A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications

Abstract

1. Introduction

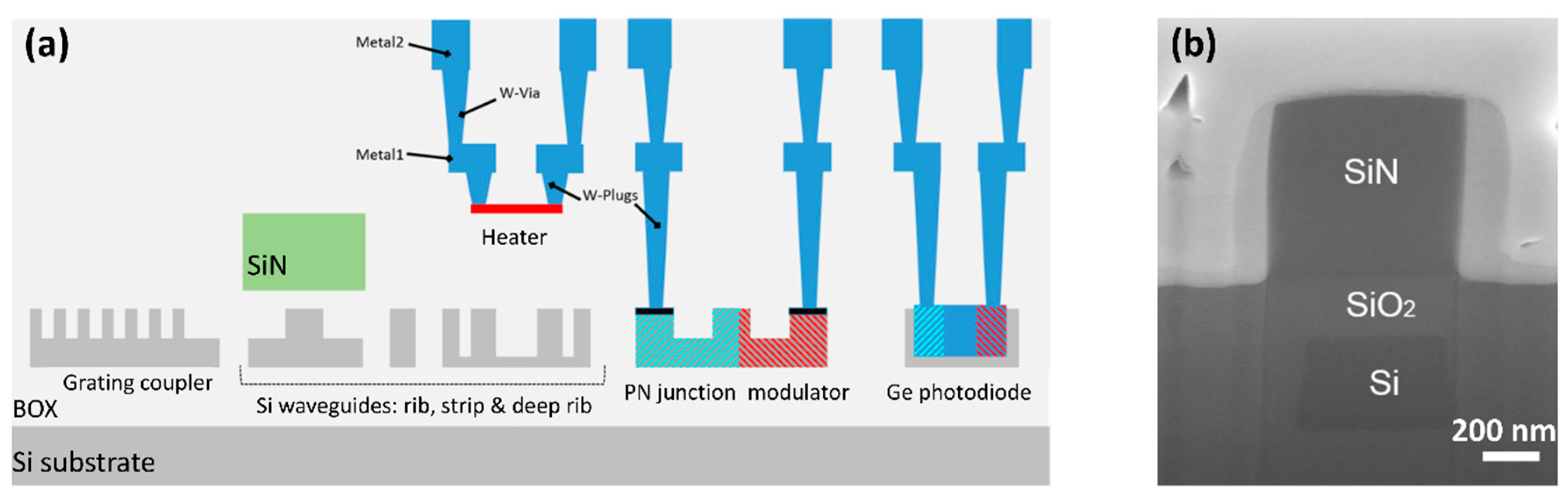

2. Fabrication Process and Waveguide Performances

2.1. Fabrication Processes

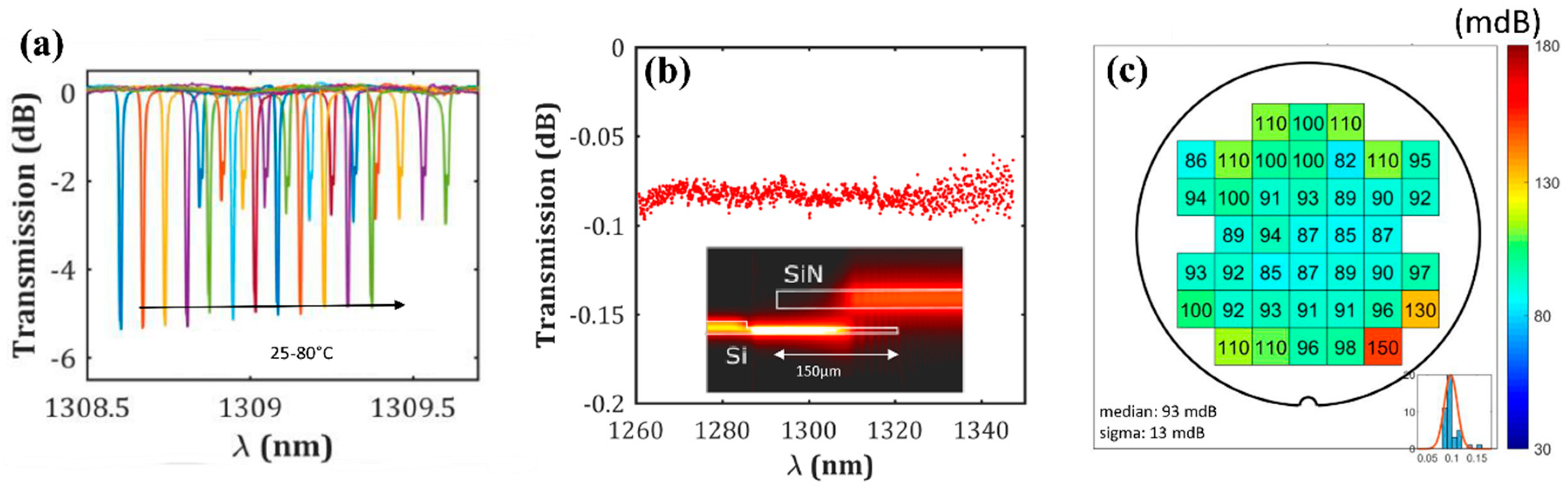

2.2. SiN Waveguide Optical Characterization

3. SiN for Coarse Wavelength Division Multiplexing (CWDM) Optical Transceivers in the O-Band

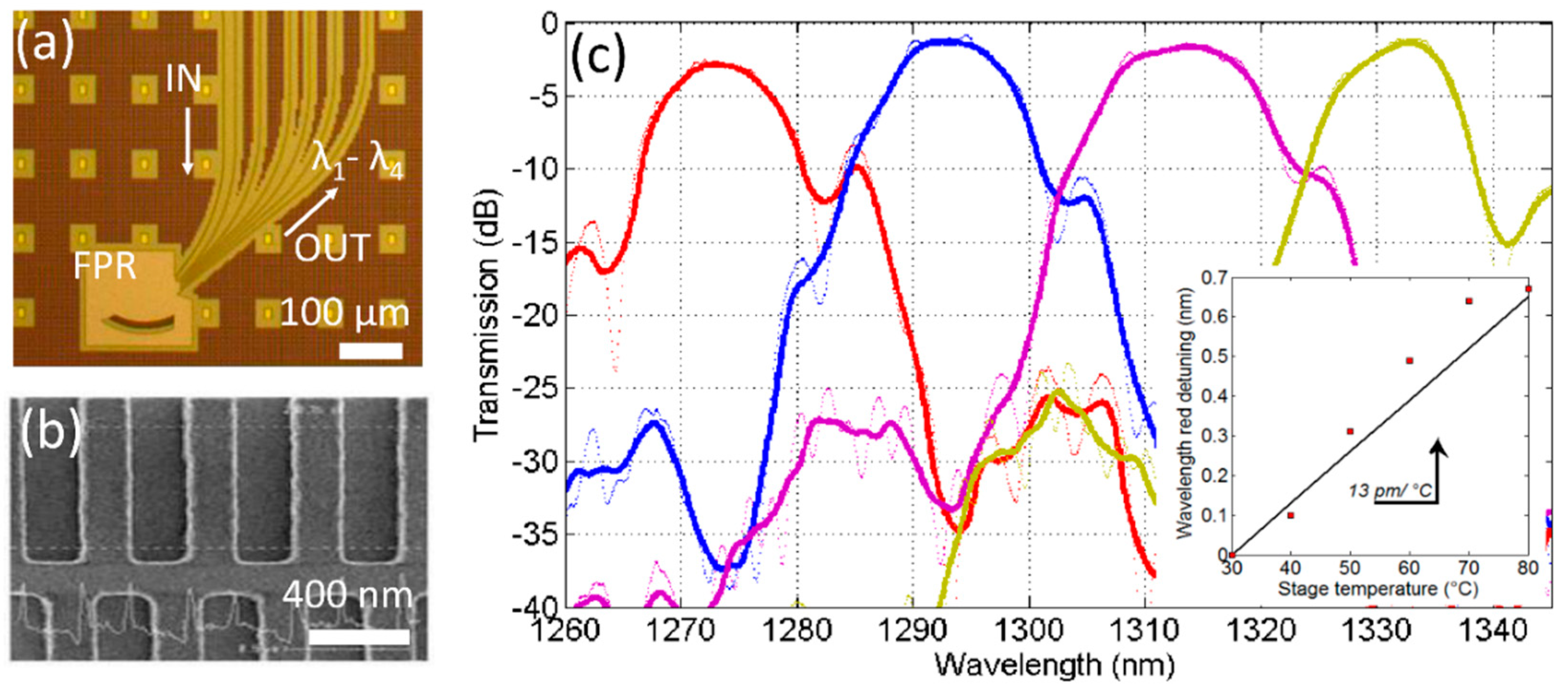

3.1. CWDM SiN Echelle Grating Multiplexer

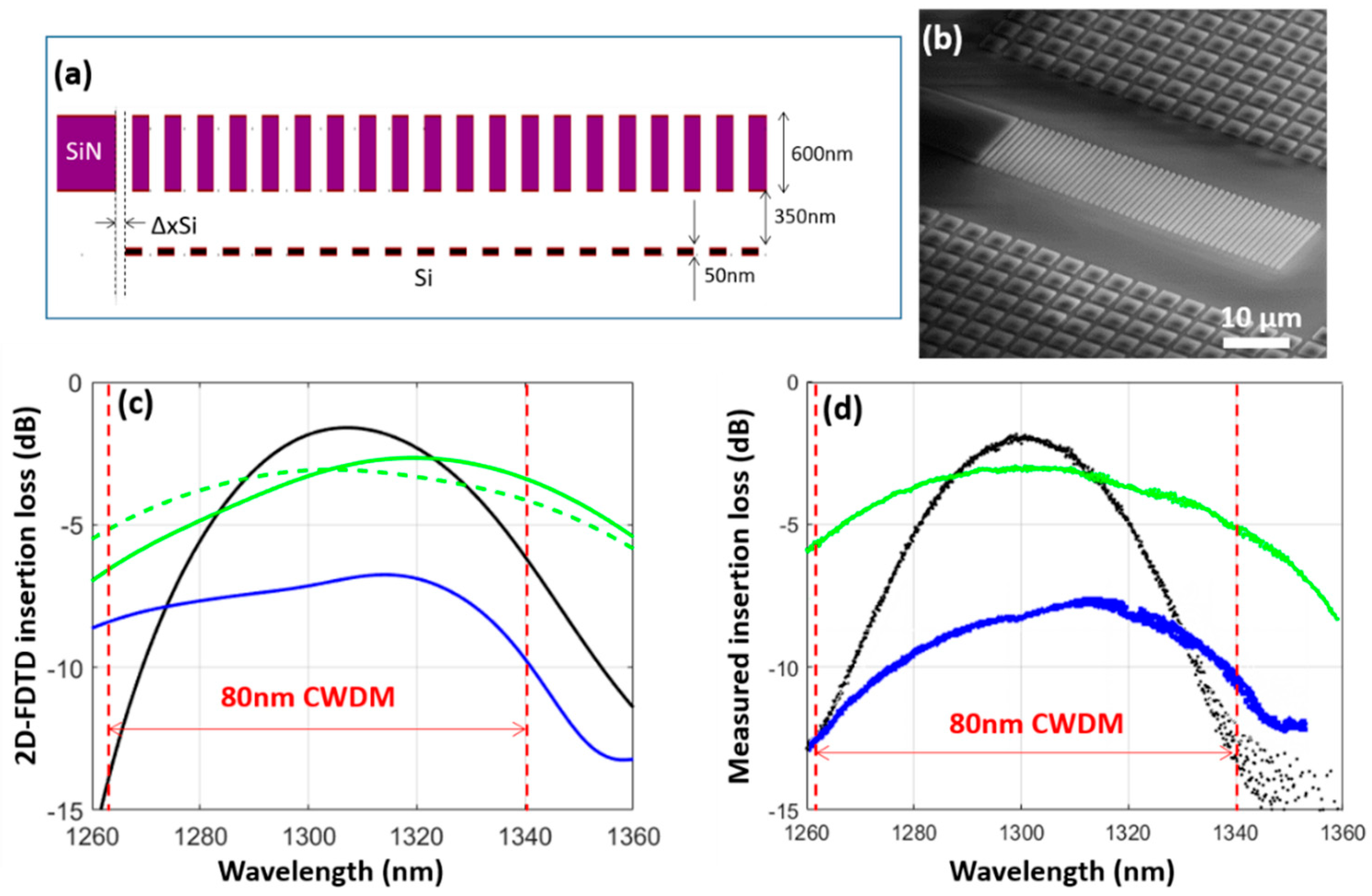

3.2. SiN-Si Hybrid Grating Fiber Coupler

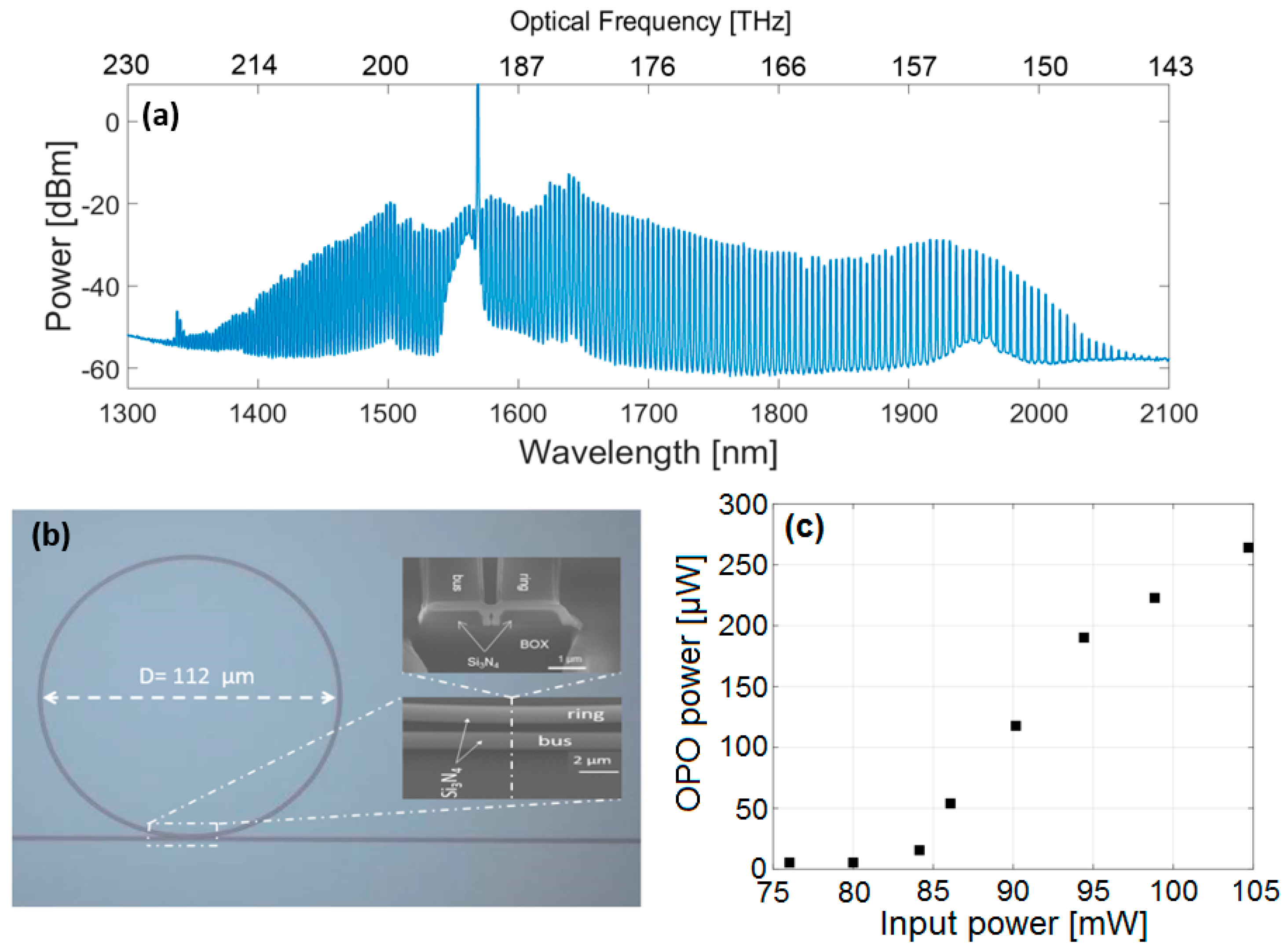

4. Optical Frequency Comb Generation in Annealing- and Crack-Free Si3N4

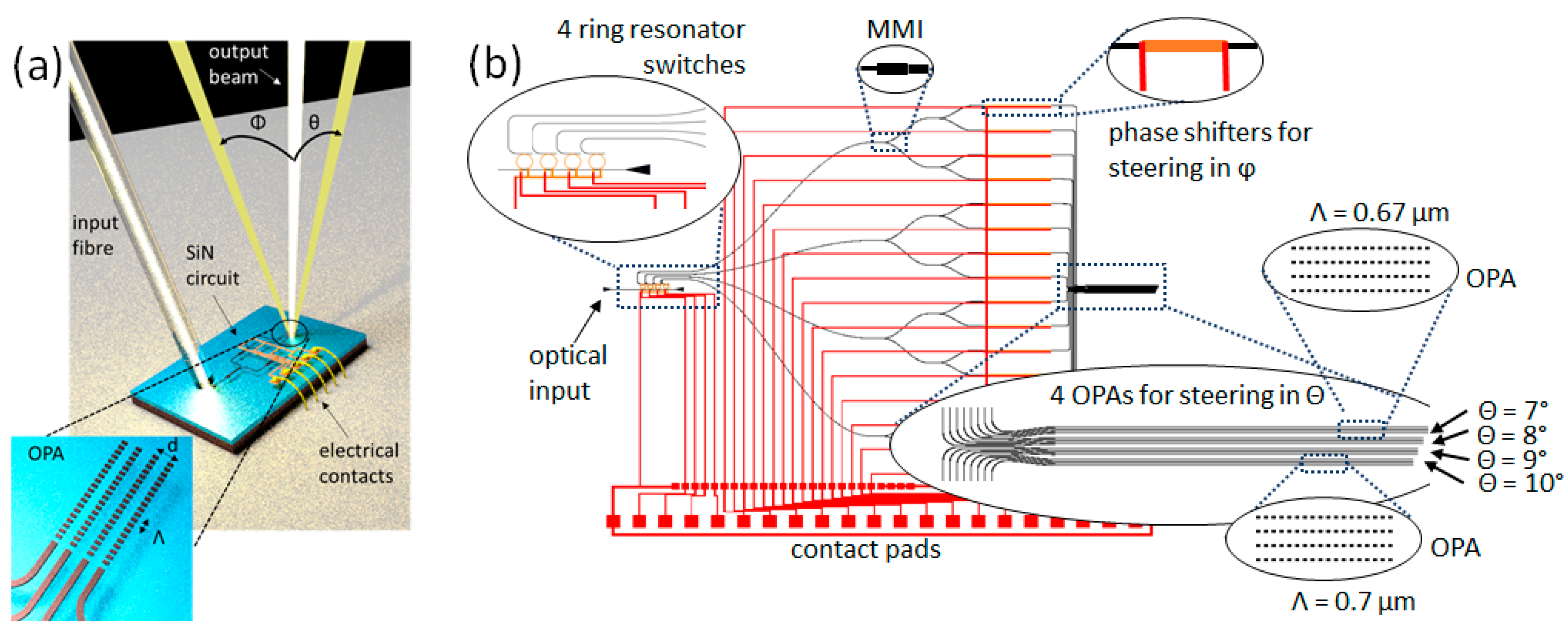

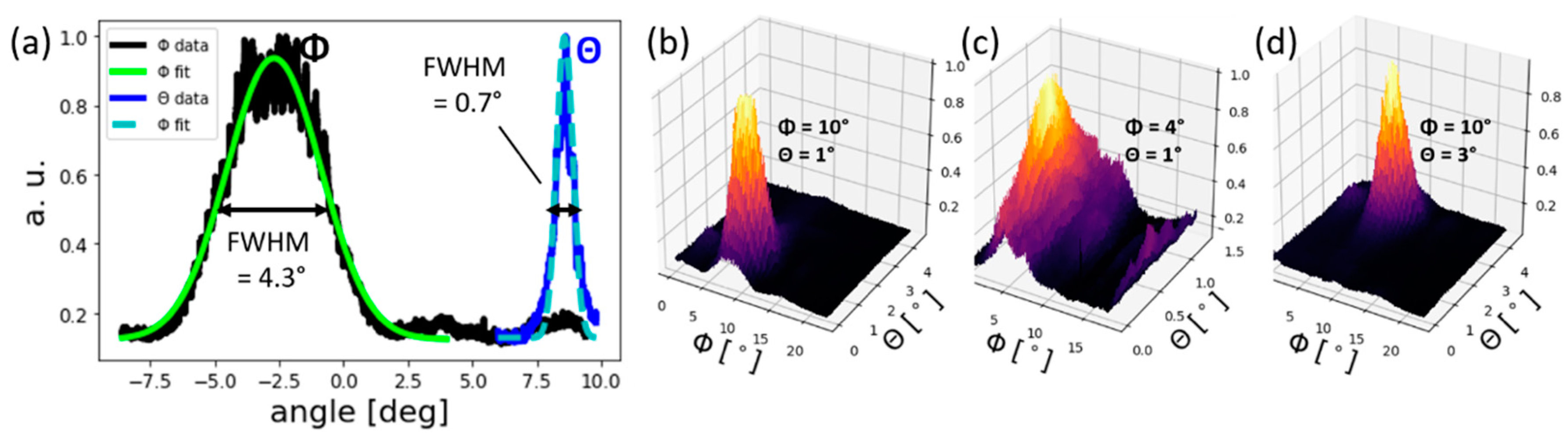

5. SiN for Near Infrared LIDAR

