High-Temperature Mechanical Properties of 4.5%Al δ-TRIP Steel

Abstract

Featured Application

Abstract

1. Introduction

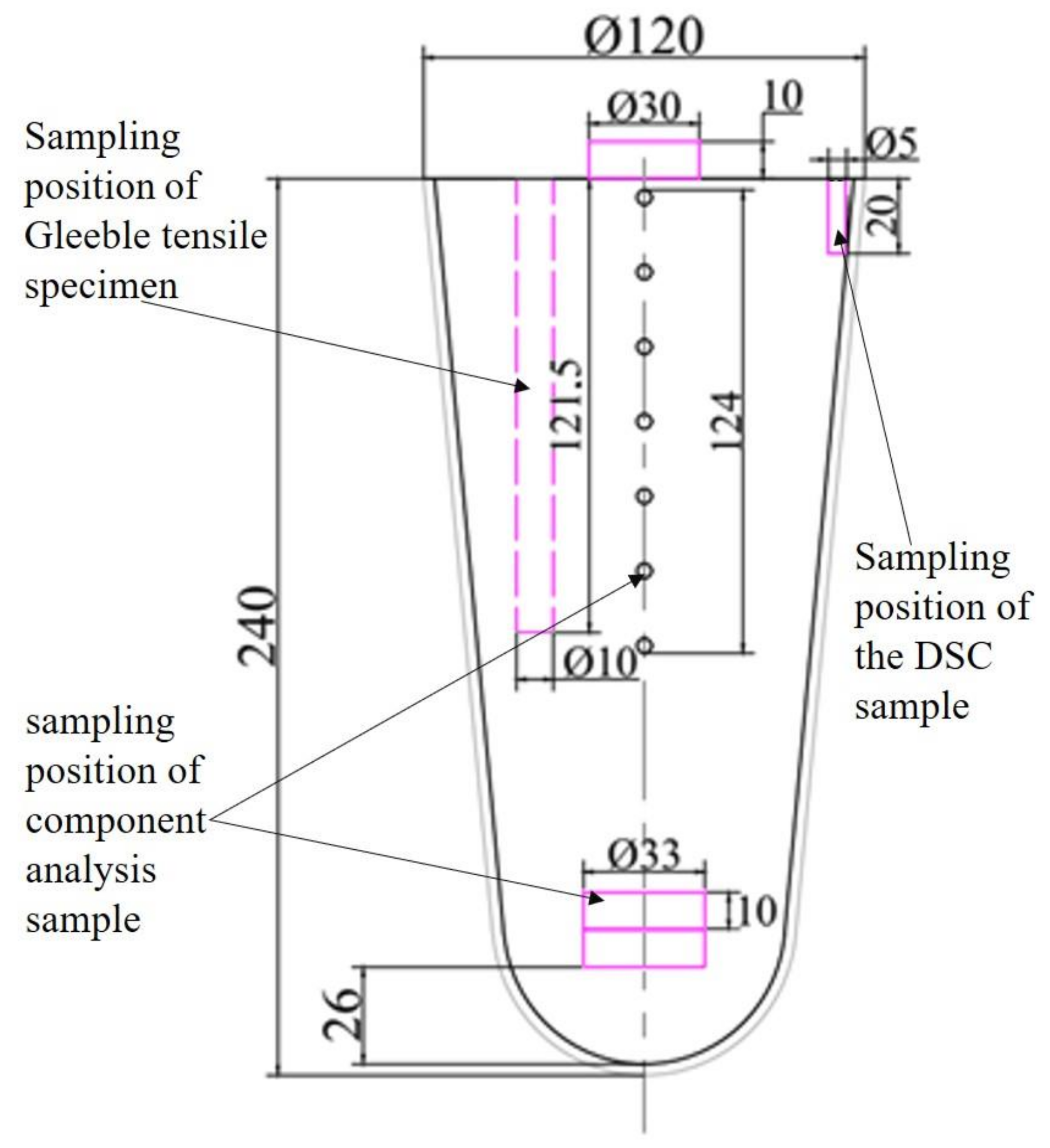

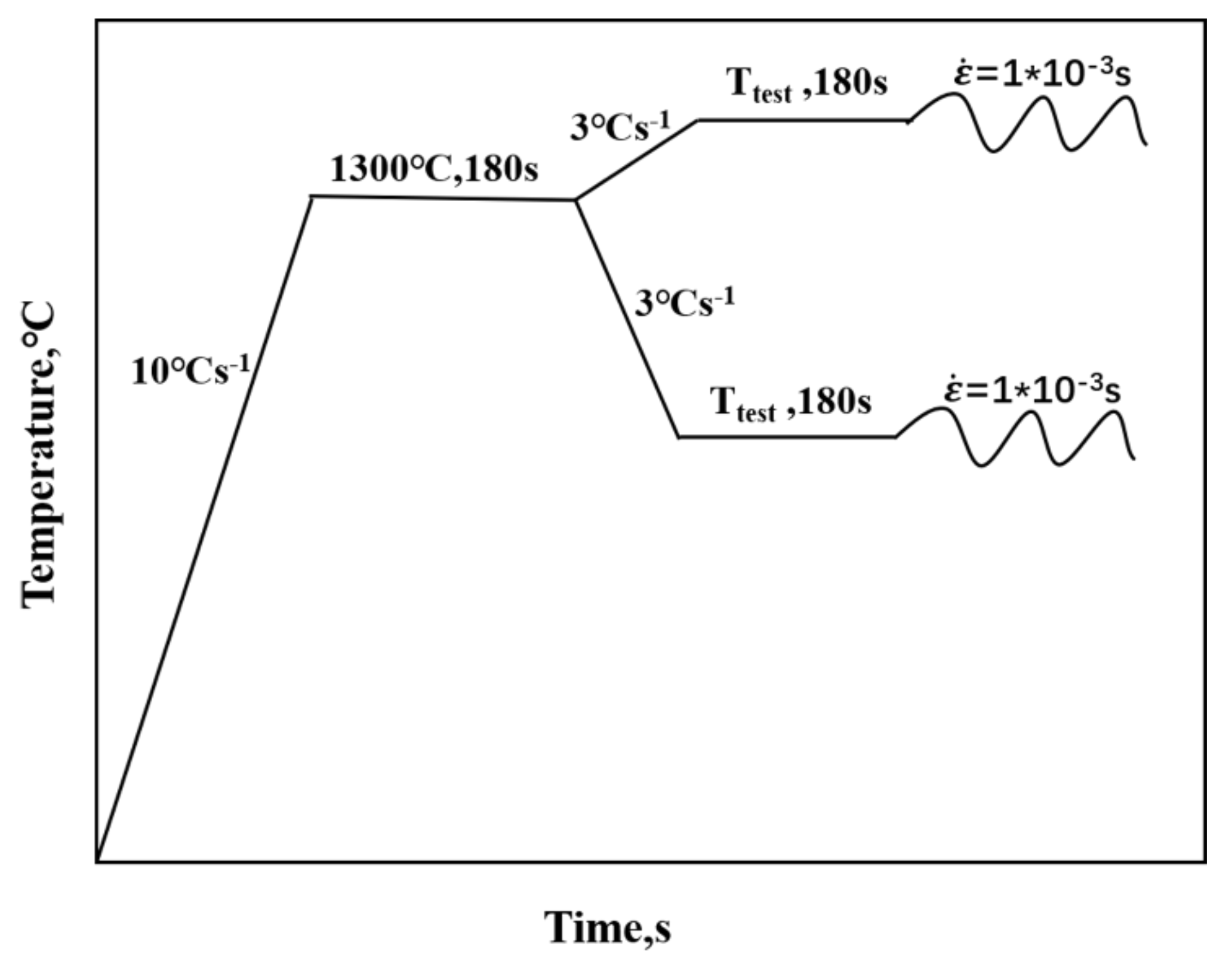

2. Materials and Methods

3. Results and Discussion

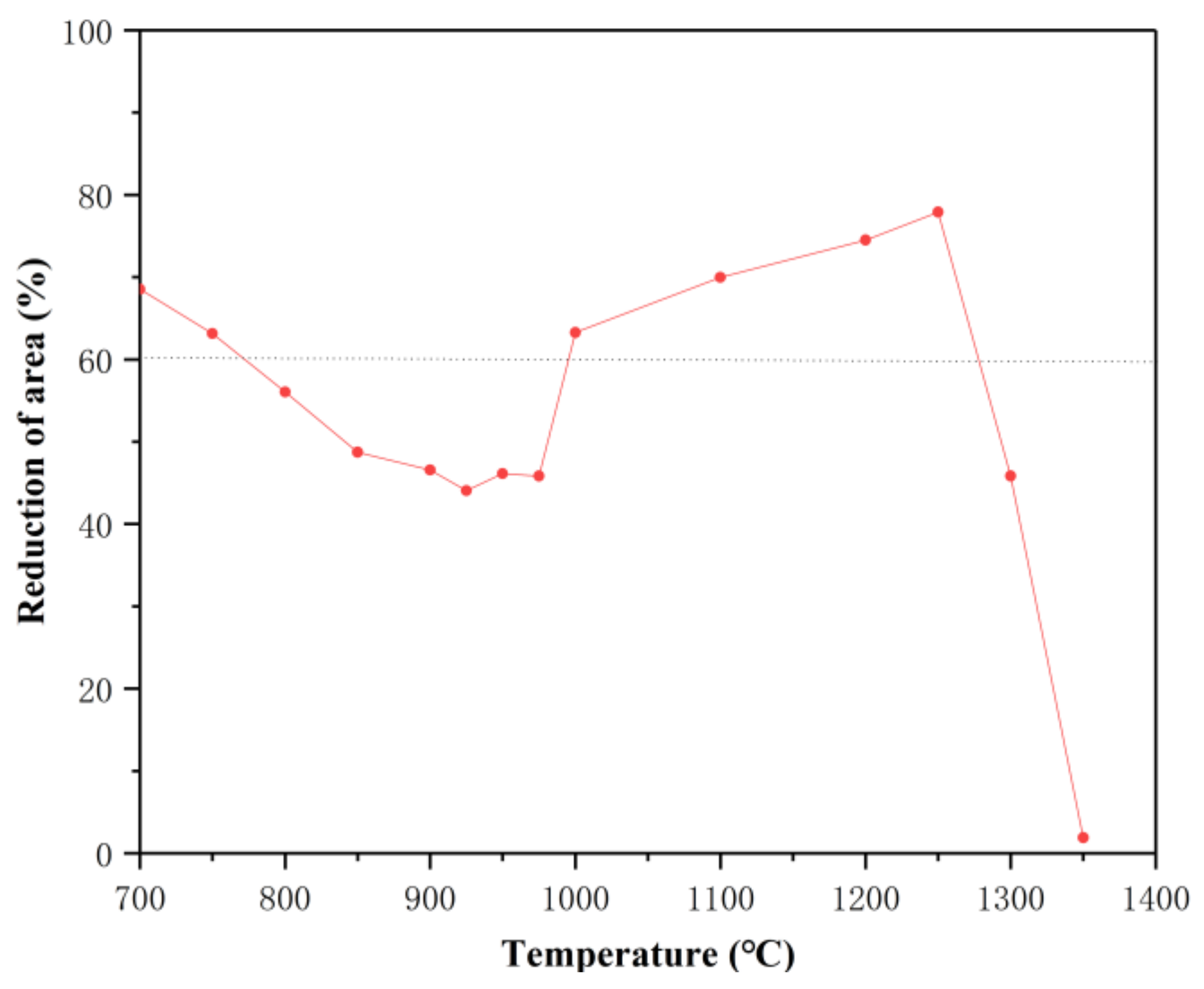

3.1. Hot Ductility

