1. Introduction

One of the main aspects of solar systems is storage. Storage density, in terms of the amount of energy per unit of volume or mass, is an important issue for applications in order to optimize the solar ratio, that is, how much of the solar radiation is useful for the heating/cooling purposes. Efficiency of appliances such as solar thermal collectors and absorption heat pumps/chillers and room consumption are important issues as well. For these reasons, it is important to investigate the possibility of using phase change materials (PCMs) in solar system applications. PCMs can potentially increase the energy density of small sized hybrid water thermal energy storage (TES) tanks, thus reducing solar storage volume for a given solar fraction, or increasing the solar fraction for a given available volume [

1]. For example, for a 10 °C temperature drop that is common in many applications such as ambient heating or single stage absorption cooling, the specific volume required can drastically decrease from values in the order of 0.1 m

3 kWh

−1 (36 MJ m

−3) to values as low as 0.02 m

3 kWh

−1 (180 MJ m

−3).

As a further advantage, heat storage and delivery normally occur over a fairly narrow temperature range (the transition zone) [

2].

Chidambaram et al. [

3] report a review of several studies developed during recent years concerning PCM heat storage. They are all related to the performance of the storage itself rather than of the system. Oró [

4] reports a study on a solar cooling and refrigeration plant in which different PCM have been tested under different conditions. Recently, many studies have been devoted to identifying possible solutions to increase the thermal conductivity of PCMs as this is usually very low (in the order of 0.2 W m

−1 K

−1), causing slow melting and solidifying processes [

5,

6].

In this regard, open-cell metal foams seem to be a promising way to enhance the PCM heat transfer performance. They consist of a stochastic distribution of interconnected pores almost homogenous in size and shape, allowing a high heat transfer area per unit of volume and high thermal conductivity [

7]. Mancin et al. [

8] carried out some experiments measuring the improvement of the heat transfer by a metal foam during the solid–liquid phase change process of different paraffin waxes. More recently, Lazzarin et al. have conducted an extensive campaign measuring the temperature distribution and loading and unloading times of hybrid water PCM TES with and without aluminum (Al) foams [

9,

10,

11]. They demonstrated significantly higher conduction heat transfer rates with the use of metal foams, as a consequence of their higher thermal conductivities.

Some numerical models for integrating PCM systems into commercial programs have been proposed in literature [

12]. Among the different available simulation tools, Trnsys [

13] is a widespread transient simulation tool for dynamic simulation of heating, ventilation, and air conditioning (HVAC) plants using renewables and heat pumps (HP). For this reason, it has been selected and implemented in the present work.

During the last decades some attempts to incorporate PCM systems in Trnsys have been made, above all into building components [

14,

15]. Active systems with PCMs as part of the thermal storage system have been investigated as well [

16,

17]. Bony and Citherlet [

18] developed a Trnsys type called “type 860” to simulate water storage tanks including PCM modules (vertical cylinders, plates, or spherical beds). The model takes conduction and convection into PCM into the account as well as at the interface between PCM and water, and it is based on an enthalpy approach. Hysteresis and subcooling of PCM are also considered. To evaluate the accuracy of the model, numerical results were validated against some experimental data, showing a good agreement [

19].

However, there is still a lack in literature of research that integrate PCM with metal foams in order to include hybrid water–PCM TES in dynamic thermo-energetic building simulations. Recently, the authors simulated the use of Al foams to improve the heat transfer capabilities of paraffin waxes in hybrid water TESs based on Trnsys type 860 [

20,

21]. They demonstrated the suitability of these enhanced surfaces for speeding up both the loading and unloading processes. The results were based on simulations with experimental validation. Nevertheless, no study concerning energy and economic evaluation of a complex HVAC plant (i.e., using solar heating/cooling and a multi-source heat pump) comparing PCM vs. enhanced PCM vs. sensible heat storage is available, to the best of the authors’ knowledge. Lazzarin et al. [

22] conducted a similar study, but it is limited to the comparison between sensible vs. PCM TES.

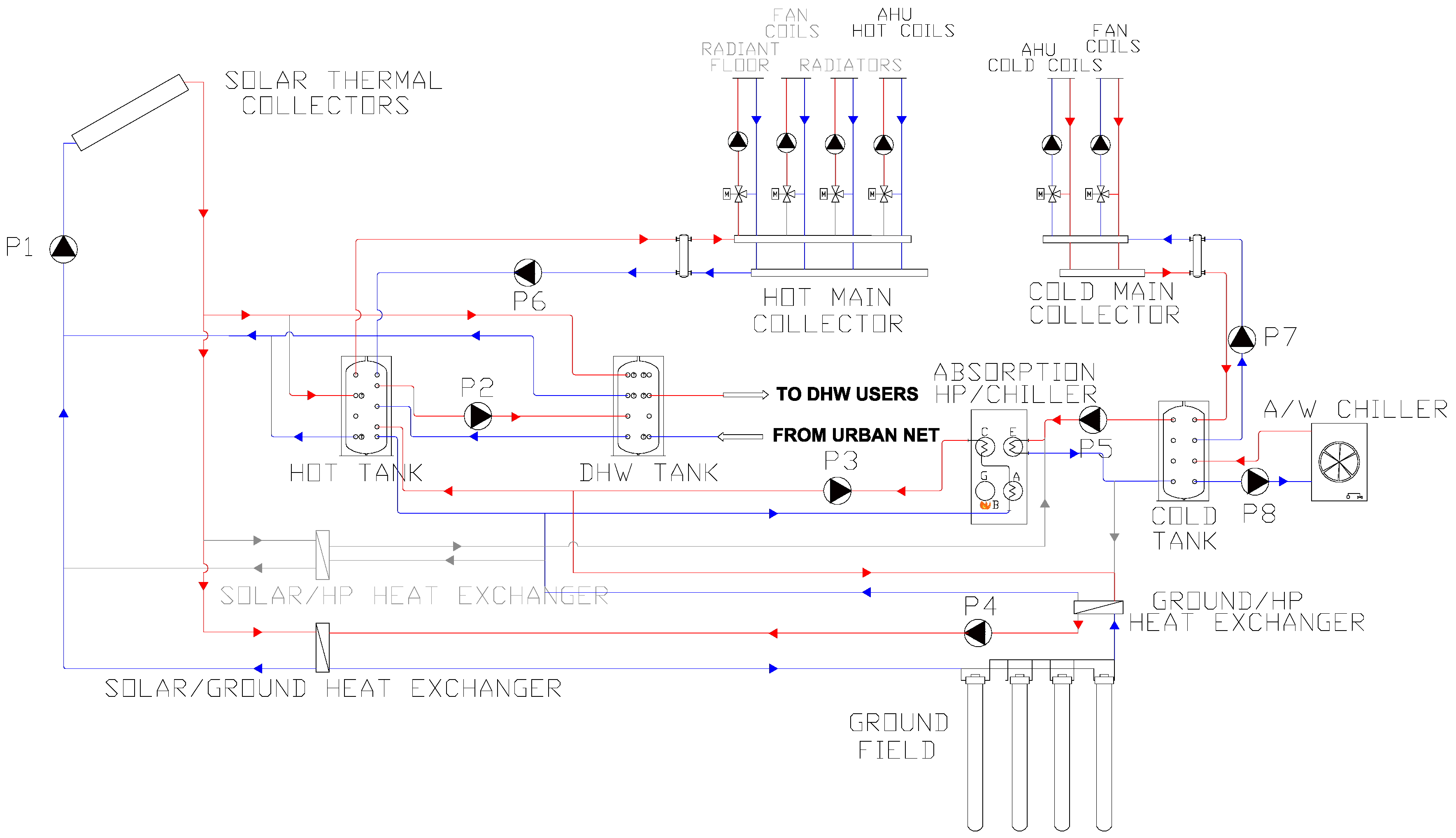

This paper reports a study of a dual source (solar thermal and ground) absorption heat pump system. The solar thermal energy is used directly for domestic hot water (DHW) and for heating, and it is also used as heat source for the heat pump, or to regenerate the ground when the system operates for summer air conditioning. In this case, condensation heat from the absorption chiller can be usefully directed to the post-heating coils of the air handling units, or to regenerate the ground as well.

