1. Introduction

The idea of a conceptual design phase was proposed by Pahl and Beitz in Germany and it has been viewed as the cornerstone of any conceptual design task. Their book has been used as the textbook for engineering design courses and implementation. Their approach was extended by introducing new technologies and tools. These technologies and tools can be embodied, and the extended design approach is called the integrated, customer driven, conceptual design method (ICDM). This approach can be applied to the entire conceptual design phase from defining demands to determining the optimal concept. Three out of the seven new ICDM tools can be used to enhance the task definition of quality function deployment (QFD), the conceptual failure mode analysis method (CFMA), and the design quality method (DQM) for assessing the satisfaction of the concepts that are generated. In addition to the Pahl and Beitz approach, ICDM also includes several steps that can contribute to the excellent design if they are fully implemented [

1]. Gielisch proposed and evaluated four different product development approaches, which include the systematic approach of Pahl and Beitz (SAPB), theory of inventive problem solving (TRIZ), concurrent engineering (CE), and lean development (LD). These four approaches are specifically for the demand of micro-assembly and production on reconfigurable manufacturing systems (RMS). They feature clear structure, high integrated production, manufacturability, and time consumption. A new approach was proposed to successfully integrate the advantages of these four existing methods. The formal composition of an abstract product contains three data types. By using these attributes and a decision tree, the process that is required by RMS can be accomplished [

2]. Fiorineschi proposed an approach to resolve the known deficiencies that can be contributed to systematic conceptual design (SCD). More precisely speaking, the well-known functional decomposition and morphology can be used to support creativity and to resolve the problem during the creation of innovative ideas during the activities of the SCD process. This approach is the problem–solution network that was developed in recent years. It provides a comprehensive guidance for the application of the TRIZ tool in SCD. In addition to their claim of resolving the deficiencies of functional decomposition and morphology (FDM), their study also considered PSN(Problem-Solution Network) for resolving problems and evolving into TRIZ integration. Their studies also proposed the application procedures to industrial case studies and carried out analyses in order to demonstrate their purpose [

3]. Becattini applied general theory of powerful thinking (OTSM) and the theory of inventive problem solving to form an OTSM–TRIZ approach for students to resolve design problems within a problem network. This approach can be used to analyze design theories and design protocols. The purpose is to support the evaluation of students’ overall achievement and to create systematic design courses for download learning. This approach also considered the process of generating new ideas and it allows people to carry out protocol studies during a limited amount of time and therefore it is very time-consuming [

4]. During the Lorenzo integration process, the benefits of these three indicators can be utilized simultaneously. Innovative data can also be extracted from these three indicators during the evaluation process [

5]. Jenab proposed a useful decision-making tooling for resolving the complexity of solutions during the conceptual design (CD) phase during the product development process. The purpose was to assess the potential new product investments so that the importance of the development strategy can be verified. The limit of the compatible information between design concepts still presents a challenge to the concept-selecting approaches. The layers within the decision standards can be aggregated to a chart, which can be used to determine the optimal alternative solution when evaluating the CD alternative [

6]. The Erden universal framework can be used to understand functional modeling (FM). This approach highlights the characteristics of the FM-related classical methods so that the fundamental thinking can be classified [

7]. Eckert proposed an approach for industrial designers, and it can be viewed as a portion of the quality function deployment (QFD) or failure mode and effect analysis (FMEA), which are suitable for functional modeling. This approach has been applied to the entire territory and has passed the formal process of an organization. Although both studies proposed the use of integrated design approaches, they were actually applied to the production demand and to form the structure rather than designing comprehensive tasks [

8]. Ulrich proposed that the tasks that were related to design and manufacturing follow a plan that regulates the development stages, from the potential customer requesting a quotation to the final delivery of products. A product’s functions can determine many related activities that should be designed to install in a specified region. A product also operates under the definite conditions so that the assembly manufacturer can work together with end users to enhance product quality and performance [

9]. From the standpoint of creativity, Toh studied the conceptual selection process of engineering students in order to determine the factors that are helpful to the selection of creative concepts. A design team of students can carry out quantitative and qualitative analyses on the data that are acquired from controlled experiments. The results of similar studies indicated that the design team of students highlighted the technical feasibility of a design during the selection and discussion period. This is also highlighted in engineering education [

10].

