Performance Evaluation and Optimization of a Building-Integrated Photovoltaic/Thermal Solar Water Heating System for Exterior Shading: A Case Study in South China

Abstract

1. Introduction

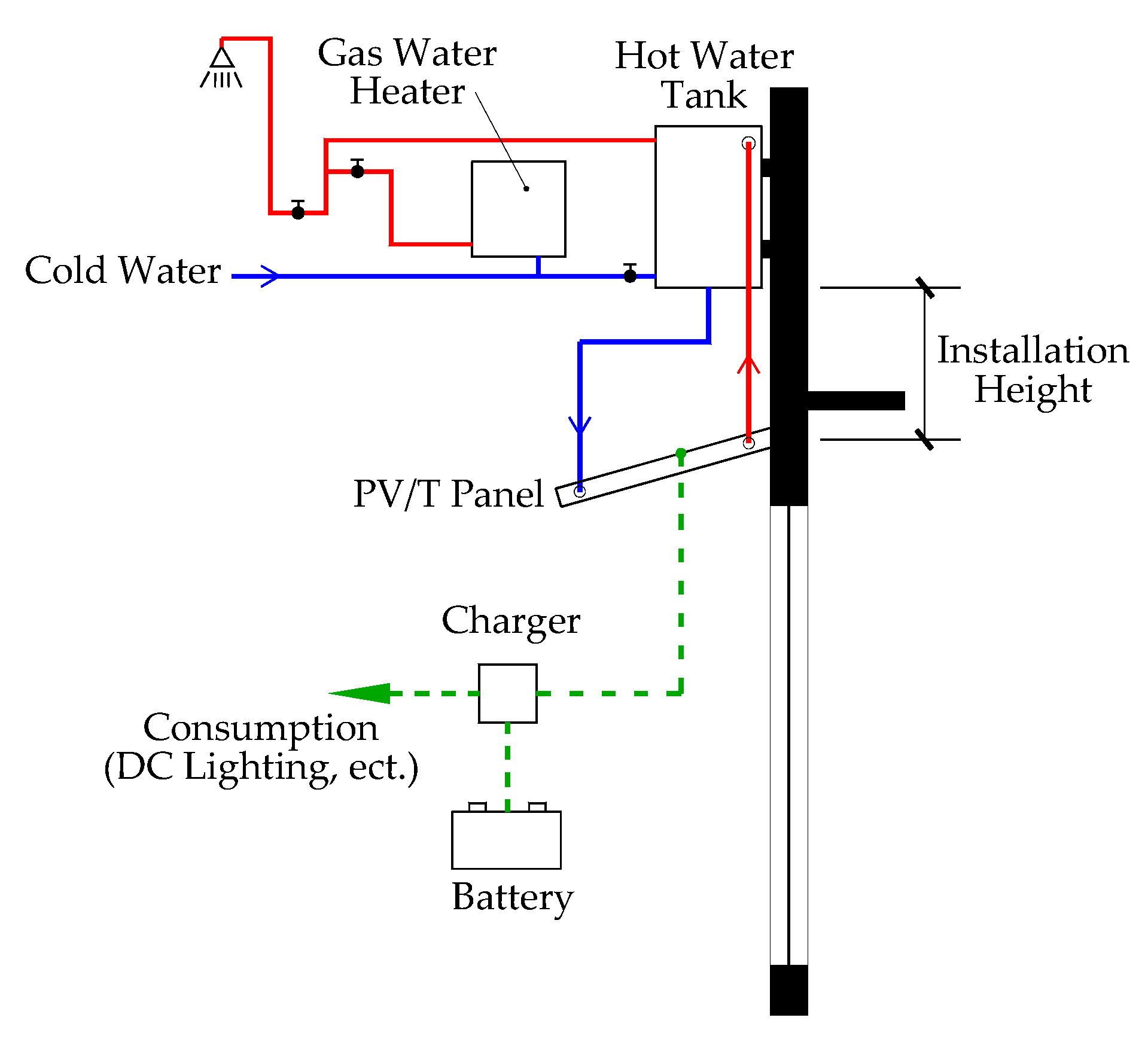

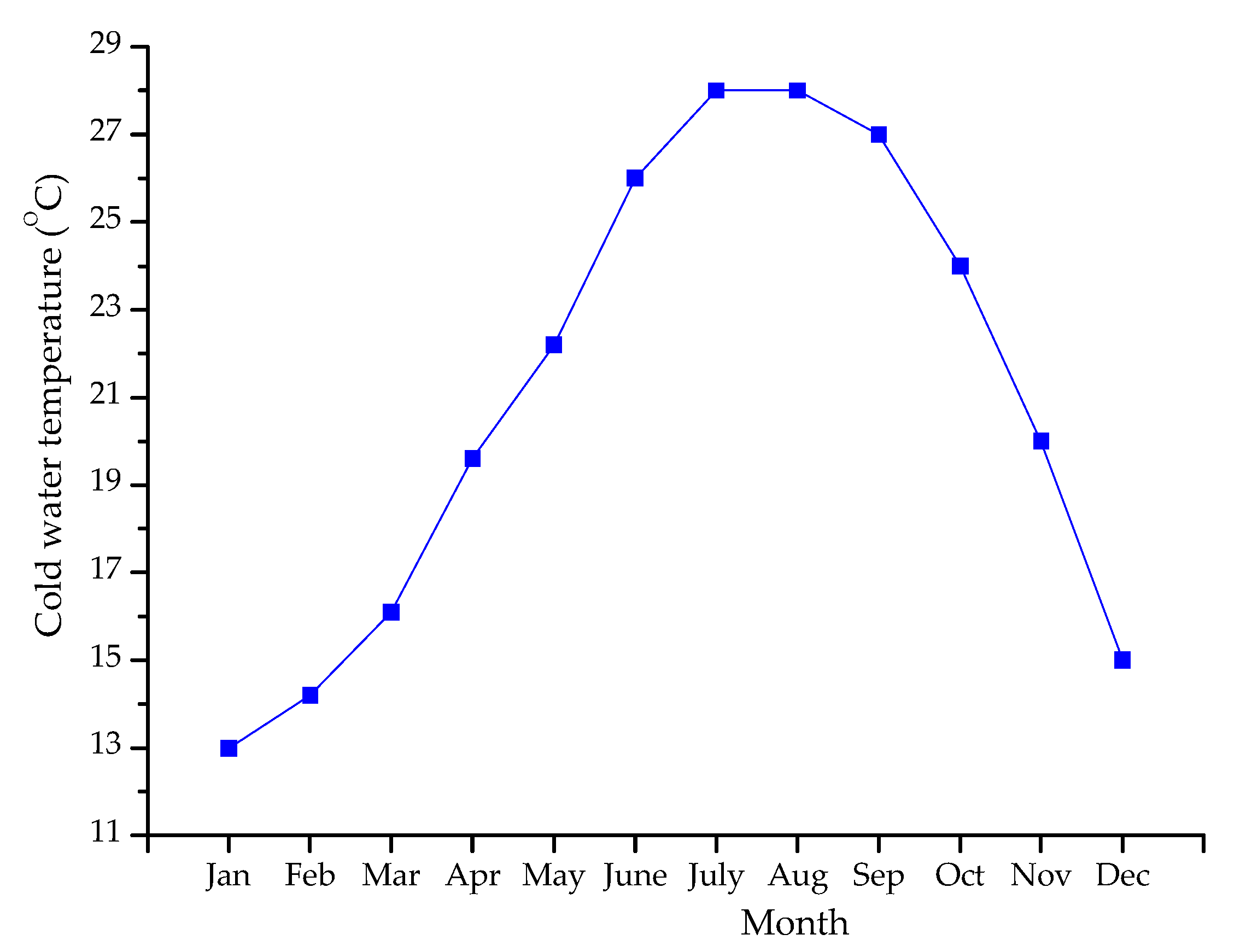

2. System Description

2.1. Description of System Configuration

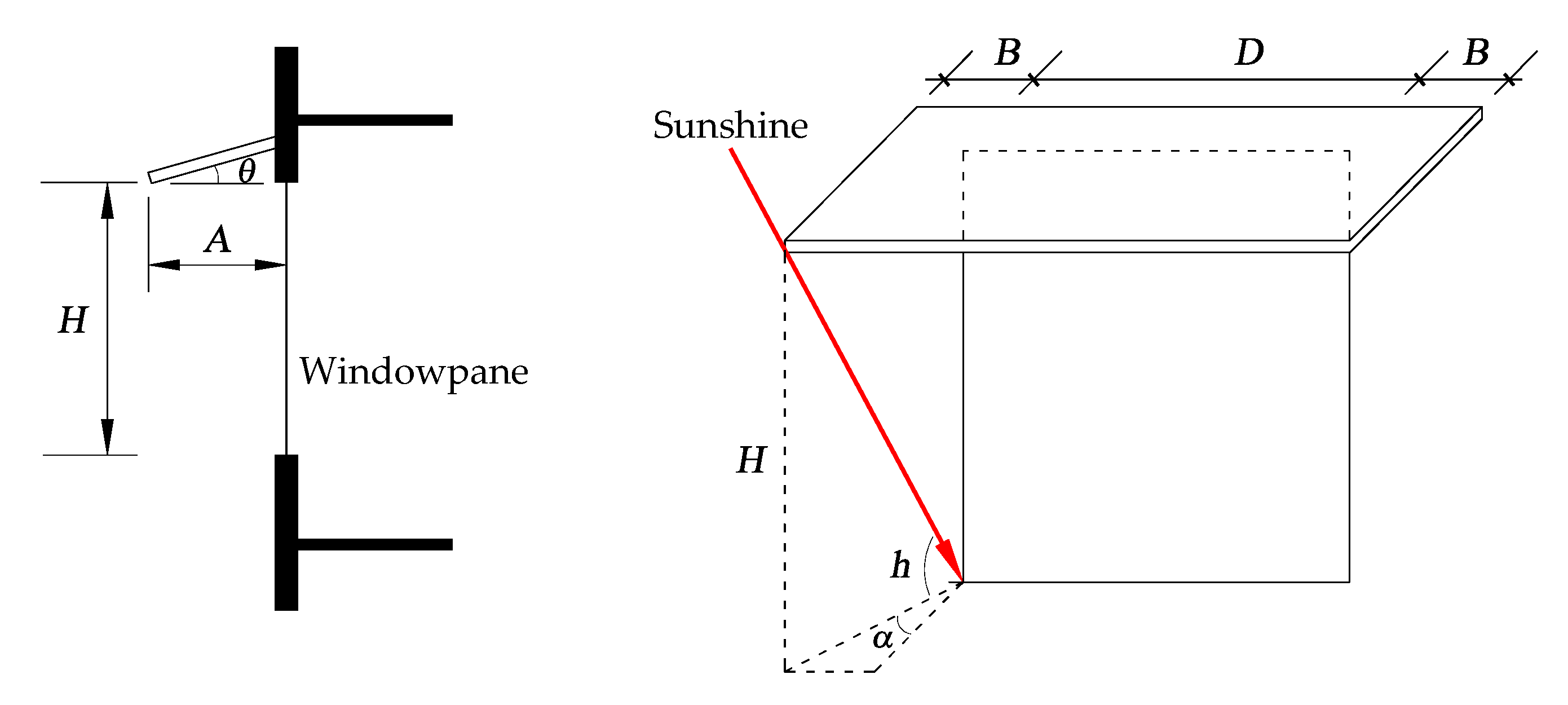

2.2. Determination of PV/T Panel Size

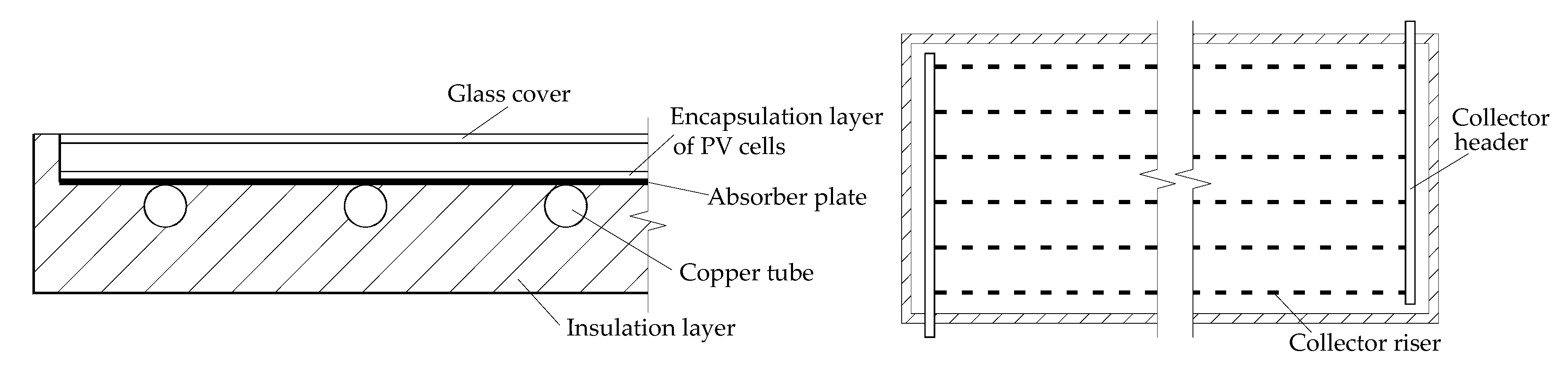

2.3. Structrue of PV/T Panel

3. Methodology

3.1. Performance Evaluation Methods

3.2. TRNSYS Modeling

