RBF Neural Network Based Backstepping Control for an Electrohydraulic Elastic Manipulator

Abstract

1. Introduction

- (1)

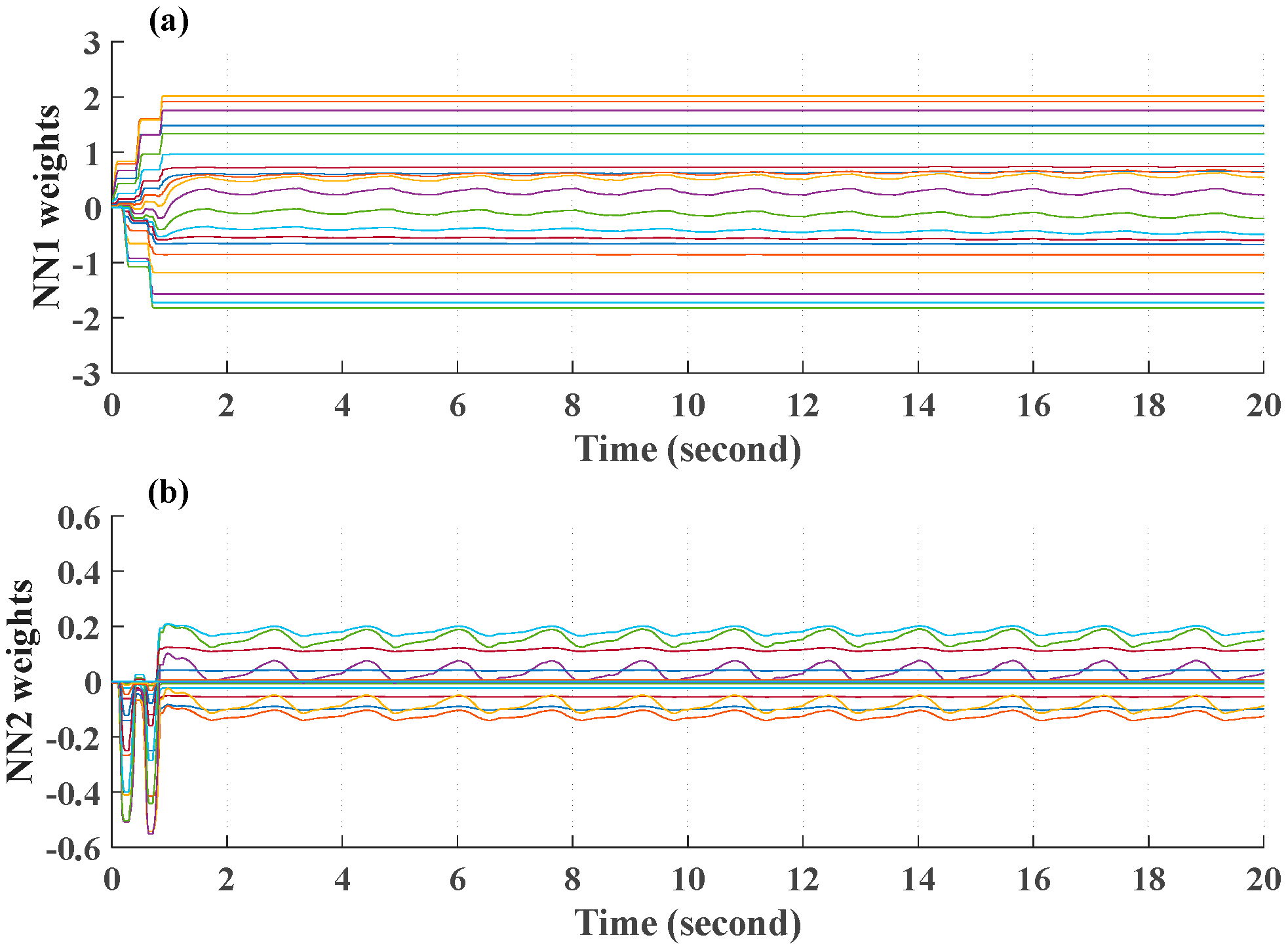

- The RBFNN is provided to approximate the uncertainties in both the hydraulic and mechanical dynamics of the EEM system. Especially, the learning laws of the weighting vector in the RBFNNs are produced by the Lyapunov approach and the project algorithm to improve the robustness of the learning laws.

- (2)

- The Lyapunov approach and the backstepping technique are used to prove the stability of the control system with the presence of matched and unmatched uncertainties.

- (3)

