Assessing the Effect of Nano Hydrophobic Silane Silica on Aggregate-Bitumen Interface Bond Strength in the Spring-Thaw Season

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Sample Preparation

2.1. Asphalt

2.2. Nano Hydrophobic Silane Silica

2.3. Asphalt Sample Preparation

3. Aggregate-Bitumen Interface Bond Strength Test

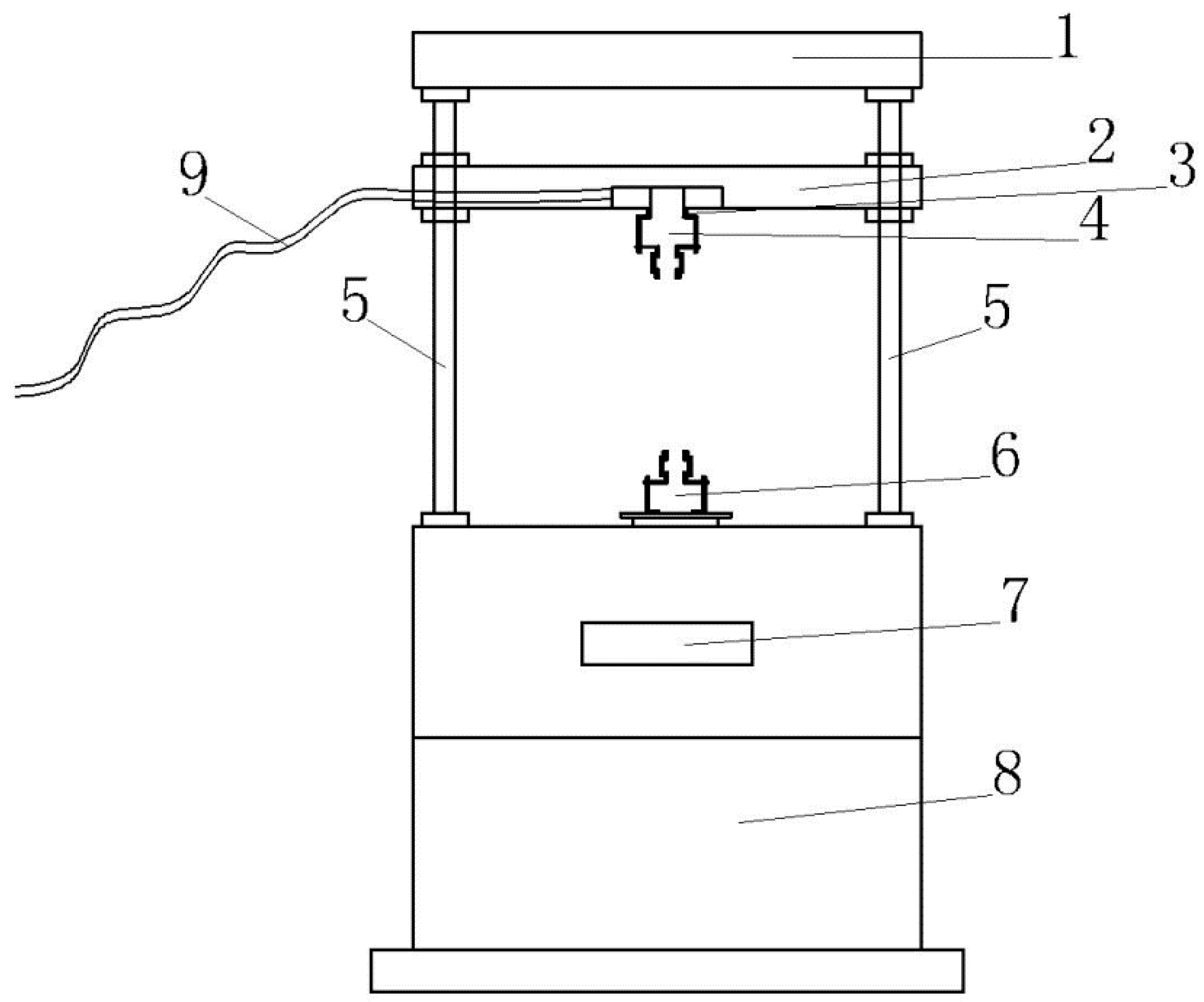

3.1. Test Equipment

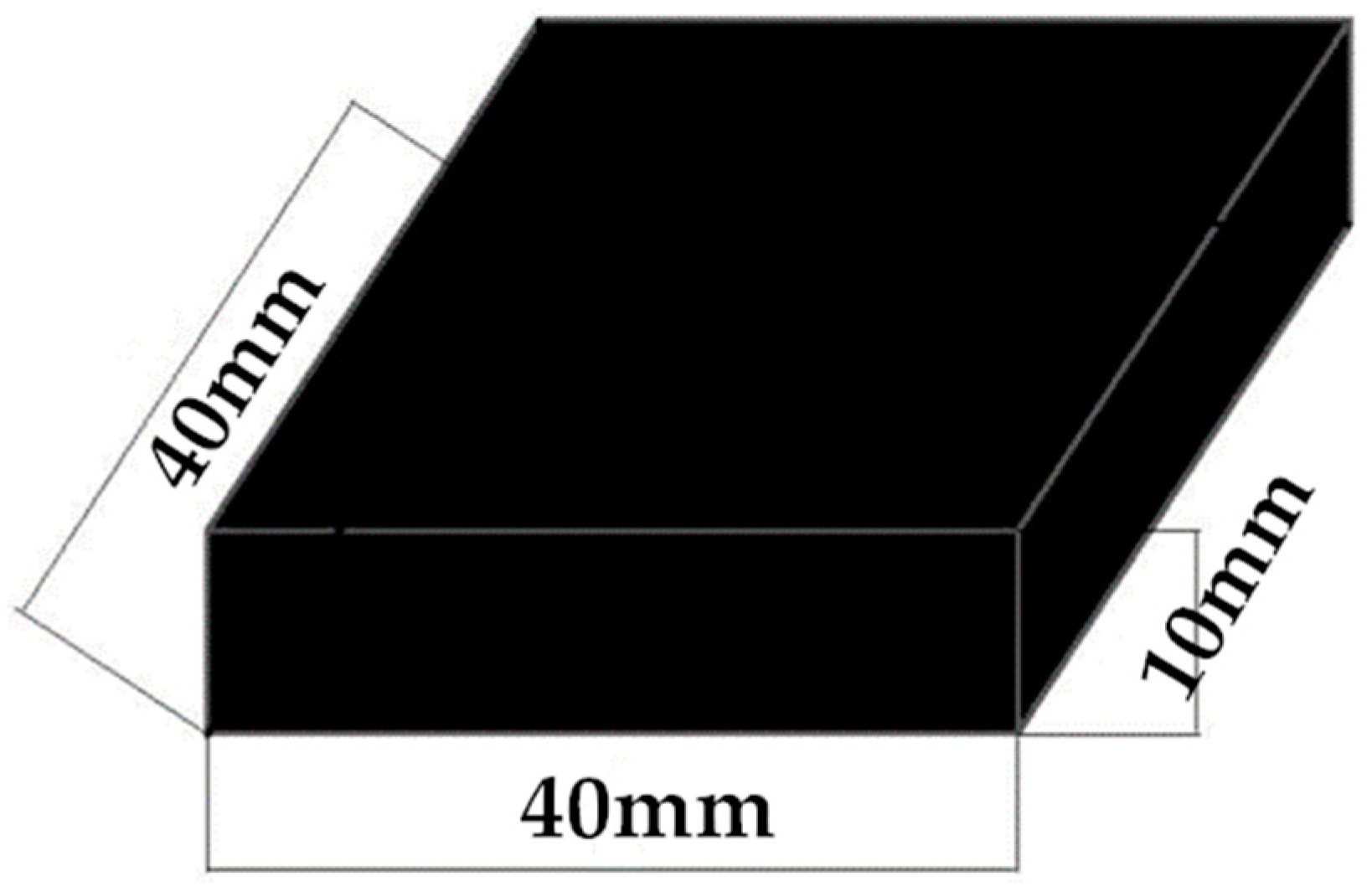

3.2. Test Sample Preparation

3.3. Test Sample Cleaning

- (1)

- The test mold with residual asphalt was frozen for about 0.5 h.

