Automatically Generating a MEP Logic Chain from Building Information Models with Identification Rules

Abstract

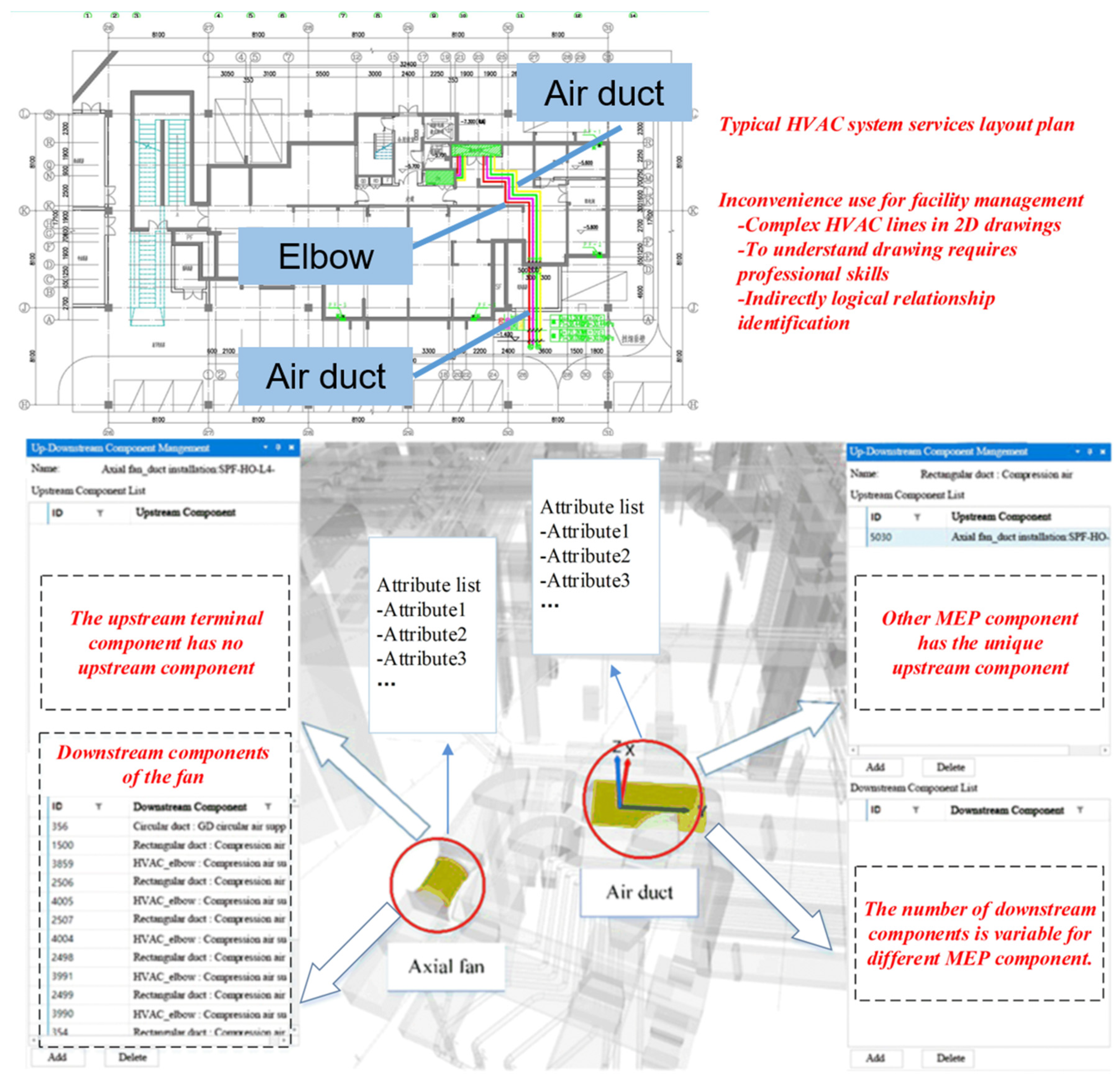

:1. Introduction

2. Existing Studies

2.1. Spatial Topological Analysis

2.2. Logical Inference through a Domain Query Language

2.3. Discussion