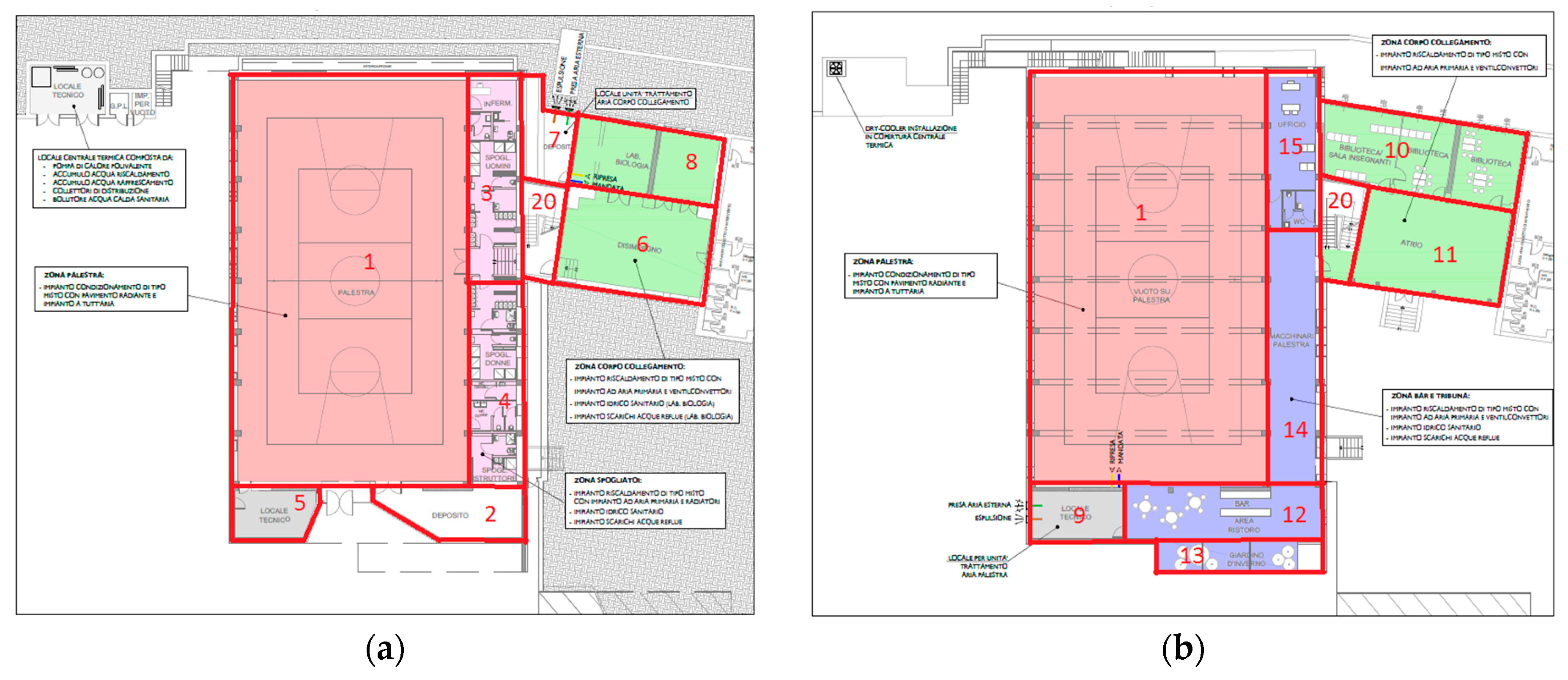

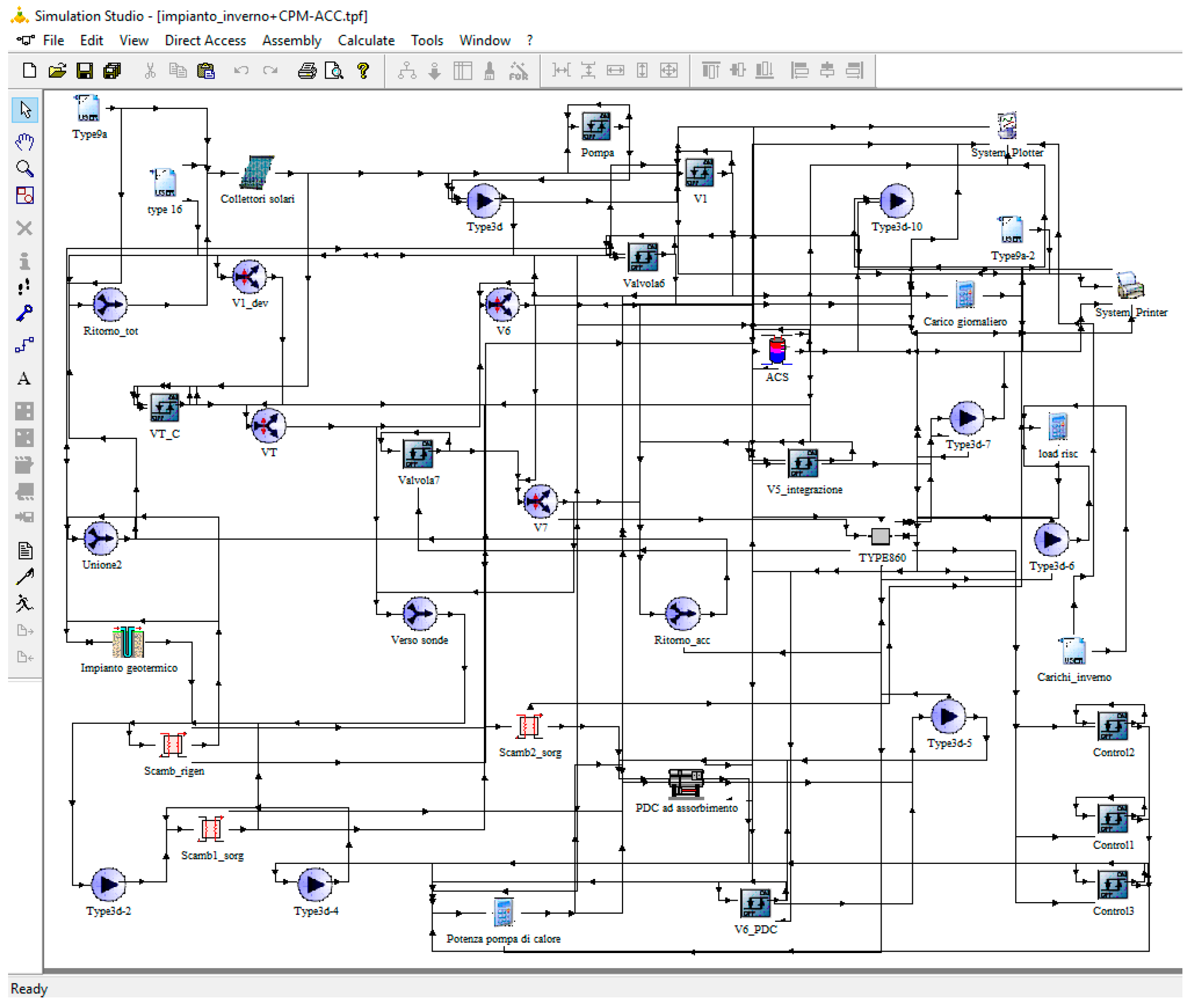

Annual simulations by the dynamic simulation software Trnsys are carried out based on an existing building that will be retrofitted during 2019 to become a nearly zero energy building (nZEB). The building is an old school sited in Feltre, northern Italy. The dual source and solar cooling/heating plant presents three thermal storage tanks: the first producing hot water for heating, the second for DHW, and the third producing cold water for cooling. An optimization of the solar and ground field designs from both energy and economic point of view is performed by dynamic simulations. Subsequently, the energy performance of the plant is evaluated by considering different cases: all the three tanks modeled as sensible (water) storage, or one of the tanks modeled as PCM storage, or as enhanced PCM with metal foam.