- (2)

- The test mold was removed from the cryostat and the residual asphalt on the surface of the test mold gently scraped with a plastic sheet.

- (3)

- The surface of the test mold was rinsed with trichloroethylene until no residual bitumen.

- (4)

- The surface of the test mold was rinsed with a small amount of acetone solution to accelerate the drying process of the test mold.

- (5)

- The rinsed test mold was placed in an oven at 100 °C for 12 h.

3.4. Test Procedure

- (1)

- The test mold was placed in 100 °C oven for 15 min.

- (2)

- BA and NHSSMA were placed in an oven at 135 °C and heated to a flowing state.

- (3)

- The quantitative asphalt binder was applied to the surface of one test mold, flat with a preheated blade, and then adhered to the surface of another test mold.

- (4)

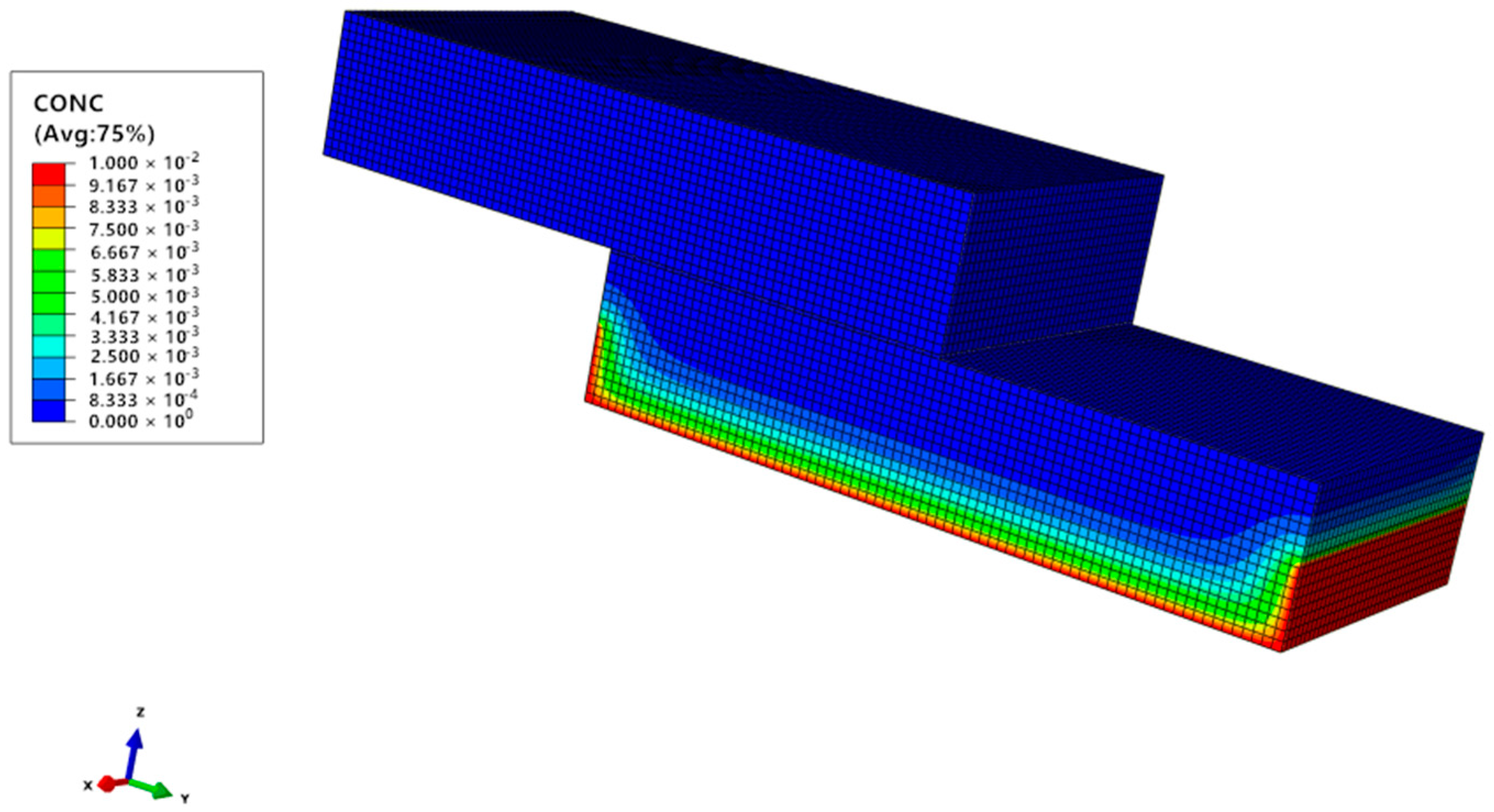

- The prepared test sample was placed in a water bath to simulate the process of moisture diffusion into the aggregate-bitumen interface. The immersion height of each test sample was consistent, and the immersion height was one-half the thickness of the test mold.

- (5)

- The test sample was tested, and the data was obtained by setting the loading rate and the test temperature through a computer. The collected data was the maximum failure load and failure area. In order to ensure the validity and repeatability of the data, the number of parallel tests in each group of experiments was 4–6. The numerical values appearing in the article are the average of the data that meet the error requirements, and the coefficient of variation of all test data was within 10%.

- (6)

- Finally, the test mold was cleaned and we the next set of tests were carried out.

