A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance

Abstract

:1. Introduction

2. Materials

3. Performance of NS RA-Modified Asphalt

3.1. Index Tests

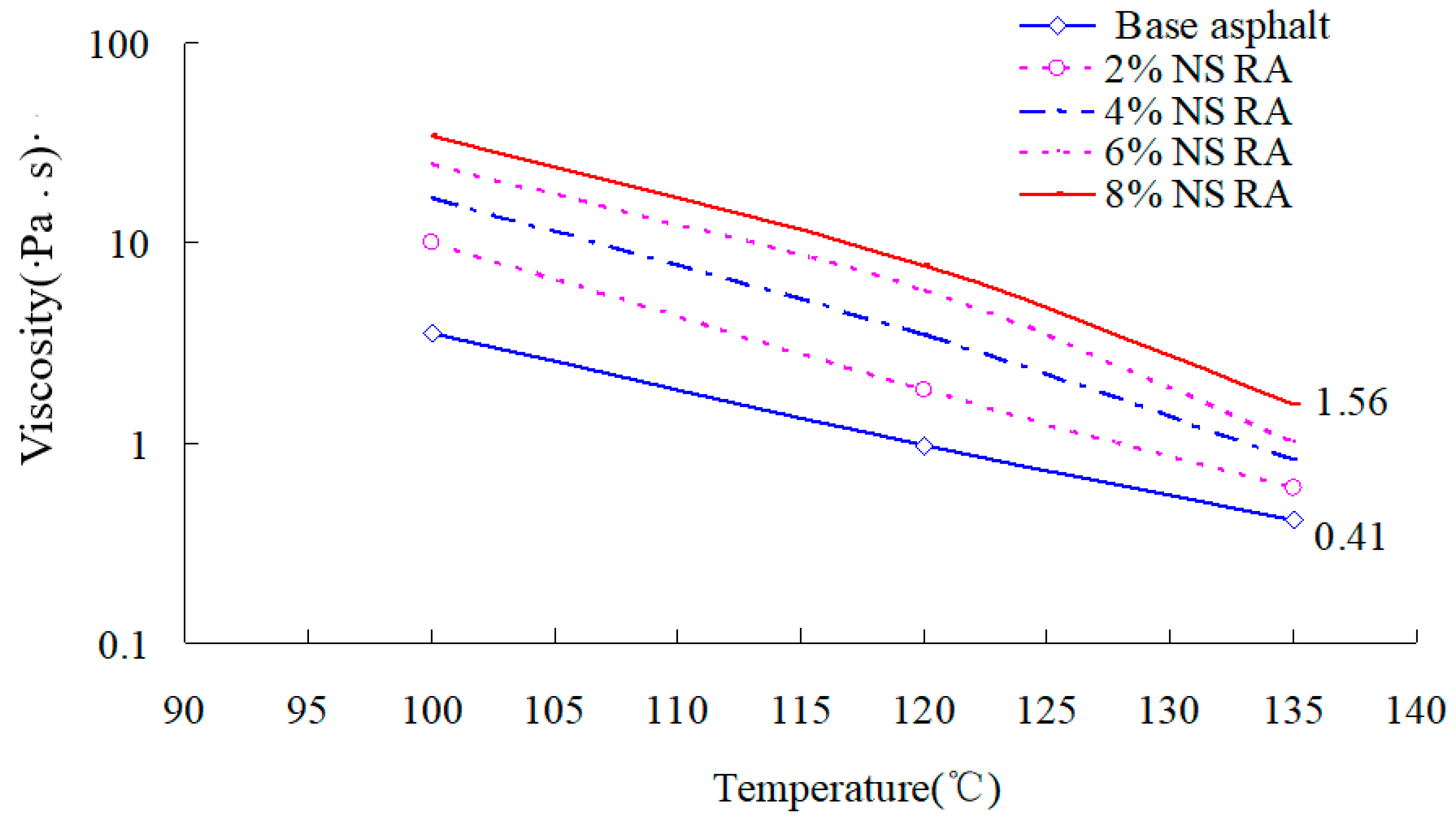

3.2. Brookfield Rotary Viscosity Test

3.3. BBR Test

4. Performance of a NS RA-Modified Asphalt Mixture Based on Anti-Rutting Performance