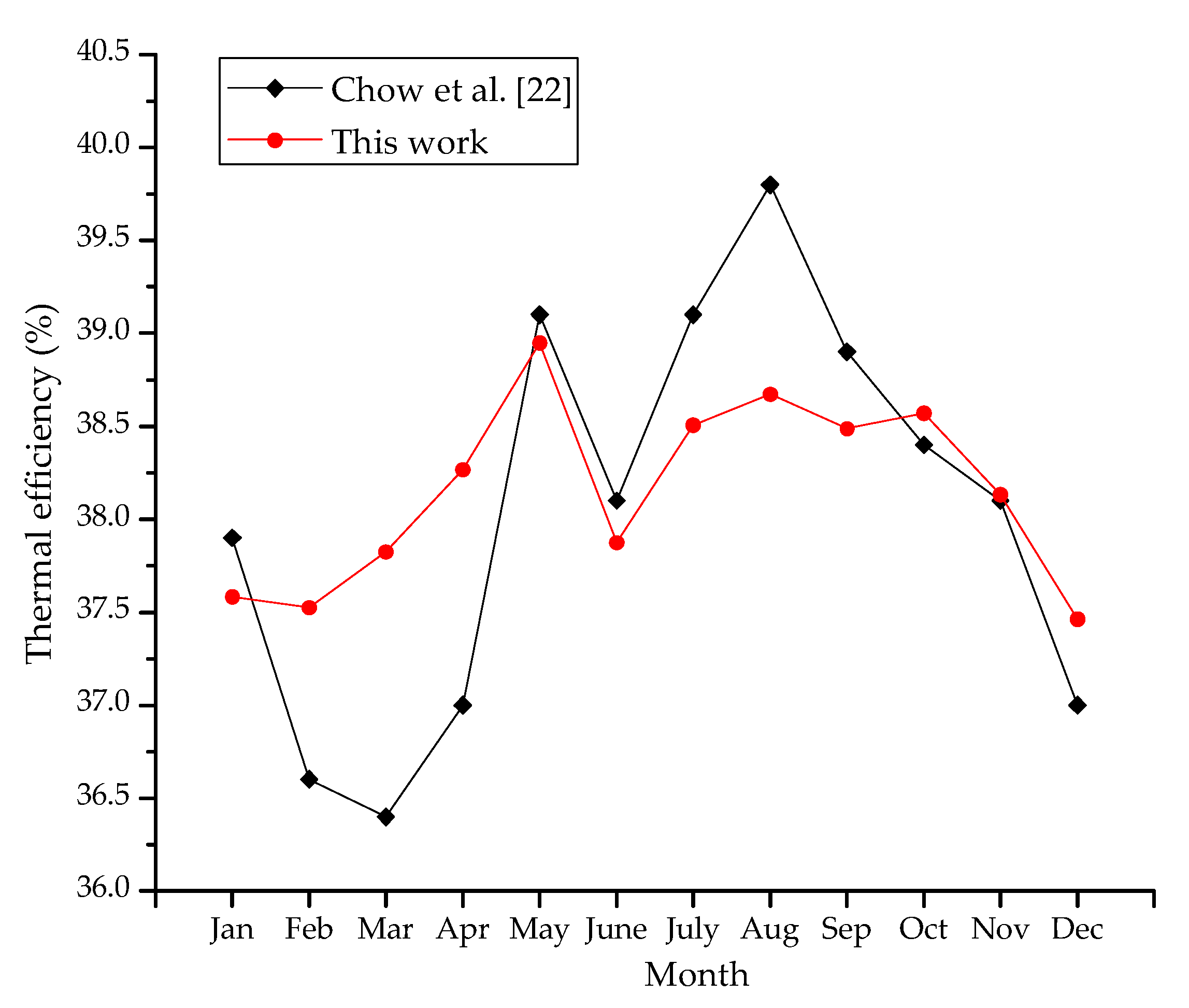

3.3. Validation of the TRNSYS Model

4. Results and Discussion

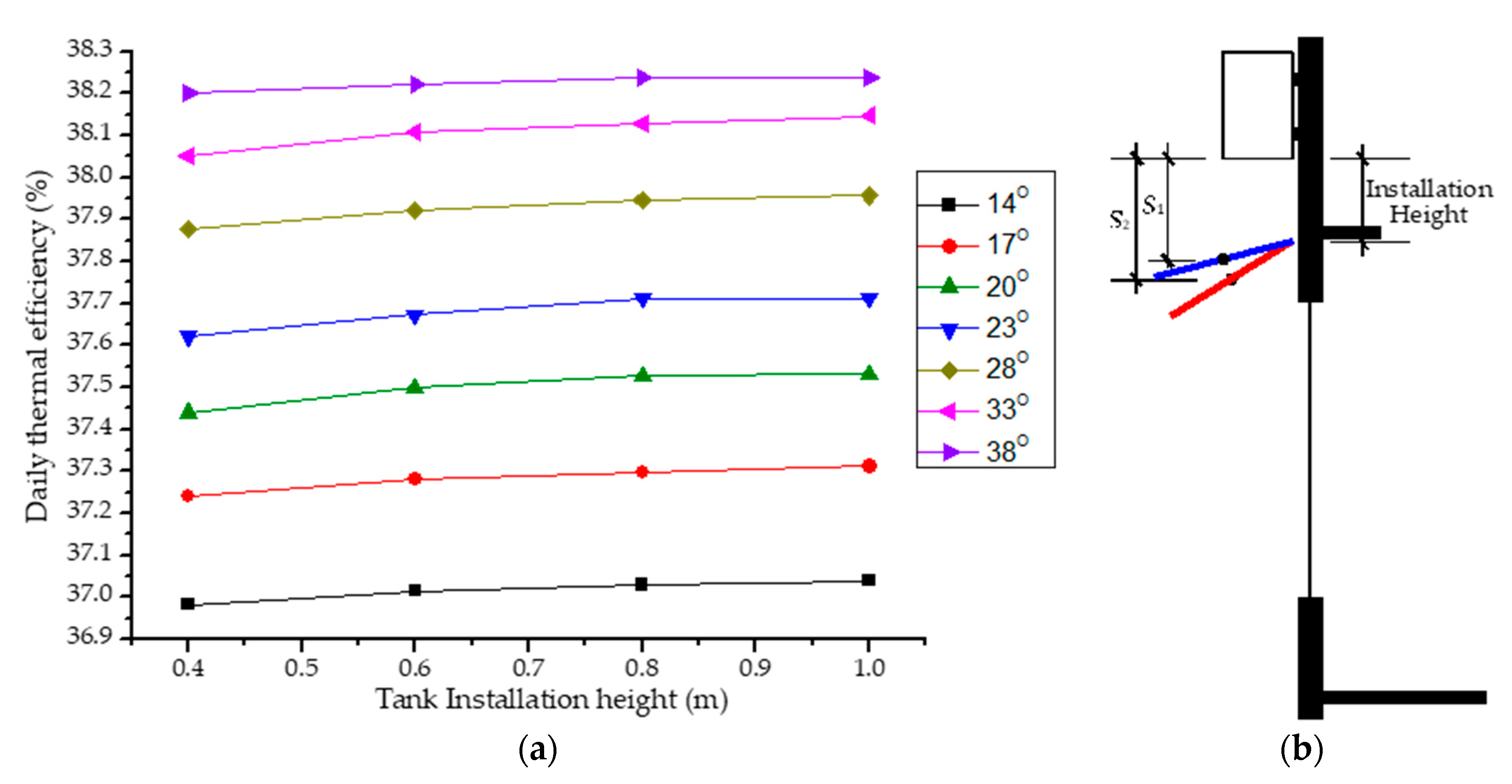

4.1. Influence ofTank Installation Height on Thermal Performance

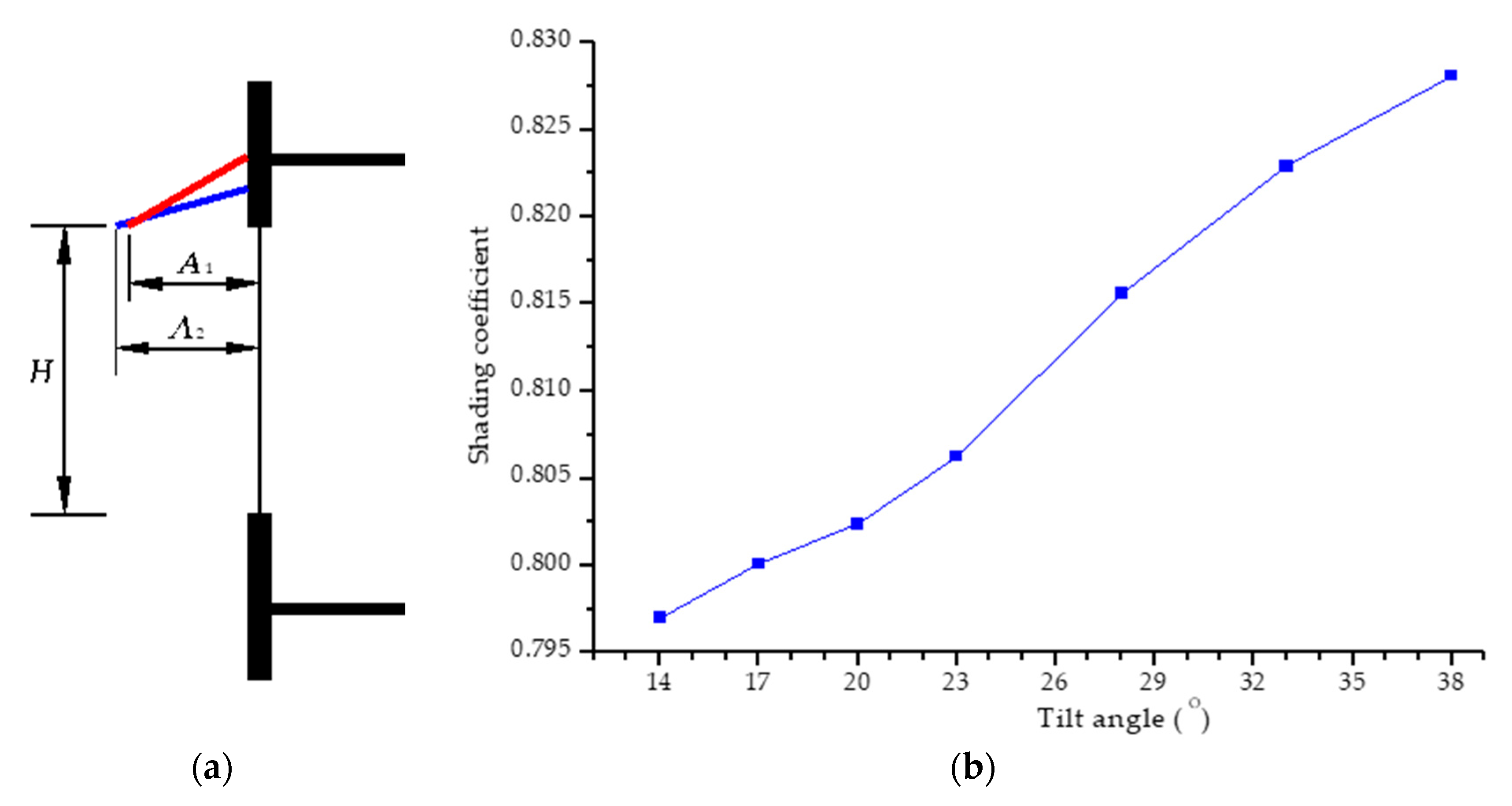

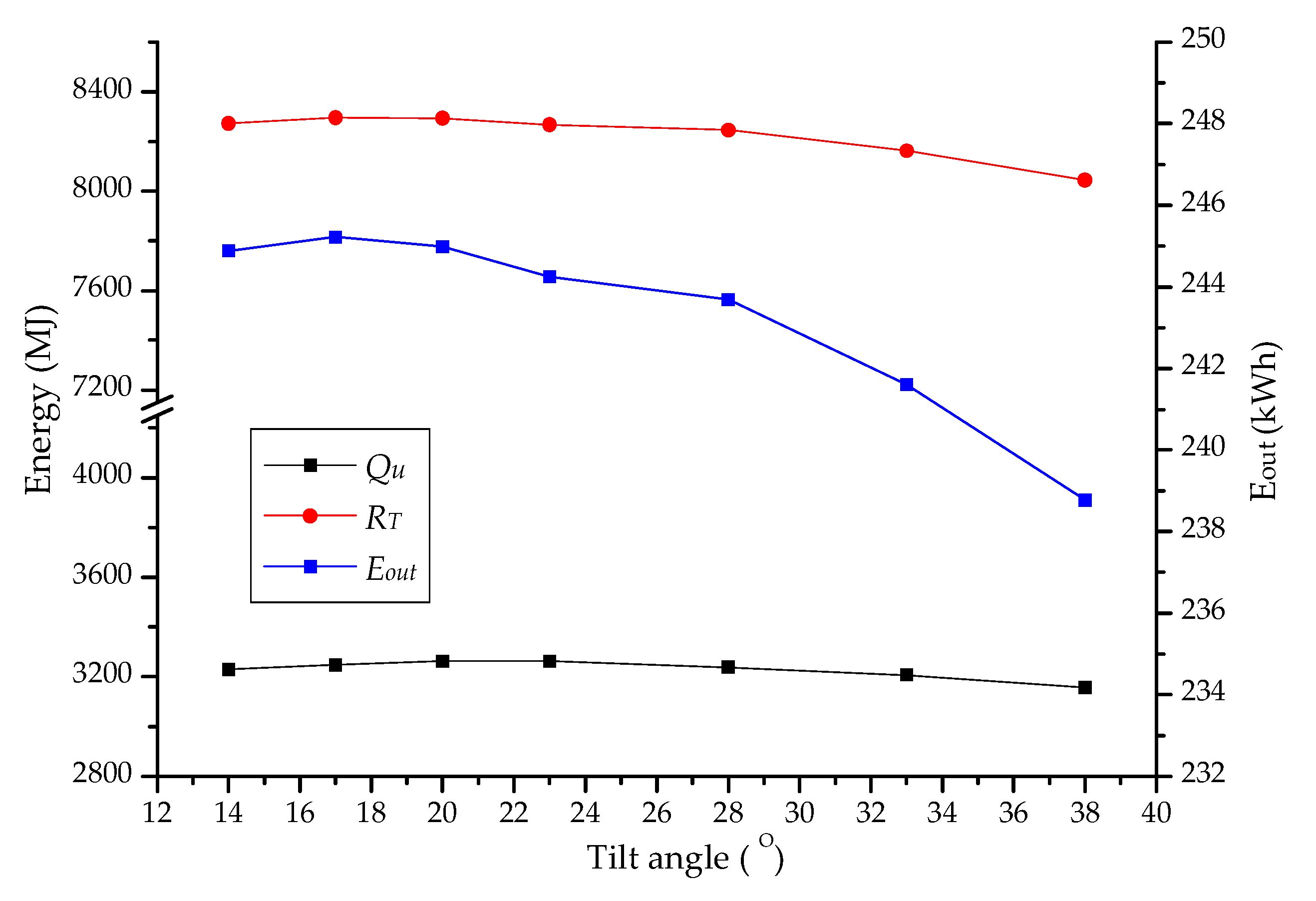

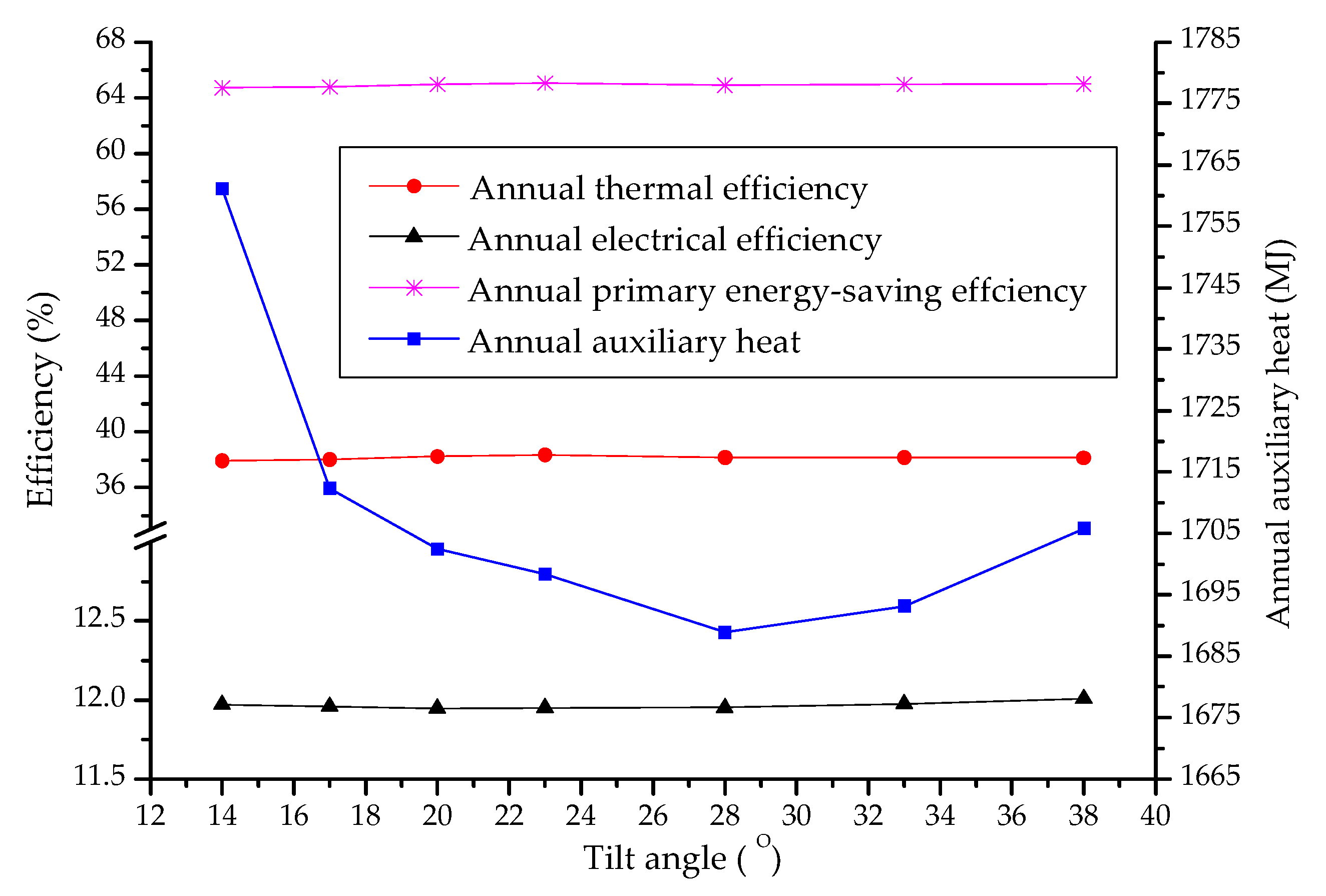

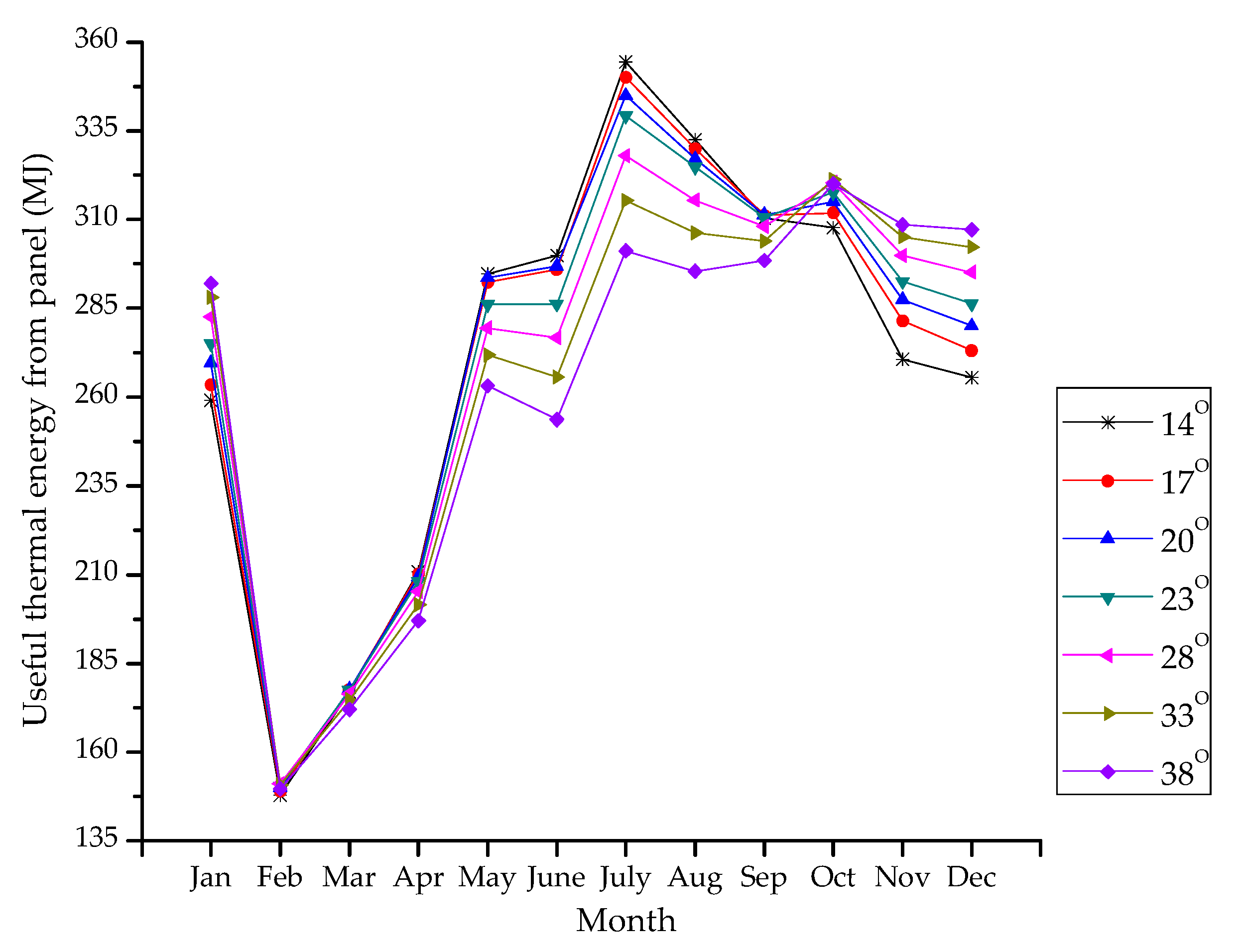

4.2. Influence of Panel Tilt Angle on System Performances

5. Conclusions

- (1)

- In view of the offset effect of the increase of flow resistance and pipe heat losses resulting from