4. Results and Discussion

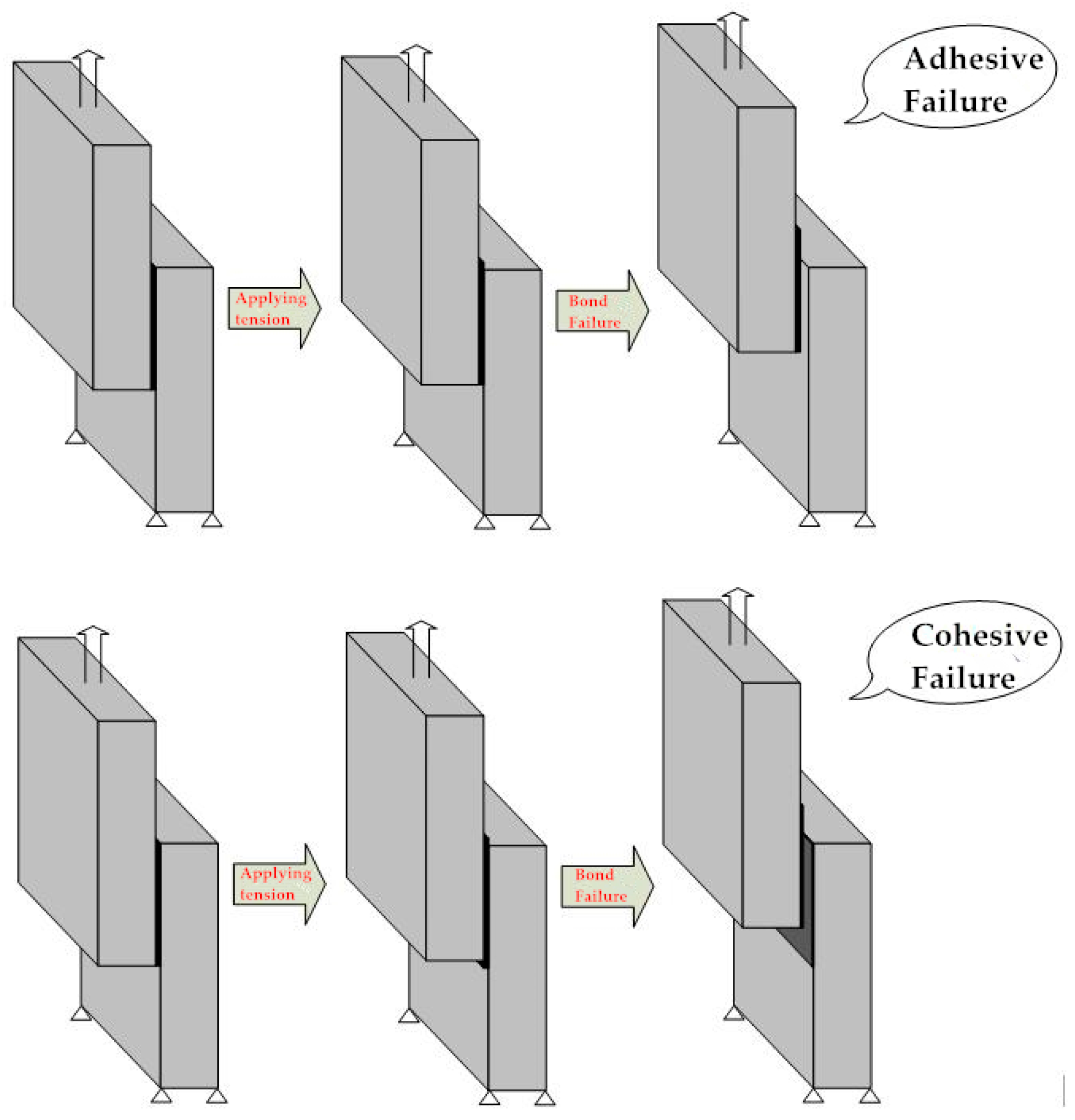

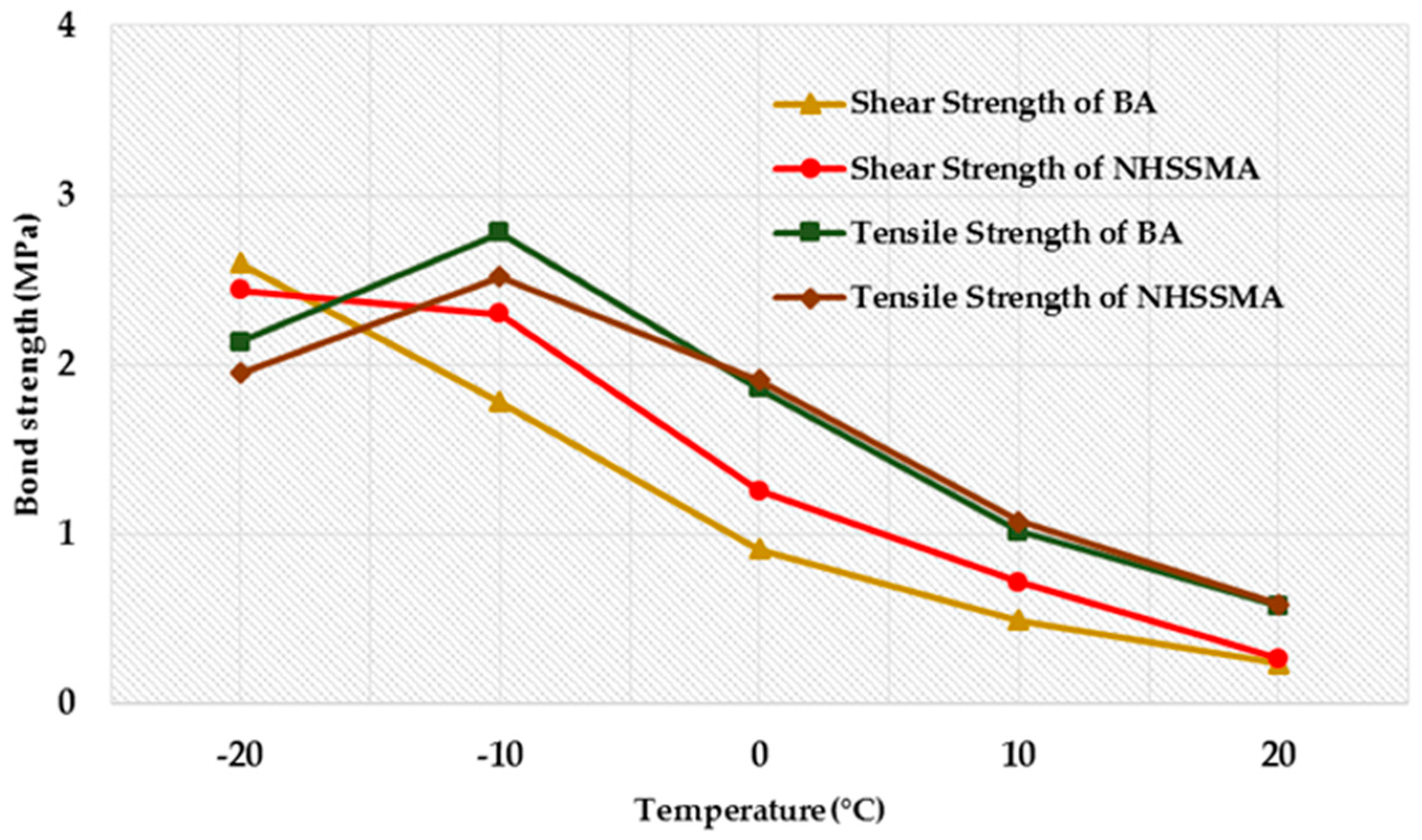

4.1. Contribution of Shear Strength and Tensile Strength to Aggregate-Bitumen Interface Bond Strength

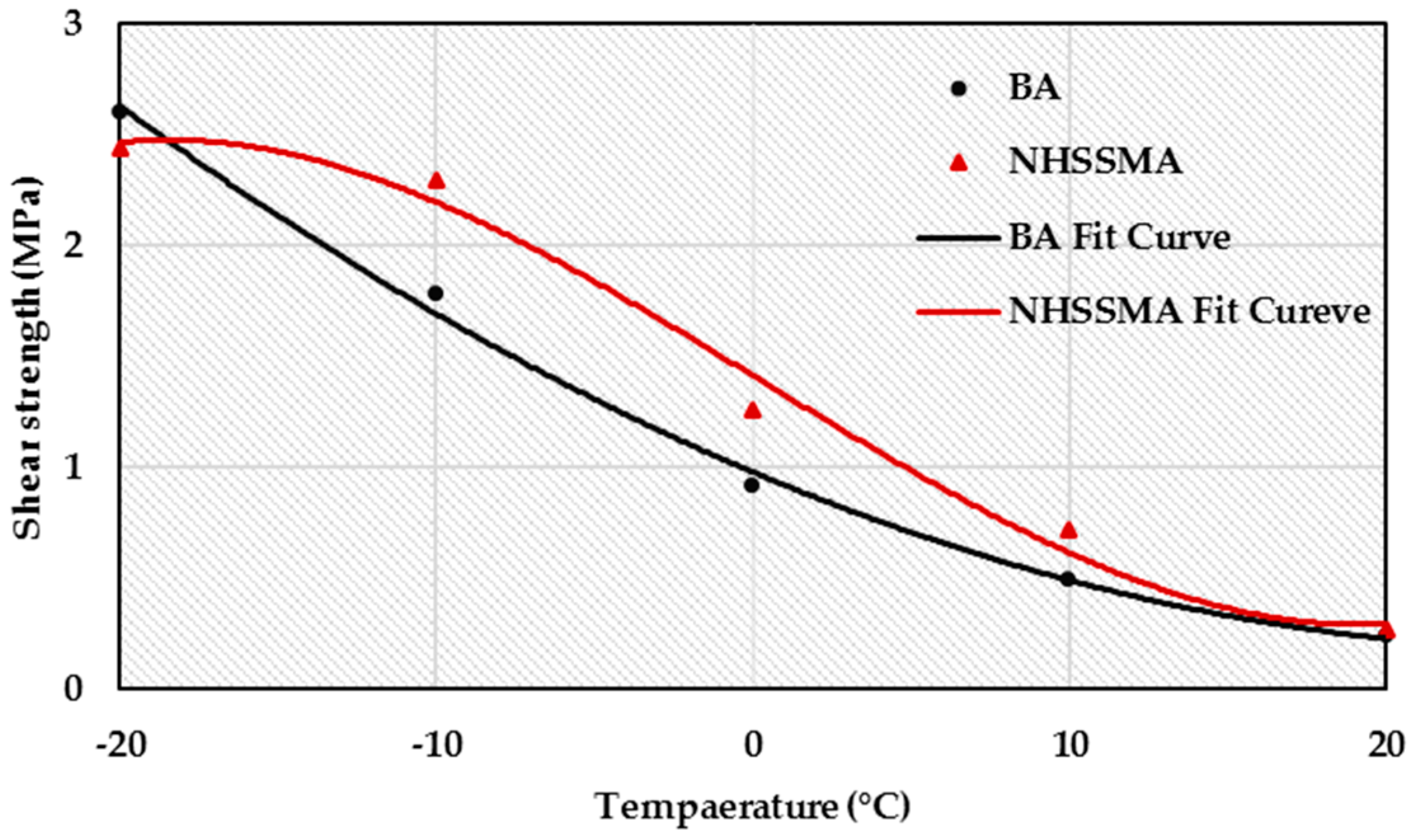

4.2. Effect of Temperature on Aggregate-Bitumen Interface Shear Strength

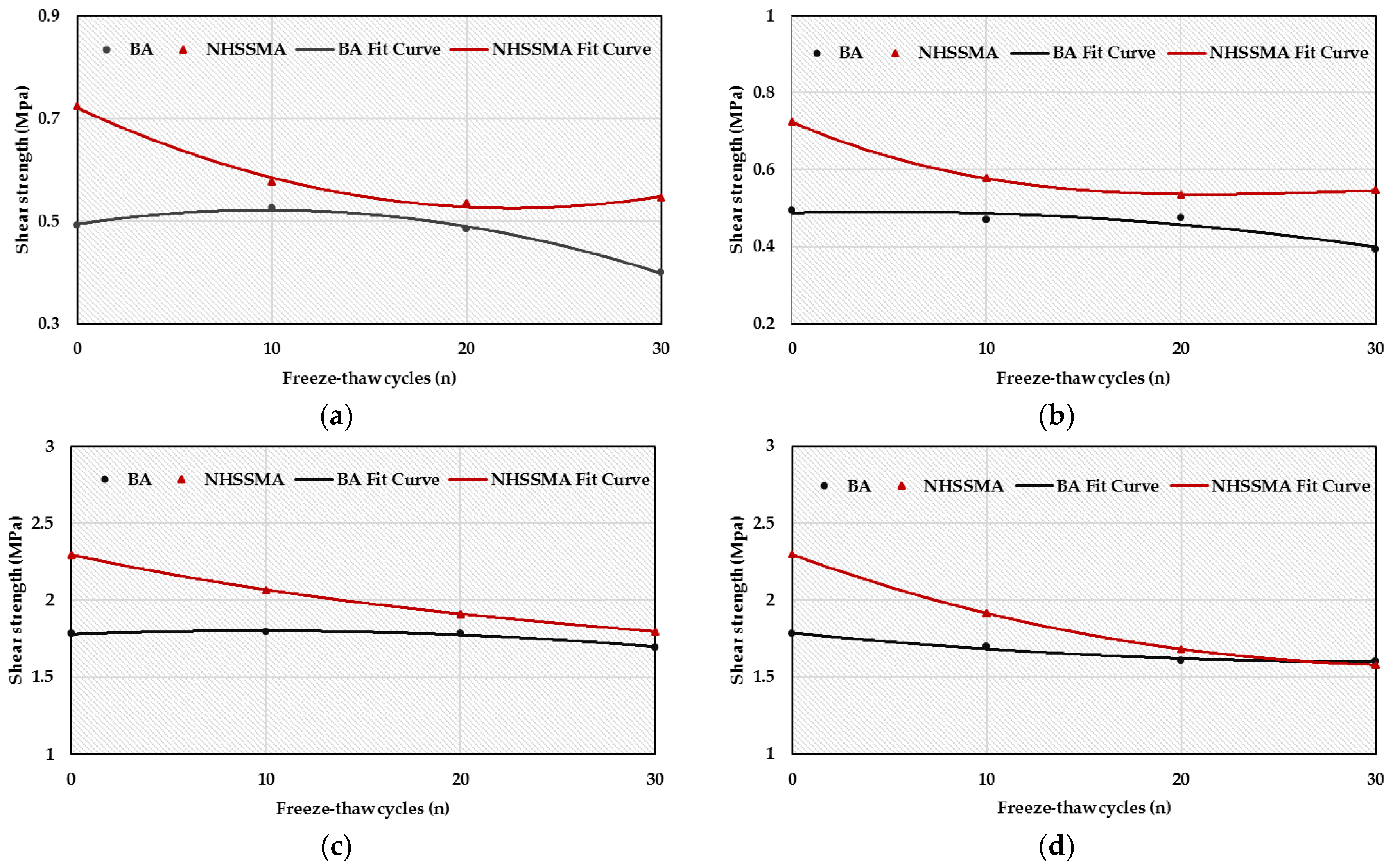

4.3. Effect of Freeze-Thaw Cycles on Aggregate-Bitumen Interface Shear Strength

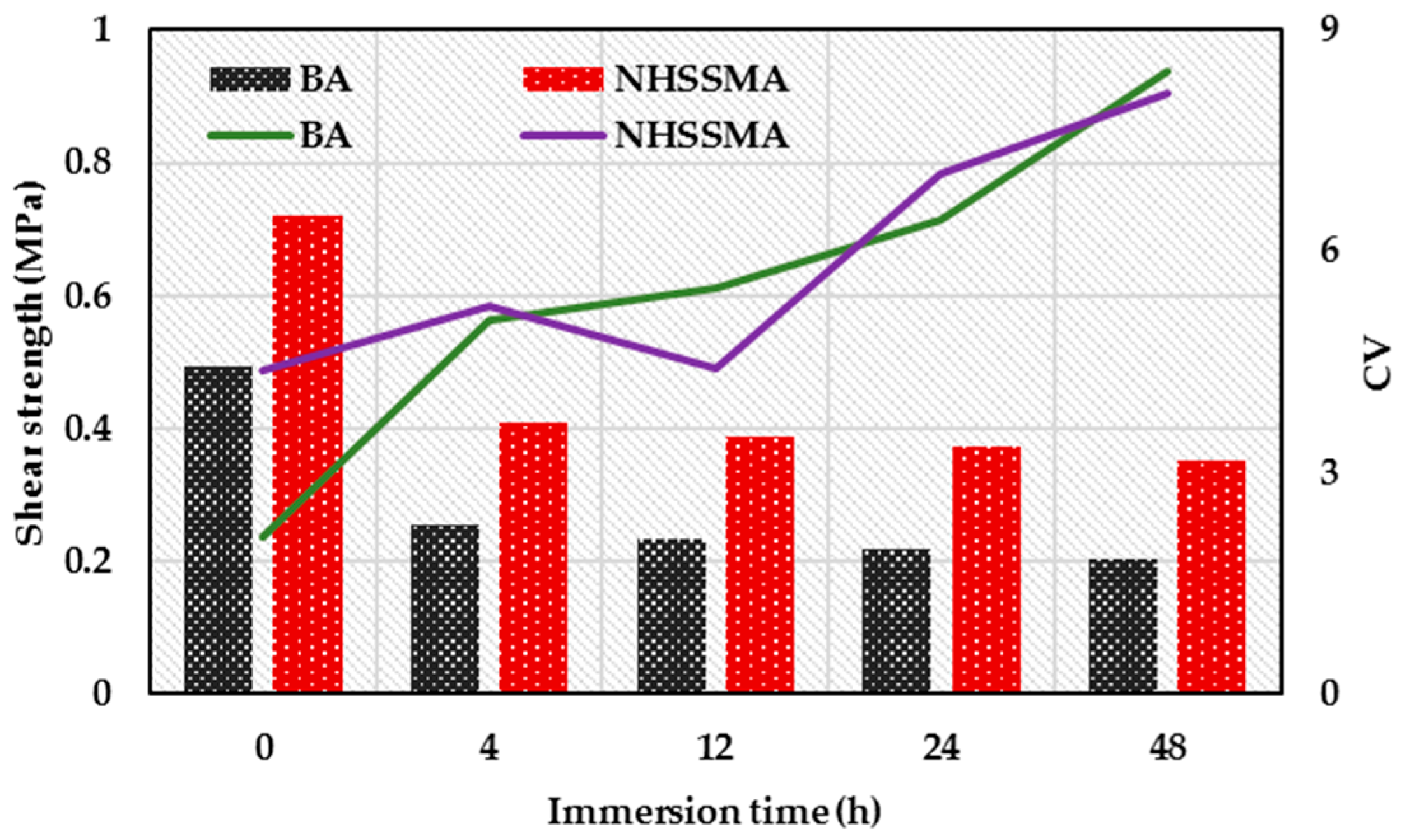

4.4. Effect of Moisture on Aggregate-Bitumen Interface Shear Strength

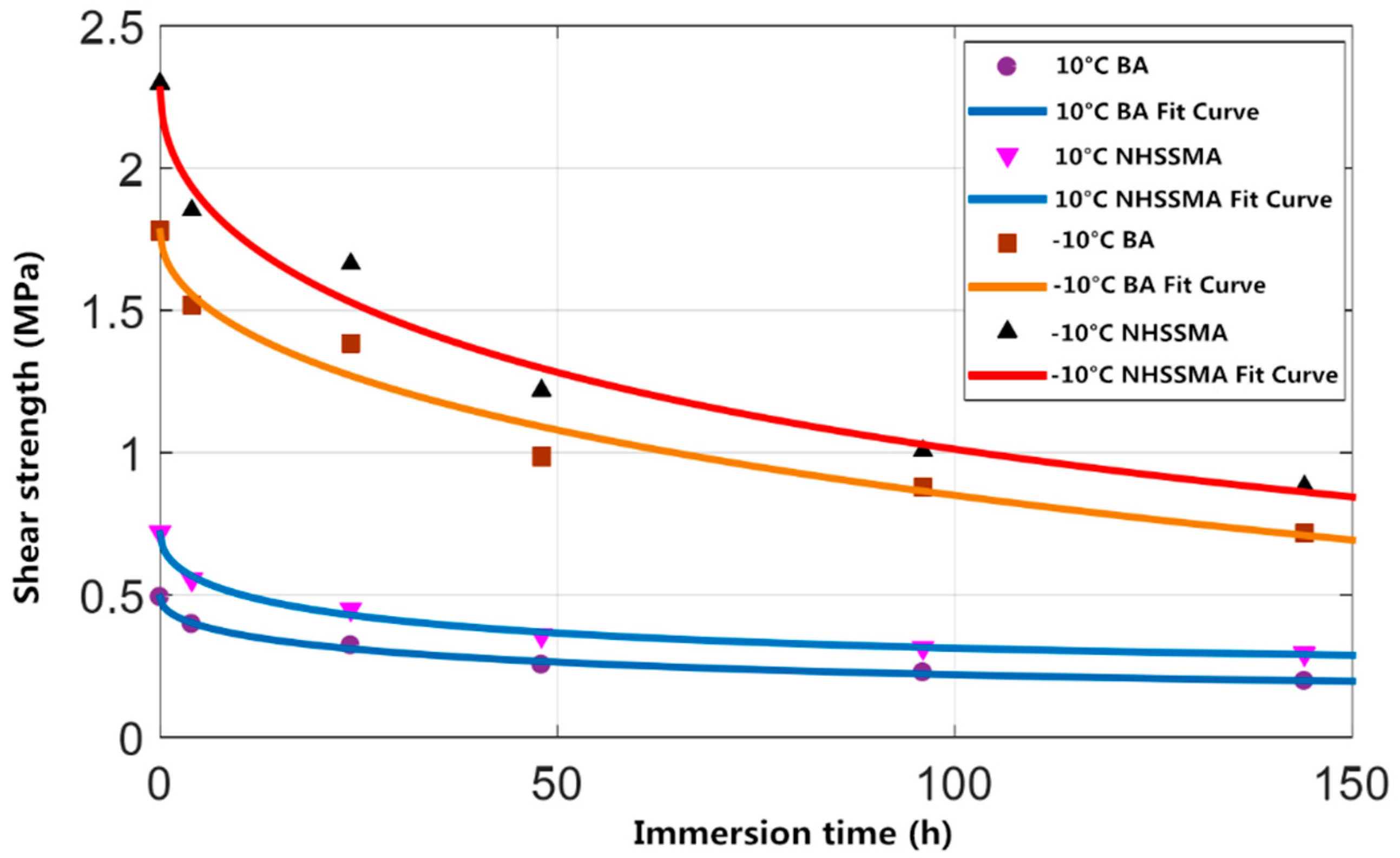

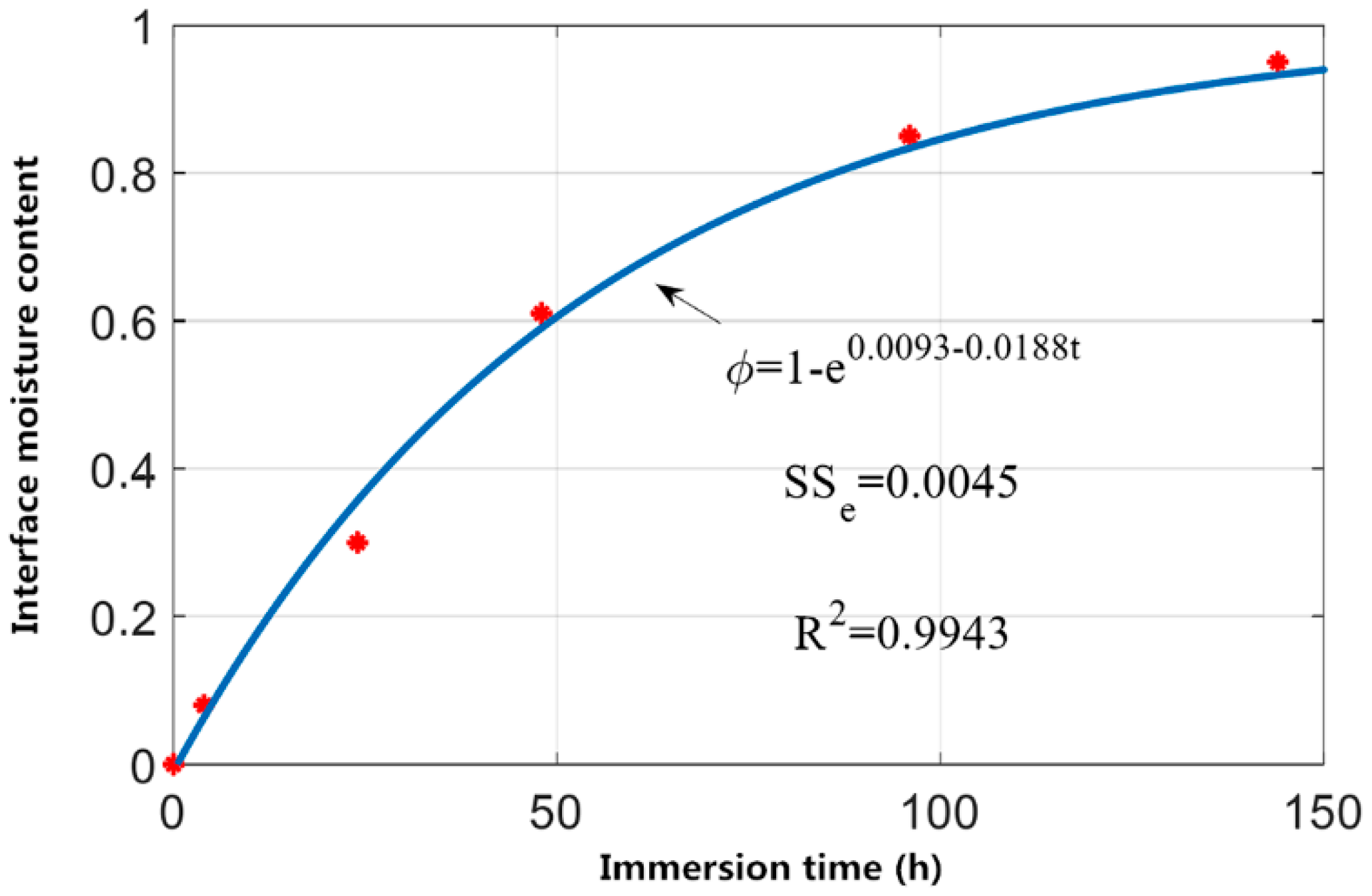

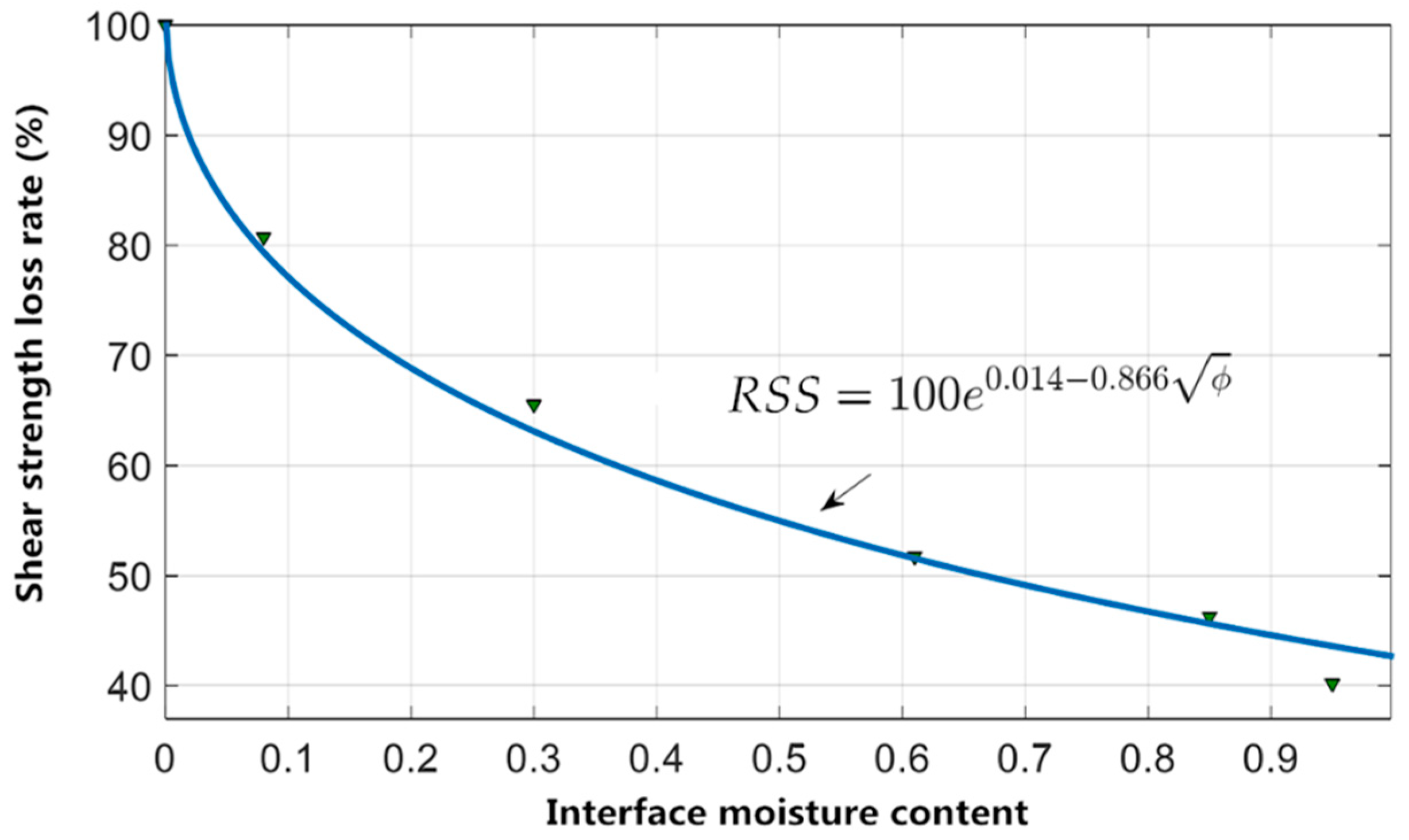

4.5. Establishment of Moisture Damage Model of Aggregate-Bitumen Interface Shear Strength

5. Conclusions

- The aggregate-bitumen interface bond strength test results illustrated that the shear failure dominated the aggregate-bitumen interface bonding failure in the spring-thaw season.

- The aggregate-bitumen interface shear strength test showed that temperature and moisture had a significant effect on interface shear strength of modified and unmodified asphalt. Moreover, the addition of NHSS could increase the aggregate-bitumen interface shear strength under any working conditions.