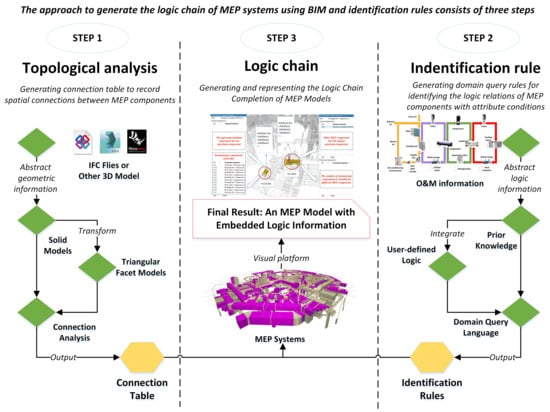

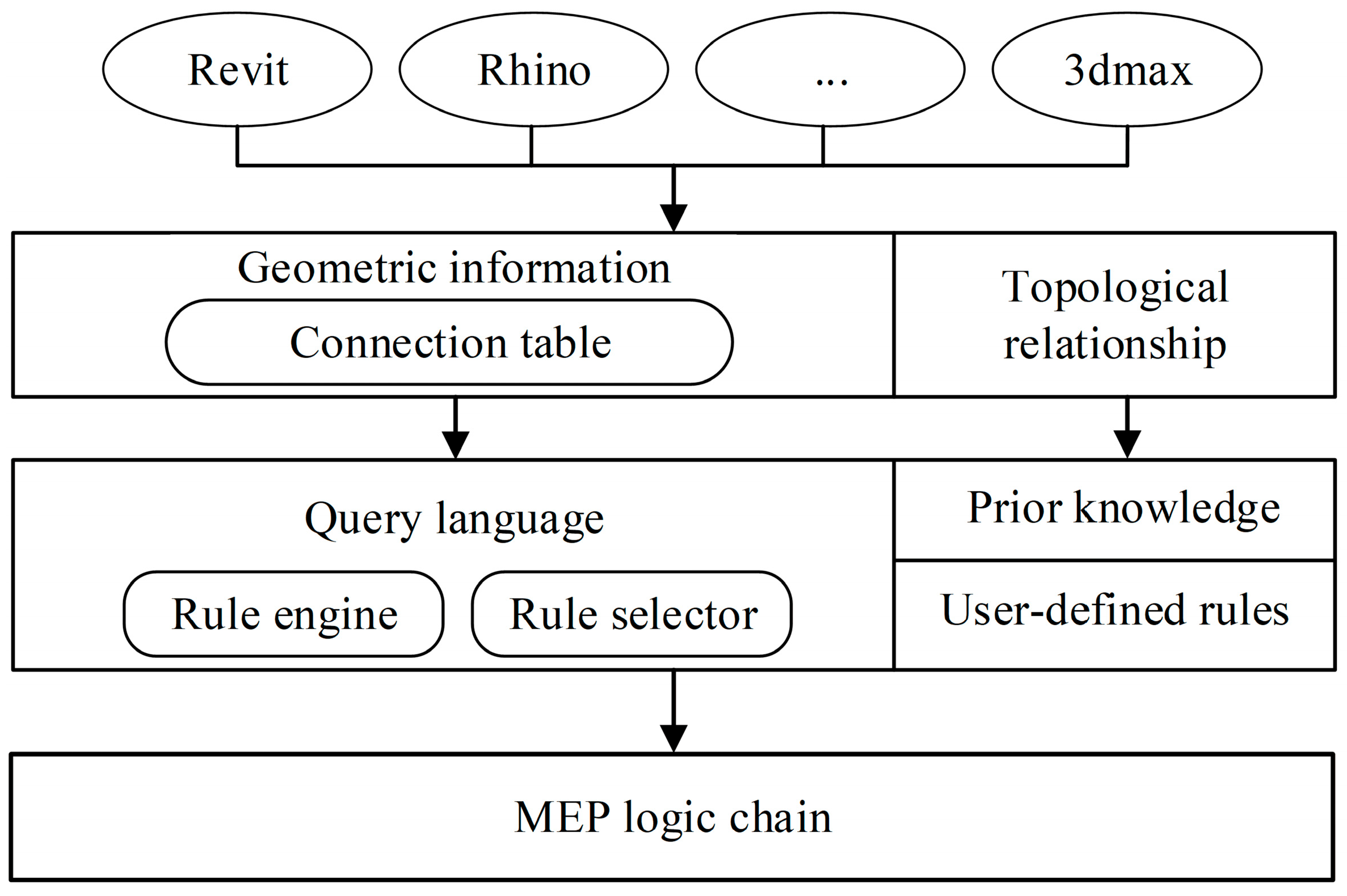

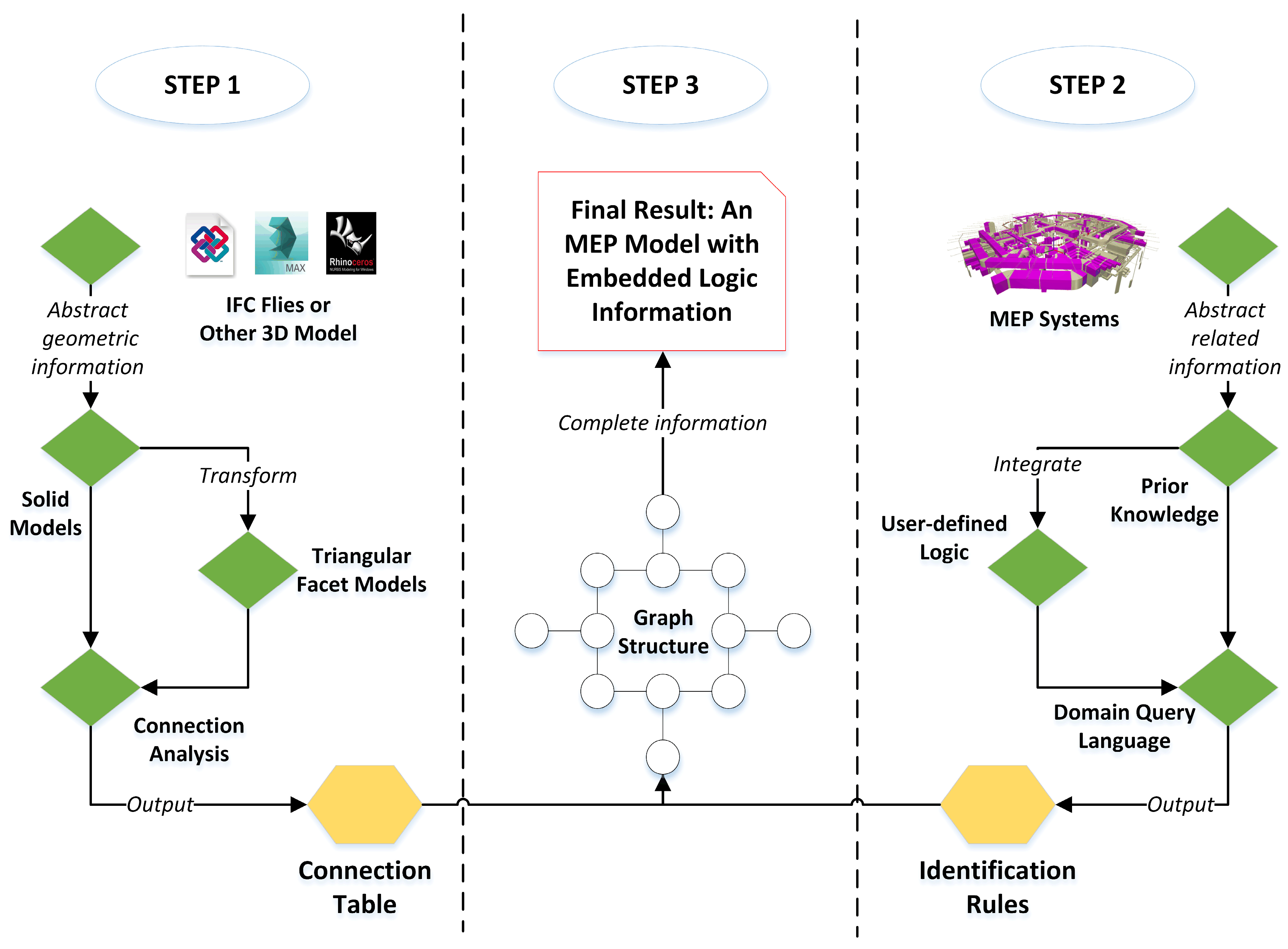

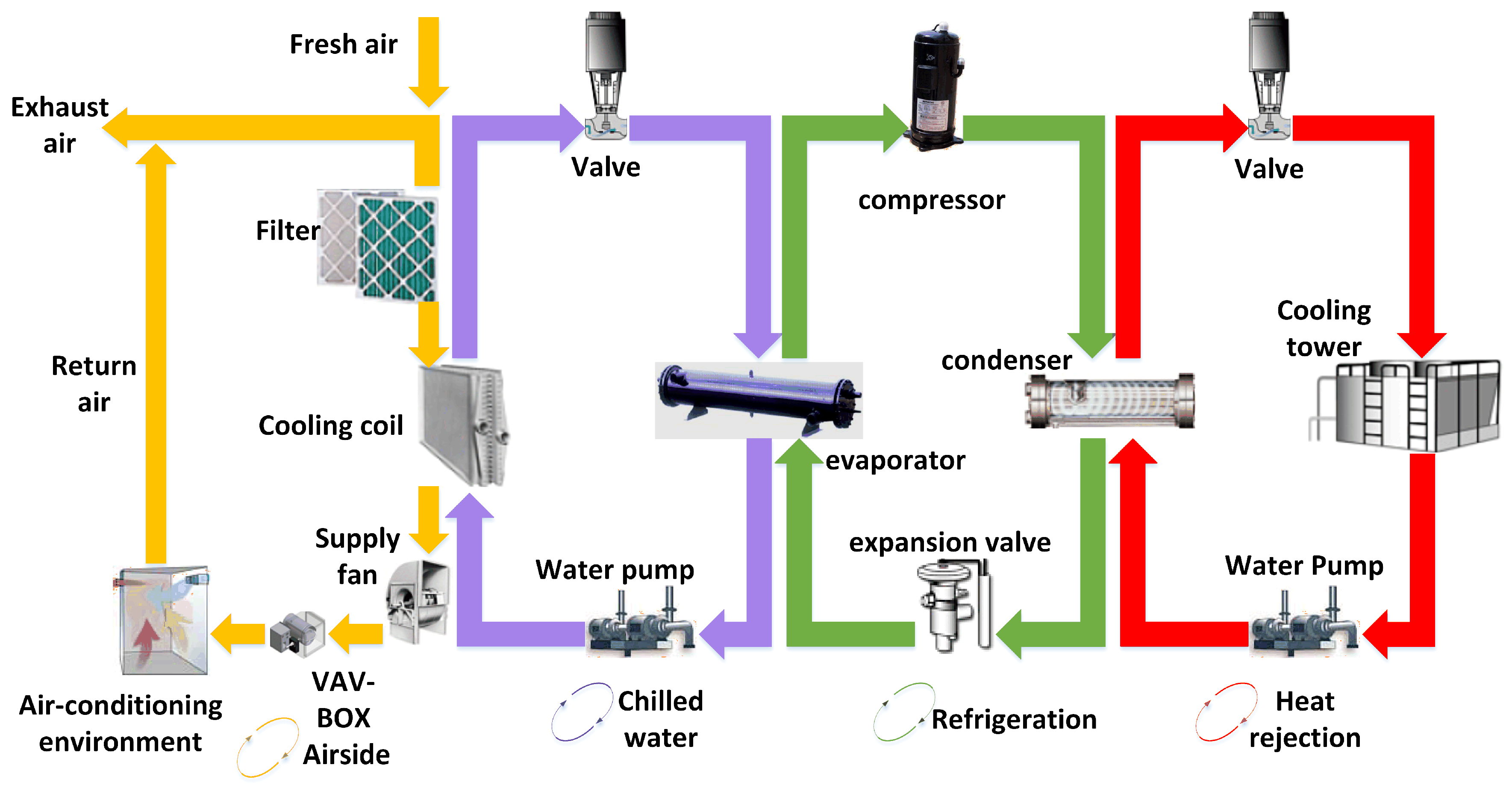

3. An Approach to Generate the MEP Logic Chain from BIMs

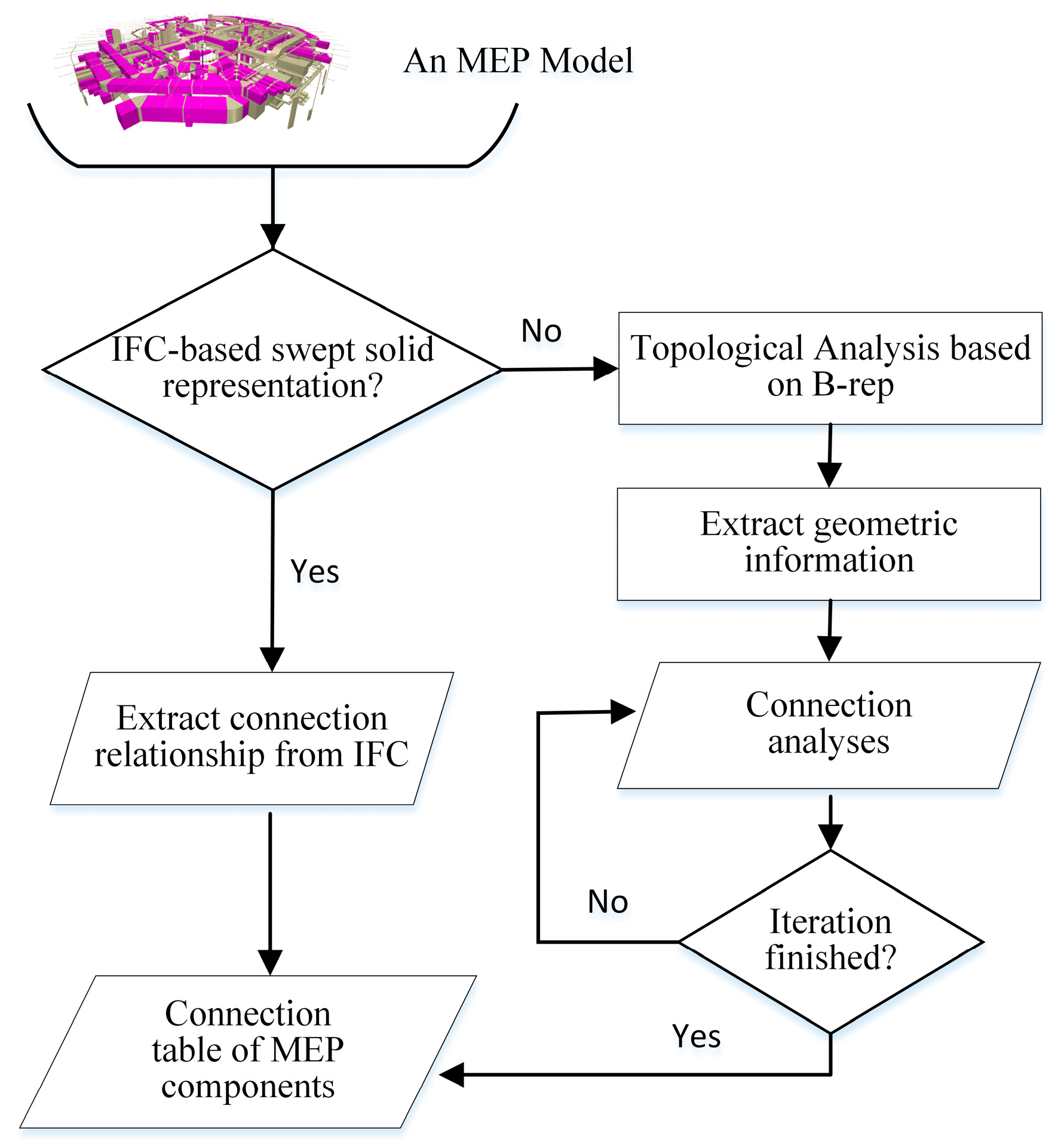

3.1. Spatial Topological Analysis within MEP Models