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boeuf, F.; Cremer, S.; Temporiti, E.; Fere, M.; Shaw, M.; Baudot, C.; Vulliet, N.; Pinguet, T.; Mekis, A.; Masini, G.; et al. Silicon Photonics R&D and Manufacturing on 300-mm Wafer Platform. J. Lightw. Technol. 2016, 34, 286–295. [Google Scholar] [CrossRef]

- Szelag, B.; Blampey, B.; Ferrotti, T.; Reboud, V.; Hassan, K.; Malhouitre, S.; Grand, G.; Fowler, D.; Brision, S.; Bria, T.; et al. Multiple Wavelength Silicon Photonic 200 mm R + D Platform for 25Gb/s and above Applications. In Proceedings of the Silicon Photonics and Photonic Integrated Circuits V, Brussels, Belgium, 3–7 April 2016; Volume 9891, p. 98911C. [Google Scholar]

- Horikawa, T.; Shimura, D.; Okayama, H.; Jeong, S.-H.; Takahashi, H.; Ushida, J.; Sobu, Y.; Shiina, A.; Tokushima, M.; Kinoshita, K.; et al. A 300-mm Silicon Photonics Platform for Large-Scale Device Integration. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–15. [Google Scholar] [CrossRef]

- Wang, J.; Long, Y. On-chip silicon photonic signaling and processing: A review. Sci. Bull. 2018, 63, 1267–1310. [Google Scholar] [CrossRef]

- Silverstone, J.W.; Bonneau, D.; O’Brien, J.L.; Thompson, M.G. Silicon Quantum Photonics. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 390–402. [Google Scholar] [CrossRef]

- Politi, A.; Cryan, M.J.; Rarity, J.G.; Yu, S.; O’Brien, J.L. Silica-on-Silicon Waveguide Quantum Circuits. Science 2008, 320, 646–649. [Google Scholar] [CrossRef]

- Qiang, X.; Zhou, X.; Wang, J.; Wilkes, C.M.; Loke, T.; O’Gara, S.; Kling, L.; Marshall, G.D.; Santagati, R.; Ralph, T.C.; et al. Large-scale silicon quantum photonics implementing arbitrary two-qubit processing. Nat. Photonics 2018, 12, 534–539. [Google Scholar] [CrossRef]