According to statistics, there is only a very small portion of people who can take the right medicine at the right time at the right dose. The chance for a patient who is more than 65 years old to take wrong medicine is seven times higher than those who are less than 65 years old. For the aged population in Taiwan, most of the elderly people who are more than 65 years old have developed more than one chronic disease. As a result, the safety issue of medicine is very important. At the moment, the pillboxes that are available on the market lack an important function of examining whether a patient has taken the same medicine repeatedly or has taken medicine with interfering effects. In order to allow a patient to take medicine regularly without worries, a new pillbox should be created for patients with chronic diseases as a solution to this type of problem. Moreover, the safety issue of taking medicine is considered in order to enhance the feasibility of a pillbox design for patients with chronic diseases so that they can take the right medicine at the right time at the right dose. As people are more concerned about environmental protection and are pursuing the goal of reducing the impact of a product on the environment to a minimum level, a new approach that integrates multi-criteria decision making (MCDM). This new approach is a fast and objective tool that is based on derivation from evidence. Earlier studies indicated that the proposed method can be applied to the evaluation of environmental functions of alternative design cases [

11]. A comprehensive product evaluation method was proposed for students of industrial design so that they can carry out an effective design evaluation even when they encountered fuzzy information during the design evaluation stage. In this study, the fuzzy analytic hierarchy process (AHP) was used to evaluate product designs and to resolve the potential problems that might occur during the product evaluation process. The questionnaire with purposive selection was based on the judgment from experts so that different weights can be assigned to each evaluation criterion. The performance indicators of a fan were verified by CFD simulation and wind tunnel measurements. An optimal product can be created for evaluation of its optimized air flow rate. The integration of these methods is not only practical and objective, but also can help students make a decision between complicated and uncertain conditions. This approach also provides students with a good reference during the follow-up stage of product design and evaluation so that the learning competitiveness of students can be enhanced [

12]. Similar to the technique for order of preference by similarity to ideal solution (TOPSIS), another framework was also proposed by integrating the analytical hierarchy process (AHP) with order priority technology. This approach can assist designers in identifying customer demands and design features. It is also helpful for determining the final design solution and for carrying out effective assessments. The proposed solution was first used in combination with the AHP for assessing customer demands and the overall relative importance of design features [

13]. Fuzzy mathematics was proposed by the American control theory expert L.A. Zadeh in 1965 [

14,

15,

16]. After years of development, the theoretical level is very comprehensive and this approach has been widely used in various areas, such as natural science and social science. Since fuzzy mathematics is used to handle objective and practical problems by its integration with precise mathematics, it is different from precise mathematics’ characteristics of “one or the other” or “one and the other.” Therefore, this approach finds a reason for its extensive applications. Moreover, the mathematical characteristics of the fuzzy approach also make it an emerging science within the design field. When assessing the quality of a lighting fixture design, for example, various factors must be considered. However, assessing the quality of a factor often includes human subjectivity and uncertainty, which leads to fuzziness. If an assessed result lacks objectivity, then reliability and validity will not be enhanced. Fuzzy mathematics can handle the condition of true and false and is also a feasible approach for measuring ideas. Whenever human thinking is involved, the fuzzy point-of-view could be a feasible approach for comprehensive assessment. Fuzzy theory can be applied to the selection of sites and studies, also indicating that the calculation of fuzzy numbers can also involve the ranking of several schemes based on their quality so that the quality of strategic analysis can be enhanced. In other studies, the fuzzy evaluation method is used to assess (computer-assisted instruction) the CAI curriculum. Fuzzy set theory is used to construct a multilevel fuzzy combined evaluation method for architecture colors. The goal is to determine the conclusion on the quality of the strategy of architectural color schemes. Kuo et al. [

17] studied the selection of system operations of mobile value-added services by fuzzy theory. The results indicated that this model can effectively reduce human subjective awareness and enhance the precision of the selection so as to serve as the basis for the development of shape ideas. When a product design comes out, the fuzzy synthetic evaluation method can be used to assess product quality. The results indicate that building up this model can assist in the rationalization of the design process, reduce the misplay in the assessment, enhance the efficiency of the strategic decision, and increase the success rate of new product development [

17].