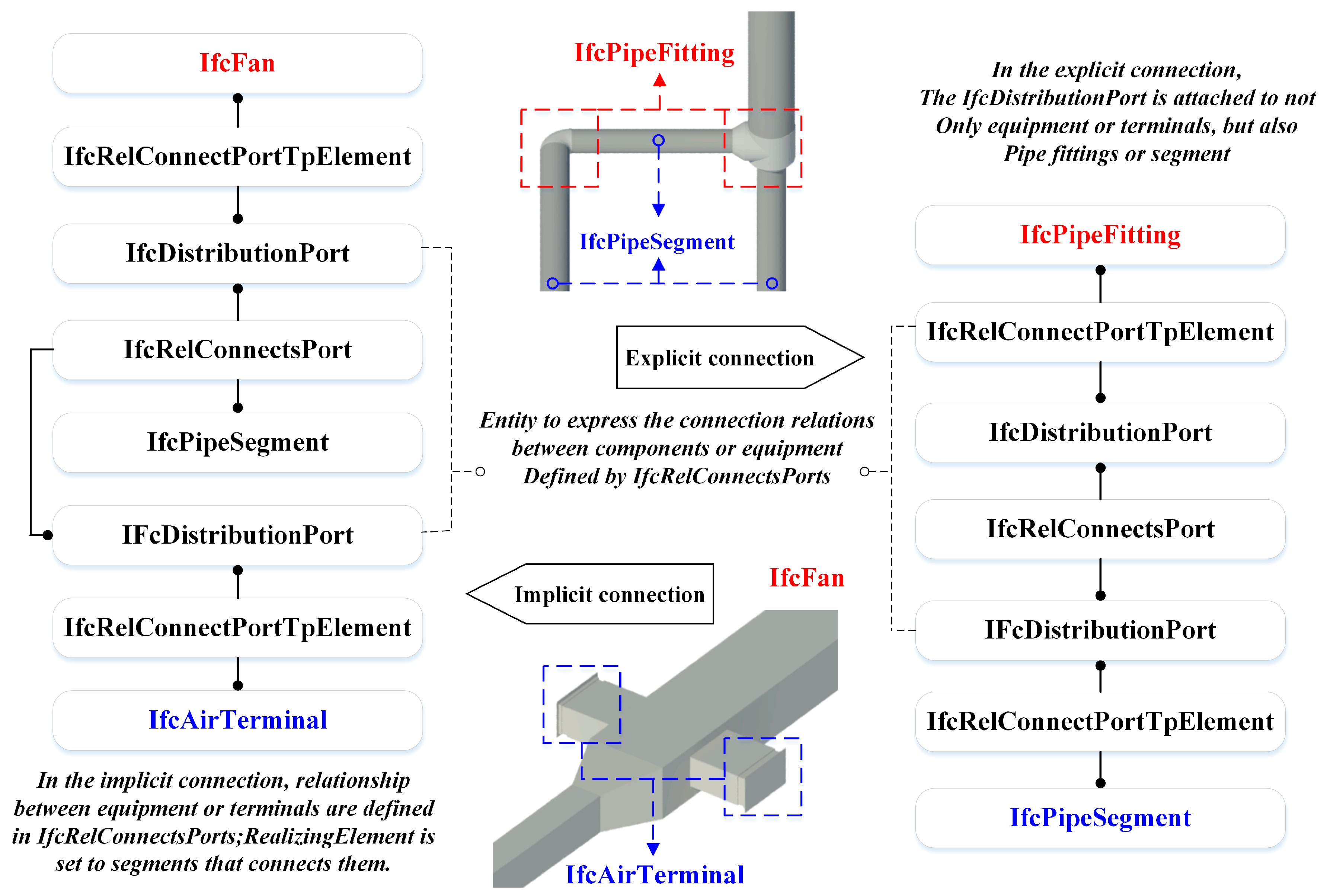

3.1.1. The IFC-Based Parametric Topological Analysis Algorithm

3.1.2. The Nonparametric Topological Analysis Algorithm

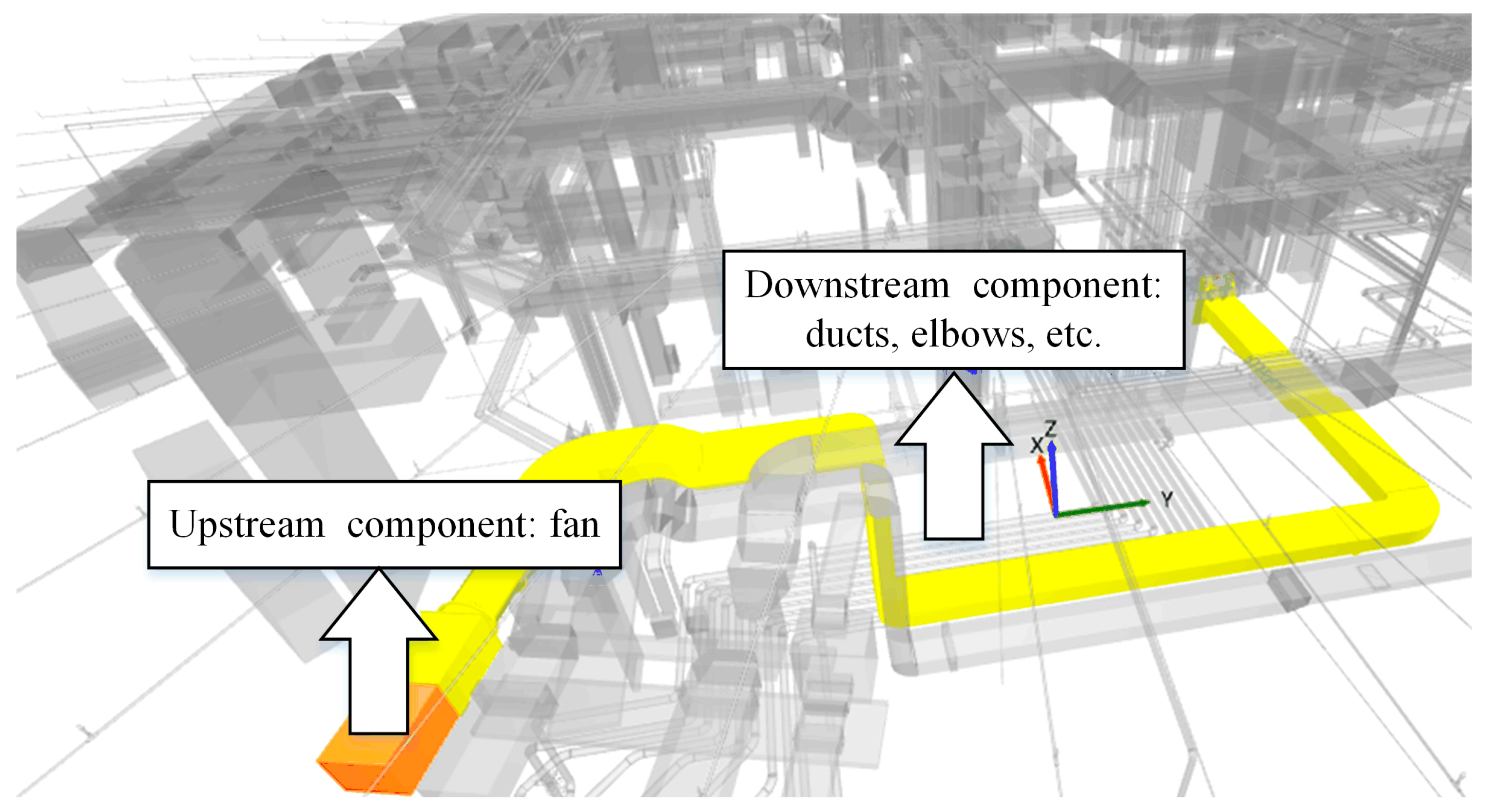

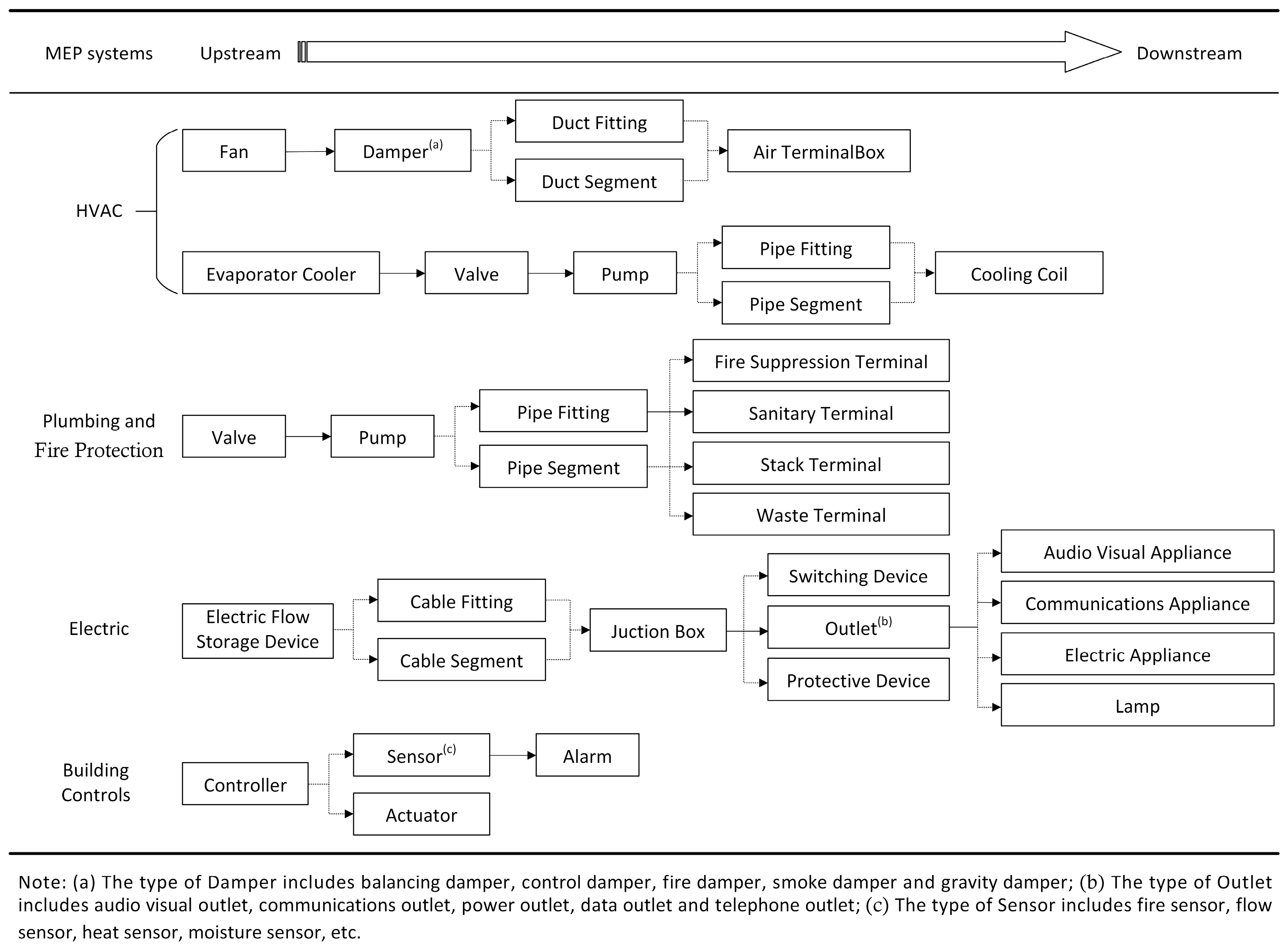

3.2. Identification Rules of Logic Chain in MEP Systems

