A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes

Abstract

1. Introduction

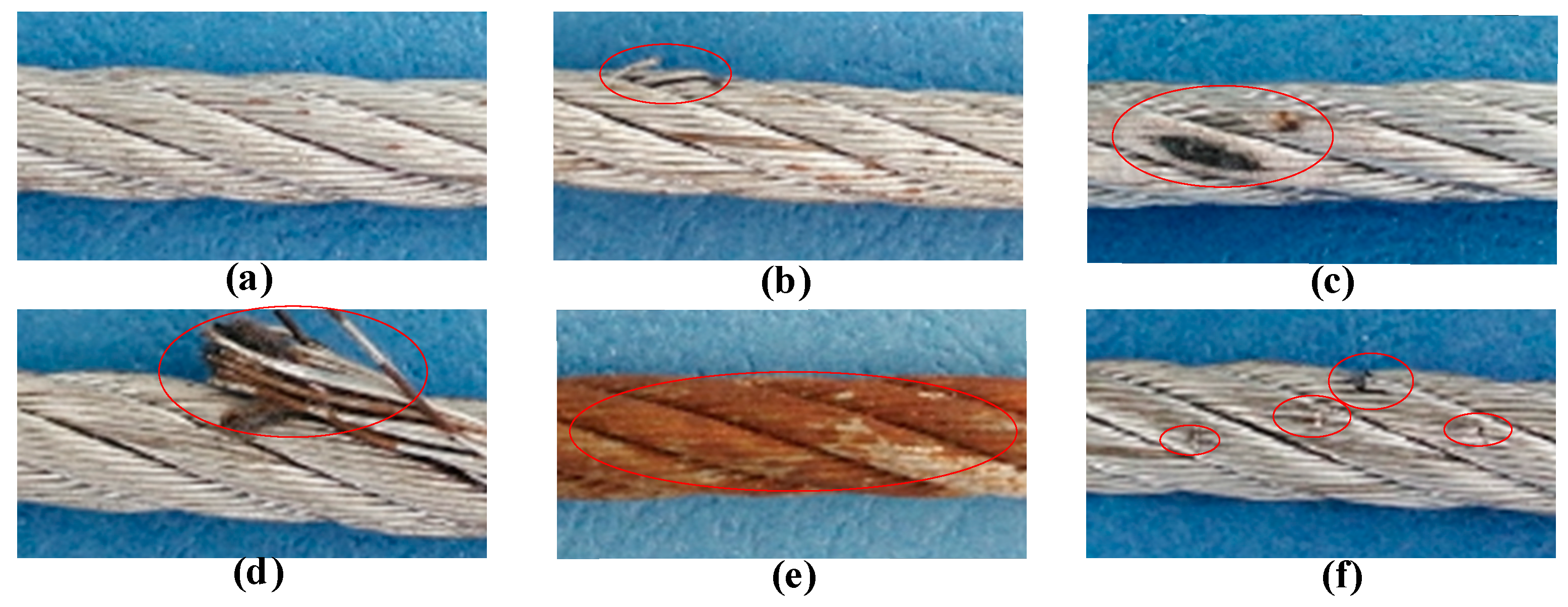

2. Damage Types of Wire Ropes

3. Non-Destructive Detection Method for Steel Wire Ropes

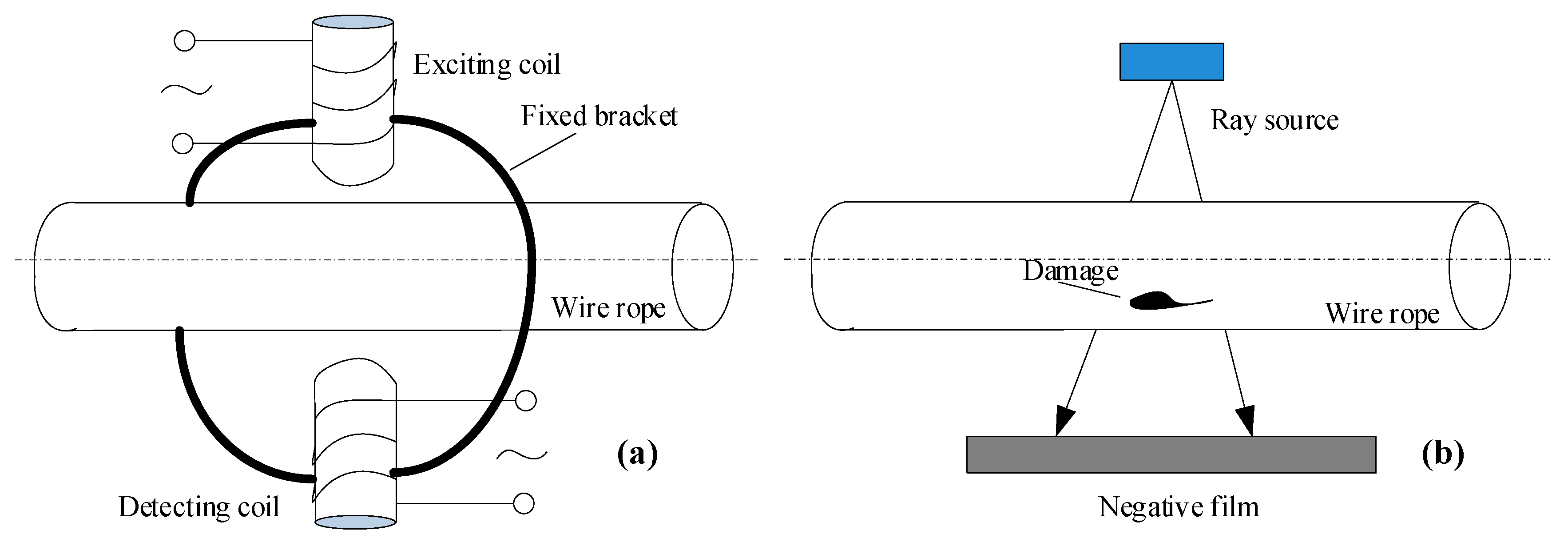

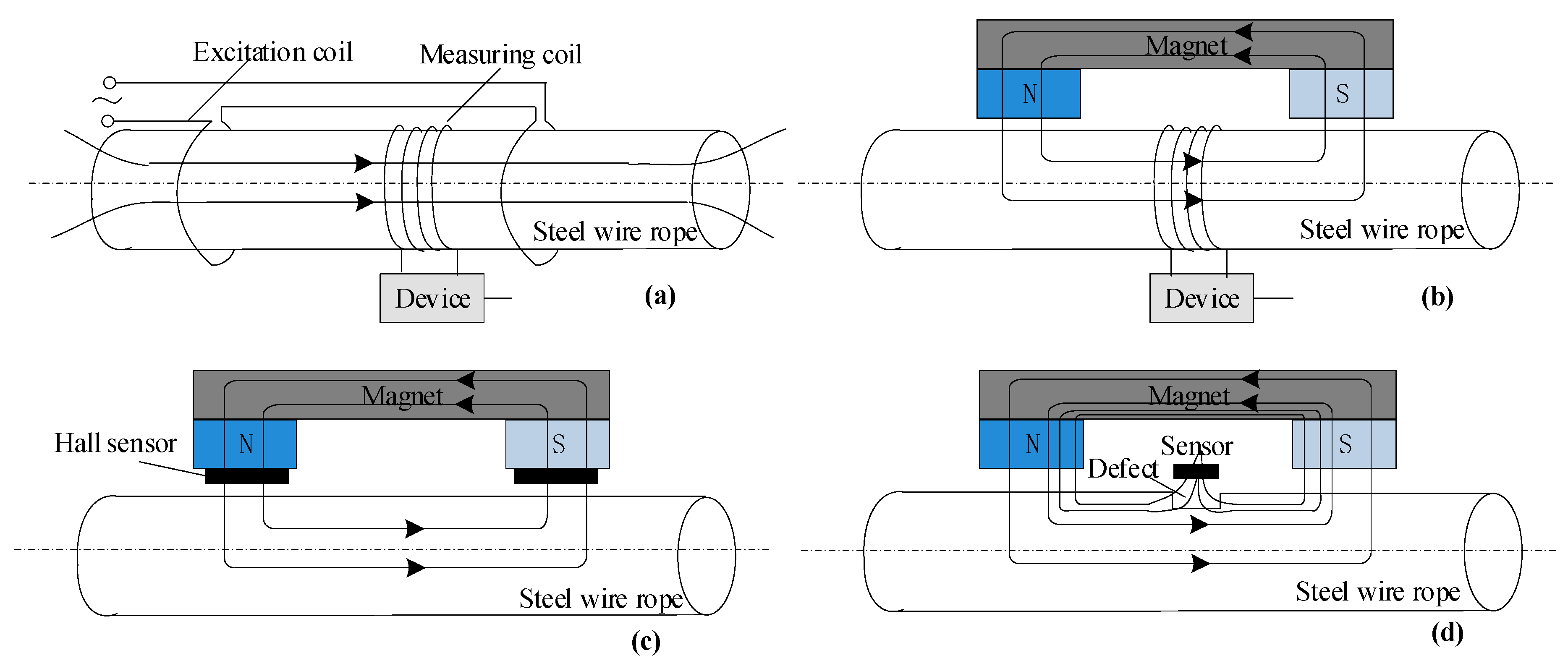

3.1. Electromagnetic Detection Method

3.1.1. Mechanism and Model

3.1.2. Magnetization Method

3.1.3. Detection Sensor

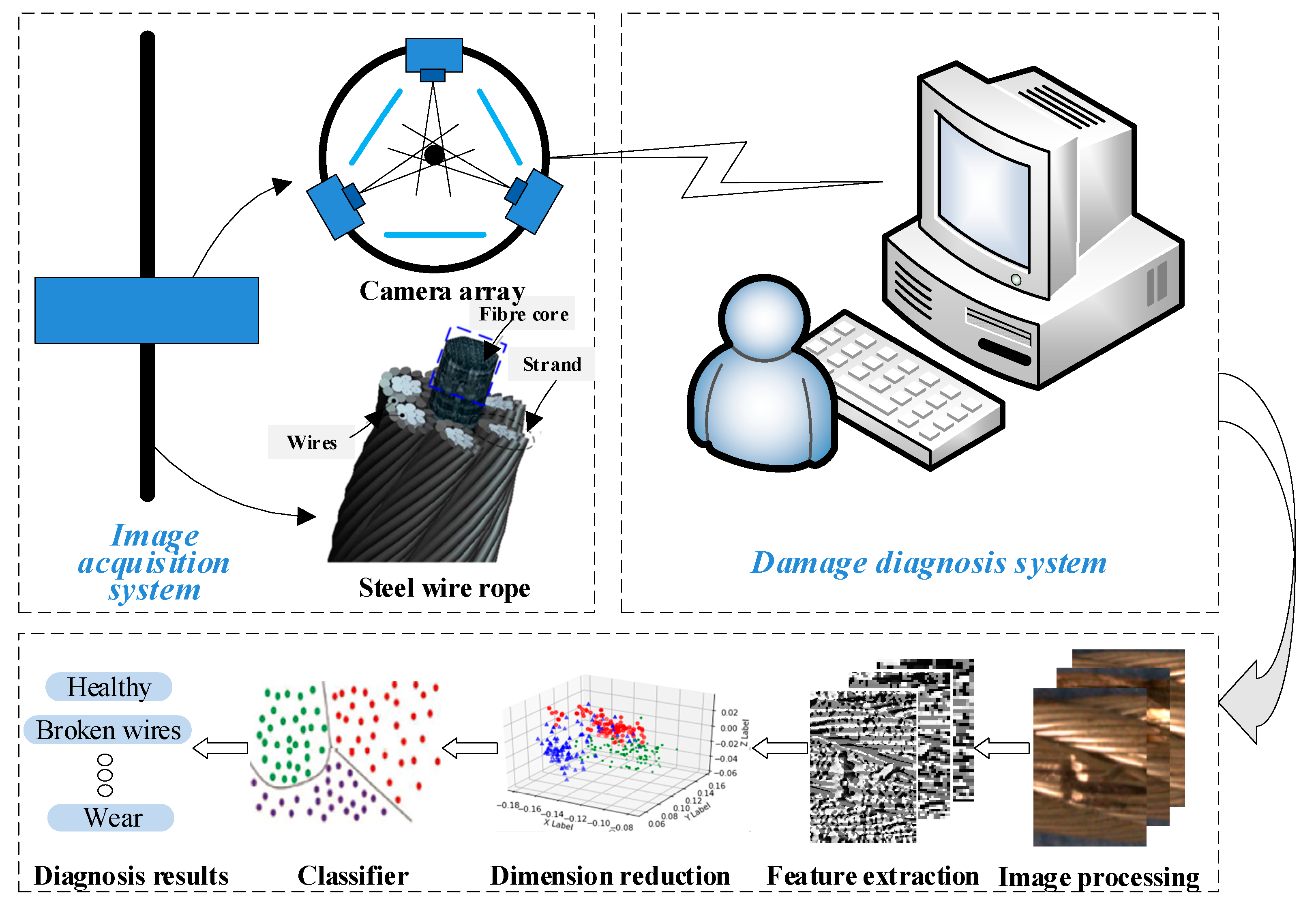

3.2. Optical Detection Method

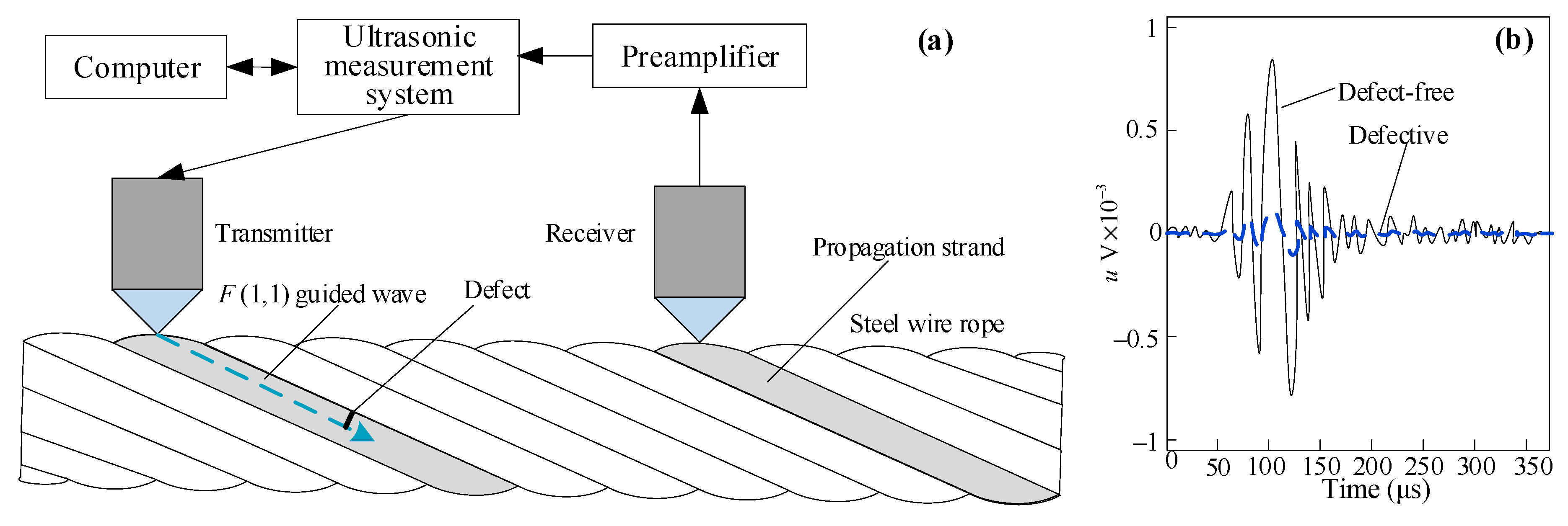

3.3. Ultrasound Guided Wave Method

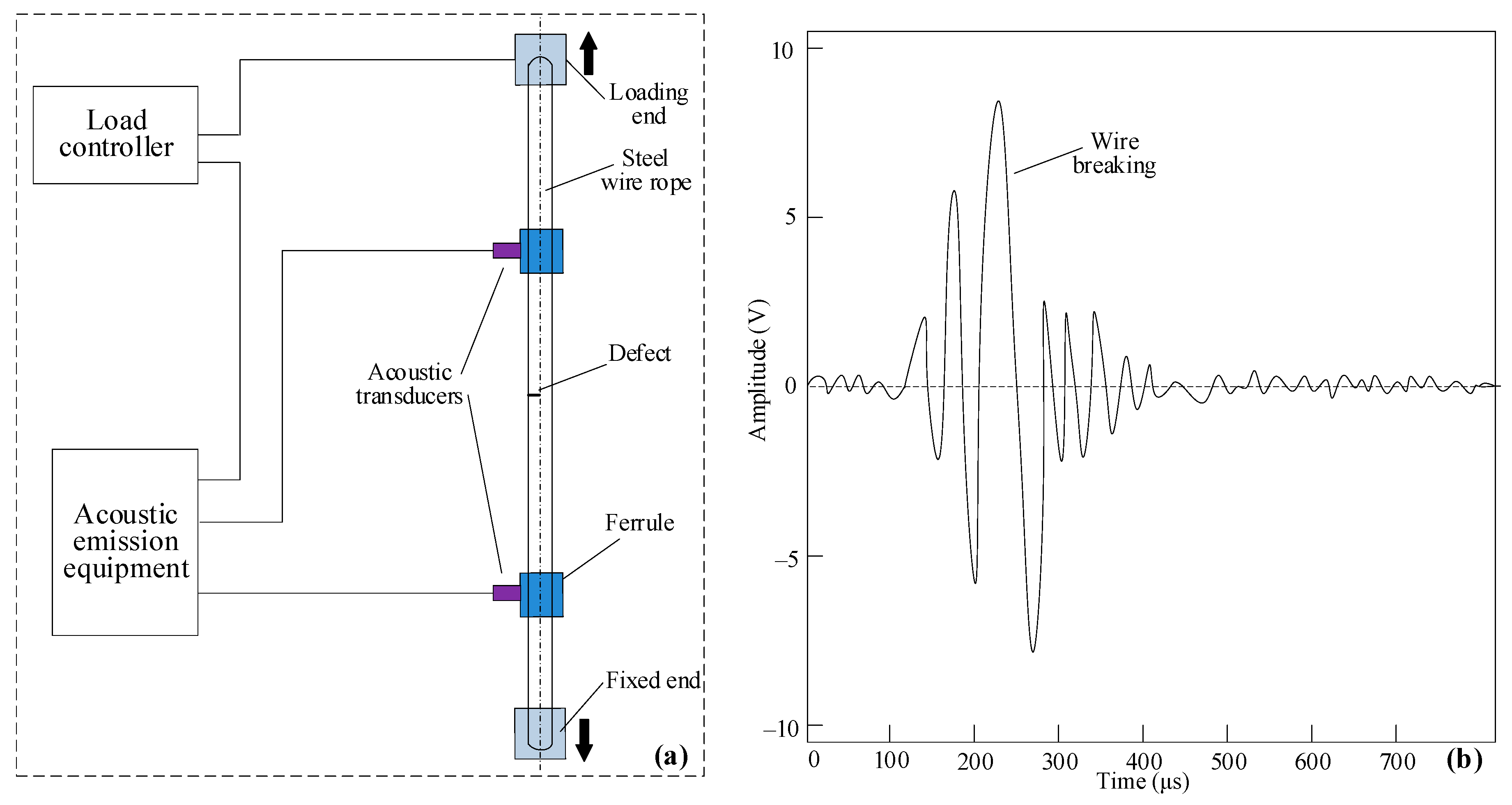

3.4. Acoustic Emission Detection Method

3.5. Other Detection Methods

4. Existing Shortcomings

- (1)

- In the field of WR electromagnetic detection, the existing theory and technology have developed in depth. However, according to the current research situation, the problems in the electromagnetic non-destructive detection of WR mainly include the influence of different WR structures on the detection signal, the quantitative analysis of LF type defects, the formulation of testing standards, and the relationship between LMA, LF defects and the strength of WRs (details can be found in reference [78]). Only by solving the quantitative detection of LF type defects and the relationship between defects and the strength of WRs, can the service life of WRs be truly and accurately predicted by non-destructive testing.

