Abstract

In the circular economy, products, components, and materials are aimed to be kept at the utility and value all the lifetime. For this purpose, repair and remanufacturing are highly considered as proper techniques to return the value of the product during its life. Directed Energy Deposition (DED) is a very flexible type of additive manufacturing (AM), and among the AM techniques, it is most suitable for repairing and remanufacturing automotive and aerospace components. Its application allows damaged component to be repaired, and material lost in service to be replaced to restore the part to its original shape. In the past, tungsten inert gas welding was used as the main repair method. However, its heat affected zone is larger, and the quality is inferior. In comparison with the conventional welding processes, repair via DED has more advantages, including lower heat input, warpage and distortion, higher cooling rate, lower dilution rate, excellent metallurgical bonding between the deposited layers, high precision, and suitability for full automation. Hence, the proposed repairing method based on DED appears to be a capable method of repairing. Therefore, the focus of this study was to present an overview of the DED process and its role in the repairing of metallic components. The outcomes of this study confirm the significant capability of DED process as a repair and remanufacturing technology.

1. Introduction

It has been reported that to markedly mitigate climate change, the level of material and energy used in the current manufacturing methods should be reduced. Indeed, almost 30% of total greenhouse gas (GHG) emissions belong to the industry. The main part of this significant fraction of industrial GHG emission is coming from the material processing. In general, material processing involves the conversion of natural resources into materials stocks followed by the manufacturing process and ultimately into the final products. By developing the new generation of manufacturing techniques, it would be possible to reduce the level of GHG emissions [1,2,3]. Following the recent research in the development of production processes, additive manufacturing (AM) technologies have been introduced as new techniques that can support environmental sustainability in manufacturing field [1,4,5]. AM technologies, like advanced manufacturing technologies, are capable of producing high-value, complex, and individually customized components [6,7,8,9,10,11].

After producing and placing the components in service, local impact, corrosion, fatigue, and thermal cycles are the main working conditions that can cause local defects or cracks. For instance, in turbine shafts and blades, cracks can be initiated due to high-cycle fatigue (HCF) or corrosion. It is reported that several high-performance and high-value components are discarded as scrap after failure, which is mainly initiated by fatigue and stress cracks. Several types of research have been carried out to reduce the level of failure and increase the lifetime of the components. For example, ultrasonic and x-ray computed tomography techniques are established as non-destructive methods to detect subsurface defects in components at the initial stages to prevent failure during the working period [12,13,14,15]. Thereafter, depending on the level and location of damages, the part is prepared for repair.

Repair and remanufacturing are processes restoring damaged parts to a workable condition. For the first time, in 1988, Steinhilper and Hudelmaier defined the remanufacturing process as an industrial process to restore the used components to ‘as good as new’ condition [16]. According to the Steinhilper procedure, the steps of the remanufacturing process can be defined as (1) disassembling of the product, (2) comprehensive cleaning of all parts, (3) inspection of components, (4) repairing or replacement of damaged components, (5) reassembling the product, (6) final testing. After that, in 2015, the Ellen MacArthur Foundation showed that in some cases, repaired components could behave better than manufactured ones. They defined the refurbishment as the process that could be used to recover the products by repairing or replenishment of major parts. After recovering the components, in addition to the small changes that could be occurred within the process, their performances, in the best condition, could be as same as a new component. This recovery of the component, which was defined as refurbishment, is also known as the reconditioning process. In 2006, King et al. defined a procedure to correct some specific faults in a component and named it as ‘repairing’. They showed that the final performance of repaired products was less than of the reconditioned or remanufactured parts [17].

When a part is damaged, its damage must be assessed from the repairing point of view. After this assessment, it would be possible to decide that the damaged part could be repaired or should be discarded or send for recycling. To bring back the recoverable parts, an appropriate repair or remanufacturing methods should be employed and thereafter, some qualify controlling must be implemented on the repaired part to evaluate its reliability to work in the working condition. From the theoretical point of view, it is believed that the remanufacturing process can be implemented on the components that are feasible to be produced. Nonetheless, it should be noted that the remanufacturing process is cheaper than the manufacturing process. For example, remanufacturing an engine needs only 55% of energy and 67% of the labor that is required for the production of a new engine [18]. Therefore, repair and remanufacturing processes should be considered as a highly efficient process that can save and reuse sources to eventually boost a country’s economy.

The first repairs exploited the welding process, so tungsten inert gas (TIG) welding, which is a fusion welding technique, has been dramatically employed [19,20]. However, this approach results in poor-quality and leads to failing parts, mainly owing to the several issues related to the high residual stresses and, consequently, distortion in the components. Thereafter, to address these problems, alternative welding techniques, such as plasma transferred arc welding (PTAW) and electron beam welding (EBW), have been developed [21,22]. However, the complexity and cost of these apparatus limit their application [21,22]. The high-velocity oxyfuel (HVOF) thermal spray has been the next technology developed to repair components in many industries. Indeed, this technique has several merits over the conventional methods, and it is possible to have less distortion in part after repair and to coat the thin and porosity-free layers. Nonetheless, extensive secondary machining, usually necessary after repairing by HVOF, has limited its application and shown the need for developing new techniques of repairing [23,24]. Table 1 compares the advantage and disadvantages of various processes that have been employed as repair and remanufacturing operations.

Table 1.

Comparison between advantages and disadvantages of various repair and remanufacturing processes.

As can be seen in Table 1, Directed Energy Deposition (DED) technology is a proper technique to repair the damaged components. Indeed, this technology presents a high capability to be employed as a repair technique mainly because of lower residual stresses, higher repeatability, and higher precision in comparison the conventional methods [26,27,28].

Nonetheless, to date, very few review articles [31] have been published on the application of DED process as a repair and remanufacturing technology. This paper aimed to contribute to this growing area of research by reviewing the previous investigations on the implementation of the DED process in the component repairing.

2. Directed Energy Deposition (DED)

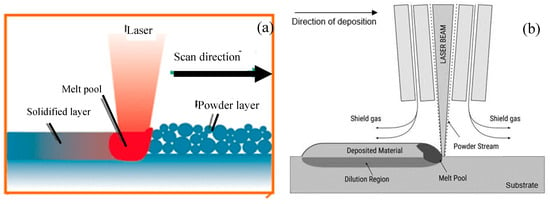

Additive manufacturing systems are divided into two broad categories; (i) powder bed systems and (ii) powder/wire feed systems [32]. In the powder bed systems, a powder bed is created by spreading powder across the building platform area. The energy source (electron beam or laser beam) delivers energy to the surface of the powder bed and melts the powder into the desired shape according to the CAD file (Figure 1a). Afterward, the new powder is spread out across the work area again, and the process is repeated to produce a solid three-dimensional component. The advantages of this system include its ability to create high resolution features, internal channels, and maintain dimensional control [33]. Whereas, in the powder or wire feeding systems, the material is delivered directly into a melt pool that is generated by a heat source on a substrate or previously deposited layers. These technologies are based on a process where the laser beam melts an alloy added onto a substrate. In particular, the delivered material and a layer of the substrate are fused using a laser beam (Figure 1b). This melting process ensures a metallurgical bonding between layer and substrate. The capability to produce fully dense, as well as gradient objects, makes the DED more attractive, concerning the powder bed systems, in the manufacturing of large and/or functionally graded components.

Figure 1.

Schematic of (a) powder bed fusion, (b) powder-based directed energy deposition processes [4].

Despite the advantages of deposition by wire, such as full materials efficiency, its requirement regarding the difficulties in delivering the wire through complex geometries and the higher surface roughness limits its applications in different fields [34,35,36]. For these reasons, the powder is preferred, and it is the most common and popular form of material used in the DED process. Spherical particles in the range of 50–200 μm have the best feeding properties in this process. Regarding the heating source, different types of laser can be used, depending on various factors, such as the laser beam spot size, the thickness of deposition, and the complexity of the part. For instance, CO2 lasers are suitable for deposition of thick layers (several millimeters) with regular geometry, while a robot-mounted diode laser beam or Nd-YAG (neodymium-doped yttrium aluminum garnet) laser can be used to deposit thin, precise layers (less than one millimeter) with very high precision [34]. It has also been revealed that in DED, an appropriate energy density, concerning the bulk materials delivered in the form of powder, should be used for deposition. Selection of a low energy density results in limited melting of provided material, while very high energy density leads to excessive melting of the substrate, undesirable dilution of deposition, and evaporation of some alloying elements from the melt pool. A sufficient beam interaction time should also be employed for deposition to provide enough time for mixing and homogenizing the deposition, and for fast cooling of the melt pool to obtain a fine microstructure with superior characteristics in comparison with corresponding materials processed through the traditional methods.