3.2.1. The Typical Prior Knowledge Rule

3.2.2. The User-Defined Logic Rule

3.3. Logic Chain Completion of MEP Models

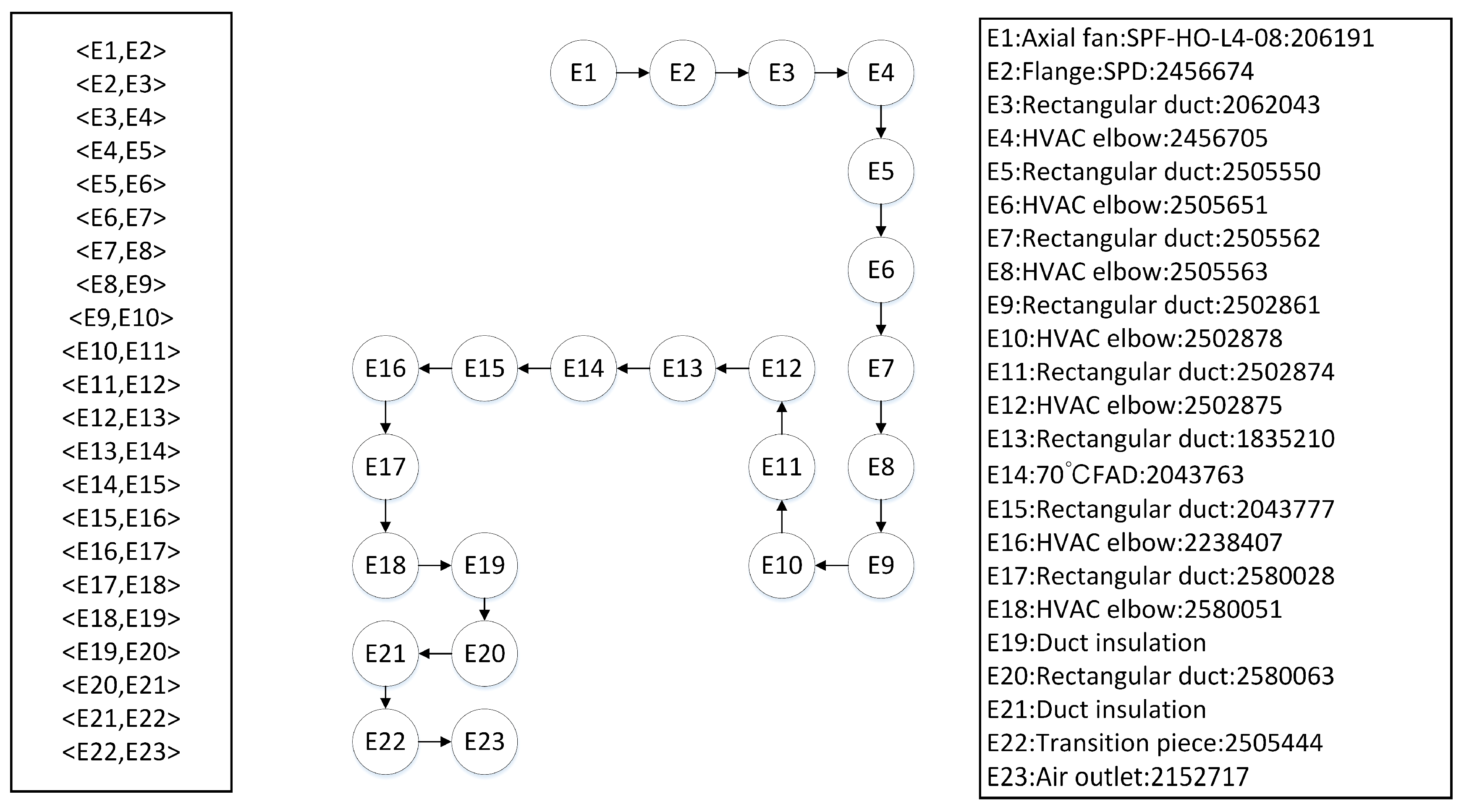

3.3.1. Graph Structure of the MEP Topology

3.3.2. MEP Logical Query Engine

3.3.3. The Enriched MEP Logic Chain Representation

4. A Case Study

4.1. Introduction to the Project

4.2. Application Details of the Approach

4.3. Evaluation and Discussion

- In 15 subsystems, both the connection table and logic model were generated with 100% accuracy, demonstrating that the approach could generate the right logic chain.