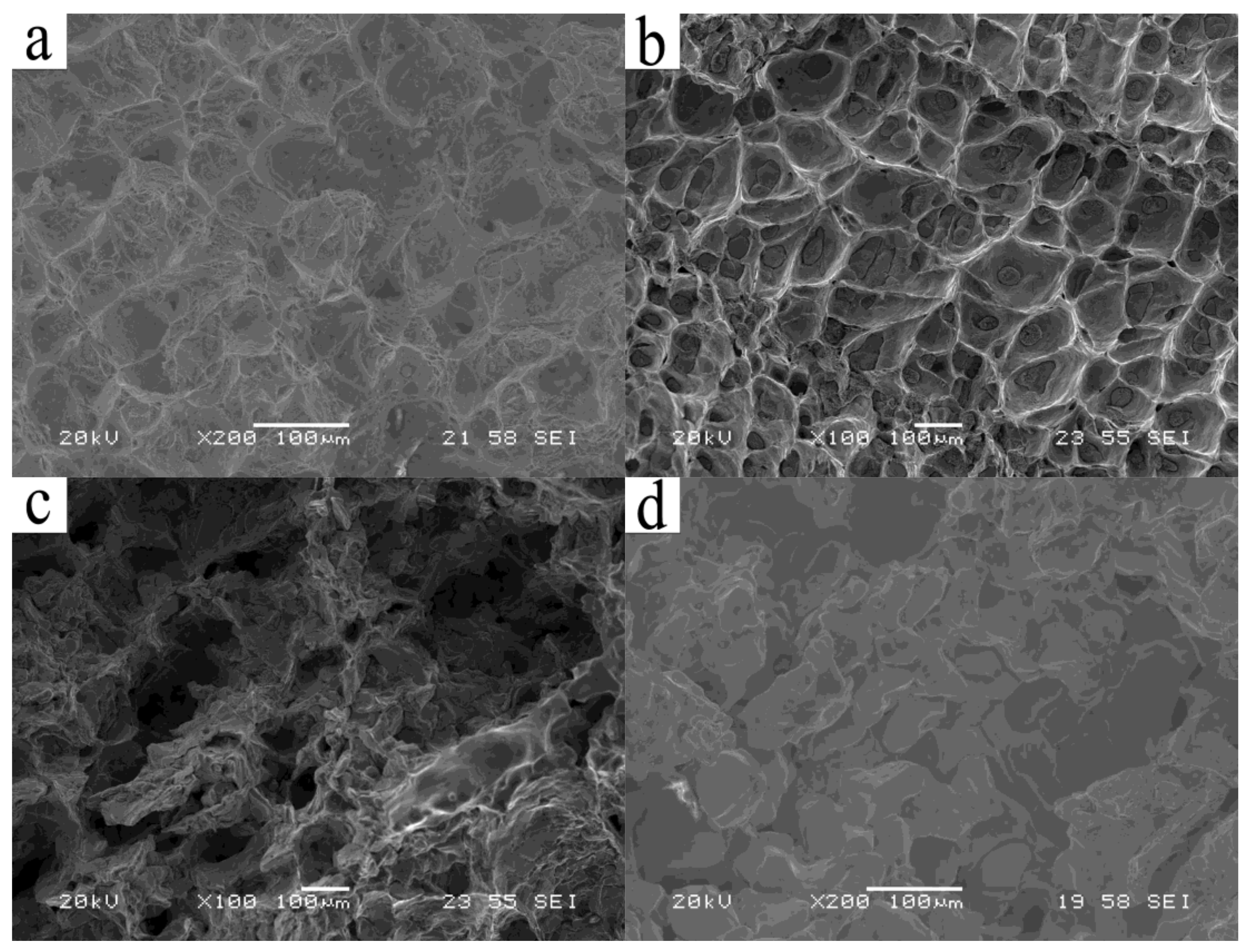

3.2. Fracture Morphology

3.3. Brittleness Analysis

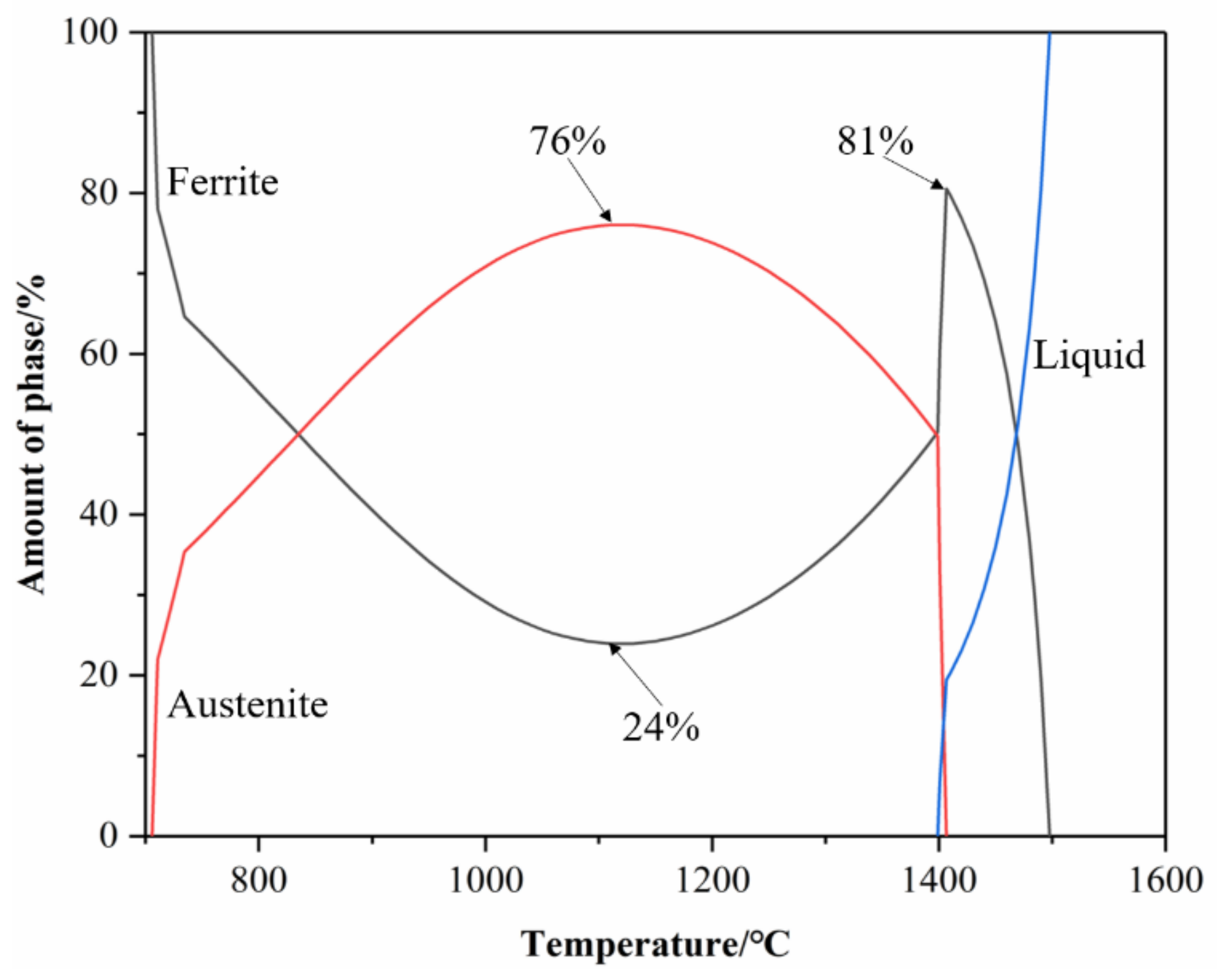

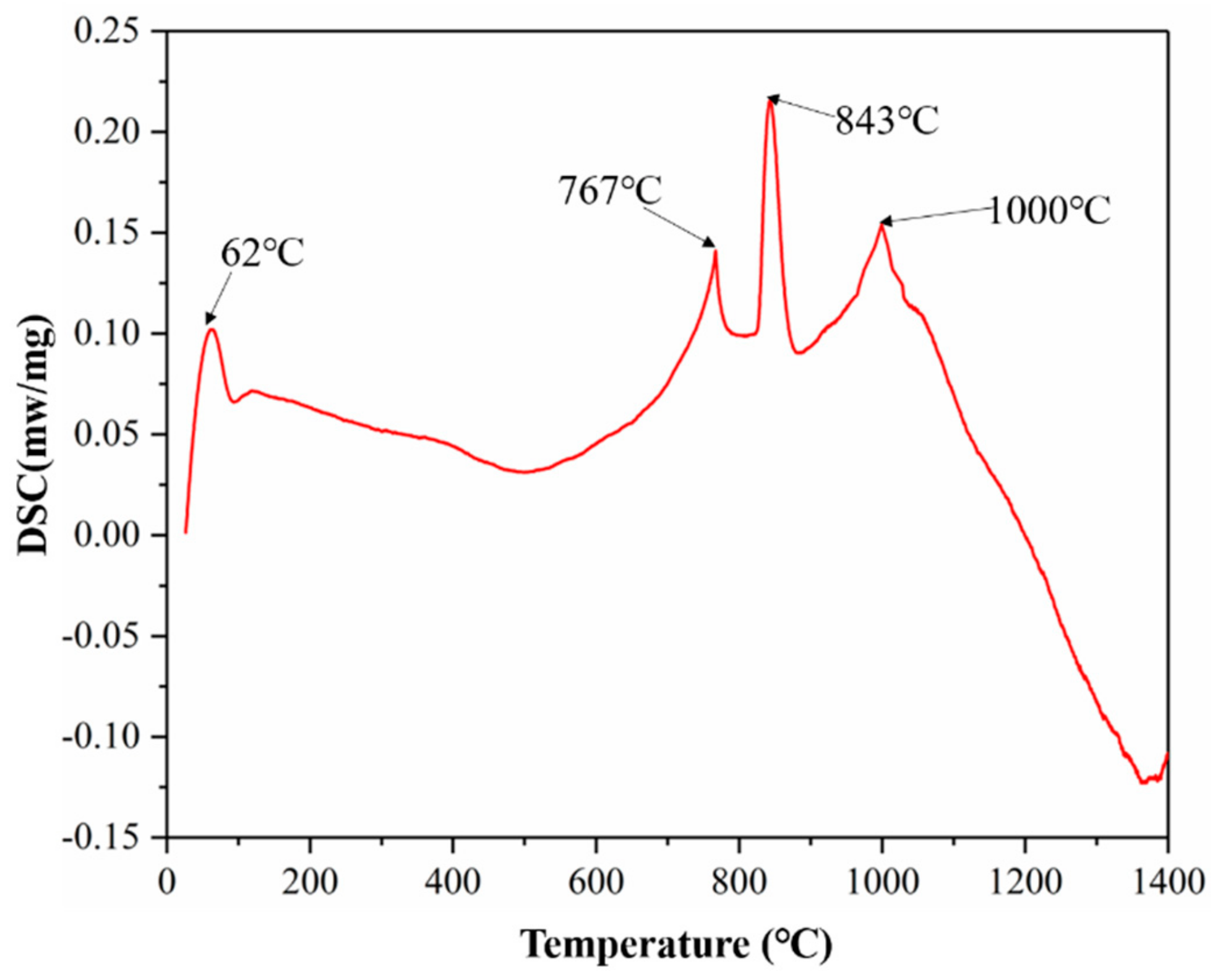

3.4. Phase Transformation Comparison

4. Conclusions

- The ZDT of the sample was 1355 °C, and the ZST was 1405 °C. The ΔT of the sample was small. The 4.5% Al-containing δ-TRIP steel had good resistance to the high-temperature cracking.

- The sample had the first brittle zone at 1300–1350 °C and the third brittle zone at 800–975 °C at a constant strain rate of 1 × 10−3 s−1. During the continuous casting process, the surface temperature of the slab should be kept away from 800 to 975 °C to reduce the possibility of surface cracking on the slab.

- The reason for the embrittlement of the third brittle zone of the 4.5% Al-containing δ-TRIP steel is that the α-ferrite formed at the austenite grain boundary caused the sample to crack along the grain boundary under stress.

- The ductility of the 4.5% Al-containing δ-TRIP steel decreased first and then increased with the increase of the α-ferrite. When the proportion of the α-ferrite reached 37%, the RA of the 4.5% Al-containing δ-TRIP steel was reduced to 44%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yi, H.L.; Sun, L.; Xiong, X.C. Challenges in the formability of the next generation of automotive steel sheets. Mater. Sci. Technol. 2018, 34, 1112–1117. [Google Scholar] [CrossRef]

- Chatterjee, S.; Murugananth, M.; Bhadeshia, H. δ-TRIP steel. Mater. Sci. Technol. 2007, 23, 819–827. [Google Scholar] [CrossRef]