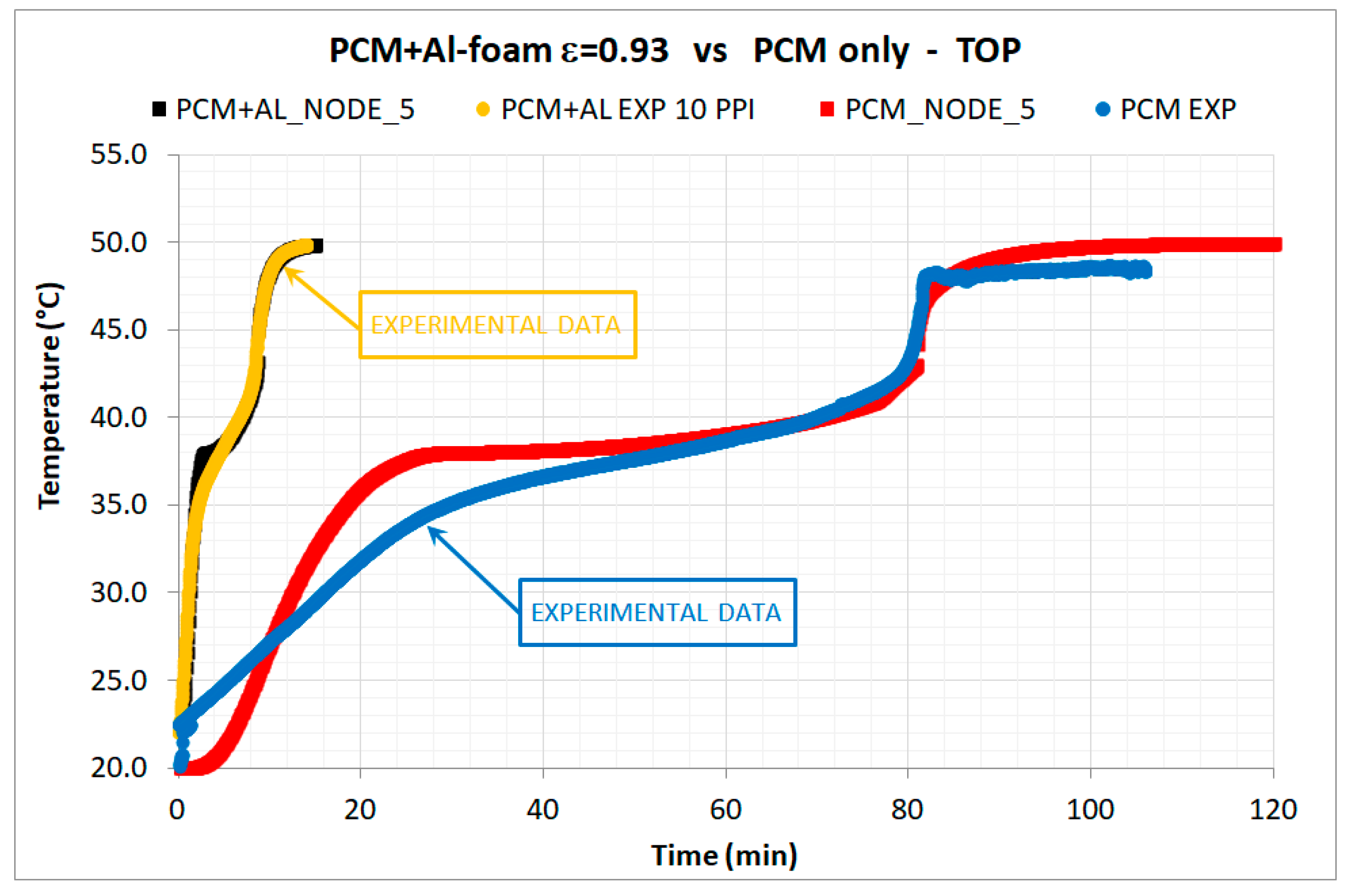

In the first part of the paper, the Trnsys type 860 is validated against some data collected during experimental tests. Then, two issues are examined with the aim of minimizing the primary energy consumption and maximizing the economic advantage with respect to a traditional heating/cooling plant: the evaluation of the best size of the solar field/ground probes/thermal storage tanks, and the best choice for designing one of the three storages as a “PCM storage” or “enhanced PCM storage”.

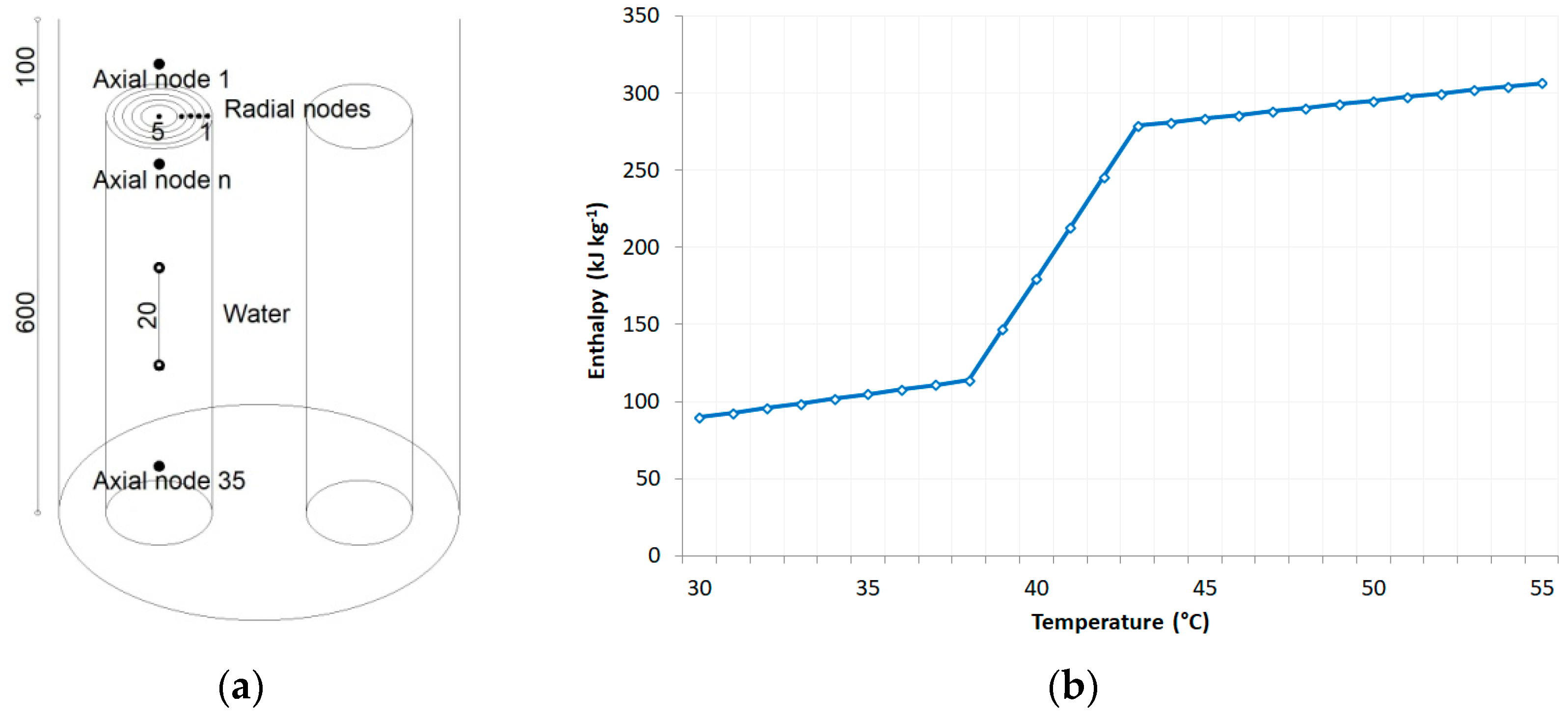

It is suitable to introduce the analysis by a brief description of PCM–water hybrid thermal storage from the modeling point of view, and its validation with experimental data (

Section 2.1). Subsequently, the retrofitting intervention on the building is described with the aim to calculate the heating, cooling, and DHW thermal loads (

Section 2.2). Then, the HVAC plant and its control logic modeled in Trnsys are described (

Section 2.3 and

Section 2.4).

Section 2.5 reports on the correct setting of the parameters of type 860 to simulate PCM and enhanced PCM with Al foam. In

Section 3, the main energy and economic results of the optimization analysis are reported and discussed.

3. Results and Discussion

A full system energy performance evaluation was undertaken at the design stage, firstly considering all three tanks (hot, cold and DHW tanks) as sensible (water) storages. Such an evaluation is useful to select the most viable mixed solution, and to optimize the size of the solar and ground fields (

Table 7). As the ground field extension can be reduced when increasing the solar field area, a first attempt of economic analysis was reported in order to evaluate the viability of the proposed solutions, and to identify the most advantageous one. For this, first, energy analysis results were reported on a monthly basis (

Section 3.1). Subsequently, annual energy performance results were reported (

Section 3.2 and

Section 3.3) in order to determine the best storage tank configuration among sensible, PCM, and enhanced PCM systems (

Table 5).