- (2)

- In the field of WR optical detection, the existing research has a small amount of data, namely no big data sets, and the algorithm is with shallow structure. It has some problems such as limited excavation ability, low computational efficiency and poor robustness. It is difficult to carry out high-speed detection, high efficiency and reliable identification, therefore can not be directly applied to real-time state health monitoring of WR. By introducing the deep learning [79,80,81,82] method into the WRs damage detection/monitoring, it is expected to achieve real-time, reliable and accurate damage identification and location, thus realizing the detection and monitoring of WR surface damage [83].

- (3)

- The ultrasonic guided wave method, acoustic emission method and other detection methods are still in the stage of theoretical research and laboratory, and there is still a certain distance away from practical application, due to the limitation of technical level and the method itself. UGW and AE method are difficult to be used in actual dynamic detection, and the signal-to-noise ratio needs to be further improved; Eddy current method is less studied and affected by skin effect. Its reliability needs further study; Ray Method’s development prospects are relatively limited compared with other methods because of the expensive instruments and the potential impact of radiation on the human body. Only by further deepening theoretical and experimental research and solving more of the above difficult problems can we promote the progress of these detection methods.

5. Summaries and Prospects

- (1)

- The types of WR damages and their causes were introduced in detail, including wire breakage, wear, rust, deformation, and fatigue. They are divided into two types: local flaw and loss of metallic cross-sectional area.

- (2)

- The development status of several important detection methods including electromagnetic detection, optical detection, ultrasonic guided wave method, acoustic emission detection, eddy current detection, and ray detection was reviewed, and their advantages and disadvantages were compared and summarized. On the whole, electromagnetic detection method has gradually been applied in practice. Optical method has shown great potential for application, while other methods are still in the laboratory stage.

- (1)

- Electromagnetic detection method: the influence of WR structure on electromagnetic signal is expected to be studied; to solve the quantitative detection of LF type defect, the relationship between LF type defect and electromagnetic signal characteristics should be further investigated; the relationship between defect and WR strength should be further determined through a large number of experimental studies, so as to achieve real and accurate prediction of WR service life; and relevant standards should be further improved and developed combining the research results with the practical experience.

- (2)

- Optical detection method: methods to reduce or eliminate the influence of oil and light on the surface of WRs should be further designed; deep learning method is expected to be introduced because of its strong data mining ability, and more efficient, accurate, and robust algorithm than the traditional machine learning should be designed; to make the designed algorithm more robust, a big data set of WR surface defects with different WR types and different sizes (diameter, wire number) is expected to be established to cover all sample space.

- (3)

- Other detection methods: theoretical and experimental research, especially ultrasonic guided wave method, acoustic emission method, eddy current detection method and ray detection method, should be further deepened, and the intrinsic relationship between detection methods and the respective parameters of WR is expected to be explored; at the same time, relevant detection equipment should be designed and optimized to promote the development of related technologies.