In DED process, which is also known as Laser cladding (LC), Laser Energy Net Shaping (LENSTM), or Laser Metal Deposition (LMD), since a thin layer of the substrate is melted, it would also be possible to create a coating layer with a nominal composition. Thus, this newly coated layer with different surface characteristics in terms of wear, corrosion, or oxidation resistance properties would increase the lifetime of some high-value parts. Owing to the disadvantages of traditional methods of coatings, DED processes have been developed to deposit some wear-resistant and high corrosion-resistant coatings obtaining a strong metallurgical bonding between the deposited material and substrate, with a high deposition rate and low wasting of material and minimal distortion. It is reported that ceramic coatings, owing to their high microhardness and wear resistance features, have been employed in many advanced technologies, such as aerospace, defense, chemical, and machinery field [37,38]. It is found that the wetting problem, which is the main challenge in the ceramics coating, through conventional manufacturing has been solved using DED process, and the overall performance of the coating has been improved [39,40,41].

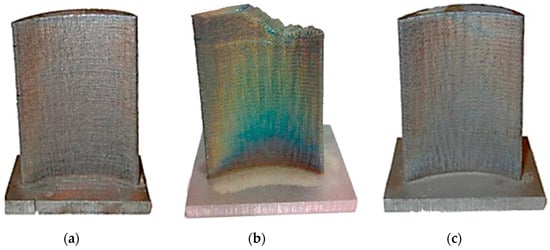

Apart from the application of DED as a coating technique, this technology has intensively been employed as a manufacturing technology [4,42,43]. Over the past decade, DED could attract more attention regarding its capability in the fabrication of parts with complex geometries to near-net-shape, with the high cost and material savings. In comparison with the other AM processes, DED has a unique position due to its potential to produce monolithic metal and functionally graded parts, as well as their repair [44]. Monolithic stainless steel, aluminum, titanium, nickel, and copper alloys have been already fabricated by DED process [4,45,46,47,48,49]. However, functionally graded parts or bimetal joining are the main purposes of engineering technology science to obtain a predominated quality of products. Some engineering structures could achieve the best efficiency by applying the parts combined of several dissimilar materials that fully realize the economic and performance advantages of each material. The bimetallic component is fabricated by joining dissimilar metals, which have particular mechanical, physical, and chemical properties, such as mechanical strength, wear resistance, thermal and electrical conductivity, corrosion resistance, etc. [50,51]. The most well-known metal couples are steel-copper, steel-aluminum, steel-nickel, and steel-titanium [52,53,54,55]. Bimetals are widely used in many areas as reservoirs, radiators, bearings, and gaskets for motor-heads in the automobile industry, as cutting tools in the paper, metal, wood, textile, food industries, kitchen utensils, heat exchangers, electro contact, first wall/blanked material for reactor, etc. [56,57,58]. Conventionally, various techniques have been used to fabricate bimetals, casting [50], explosive welding [59], rolling [60], diffusion bonding [58], powder metallurgy [61], etc. However, their limited capability to specific shapes and materials, multiple process steps, non-ideal bonding ability, and also their high manufacturing expenses have limited their applications [51]. On the contrary, DED shows great potential to be used in the manufacturing of bimetal materials without the limitation of conventional processes. Indeed, DED can be used as a manufacturing method of any weldable metallic materials [62]. For instance, Figure 2a–c show the interface between two deposited materials in as-fabricated bimetallic structures of Ti-6Al-4V/Inconel 718, Ti-6Al-4V/stainless steel, and Inconel 718/copper [63,64,65]. Moreover, Seltzer et al. indicated that due to the variation in build geometry and temperature during the repair process, the consistency of the quality of the components should be monitored [66]. Therefore, in their work, melt pool geometry was recorded via a camera and then verified with the results obtained by an optical profilometer. Thereafter, the experimental results were compared with the numerical simulations. They confirmed that through the real-time regulation of measurable process parameters via a feedback control system, it would be possible to enhance the repair quality. Reutzel et al. showed that sensing and control systems to monitor the process variables, such as melt pool geometry, temperature, and layer build height, played key roles in the final quality of the parts, including dimensional tolerance, microstructure, and properties [67].

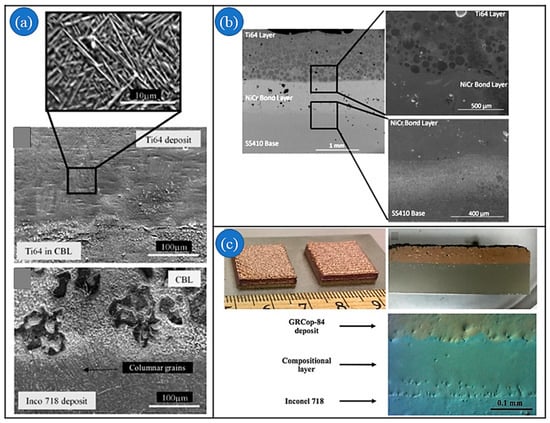

Figure 2.

(a) SEM images of the Interface of the as-built bimetallic structure of Ti-6Al-4V and In718 [63], (b) Cross-Sectional SEM image of Ti-6Al-4V bonded to SS410 processed using LENS™ [64], (c) as-fabricated bimetallic structure of In 718 and copper [65].

Last but not least, the capability of DED for repairing and remanufacturing of damaged high-value parts need also to be considered. DED is increasingly used by many high technology manufacturing companies, which offer technology-intensive products (Table 2). It is revealed that repair using the conventional technologies is faced with several challenges, such as high residual stress and, consequently, distortion in the repaired component, extensive post-machining, and low flexibility in terms of geometry. To address all these challenges and issues, DED is developed and used.

Table 2.

Summary of some applications of DED as repair and dedicated systems for repairing.

3. Identified DED Capabilities in Repair

In recent years, there has been an increasing amount of literature focused on the application of DED process in the repair and remanufacturing of damaged components [71,72,73]. This high level of interest in DED technologies is due to its advantages, such as high precision, narrow melting, and heat-affected zones (HAZ), that result in the low part distortion. According to literature, the critical concerns in the repair of metallic components by DED studied by various researchers are the type of repair, the microstructure of components, repaired part and their interface, the mechanical properties of the repaired parts in comparison with the as-built and conventionally processed parts, the microstructure and mechanical performance of the HAZ, and the feasibility of using different materials to repair the components and improve its performance.

For instance, Sun et al. studied the microstructure and mechanical response of AISI 4340 steel components repaired by DED [74]. In their research, they showed that austenite dendrites were the only present phase in the deposited layer, which had been grown in the solidification direction. Depending on the cooling rate and consequently the temperature gradient, two types of dendritic, cellular and columnar, consisting of a fine martensitic phase, had been detected in the microstructure of the deposited part. The combination of phases in the deposited material was formed as a consequence of fast cooling of the melt pool, leading to 30–40% higher hardness concerning the base alloy. However, it is revealed that the martensite, which was formed in the HAZ area as a consequence of high cooling rate, is generally brittle and reduces the ductility and the toughness, and thus further thermal treatment is necessary. Moreover, it was found that by increasing dilution, a smother hardness transition happened at the melted zone/HAZ interface, and consequently the stress concentrator sites that can deteriorate the fatigue properties of the material were eliminated.

Table 3 compares the mechanical properties of as-built and as-repaired Inconel® 625 alloys. As can be seen, the mechanical properties of repaired Inconel® 625 were in line with the features of annealed bars, confirming the potential of DED technology as a repair one.

Table 3.

Mechanical properties of manufactured or remanufactured Inconel® 625.

