Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy by Reactive Multilayer Films and Low Power Semiconductor Laser Heating

Abstract

:1. Introduction

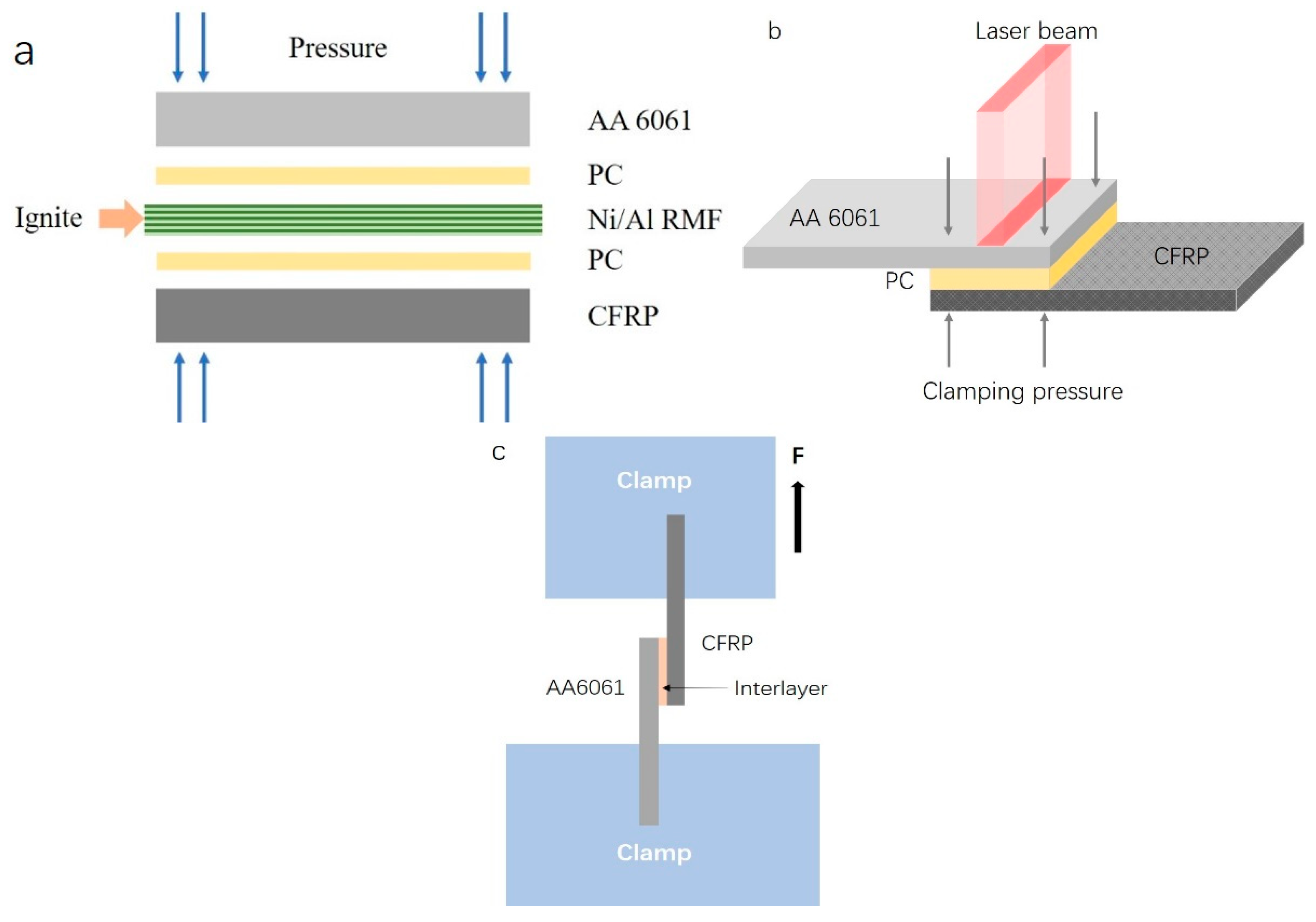

2. Materials and Methods

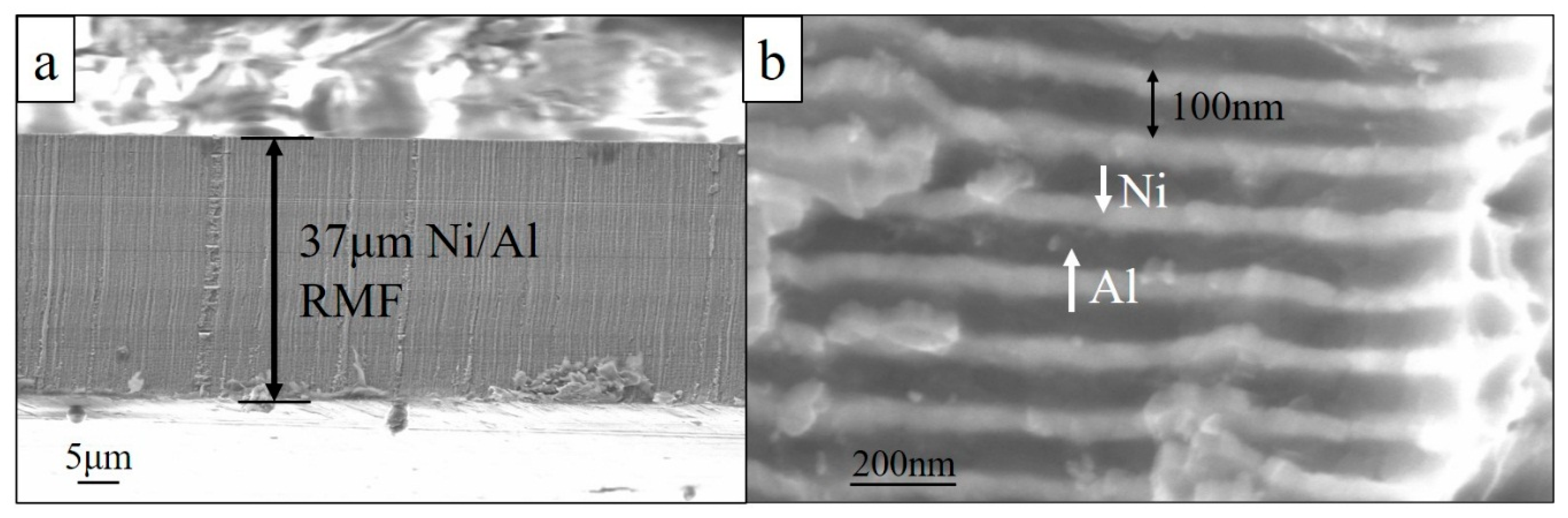

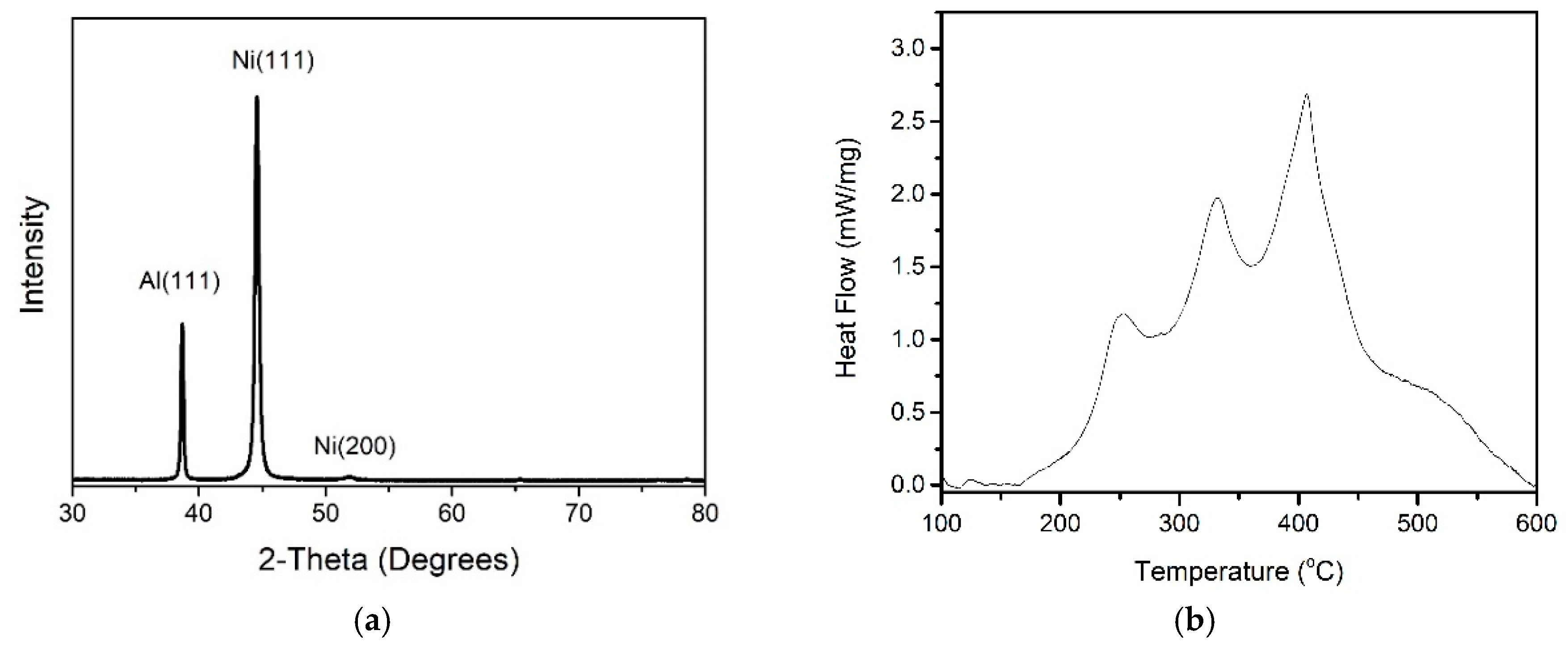

2.1. Preparation of Ni/Al RMFs

2.2. Pretreatment of CFRP and Aluminum Alloy