- (4)

- Comprehensive application: a promising avenue for research is to combine various methods to characterize and detect damages from multiple dimensions. For example, the combination of electromagnetic method and optical method can not only grasp the size of effective cross-sectional area of WRs, the types of internal and external damages in real time, but also intuitively master its surface morphology characteristics, so as to provide more valuable parameters for the WR health evaluation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mouradi, H.; Barkany, A.E.; Biyaali, A.E. Steel wire ropes failure analysis: Experimental study. Eng. Fail. Anal. 2018, 91, 234–242. [Google Scholar] [CrossRef]

- Henao, H.; Fatemi, S.M.J.R.; Capolino, G.A.; Sieg-Zieba, S. Wire rope fault detection in a hoisting winch system by motor torque and current signature analysis. IEEE Trans. Ind. Electron. 2011, 58, 1727–1736. [Google Scholar] [CrossRef]

- Peng, Y.X.; Chang, X.D.; Sun, S.S.; Zhu, Z.C.; Gong, X.S.; Zou, S.Y.; Xu, W.X.; Mi, Z.T. The friction and wear properties of steel wire rope sliding against itself under impact load. Wear 2018, 400, 194–206. [Google Scholar] [CrossRef]

- Krešák, J.; Peterka, P.; Kropuch, S.; Novákb, L. Measurement of tight in steel ropes by a mean of thermovision. Measurement 2014, 50, 93–98. [Google Scholar] [CrossRef]

- Yuan, F.; Hu, B.L.; Zhou, Z.J. An analysis on the research status quo and prospects of defect detection methods of wire ropes. Mach. Des. Manuf. 2010, 2, 260–262. [Google Scholar] [CrossRef]

- Čereška, A.; Zavadskas, E.K.; Bucinskas, V.; Podvezko, V.; Sutinys, E. Analysis of steel wire rope diagnostic data applying multi-criteria methods. Appl. Sci. 2018, 8, 260. [Google Scholar] [CrossRef]

- Zhang, J.W.; Tan, X.J.; Zheng, P.B. Non-destructive detection of wire rope discontinuities from residual magnetic field images using the hilbert-huang transform and compressed sensing. Sensors 2017, 17, 608. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.W. Principle and Technology of Steel Wire Rope Safety Detection; Science Press: Beijing, China, 2009. [Google Scholar]

- Yang, S.Z.; Kang, Y.H.; Chen, H.G.; Yuan, J.M. Electromagnetic Nondestructive Testing of Wire Ropes; Machinery Industry Press: Beijing, China, 2017. [Google Scholar]

- Gu, W.; Chu, J.X. A transducer made up of fluxgate sensors for testing wire rope defects. IEEE Trans. Instrum. Meas. 2002, 51, 120–124. [Google Scholar] [CrossRef]

- Tan, X.J. Research on Non-Destructive Testing of Ferromagnetic Components with Weak Magnetic Imaging: In a Case of Wire Rope. Master’s Thesis, Henan University of Science and Technology, Henan, China, 2018. [Google Scholar]

- Norouzi, E.; Ravanbod, H. Optimization of the flux distribution in magnetic flux leakage testing. Mater. Eval. 2010, 3, 360–364. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.L. Magnetic flux leakage of typical defect of wire rope based on FE simulation. Nondestr. Test. 2009, 31, 177–180. [Google Scholar]

- Lenard, S.; Atherton, D.L. Calculation of the effects of anisotropy on magnetic flux leakage detector signals. IEEE Trans. Magn. 1996, 32, 1905–1909. [Google Scholar] [CrossRef]

- Krzywosz, K. Comparion of electromagnetic techniques for nondestructive inspetion of ferromagnetic tubing. Mater. Eval. 1990, 48, 42–45. [Google Scholar]

- Kalwa, E.; Piekarski, K. Design of inductive sensors for magnetic testing of steel ropes. NDT E Int. 1991, 24, 328. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H.; Stanley, R.K. Simulation and analysis of 3-D magnetic flux leakage. IEEE Trans. Magn. 2009, 45, 1966–1972. [Google Scholar] [CrossRef]

- Trevino, D.A.G.; Dutta, S.M.; Ghorbel, F.H.; Karkoub, M. An improved dipole model of 3-D magnetic flux leakage. IEEE Trans. Magn. 2016, 52, 1–7. [Google Scholar] [CrossRef]

- Sun, Y.H.; Kang, Y.H. Magnetic mechanisms of magnetic flux leakage nondestructive testing. Appl. Phys. Lett. 2013, 103, 184104. [Google Scholar] [CrossRef]

- Gao, G.H.; Lian, M.J.; Xu, Y.G.; Qin, Y.N.; Gao, L. The effect of variable tensile stress on the MFL signal response of defective wire ropes. INSIGHT 2016, 58, 135–141. [Google Scholar] [CrossRef]

- Coramik, M.; Ege, Y. Discontinuity inspection in pipelines: A comparison review. Measurement 2017, 111, 359–373. [Google Scholar] [CrossRef]

- Kang, Y.H.; Li, Z.J.; Yang, Y.; Qiu, C. Mini-micro sensor and device for wire rope MFL testing. Nondestr. Test. 2014, 36, 11–15. [Google Scholar]

- Wang, H.Y.; Hua, G.; Tian, J. Research on detection device for broken wires of coal mine-hoist cable. J. Chin. Univ. Mini. Technol. 2007, 17, 376–381. [Google Scholar] [CrossRef]

- Jomdecha, C.; Prateepasen, A. Design of modified electromagnetic main-flux for steel wire rope inspection. NDT E Int. 2009, 42, 77–83. [Google Scholar] [CrossRef]

- Wang, H.Y.; Xu, Z.; Hua, G.; Tian, J.; Zhou, B.B.; Lu, Y.H.; Chen, F.J. Key technique of a detection sensor for coal mine wire ropes. Min. Sci. Technol. 2009, 19, 170–175. [Google Scholar] [CrossRef]