Sun et al. [

18] proposed applying triangular fuzzy numbers that cannot increase the reliability and authenticity of linear assessment by human sensory capture. Questionnaires are conducted in a qualitative manner to understand consumer preferences and needs through self-subjective judgments, matching collected terms, and screening consumers’ shapes and functions for self-framed image vocabulary and expectation psychology. Then, using the quantization method, triangulation is used to calculate the ideal preference for the vocabulary closest to the consumer in different self-species. In their research, Hu and Liao studied 18-to-38-year-old individuals at colleges and universities, and then discussed various lifestyle attitudes and emotional consumption patterns of consumer groups. Consumer groups and frame styles have different factors to consider facets by evaluating various attributes of the vocabulary. By grouping consumers, they can understand the consumer groups and the consumption concepts they belong to and clearly understand their own positioning. Through the guidance of emotional imagery, consumers can find a path that suits them [

19,

20].

Fuzzy theory is a science used to study and deal with fuzzy phenomena. It was originally proposed by the computer scientist L.A. Zadeh of the University of California in 1965. It has been around for more than 40 years. It is used to process inaccurate and fuzzy data and operates through rigorous mathematical methods to solve decision problems in a fuzzy environment [

21,

22,

23]. There are many objectives in the design evaluation, such as aesthetics (overall effect, shape, color, decoration, etc.), pleasure, safety, processability, etc., which are difficult to achieve by traditional quantitative analysis methods. To this end, it is necessary to introduce linguistic variables to describe and solve problems, and then use fuzzy mathematics to quantify the fuzzy information for quantitative evaluation [

16].

Hsiao used fuzzy theory and analytic hierarchy analysis to make product decisions [

14,

24], and used fuzzy theory to perform monochrome color matching in the automotive design phase for related evaluations. In addition, he used fuzzy semantics to make automotive design decisions and lexical transformation product design descriptions to evaluate computer-aided industrial designs and images.

In addition, some scholars have proposed computer-aided systems to help design engineers reduce development and file processing time. Moskowitz and Kim proposed an optimal product design decision-support system in 1997 [

15]. Developing an annual reasoning structure can infer the relationship between customer demand (CR) and design requirements (DR) [

25]. However, developing these systems requires expertise and experience to build the rules while facing issues such as whether the system is performing well. According to fuzzy set theory, Kim et al. used supplier competition analysis to construct a relationship function between CR and DR and proposed a fuzzy multi-objective model. However, constructing these relationship functions has its difficulties, especially when developing a brand-new product. Data from competitors can be used for analysis [

18]. Other scholars apply fuzzy sets, fuzzy operations, or defuzzification techniques to deal with complex and inaccurate quality functional problems; however, these methods do not consider the relationships between engineering design requirements [

12,

26]. Other scholars have emphasized that in addition to determining the degree of DR implementation based on customer satisfaction, we should also consider organizational conditions such as cost factors and technical difficulties to make economic, customer-friendly best decisions.