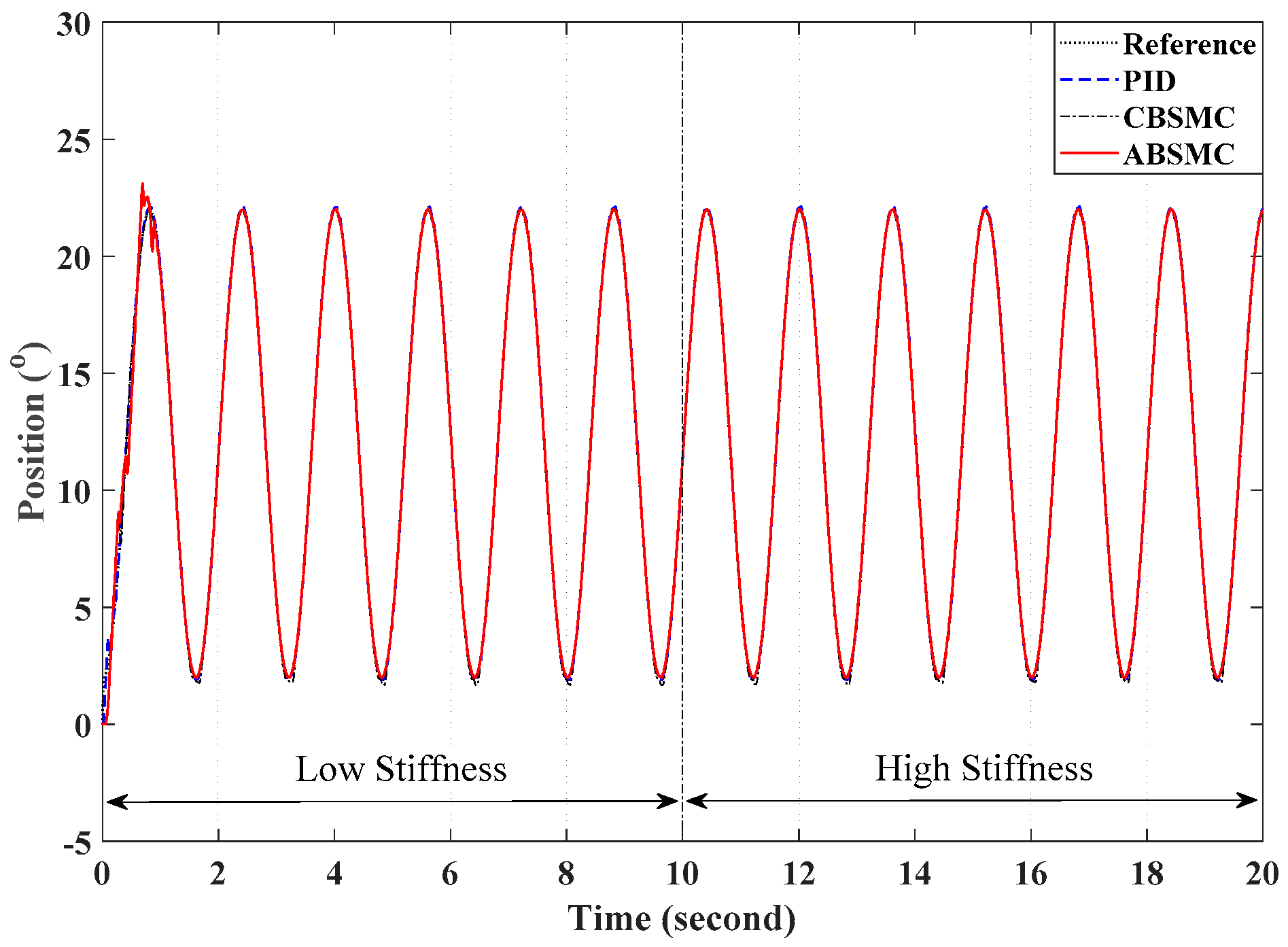

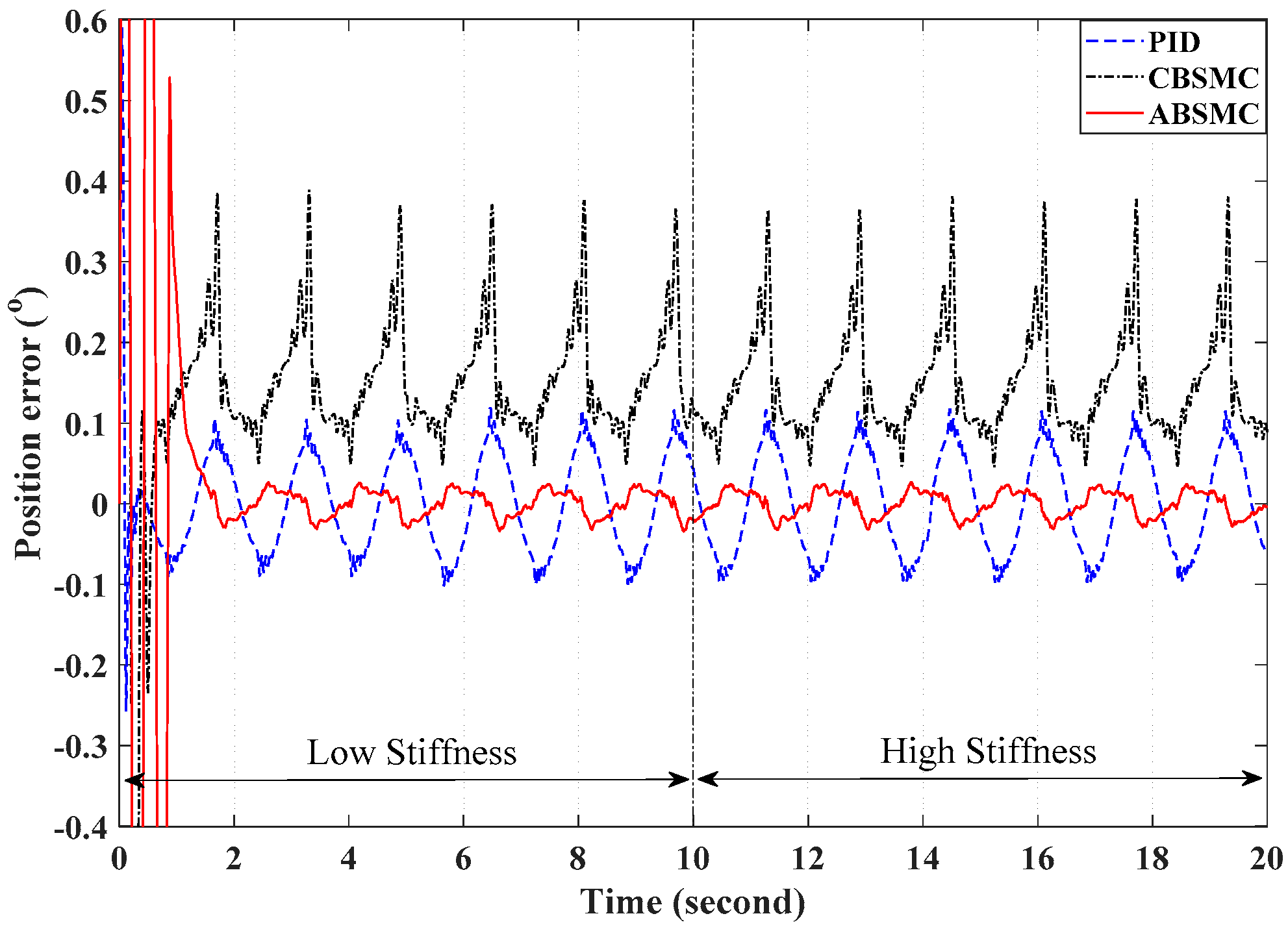

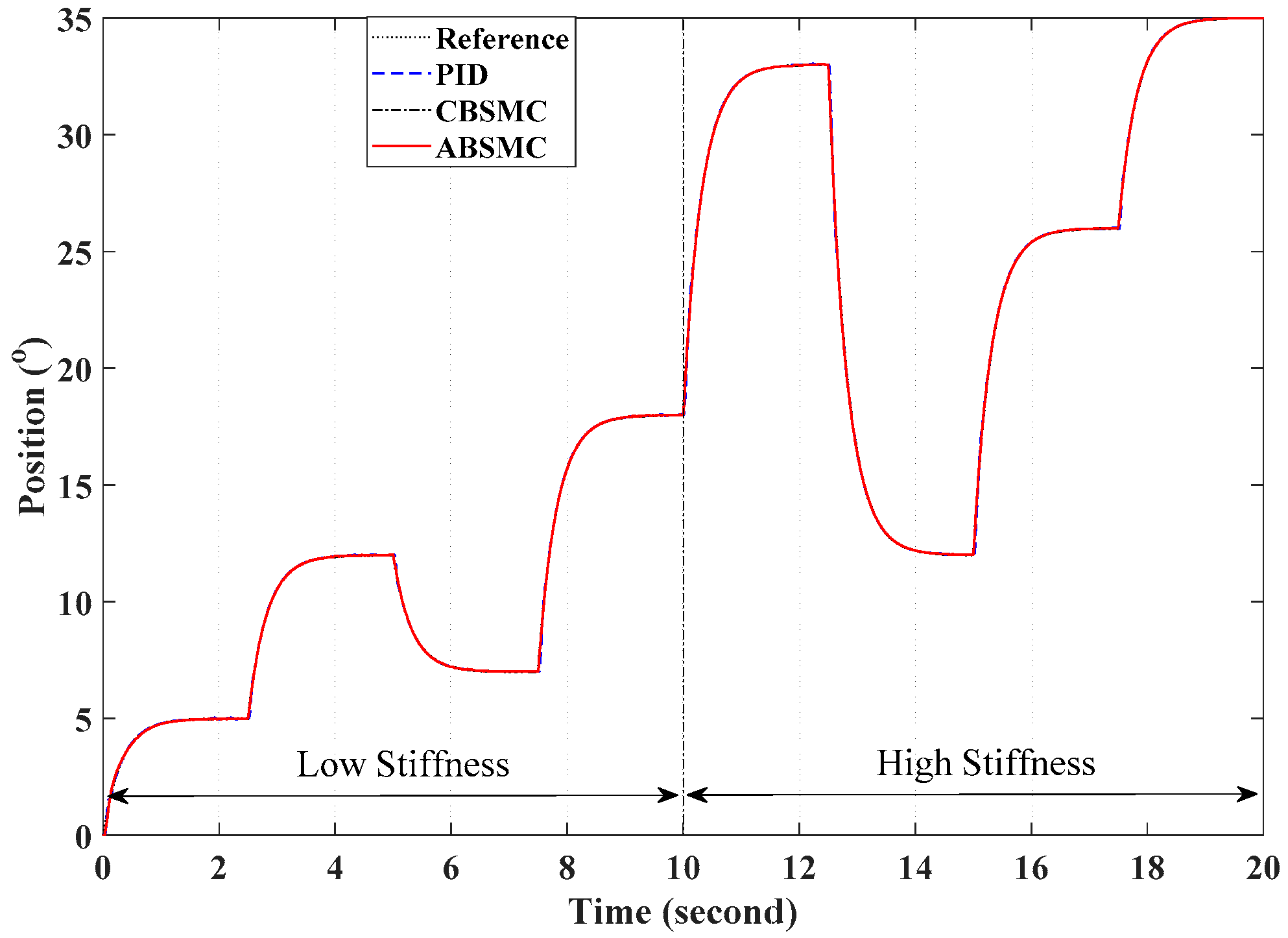

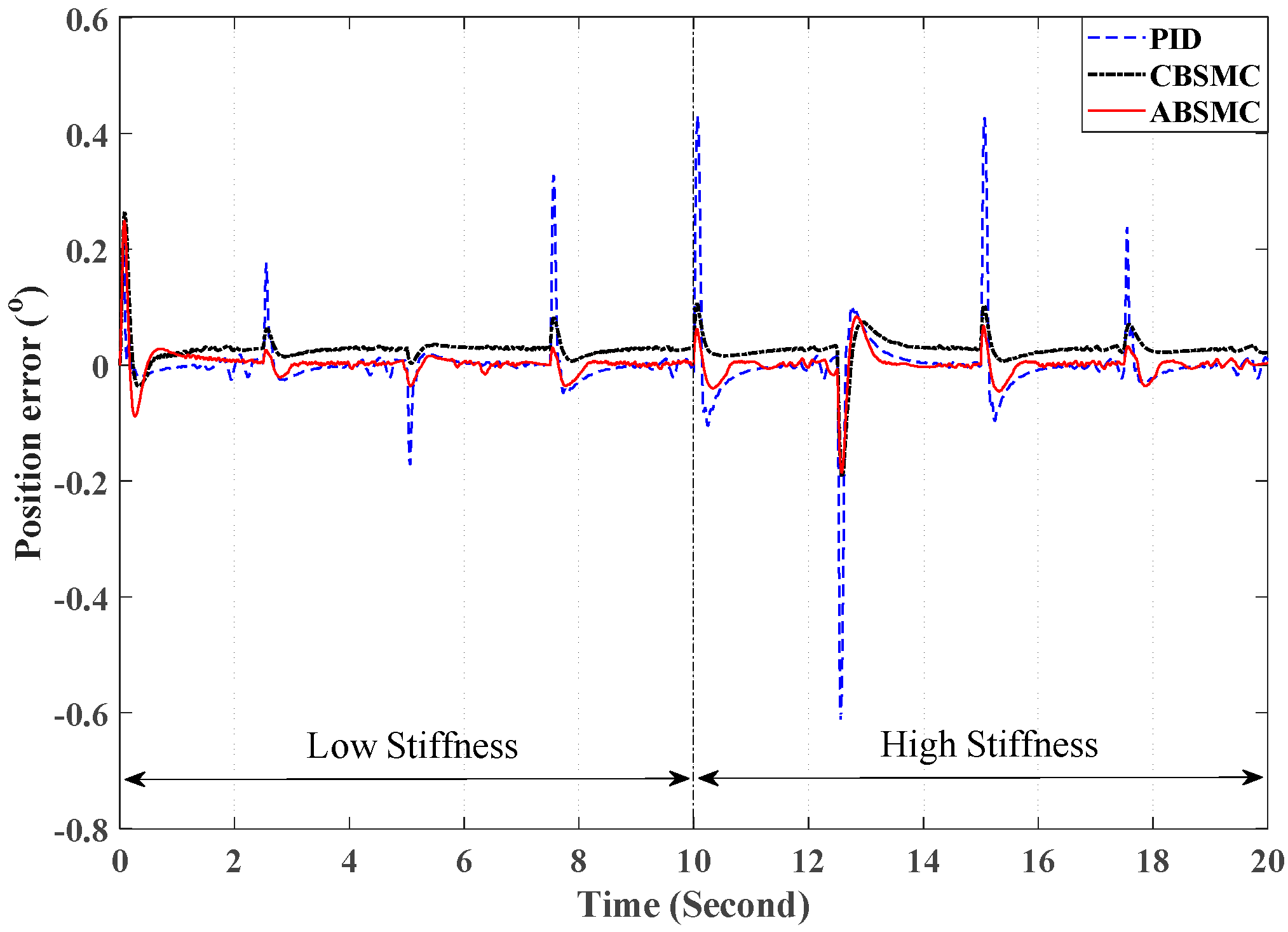

- Some experiments are implemented on the real test rig, and the results are compared to the Proportional integral derivative (PID) control and the conventional backstepping sliding mode control (CBSMC) to verify the effectiveness of the proposed control with the variant stiffness.