- Yi, H.L.; Chen, P.; Hou, Z.Y.; Hong, N.; Cai, H.L.; Xu, Y.B.; Wu, D.; Wang, G.D. A novel design: Partitioning achieved by quenching and tempering (Q–T & P) in an aluminium-added low-density steel. Scr. Mater. 2013, 68, 370–374. [Google Scholar]

- Abedi, H.R.; Hanzaki, A.Z.; Liu, Z.; Xin, R.; Haghdadi, N.; Hodgson, P.D. Continuous dynamic recrystallization in low density steel. Mater. Des. 2017, 114, 55–64. [Google Scholar] [CrossRef]

- Shiri, S.G.; Jahromi, S.A.J.; Palizdar, Y.; Belbasi, M. Unexpected Effect of Nb Addition as a Microalloying Element on Mechanical Properties of δ-TRIP Steels. J. Iron Steel Res. Int. 2016, 23, 988–996. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Yu, C.Y.; Liu, C.T. Effects of Mn partitioning on nanoscale precipitation and mechanical properties of ferritic steels strengthened by NiAl nanoparticles. Acta Mater. 2015, 84, 283–291. [Google Scholar] [CrossRef]

- Choi, Y.J.; Suh, D.W.; Bhadeshia, H. Retention of δ-ferrite in aluminium-alloyed TRIP-assisted steels. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 2904–2914. [Google Scholar] [CrossRef]

- Hwang, S.W.; Ji, J.H.; Lee, E.G.; Park, K.-T. Tensile deformation of a duplex Fe-20Mn-9Al-0.6C steel having the reduced specific weight. Mater. Sci. Eng. A 2011, 528, 5196–5203. [Google Scholar] [CrossRef]

- Kaar, S.; Krizan, D.; Schwabe, J.; Hofmann, H.; Hebesberger, T.; Commenda, C.; Samek, L. Influence of the Al and Mn content on the structure-property relationship in density reduced TRIP-assisted sheet steels. Mater. Sci. Eng. A 2018, 735, 475–486. [Google Scholar] [CrossRef]

- Xiong, X.C.; Sun, L.; Wang, J.F.; Jin, X.Y.; Wang, L.; Xu, B.Y.; Chen, P.; Wang, G.D.; Yi, H.L. Properties assessment of the first industrial coils of low-density duplex δ-TRIP steel. Mater. Sci. Technol. 2016, 32, 1403–1408. [Google Scholar] [CrossRef]

- Tuling, A.; Banerjee, J.R.; Mintz, B. Influence of peritectic phase transformation on hot ductility of high aluminium TRIP steels containing Nb. Mater. Sci. Technol. 2011, 27, 1724–1731. [Google Scholar] [CrossRef]

- Su, H.; Gunawadarna, W.D.; Tuling, A.; Mintz, B. Influence of Al and P additions on hot ductility of steels. Mater. Sci. Technol. 2007, 23, 1357–1366. [Google Scholar] [CrossRef]

- Qaban, A.; Mintz, B.; Kang, S.E.; Naher, S. Hot ductility of high Al TWIP steels containing Nb and Nb-V. Mater. Sci. Technol. 2017, 33, 1645–1656. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Wu, B.; Shen, Y.; He, Y.; Ding, H.; Su, X. Effect of Mn and Al contents on hot ductility of high alloy Fe-xMn-C-yAl austenite TWIP steels. Mater. Sci. Eng. A 2017, 08, 60–374. [Google Scholar] [CrossRef]

- Kang, S.E.; Tuling, A.; Banerjee, J.R.; Gunawardana, W.D.; Mintz, B. Hot ductility of TWIP steels. Mater. Sci. Technol. 2011, 27, 95–100. [Google Scholar] [CrossRef]

- Xiong, Z.P.; Kostryzhev, A.G.; Stanford, N.E.; Pereloma, E.V. Effect of deformation on microstructure and mechanical properties of dual phase steel produced via strip casting simulation. Mater. Sci. Eng. A 2016, 651, 291–305. [Google Scholar] [CrossRef]

- He, Y.; Liu, J.; Qiu, S.; Deng, Z.; Yang, Y.; McLean, A. Microstructure and high temperature mechanical properties of as-cast FeCrAl alloys. Mater. Sci. Eng. A 2018, 726, 56–63. [Google Scholar] [CrossRef]