Wang et al. have investigated the effect of using a dual-beam laser for repairing surface cracks in Ni-based superalloy parts [13]. Indeed, in their work, the first laser beam was employed for melting the materials around the crack, and the second one was used to fill the generated gap. Their outcomes showed that the surface cracks in the range of 0.1–0.3 mm could be successfully repaired and consequently, the part could be reused before the final failure [13].

However, with DED technique, the repair of internal cracks is more difficult than the surface ones. This difficulty is because of the difference in the accessibility to the crack and, in the case of internal cracks, it is necessary to mill a lot down to eliminate the crack and surrounding area and then refilling with the same material. Pinkerton et al. have evaluated the type of materials removal, for instance, machining a volume rectangular and triangular in cross-section, and their influence on the quality of the repaired part made of H13 hot-work tool steel parts [16]. In both cases, the final microstructure was tempered martensite surrounded a HAZ of untempered martensite. It is found that in both geometries, despite achieving a uniform deposition with fine microstructure and good fusion bonding, the formation of porosity is a critical problem. Diaz et al. employed the DED process to coat Stellite® and Tribaloy® families, which offer good impact resistance, corrosion, and erosion resistance at high temperatures, on the repaired steam circuit parts of thermal power station [14]. They have shown that, in comparison with conventional welding processes, DED of Co-based alloys has some advantages, such as low thermal strains, smaller dilution zone between the deposition and base materials, and smaller HAZ, that can result in the final properties equal to those of base part. Zhu et al. studied the feasibility of repairing of an Invar alloy mold using DED technology [76]. They showed that the microstructure of the repaired specimen was divided into three different regions, the deposited layer, the HAZ, and the base metal. Their microstructural analysis confirmed that the super-cooling degree of liquid/solid interface affected the microstructure of the deposited layer. It means, from the bottom to the surface of the deposited layer, the grains are transformed from irregular to regular ones as a consequence of the change of super-cooling. Moreover, it is found that the typical grain growth direction is perpendicular to the liquid/solid interface that has the maximum temperature gradient.

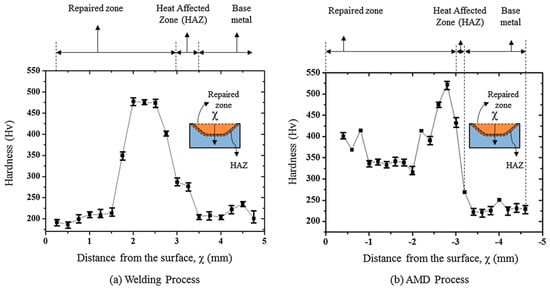

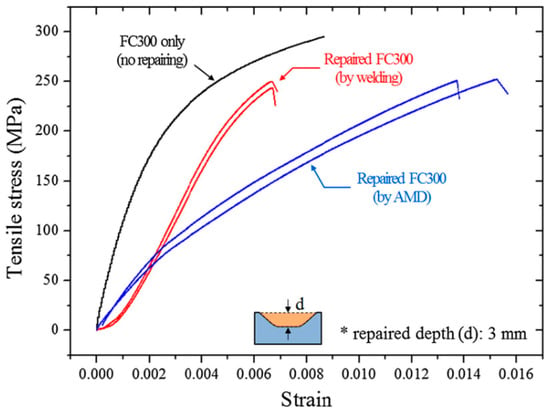

Yu et al. have studied the effect of HAZ on the mechanical properties of gray cast iron parts repaired by the traditional welding process and DED technology as an advanced one [77]. For this reason, the hardness of repaired parts was measured from the top surface to base metal, and the results are reported in Figure 3. As can be seen, the maximum hardness of the HAZ was achieved in the samples repaired by DED but even more important, concerning the tensile results, is that the HAZ size of samples repaired by welding was 21.5 times larger than the size when repaired by DED. The comparison between the tensile results of the parts repaired by both technologies revealed that there was no difference in tensile strength between the two methods (Figure 4). However, it was revealed that the elongation of repairing by DED had a 62% increase in average, mainly owing to its smaller HAZ size, which is a high hardness zone.

Figure 3.

The hardness of cast iron parts repaired by using (a) traditional welding process and (b) Additive Metal Layer Deposition (AMD) process [77].

Figure 4.

Tensile stress-strain curve of a cast-iron repaired via a traditional welding and DED process (AMD in the figure) [77].

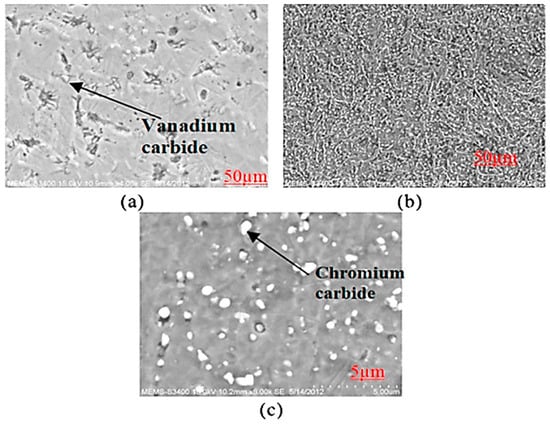

Kattire et al. studied the laser cladding of CPM 9V on H13 tool steel that has superior dimensional stability, excellent hot working properties, and high-quality surface toughness at high temperatures to repair the damaged H13 components and improve its combination of toughness, hardness, and wear resistance (Figure 5) [78].

Figure 5.

SEM images of CPM 9V: (a) deposition zone, (b) interface zone, (c) HAZ [78].

According to their microstructure analysis (Figure 5a,b), in the deposition zone, rod-like and globular carbides were scattered all around the martensite and retained austenite matrix. The interface zone showed a quenched martensite and retained austenite matrix. The structure of HAZ was formed of chromium carbides embedded in a tempered martensite matrix. This variation of phase composition and microstructure, as a consequence of maximum reached temperature and cooling rate, resulted in a decreasing trend of microhardness from the deposition zone to HAZ. Moreover, it was found that compressive residual stresses in the normal direction were generated during the DED process. These residual stresses would be beneficial for dies that are exposed to cyclic thermomechanical loading.

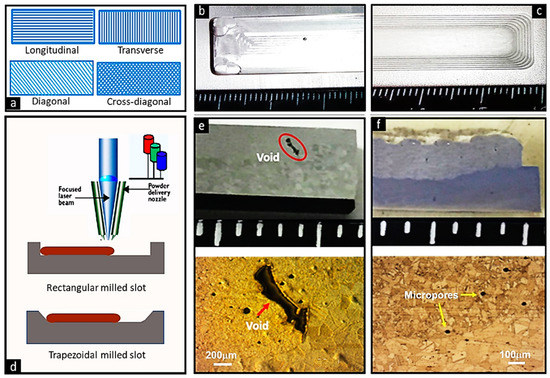

Paydas et al. studied the effect of building strategy on the microstructure and hardness of Ti-6Al-4V component repaired by DED process [79]. In their work, the effects of deposition strategy (decreasing track length and constant track length) and laser energy density (LED) on the metallurgical characteristics of the deposited layer had been investigated. It was revealed that with a decreasing track length deposition strategy, the microstructure could be rather homogeneous with respect to the constant. On the other hand, it was found that at LED, the microstructure seemed to be more homogeneous and composed of martensite, whereas for high LED, the microstructure was very heterogeneous and the majority of the microstructure composed of Widmanstädtten. Finally, it could be concluded that the nature of obtained microstructure and the hardness ranges of Ti-6Al-4V alloy linked to the cooling rates during the laser processing, and so this technique could be taken into account as a proper technology for repairing of this alloy. It is also reported that on the contrary to the repair of surface defects via DED, which is very simple, repair of sub-surface defects is still challenging. For instance, some internal cracks have been repaired by milling different slots like rectangular, triangular, and U-grooved, followed by filling them using DED. However, it is found that large porosities and voids are apparent at sharp transition areas, and consequently, the strategy for preparation of different damaged zones would be different. Recently, Onuike et al. used LENSTM technology to repair the internal cracks in IN 718 alloy [80]. In this work, the different strategy, like varying deposition orientation, to repair the Inconel 718 parts with different damaged zones, was investigated. This work indicated that in comparison with rectangular cross-section, trapezoidal shape cross-section had a better furoin and smoother transition of deposit material along the sidewall without void inclusion (Figure 6) [80].