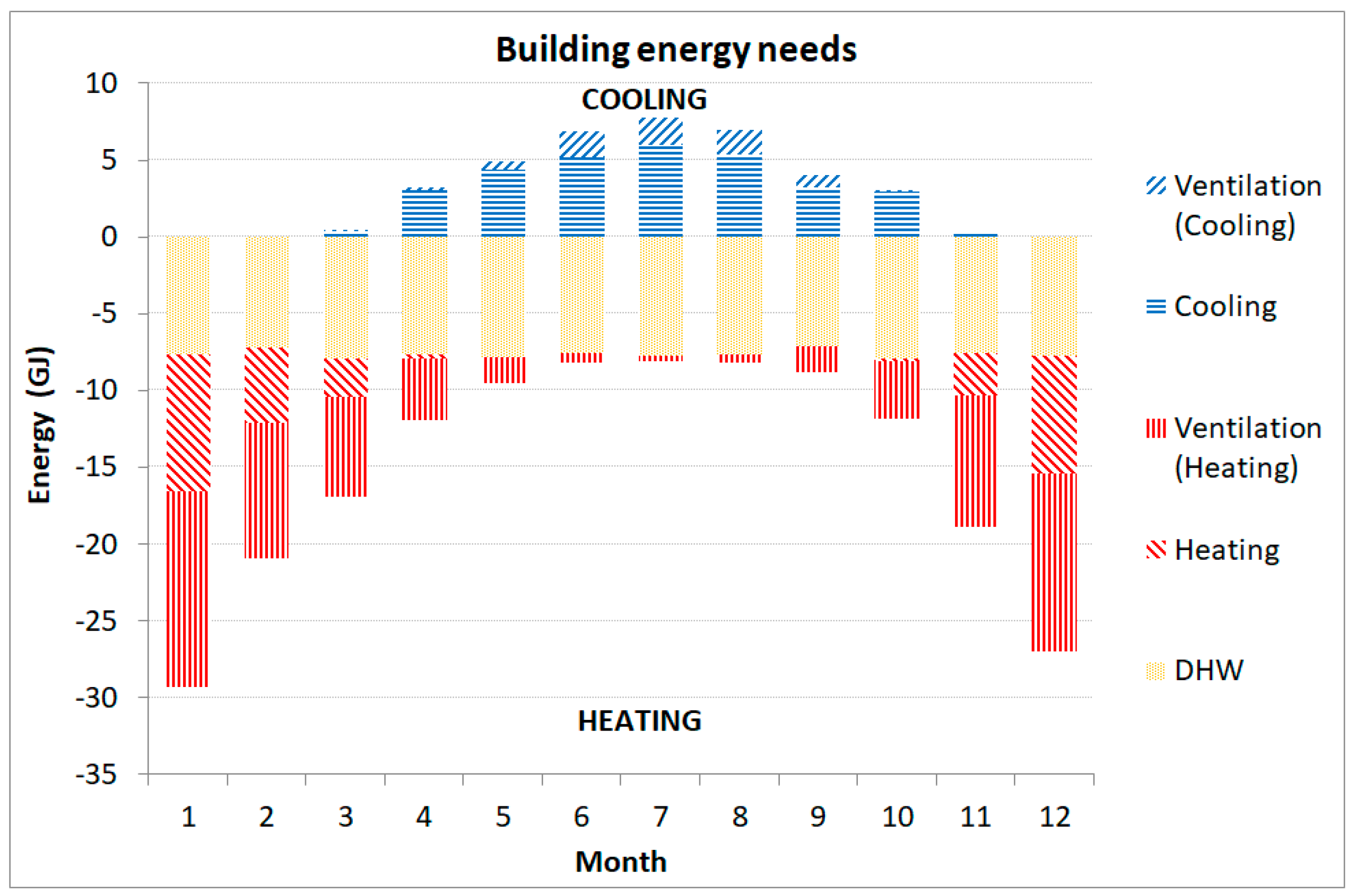

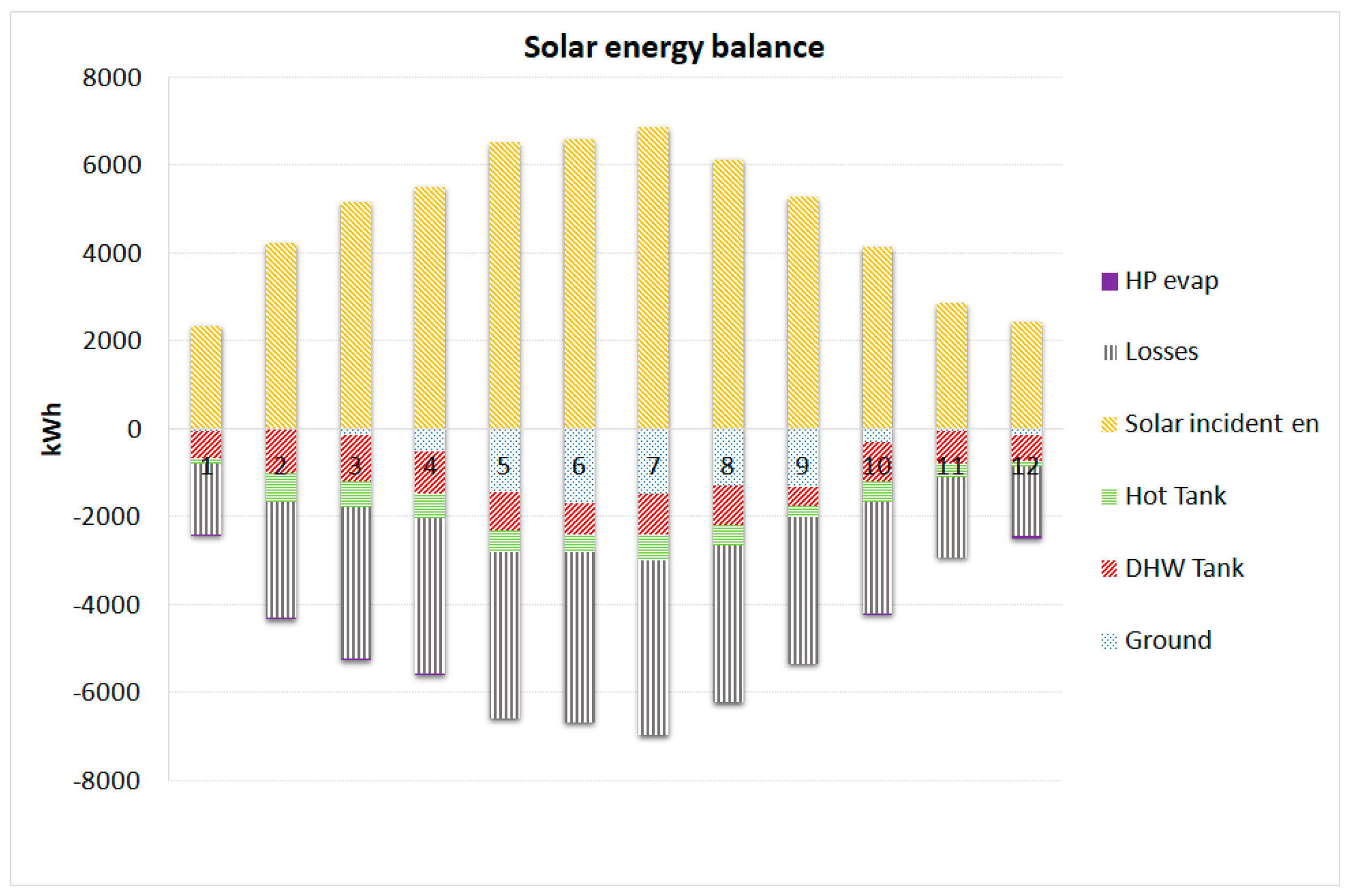

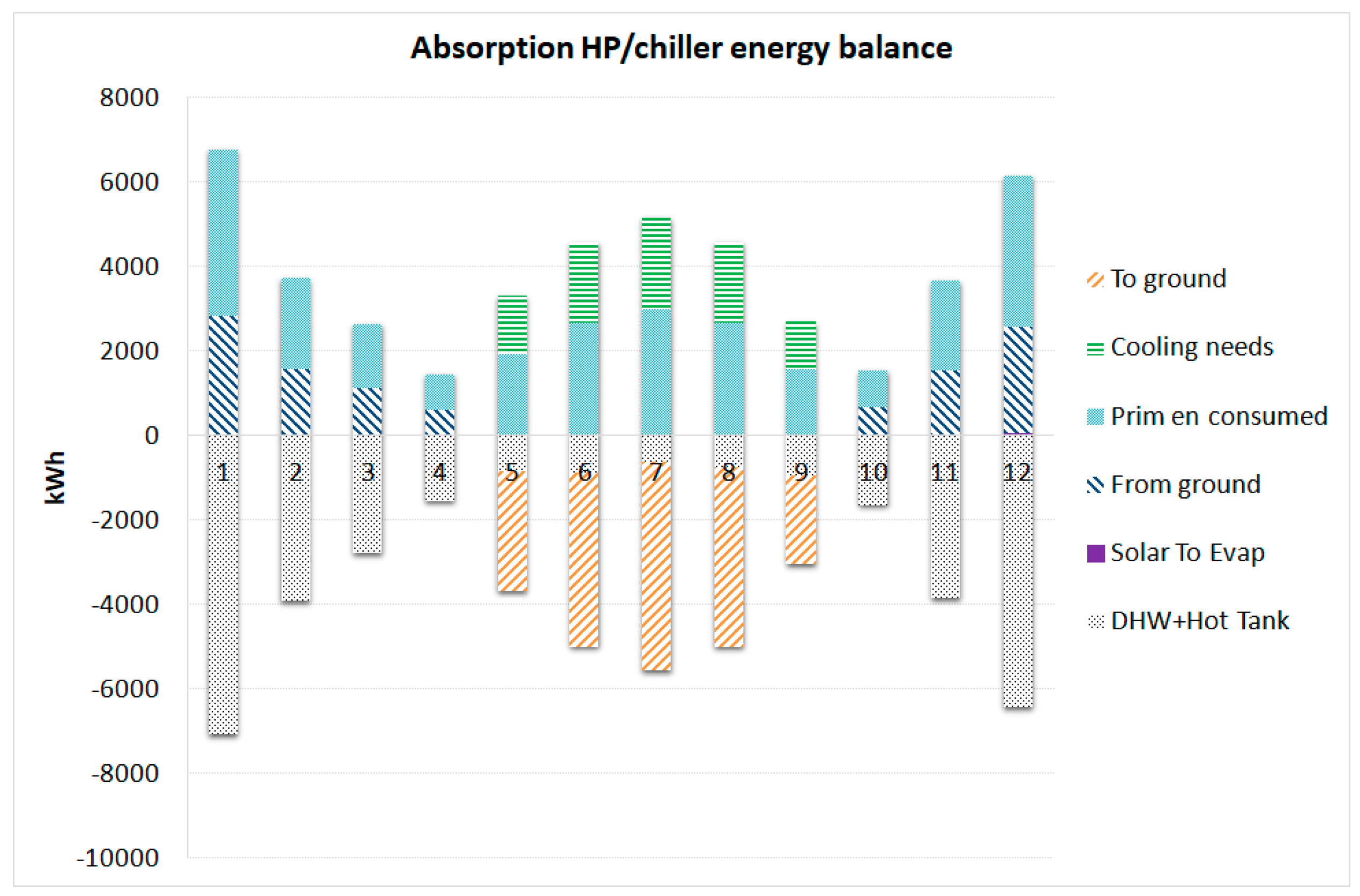

3.1. Monthly Energy Analysis

Some first results are reported here on a monthly basis (

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15), referring to the A3 case only (40 m

2 evacuated tube—300 m ground probes). Solar energy was used to provide hot water for heating (green in

Figure 11) and sanitary uses (red) during the whole year, and to regenerate the ground mainly in the summer months (light blue). While the latter quota increased proportionally to the increasing of the solar field area, the former increased less than proportionally due to the very small heating demand in summer. The quota of solar energy directed to the HP evaporator was negligible. Only A5 presented a meaningful value. This was due to the lower thermal efficiency of the flat plate collectors in winter conditions with respect to the evacuated tube, so it was more frequent that outlet solar circuit temperatures were lower than the hot tank or DHW tank temperatures.