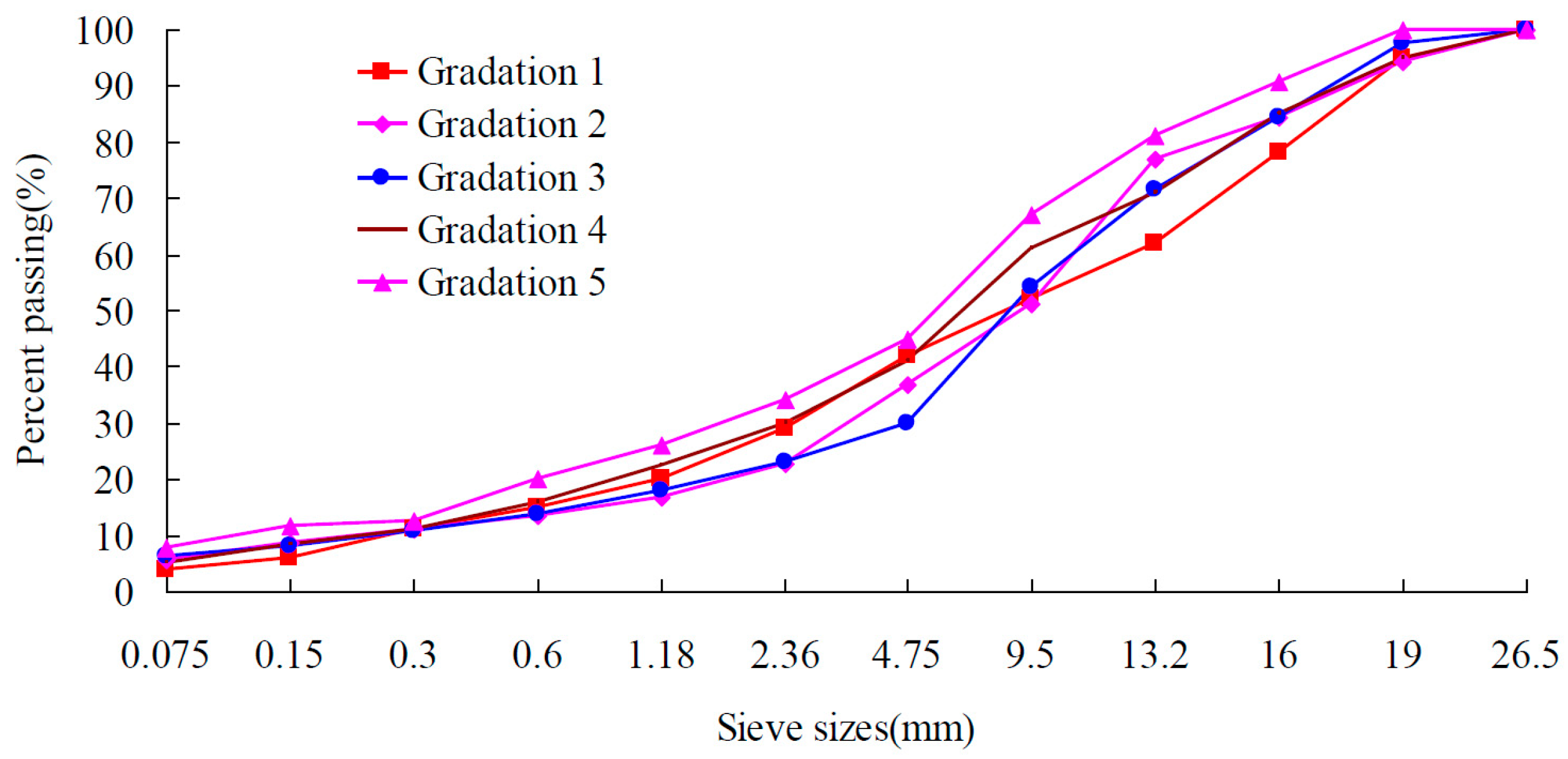

4.1. Preparation of the NS RA-Modified Asphalt Mixture

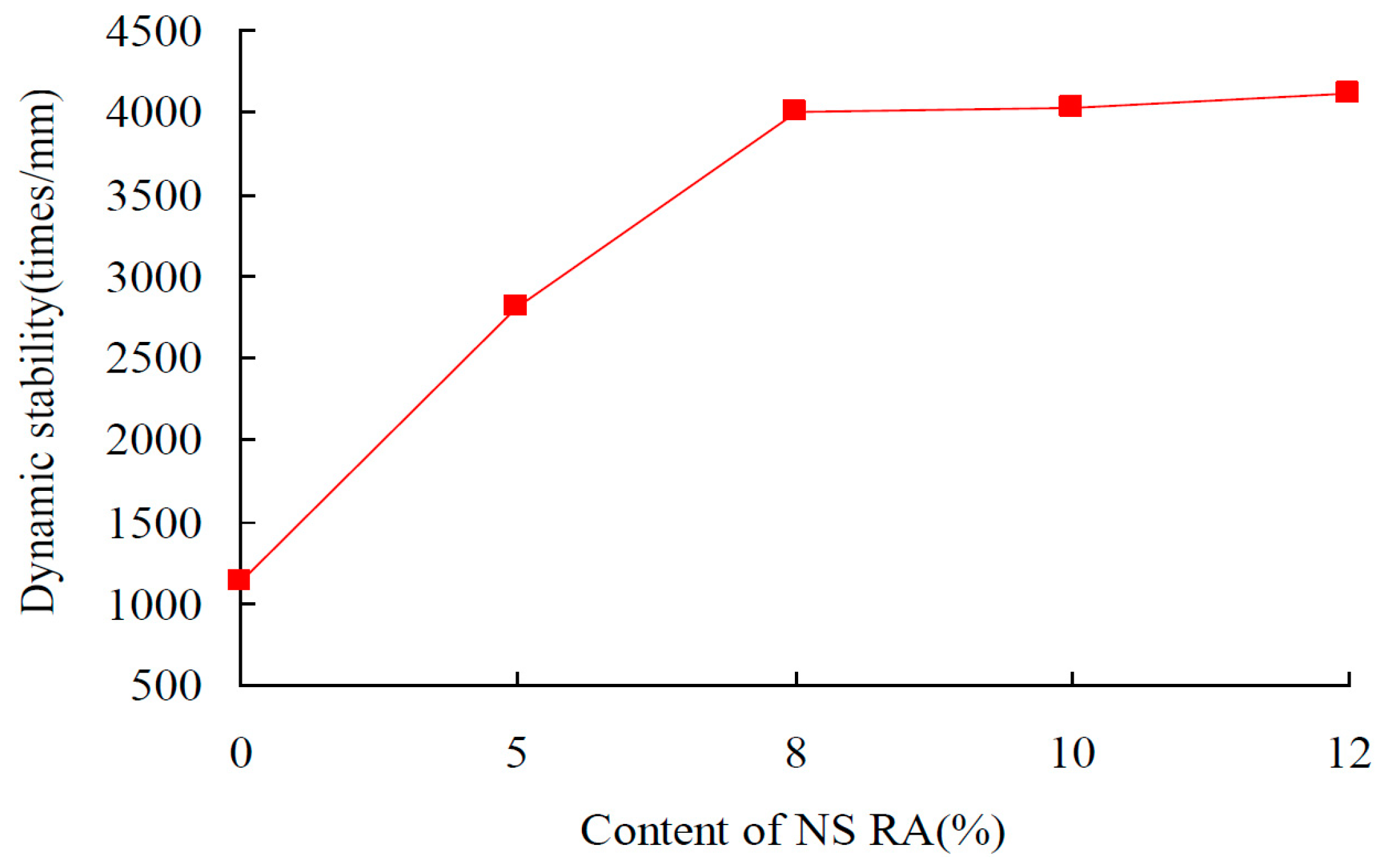

4.2. Determination of the Optimum NS RA Content

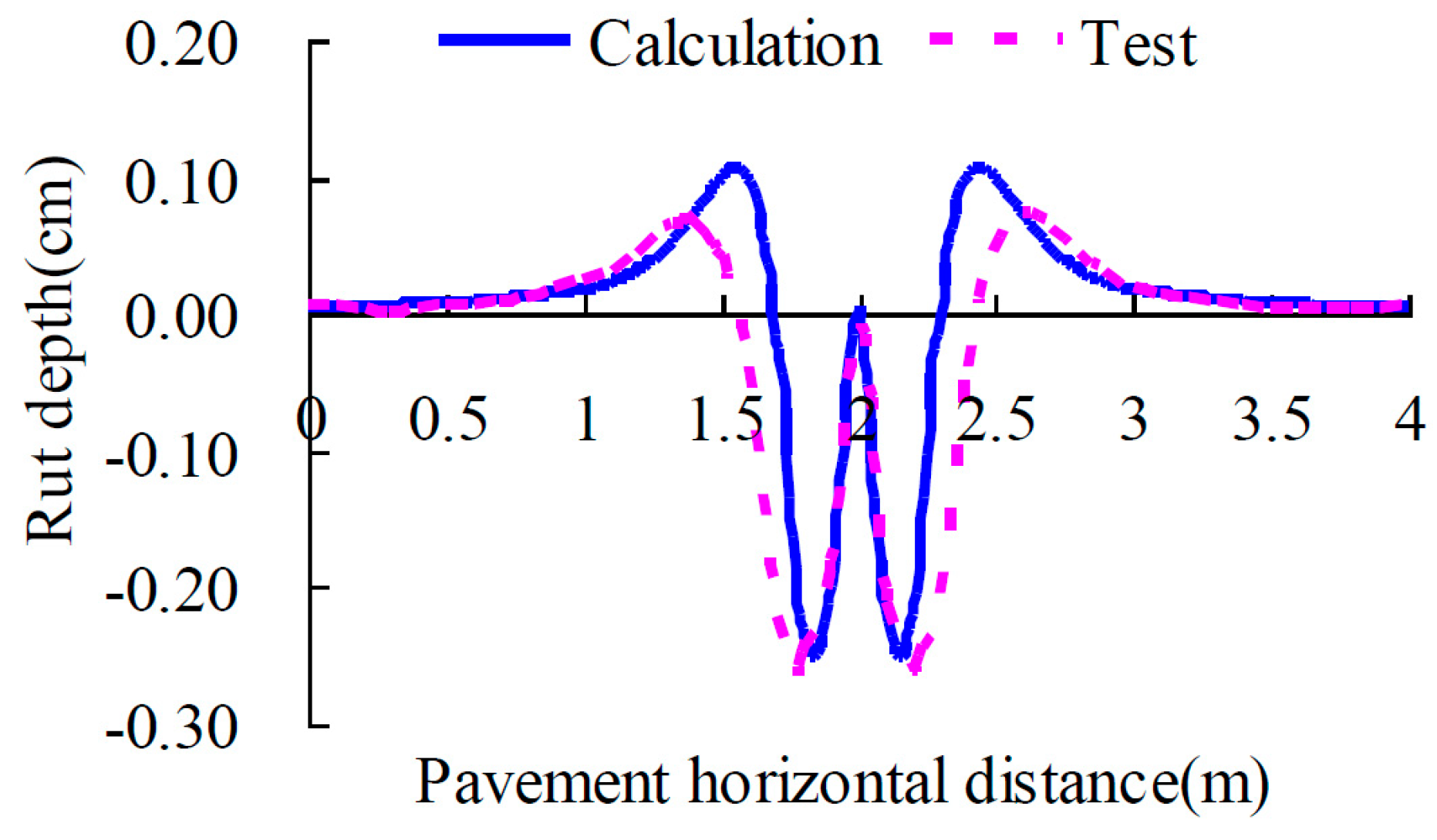

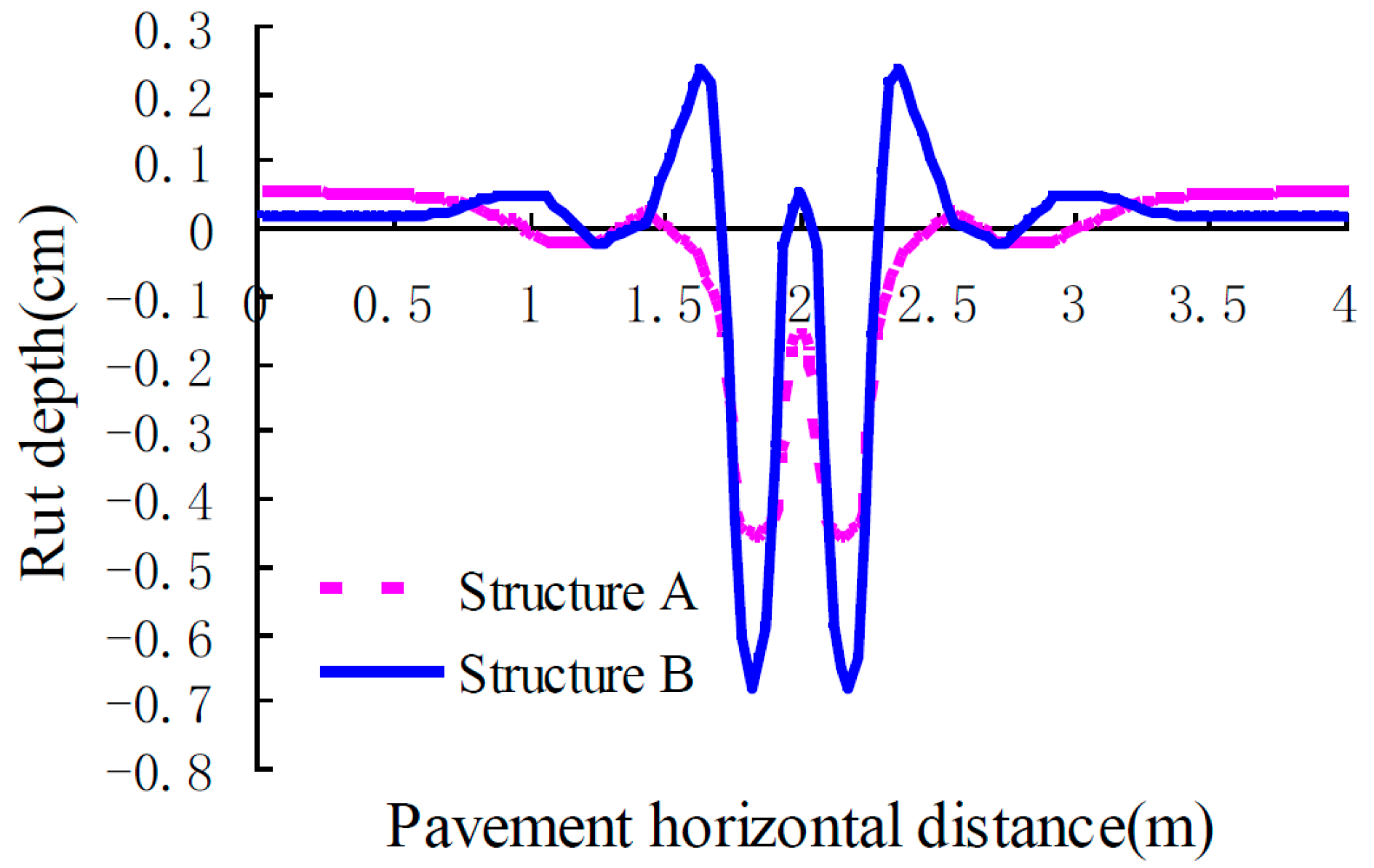