Figure 6.

Processing strategies and sample cross-section. (a) Different build directions. (b) rectangular, (c) trapezoidal, milled slots. (d) LENS™ deposition schematic. (e) Void inclusion on rectangular and (f) Smooth transition on trapezoidal, milled slots [80].

In parallel to the efforts that have been paid to the capability of DED as repair, a large amount of work has also been carried out to explore the quality and repeatability of repair by this technology [12]. For instance, Wang et al. indicated that after repairing a component, the required dimensional specification and tolerances should be controlled and then the performance of the part under the working condition should be tested via simulation [12].

4. Industrial Case Studies

In principle, different industries intend to repair the components that need to withstand severe working conditions and are also vital to the whole process. Thus, the quality of repair is highly considered and evaluated after the process to achieve in the repaired part final properties equal to the base components. Table 4 resumes the most common industrial applications of DED to repair various components.

Table 4.

Application of DED in repairing the various components.

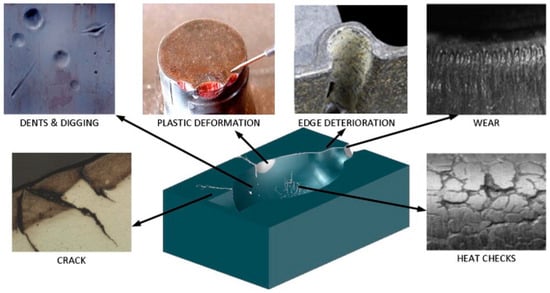

One of the most important steps in the manufacturing of dies and molds is materials selection that is also very important from the economic point of view. Indeed, it is found that materials selection has a direct effect on the life and cost of molds and dies. Nonetheless, in the production of dies and molds, both design aspects, such as ductility, fatigue strength toughness, wear, and corrosion resistance, and aspects related to the manufacturing like hardness, polishability, machinability, dimensional stability should be also considered [92]. Different materials under different working environments behave differently and have multiple types of failure. Substantially, change in the dimensions, geometry, and materials properties of the dies during the working condition would negatively affect their performance and lead to failure. Different sorts of defects in dies and molds are shown in Figure 7. It has been revealed that the lifetime of these components are shorter than the expected life, and many of these defects appear in a shorter time than the anticipated period. Therefore, from the economic point of view, it is believed that restoration and remanufacturing is an interesting solution to recover the dies and molds [93].

Figure 7.

Different types of defects in dies and molds [94].

There are several techniques to be employed for repairing die and molds. In Table 5, these technologies are compared, in terms of deposition rate, post repairing metallurgical characteristics, and necessity of post heat treatment. As can be seen in Table 5, repair with traditional techniques, such as TIG/Plasma and GTAW, has higher deposition rates and poor metallurgical characteristics, which is not desirable. On the contrary, it is clear that advanced methods, like DED, provide sharper, smaller deposition with focused and concentrated high laser energy and consequently lead to good metallurgical properties after deposition.

Table 5.

Comparison between different repair methods for dies and molds [94,95,96].

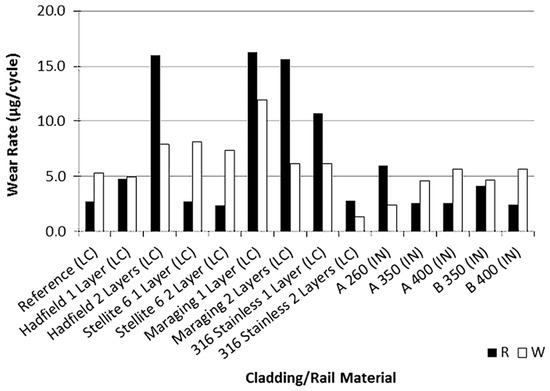

Rail maintenance and substitution is a significant fraction of expenses of running a rail network. Wear and rolling contact fatigue (RCF) are the main defects that can reduce the lifetime of rail tracks. Switches and crossing are the main parts that can undergo wear, and it is found that their maintenance costs are 330 times higher than straight tracks on a per meter basis [97]. It is known that their wear and RCF properties can be improved via some surface treatments like case hardening, peening, or surface coating. For this reason, DED is of great interest to be used as a coating method to weld different materials on the top of the running surface of the substrate. In fact, through DED process, it would be possible to deposit a wide range of beneficial materials, i.e., alternative steels of hard facing alloys, on areas of the tracks prone to wear and/or RCF. Lewis et al. studied the wear properties of repaired rail disks with various materials and have found that wear behavior of rail track was not always improved after depositing a coating layer by DED. Figure 8 compares the wear rates of the repaired disks after 5000 cycles. As can be seen, stellite showed the lowest wear rate with an average of 0.18 μg/cycle in comparison with the as-built sample with 1.59 μg/cycle [97]. On the contrary, the least consistency in the wear rate and the highest wear rate was revealed with the Margining and Stainless steel coatings. Also, Clare et al. and Lewis et al. investigated rail track repairing using DED process [83,97]. According to their research, the expense for maintenance of some components, such as switches and crossings, is very low for the straight track parts, and therefore, it is highly recommended to repair those simple geometry components instead of replacing them.

Figure 8.

Comparison between the wear rate of repaired discs after 5000 wet cycles; R indicates wear rate of the rail disc, W indicates wear rate of wheel disc [97].

Rooyen et al. used the DED process to repair the cracks in the austenitic stainless steel vessels that withstand internal water pressure up to 2 bar [85]. In this work, the DED process parameters for in-situ repairing of through-wall cracks in parts or vessels were developed. They found that crack sealing of 4.5 and 6.0 mm plate thickness underwater pressure could be successfully repaired under worst-case conditions with a rather high powder efficiency [85].

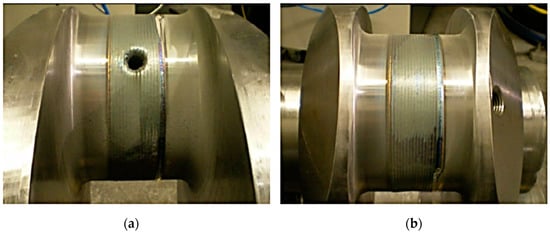

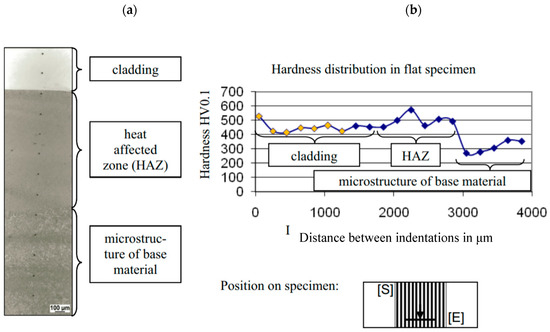

Over the last 100 years, diesel engines have undergone revolutionary improvements in their design and performance. The crankshaft is one of the most important parts that is heavily used in the engine. A crankshaft is a very critical component that needs very high precision production process and servicing requirements [98]. However, it is noticed that repairing this part via conventional technologies is faced with some challenges like bending stiffness and also is very expensive [86]. Koehler et al. have repaired marine diesel crankshaft using DED process (Figure 9). According to their microstructural observation, there was a very good interfacial bonding between the deposited layer and the base metal (Figure 10a). The Vickers hardness outcomes showed that there was a drop from 500 to 300 HV from HAZ to unaffected zone (Figure 10b). Finally, they concluded that the resulting component showed a high quality in terms of interfacial bonding and dilution [86].

Figure 9.

DED crankshaft segment (a) around oil bore, (b) on the bottom side at the lower dead center position [86].

Figure 10.

(a) Microstructure, (b) hardness distribution and location of both in DED flat specimen (bottom, the Starting point (S), Endpoint (E)) [86].