Figure 12 reports the absorption HP/chiller energy balance; the limited use of solar energy as heat source of the HP is confirmed. The highest efficiency (1.83) was reported during the mid seasons (April and October), whereas during cooling season the gas utilization efficiency (GUE) was between 0.74 and 0.79.

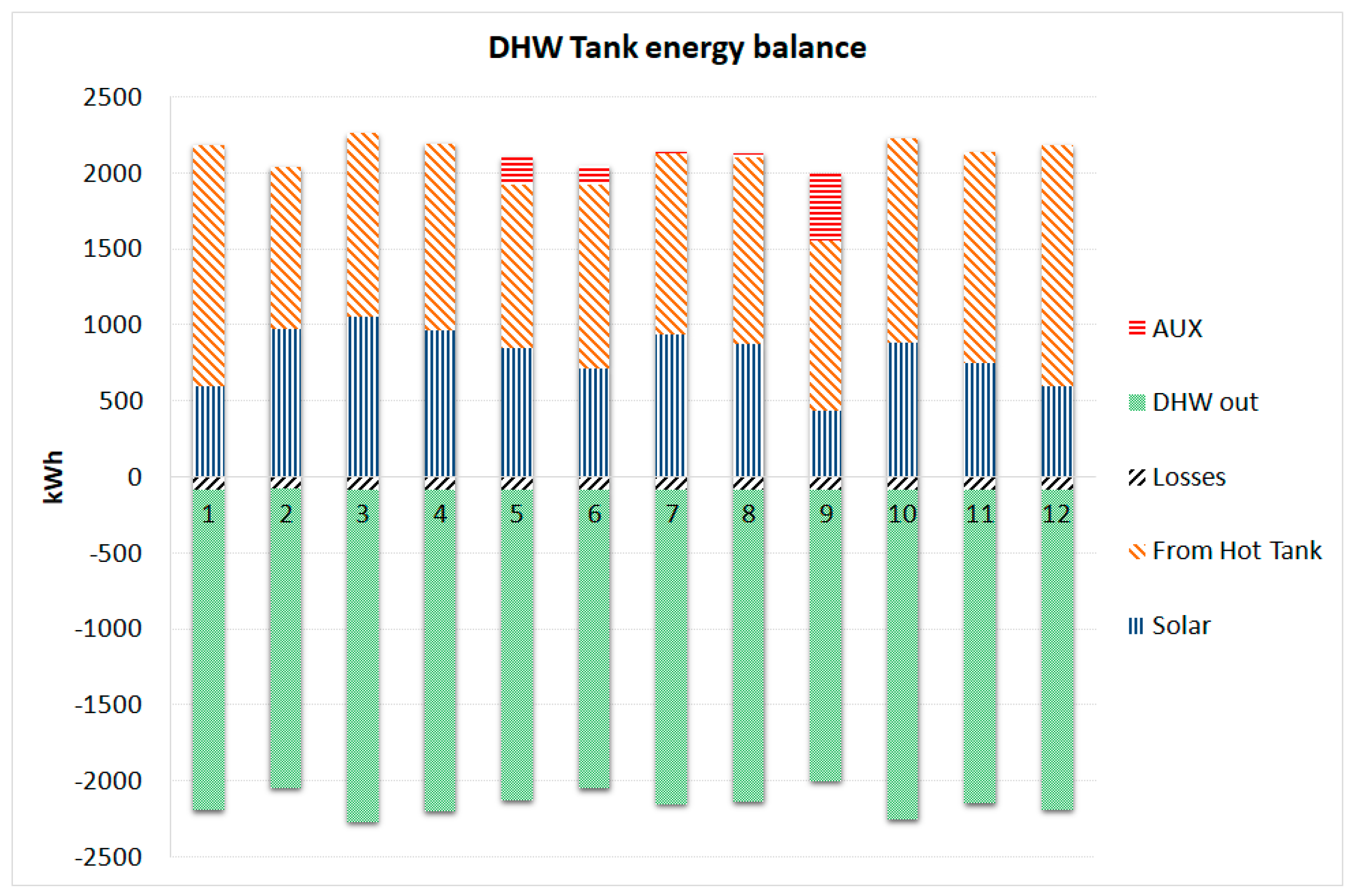

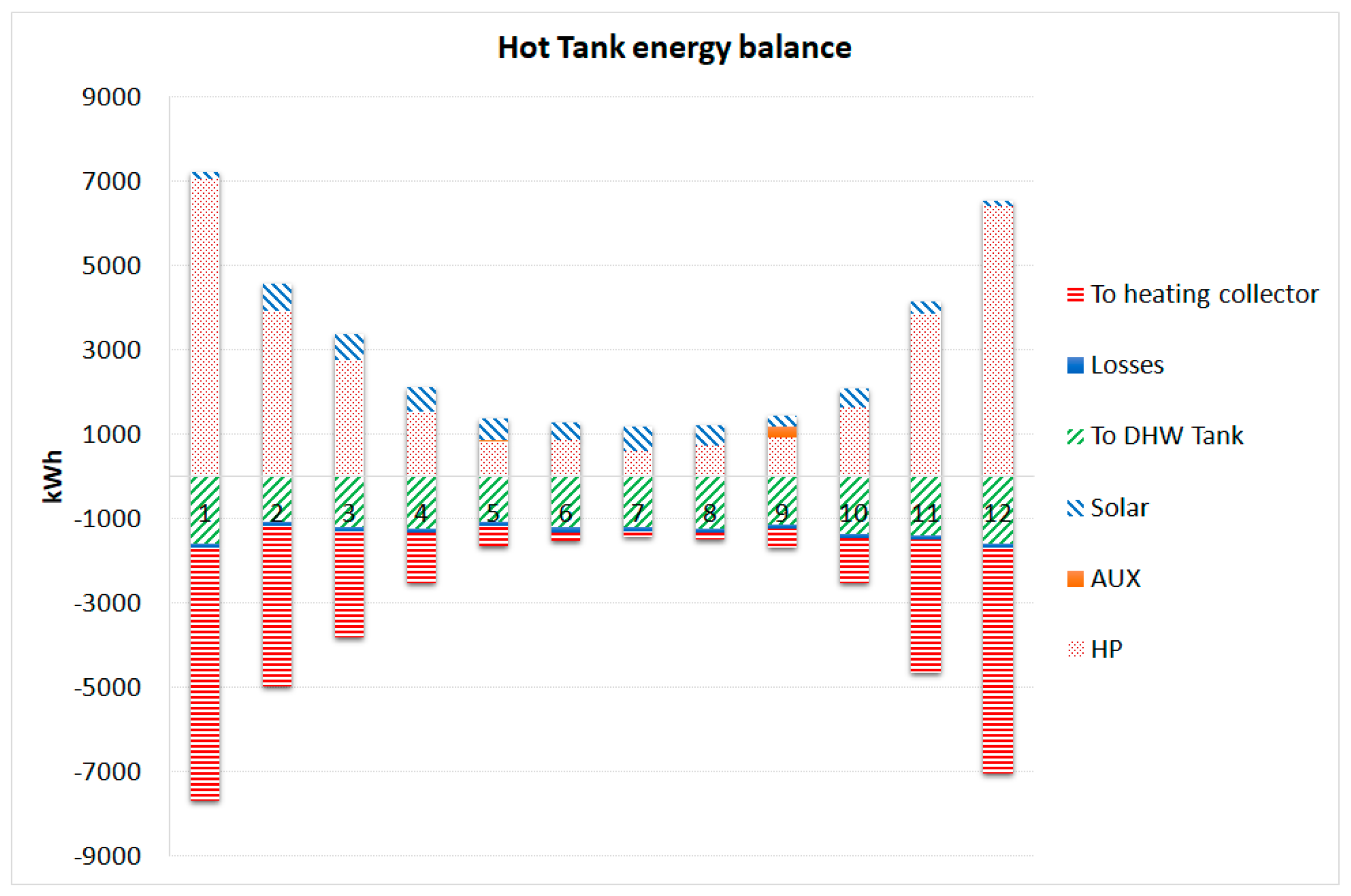

Figure 13 and

Figure 14 report the energy balance of the DHW tank and hot tank, respectively. Solar energy was assured an appreciable contribution to DHW demand, even if the hot tank contribution prevailed above all in the colder months.