- Song, K.; Chen, C.; Kang, Y.H.; Li, J.J.; Ren, J.L. Mechanism study of AC-MFL method using U-shape inducer. Chin. J. Sci. Instrum. 2012, 33, 1980–1985. [Google Scholar] [CrossRef]

- Yan, X.L.; Zhang, D.L.; Pan, S.M.; Zhao, E.C.; Gao, W. Online nondestructive testing for fine steel wire rope in electromagnetic interference environment. NDT E Int. 2017, 92. [Google Scholar] [CrossRef]

- Kaur, A.; Gupta, A.; Aggarwal, H.; Arora, K.; Garg, N.; Sharma, M.; Sharma, S.; Aggarwal, N.; Sapra, G.; Goswamy, J.K. Non-destructive evaluation and development of a new wire rope tester using parallely magnetized NdFeB magnet segments. J. Nondestr. Eval. 2018, 37, 61. [Google Scholar] [CrossRef]

- Sun, Y.H.; Wu, J.B.; Feng, B.; Kang, Y.H. An opening electric-mfl detector for the ndt of in-service mine hoist wire. IEEE Sens. J. 2014, 14, 2042–2047. [Google Scholar] [CrossRef]

- Liu, X.C.; Xiao, J.W.; Wu, B.; He, C.F. A novel sensor to measure the biased pulse magnetic response in steel stay cable for the detection of surface and internal flaws. Sens. Actuators A Phys. 2018, 269, 218–226. [Google Scholar] [CrossRef]

- Yan, X.L.; Zhang, D.L.; Zhao, F. Improve the signal to noise ratio and installation convenience of the inductive coil for wire rope nondestructive testing. NDT E Int. 2017, 92, 221–227. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnár, V.; Ferková, Ž.; Peterka, P.; Krešák, J.; Tomašková, M. Possibilities of failure analysis for steel cord conveyor belts using knowledge obtained from non-destructive testing of steel ropes. Eng. Fail. Anal. 2016, 67, 33–45. [Google Scholar] [CrossRef]

- Sun, Y.H.; Liu, S.W.; Li, R.; Ye, Z.J.; Kang, Y.H.; Chen, S.B. A new magnetic flux leakage sensor based on open magnetizing method and its on-line automated structural health monitoring methodology. Struct. Health Monit. 2015, 14, 583–603. [Google Scholar] [CrossRef]

- Xu, F.Y.; Wang, X.S.; Wu, H.T. Inspection method of cable-stayed bridge using magnetic flux leakage detection: Principle, sensor design, and signal processing. J. Mech. Sci. Technol. 2012, 26, 661–669. [Google Scholar] [CrossRef]

- Wang, H.T.; Tian, J.; Meng, G.Y. A sensor model for defect detection in mine hoisting wire ropes based on magnetic focusing. INSIGHT 2017, 59, 143–148. [Google Scholar] [CrossRef]

- Kim, J.W.; Park, S. Magnetic flux leakage sensing and artificial neural network pattern recognition-based automated damage detection and quantification for wire rope non-destructive evaluation. Sensors 2018, 18, 109. [Google Scholar] [CrossRef]

- Tian, J.; Wang, H.Y. Research on magnetic excitation model of magnetic flux leakage for coal mine hoisting wire rope. Adv. Mech. Eng. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Zhou, J.Y.; Tian, J.; Wang, H.Y.; Li, Y.M.; Wu, M. Numerical simulation of magnetic excitation based on a permanent magnet co-directions array sensor. INSIGHT 2018, 60, 568–574. [Google Scholar] [CrossRef]

- Singh, W.S.; Rao, B.P.C.; Mukhopadhyay, C.K.; Jayakumar, T. GMR-based magnetic flux leakage technique for condition monitoring of steel track rope. INSIGHT 2011, 53, 377–381. [Google Scholar] [CrossRef]

- Liu, X.C.; Wang, Y.J.; Wu, B.; Gao, Z.; He, C.F. Design of tunnel magnetoresistive-based circular MFL sensor array for the detection of flaws in steel wire rope. J. Sens. 2016, 2016. [Google Scholar] [CrossRef]

- Lu, T.; Zhang, L.H. Wire Rope Inspector; China University of Mining and Technology Press: Xuzhou, China, 2007; pp. 74–78. [Google Scholar]

- Zhou, P.; Zhou, G.B.; He, Z.Z.; Tang, C.Q.; Zhu, Z.C.; Li, W. A novel texture-based damage detection method for wire ropes. Measurement 2019. under review. [Google Scholar]

- Vallan, A.; Molinari, F. A vision-based technique for lay length measurement of metallic wire ropes. IEEE Trans. Instrum. Meas. 2009, 58, 1756–1762. [Google Scholar] [CrossRef]

- Yaman, O.; Karakose, M. Auto-correlation based elevator rope monitoring and fault detection approach with image processing. In Proceedings of the 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), Malatya, Turkey, 16–17 September 2017. [Google Scholar]

- Sun, H.X.; Zhang, Y.H.; Luo, F.L. Texture segmentation and boundary recognition of wire rope images in complicated background. Acta Photonica Sinica 2010, 39, 1666–1671. [Google Scholar] [CrossRef]

- Platzer, E.S.; Nägele, J.; Wehking, K.H.; Denzler, J. HMM-based defect localization in wire ropes–a new approach to unusual subsequence recognition. Pattern Recognition. In Proceedings of the Dagm Symposium, Jena, Germany, 9–11 September 2009; pp. 442–451. [Google Scholar]

- Platzer, E.S.; Wehking, K.H.; Denzler, J. On the suitability of different features for anomaly detection in wire ropes. In Proceedings of the International Conference on Computer Vision, Imaging and Computer Graphics, Lisboa, Portugal, 5–8 February 2009; pp. 296–308. [Google Scholar]