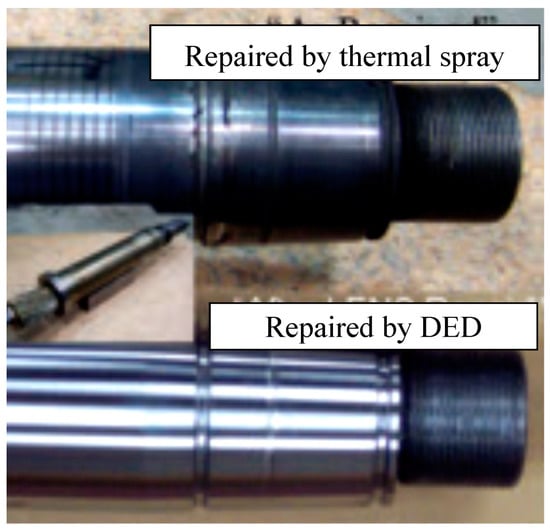

A drive shaft, which is a mechanical part that transmits torque and rotation, is also repaired successfully by employing DED process. In principle, the high level of torsion and shear stresses that applied on the torque under the working condition damage the surface of this shaft. Traditionally, to repair theses shafts, thermal spry processes have been employed, but thereafter, in some cases, some defects, such as severe spalling, have been revealed on some repaired shafts (the top shaft in Figure 11). Afterward, more deep investigations have shown that DED can provide better metallurgical and mechanical bonding concerning the thermal spray processes and can be considered as a more reliable solution to repair the drive shafts. These shafts are already repaired by 420 stainless steel, and this repair results in the formation of a harder layer (50 RC higher) with higher corrosion resistance with respect to the as-produced parts or the repaired ones that are recovered by thermal spray methods. Moreover, from the economic point of view, it is interestingly found that the cost repairing of drive shafts via DED is 50% of the production of a new drive shaft [87].

Figure 11.

A drive shaft repaired by thermal spray (top) and DED (bottom) processes [87].

Another critical part that can be successfully repaired using DED process is a four-stroke marine piston. During the working condition, high level of forces and temperature damage the surface of pistons. Wear, which is the main defect, happens on the edges of the grooves under the working environment and, thus, the pistons should be repaired or replaced as soon as the grooves reach the tolerance limit [88]. Kimi company has repaired these pistons by DED process as an economical and technical solution that not only repairs the part but also improves the resistance of groves against the erosion and corrosion (Figure 12).

Figure 12.

Four-stroke pistons repaired by DED (Courtesy of KIMI) [88].

Maintenance and repair of aero-engine parts, such as gas turbine, low and high-pressure turbine blades, and so on, are of the critical concerns in aerospace industries as a consequence of the increase in the raw material and manufacturing costs. Gas turbine Inconel® 718 compressor seal is a critical and high-value component that can be repaired using the DED process. The application of this seal in the gas turbine aims to prevent gas leakage in gas turbine engines. In this component, the main damage is the excessive wear in the labyrinth seal that negatively affects the performance of the gas turbine. Figure 13 shows a very finesse repair of a damaged gas turbine compressor seal [87].

Figure 13.

Gas turbine Inconel ®718 compressor seal repaired by DED process [87].

Interestingly, it was found that the cost of a repaired compressor seal was 45% of a new one, and this confirmed the great potential of DED as a repair technology from the economic point of view. From a technical point of view, during the inspection process, it was revealed that the repair deposit resulted in a minor shrinkage of two inside diameters. Thereafter, those diameters were machined to reach the standard tolerances, and ultimately, the repaired seal had been approved by the customer [87]. In general, it is found that to be in the acceptable tolerance, further machining after repairing seems to be essential.

Bendeich et al. have investigated the residual stress in a low-pressure turbine blade after repairing by DED [89]. A low-pressure turbine blade in powder station operated at 3000 rpm, and this speed generated almost supersonic speed near the blade tips [89]. The main issue in these blades was the erosion in the leading edges that happened as a consequence of condensing water impingement and resulted in the premature retirement of these expensive blades. Thus, to extend their life, DED process was used to repair the eroded edges. The results demonstrated that significant tensile and compressive stresses were generated both in the blade and in the repaired area. It was also found that in both regions, tensile stresses were located on the surface and could promote crack initiation in the fatigue condition. However, it was reported that the magnitude of these stresses and, accordingly, the increasing resistance to cracking of these regions could be minimized using a post-heat treatment [89].

Wilson et al. have used the DED process to repair or remanufacture the turbine airfoil [18]. In particular, their work demonstrated the successful repair of defective voids in turbine airfoils according to a novel semi-automated geometric reconstruction algorithm and DED. Figure 14a shows an undamaged turbine blade, and Figure 14b indicates that, in turbine blades, damage commonly happens in their tip. This defect can affect the performance of the engine, and so the reconstruction of this area is vital. For this purpose, after scanning, the blade is digitized and transformed into a meshed representation that provides the net shape of the blade.

Figure 14.

(a) Turbine blade produced by DED process, (b) damaged turbine blade, (c) restored blade by DED [18].

The process of finding a parameterized geometric model required to repair a turbine blade developed by Wilson et al. is schematized in Figure 15. In this model, firstly the point clouds of the damaged blade were acquired and meshed (Figure 15a). After that, the Prominent Cross Section (PCS) algorithm was run on the mesh surface and the resulting PCS data, lying strictly over the non-defective region of the blade, was imported into a software. In this software, the PCS points in the non-defective area were read and used for the construction of splines that represent incremental blade cross-sections of the non-defective area (Figure 15b). Afterward, a solid body was built from the resulting combination of surfaces (Figure 15c). Once the extrapolated surface was created, a Boolean (Figure 2) operation was executed to extract the difference between the reconstructed blade and the original meshed surface of the defective blade model, leaving us with the desired repair volume, as shown in Figure 15d [18]. Ultimately, Wilson et al. demonstrated that the DED process lent itself to repair high-value parts in an environmentally friendly manner. Moreover, their outcomes confirmed the effectiveness of DED process in the repair and remanufacturing of a wide range of damages.

Figure 15.

Process for generating a parameterized geometric model required for DED-based defect repair: (a) acquire point clouds and generate mesh, (b) extract Prominent Cross Section (PCS) from non-defective region and extrapolate missing section, (c) reconstruct repaired model in CATIA™, and (d) extract Boolean difference between (a) and (c) to obtain the repair volume [18].

High-pressure single-crystal turbine blades made of Ni-based superalloys have superior creep and fatigue properties with respect to the polycrystalline ones and, accordingly, they can sustain temperatures up to 1100 °C. However, as a consequence of the extreme conditions in the engine of commercial airplanes, they undergo erosion and cracking [90,99,100]. Kaierle et al. demonstrated that the DED process had promising results in the building-up of a single crystal or directionally solidified structures, while laser remelting could be used to extend this monocrystalline height [99]. However, in this work, due to the varying geometry and consequently different thermal story during the deposition, two types of deposition for repairing had been used: notch and flat. The multilayer deposition on the blade tips was found challenging so that as the number of layers increased, the susceptibility to porosity and crack formation increased. In the case of notch repair, it was found that the highest quality of deposited material could be achieved by using a remelting speed higher than deposition speeds.

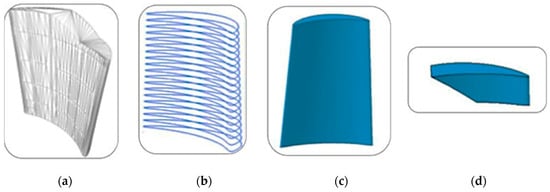

Yilmaz et al. studied a repair and overhaul methodology to recover the complex geometry of expensive parts for aerospace industries [91]. They successfully implemented their repair process on a critical aero-engine component like thin-curved compressor blade (Figure 16). Their repair approach included the 3-D non-contact digitization, free-form surface reconstruction using DED process, and milling operations in an automatic hybrid process. It was found that the total repair time through their approach was 30% lower than the conventional methods. According to Yilmaz et al., the proposed repair methodology could be taken into account as a reliable and time-cost effective approach in comparison with the conventional repair methods. However, to implement this approach, several challenges should be considered and addressed, for instance, an adaptive and automated digitizing, adaptive surface reconstruction, and precise machining strategy, for individual blade geometry to obtain a reliable and cost-time effective repair approach.

Figure 16.

Thin-curved compressor blade before and after repairing [91].