The contribution of electric auxiliaries was quite limited, and it was present mainly during the summer or mid-season. This was because in winter the absorption machine operated as HP, and it was controlled by the hot tank set point temperature. In this way, the DHW tank was also satisfied mainly by solar energy and the hot tank. Differently, during the summer or mid-season the absorption machine operated as chiller, controlled by the cold tank set point temperature. Then heat recovered by the condenser was available from the absorption machine only when it is on.

The hot tank was quite fully satisfied by solar energy (light blue in

Figure 14) during the summer months.

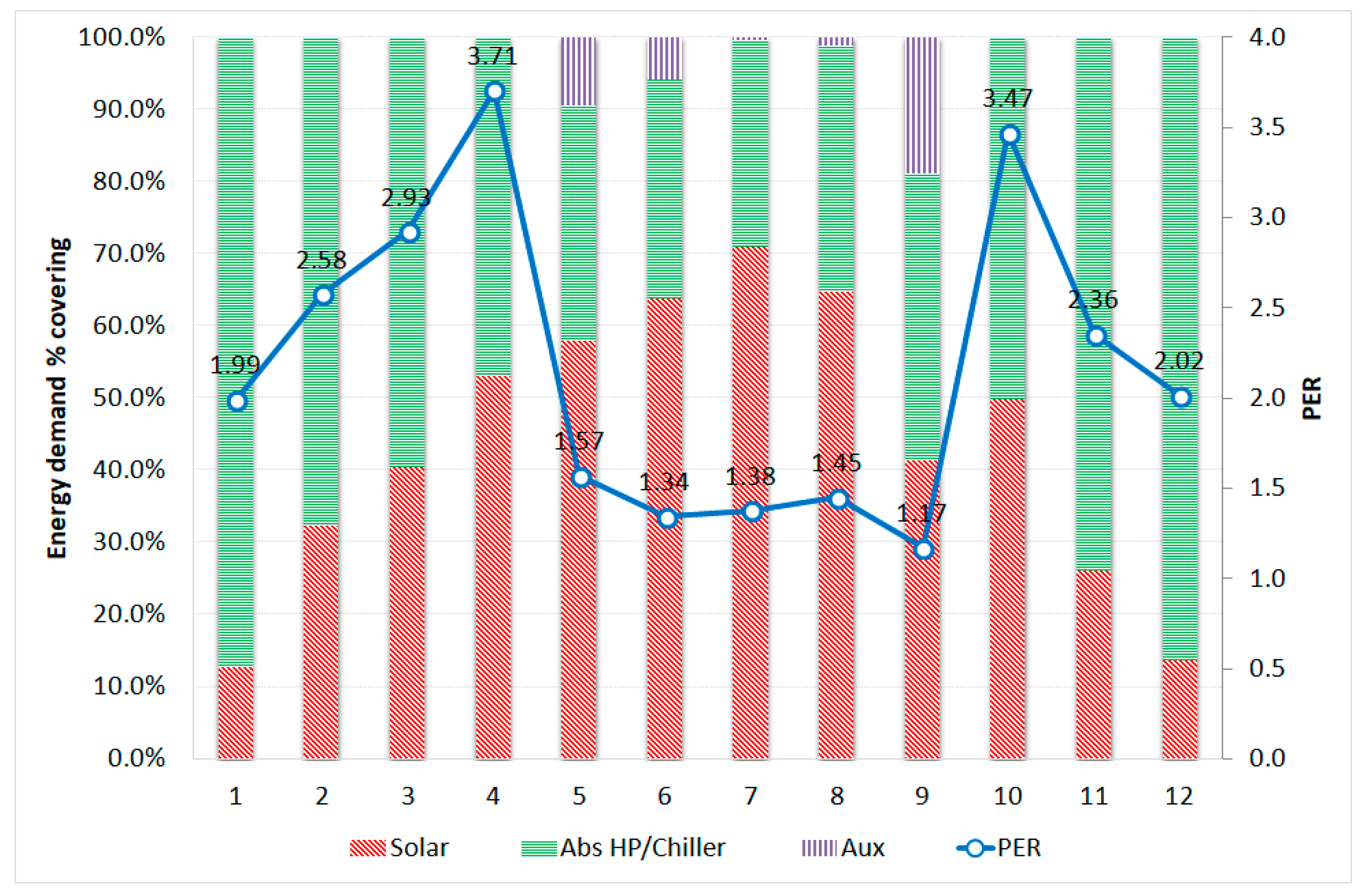

Figure 15 reports the percentage covering of different heat generators (solar collectors, absorption HP, and electric auxiliaries), and the primary energy ratio (PER) for the A3 alternative. PER is defined as the ratio between useful energy produced by the plant (energy from the three tanks to the main collectors of

Figure 8) and the total no-renewable requested primary energy. The latter includes natural gas (NG) supplied to the absorption machine, and electricity to the auxiliaries of the hot tank and DHW tank. According to Italian standard DM 26/06/2015, such electricity consumptions are converted to primary energy by the no-renewable primary factor f

p,nren = 1.95.

During winter months, PER was always greater than 1.94, and that was the nominal value of the HP GUE. The heat pump covered the largest fraction of heating and DHW demand. During summer months the lowest values of PER were reported. This was due to the low GUE of the absorption machine in chiller mode, and to the low contribution of the heat recovered by the chiller to the heating and DHW demand. As a matter of fact, the demand was largely satisfied by solar energy.

The ground energy balance was positive for all the alternatives, that is, energy injected into the ground exceeded energy extracted. The larger the solar field area, the greater the energy from solar collectors directed to regenerate the ground, and the lower the energy extracted from the ground for heating purpose. As this is one of the more important benefits of a multi-source HP plant with a solar system, a ten-year long simulation was performed in order to evaluate such an effect on ground temperature. Average ground temperature for the A3 case during the first years of simulation appreciably increased, starting from 7 °C and stabilizing around 10 °C at the end of the period. Differently, in the case of no-ground regeneration (alternative A1), the ground temperature varied around the initial value but with a slight decreasing trend during the ten year period. The beneficial effect of ground regeneration using solar energy that exceeds direct use is apparent.