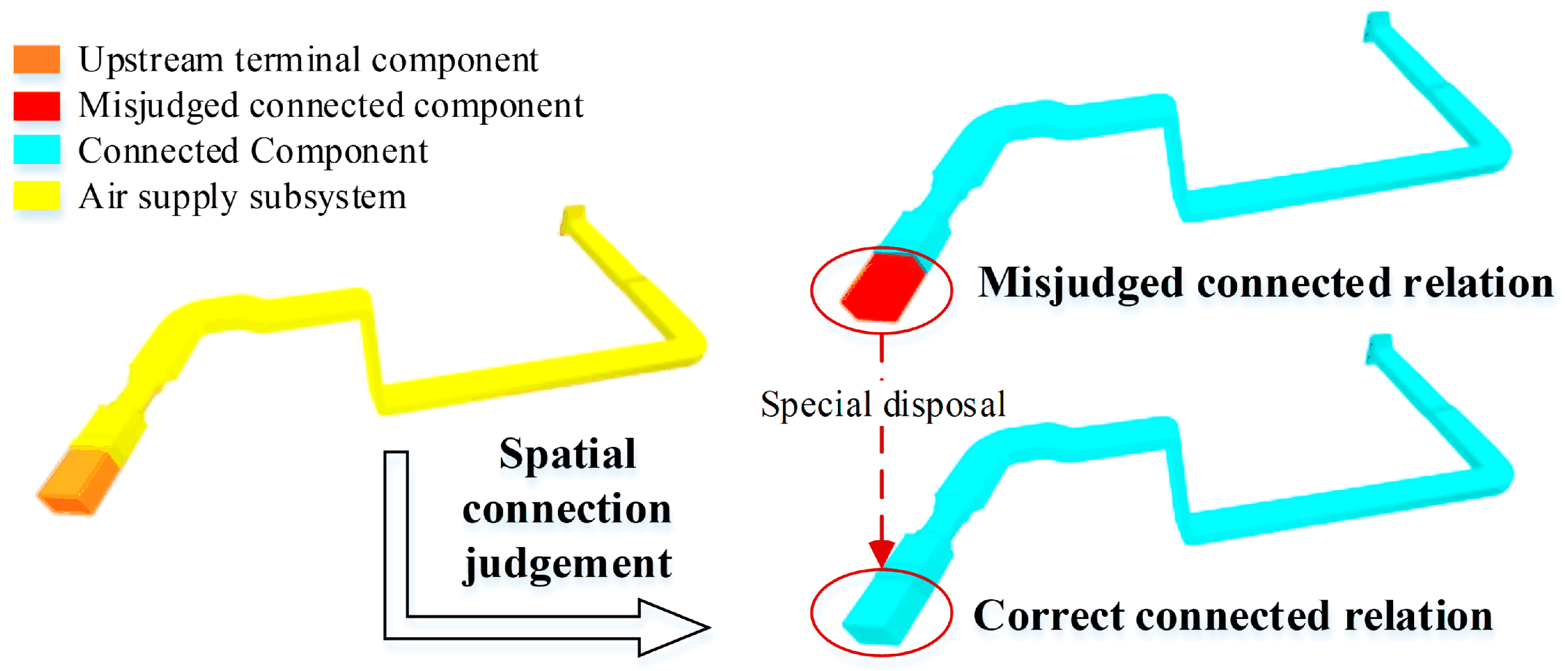

- There were ten subsystems with 1–5 omissions when generating the connection tables, and the accuracy rates remained higher than 80%. The spatial connection was misjudged for the following reasons in these cases:

- There were deviations in the position of the component during modeling. When the model was observed under magnification, there was no connection between components that were, in fact, connected to each other in practical engineering.

- A portion of the information was missing or incorrect in the modeling process. System classification and system name attributes were missing or missing in certain subsystem components’ properties, which influenced the inspection of components.

- The intersection judgment of space triangles was not sufficiently accurate. Because the triangular size was small, improper handling of truncation errors for intermediate calculations considerably affected on the results. Therefore, the algorithm should be improved.

Among the three types of problems, missing or incorrect information during modeling occurred most frequently, followed by misjudgments of triangle intersections and then deviations in the component positions during modeling. During the modeling process, information about the system classification and system name were generally inputted in commercial software. Designers or modelers were likely to ignore the accuracy of relevant property information, which, when combined with the lack of relevant modeling standards, led to the problem of missing or incorrect information.If two components of a subsystem were spatially connected to each other but the model assessed the connection incorrectly, the two components were distinguished as shown as Figure 14. In addition, the connection table could be manually added with two adjacent components to correct such omissions so that a complete connected path could be obtained. - There were four subsystems with less than two errors when generating logic models and the accuracy rates remained higher than 90%. An analysis of the results demonstrated that the values of properties were ambiguous in terms of their semantic meanings. For example, the fire damper was one of the valves in the HVAC system. However, if users used “valve” to represent the damper instead of using “damper”, the algorithm was unable to match the valve description with the fire damper component. Such problems were corrected by adding and deleting upstream and downstream components manually.

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akbarnezhad, A.; Ong, K.C.G.; Chandra, L.R. Economic and environmental assessment of deconstruction strategies using building information modeling. Autom. Constr. 2014, 37, 131–144. [Google Scholar] [CrossRef]

- Akcamete, A.; Akinci, B.; Garrett, J.H. Potential utilization of building information models for planning maintenance activities. In Proceedings of the 13th International Conference on Computing in Civil and Building Engineering, Nottinham, UK, 30 June–2 July 2010; pp. 151–158. [Google Scholar]

- Chotipanich, S. Positioning facility management. Facilities 2004, 22, 364–372. [Google Scholar] [CrossRef]

- Shen, W.; Hao, Q.; Mak, H.; Neelamkavil, J.; Xie, H.; Dickinson, J.; Thomas, R.; Pardasani, A.; Xue, H. Systems integration and collaboration in architecture, engineering, construction, and facilities management: A review. Adv. Eng. Inform. 2010, 24, 196–207. [Google Scholar] [CrossRef] [Green Version]

- Parn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Becerik-Gerber, B.; Jazizadeh, F.; Li, N.; Calis, G. Application Areas and Data Requirements for BIM-Enabled Facilities Management. J. Constr. Eng. Manag. 2012, 138, 431–442. [Google Scholar] [CrossRef]

- Hu, Z.-Z.; Tian, P.-L.; Li, S.-W.; Zhang, J.-P. Bim-Based Integrated Delivery Technologies for Intelligent Mep Management in the Operation and Maintenance Phase. Adv. Eng. Softw. 2018, 115, 1–16. [Google Scholar] [CrossRef]

- Chen, S.; Zheng, J.; Bi, K.; Zhang, P. BIM-Based Logic Retrieval of MEP Systems. J. Eng. Manag. 2016, 30, 132–137. [Google Scholar]

- BuildingSMART. IFC4 Release Candidate 4. Retrieved from BuildingSMART. 2013. Available online: http://www.buildingsmart-tech.org/ifc/IFC2x4/rc4/html/index.html (accessed on 24 September 2015).