3. Case Design

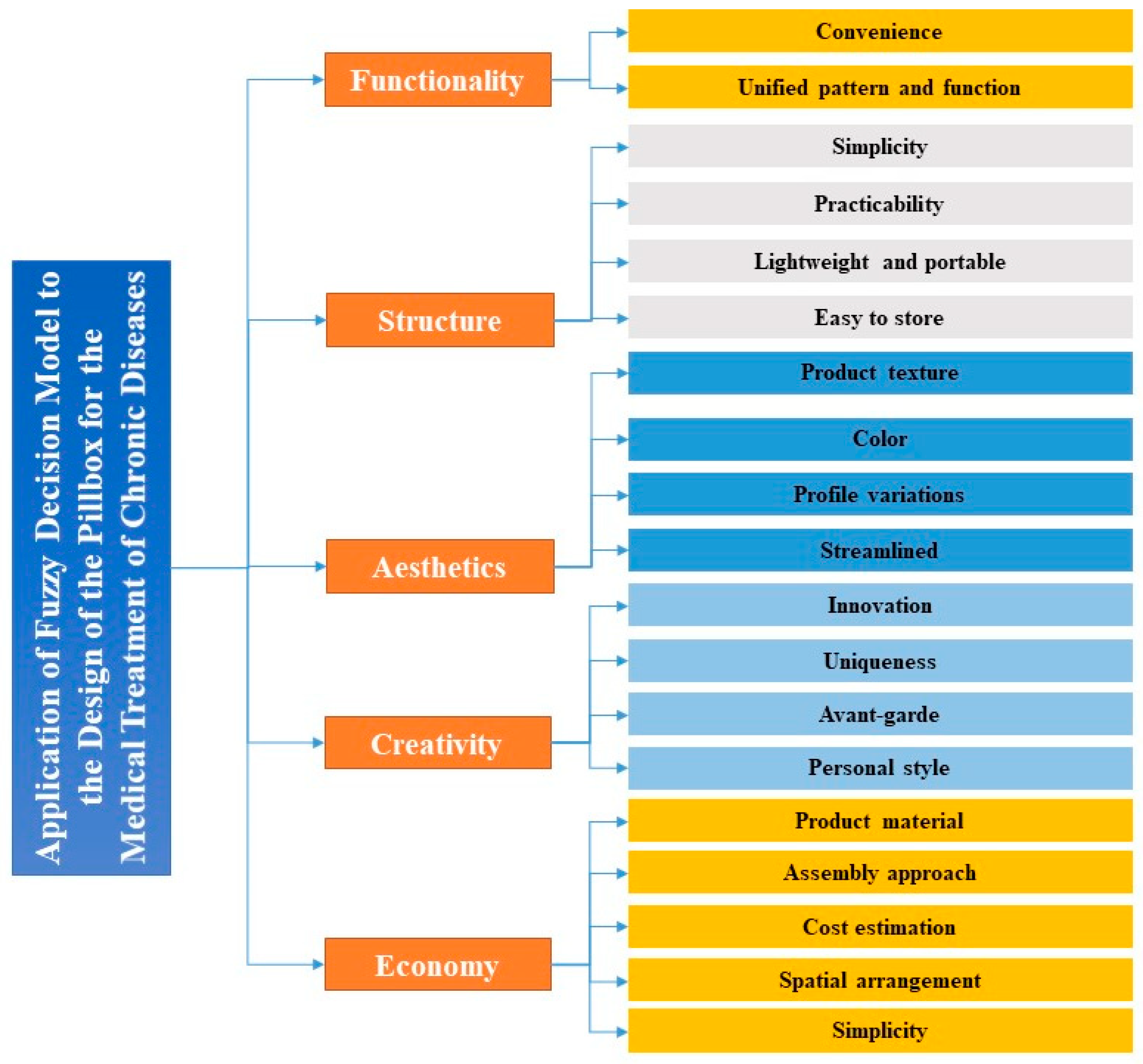

The objective of this study is to build an evaluation index for the design of a pillbox for patients with chronic diseases. The first step is to classify and determine the items to be scored for product design. In order to identify the relevance of the preliminary evaluation indices, semi-structured interviews were conducted. The researchers surveyed professionals in related fields for their opinions, aiming at collecting an organized evaluation indicator based on their capacity to make professional judgments, assessing the importance of each question, and applying corrections or supplements to these evaluation indices. In addition to the drafted evaluation indices, the interview contents and questions were prepared so that the interviewees were asked questions such as “Any other factors to be included as the evaluation indices?” and “What are the criteria for a pillbox for patients with chronic diseases?”. The interview procedure included preparing for the interview, drafting interview contents and an outline, determining the interviewees, questioning and making records, ending the interview, and collecting and analyzing the data. After interviewing the experts, the appraisal process for a pillbox for patients with chronic diseases could be determined. In addition, assessing the professional literacy of the interviewees, the conditions of the pillbox are among the critical factors during the evaluation process. Therefore, the evaluation indices can be determined, and include the first level, i.e., the goal level, which is the eventual goal of appraising product designs. The second level is the objective level, which includes five constituent elements: functionality, structure, aesthetics, creativeness, and economy. The third level covers 19 evaluation criteria. In order to carry out systematic evaluation and analysis, the evaluation factors and constituent elements were chosen to build the hierarchical structure, as shown in

Figure 1. Since numerous factors could affect the selection of interviewees, quantification of the degree of influence of each factor had to be carried out. After that, the degrees of influence of various factors were combined and calculated by utilizing a systematic approach in order to obtain quantization results. The definitions of the assessment items are as follows.