- Based on a research method combining numerical calculations and laboratory tests, the moisture damage model of aggregate-bitumen interface shear strength of BA and NHSSMA was established. Model parameter a and parameter b could be used to evaluate the moisture damage degree and moisture damage rate of aggregate-bitumen interface shear strength, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, D.; Chen, M.Z.; Wu, S.P.; Riara, M.; Wan, J.M.; Li, Y.Y. Thermal and rheological performance of asphalt binders modified with expanded graphite/polyethylene glycol composite phase change material (EP-CPCM). Constr. Build. Mater. 2019, 194, 83–91. [Google Scholar] [CrossRef]

- El-Hakim, M.; Tighe, S.L. Impact of freeze-thaw cycles on mechanical properties of asphalt mixes. Transp. Res. Rec. 2014, 2444, 20–27. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Rossi, C.O.; Teltayev, B.; Angelico, R. Adhesion promoters in bituminous road materials: A review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Liu, L.H.; Suo, Z.; Zhai, P.; Yang, X.; You, Z.P. Adhesion evaluation of asphalt-aggregate interface using surface free energy method. Appl. Sci. 2017, 7, 156. [Google Scholar] [CrossRef]

- Wang, W.T.; Wang, L.B.; Xiong, H.C.; Luo, R. A review and perspective for research on moisture damage in asphalt pavement induced by dynamic pore water pressure. Constr. Build. Mater. 2019, 204, 631–642. [Google Scholar] [CrossRef]