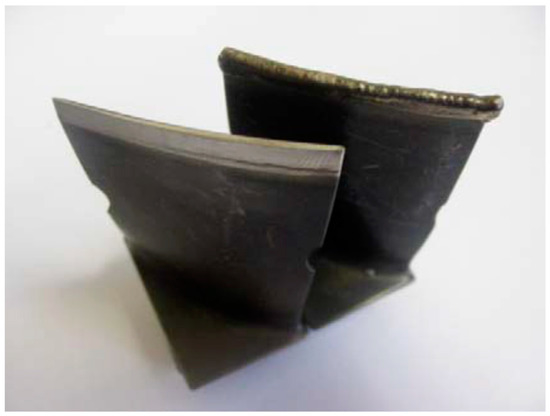

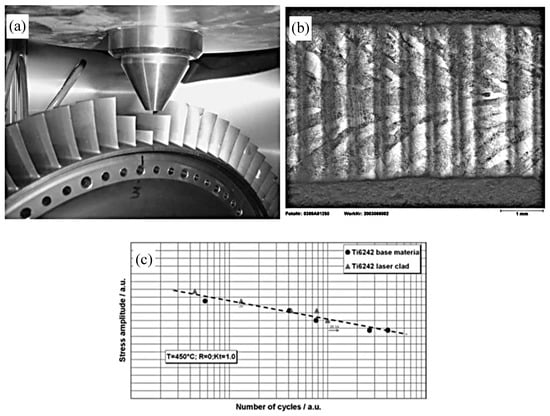

Integral rotors of an aircraft engine, which are commonly known as bladed disks or ‘‘blisks’’, are made of titanium alloys. In general, these blisks get locally damaged over their larger areas (Figure 17a). It is reported that due to their aerodynamic profile that must be repaired precisely, the repair of these blisks faced several challenges.

Figure 17.

(a) Repairing for damaged titanium blisk, (b) microstructure of the laser deposited titanium build-up, (c) High-cycle fatigue (HCF) results of laser-generated titanium alloy compared to the reference material [101].

Another limitation in their repair was the high-reactivity of the titanium that resulted in undesired hard phases in the final microstructure. The solution was to carry out the repair process in a closed inert gas chamber, and consequently, the undesired reaction could be reliably suppressed. The cross-section of a compressor blade repaired by DED, as indicated in Figure 17b, demonstrated that a dense part with fine crystalline microstructure was achieved. Thereafter, the high-cycle fatigue behavior of those specimens was evaluated, and it was found that the fatigue strength of the deposited sample was slightly higher than that of the reference material, as visible in Figure 17c.

5. Conclusions

In principle, different industries intend to repair components that need to withstand severe working conditions and also are vital to the whole process. Thus, the quality of repair is highly considered and evaluated to achieve the final properties of the repaired part, equal to those of the base component. DED is a maturing disruptive AM technology that provides new possibilities to repair complex geometry and expensive parts for various industries, from automotive to aerospace ones. In comparison with traditional methods, the main advantage of DED process is its flexibility according to a CAD model, lower heat input, and consequently small HAZ and dilution zones and lower residual stresses. All the research studies on this topic reported that the repair process using DED is not only cost-effective but also time-saving. The free formability of DED process can also significantly change the existing manufacturing processes by the concept of adding special features to a simple damaged cast and forged components to repair and improve their performances. Apart from the scientific and lab-scale investigation, the repair approach based on DED is successfully being used in different industries for various applications to reduce remanufacturing costs. Nonetheless, since this technology is rather new, and there is no handbook available, the qualification phase is quite long before the final approval of the components. The next step is to define a standard procedure for repairing to reduce the period of qualification phase.

Author Contributions

To write this review article, A.S., G.M., and A.A. collected the papers and wrote the article; S.B., M.L., and P.F. revised the article technically and scientifically.

Funding

This research was funded by Horizon 2020 research and innovation program with grant number [723795].

Acknowledgments

The authors would like to acknowledge the European research project belonging to the Horizon 2020 research and innovation program; 4D Hybrid—Novel ALL-IN-ONE machines, robots, and systems for affordable, worldwide, and lifetime Distributed 3D hybrid manufacturing and repair operations (grant agreement no.723795).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy, Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Fischedick, M.; Roy, J.; Abdel-aziz, A.; Acquaye, A.; Allwood, J.M.; Ceron, J.-P.; Geng, Y.; Kheshgi, H.; Lanza, A.; Perczyk, D.; et al. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- Comission, E. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. Cirp Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Acharya, R.; Das, S. Additive Manufacturing of IN100 Superalloy Through Scanning Laser Epitaxy for Turbine Engine Hot-Section Component Repair: Process Development, Modeling, Microstructural Characterization, and Process Control. Metall. Mater. Trans. A 2015, 46, 3864–3875. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Liu, D.; Wang, H.-M. Microstructure and mechanical behavior of commercial purity Ti/Ti–6Al–2Zr–1Mo–1V structurally graded material fabricated by laser additive manufacturing. Scr. Mater. 2014, 74, 80–83. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Bosio, F.; Saboori, A.; Lacagnina, A.; Librera, E.; de Chirico, M.; Biamino, S.; Fino, P.; Lombardi, M. Directed energy deposition of 316L steel: Effect of type of powders and gas related parameters. In Proceedings of the Euro PM2018 Congress Exhebition, Bilbao, Spain, 14–18 October 2018. [Google Scholar]

- Wang, J.; Prakash, S.; Joshi, Y.; Liou, F.W. Laser Aided Part Repair-A Review. In Solid Free. Fabr. Proc.; University of Texas Press: Austin, TX, USA, 2004. [Google Scholar]

- Wang, Z.-K.; Ye, H.-Q.; Xu, D.-S.; Huang, S.-Y. Laser repairing surface crack of Ni-based superalloy components. Trans. Nonferrous Met. Soc. China 2011, 11, 572–575. [Google Scholar]

- Díaz, E.; Amado, J.M.; Montero, J.; Tobar, M.J.; Yáñez, A. Comparative Study of Co-based Alloys in Repairing Low Cr-Mo steel Components by Laser Cladding. Phys. Procedia 2012, 39, 368–375. [Google Scholar] [CrossRef]

- Thompson, A.; Maskery, I.; Leach, K.R. X-ray computed tomography for additive manufacturing: A review. Meas. Sci. Technol. 2016, 27, 1–17. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Wang, W.; Li, L. Component repair using laser direct metal deposition. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 827–836. [Google Scholar] [CrossRef]

- King, A.M.; Burgess, S.C.; Ijomah, W.; McMahon, C.A. Reducing waste: Repair, recondition, remanufacture or recycle? Sustain. Dev. 2006, 14, 257–267. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Yushchenko, K.A.; Savchenko, V.S.; Chervyakova, L.V.; David, S.A.; Vitek, J.M. Study of Weldability and Development of the Technology for Repair of High-Nickel Alloy Components; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1943. [Google Scholar]

- Ramalho, A.L.; Ferreira, J.A.M.; Branco, C.A.G.M. Fatigue behaviour of T welded joints rehabilitated by tungsten inert gas and plasma dressing. Mater. Des. 2011, 32, 4705–4713. [Google Scholar] [CrossRef]

- Su, C.Y.; Chou, C.P.; Wu, B.C.; Lih, W.C. Plasma transferred arc repair welding of the nickel-base superalloy IN-738LC. J. Mater. Eng. Perform. 1997, 6, 619–627. [Google Scholar] [CrossRef]

- Bi, G.; Gasser, A. Restoration of Nickel-Base Turbine Blade Knife-Edges with Controlled Laser Aided Additive Manufacturing. Phys. Procedia 2011, 12, 402–409. [Google Scholar] [CrossRef]

- Darut, G.; Liao, H.; Coddet, C.; Bordes, J.M.; Diaby, M. Steel coating application for engine block bores by Plasma Transferred Wire Arc spraying process. Surf. Coat. Technol. 2015, 268, 115–122. [Google Scholar] [CrossRef]

- Tan, J.C.; Looney, L.; Hashmi, M.S.J. Component repair using HVOF thermal spraying. J. Mater. Process. Technol. 1999, 92, 203–208. [Google Scholar] [CrossRef]