First, the functionality part indicates the functionality of the pillbox for patients with chronic diseases. It covers two criteria, a product’s “convenience” and its “unified pattern and function.” Structure comprises “simplicity, “practicability,”, “lightweight and portable,” and “easy to store.” Aesthetics comprises “product texture,” “color,” “shape variation,” and “streamlined.” Creativeness comprises “innovation,” “uniqueness,” “avant-garde,” and “personal style.” Economy comprises “product material,” “assembly approach,” “cost estimation,” “spatial arrangement,” and “simplicity.”

In addition, the interviewees were mainly experts who could provide answers to the questions. Through the investigation and questionnaire, the resulting data were processed by the quantization approach. A total of 24 experts participated in this study, including 14 who run a business in an industry related to the pillbox and 10 workers in this industry. The information on their backgrounds is shown in

Table 1. The participants were asked to consider the evaluation factors of the design of a pillbox for patients with chronic diseases. Answers, including the implementation of the AHP method and the fuzzy comprehensive evaluation, were checked. The goal was to obtain objective results from the questionnaire survey. After the relative weight of each factor was obtained by the AHP method and the consistency examination was carried out, Model 4 of the fuzzy synthetic method was used to apply the evaluation indices to obtain the final evaluation results.

Fuzzy multicriteria decision-making was used in this study to determine the evaluation indices of a pillbox design for patients with chronic diseases. Based on the above-mentioned analysis and construction of the evaluation factors for the pillbox, a total of 5 constituent elements and 19 evaluation criteria were obtained. They were classified into upper-level and lower-level factors as follows:

Upper-level factors: U = {Functionality (U1), Structure (U2), Aesthetics (U3), Creativity (U4), Economy (U5)}

Lower-level factors: U1 = {Convenience (u11), Unified pattern and function (u12)}

U2 = {Simplicity (u21), Practicability (u22), Lightweight and portable (u23), Easy to store (u24)}

U3 = {Product texture (u31), Color (u32), Shape variation (u33), Streamlined (u34)}

U4 = {Innovation (u41), Uniqueness (u42), Avant-garde (u43), Personal style (u44)}

U5 = {Product material (u51), Assembly approach (u52), Cost estimation (u53), Spatial arrangement (u54), Simplicity (u54)}