- Mozaffari, S.; Tchoukov, P.; Atias, J.; Czarnecki, J.; Nazemifard, N. Effect of Asphaltene Aggregation on Rheological Properties of Diluted Athabasca Bitumen. Energy Fuels 2015, 29, 5595–5599. [Google Scholar] [CrossRef]

- Luo, R.; Huang, T.T.; Zhang, D.R.; Lytton, R.L. Water vapor diffusion in asphalt mixtures under different relative humidity differentials. Constr. Build. Mater. 2017, 136, 126–138. [Google Scholar] [CrossRef]

- Molenaar, A.A.A.; Hagos, E.T.; van de Ven, M.F.C. Effects of aging on the mechanical characteristics of bituminous binders in PAC. J. Mater. Civ. Eng. 2010, 22, 779–787. [Google Scholar] [CrossRef]

- Mozaffari, S.; Tchoukova, P.; Mozaffari, A.; Atias, J.; Czarnecki, J.; Nazemifard, N. Capillary driven flow in nanochannels—Application to heavy oil rheology studies. Colloids Surf. A. 2017, 513, 178–187. [Google Scholar] [CrossRef]

- Nian, T.F.; Li, P.; Wei, X.Y.; Wang, P.H.; Li, H.S.; Guo, R. The effect of freeze-thaw cycles on durability properties of SBS-modified bitumen. Constr. Build. Mater. 2018, 187, 77–88. [Google Scholar] [CrossRef]

- Darjani, S.; Koplik, J.; Pauchard, V. Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys. Rev. E 2017, 96, 052803. [Google Scholar] [CrossRef] [PubMed]