2.3. RMF Joining and Laser Joining Processes

2.4. Characterization Techniques

3. Results and Discussion

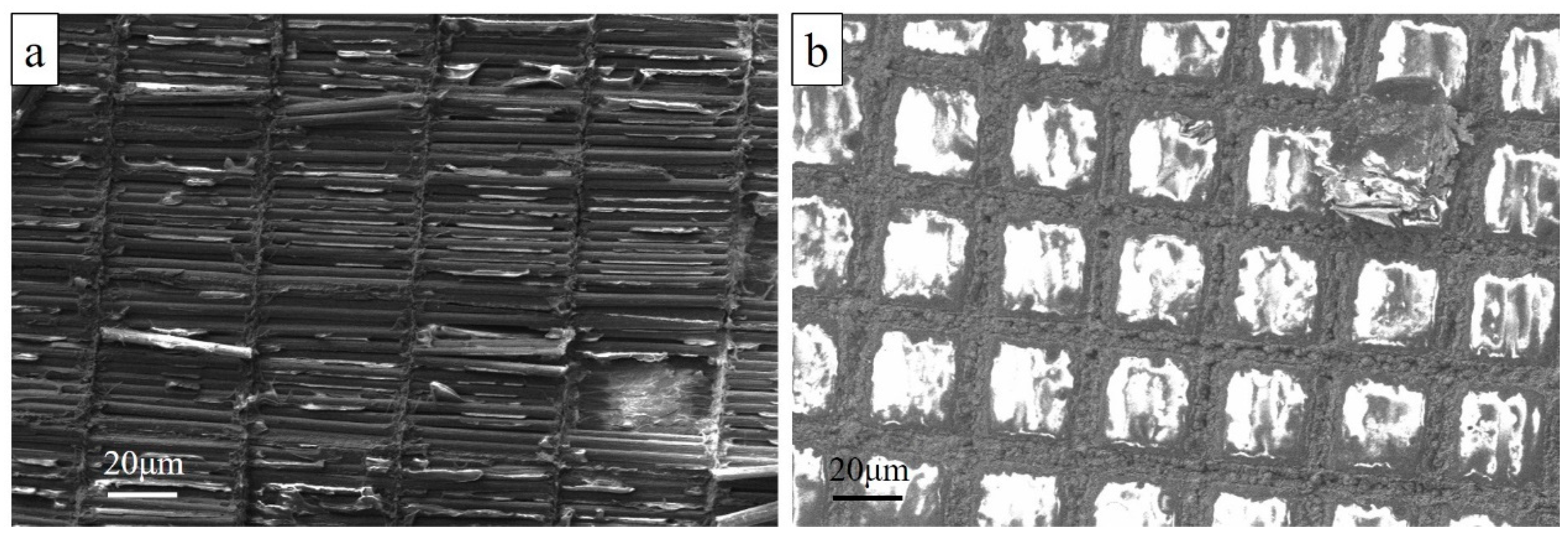

3.1. Characterization of RMFs and Laser Pretreated CFRP and Aluminum Surfaces

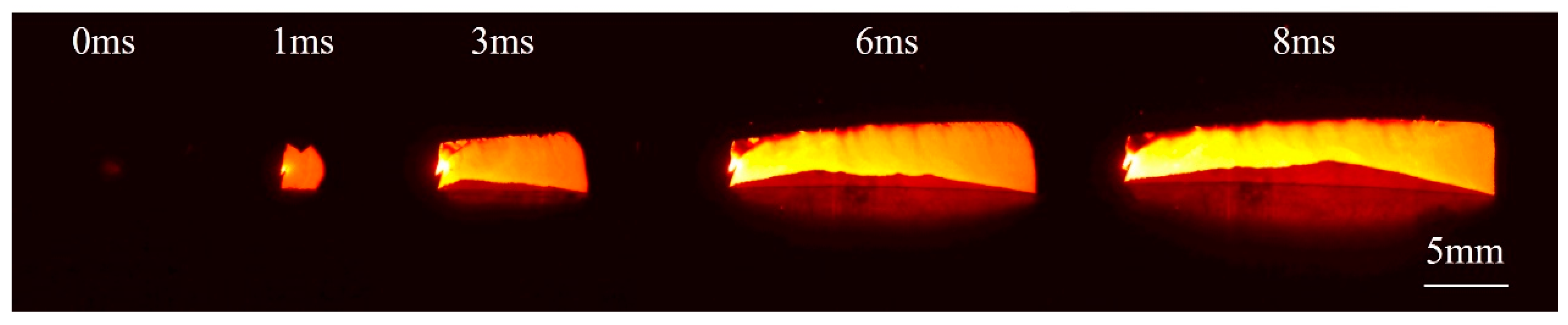

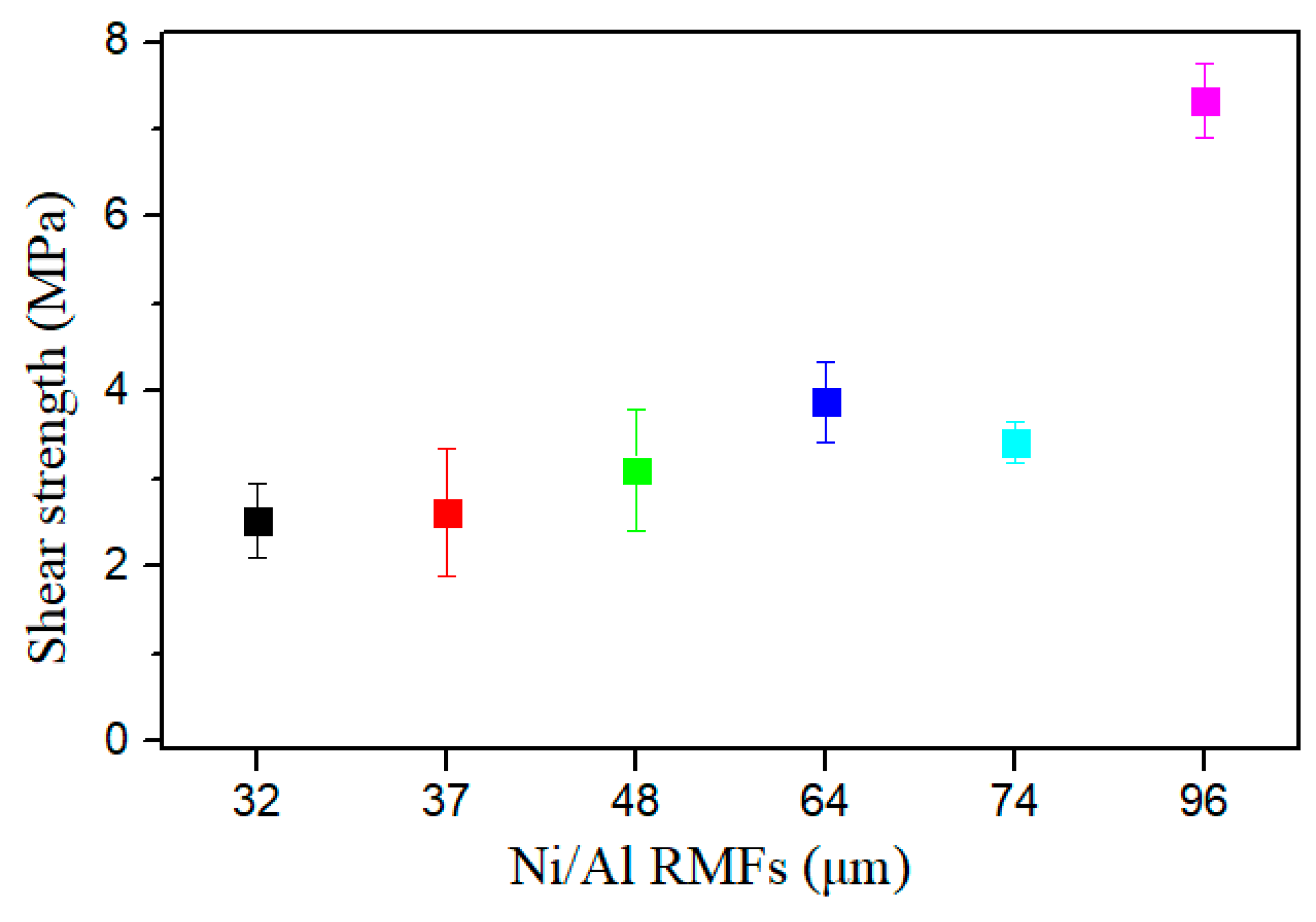

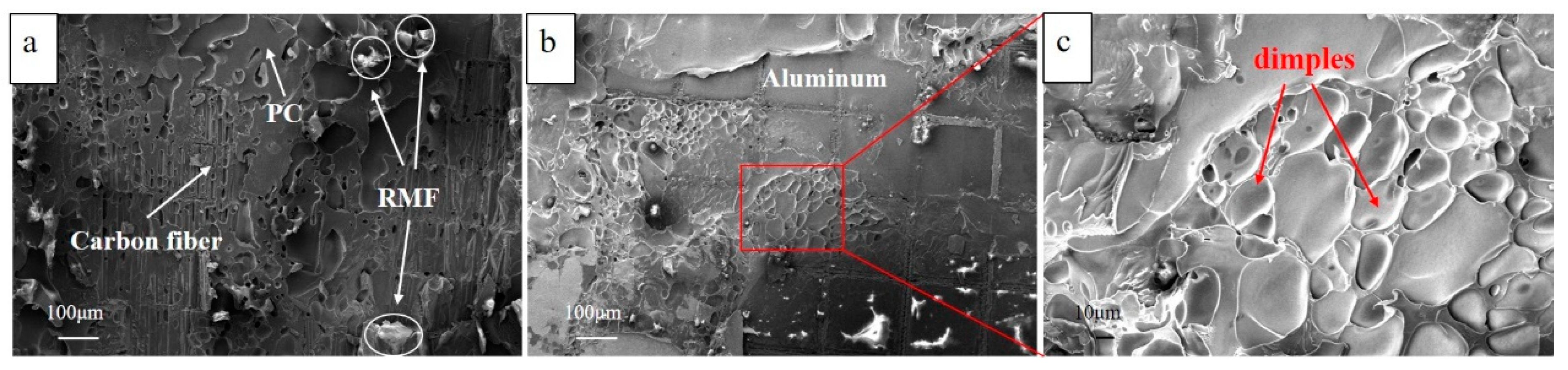