4.3. Anti-Rutting Performance

4.4. Other Performance Verifications based on Anti-Rutting Performance

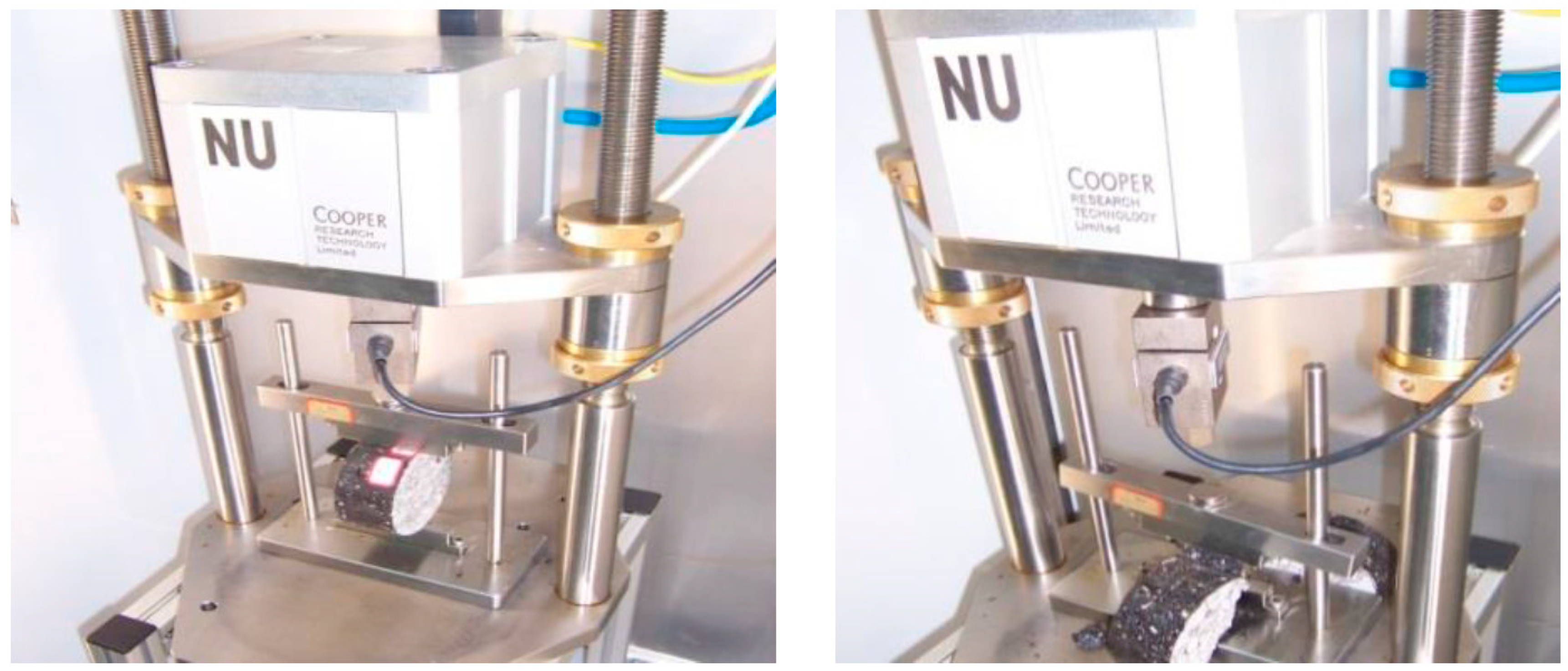

4.4.1. Fatigue Performance

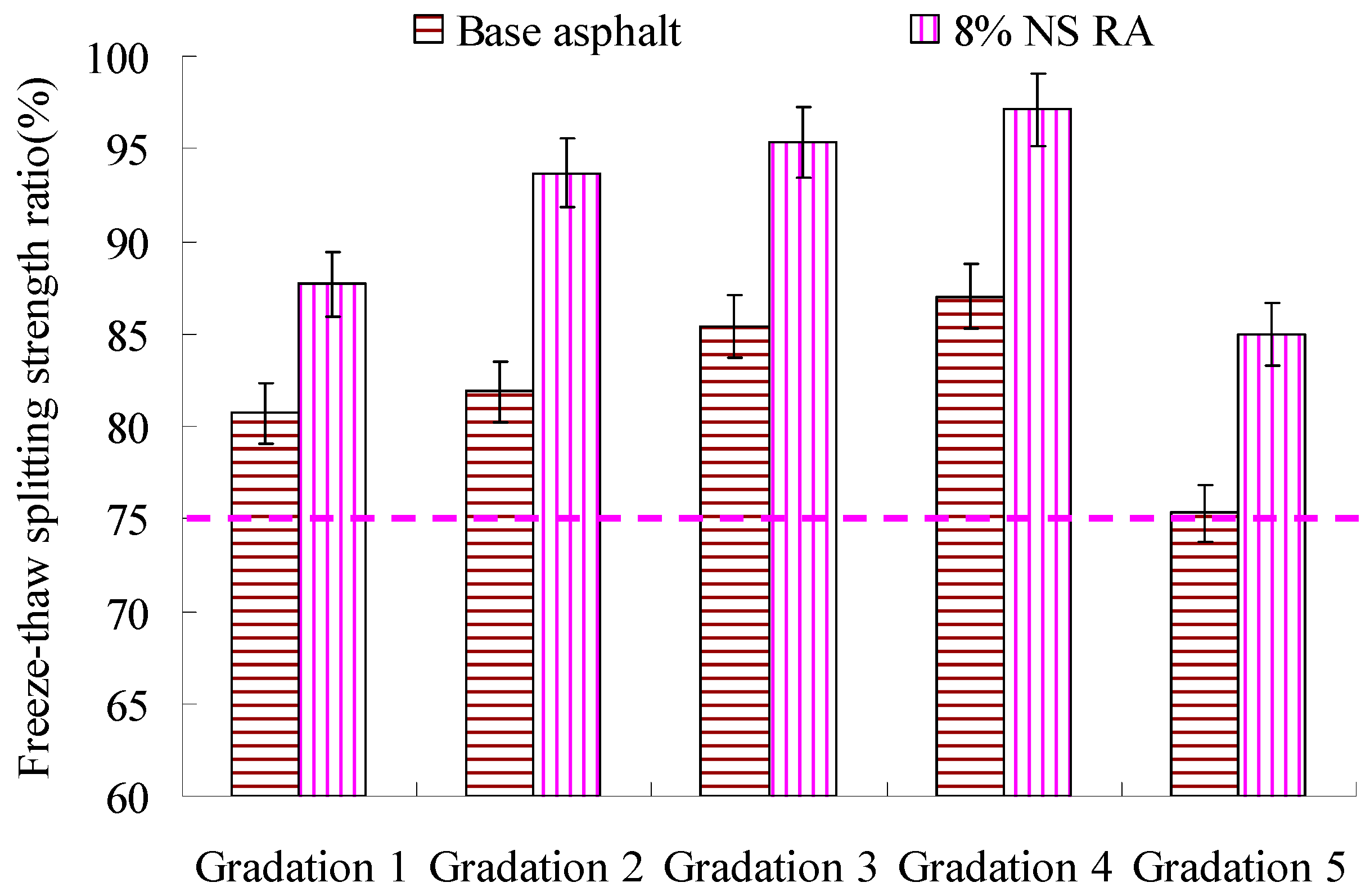

4.4.2. Moisture Susceptibility

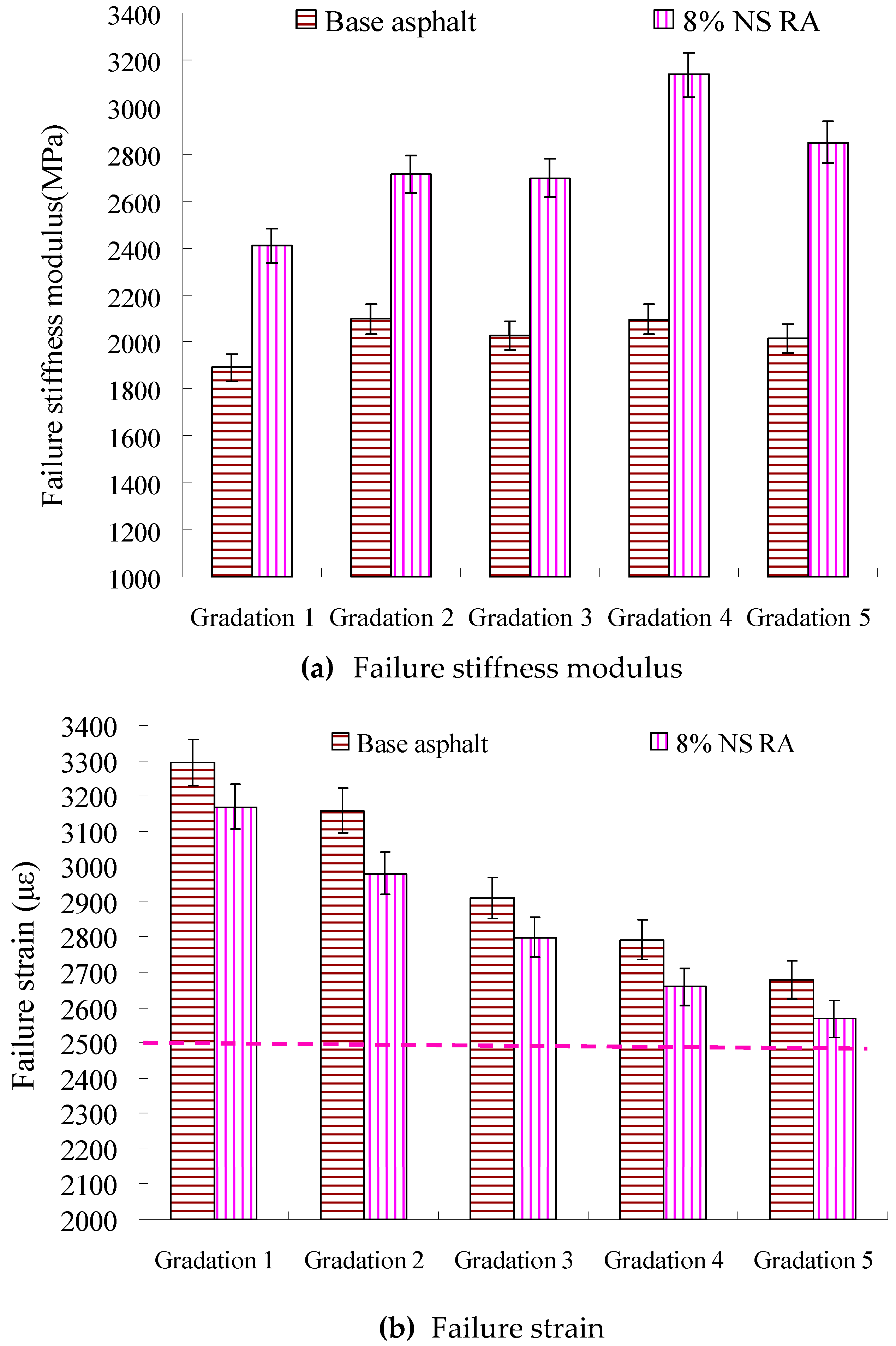

4.4.3. Low-Temperature Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Drescher, A.; Kim, J.R.; Newcomb, D.E. Permanent deformation in asphalt concrete. J. Mater. Civ. Eng. 1993, 5, 112–128. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; You, Z.; Liu, Y.; Yang, X.; Xiao, J. Prediction on rutting decay curves for asphalt pavement based on the pavement-ME and matter element analysis. Int. J. Pavement Res. Technol. 2017, 10, 466–475. [Google Scholar] [CrossRef]

- Lv, S.; Wang, S.; Guo, T.; Xia, C.; Li, J.; Hou, G. Laboratory evaluation on performance of compound-modified aphalt for rock asphalt/styrene-butadiene rubber (SBR) and rock asphalt/Nano-CaCO3. Appl. Sci. 2018, 8, 1009. [Google Scholar] [CrossRef]

- Cai, L.; Shi, X.; Xue, J. Laboratory evaluation of composed modified asphalt binder and mixture containing nano-silica/rock asphalt/SBS. Constr. Build. Mater. 2017, 172, 204–211. [Google Scholar] [CrossRef]