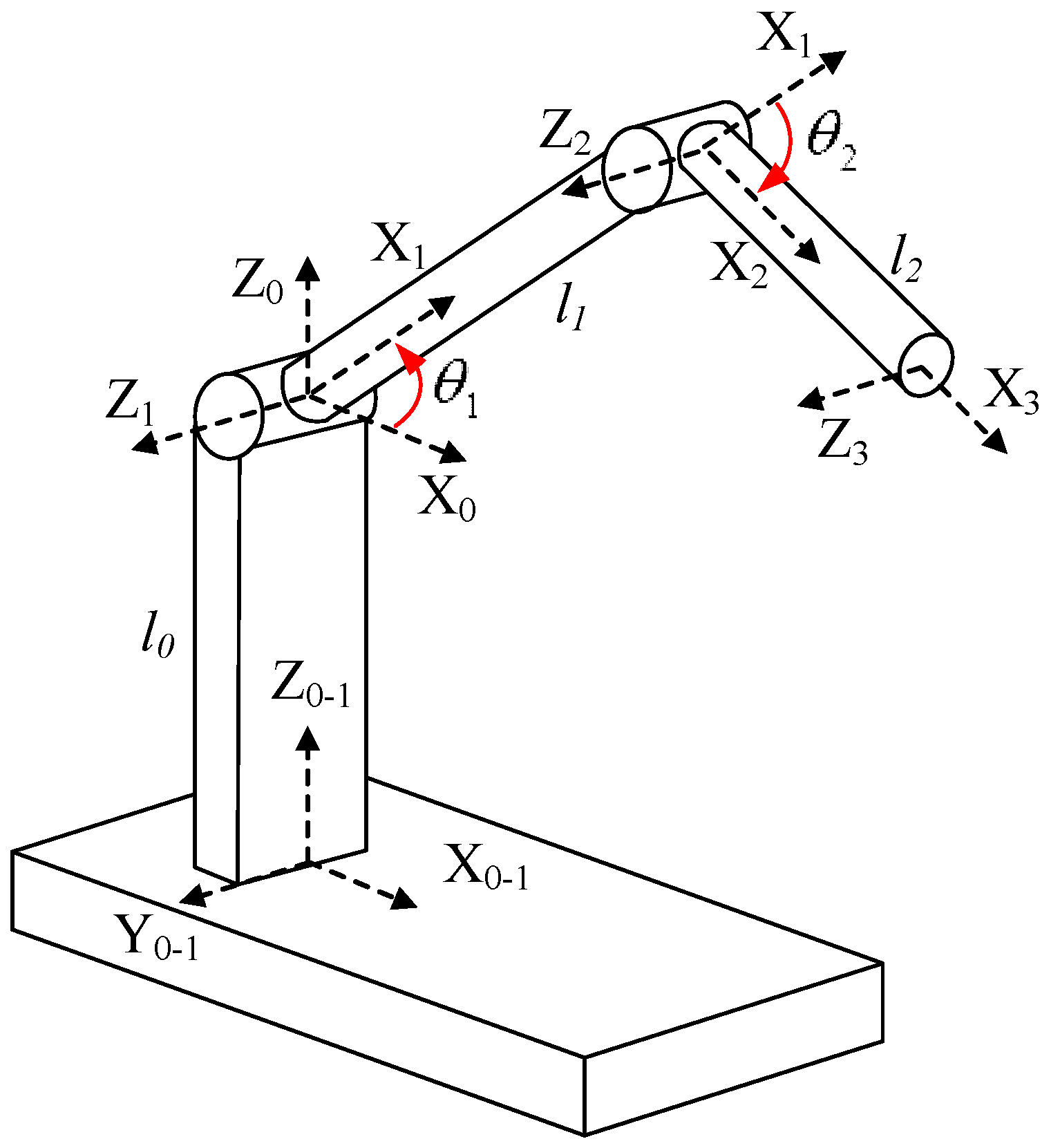

2. Electrohydraulic Elastic Manipulator Dynamics

2.1. Dynamics of the Electrohydraulic Servo System

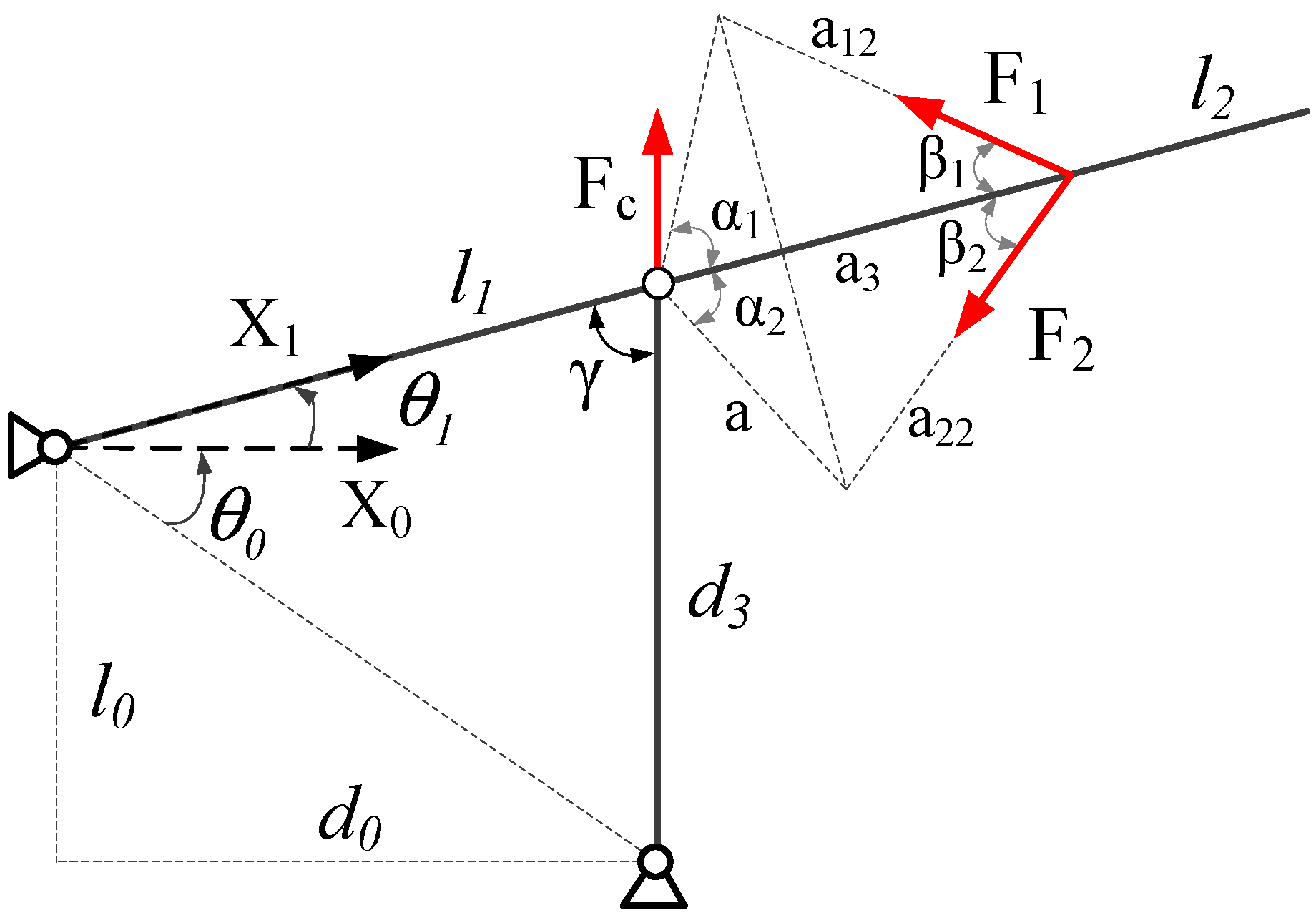

2.2. Mechanical Dynamics

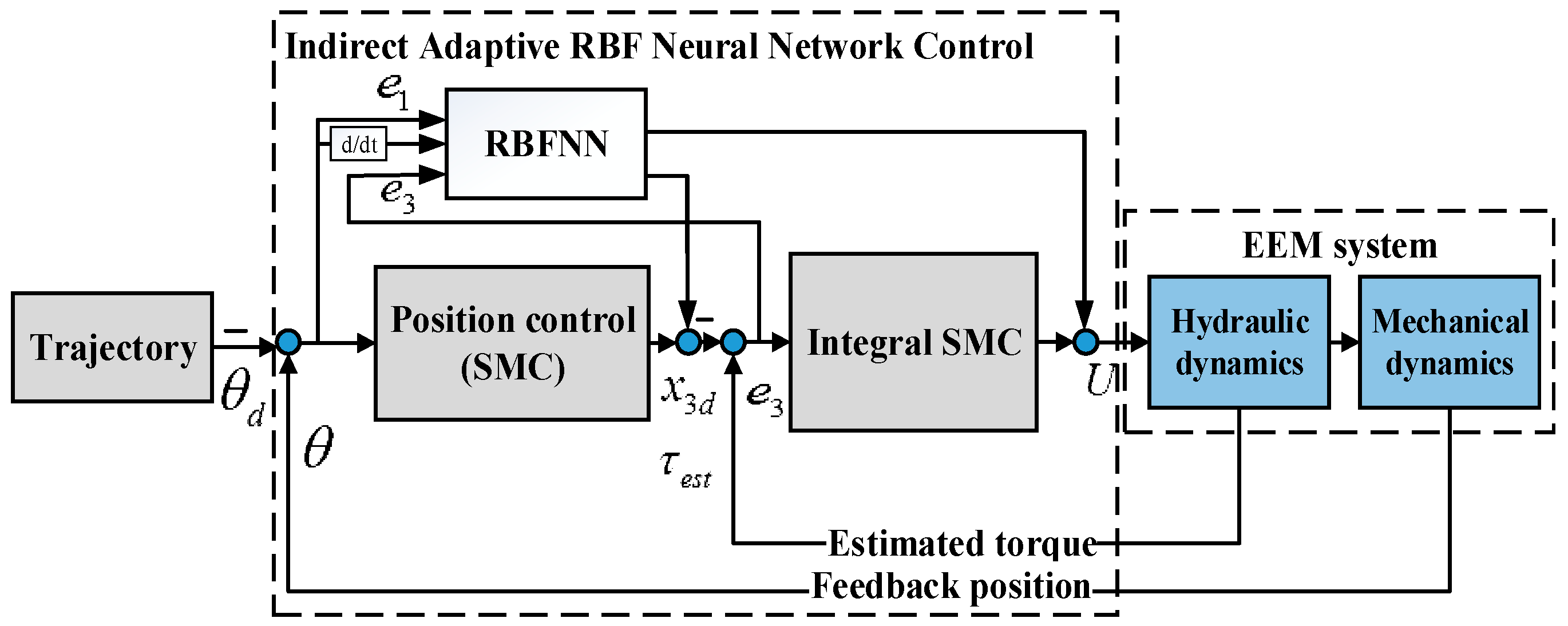

3. Control Design

3.1. Backstepping Sliding Mode Control

3.2. Adaptive Backstepping Control Based RBFNN

3.2.1. Adaptive Approximation via RBFNN

3.2.2. Proposed Control

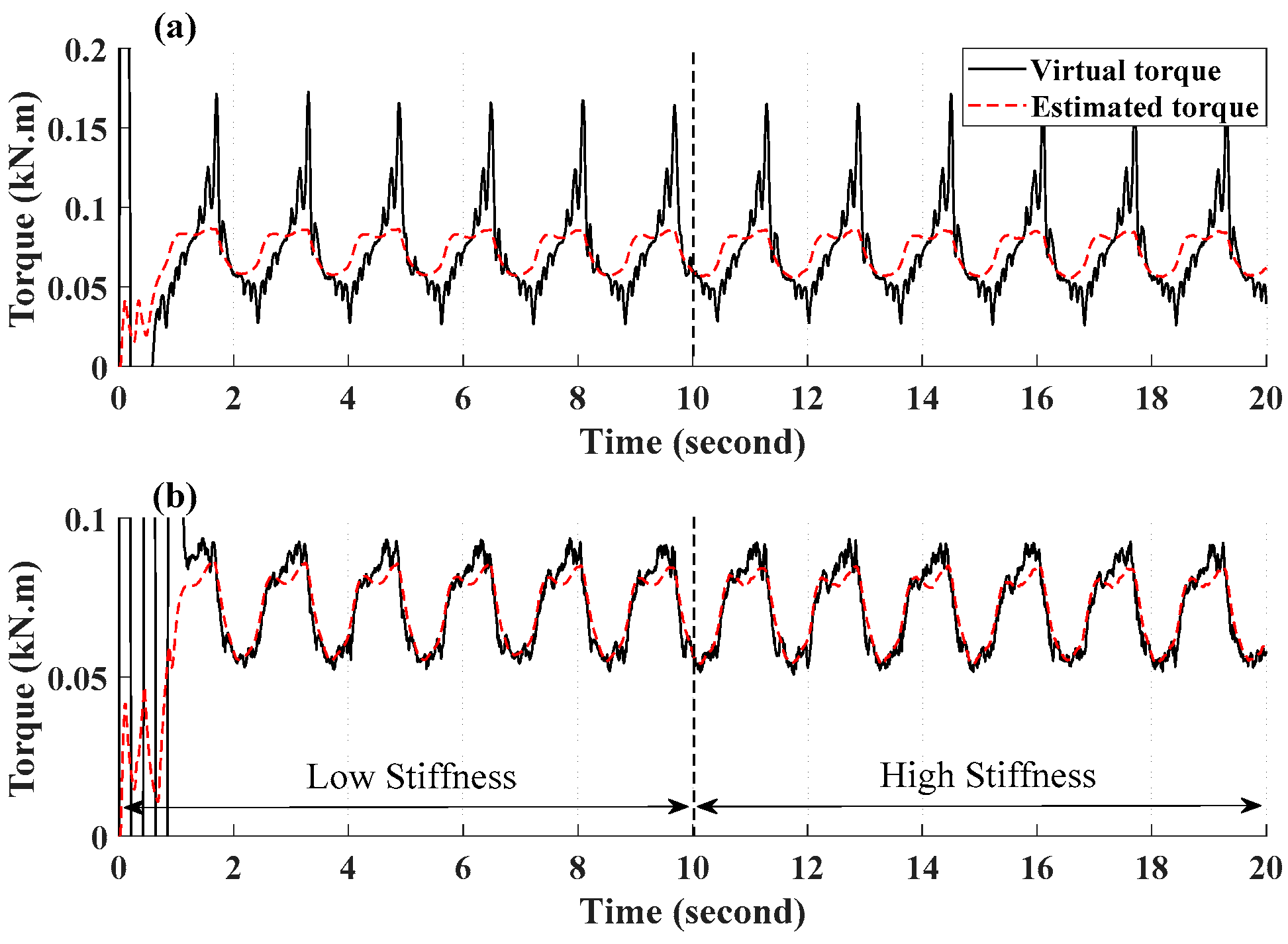

4. Experimental Results

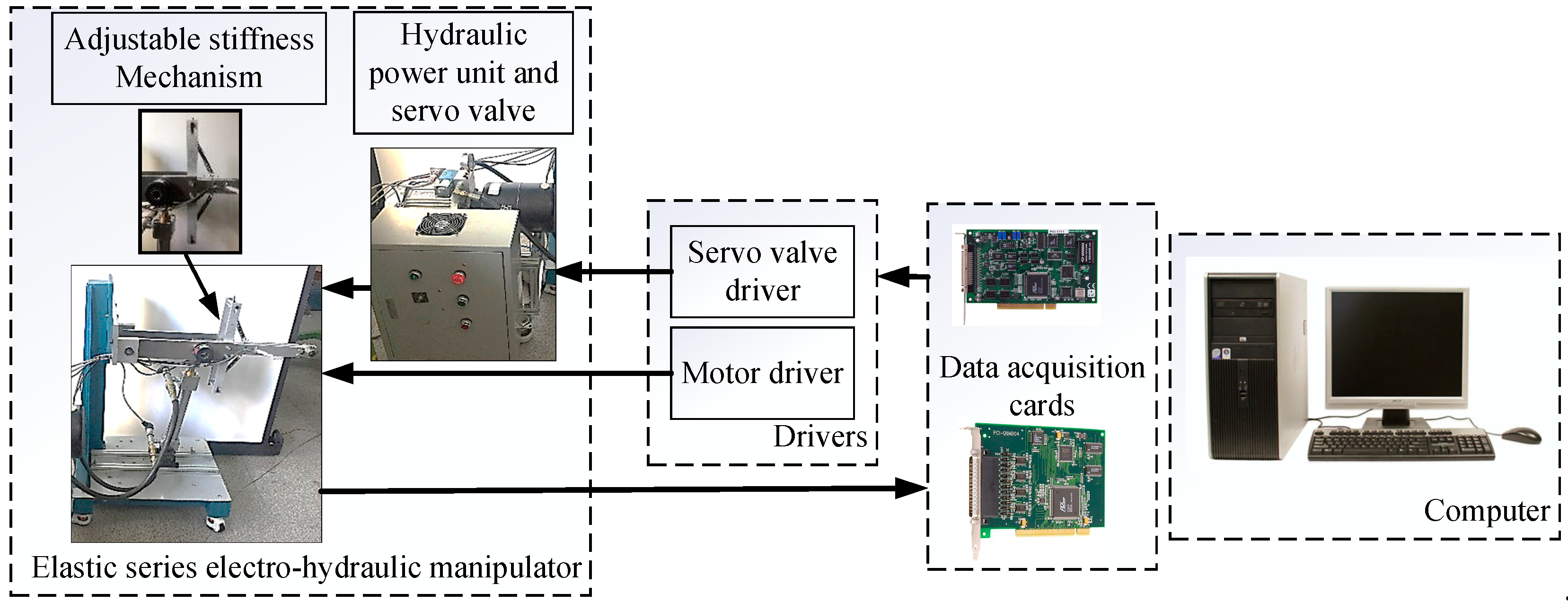

4.1. Electrohydraulic System Description

4.2. Performance Indexes

4.3. The Experimental Procedures

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

References

- Grioli, G.; Wolf, S.; Garabini, M.; Catalano, M.G.; Burdet, E.; Caldwell, D.G.; Carloni, R.; Friedl, W.; Grebenstein, M.; Laffranchi, M.; et al. Variable stiffness actuators: The user’s point of view. Int. J. Robot. Res. 2015, 34, 727–743. [Google Scholar] [CrossRef]