the increase of tank installation height, the suggested tank installation height is 0.6~0.8 m.

- (2)

- The annual auxiliary heat reaches the minimum when the panel tilt angle equals 28°, while the annual electric energy output reaches the maximum when the panel tilt angle equals 17°. The annual electric energy output changes slightly with the variation of tilt angle. Nevertheless, the smaller tilt angle will cause better shading performance. Comprehensively considering thermal, electrical, and shading performances, it is suggested that the value of the tilt angle ranges from 20° to 28°. The average thermal, electrical, and primary energy-saving efficiencies were found to be, respectively, 38.25%, 11.95%, and 64.97% when the tilt angle ranges from 20° to 28°.

- (3)

- Considering that the influence of the tank installation height within the suggested range of 0.6 to 0.8 m on thermal performance is small, the optimization result for the tank installation height of 0.7 m has reference significance to other scenarios within the range of 0.6 to 0.8 m. Overall, the presented BIPV/T solar water heating system for exterior shading is suitable for residential application in the area that has a similar climate to that of Guangzhou.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- National Energy Administration of P.R. China. China is Leading the Development of Global Renewable Energy. Available online: http://www.nea.gov.cn/2019-08/21/c_138326148.htm (accessed on 17 October 2019).

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Henemann, A. BIPV: Built-in solar energy. Renew. Energy Focus 2008, 9, 14–19. [Google Scholar] [CrossRef]