- Airey, G.D.; Collop, A.C.; Zoorob, S.E.; Elliott, R.C. The influence of aggregate, filler and bitumen on asphalt mixture moisture damage. Constr. Build. Mater. 2008, 22, 2015–2024. [Google Scholar] [CrossRef]

- Wang, H.; Li, E.Q.; Xu, G.J. Molecular dynamics simulation of asphalt-aggregate interface adhesion strength with moisture effect. Int. J. Pavement Eng. 2017, 18, 414–423. [Google Scholar] [CrossRef]

- Cucalon, L.G.; Bhasin, A.; Kassem, E.; Little, D.; Herbert, B.E.; Masad, E. Physicochemical characterization of binder-aggregate adhesion varying with temperature and moisture. J. Transp. Eng. Part B Pavement. 2017, 143, 04017007. [Google Scholar] [CrossRef]

- Berdahl, P.; Akbari, H.; Levinson, R. Weathering of roofing materials—An overview. Constr. Build. Mater. 2008, 22, 423–433. [Google Scholar] [CrossRef]

- Liu, F.; Darjani, S.; Akhmetkhanova, N.; Maldarelli, C.; Banerjee, S.; Pauchard, V. Mixture Effect on the Dilatation Rheology of Asphaltenes-Laden Interfaces. Langmuir 2017, 33, 1927–1942. [Google Scholar] [CrossRef]

- Lin, Y.M.; Hu, C.C.; Adhikari, S.; Wu, C.H.; Yu, M. Evaluation of Waste Express Bag as a Novel Bitumen Modifier. Appl. Sci. 2019, 9, 1242. [Google Scholar] [CrossRef]

- Kok, B.V.; Yilmaz, M. The effects of using lime and styrene-butadiene-styrene on moisture sensitivity resistance of hot mix asphalt. Constr. Build. Mater. 2009, 23, 1999–2006. [Google Scholar] [CrossRef]