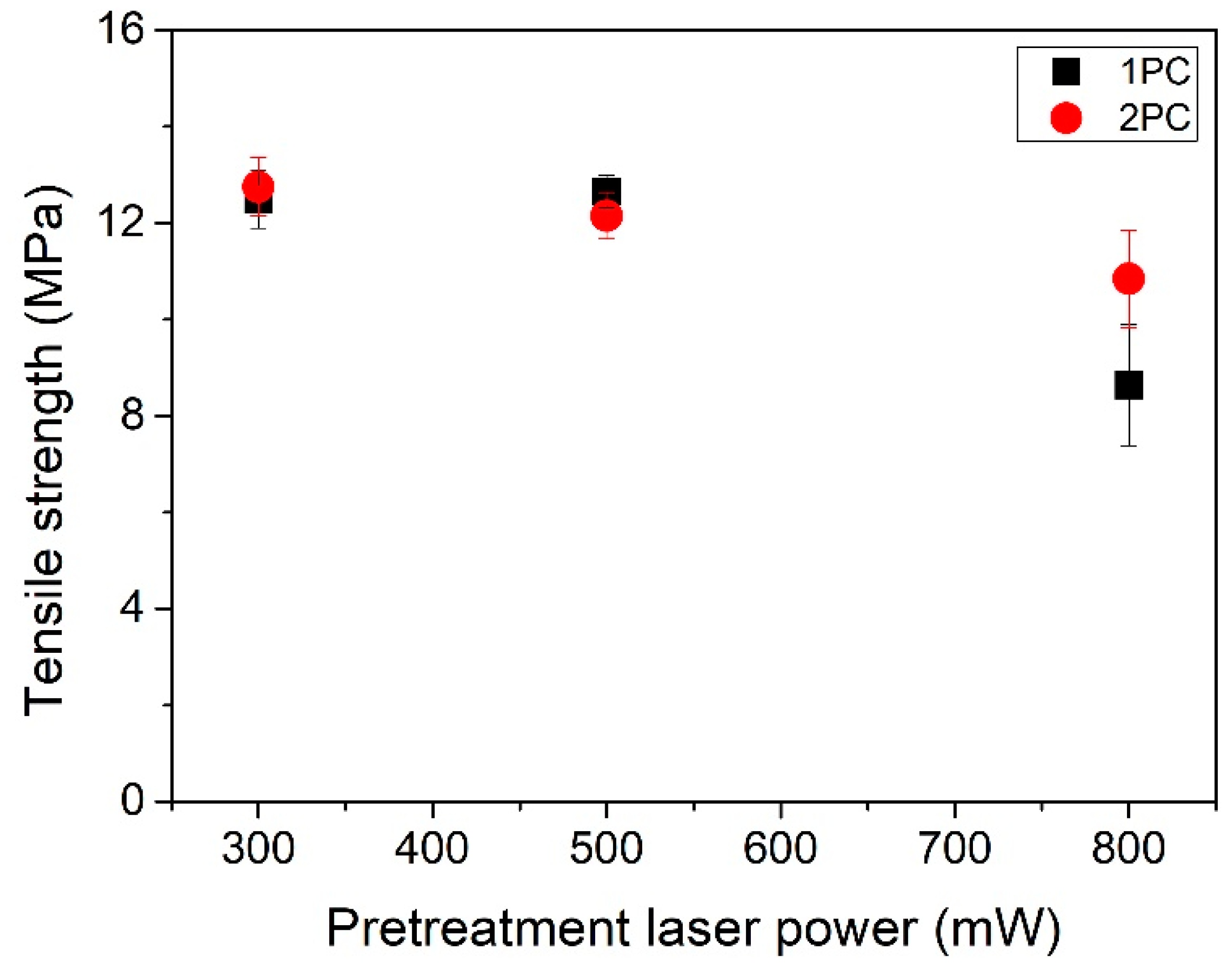

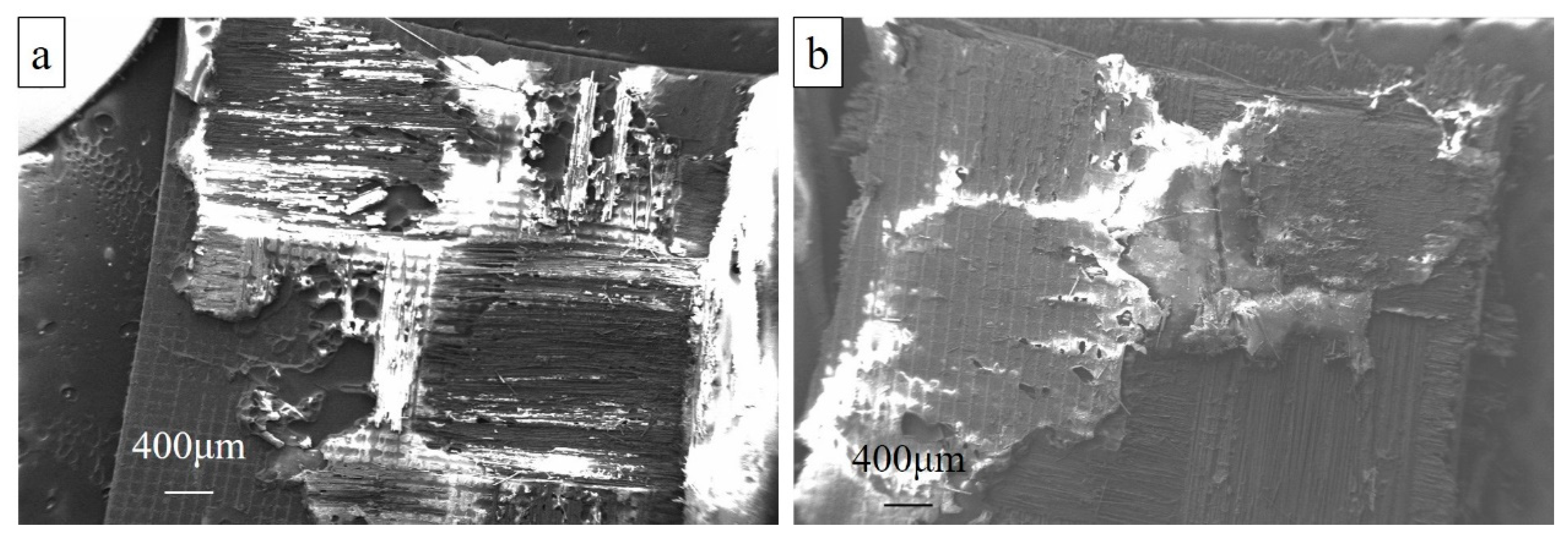

3.2. Joining of CFRP to Aluminum Using RMFs

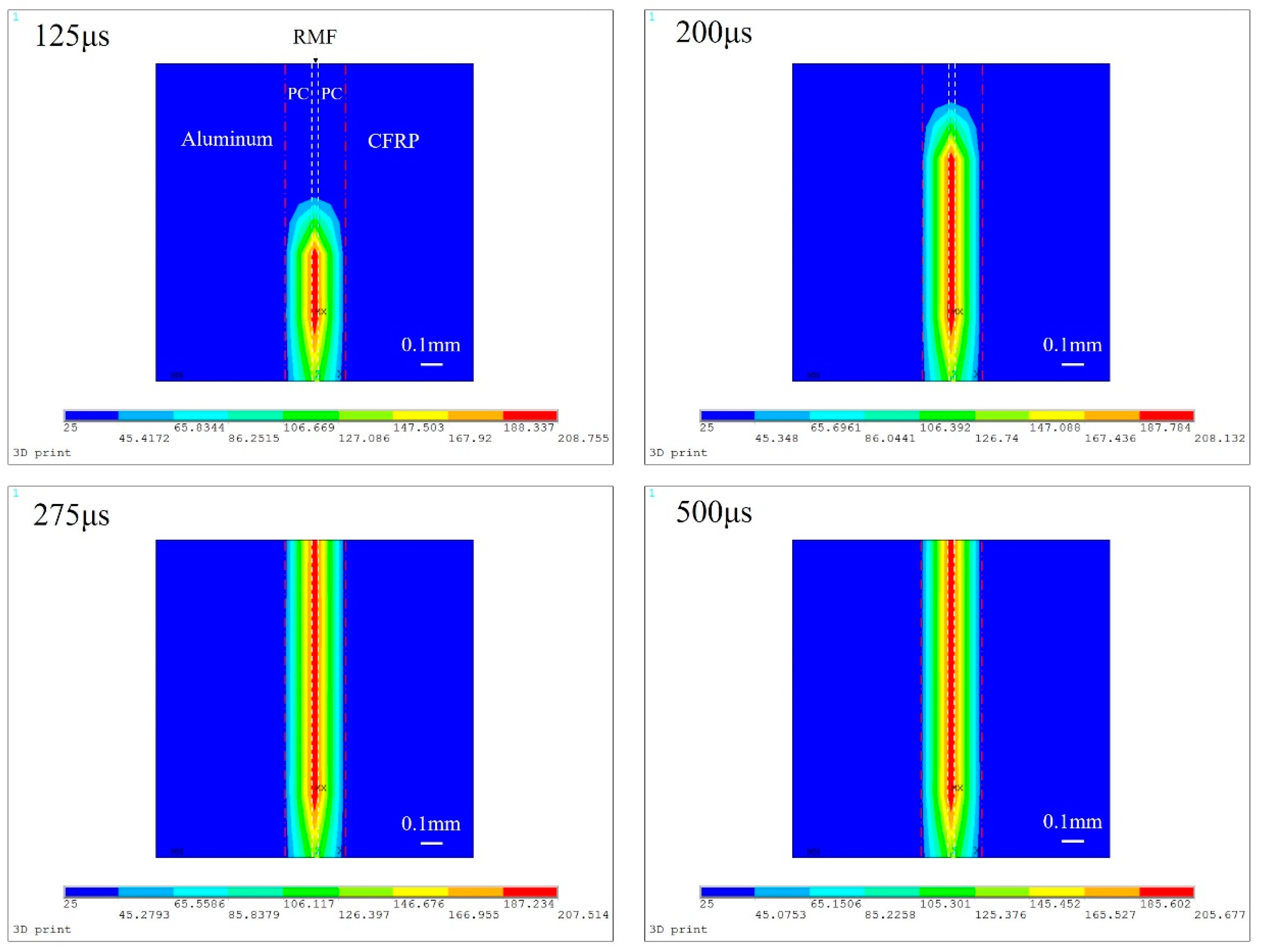

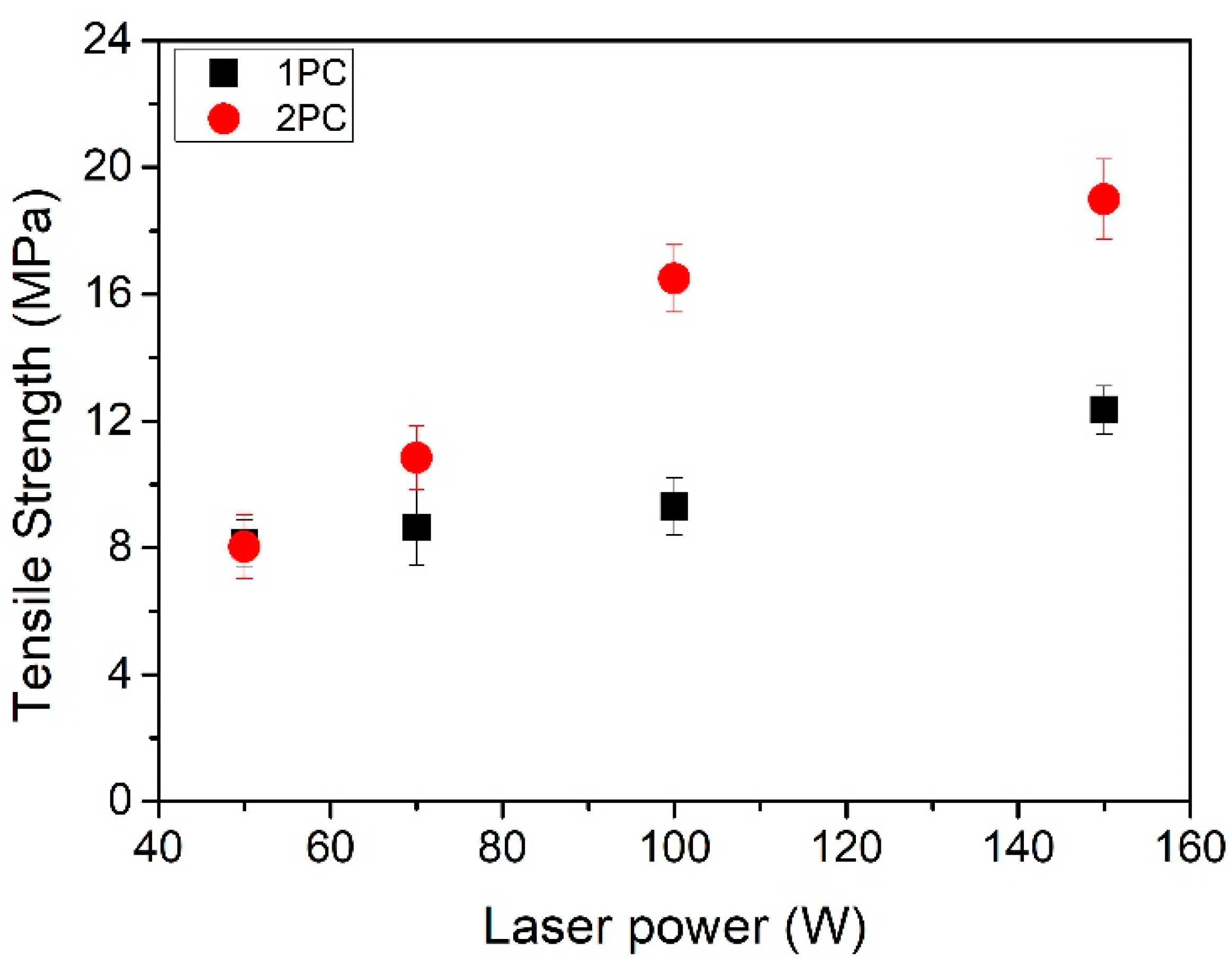

3.3. Joining of CFRP to Aluminum Using a Diode Laser

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Esteves, J.V.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Hage, E., Jr.; Amancio-Filho, S.T. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly (phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2015, 66, 437–445. [Google Scholar] [CrossRef]

- Karabutov, A.A.; Podymova, N.B. Quantitative analysis of the influence of voids and delaminations on acoustic attenuation in CFRP composites by the laser-ultrasonic spectroscopy method. Compos. Part B Eng. 2014, 56, 238–244. [Google Scholar] [CrossRef]

- Arenas, J.M.; Alía, C.; Narbón, J.J.; Ocaña, R.; González, C. Considerations for the industrial application of structural adhesive joints in the aluminium–composite material bonding. Compos. Part B Eng. 2013, 44, 417–423. [Google Scholar] [CrossRef]

- Min, J.; Li, Y.; Li, J.; Carlson, B.E.; Lin, J. Friction stir blind riveting of carbon fiber-reinforced polymer composite and aluminum alloy sheets. Int. J. Adv. Manuf. Technol. 2015, 76, 1403–1410. [Google Scholar] [CrossRef]

- Balle, F.; Eifler, D. Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints. Materialwiss. Werkstofftech. 2012, 43, 286–292. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.G.; Tan, X.H.; Zhang, J. Effect of anodizing pretreatment on laser joining CFRP to aluminum alloy A6061. Int. J. Adhes. Adhes. 2016, 70, 142–151. [Google Scholar] [CrossRef]

- Kumar, S.B.; Sridhar, I.; Sivashanker, S.; Osiyemi, S.O.; Bag, A. Tensile failure of adhesively bonded CFRP composite scarf joints. Mater. Sci. Eng. B 2006, 132, 113–120. [Google Scholar] [CrossRef]