- Arisona, A.; Nawawi, M.; Nuraddeen, U.; Hamzah, M. A preliminary mineralogical evaluation study of natural asphalt rock characterization, southeast Sulawesi, Indonesia. Arab. J. Geosci. 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Shi, X.; Cai, L.; Xu, W.; Fan, J.; Wang, X. Effects of nano-silica and rock asphalt on rheological properties of modified bitumen. Constr. Build. Mater. 2018, 161, 705–714. [Google Scholar] [CrossRef]

- Chunmei, Z.; Yuntao, L.; Xiaowei, C.; Shihan, L.; Xiaoyang, G.; Huijie, Z.; Yun, L.S. Effects of plasma-treated rock asphalt on the mechanical properties and microstructure of oil-well cement. Constr. Build. Mater. 2018, 186, 163–173. [Google Scholar]

- Zeng, M.; Zhu, Y.; Tian, W.; Xie, X. Experimental study on performance of European rock asphalt modified asphalt mixture. J. Hunan Univ. 2017, 44, 156–161. (In Chinese) [Google Scholar]

- Huang, W. Research on Characteristic Behavior for North American Rock Asphalt and Asphalt Mixtures. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Li, R.; Karki, P.; Hao, P.; Bhasin, A. Rheological and low temperature properties of asphalt composites containing rock asphalts. Constr. Build. Mater. 2015, 96, 47–54. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, S.; Wu, Y. Influence of Buton rock on performance of asphalt mixture. J. Build. Mater. 2015, 18, 450–457. (In Chinese) [Google Scholar]

- Zeng, M.; Chen, W.; Zhu, Y.; Liang, H. Effects of proportion of Buton rock asphalt on performance of modified asphalt mixture with wet method. J. Hunan Univ. 2018, 45, 94–101. (In Chinese) [Google Scholar]

- Liu, L.; Qin, J.; Hong, Y. Effect of production processes on high temperature performance of Buton rock asphalt mixture. J. Wuhan Univ. Technol. 2018, 45, 94–101. (In Chinese) [Google Scholar]

- Lv, S.; Fan, X.; Yao, H.; You, L.; You, Z. Analysis of performance and mechanism of Buton rock asphalt modified asphalt. Appl. Sci. 2019, 136, 46903. [Google Scholar] [CrossRef]

- Li, H. Study on Modification Mechanism of Wuerhe Rock Asphalt. Master’s Thesis, Xinjiang Agricutural University, Xinjiang, China, 2010. [Google Scholar]

- Zhong, K.; Xu, Y.; Luo, S. Performance evaluation of petroleum bitumen binders and mixtures modified by natural rock asphalt from Xinjiang China. Constr. Build. Mater. 2017, 154, 623–631. [Google Scholar] [CrossRef]

- Li, L.; He, Z.; Liu, W.; Jiang, J.; Hu, C. Modification mechanism and performance of Qingchuan rock asphalt-modified asphalt. J. Test. Eval. 2018, 46, 1610–1621. [Google Scholar] [CrossRef]

- Lu, Z.; He, Z.; Qin, M. Pavement performance of asphalt mixture modified by rock asphalt. J. Cent. South Univ. 2010, 41, 2407–2411. [Google Scholar]

- Lu, Z.F.; He, Z.Y.; Huang, G.; Min, Q. Performance Analysis on Modified Bitumen by Nature Rock Asphalt. In Proceedings of the American Society of Civil Engineers Tenth International Conference of Chinese Transportation Professionals (ICCTP’2010), Beijing, China, 4–8 August 2010. [Google Scholar]

- Lu, Z.; He, Z.; Huang, G. Study on performance and modification mechanism of modified asphalt by native Rock-asphalt. J. Wuhan Univ. Technol. 2011, 35, 1161–1164. [Google Scholar]

- Yilmaz, M.; Çeloglu, M. Effects of SBS and different natural asphalts on the properties of bituminous binders and mixtures. Constr. Build. Mater. 2013, 44, 533–540. [Google Scholar] [CrossRef]

- China Ministry of Transport. JTG E20-2011 Specifications and Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011.

- China Ministry of Transport. JTG E42-2005 Test Methods of Aggregate for Highway Engineering; China Communications Press: Beijing, China, 2005.

- Li, L. Design Method Study on the Large-stone Flexible Base Durable Asphalt Pavement of Resisting Rutting. Ph.D. Thesis, Central South University, Changsha, China, 2011. [Google Scholar]

- Li, L.; He, Z.; Jiang, J.; Lei, T. Calculation method and influence law of pavement rut under dynamic load. J. Test. Eval. 2016, 44, 827–837. [Google Scholar] [CrossRef]

- China Ministry of Transport. JTG F40-2004 Technical Specification for Construction of Highway Asphalt Pavements; China Communications Press: Beijing, China, 2004.

| Properties | Color | Flash Point (°C) | Water Content (%) | Passing Percentage of Sieves (%) | ||

|---|---|---|---|---|---|---|

| 0.075 mm | 0.3 mm | 1.18 mm | ||||

| North American rock asphalt | Block | >260 | 1.0 | 26.1 | 99.4 | 100 |

| North Sichuan rock asphalt | Block blown | >260 | 1.2 | 24.1 | 99.7 | 100 |

| Methods | T0611-2011 [22] | T0612-1993 [22] | T0351-2000 [23] | |||

| Properties | Criteria | Zhonghai AH-70 | Esso AH-70 | Methods | |

|---|---|---|---|---|---|

| Ductility at 15 °C (cm) | ≥100 | 135 | 195 | T0604-2011 [22] | |

| Penetration degree at 25 °C (0.1mm) | 60~80 | 70 | 60.0 | T0605-2011 [22] | |

| Softening point (°C) | ≥46 | 51 | 49 | T0606-2011 [22] | |

| Dynamic viscosity at 60 °C (Pa·s) | ≥180 | 217 | 223 | T0625-2011 [22] | |

| After the thin film oven test (TFOT) (163 °C, 5 h) | Mass loss (%) | ±0.8 | −0.15 | −0.36 | T0609-2011 [22] |