- Kassem, M.; Kelly, G.; Dawood, N.; Serginson, M.; Lockley, S. BIM in facilities management applications: A case study of a large university complex. Built Environ. Proj. Asset Manag. 2015, 5, 261–277. [Google Scholar] [CrossRef]

- Lee, Y.C.; Eastman, C.M. Logic for ensuring the data exchange integrity of building information models. Autom. Constr. 2018, 93, 388–401. [Google Scholar] [CrossRef]

- Hassanain, M.A.; Froese, T.M.; Vanier, D.J. Development of a maintenance management model based on IAI standards. Artif. Intell. Eng. 2001, 15, 177–193. [Google Scholar] [CrossRef] [Green Version]

- Krijnen, T.; Beetz, J. An IFC schema extension and binary serialization format to efficiently integrate point cloud data into building models. Adv. Eng. Inform. 2017, 33, 473–490. [Google Scholar] [CrossRef] [Green Version]

- Cho, G.H.; Won, J.S.; Kim, J.-U. The Extension of IFC Model Schema for Geometry Part of Road Drainage Facility. J. Korea Acad. Ind. Cooper. Soc. 2013, 14, 5987–5992. (In Korea) [Google Scholar] [CrossRef] [Green Version]

- Brilakis, I.; Lourakis, M. Toward automated generation of parametric BIMs based on hybrid video and laser scanning data. Adv. Eng. Inform. 2010, 24, 456–465. [Google Scholar] [CrossRef]

- Nguyena, T.H.; Oloufa, A.A.; Nassar, K. Algorithms for automated deduction of topological information. Autom. Constr. 2005, 14, 59–70. [Google Scholar] [CrossRef]

- Bruno, S.; De Fino, M.; Fatiguso, F. Historic building information modeling: Performance assessment for diagnosis-aided information modeling and management. Autom. Constr. 2018, 86, 256–276. [Google Scholar] [CrossRef]

- Nepal, M.P.; Staub-French, S.; Zhang, J. Deriving construction features from an IFC model. In Proceedings of the Annual Conference–Canadian Society for Civil Engineering, Québec, QC, USA, 10–13 June 2008. [Google Scholar]

- Borrmann, A.; Rank, E. Specification and implementation of directional operators in a 3D spatial query language for building information models. Adv. Eng. Inform. 2009, 23, 32–44. [Google Scholar] [CrossRef]

- Daum, S.; Borrmann, A. Processing of Topological BIM Queries using Boundary Representation Based Methods. Adv. Eng. Inform. 2014, 28, 272–286. [Google Scholar] [CrossRef] [Green Version]

- Bertino, E.; Negri, M.; Pelagatti, G.; Sbattella, L. Objectoriented query languages: The notion and the issues. IEEE Trans. Knowl. Data Eng. 1992, 4, 223–237. [Google Scholar] [CrossRef]

- Kang, T.W. Object composite query method using IFC and LandXet ML based on BIM linkage model. Autom. Constr. 2017, 76, 14–23. [Google Scholar] [CrossRef]

- Mazairac, W.; Beetz, J. BIMQL—An open query language for building information models. Adv. Eng. Inform. 2013, 27, 444–456. [Google Scholar] [CrossRef]

- Dong, J.S.; Feng, Y.; Sun, J. Sensor Based Designs for Smart Space; Technical Report; Computer Science Department, National University of Singapore: Singapore, 2004. [Google Scholar]

- Solihin, W.; Eastman, C.; Lee, Y.C. A simplified relational database schema for transformation of BIM data into a query-efficient and spatially enabled database. Autom. Constr. 2017, 82, 367–383. [Google Scholar] [CrossRef]

- Preidel, C.; Daum, S.; Borrmann, A. Data retrieval from building information models based on visual programming. Vis. Eng. 2017, 5, 18–32. [Google Scholar] [CrossRef]

- Thambirajah, J.; Benabbas, L.; Bauer, M.; Thornhill, N.F. Cause-and-effect analysis in chemical processes utilizing XML, plant connectivity and quantitative process history. Comput. Chem. Eng. 2009, 33, 503–512. [Google Scholar] [CrossRef] [Green Version]

- Son, H.; Kim, C.; Kim, C. 3D reconstruction of as-built industrial instrumentation models from laser-scan data and a 3D CAD database based on prior knowledge. Autom. Constr. 2015, 49, 193–200. [Google Scholar] [CrossRef]

- Tang, P.B.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic reconstruction of as-built building information models from laser-scanned point clouds: A review of related techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Alhussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 88, 235–249. [Google Scholar] [CrossRef]

- Yarmohammadi, S.; Castro-Lacouture, D. Automated performance measurement for 3D building modeling decisions. Autom. Constr. 2018, 93, 91–111. [Google Scholar] [CrossRef]

- Leite, F.; Akcamete, A.; Akinci, B. Analysis of modeling effort and impact of different levels of detail in building information models. Autom. Constr. 2011, 20, 601–609. [Google Scholar] [CrossRef]

- Ciribini, A.L.C.; Mastrolembo Ventura, S.; Paneroni, M. Implementation of an interoperable process to optimise design and construction phases of a residential building: A BIM Pilot Project. Autom. Constr. 2016, 271, 62–73. [Google Scholar] [CrossRef]

- Wang, L.; Leite, F. Process Knowledge Capture in BIM-Based Mechanical, Electrical, and Plumbing Design Coordination Meetings. J. Comput. Civ. Eng. 2016, 30, 04015017. [Google Scholar] [CrossRef]

- Hu, Z.Z.; Zhang, J.P.; Yu, F.Q. Construction and facility management of large MEP projects using a multi-Scale building information model. Adv. Eng. Softw. 2016, 100, 215–230. [Google Scholar] [CrossRef]

- Li, W.; Fernanda, L. Knowledge Discovery of Spatial Conflict Resolution Philosophies in BIM-Enabled MEP Design Coordination Using Data Mining Techniques: A Proof-of-Concept. In Proceedings of the ASCE International Workshop on Computing in Civil Engineering, Los Angeles, CA, USA, 23–25 June 2013; pp. 419–426. [Google Scholar] [CrossRef]

- Driscoll, J.R.; Lien, Y.E. A selective traversal algorithm for binary search trees. Commun. ACM 1978, 21, 445–447. [Google Scholar] [CrossRef]