3.2. Annual Energy and Economic Analysis

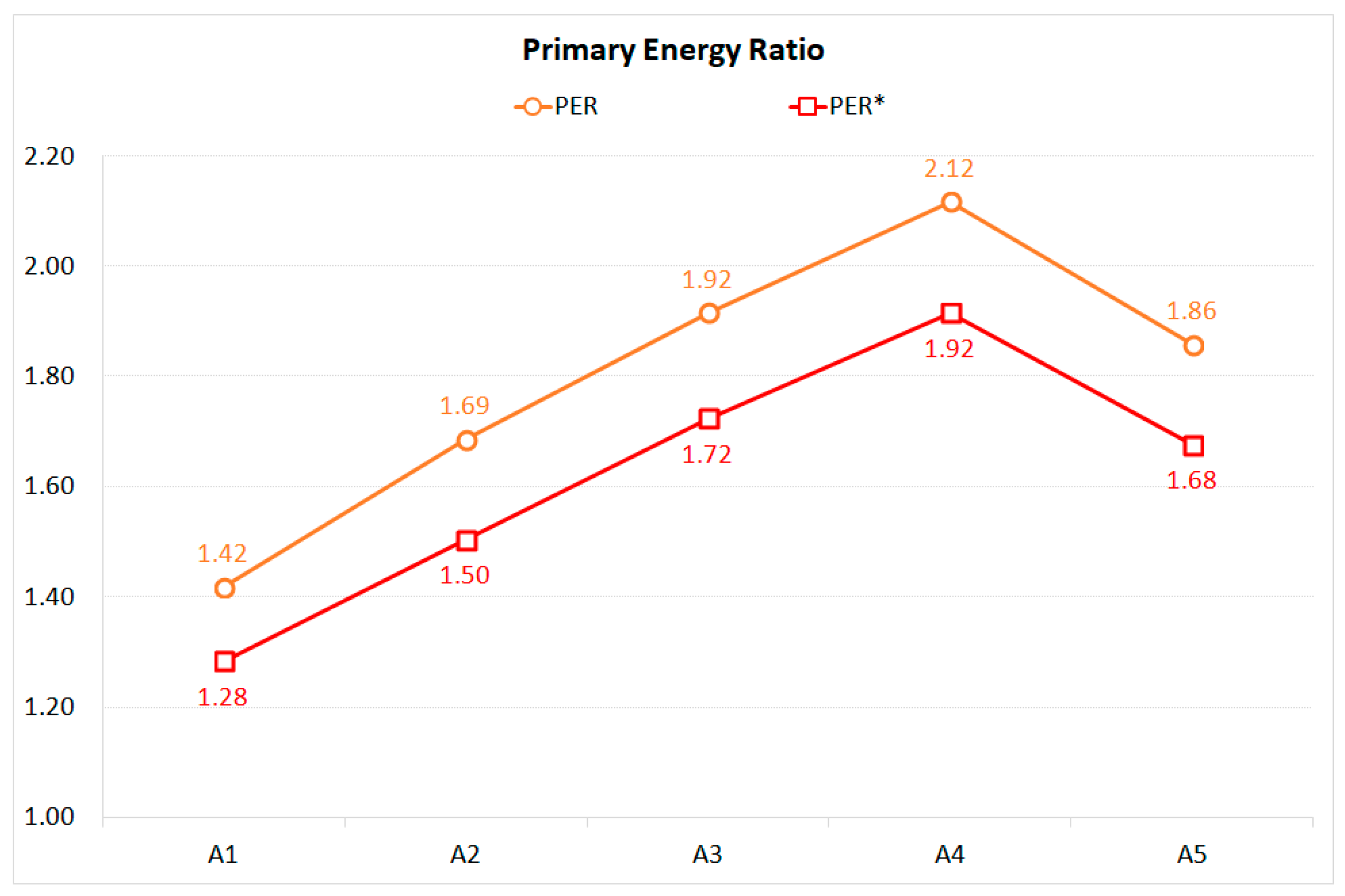

The annual PER is reported in

Figure 16, also considering the electricity consumption by the circulation pumps (PER*). The latter was not negligible at all, mainly due to the pressure drops of the ground circuit. For example, for the A3 case the annual pump electricity consumption was around 1650 kWh: this was 3% of the total thermal and cooling useful energy, and around 11% of the total no-renewable primary energy supplied to the plant. Such a percentage was consistent with data found in previous authors’ work in similar multi-source heat pump plants [

26,

27].

From the energy performance point of view, the best solution was A4 (PER = 2.12, PER* = 1.92), whereas A3 was in second place.

A more comprehensive choice of the preferred alternative can be done by considering the economic point of view as well. A reasonable estimate of the absorption single effect machine investment cost, and the evacuated tube and flat plate solar collectors specific cost was 26,500 €, 545 € m

−2, and 310 € m

−2 respectively (literature and manufacturer’s average values [

29,

30,

31,

32,

33]). The total investment costs for the solar thermal plant reported in

Table 8 were determined by further reasonable hypotheses about the cost of other equipment (pumps, tubes, boiler, valves, etc.), and considering a 30% discount on price catalogue values. The cost of the ground field was calculated considering 10,000 € of fixed cost plus 25 € per meter of ground heat exchanger. The same table also reports the value of the economic incentive (“Conto Energia Termico 2.0”), that is defined as 65% of the plant total investment cost for retrofitting of nZEB [

34]. For public buildings like schools, such an incentive can be allocated once at the beginning of the intervention.

Other parameters useful for the economic analysis are: NG cost fixed at 0.70 € Nm−3, electricity cost at 0.22 € kWh−1, real interest rate 0.565%, and the 20 year period of the economic analysis.

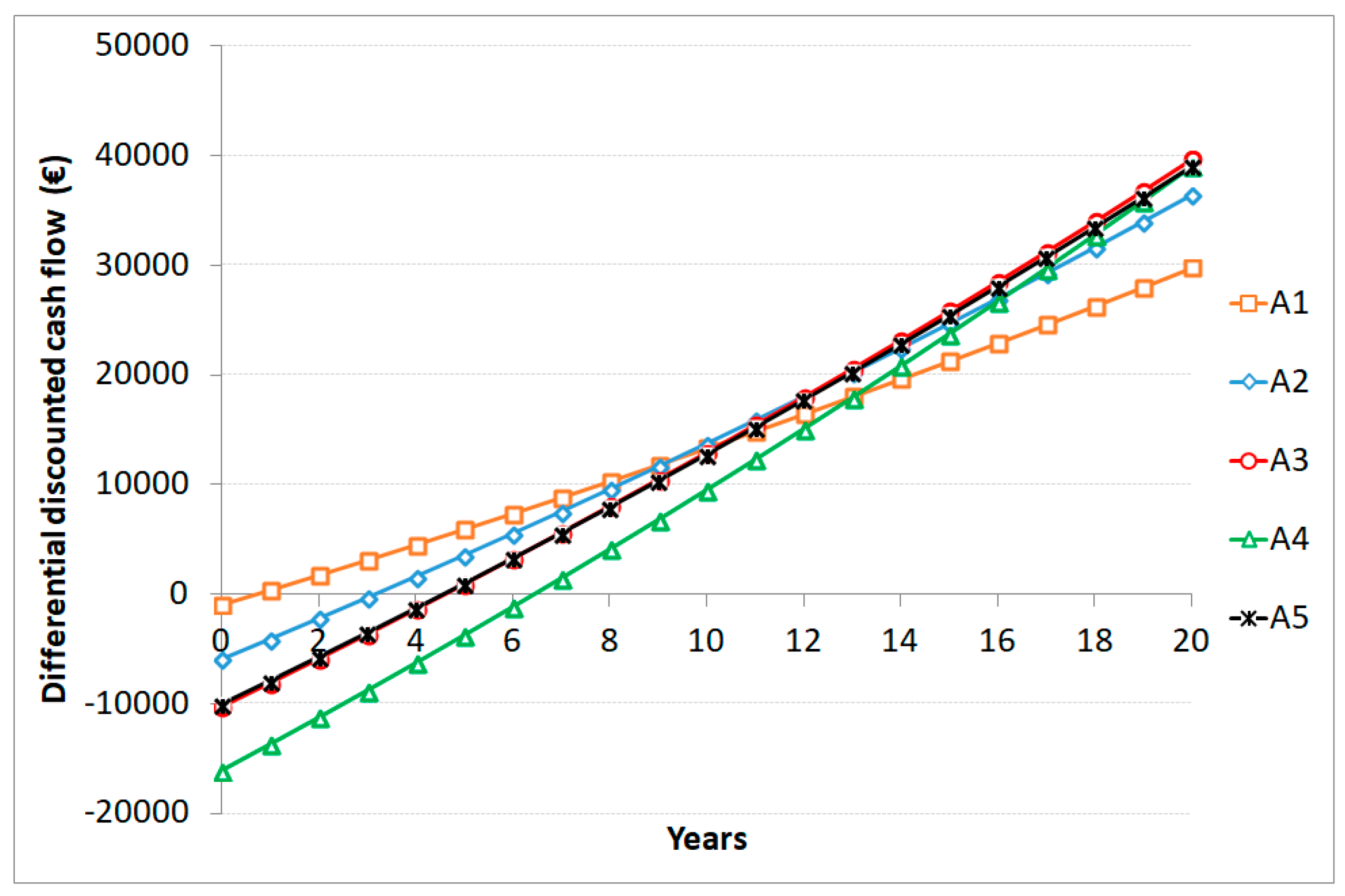

Figure 17 reports the results of the economic analysis of the different solutions with respect to a “reference solution” A0, set up by three 25 kW NG condensing boilers with an efficiency of 100% and an air cooled electric vapor compression chiller. The investment cost of A0 was evaluated as 26,910 €. The only-ground HP plant (A1) allowed the shortest discounted payback period (DPB), around one year, whereas the most efficient multi-source solutions (A3, A4) performed worse (5 and 7 years respectively). However, the shortest DPB criterion was short sighted for a HVAC plant. Instead, in terms of differential (with respect to A0) discounted net present worth (NPW), the most profitable solution was a multi-source HP plant with 40 m

2 of evacuated tube and 300 m boreholes (A3), that allowed gains of around 40 k€ in 20 years.

3.3. Annual Energy Analysis for Determining the Best Storage Tank Configuration

In previous sections, the plant had been optimized from the economic point of view in terms of size of solar and ground fields. In this section, the results of the viability of using PCM and enhanced PCM hybrid storage tanks are reported.