- Yoo, S.H.; Manz, H. Available remodeling simulation for a BIPV as a shading device. Sol. Energy Mater. Sol. Cells 2011, 95, 394–397. [Google Scholar] [CrossRef]

- Asfour, O.S. Solar and shading potential of different configurations of building integrated photovoltaics used as shading devices considering hot climatic conditions. Sustainability 2018, 10, 4373. [Google Scholar] [CrossRef]

- Lee, H.M.; Kim, S.C.; Lee, C.S.; Yoon, J.H. Power Performance Loss Factor Analysis of the a-Si BIPV Window System Based on the Measured Data of the BIPV Test Facility. Appl. Sci. 2018, 8, 1645. [Google Scholar] [CrossRef]

- Candanedo, J.A.; Athienitis, A. Simulation of the performance of a BIPV/T system coupled to a heat pump in a residential heating application. In Proceedings of the 9th International IEA Heat Pump Conference, Zürich, Switzerland, 20–22 May 2008. [Google Scholar]

- Chen, Y.X.; Athienitis, A.K.; Galal, K. Modeling, design and thermal performance of a BIPV/T system thermally coupled with a ventilated concrete slab in a low energy solar house: Part 1, BIPV/T system and house energy concept. Sol. Energy 2010, 84, 1892–1907. [Google Scholar] [CrossRef]