- He, Y.; Liu, J.; Han, Z.; Deng, Z.; Su, X.; Ji, Y. Phase transformation and precipitation during solidification of FeCrAl alloy for automobile exhaust gas purifying systems. J. Alloy. Compd. 2017, 714, 251–257. [Google Scholar] [CrossRef]

- Grajcar, A.; Kwaśny, W. Microstructural study on retained austenite in advanced high-strength multiphase 3Mn-1.5 Al and 5Mn-1.5 Al steels. J. Exp. Bot. 2012, 54, 168–177. [Google Scholar]

- Hechu, K.; Slater, C.; Santillana, B.; Clark, S.; Sridhar, S. A novel approach for interpreting the solidification behaviour of peritectic steels by combining CSLM and DSC. Mater. Charact. 2017, 133, 25–32. [Google Scholar] [CrossRef]

- Li, Z.C.; Misra, R.D.K.; Cai, Z.H.; Li, H.X.; Ding, H. Mechanical properties and deformation behavior in hot-rolled 0.2 C-1.5/3Al-8.5 Mn-Fe TRIP steel: The discontinuous TRIP effect. Mater. Sci. Eng. A 2016, 673, 63–72. [Google Scholar] [CrossRef]

- Li, Z.C.; Ding, H.; Cai, Z.H. Mechanical properties and austenite stability in hot-rolled 0.2C-1.6/3.2Al-6Mn-Fe TRIP steel. Mater. Sci. Eng. A 2015, 639, 559–566. [Google Scholar] [CrossRef]

- Cui, H.; Zhang, K.; Wang, Z.; Chen, B.; Liu, B.; Qing, J.; Li, Z. Formation of surface depression during continuous casting of high-Al TRIP steel. Metals 2019, 9, 204. [Google Scholar] [CrossRef]

- Nakagawa, T.; Umeda, T.; Murata, J.; Kamimura, Y.; Niwa, N. Deformation behavior during solidification of steels. ISIJ Int. 1995, 35, 723–729. [Google Scholar] [CrossRef]

- Yu, C.H.; Suzuki, M.; Shibata, H.; Emi, T. Simulation of crack formation on solidifying steel shell in continuous casting mold. ISIJ Int. 1996, 36, S159–S162. [Google Scholar] [CrossRef]

- Suzuki, H.G.; Eylon, D. Hot ductility of titanium alloy: A challenge for continuous casting process. Mater. Sci. Eng. A 1998, 243, 126–133. [Google Scholar] [CrossRef]

- Li, S.Q.; Liu, J.H.; Liu, H.B.; Zhuang, C.L.; Liu, J.; Han, Z.B. Study on high-temperature mechanical properties of low-carbon Fe-Mn-Si-Al TWIP steel. High Temp. Mater. Process. 2017, 36, 505–513. [Google Scholar] [CrossRef]

- Suzuki, H.G.; Nishimura, S.; Imamura, J.; Nakamura, Y. Hot Ductility in Steels in the Temperature Range between 900 and 600 C. Trans. Iron Steel Inst. Jpn. 1981, 67, 1180–1189. [Google Scholar] [CrossRef][Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Cui, H.; Wang, R. High-Temperature Mechanical Properties of 4.5%Al δ-TRIP Steel. Appl. Sci. 2019, 9, 5094. https://doi.org/10.3390/app9235094

Chen D, Cui H, Wang R. High-Temperature Mechanical Properties of 4.5%Al δ-TRIP Steel. Applied Sciences. 2019; 9(23):5094. https://doi.org/10.3390/app9235094

Chicago/Turabian StyleChen, Dayu, Heng Cui, and Rudong Wang. 2019. "High-Temperature Mechanical Properties of 4.5%Al δ-TRIP Steel" Applied Sciences 9, no. 23: 5094. https://doi.org/10.3390/app9235094

APA StyleChen, D., Cui, H., & Wang, R. (2019). High-Temperature Mechanical Properties of 4.5%Al δ-TRIP Steel. Applied Sciences, 9(23), 5094. https://doi.org/10.3390/app9235094