- Sengoz, B.; Agar, E. Effect of asphalt film thickness on the moisture sensitivity characteristics of hot-mix asphalt. Build. Sci. 2007, 42, 3621–3628. [Google Scholar] [CrossRef]

- Yang, X.L.; Shen, A.Q.; Guo, Y.C.; Zhou, S.B.; He, T.Q. Deterioration mechanism of interface transition zone of concrete pavement under fatigue load and freeze-thaw coupling in cold climatic areas. Constr. Build. Mater. 2018, 160, 588–597. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D. Moisture susceptibility of asphalt mixtures, Part 1: Mechanisms. Int. J. Pavement Eng. 2008, 9, 81–98. [Google Scholar] [CrossRef]

- Preeda, C.; Hussain, U.B. Effect of moisture on the cohesion of asphalt mastics and bonding with surface of aggregates. Road Mater. Pavement Des. 2018, 19, 741–753. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Observation of reversible moisture damage in asphalt mixtures. Constr. Build. Mater. 2014, 60, 73–80. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Airey, G.D.; Grenfell, J.; Apeagyei, A.K. Moisture damage evaluation of aggregate-bitumen bonds with the respect of moisture absorption, tensile strength and failure surface. Road Mater. Pavement Des. 2017, 18, 833–848. [Google Scholar] [CrossRef]