- Aoshima, S. Electro-Spark Process for Repair and Maintenance of Die-Casting Dies; TechnoCoat Int.: Fujieda, Japan, 1999; pp. 1–3. [Google Scholar]

- Roy, T.; Abrahams, R.; Paradowska, A.; Lai, Q.; Mutton, P.; Soodi, M.; Fasihi, P.; Yan, W. Evaluation of the mechanical properties of laser cladded hypereutectoid steel rails. Wear 2019, 432–433, 202930. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding, 1st ed.; Taylor Francis Group: Boca Raton, FL, USA, 2004. [Google Scholar]

- Baufeld, B.; Brandl, E.; van der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Tech. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Singh, H.; Jain, P.K. Past, present and future the characterization of surface topography of plasmatransferred arc coatings. In Proceedings of the Indian Conference on Applied Mechanics, New Delhi, India, 13–15 July 2015. [Google Scholar]

- Alberti, E.A.; Bueno, B.M.P.; D’Oliveira, A.S.C.M. Additive manufacturing using plasma transferred arc. Int. J. Adv. Manuf. Technol. 2016, 83, 1861–1871. [Google Scholar] [CrossRef]

- Ahn, D.-G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Saboori, A.; Bosio, F.; Librera, E.; de Chirico, M.; Biamino, S.; Lombardi, M.; Fino, P. Accelerated Process Parameter Optimization for Directed Energy Deposition of 316L Stainless Steel. In Proceedings of the Euro PM2018 Congress Exhebition, Bilbao, Spain, 14–18 October 2018. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Torims, T. The Application of Laser Cladding to Mechanical Component Repair, Renovation and Regeneration. In DAAAM International Scientific Book 2013; DAAAM International: Vienna, Austria, 2013; pp. 587–602. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes. In Addit. Manuf. Technol. 3D Printing, Rapid Prototyping, Direct Digit. Manuf.; Springer: New York, NY, USA, 2015; pp. 245–268. [Google Scholar]

- Mazzucato, F.; Tusacciu, S.; Lai, M.; Biamino, S.; Lombardi, M.; Valente, A. Monitoring Approach to Evaluate the Performances of a New Deposition Nozzle Solution for DED Systems. Technologies 2017, 5, 29. [Google Scholar] [CrossRef]

- Li, Z.; Wei, M.; Xiao, K.; Bai, Z.; Xue, W.; Dong, C.; Wei, D.; Li, X. Microhardness and wear resistance of Al2O3-TiB2-TiC ceramic coatings on carbon steel fabricated by laser cladding. Ceram. Int. 2019, 45, 115–121. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, Y.; Chu, Z.; Yang, Y.; Li, Y.; Yan, D. Corrosion behavior of plasma sprayed ceramic and metallic coatings on carbon steel in simulated seawater. Mater. Des. 2013, 52, 630–637. [Google Scholar] [CrossRef]

- Sun, W.; He, S.; Guo, G.; Zhao, H.; He, Z. Integration detection of maneuvering target in strong clutter background with high range resolution radar. Tien Tzu Hsueh Pao Acta Electron. Sin. 1998, 26, 12–15. [Google Scholar]

- Guo, G.F.; Chen, F.R.; Li, L.H. Application of laser cladding technology in surface modification of titanium alloys. Surf. Technol. 2006, 35, 66–69. [Google Scholar]

- Gao, C.; Xu, B. Advances in laser cladding ceramic particle reinforced metal mateix composite coating technology. Surf. Technol. 2008, 37, 63–66. [Google Scholar]

- Keist, J.S.; Palmer, T.A. Development of strength-hardness relationships in additively manufactured titanium alloys. Mater. Sci. Eng. A 2017, 693, 214–224. [Google Scholar] [CrossRef]

- Kumara, C.; Segerstark, A.; Hanning, F.; Dixit, N.; Joshi, S.; Moverare, J.; Nylén, P. Microstructure modelling of laser metal powder directed energy deposition of alloy 718. Addit. Manuf. 2019, 25, 357–364. [Google Scholar] [CrossRef]

- Saboori, A.; Tusacciu, S.; Busatto, M.; Lai, M.; Biamino, S.; Fino, P.; Lombardi, M. Production of Single Tracks of Ti-6Al-4V by Directed Energy Deposition to Determine the Layer Thickness for Multilayer Deposition. J. Vis. Exp. 2018, 2018, e56966. [Google Scholar] [CrossRef]

- de Lima, M.S.F.; Sankaré, S. Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des. 2014, 55, 526–532. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Lia, F.; Park, J.; Tressler, J.; Martukanitz, R. Partitioning of laser energy during directed energy deposition. Addit. Manuf. 2017, 18, 31–39. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P.; Bai, P.; Wu, L.; Liu, B.; Zhao, Z. Microstructure and properties of Ti/TiBCN coating on 7075 aluminum alloy by laser cladding. Surf. Coat. Technol. 2018, 334, 142–149. [Google Scholar] [CrossRef]

- Şimşir, M.; Kumruoğlu, L.C.; Özer, A. An investigation into stainless-steel/structural-alloy-steel bimetal produced by shell mould casting. Mater. Des. 2009, 30, 264–270. [Google Scholar] [CrossRef]

- Liu, L.; Zhuang, Z.; Liu, F.; Zhu, M. Additive manufacturing of steel--bronze bimetal by shaped metal deposition: Interface characteristics and tensile properties. Int. J. Adv. Manuf. Technol. 2013, 69, 2131–2137. [Google Scholar] [CrossRef]

- Gómez, X.; Echeberria, J. Microstructure and mechanical properties of carbon steel A210–superalloy Sanicro 28 bimetallic tubes. Mater. Sci. Eng. A 2003, 348, 180–191. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial characterization of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Krishna, B.V.; Xue, W.; Bose, S. Application of Laser Engineered Net Shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants. J. Mater. Sci. Mater. Med. 2008, 20, 29. [Google Scholar] [CrossRef]

- Al-Jamal, O.M.; Hinduja, S.; Li, L. Characteristics of the bond in Cu–H13 tool steel parts fabricated using SLM. CIRP Ann. 2008, 57, 239–242. [Google Scholar] [CrossRef]

- Guobin, L.; Jianjun, W.; Xiangzhi, L.; Guiyun, L. The properties and application of bi-metal hot-forging die. J. Mater. Process. Technol. 1998, 75, 152–156. [Google Scholar] [CrossRef]

- Nakano, J.; Miwa, Y.; Tsukada, T.; Kikuchi, M.; Kita, S.; Nemoto, Y.; Tsuji, H.; Jitsukawa, S. Characterization of 316L(N)-IG SS joint produced by hot isostatic pressing technique. J. Nucl. Mater. 2002, 307, 1568–1572. [Google Scholar] [CrossRef]

- Yilmaz, O.; Çelik, H. Electrical and thermal properties of the interface at diffusion-bonded and soldered 304 stainless steel and copper bimetal. J. Mater. Process. Technol. 2003, 141, 67–76. [Google Scholar] [CrossRef]

- Durgutlu, A.; Okuyucu, H.; Gulenc, B. Investigation of effect of the stand-off distance on interface characteristics of explosively welded copper and stainless steel. Mater. Des. 2008, 29, 1480–1484. [Google Scholar] [CrossRef]

- Xiong, B.; Cai, C.; Wan, H.; Lu, B. Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid–solid casting in electromagnetic induction field. Mater. Des. 2011, 32, 2978–2982. [Google Scholar] [CrossRef]

- Krishna, B.V.; Venugopal, P.; Rao, K.P. Co-extrusion of dissimilar sintered P/M preforms—An explored route to produce bimetallic tubes. Mater. Sci. Eng. A 2005, 407, 77–83. [Google Scholar] [CrossRef]

- Baufeld, B.; van der Biest, O.; Gault, R.; Ridgway, K. Manufacturing Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. IOP Conf. Ser. Mater. Sci. Eng. 2011, 26, 12001. [Google Scholar] [CrossRef]