- Heck, M.J.R. Highly integrated optical phased arrays: Photonic integrated circuits for optical beam shaping and beam steering. Nanophotonics 2017, 6, 93–107. [Google Scholar] [CrossRef]

- Van Acoleyen, K.; Bogaerts, W.; Jágerská, J.; Le Thomas, N.; Houdré, R.; Baets, R. Off-chip beam steering with a one-dimensional optical phased array on silicon-on-insulator. Opt. Lett. 2009, 34, 1477–1479. [Google Scholar] [CrossRef] [PubMed]

- Hulme, J.C.; Doylend, J.K.; Heck, M.J.R.; Peters, J.D.; Davenport, M.L.; Bovington, J.T.; Coldren, L.A.; Bowers, J.E. Fully integrated hybrid silicon two dimensional beam scanner. Opt. Express 2015, 23, 5861–5874. [Google Scholar] [CrossRef]

- Chung, S.; Abediasl, H.; Hashemi, H. A Monolithically Integrated Large-Scale Optical Phased Array in Silicon-on-Insulator CMOS. IEEE J. Solid State Circuits 2018, 53, 275–296. [Google Scholar] [CrossRef]

- Levy, J.S.; Gondarenko, A.; Foster, M.A.; Turner-Foster, A.C.; Gaeta, A.L.; Lipson, M. CMOS-compatible multiple-wavelength oscillator for on-chip optical interconnects. Nat. Photonics 2010, 4, 37–40. [Google Scholar] [CrossRef]

- Moss, D.J.; Morandotti, R.; Gaeta, A.L.; Lipson, M. New CMOS-compatible platforms based on silicon nitride and Hydex for nonlinear optics. Nat. Photonics 2013, 7, 597–607. [Google Scholar] [CrossRef]

- Marin-Palomo, P.; Kemal, J.N.; Karpov, M.; Kordts, A.; Pfeifle, J.; Pfeiffer, M.H.P.; Trocha, P.; Wolf, S.; Brasch, V.; Anderson, M.H.; et al. Microresonator-based solitons for massively parallel coherent optical communications. Nature 2017, 546, 274–279. [Google Scholar] [CrossRef]