| Ductility at 15 °C (cm) | 16.2 | 21.2 | ≥15 | T0604-2011 [22] | |

| Ductility at 10 °C (cm) | ≥6 | 9.1 | 6.7 | T0604-2011 [22] | |

| Penetration degree ratio at 25 °C (%) | −61.5 | 65 | ≥58 | T0605-2011 [22] | |

| Technical Indexes | Results | Criteria | Methods |

|---|---|---|---|

| Crush value (%) | 13.5 | ≤28 | T0316-2005 [23] |

| Content of acicular and flaky shape particles (%) | 8.06 | ≤15 | T0312-2005 [23] |

| Losses of the Los Angeles Abrasion Test (%) | 17 | ≤30 | T0317-2005 [23] |

| Water absorption (%) | 0.22 | ≤2 | T0307-2005 [23] |

| Asphalt adhesion (graduation) | 4 | ≥4 | T0616-1993 [23] |

| Impact value (%) | 17 | ≤30 | T0322-2000 [23] |

| Firmness (%) | 2.8 | ≤12 | T0314-2000 [23] |

| Mud content (%) | 0.7 | ≤1 | T0310-2005 [23] |

| Properties | Hydrophilic Coefficient | Water Content (%) | Apparent Density (t/m3) | Size Distributions (%) | ||

|---|---|---|---|---|---|---|

| <0.075 mm | <0.15 mm | <0.6 mm | ||||

| Results | 0.622 | 0.932 | 2.699 | 77.17 | 99.62 | 100 |

| Criteria | <1 | ≤1 | ≥2.50 | 75~100 | 90~100 | 100 |

| Methods | T0353-2000 [23] | T0350-1994 [23] | T0352-2000 [23] | T0351-2000 [23] | ||

| Structure A | Structure B |

|---|---|

| 4 cm AC-13C | 4 cm AC-13C |

| 6 cm AC-20 (NS RA modified asphalt) | 6 cm AC-20C (Shell SBS-70 modified asphalt) |

| 8 cm AC-25C | 8 cm AC-25C |

| 8 cm ATB-25 | 8 cm ATB-25 |

| 20 cm Cement stabilized aggregate | 20 cm cement-stabilized aggregate |

| 20 cm Lime soil | 20 cm Lime soil |

| subgrade | subgrade |

| Gradation Type | Asphalt Type | Temperature (°C) | E1 (kg/cm2) | η1 (Pa.s) | E2 (kg/cm2) | η2 (Pa.s) |

|---|---|---|---|---|---|---|

| AC-13 | Shell SBS-70 modified asphalt | 60 | 1000 | 34,652 | 450 | 1,684,652 |

| 35 | 3000 | 111,357 | 597 | 1,641,532 | ||

| 20 | 4000 | 74,856 | 1365 | 3,270,865 | ||

| AC-20 | Shell SBS-70 modified asphalt | 60 | 800 | 9761 | 511 | 1,412,325 |

| 35 | 2200 | 99,462 | 461 | 1,806,501 | ||

| 20 | 3500 | 50,317 | 1647 | 2,334,658 | ||

| AC-20 | NS RA modified asphalt | 60 | 229 | 117,804 | 277 | 146,463 |

| 40 | 738 | 731,707 | 344 | 61,424 | ||

| 15 | 7559 | 4,227,813 | 2043 | 433,027 | ||

| AC-25 | Zhonghai AH-70 base asphalt | 60 | 600 | 8890 | 494 | 1,532,292 |

| 35 | 2050 | 9057 | 1322 | 2,003,491 | ||

| 20 | 2800 | 16,652 | 1597 | 2,628,311 | ||

| ATB-25 | Zhonghai AH-70 base asphalt | 60 | 580 | 8245 | 487 | 1,256,866 |

| 35 | 1860 | 72,784 | 1087 | 1,819,868 | ||

| 20 | 2780 | 13,618 | 1394 | 2,588,862 |

| Material Type | Thickness (cm) | Elastic Modulus (MPa) | Poisson Ratio | Friction Angle (°) | Cohesive Force (KPa) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| Cement Stabilized aggregate | 19 | 1500 | 0.25 | - | - | 2400 |

| Lime soil | 20 | 550 | 0.35 | 22 | 55 | 1930 |

| subgrade | - | 48 | 0.40 | 16 | 30 | 1900 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; He, Z.; Liu, W.; Hu, C. A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance. Appl. Sci. 2019, 9, 870. https://doi.org/10.3390/app9050870

Li L, He Z, Liu W, Hu C. A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance. Applied Sciences. 2019; 9(5):870. https://doi.org/10.3390/app9050870

Chicago/Turabian StyleLi, Limin, Zhaoyi He, Weidong Liu, and Cheng Hu. 2019. "A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance" Applied Sciences 9, no. 5: 870. https://doi.org/10.3390/app9050870

APA StyleLi, L., He, Z., Liu, W., & Hu, C. (2019). A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance. Applied Sciences, 9(5), 870. https://doi.org/10.3390/app9050870