- Wolf, S.; Grioli, G.; Friedl, W.; Grebenstein, M.; Hoeppner, H.; Burdet, E.; Caldwell, D.; Bicchi, A.; Stramigioli, S.; VanderBorght, B. Variable Stiffness Actuators: Review on Design and Components. IEEE/ASME Trans. Mech. 2016, 21, 2418–2430. [Google Scholar] [CrossRef]

- Haddadin, S.; Laue, T.; Frese, U.; Wolf, S.; Albu-Schäffer, A.; Hirzinger, G. Kick it with elasticity: Safety and performance in human–robot soccer. Robot. Auton. Syst. 2009, 57, 761–775. [Google Scholar] [CrossRef]

- Jeong, H.; Cheong, J.; Kwon, S. Dual-mode variable stiffness actuator using two-stage worm gear transmission for safe robotic manipulators. Int. J. Precis. Eng. Manuf. 2015, 16, 1761–1769. [Google Scholar] [CrossRef]

- Hoang, K.-D.; Ahn, H.-J. A Passive RFC (Reaction Force Compensation) Mechanism Using Adjustable Piecewise Linear Stiffness of Pre-Compressed Springs. Int. J. Precis. Eng. Manuf. 2018, 19, 1317–1322. [Google Scholar] [CrossRef]

- Ham, K.; Han, J.; Park, Y.-J. Soft Gripper using Variable Stiffness Mechanism and Its Application. Int. J. Precis. Eng. Manuf. 2018, 19, 487–494. [Google Scholar] [CrossRef]

- Huh, T.M.; Park, Y.-J.; Cho, K.-J. Design and analysis of a stiffness adjustable structure using an endoskeleton. Int. J. Precis. Eng. Manuf. 2012, 7, 1255–1258. [Google Scholar] [CrossRef]

- Jafari, A.; Tsagarakis, N.G.; Caldwell, D.G. Exploiting natural dynamics for energy minimization using an Actuator with Adjustable Stiffness (AwAS). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 4632–4637. [Google Scholar]

- Kim, N.-H.; Kim, J.-M.; Khatib, O.; Shin, D. Design optimization of hybrid actuation combining macro-mini actuators. Int. J. Precis. Eng. Manuf. 2017, 18, 519–527. [Google Scholar] [CrossRef]

- Manring, N. Hydraulic Control Systems; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Slotine, J.-J.E.; Li, W. Applied Nonlinear Control; no. 1; Prentice Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Baek, J.; Jin, M.; Han, S. A New Adaptive Sliding-Mode Control Scheme for Application to Robot Manipulators. IEEE Trans. Ind. Electron. 2016, 63, 3628–3637. [Google Scholar] [CrossRef]