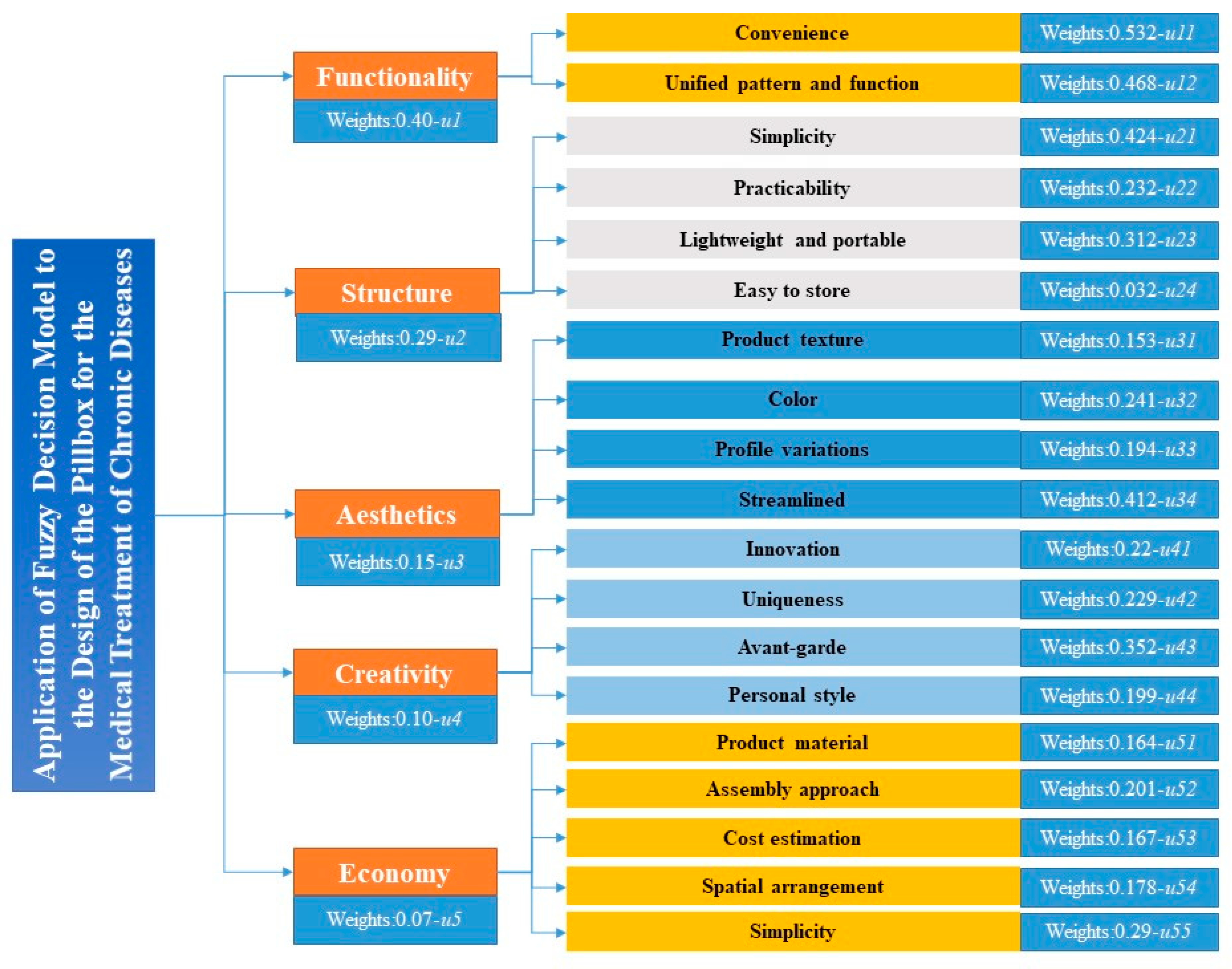

In order to reflect the importance of each factor, the AHP was implemented to obtain the relative weights determined by the experts in this study. The questionnaire contents included a letter of instruction, instructions for filling out the questionnaire and examples, the standards of the intensity of importance, the hierarchical framework of indices, explanations, and questions. The importance of two factors in each subsystem was compared. The evaluation scale basically can be divided into five levels: equally important, slightly important, considerably important, very important, and absolutely important. They were assigned weights of 1, 3, 5, 7, and 9. An additional four levels between these five levels were assigned weights of 2, 4, 6, and 8. Left-aligned scales indicated that the factors on the left were more important than the factors on the right. On the other hand, right-aligned scales indicated that the factors on the right were more important than the factors on the left. The experts were asked to tick adequate assessment items, and the results are shown in

Table 3 and

Table 4.

In addition, it is known from the AHP method that when

, it can be determined that the judgment matrix has satisfactory consistency. It also demonstrated that the weight distribution is reasonable, and the results are shown in

Table 3 and

Table 4.

Based on the results in

Table 2 and

Table 3 and from Equation (2), the weight set of each factor can be obtained as follows:

| , | , |

| , | , |

| , | . |

Moreover, the set of evaluation results obtained from the participants’ judgment of the evaluation target can be classified into five levels: V = {completely agree, agree, neither agree nor disagree, disagree, completely disagree}. Based on the factor set and evaluation set, the questionnaire for comprehensive evaluation of the designs allowed experts to fill in their answers to evaluate each factor. After the researchers collected the questionnaires for further statistical analysis, the membership grade of the evaluation of each factor was determined in order to obtain their fuzzy evaluation matrices. The fuzzy set is summarized as follows:

The fuzzy evaluation matrix can be obtained from the above-mentioned procedures. The comprehensive evaluation and operation were carried out by implementing Model 4 of the fuzzy synthetic method. This synthetic method only requires carrying out normalization of

. Therefore, there is no need to normalize the results obtained from the fuzzy comprehensive evaluation. The operations are as follows for the low-level evaluation:

It is known from

Table 2 that the weights of the high-level factors can be determined, and the high-level judgment matrix is as follows:

Therefore, the result of the high-level fuzzy comprehensive evaluation is

As for the processing of evaluation indices, typical methods in common use are maximum degree of membership and weighted averaging. Weighted averaging can turn vague values into definite values. This is the so-called defuzzification effect. The purpose of defuzzification is to transform the final data or results with vague properties into definite values and data. If vague values are used in the operations, the result is also a vague value. Defuzzification of vague values must be done so that they can turn into definite values with their own representativeness for the benefit of follow-up comparison and ranking operations. Therefore, by calculating with the weighted-average method in this study, the concept of a hierarchy of values is applied to the results (Kuo and Chen, 2006). Assigning V = {completely agree, agree, neither agree nor disagree, disagree, completely disagree} = {1, 0.75, 0.50, 0.25, 0}, the researchers calculated defuzzified values of evaluation results D, shown in

Table 5 and

Table 6.