- Duan, G.-H.; Jany, C.; Le Liepvre, A.; Accard, A.; Lamponi, M.; Make, D.; Kaspar, P.; Levaufre, G.; Girard, N.; Lelarge, F.; et al. Hybrid III–V on Silicon Lasers for Photonic Integrated Circuits on Silicon. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 158–170. [Google Scholar] [CrossRef]

- Durel, J.; Ferrotti, T.; Chantre, A.; Cremer, S.; Harduin, J.; Bernabé, S.; Kopp, C.; Boeuf, F.; Ben Bakir, B.; Broquin, J.-E. Realization of Back-Side Heterogeneous Hybrid III-V/Si DBR Lasers for Silicon Photonics. In Proceedings of the Integrated Optics: Devices, Materials and technologies XX, San Francisco, CA, USA, 13–18 February 2016; Volume 9750, p. 97500O. [Google Scholar]

- Szelag, B.; Hassan, K.; Adelmini, L.; Ghegin, E.; Rodriguez, P.; Bensalem, S.; Nemouchi, F.; Bria, T.; Brihoum, M.; Brianceau, P.; et al. Hybrid III-V/Si DFB laser integration on a 220 mm fully CMOS-compatible silicon photonics platform. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017. [Google Scholar]

- Virot, L.; Benedikovic, D.; Szelag, B.; Alonso-Ramos, C.; Karakus, B.; Hartmann, J.-M.; Le Roux, X.; Crozat, P.; Cassan, E.; Marris-Morini, D.; et al. Integrated waveguide PIN photodiodes exploiting lateral Si/Ge/Si heterojunction. Opt. Express 2017, 25, 19487–19496. [Google Scholar] [CrossRef]

- Ferrotti, T.; Blampey, B.; Jany, C.; Duprez, H.; Chantre, A.; Boeuf, F.; Seassal, C.; Ben Bakir, B. Co-integrated 13µm hybrid III-V/silicon tunable laser and silicon Mach-Zehnder modulator operating at 25 Gb/s. Opt. Express 2016, 24, 30379–30401. [Google Scholar] [CrossRef]

- Sacher, W.D.; Huang, Y.; Lo, G.-Q.; Poon, J.K.S. Multilayer Silicon Nitride-on-Silicon Integrated Photonic Platforms and Devices. J. Lightw. Technol. 2015, 33, 901–910. [Google Scholar] [CrossRef]

- Rahim, A.; Ryckeboer, E.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Dhakal, A.; Raza, A.; Hermans, A.; Muneeb, M.; Dhoore, S.; et al. Expanding the Silicon Photonics Portfolio With Silicon Nitride Photonic Integrated Circuits. J. Lightw. Technol. 2017, 35, 639–649. [Google Scholar] [CrossRef]

- Zhang, Z.; Yako, M.; Ju, K.; Kawai, N.; Chaisakul, P.; Tsuchizawa, T.; Hikita, M.; Yamada, K.; Ishikawa, Y.; Wada, K. A new material platform of Si photonics for implementing architecture of dense wavelength division multiplexing on Si bulk wafer. Sci. Technol. Adv. Mater. 2017, 18, 283–293. [Google Scholar] [CrossRef]

- Wilmart, Q.; Fowler, D.; Sciancalepore, C.; Hassan, K.; Plantier, S.; Adelmini, L.; Garcia, S.; Robin-Brosse, D.; Malhouitre, S.; Olivier, S. A hybrid SOI/SiN photonic platform for high-speed and temperature-insensitive CWDM optical transceivers. In Proceedings of the Silicon Photonics XIII, San Francisco, CA, USA, 27 January–1 February 2018; Volume 10537, p. 1053709. [Google Scholar]

- Boeuf, F.; Baudot, C.; Le Maitre, P.; Vulliet, N.; Planchot, J.; Babaud, L.; Carpentier, J.-F.; Messaoudene, S.; Khedim, M.; Orlandi, P.; et al. Evaluation of Advanced Process Integration Options for Next Generation of Si-Photonics Platform. In Proceedings of the International Conference on Solid State Devices and Materials, Tokyo, Japan, 9–13 September 2018. [Google Scholar]

- Baets, R.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Bienstman, P.; Le Thomas, N.; Roelkens, G.; Van Thourhout, D.; Helin, P.; Severi, S. Silicon Photonics: Silicon nitride versus silicon-on-insulator. In Proceedings of the Optical Fiber Communication Conference, Anaheim, CA, USA, 20–22 March 2016. [Google Scholar]

- Arbabi, A.; Goddard, L.L. Measurements of the refractive indices and thermo-optic coefficients of Si3N4 and SiO_x using microring resonances. Opt. Lett. 2013, 38, 3878–3881. [Google Scholar] [CrossRef]

- Iadanza, S.; Bakoz, A.P.; Singaravelu, P.K.J.; Panettieri, D.; Schulz, S.A.; Devarapu, G.C.R.; Guerber, S.; Baudot, C.; Boeuf, F.; Hegarty, S.; et al. Thermally stable hybrid cavity laser based on silicon nitride gratings. Appl. Opt. 2018, 57, E218–E223. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Chen, D.; Tao, S.; Zhang, Y.; Zhu, S.; Xiao, X.; Xia, J. Silicon nitride O-band (de)multiplexers with low thermal sensitivity. Opt. Express 2017, 25, 12260–12267. [Google Scholar] [CrossRef] [PubMed]