- Lopez-Santos, O.; Martinez-Salamero, L.; Garcia, G.; Valderrama-Blavi, H.; Sierra-Polanco, T. Robust Sliding-Mode Control Design for a Voltage Regulated Quadratic Boost Converter. IEEE Trans. Power Electron. 2015, 30, 2313–2327. [Google Scholar] [CrossRef]

- Jin, M.; Lee, J.; Ahn, K.K. Continuous Nonsingular Terminal Sliding-Mode Control of Shape Memory Alloy Actuators Using Time Delay Estimation. IEEE/ASME Trans. Mechatron. 2015, 20, 899–909. [Google Scholar] [CrossRef]

- Shi, S.; Li, J.; Fang, Y. Extended-State-Observer-Based Chattering Free Sliding Mode Control for Nonlinear Systems With Mismatched Disturbance. IEEE Access 2018, 6, 22952–22957. [Google Scholar] [CrossRef]

- Perruquetti, W.; Barbot, J.-P. Sliding Mode Control in Engineering; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Huang, Y.J.; Kuo, T.C.; Chang, S.H. Adaptive Sliding-Mode Control for NonlinearSystems With Uncertain Parameters. IEEE Trans. Syst. Man Cybern. Part B 2008, 38, 534–539. [Google Scholar] [CrossRef]

- Ahn, K.K.; Nam, D.N.C.; Jin, M. Adaptive Backstepping Control of an Electrohydraulic Actuator. IEEE/ASME Trans. Mechatron. 2014, 19, 987–995. [Google Scholar] [CrossRef]

- Tri, N.M.; Nam, D.N.C.; Park, H.G.; Ahn, K.K. Trajectory control of an electro hydraulic actuator using an iterative backstepping control scheme. Mechatronics 2015, 29, 96–102. [Google Scholar] [CrossRef]

- Wang, T.; Fei, J. Adaptive Neural Control of Active Power Filter Using Fuzzy Sliding Mode Controller. IEEE Access 2016, 4, 6816–6822. [Google Scholar] [CrossRef]

- Liu, N.; Fei, J. Adaptive Fractional Sliding Mode Control of Active Power Filter Based on Dual RBF Neural Networks. IEEE Access 2017, 5, 27590–27598. [Google Scholar] [CrossRef]

- Dinh, T.X.; Ahn, K.K. Radial basis function neural network based adaptive fast nonsingular terminal sliding mode controller for piezo positioning stage. Int. J. Control Autom. Syst. 2017, 15, 2892–2905. [Google Scholar] [CrossRef]

- Tuan, L.A.; Joo, Y.H.; Tien, L.Q.; Duong, P.X. Adaptive neural network second-order sliding mode control of dual arm robots. Int. J. Control Autom. Syst. 2017, 15, 2883–2891. [Google Scholar] [CrossRef]

- Farrell, J.A.; Polycarpou, M.M. Adaptive Approximation Based Control: Unifying Neural, Fuzzy and Traditional Adaptive Approximation Approaches; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Krstic, M.; Kanellakopoulos, I.; Kokotovic, P.V. Nonlinear and Adaptive Control Design; Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Merritt, H.E. Hydraulic Control Systems; John Wiley & Sons: Hoboken, NJ, USA, 1967. [Google Scholar]

- Oh, S.; Kong, K. Two-Degree-of-Freedom Control of a Two-Link Manipulator in the Rotating Coordinate System. IEEE Trans. Ind. Electron. 2015, 62, 5598–5607. [Google Scholar] [CrossRef]

- Olsson, H.; Åström, K.J.; Canudas de Wit, C.; Gäfvert, M.; Lischinsky, P. Friction Models and Friction Compensation. Eur. J. Control 1998, 4, 176–195. [Google Scholar] [CrossRef]

- Khalil, H.K. Noninear Systems; no. 5; Prentice Hall: Englewood Cliffs, NJ, USA, 1996; Volume 2, p. 748. [Google Scholar]

- Wai, R.J.; Muthusamy, R. Design of Fuzzy-Neural-Network-Inherited Backstepping Control for Robot Manipulator Including Actuator Dynamics. IEEE Trans. Fuzzy Syst. 2014, 22, 709–722. [Google Scholar] [CrossRef]

- Wang, L.-X. A Course in Fuzzy Systems; Prentice-Hall Press: Englewood Cliffs, NJ, USA, 1999. [Google Scholar]

- Wang, L.; Chai, T.; Zhai, L. Neural-Network-Based Terminal Sliding-Mode Control of Robotic Manipulators Including Actuator Dynamics. IEEE Trans. Ind. Electron. 2009, 56, 3296–3304. [Google Scholar] [CrossRef]

| Controller | PID | CBSMC | ABSMC | |

|---|---|---|---|---|

| Sin | Index 1 | 0.2162 | 0.5479 | 0.0614 |

| Index 2 | 0.1811 | 0.5673 | 0.0548 | |

| Multistep | Index 1 | 0.4083 | 0.1419 | 0.1083 |

| Index 2 | 1.3697 | 0.3248 | 0.3145 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, D.-T.; Nguyen, M.-N.; Ahn, K.K. RBF Neural Network Based Backstepping Control for an Electrohydraulic Elastic Manipulator. Appl. Sci. 2019, 9, 2237. https://doi.org/10.3390/app9112237

Tran D-T, Nguyen M-N, Ahn KK. RBF Neural Network Based Backstepping Control for an Electrohydraulic Elastic Manipulator. Applied Sciences. 2019; 9(11):2237. https://doi.org/10.3390/app9112237

Chicago/Turabian StyleTran, Duc-Thien, Minh-Nhat Nguyen, and Kyoung Kwan Ahn. 2019. "RBF Neural Network Based Backstepping Control for an Electrohydraulic Elastic Manipulator" Applied Sciences 9, no. 11: 2237. https://doi.org/10.3390/app9112237

APA StyleTran, D.-T., Nguyen, M.-N., & Ahn, K. K. (2019). RBF Neural Network Based Backstepping Control for an Electrohydraulic Elastic Manipulator. Applied Sciences, 9(11), 2237. https://doi.org/10.3390/app9112237