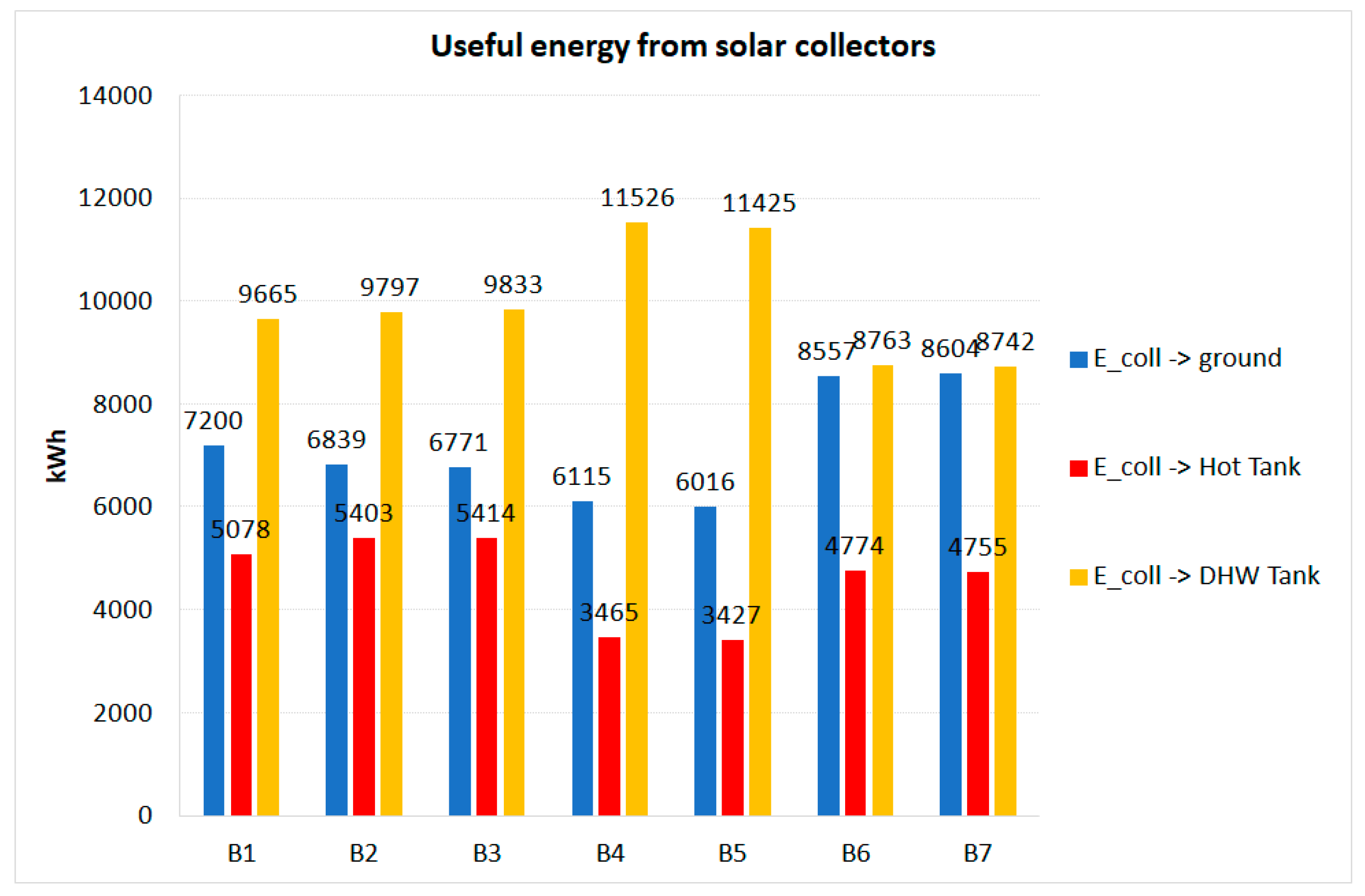

Among the alternatives here considered (

Table 5), the best performances were featured by the B2 and B3 solutions (

Figure 18). They allowed for the lowest no-renewable primary energy consumption and the highest PER of the plant. As a matter of fact, using PCM in the hot tank allowed the increase of the use of solar energy for heating because 7% more energy could be stored in the tank. Moreover, placing PCM tubes in the DHW tank was advantageous as well, as it increased the use of solar energy for DHW production (the increase of stored energy was 19%), even if at the same time the use of solar energy in the hot tank decreased by 32% (

Figure 19). As a consequence, as the heat pump operated at a higher temperature to produce hot water for the hot tank with respect to the DHW tank, higher energy saving could be obtained using PCM tubes in the hot tank because the heat pump operated with a higher GUE.

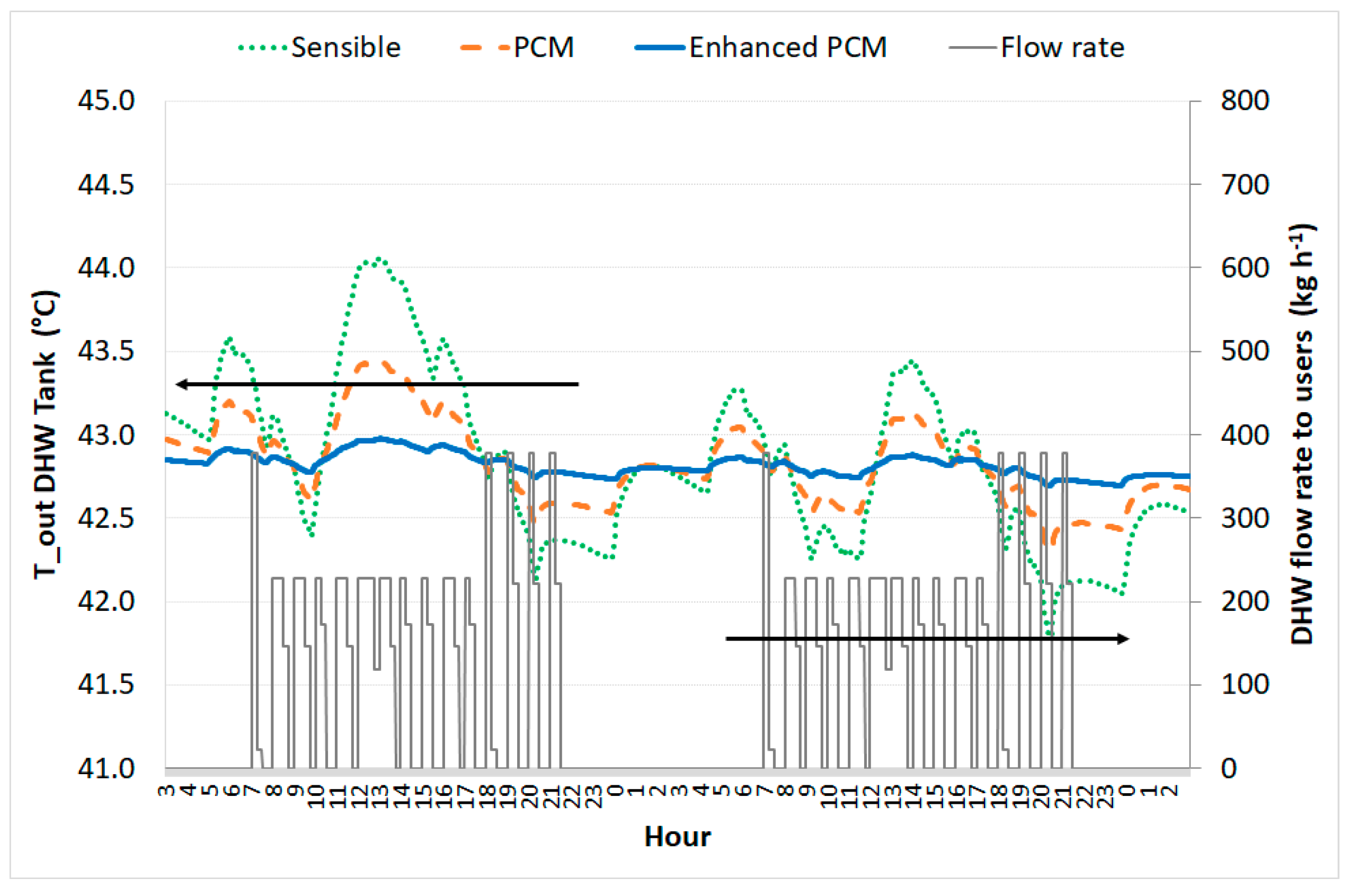

Using enhanced PCM did not allow appreciable energy savings with respect to PCM (

Figure 18). However, an advantage was a narrower temperature range of hot water at the outlet of the tank when the Al-foam enhanced PCM tubes were used. This in principle might seem like a minor advantage, but it means that the heat stored inside the PCM was efficiently rejected to the water when the Al-foams were used. One of the main drawbacks of the PCMs was related to their low thermal conductivity; thus, the melting and solidification processes always occur slowly (see

Figure 4). In fact, when the DHW tank was loaded, the energy could not be effectively extracted and the outlet water temperature could not be kept constant without foam. For example,

Figure 20 reports the outlet temperature of the DHW tank for two typical days in three cases: sensible (water), PCM, and enhanced PCM storage. The more constant temperature of hot water at the outlet of the tank when using enhanced PCM guaranteed a higher level of service for the DHW produced.

4. Conclusions

The study reports the energy and economic analysis of a multi-source (solar and ground) absorption heat pump plant for the heating and cooling of a retrofitted school building. The main objective of the analysis is to define the size and the type (sensible or PCM or enhanced PCM) of the three thermal energy storage systems (for DHW production, for heating, and for cooling). As a matter of fact, the operating temperature of the storage depends on the solar collectors’ area, on the volume of the storage tanks, and on the kind and entity of the thermal loads to be faced. For this reason, only a transient simulation allows a reliable comparison between different layouts and sizes of system components. From the energy point of view, the best solution is given by 40 m2 evacuated tube, 300 m ground probes, 3000 L hot tank and DHW tank capacity, and 1000 L cold tank capacity, the former tanks filled with PCM RT47, and the other as sensible storage (water). Such a configuration features the higher primary energy ratio and solar ratio between the different scenarios considered, because the mean operating temperature of the hot tank is longer near the melting temperature of the PCM during the year. The use of Al-foam enhanced PCM does not yield an additional advantage from the energy performance point of view. Instead, a more constant hot water temperature is guaranteed. This allows a higher level of service for the hot water produced. Further development of this research could address a wider economic evaluation of the proposed study, as the greater investment cost of PCM and enhanced PCM technologies with respect to sensible storage means their viability must be carefully evaluated.