- Bucio, T.D.; Khokhar, A.Z.; Mashanovich, G.Z.; Gardes, F.Y. Athermal silicon nitride angled MMI wavelength division (de)multiplexers for the near-infrared. Opt. Express 2017, 25, 27310–27320. [Google Scholar] [CrossRef] [PubMed]

- Pommarede, X.; Hassan, K.; Billondeau, P.; Hugues, V.; Grosse, P.; Charbonnier, B.; Duan, G.-H. 16x100 GHz Echelle Grating-Based Wavelength Multiplexer on Silicon-on-Insulator Platform. IEEE Photonics Technol. Lett. 2017, 29, 493–495. [Google Scholar] [CrossRef]

- Dong, P. Silicon Photonic Integrated Circuits for Wavelength-Division Multiplexing Applications. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 370–378. [Google Scholar] [CrossRef]

- El Dirani, H.; Kamel, A.; Casale, M.; Kerdiles, S.; Monat, C.; Letartre, X.; Pu, M.; Oxenløwe, L.K.; Yvind, K.; Sciancalepore, C. Annealing-free Si3N4 frequency combs for monolithic integration with Si photonics. Appl. Phys. Lett. 2018, 113. [Google Scholar] [CrossRef]

- El Dirani, H.; Casale, M.; Kerdiles, S.; Socquet-Clerc, C.; Letartre, X.; Monat, C.; Sciancalepore, C. Crack-Free Silicon-Nitride-on-Insulator Nonlinear Circuits for Continuum Generation in the C-Band. IEEE Photonics Technol. Lett. 2018, 30, 355–358. [Google Scholar] [CrossRef]

- Poulton, C.V.; Byrd, M.J.; Raval, M.; Su, Z.; Li, N.; Timurdogan, E.; Coolbaugh, D.; Vermeulen, D.; Watts, M.R. Large-scale silicon nitride nanophotonic phased arrays at infrared and visible wavelengths. Opt. Lett. 2017, 42, 21–24. [Google Scholar] [CrossRef]

- Bauters, J.F. Ultra-Low Loss Waveguides with Application to Photonic Integrated Circuits; University of California: Santa Barbara, CA, USA, 2013. [Google Scholar]

- Huang, Y.; Song, J.; Luo, X.; Liow, T.-Y.; Lo, G.-Q. CMOS compatible monolithic multi-layer Si3N4-on-SOI platform for low-loss high performance silicon photonics dense integration. Opt. Express 2014, 22, 21859–21865. [Google Scholar] [CrossRef] [PubMed]

- Hosseinnia, A.H.; Atabaki, A.H.; Eftekhar, A.A.; Adibi, A. High-quality silicon on silicon nitride integrated optical platform with an octave-spanning adiabatic interlayer coupler. Opt. Express 2015, 23, 30297–30307. [Google Scholar] [CrossRef] [PubMed]

- Sacher, W.D.; Huang, Y.; Ding, L.; Taylor, B.J.F.; Jayatilleka, H.; Lo, G.-Q.; Poon, J.K.S. Wide bandwidth and high coupling efficiency Si3N4-on-SOI dual-level grating coupler. Opt. Express 2014, 22, 10938–10947. [Google Scholar] [CrossRef] [PubMed]

- Sciancalepore, C.; Lycett, R.J.; Dallery, J.A.; Pauliac, S.; Hassan, K.; Harduin, J.; Duprez, H.; Weidenmueller, U.; Gallagher, D.F.G.; Menezo, S.; et al. Low-Crosstalk Fabrication-Insensitive Echelle Grating Demultiplexers on Silicon-on-Insulator. IEEE Photonics Technol. Lett. 2015, 27, 494–497. [Google Scholar] [CrossRef]

- Luke, K.; Dutt, A.; Poitras, C.B.; Lipson, M. Overcoming Si3N4 film stress limitations for high quality factor ring resonators. Opt. Express 2013, 21, 22829–22833. [Google Scholar] [CrossRef] [PubMed]

- Pfeiffer, M.H.P.; Kordts, A.; Brasch, V.; Zervas, M.; Geiselmann, M.; Jost, J.D.; Kippenberg, T.J. Photonic Damascene process for integrated high-Q microresonator based nonlinear photonics. Optica 2016, 3, 20–25. [Google Scholar] [CrossRef]

- Kim, S.; Han, K.; Wang, C.; Jaramillo-Villegas, J.A.; Xue, X.; Bao, C.; Xuan, Y.; Leaird, D.E.; Weiner, A.M.; Qi, M. Dispersion engineering and frequency comb generation in thin silicon nitride concentric microresonators. Nat. Commun. 2017, 8, 372. [Google Scholar] [CrossRef] [PubMed]

- Herr, T.; Hartinger, K.; Riemensberger, J.; Wang, C.Y.; Gavartin, E.; Holzwarth, R.; Gorodetsky, M.L.; Kippenberg, T.J. Universal formation dynamics and noise of Kerr-frequency combs in microresonators. Nat. Photonics 2012, 6, 480–487. [Google Scholar] [CrossRef]