In this study, the evaluation of pillbox designs for patients with chronic diseases was carried out by the fuzzy theory. The research results are shown in

Table 5 and

Table 6. The degrees of conformity of various factors determined by the interviewees are shown in

Table 5. The degrees of conformity of the index framework for evaluation by the interviewees are shown in

Table 6. If the principle of maximum membership serves for the processing of evaluation indices, for the Structure factor, the evaluation items include “simplicity” (

u21), “practicability” (

u22), “lightweight and portable” (

u23), and “easy to store” (

u24). The evaluation result indicates that using the factors as constituent elements of the pillbox design is at the level

If the values obtained after defuzzification serve as evaluation indices for processing, it is known from the comprehensive evaluation that the result of the Functionality factor is 0.716, which indicates a level of “Completely agree” for the pillbox design, followed by Structure at 0.713, Aesthetics at 0.686, Creativity at 0.694, and Economy at 0.691. Since the design of a pillbox for patients with chronic diseases should follow regulated dimensions and patterns, according to the AHP, the factor weights are as shown in

Table 3 and

Table 4. The weight of the Structure factor is 0.319, which corresponds to the ranking from the fuzzy comprehensive evaluation. However, the pairwise comparison matrix in the AHP has the problems of subjectivity, inaccuracy, and vagueness. In order to resolve this problem, the AHP approach must be extended to the vague environment in order to compensate for the deficiency of the vagueness problems that the AHP cannot resolve. After that, the fuzzy comprehensive evaluation is implemented to select the evaluation items in order to obtain their fuzzy values. Therefore, the result can be viewed as a dual verification, which indicates a certain degree of commonality between two factors in order to enhance the accuracy of the research. Moreover, the resulting values in

Table 5 indicate that the overall index of the evaluation of the pillbox design is 0.723, which is between the levels “Completely agree” and “Agree.” This indicates that the framework of the evaluation indices is acceptable. The result serves as a good reference for the process of designing a pillbox for patients with chronic diseases, as shown in

Figure 2.

