of concrete |

| 0.27 | 0.3239 | 0.400 | 0.834 | −3.50 | 5.25 | 1139.59 | |

| 0.34 | 0.4391 | 0.542 | 0.774 | −3.50 | 2.95 | 641.40 | |

| 0.35 | 0.4576 | 0.565 | 0.765 | −3.50 | 2.69 | 584.60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheerer, S.; Zobel, R.; Müller, E.; Senckpiel-Peters, T.; Schmidt, A.; Curbach, M. Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application. Appl. Sci. 2019, 9, 1322. https://doi.org/10.3390/app9071322

Scheerer S, Zobel R, Müller E, Senckpiel-Peters T, Schmidt A, Curbach M. Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application. Applied Sciences. 2019; 9(7):1322. https://doi.org/10.3390/app9071322

Chicago/Turabian StyleScheerer, Silke, Robert Zobel, Egbert Müller, Tilo Senckpiel-Peters, Angela Schmidt, and Manfred Curbach. 2019. "Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application" Applied Sciences 9, no. 7: 1322. https://doi.org/10.3390/app9071322

APA StyleScheerer, S., Zobel, R., Müller, E., Senckpiel-Peters, T., Schmidt, A., & Curbach, M. (2019). Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application. Applied Sciences, 9(7), 1322. https://doi.org/10.3390/app9071322