- Yang, T.T.; Athienitis, A.K. Experimental investigation of a two-inlet air-based building integrated photovoltaic/thermal (BIPV/T) system. Appl. Energy 2015, 159, 70–79. [Google Scholar] [CrossRef]

- Yang, T.T.; Athienitis, A.K. A review of research and developments of building-integrated photovoltaic/thermal (BIPV/T) systems. Renew. Sustain. Energy Rev. 2016, 66, 886–912. [Google Scholar] [CrossRef]

- Corbin, C.D.; Zhai, Z.Q.J. Experimental and numerical investigation on thermal and electrical performance of a building integrated photovoltaic-thermal collector system. Energy Build. 2010, 42, 76–82. [Google Scholar] [CrossRef]

- Davidsson, H.; Perers, B.; Karlsson, B. System analysis of a multifunctional PV/T hybrid solar window. Sol. Energy 2012, 86, 903–910. [Google Scholar] [CrossRef]

- Buker, M.S.; Mempouo, B.; Riffat, S.B. Performance evaluation and techno-economic analysis of a novel building integrated PV/T roof collector: An experimental validation. Energy Build. 2014, 76, 164–175. [Google Scholar] [CrossRef]

- Mehdipour, C.; Mohammadi, F. Design and analysis of a stand-alone photovoltaic system for footbridge lighting. J. Sol. Energy Res. 2019, 4, 85–91. [Google Scholar]

- Mohammadi, F. Design, analysis, and electrification of a solar-powered electric vehicle. J. Sol. Energy Res. 2018, 3, 293–299. [Google Scholar]

- Fudholi, A.; Sopian, K.; Yazdi, M.H.; Ruslan, M.H.; Ibrahim, A.; Kazem, H.A. Performance analysis of photovoltaic thermal (PVT) water collectors. Energy Convers. Manag. 2014, 78, 641–651. [Google Scholar] [CrossRef]

- Ji, J.; Guo, C.; Sun, W.; He, W.; Wang, Y.; Li, G. Experimental investigation of tri-functional photovoltaic/thermal solar collector. Energy Convers. Manag. 2014, 88, 650–656. [Google Scholar] [CrossRef]

- Long, E.S.; Chen, J.H. Are the annual relative variation rates of energy consumption approximate in different cities with the same shading coefficient? Build. Environ. 2005, 40, 507–515. [Google Scholar]

- DesignBuilder Simulation and CFD Training Guide; DesignBuilder Software Ltd.: Stroud, UK, 2009.

- TRNSYS 17: A Transient Simulation and Program; Solar Energy Laboratory, University of Wisconsin-Madison, 2010. Available online: http://web.mit.edu/parmstr/Public/TRNSYS/04-MathematicalReference.pdf (accessed on 28 October 2019).

- Chow, T.T.; He, W.; Ji, J. Hybrid photovoltaic-thermosyphon water heating system for residential application. Sol. Energy 2006, 80, 298–306. [Google Scholar] [CrossRef]

- Chow, T.T.; He, W.; Ji, J.; Chan, A.L.S. Performance evaluation of photovoltaic—Thermosyphon system for subtropical climate application. Sol. Energy 2007, 81, 123–130. [Google Scholar] [CrossRef]

- ASHRAE Guideline 14-2014. Measurement of Energy, Demand, and Water Savings; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2014. [Google Scholar]

| Latitude and Longitude of Guangzhou | 23°08′ N, 113°20′ E |

|---|---|

| Window height (mm) | 1800 |

| Window width (mm) | 1600 |

| Embedded depth of windowpane (mm) | 200 |

| Tilt angle of panel (°) | 28 |

| Panel width (mm) | 646 |

| Panel length (mm) | 2648 |

| Gross area of panel (m2) | 1.71 |

| Net Collector Area (m2) | 1.60 |

| Intercept efficiency of the collector (%) | 56.6 |

| Efficiency slope the collector [kJ/(h·m2·K)] | 21.88 |

| Heat loss coefficient of PV/T panel [kJ/(h·m2·K)] | 34.52 |

| Tank height (m) | 0.96 |

| Pipe loss coefficient (kJ/(h·m2·K)) | 3.42 |

| Overall loss coefficient of storage tank (kJ/(h·K)) | 4.97 |

| Collector fin efficiency factor | 0.1454 |

| Collector plate absorptance | 0.95 |

| Cover transmittance | 0.94 |

| Temperature coefficient of solar cell efficiency (1/K) | 0.0045 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, W.; Luo, D.; Zhu, C. Performance Evaluation and Optimization of a Building-Integrated Photovoltaic/Thermal Solar Water Heating System for Exterior Shading: A Case Study in South China. Appl. Sci. 2019, 9, 5395. https://doi.org/10.3390/app9245395

Chen X, Wang W, Luo D, Zhu C. Performance Evaluation and Optimization of a Building-Integrated Photovoltaic/Thermal Solar Water Heating System for Exterior Shading: A Case Study in South China. Applied Sciences. 2019; 9(24):5395. https://doi.org/10.3390/app9245395

Chicago/Turabian StyleChen, Xiao, Wanying Wang, Dandan Luo, and Chihui Zhu. 2019. "Performance Evaluation and Optimization of a Building-Integrated Photovoltaic/Thermal Solar Water Heating System for Exterior Shading: A Case Study in South China" Applied Sciences 9, no. 24: 5395. https://doi.org/10.3390/app9245395

APA StyleChen, X., Wang, W., Luo, D., & Zhu, C. (2019). Performance Evaluation and Optimization of a Building-Integrated Photovoltaic/Thermal Solar Water Heating System for Exterior Shading: A Case Study in South China. Applied Sciences, 9(24), 5395. https://doi.org/10.3390/app9245395