- Rhee, K.Y.; Shin, M.K.; Choi, N.S.; Park, S.J. Investigation on surface treatments of CFRP and aluminum to improve fracture toughness of adhesively-bonded CFRP–aluminum joints. J. Adhes. Sci. Technol. 2003, 17, 1619–1634. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, Q.; Wang, F.; Zan, S.; Zhang, W. Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers. J. Mater. Process. Technol. 2017, 240, 362–369. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yue, T.M.; Guo, Z.N. Laser joining of metals to plastics with ultrasonic vibration. J. Mater. Process. Technol. 2017, 249, 441–451. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Leone, C.; Paoletti, A. Laser-assisted direct-joining of carbon fibre reinforced plastic with thermosetting matrix to polycarbonate sheets. Opt. Laser Technol. 2017, 94, 45–58. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Takahashi, M.; Katayama, S. Laser direct joining of carbon fiber reinforced plastic to aluminum alloy. J. Laser Appl. 2013, 25, 032003. [Google Scholar] [CrossRef]

- Simões, S.; Ramos, A.S.; Viana, F.; Vieira, M.T.; Vieira, M.F. Joining of TiAl to steel by diffusion bonding with Ni/Ti reactive multilayers. Metals 2016, 6, 96. [Google Scholar] [CrossRef]

- Hussein, A.; Alkhoori, A.; Al Zaabi, A.; Stefanini, C.; Renda, F.; Jaffar, S.; Gunduz, I.E.; Polychronopoulou, K.; Rebholz, C.G.; Doumanidis, C.C. Underwater Robotic Welding of Lap Joints with Sandwiched Reactive Multilayers: Thermal, Mechanical and Material Analysis. MRS Adv. 2018, 3, 911–920. [Google Scholar] [CrossRef]

- Ma, Y.; Li, H.; Bridges, D.; Peng, P.; Lawrie, B.; Feng, Z.; Hu, A. Zero-dimensional to three-dimensional nanojoining: Current status and potential applications. RSC Adv. 2016, 6, 75916–75936. [Google Scholar] [CrossRef]

- Zhu, W.; Wu, F.; Wang, B.; Hou, E.; Wang, P.; Liu, C.; Xia, W. Microstructural and mechanical integrity of Cu/Cu interconnects formed by self-propagating exothermic reaction methods. Microelectron. Eng. 2014, 128, 24–30. [Google Scholar] [CrossRef]

- Wang, J.; Besnoin, E.; Knio, O.M.; Weihs, T.P. Effects of physical properties of components on reactive nanolayer joining. J. Appl. Phys. 2005, 97, 114307. [Google Scholar] [CrossRef]

- Bridges, D.; Rouleau, C.; Gosser, Z.; Smith, C.; Zhang, Z.; Hong, K.; Hu, A. Self-Powered Fast Brazing of Ti-6Al-4V Using Ni/Al Reactive Multilayer Films. Appl. Sci. 2018, 8, 985. [Google Scholar] [CrossRef]

- Goyal, P.K.; Kumar, V.; Gupta, R.; Mahendia, S.; Kumar, S. Modification of polycarbonate surface by Ar+ ion implantation for various opto-electronic applications. Vacuum 2012, 86, 1087–1091. [Google Scholar] [CrossRef]

- Wright, W.W. Polymers in aerospace applications. Mater. Des. 1991, 12, 222–227. [Google Scholar] [CrossRef]

| RMF Thickness (μm) | Pressure (MPa) | Ignition Method | Pretreatment Laser Power (W) |

|---|---|---|---|

| 32–96 | 5 | 13 V DC | 1 |

| Materials | Length (mm) | Width (mm) | Thickness (mm) | Thermal Conductivity (W/m-K) | Density (g/cm3) | Heat Capacity (J/g-K) |

|---|---|---|---|---|---|---|

| RMF | 8.000 | 5.000 | 0.037 | 76.000 | 4.910 | 0.536 |

| PC | 8.000 | 5.000 | 0.100 | 0.220 | 1.200 | 1.300 |

| Pretreatment Laser Power (mW) | Joining Laser Power (W) | Joining Laser Wavelength (nm) | Joining Laser Size (mm) | PC Thickness (μm) |

|---|---|---|---|---|

| 300–800 | 50–150 | 806 | 5 × 2 | 150 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Bridges, D.; Yu, Y.; Han, J.; Li, H.; Hu, A. Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy by Reactive Multilayer Films and Low Power Semiconductor Laser Heating. Appl. Sci. 2019, 9, 319. https://doi.org/10.3390/app9020319

Ma Y, Bridges D, Yu Y, Han J, Li H, Hu A. Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy by Reactive Multilayer Films and Low Power Semiconductor Laser Heating. Applied Sciences. 2019; 9(2):319. https://doi.org/10.3390/app9020319

Chicago/Turabian StyleMa, Ying, Denzel Bridges, Yongchao Yu, Jitai Han, Hong Li, and Anming Hu. 2019. "Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy by Reactive Multilayer Films and Low Power Semiconductor Laser Heating" Applied Sciences 9, no. 2: 319. https://doi.org/10.3390/app9020319

APA StyleMa, Y., Bridges, D., Yu, Y., Han, J., Li, H., & Hu, A. (2019). Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy by Reactive Multilayer Films and Low Power Semiconductor Laser Heating. Applied Sciences, 9(2), 319. https://doi.org/10.3390/app9020319