- Wacker, E.S.; Denzler, J. Enhanced anomaly detection in wire ropes by combining structure and appearance. Pattern Recognit. Lett. 2013, 34, 942–953. [Google Scholar] [CrossRef]

- Wacker, E.S.; Denzler, J. An analysis-by-synthesis approach to rope condition monitoring. In Proceedings of the International Symposium on Visual Computing, Las Vegas, NV, USA, 29 November–1 December 2010; pp. 459–468. [Google Scholar]

- Sanchez-Brea, L.M.; Siegmann, P.; Rebollo, M.A.; Bernabeu, E. Optical technique for the automatic detection and measurement of surface defects on thin metallic wires. Appl. Opt. 2000, 39, 539–545. [Google Scholar] [CrossRef] [PubMed]

- Laguerre, L.; Treyssede, F. Non-destructive evaluation of seven-wire strands using ultrasonic guided waves. Eur. J. Environ. Civil Eng. 2011, 15, 487–500. [Google Scholar] [CrossRef]

- Raisutis, R.; Kazys, R.; Mazeika, L.; Zukauskas, E.; Samaitis, V.; Jankauskas, A. Ultrasonic guided wave-based testing technique for inspection of multi-wire rope structures. NDT E Int. 2014, 62, 40–49. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhao, J.C.; Wu, B.; Zhang, Y.N.; He, C.F. Configuration optimization of magnetostrictive transducers for longitudinal guided waves inspection in seven-wire steel strands. NDT E Int. 2010, 43, 484–492. [Google Scholar] [CrossRef]

- Treyssède, F.; Laguerre, L. Investigation of elastic modes propagating in multi-wire helical waveguides. J. Sound Vib. 2010, 329, 1702–1716. [Google Scholar] [CrossRef]

- Vanniamparambil, P.A.; Khan, F.; Hazeli, K.; Cuadra, J.; Schwartz, E.; Kontsos, A.; Bartoli, I. Novel optico-acoustic nondestructive testing for wire break detection in cables. Struct. Control Health Monit. 2013, 1319–1350. [Google Scholar] [CrossRef]

- Xu, J.; Wu, X.J.; Sun, P.F. Detecting broken-wire flaws at multiple locations in the same wire of prestressing strands using guided waves. Ultrasonics 2013, 53, 150–156. [Google Scholar] [CrossRef]

- Raisutis, R.; Kazys, R.; Mazeika, L.; Samaitis, V.; Zukauskas, E. Propagation of ultrasonic guided waves in composite multi-wire ropes. Materials 2016, 9, 451. [Google Scholar] [CrossRef]

- Tse, P.W.; Rostami, J. Advanced signal processing methods applied to guided waves for wire rope defect detection. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2016; Volume 1706, p. 030006. [Google Scholar]

- Li, H.; Wang, W.T.; Zhou, W.S. Fatigue damage monitoring and evolution for basalt fiber reinforced polymer materials. Smart Struct. Syst. 2014, 14, 307–325. [Google Scholar] [CrossRef]

- Hoon, S.; Gyuhae, P.; Jeannette, R.W.; Nathan, P.L.; Charles, R.F. Wavelet-based active sensing for delamination detection in composite structures. Smart Mater. Struct. 2003, 13, 153. [Google Scholar] [CrossRef]

- Drummond, G.; Watson, J.F.; Acarnley, P.P. Acoustic emission from wire ropes during proof load and fatigue testing. NDT E Int. 2007, 40, 94–101. [Google Scholar] [CrossRef]

- Bai, W.; Chai, M.; Li, L.; Li, Y.; Duan, Q. Acoustic emission from elevator wire ropes during tensile testing. In Advances in Acoustic Emission Technology: Proceedings of the World Conference on Acoustic Emission-2013; Springer: New York, NY, USA, 2013; pp. 217–224. [Google Scholar]

- Casey, N.F.; Taylor, J.L. Acoustic emission of steel wire ropes. Wire Ind. 1984, 51, 79–82. [Google Scholar]

- Casey, N.F.; Taylor, J.L. Evaluation of wire ropes by AE techniques. Brit. J. Non. Destruct. Test. 1985, 27, 351–356. [Google Scholar]

- Casey, N.F.; Wedlake, D.; Taylor, J.L.; Holford, K.M. Acoustic detection of wire rope failure. Wire Ind. 1985, 52, 307–309. [Google Scholar]

- Casey, N.F.; Taylor, J.L.; Holford, K.M. Wire break detection during tensile fatigue testing of 40 mm wire rope. Brit. J. Non. Destruct. Test. 1985, 30, 338–341. [Google Scholar]

- Casey, N.F.; White, H.; Taylor, J.L. Frequency analysis of the signals generated by the failure of constituent wires of a wire rope. NDT E Int. 1989, 56, 583–586. [Google Scholar] [CrossRef]

- Casey, N.F.; Laura, P.A.A. A review of the acoustic-emission monitoring of wire rope. Ocean Eng. 1997, 24, 935–947. [Google Scholar] [CrossRef]

- Shao, Y.B.; Yu, D.; Wang, S.; Zhu, Z.M.; Yin, W.Q. Quantitative method to detect wire break in wire rope by acoustic emission techniques. J. Northeast. Univ. Nat. Sci. 1999, 20, 130–132. [Google Scholar]

- Ding, Y.; Reuben, R.L.; Steel, J.A. A new method for waveform analysis for estimating AE wave arrival times using wavelet decomposition. NDT E Int. 2004, 37, 279–290. [Google Scholar] [CrossRef]

- Li, S.; Wu, Y.; Shi, H. A novel acoustic emission monitoring method of cross-section precise localization of defects and wire breaking of parallel wire bundle. Struct. Control Health Monit. 2019, 26, e2334. [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Chen, W.L.; Ma, M.L.; Tao, D.W.; Ou, J.P. Estimation and warning of fatigue damage of FRP stay cables based on acoustic emission techniques and fractal theory. Comput. Aided Civil Infrastruct. Eng. 2011, 26, 500–512. [Google Scholar] [CrossRef]