- Cho, D.W.; Kim, K. The mechanisms of moisture damage in asphalt pavement by applying chemistry aspects. KSCE J. Civil Eng. 2010, 14, 333–341. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D. Micromechanical modeling of the influence of material properties on moisture-induced damage in asphalt mixtures. Constr. Build. Mater. 2010, 24, 1184–1192. [Google Scholar] [CrossRef]

- Moraes, R.; Velasquez, R.; Bahia, H.U. Measuring the effect of moisture on asphalt-aggregate bond with the bitumen bond strength test. Transp. Res. Rec. 2011, 2209, 70–81. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.L.; You, Z.P. Chemo-physical analysis and molecular dynamics (MD) simulation of moisture susceptibility of nano hydrated lime modified asphalt mixtures. Constr. Build. Mater. 2015, 101, 536–547. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Zaman, A.M. Nanoscale evaluation of moisture damage in polymer modified asphalts. J. Mater. Civ. Eng. 2010, 22, 714–725. [Google Scholar] [CrossRef]

- Rossi, C.O.; Ashimova, S.; Calandra, P.; De Santo, M.P.; Angelico, R. Mechanical resilience of modified bitumen at different cooling rates: A rheological and atomic force microscopy investigation. Appl. Sci. 2017, 7, 779. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Breem, A.A.S.; Alattug, H.N.M.; Hamim, A.; Ahmad, J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- Gorkem, C.; Sengoz, B. Predicting stripping and moisture induced damage of asphalt concrete prepared with polymer modified bitumen and hydrated lime. Constr. Build. Mater. 2009, 23, 2227–2236. [Google Scholar] [CrossRef]

- Palit, S.K.; Reddy, K.S.; Pandey, B.B. Laboratory evaluation of crumb rubber modified asphalt mixes. J. Mater. Civ. Eng. 2004, 16, 45–53. [Google Scholar] [CrossRef]

- Goh, S.W.; Akin, M.; You, Z.P.; Shi, X.M. Effect of deicing solutions on the tensile strength of micro- or nano-modified asphalt mixture. Constr. Build. Mater. 2011, 25, 195–200. [Google Scholar] [CrossRef]

- Mozaffari, S.; Li, W.H.; Thompson, C.; Ivanov, S.; Seifert, S.; Lee, B.; Kovarik, L.; Karim, A.M. Colloidal nanoparticle size control: Experimental and kinetic modeling investigation of the ligand metal binding role in controlling the nucleation and growth kinetics. Nanoscale 2017, 9, 13772–13785. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.D.; Sun, M.Z.; Dai, W.T. Evaluation of the durability and the property of an asphalt concrete with nano hydrophobic silane silica in spring-thawing season. Appl. Sci. 2018, 8, 1475. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.D.; Chang, M.Y.; Dai, W.T. Evaluating the effect of hydrophobic nanosilica on the viscoelasticity property of asphalt and asphalt mixture. Materials 2018, 11, 2328. [Google Scholar] [CrossRef] [PubMed]

| Technical Parameters | Penetration (0.1 mm) | 25 °C Ductility (cm) | Softening Point (°C) | Flash Point (°C) | Solubility (%) | Density (g·cm−3) | ||

|---|---|---|---|---|---|---|---|---|

| 15 °C | 25 °C | 30 °C | ||||||

| Test results | 25.3 | 86.9 | 142.4 | >130 | 44.6 | 340 | 99.9 | 1.003 |

| Test procedure | GB/T0606-2011 | GB/T0605-2011 | GB/T0606-2011 | GB/T0611-2011 | GB/T0607-2011 | GB/T0603-2011 | ||

| Technical Parameters | Water Characteristics | BET (m2/g) | Average Particle Size (nm) | PH Value | SiO2 Content (%) |

|---|---|---|---|---|---|

| Test results | Hydrophobia | 125 ± 20 | 12 | 5.0–8.0 | ≥99.8 |

| Standard values | ------ | 130 ± 30 | ≤20 | 3.7–6.5 | ≥99.8 |

| Test procedure | GB/T20020 | GB/T20020 | GB/T20020 | GB/T20020 | GB/T20020 |

| Technical Parameters | Penetration | 10 °C Ductility | Softening Point | PI Value | 135 °C Rotational Viscosity | ||

|---|---|---|---|---|---|---|---|

| 15 °C | 25 °C | 30 °C | |||||

| Units | 0.1 mm | mm | °C | - | mpa | ||

| Test results | 20.8 | 64.1 | 115 | 233 | 48.1 | −1.357 | 912.1 |

| Asphalt Category | Test Temperature | Regression Equation | Equation Parameters | SSe | R2 | ||

|---|---|---|---|---|---|---|---|

| a | b | c | |||||

| BA | 10 °C | 0.193 | 0.276 | 0.721 | 0.0001 | 0.99 | |

| BA | −10 °C | 2.806 | 0.066 | 14.71 | 0.03 | 0.96 | |

| NHSSMA | 10 °C | −0.221 | 0.764 | 0.084 | 0.0001 | 0.99 | |

| NHSSMA | −10 °C | 3.897 | 0.029 | 46.94 | 0.023 | 0.98 | |

| Asphalt Category | Test Temperature | Regression Equation | Equation Parameters | SSe | R2 | |

|---|---|---|---|---|---|---|

| a | b | |||||

| BA | 10 °C | R | 0.014 | 0.866 | 21.85 | 0.99 |

| BA | −10 °C | 0.039 | 0.791 | 189.2 | 0.93 | |

| NHSSMA | 10 °C | 0.0008 | 0.899 | 3.035 | 0.99 | |

| NHSSMA | −10 °C | 0.025 | 0.866 | 118.8 | 0.95 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, W.; Guo, X.; Li, J.; Li, Y.; Sun, M.; Dai, W. Assessing the Effect of Nano Hydrophobic Silane Silica on Aggregate-Bitumen Interface Bond Strength in the Spring-Thaw Season. Appl. Sci. 2019, 9, 2393. https://doi.org/10.3390/app9122393

Guo W, Guo X, Li J, Li Y, Sun M, Dai W. Assessing the Effect of Nano Hydrophobic Silane Silica on Aggregate-Bitumen Interface Bond Strength in the Spring-Thaw Season. Applied Sciences. 2019; 9(12):2393. https://doi.org/10.3390/app9122393

Chicago/Turabian StyleGuo, Wei, Xuedong Guo, Jilu Li, Yingsong Li, Mingzhi Sun, and Wenting Dai. 2019. "Assessing the Effect of Nano Hydrophobic Silane Silica on Aggregate-Bitumen Interface Bond Strength in the Spring-Thaw Season" Applied Sciences 9, no. 12: 2393. https://doi.org/10.3390/app9122393

APA StyleGuo, W., Guo, X., Li, J., Li, Y., Sun, M., & Dai, W. (2019). Assessing the Effect of Nano Hydrophobic Silane Silica on Aggregate-Bitumen Interface Bond Strength in the Spring-Thaw Season. Applied Sciences, 9(12), 2393. https://doi.org/10.3390/app9122393