3.1. Design Case Comparison

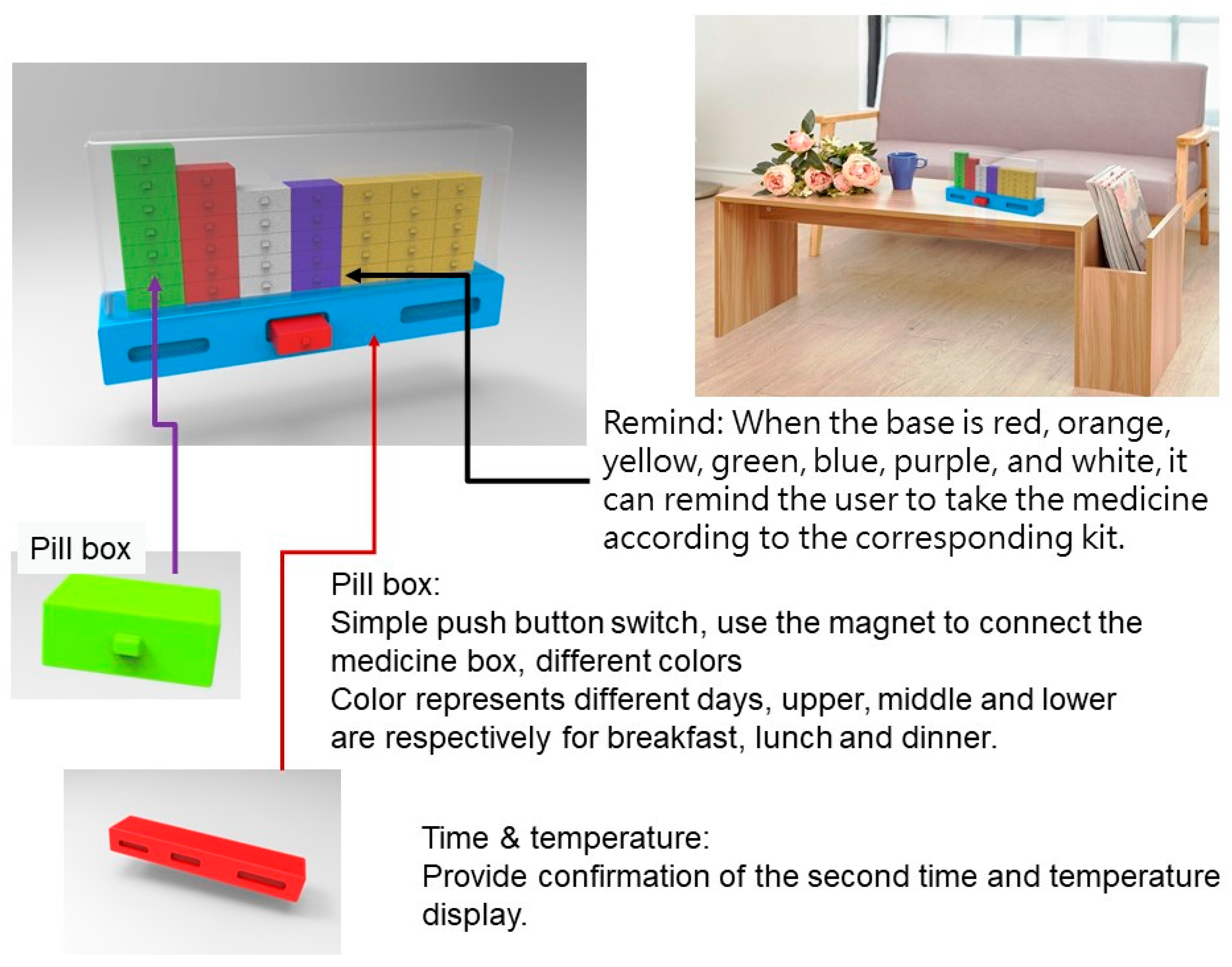

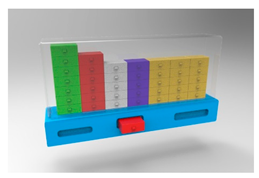

Finally, three pillbox designs with different forms and styles are shown in

Table 7. Case 1 presents a timed pillbox design as the main body and its contents show a simple and convenient design. This design provides a simple and convenient way of reminding users of the time and function of taking a pill. Case 2 presents a concept of a pillbox composed of a button-type storage compartment. This design is simple and easy to use. Case 3 features a rotating pillbox. The main idea is to implement a rotating shape in an attempt to increase the storage space. Each of these three designs has a different style.

For the evaluation of the overall schemes, it is known from

Figure 3 that the defuzzified values of Case 3 is 0.74, which is at the “Satisfied” level, followed by Case 1, which has a defuzzified value of 0.62, at the “Neither satisfied nor dissatisfied” level. Therefore, Case 1 is one the most favored by subjects who made the decision. This scheme is not only full of functionality and economical, but it also performs well considering the coordination between humans, machines, and the environment. The advantage of this scheme lies in its creativity and aesthetics. Follow-up studies are advised to highlight the consideration of aesthetics. The results also indicate that Case 2 is inferior in terms of aesthetics. On the other hand, the economic aspect of Case 1 should be further enhanced as well.

The pillbox design of Case 3 provides the function of a favorable performance design with portable pill cells. Since patients are not professional medical personnel (

Figure 4), they might take the wrong medicine by mistake or by misunderstanding the information. In order to create an intelligent pillbox that can recognize prescriptions and scheduling, a new type of portable cell is created. It is similar to the design of hospital medicine bags that can prevent cross-contamination of different medicines. Each cell is loaded with only one type of medicine and there is a barcode for the medicine information on the top. The information includes patient name, medicine name, and dose, as well as medication instructions. Based on doctors’ prescriptions, pharmacists load the medicines into the portable cells and seal them for patients.

In addition, the design of the pillbox control module is to house the portable medicine cells. The top cover is opened to display the barcodes of the cells so that patients can scan for prescriptions. Moreover, in order to effectively avoid medication errors, the pillbox control module is equipped with a mechanical device that includes an electronic lock, sensors, and LEDs for controlling and managing the cells. The functions of the control module include detecting whether the portable medicine cell is loaded and the top cover is sealed, locking the pillbox, and indicating medicine locations by LEDs, etc.