- Cao, Q.S.; Liu, D.; Zhou, J.H.; Zhou, J.M. Non-destructive and quantitative detection method for broken wire rope. Chin. J. Sci. Instrum. 2011, 32, 787–794. [Google Scholar] [CrossRef]

- Cao, Q.S.; Liu, D.; He, Y.H.; Zhou, J.H.; Codrington, J. Nondestructive and quantitative evaluation of wire rope based on radial basis function neural network using eddy current inspection. NDT E Int. 2012, 46, 7–13. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Xu, G.Y.; Cui, J. System used to detect steel wire rope based on X-ray digital imaging technology. Image Technol. 2008, 2, 33–39. [Google Scholar]

- Peng, P.C.; Wang, C.Y. Use of gamma rays in the inspection of steel wire ropes in suspension bridges. NDT E Int. 2015, 75, 80–86. [Google Scholar] [CrossRef]

- Cao, Y.N.; Zhang, D.L.; Xu, D.G. The state-of-art of quantitative nondestructive testing of wire ropes. Nondestruct. Test. 2005, 27, 91–95. [Google Scholar]

- Wu, P.; Hua, H.Y. Discussion on the existing problems of steel wire rope nondestructive testing. Nondestruct. Test. 2017, 39, 65–68. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.B.; Zhu, Z.C.; Tang, C.Q.; He, Z.Z.; Li, W.; Jiang, F. Health monitoring for balancing tail ropes of a hoisting system using a convolutional neural network. Appl. Sci. 2018, 8, 1346. [Google Scholar] [CrossRef]

- Guo, X.J.; Chen, L.; Shen, C.Q. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.Q.; Chen, Z.H.; Mao, K.Z.; Wang, P.; Gao, X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Guo, X.J.; Shen, C.Q.; Chen, L. Deep fault recognizer: An integrated model to denoise and extract features for fault diagnosis in rotating machinery. Appl. Sci. 2017, 7, 41. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.B.; He, Z.Z.; Zhu, Z.C.; Tang, C.Q.; Li, W. A novel deep learning-based damage monitoring and diagnosis method for wire ropes. Mech. Syst. Signal Process. 2019. under review. [Google Scholar]

| Types | Description |

|---|---|

| Wire breakage | Fatigue breakage and wear breakage are the main causes of wire breakage. Wire breakage will reduce the WR strength and increase the potential safety hazards of WRs. |

| Wear | Wear is one of the most common phenomena of WR, which usually evolves from normal wear to failure wear. The wire wear will reduce the tension it can bear. |

| Rust | Rust is a fault phenomenon of WRs caused by the chemical and electrochemical action of surrounding medium, which has a significant impact on the life of WRs. |

| Deformation | Impact on the WR causes damages (including flattening, strand relaxation, kinking, bending, and strand breakage) to the original structure, which accelerates the scrap. |

| Fatigue | After repeated bending for a certain number of times or repeated stretching and twisting, fatigue occurs, which leads to changes in the internal and external performance of the WR. |

| Methods | Measurement Principle | Presentation Way | Advantages | Main Disadvantages |

|---|---|---|---|---|

| Artificial visual method | Inspect the WR surface at a slow speed | Direct analysis and judgment | Simple and direct judgment of surface damage | Time-consuming, and the result is affected by oil pollution and man-made factors |

| Electromagnetic detection method [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40] | Measure leakage magnetic flux | Graph line | Qualitative determination of wire breakage, rust, wear and other defects | Difficult to make quantitative measurement and distinguish defects exist at the same time |

| Measure main magnetic flux | Graph line | Measure the change of WR metal cross section area | Not suitable for detecting broken wire, especially when the fracture is not obvious | |

| Optical detection method [42,43,44,45,46,47,48,49,50] | Detect WR surface using camera | Image | Intuitive, and high accuracy of detection | Influenced by environmental factors, data size and machine learning algorithm performance |

| Ultrasound guided wave method [51,52,53,54,55,56,57,58] | Ultrasound propagates in the medium | Echogram | Detect wire breakage, long distance of single detection | Weak anti-noise ability, cannot reflect the condition of WR in detail |

| Acoustic emission method [61,62,63,64,65,66,67,68,69,70,71,72] | Measure the ultrasound emitted by the structural change of steel wire rope | Sound transmission analysis | Detect wire breakage and deformation | Can only be used in the static load part, has low signal-to-noise ratio, high instrument cost and is difficult to measure dynamically. |

| Eddy current method [73,74] | Eddy current effect | Graph line | Detect wire breakage and rust | Skin effect affects wire breakage detection, and the signal-to-noise ratio is low |

| Ray method [75,76] | Radiation vertical to the rope with strong X-ray/gamma-ray | Image | Determine wire breakage | Instruments and radiation protection devices are expensive and cannot be continuously measured for long exposure periods |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Zhou, G.; Zhu, Z.; He, Z.; Ding, X.; Tang, C. A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes. Appl. Sci. 2019, 9, 2771. https://doi.org/10.3390/app9132771

Zhou P, Zhou G, Zhu Z, He Z, Ding X, Tang C. A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes. Applied Sciences. 2019; 9(13):2771. https://doi.org/10.3390/app9132771

Chicago/Turabian StyleZhou, Ping, Gongbo Zhou, Zhencai Zhu, Zhenzhi He, Xin Ding, and Chaoquan Tang. 2019. "A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes" Applied Sciences 9, no. 13: 2771. https://doi.org/10.3390/app9132771

APA StyleZhou, P., Zhou, G., Zhu, Z., He, Z., Ding, X., & Tang, C. (2019). A Review of Non-Destructive Damage Detection Methods for Steel Wire Ropes. Applied Sciences, 9(13), 2771. https://doi.org/10.3390/app9132771