- Djuric, N.; Novakovic, V.; Frydenlund, F. Heating system performance estimation using optimization tool and BEMS data. Energy Build. 2008, 40, 1367–1376. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.S.; Akinci, B.; Bergés, M.; Garrett, J.H., Jr. Domain-Specific Querying Formalisms for Re-trieving Information about HVAC Systems. J. Comput. Civ. Eng. 2014, 28, 40–49. [Google Scholar] [CrossRef]

| Class | Relationship Modeling | Relationship Completion Mode | Platform | Geometric Data Source | |||||

|---|---|---|---|---|---|---|---|---|---|

| Sub-Class | Spatial | Logic | Manual | Automatic | Business Software | Self-Developed Engine | IFC Files | 3D CAD Model | 3D Point Clouds from Laser-Scan Data |

| Son et al. [28] | • | • | • | • | • | • | • | ||

| Hu et al. [7,35] | • | • | • | • | |||||

| Nguyena et al. [16] | • | • | • | • | |||||

| Borrmann et al. [19] | • | • | • | • | • | ||||

| Chen et al. [8] | • | • | • | • | |||||

| Proposed approach | • | • | • | • | • | • | |||

| Predicate | Syntax | Description |

|---|---|---|

| = | v1 = v2 | True if value v1 equals to v2 |

| Contains | v1 contains v2 | true if value v2 is a substring of value v1 |

| Connects | v1 connects v2 | true if value v2 is topologically connected to value v1 |

| Definition | Syntax | Example | Explanations |

|---|---|---|---|

| 1 | E | Valve | E represents an entity type that defines the scope of an entity to which an inspection rule is applied. |

| 2 | Valve.Name | represents an inspection rule, and P is an attribute of the relevant component; then, is the specified attribute value of the upstream component examined by the inspection rule. | |

| 3 | (Valve.Name, contains, “XX”) | represents an inspection rule, P is an attribute of the relevant component, is a predicate, and v is the value; then, is an inspection rule for all instances in UE that have values for property P that satisfy the predication. | |

| 4 | ((Valve.Name, contains, “XX”), UpstreamOf, (Pipe.Name, contains, “XX”)) | If and are two queries for instances and R provides a relationship (UpstreamOf or DownstreamOf) of these two groups of instances, then is a complete inspection rule for the generated part of the MEP logic chain. |

| Attributes | Types | Brief Description |

|---|---|---|

| Element Id | Number | Unique Id in BIM model for every element. |

| Element Location | Coordinate Point | The element location point. |

| Space Located | String | The spaces of this element located. |

| System classification | String | The system classification includes supply air, return air, etc. |

| System name | String | The name of system which elements belong to, such as supply air, return air, etc. |

| Flow | Number | Flow in and out of a diffuser or duct. |

| Start Point | Coordinate Point | Start point of a duct. For duct only. |

| End Point | Coordinate Point | End point of a duct. For duct only. |

| No. | Inspection Rules of A Supply Air Subsystems |

| 1 | (Component.Name, contains, “Fan”), UpstreamOf, (Valve.Name, contains, “FAD”) |

| 2 | (Component.Name, contains, “Fan”), UpstreamOf, (Duct.Name, contains, “duct”) |

| 3 | (Component.Name, contains, “Fan”), UpstreamOf, (Duct.Name, contains, “elbow”) |

| 4 | (Component.Name, contains, “Fan”), UpstreamOf, (Duct.Name, contains, “Transition”) |

| 5 | (Duct.Name, contains, “Transition”), UpstreamOf, (Duct.Name, contains, “outlet”) |

| No. | Inspection Rules of A Fire Sprinkler Subsystems |

| 1 | (Component.Name, contains, “Riser”), UpstreamOf, (Pipe.Name, contains, “Valve”) |

| 2 | (Component.Name, contains, “Riser”), UpstreamOf, (Pipe.Name, contains, “pipe”) |

| 3 | (Component.Name, contains, “Riser”), UpstreamOf, (Pipe.Name, contains, “elbow”) |

| 4 | (Component.Name, contains, “Riser”), UpstreamOf, (Pipe.Name, contains, “Transition”) |

| 5 | (Duct.Name, contains, “Transition”), UpstreamOf, (Pipe.Name, contains, “sprinkler”) |

| Subsystem Name | Number of Components | Generate Connection Table Process | Generate Logic Model Process | ||

|---|---|---|---|---|---|

| Omissions (Pairs) | Accuracy (%) | Errors (Pairs) | Accuracy (%) | ||

| Return air 1 | 23 | 0 | 100 | 0 | 100 |

| Return air 2 | 19 | 0 | 100 | 1 | 96.8 |

| Return air 3 | 28 | 3 | 88.9 | 2 | 92.6 |

| Return air | 70 | 3 | 95.7 | 3 | 95.7 |

| Supply air 1 | 32 | 1 | 96.8 | 0 | 100 |

| Supply air 2 | 34 | 0 | 100 | 0 | 100 |

| Supply air 3 | 41 | 0 | 100 | 0 | 100 |

| Supply air 4 | 32 | 2 | 96.7 | 0 | 100 |

| Supply air 5 | 23 | 0 | 100 | 0 | 100 |

| Supply air 6 | 26 | 0 | 100 | 0 | 100 |

| Supply air | 188 | 3 | 98.4 | 0 | 100 |

| Intake air 1 | 21 | 1 | 95 | 0 | 100 |

| Intake air 2 | 19 | 0 | 100 | 0 | 100 |

| Intake air 3 | 29 | 5 | 82.1 | 2 | 92.9 |

| Intake air 4 | 24 | 2 | 91.3 | 1 | 95.7 |

| Intake air 5 | 32 | 0 | 100 | 0 | 100 |

| Intake air 6 | 35 | 0 | 100 | 0 | 100 |

| Intake air | 160 | 8 | 95 | 3 | 98.1 |

| Wet pipe 1 | 23 | 0 | 100 | 0 | 100 |

| Wet pipe 2 | 28 | 0 | 100 | 0 | 100 |

| Wet pipe 3 | 40 | 1 | 97.5 | 2 | 100 |

| Wet pipe 4 | 34 | 1 | 97.1 | 1 | 100 |

| Wet pipe 5 | 23 | 0 | 100 | 0 | 100 |

| Wet pipe 6 | 30 | 0 | 100 | 0 | 100 |

| Wet pipe | 178 | 2 | 98.9 | 3 | 98.3 |

| Dry pipe 1 | 20 | 0 | 100 | 0 | 100 |

| Dry pipe 2 | 28 | 0 | 100 | 0 | 100 |

| Dry pipe 3 | 14 | 0 | 100 | 2 | 85.7 |

| Dry pipe 4 | 33 | 1 | 97.0 | 0 | 100 |

| Dry pipe 5 | 28 | 0 | 100 | 0 | 100 |

| Dry pipe 6 | 44 | 2 | 95.5 | 2 | 95.5 |

| Dry pipe | 167 | 3 | 98.2 | 0 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.-Q.; Li, S.-W.; Hu, Z.-Z. Automatically Generating a MEP Logic Chain from Building Information Models with Identification Rules. Appl. Sci. 2019, 9, 2204. https://doi.org/10.3390/app9112204

Xiao Y-Q, Li S-W, Hu Z-Z. Automatically Generating a MEP Logic Chain from Building Information Models with Identification Rules. Applied Sciences. 2019; 9(11):2204. https://doi.org/10.3390/app9112204

Chicago/Turabian StyleXiao, Ya-Qi, Sun-Wei Li, and Zhen-Zhong Hu. 2019. "Automatically Generating a MEP Logic Chain from Building Information Models with Identification Rules" Applied Sciences 9, no. 11: 2204. https://doi.org/10.3390/app9112204

APA StyleXiao, Y.-Q., Li, S.-W., & Hu, Z.-Z. (2019). Automatically Generating a MEP Logic Chain from Building Information Models with Identification Rules. Applied Sciences, 9(11), 2204. https://doi.org/10.3390/app9112204