- Onuike, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Ti6Al4V bimetallic structures. Addit. Manuf. 2018, 22, 844–851. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Harrison, R.; Carpenter, C.; Bandyopadhyay, A. Stainless steel to titanium bimetallic structure using LENSTM. Addit. Manuf. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Copper alloy bimetallic structure using laser engineered net shaping (LENSTM). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- Seltzer, D.; Wang, X.; Nassar, A.; Schaino, J.; Reutzal, E. System Identification and Feedback Control for Directed-Energy Metal-Based Additive Manufacturing. In Proceedings of the Solid Freeform Fabrication Proceedings, Austin, TX, USA, 10–12 August 2015. [Google Scholar]

- Reutzel, E.W.; Nassar, A.R. A Survey of Sensing and Control Systems for Machine and Process Monitoring of Directed-Energy, Metal-Based Additive Manufacturing. Rapid Prototyp. J. 2015, 21, 159–167. [Google Scholar] [CrossRef]

- Camp, J.D.; Bergan, P. Implementation of Laser Repair Process for Navy Aluminum Components. In Proceedings of the Diminishing Manufacturing Sources and Material Shortages Conference, Phoenix, AZ, USA, 2–5 December 2019. [Google Scholar]

- Bremer, C. Adaptive Welding Strategies for Repair and Overhaul of Turbine Blades and Blisks. In Proceedings of the 3rd LANE, Laser Assisted Net Shape Engineering 3, Erlangen, Germany, 28–31 August 2001. [Google Scholar]

- Stefan, K. An Advanced Repair Technique: Laser Powder Build-up Welding. Sulzer Tech. Rev. 2001, 83, 4–6. [Google Scholar]

- Kistler, N.A.; Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, M.A. Effect of processing conditions on the microstructure, porosity, and mechanical properties of Ti-6Al-4V repair fabricated by directed energy deposition. J. Mater. Process. Technol. 2019, 264, 172–181. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Zheng, H.; Tang, K.; Li, H.; Gong, S. TC17 titanium alloy laser melting deposition repair process and properties. Opt. Laser Technol. 2016, 82, 1–9. [Google Scholar] [CrossRef]

- Kumar, L.J.; Nair, C.G.K. Laser metal deposition repair applications for Inconel 718 alloy. Mater. Today Proc. 2017, 4, 11068–11077. [Google Scholar] [CrossRef]

- da Sun, S.; Liu, Q.; Brandt, M.; Janardhana, M.; Clark, G. Microstructure and mechanical properties of laser cladding repair of aisi 4340 steel. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Griffith, M.L. Understanding the microstructure and properties of components fabricated by laser engineered net shaping (LENSTM). Mat. Res. Soc. Symp. Proc. 2000, 625. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, W.; Zhan, X.; Ding, L.; Zhou, J. Parameter optimisation of laser cladding repair for an Invar alloy mould. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2018. [Google Scholar] [CrossRef]

- Yu, J.-H.; Choi, Y.-S.; Shim, D.-S.; Park, S.-H. Repairing casting part using laser assisted additive metal-layer deposition and its mechanical properties. Opt. Laser Technol. 2018, 106, 87–93. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W. Experimental characterization of laser cladding of CPM 9V on H13 tool steel for die repair applications. J. Manuf. Process. 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Paydas, H.; Mertens, A.; Carrus, R.; Lecomte-Beckers, J.; Tchuindjang, J.T. Laser cladding as repair technology for Ti-6Al-4V alloy: Influence of building strategy on microstructure and hardness. Mater. Des. 2015, 85, 497–510. [Google Scholar] [CrossRef]

- Onuike, B.; Bandyopadhyay, A. Additive manufacturing in repair: Influence of processing parameters on properties of Inconel 718. Mater. Lett. 2019, 252, 256–259. [Google Scholar] [CrossRef]

- Borrego, L.P.; Pires, J.T.B.; Costa, J.M.; Ferreira, J.M. Mould steels repaired by laser welding. Eng. Fail. Anal. 2009, 16, 596–607. [Google Scholar] [CrossRef]

- Grum, J.; Slabe, J.M. Possibility of introducing laser surfacing into maintenance service of die-casting dies. Surf. Coat. Technol. 2004, 180, 596–602. [Google Scholar] [CrossRef]

- Clare, A.T.; Oyelola, O.; Abioye, T.E.; Farayibi, P.K. Laser cladding of rail steel with Co–Cr. Surf. Eng. 2013, 29, 731–736. [Google Scholar] [CrossRef]

- Leunda, J.; Soriano, C.; Sanz, C.; Navas, V.G. Laser Cladding of Vanadium-Carbide Tool Steels for Die Repair. Phys. Procedia 2011, 12, 345–352. [Google Scholar] [CrossRef]

- van Rooyen, C.; Burger, H.; Theron, M.; Doubell, P. In-situ Crack Repair by Laser Cladding. In Proceedings of the Fifth Int. WLT-Conference Lasers Manuf, Munich, Germany, 15–18 June 2009. [Google Scholar]

- Koehler, H.; Partes, K.; Seefeld, T.; Vollertsen, F. Laser reconditioning of crankshafts: From lab to application. Phys. Procedia 2010, 5, 387–397. [Google Scholar] [CrossRef]

- Mudge, R.P.; Wald, N.R. Laser Engineered Net Shaping Advances Additive Manufacturing and Repair. Weld. J. N. Y. 2007, 86, 44. [Google Scholar]

- Available online: https://www.kimi-sa.com/marine/diesel-engine-machinery/four-stroke-piston-repair (accessed on 1 July 2019).

- Bendeich, P.; Alam, N.; Brandt, M.; Carr, D.; Short, K.; Blevins, R.; Curfs, C.; Kirstein, O.; Atkinson, G.; Holden, T.; et al. Residual stress measurements in laser clad repaired low pressure turbine blades for the power industry. Mater. Sci. Eng. A 2006, 437, 70–74. [Google Scholar] [CrossRef]

- Rottwinkel, B.; Nölke, C.; Kaierle, S.; Wesling, V. Crack Repair of Single Crystal Turbine Blades Using Laser Cladding Technology. Procedia CIRP 2014, 22, 263–267. [Google Scholar] [CrossRef]

- Yilmaz, O.; Gindy, N.; Gao, J. A repair and overhaul methodology for aeroengine components. Robot. Comput. Integr. Manuf. 2010, 26, 190–201. [Google Scholar] [CrossRef]

- Pleterski, M.; Tušek, J.; Kosec, L.; Muhič, M.; Muhič, T. Laser Repair welding of molds with various pulse shapes. Metalurgija 2010, 49, 41–44. [Google Scholar]

- Persson, A.; Hogmark, S.; Bergström, J. Thermal fatigue cracking of surface engineered hot work tool steels. Surf. Coat. Technol. 2005, 191, 216–227. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Sun, Y.; Hanaki, S.; Uchida, H.; Sunada, H.; Tsujii, N. Repair effect of hot work tool steel by laser-melting process. J. Mater. Sci. Technol. 2003, 19, 91–93. [Google Scholar]

- Ebara, R.; Kubota, K. Failure analysis of hot forging dies for automotive components. Eng. Fail. Anal. 2008, 15, 881–893. [Google Scholar] [CrossRef]

- Lewis, S.R.; Lewis, R.; Fletcher, D.I. Assessment of laser cladding as an option for repairing/enhancing rails. Wear 2015, 330, 581–591. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, K.; Li, M. Laser Cladding Device for In Situ Repairs of Marine Crankshafts. Adv. Mater. Res. 2013, 712, 709–714. [Google Scholar] [CrossRef]

- Kaierle, S.; Overmeyer, L.; Alfred, I.; Rottwinkel, B.; Hermsdorf, J.; Wesling, V.; Weidlich, N. Single-crystal turbine blade tip repair by laser cladding and remelting. CIRP J. Manuf. Sci. Technol. 2017, 19, 196–199. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Cui, W.; Liou, F. Modeling of worn surface geometry for engine blade repair using Laser-aided Direct Metal Deposition process. Manuf. Lett. 2018, 15, 1–4. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Beyer, E.; Richter, K.-H. Laser Beam Build-Up Welding: Precision in Repair, Surface Cladding, and Direct 3D Metal Deposition. J. Therm. Spray Technol. 2007, 16, 344–348. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).