- Vasey, F.; Reinhart, F.K.; Houdré, R.; Stauffer, J.M. Spatial optical beam steering with an AlGaAs integrated phased array. Appl. Opt. 1993, 32, 3220–3232. [Google Scholar] [CrossRef]

- Guo, W.; Binetti, P.R.A.; Althouse, C.; Masanovic, M.L.; Ambrosius, H.P.M.M.; Johansson, L.A.; Coldren, L.A. Two-Dimensional Optical Beam Steering with InP-Based Photonic Integrated Circuits. IEEE J. Sel. Top. Quantum Electron. 2013, 19. [Google Scholar] [CrossRef]

- Jalali, B.; Fathpour, S. Silicon Photonics. J. Lightw. Technol. 2006, 24, 4600–4615. [Google Scholar] [CrossRef]

- Poulton, C.V.; Yaacobi, A.; Cole, D.B.; Byrd, M.J.; Raval, M.; Vermeulen, D.; Watts, M.R. Coherent solid-state LIDAR with silicon photonic optical phased arrays. Opt. Lett. 2017, 42, 4091–4094. [Google Scholar] [CrossRef]

- Martin, A.; Dodane, D.; Leviandier, L.; Dolfi, D.; Naughton, A.; O’Brien, P.; Spuessens, T.; Baets, R.; Lepage, G.; Verheyen, P.; et al. Photonic Integrated Circuit-Based FMCW Coherent LiDAR. J. Lightw. Technol. 2018, 36, 4640–4645. [Google Scholar] [CrossRef]

- Sabouri, S.; Jamshidi, K. Design Considerations of Silicon Nitride Optical Phased Array for Visible Light Communications. IEEE J. Sel. Top. Quantum Electron. 2018, 24. [Google Scholar] [CrossRef]

- Zadka, M.; Chang, Y.-C.; Mohanty, A.; Phare, C.T.; Roberts, S.P.; Lipson, M. On-chip platform for a phased array with minimal beam divergence and wide field-of-view. Opt. Express 2018, 26, 2528–2534. [Google Scholar] [CrossRef] [PubMed]

- Tyler, N.; Fowler, D.; Malhouitre, S.; Garcia, S.; Grosse, P.; Rabaud, W.; Szelag, B. SiN integrated optical phased arrays for 2-dimensional beam steering at a single near-infrared wavelength. Under review. Opt. Express. 2018, unpublished. [Google Scholar]

| Waveguide | Si Rib | Si Strip | SiN PECVD 1310 nm | Si3N4 LPCVD 1550 nm | SiN PECVD 940 nm | Si3N4 LPCVD 940 nm |

|---|---|---|---|---|---|---|

| dimension w × h (µm) | 0.4 × 0.3 | 0.35 × 0.3 | 0.7 × 0.6 | 0.75 × 0.75 | 0.6 × 0.3 | 0.6 × 0.3 |

| Propagation Loss (dB/cm) | 1.5 | 3.6 | 0.8 | 1.5 | 1.5 | 1.0 |

| 3 sigma (dB/cm) | 0.45 | 0.9 | 0.3 | - | - | 0.4 |

| Grating Type | Period (nm) | ΔxSi (nm) | Unetched/Etched Thickness (nm) | 2D-FDTD CWDM IL (nm) | 2D-FDTD 1 dB BW (nm) | Measured CWDM IL (dB) | Measured 1 dB BW (nm) |

|---|---|---|---|---|---|---|---|

| Si | 468–488 | - | 300/150 | 1.6–15 | 30 | 1.9–13.0 | 26 |

| SiN | 965 | - | 600 | 6.8–10.0 | 54 | 8.0–13.0 | 45 |

| Si/SiN a | 950 | 200 | 600 | 3.0–5.5 | 64 | - | - |

| Si/SiN b | 975 | 150 | 600/50 | 2.7–6.9 | 50 | 2.9–5.2 | 48 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilmart, Q.; El Dirani, H.; Tyler, N.; Fowler, D.; Malhouitre, S.; Garcia, S.; Casale, M.; Kerdiles, S.; Hassan, K.; Monat, C.; et al. A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications. Appl. Sci. 2019, 9, 255. https://doi.org/10.3390/app9020255

Wilmart Q, El Dirani H, Tyler N, Fowler D, Malhouitre S, Garcia S, Casale M, Kerdiles S, Hassan K, Monat C, et al. A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications. Applied Sciences. 2019; 9(2):255. https://doi.org/10.3390/app9020255

Chicago/Turabian StyleWilmart, Quentin, Houssein El Dirani, Nicola Tyler, Daivid Fowler, Stéphane Malhouitre, Stéphanie Garcia, Marco Casale, Sébastien Kerdiles, Karim Hassan, Christelle Monat, and et al. 2019. "A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications" Applied Sciences 9, no. 2: 255. https://doi.org/10.3390/app9020255

APA StyleWilmart, Q., El Dirani, H., Tyler, N., Fowler, D., Malhouitre, S., Garcia, S., Casale, M., Kerdiles, S., Hassan, K., Monat, C., Letartre, X., Kamel, A., Pu, M., Yvind, K., Oxenløwe, L. K., Rabaud, W., Sciancalepore, C., Szelag, B., & Olivier, S. (2019). A Versatile Silicon-Silicon Nitride Photonics Platform for Enhanced Functionalities and Applications. Applied Sciences, 9(2), 255. https://doi.org/10.3390/app9020255