Cycle-to-Cycle Variation of a Diesel Engine Fueled with Fischer–Tropsch Fuel Synthesized from Coal

Abstract

:1. Introduction

2. Materials and Methods

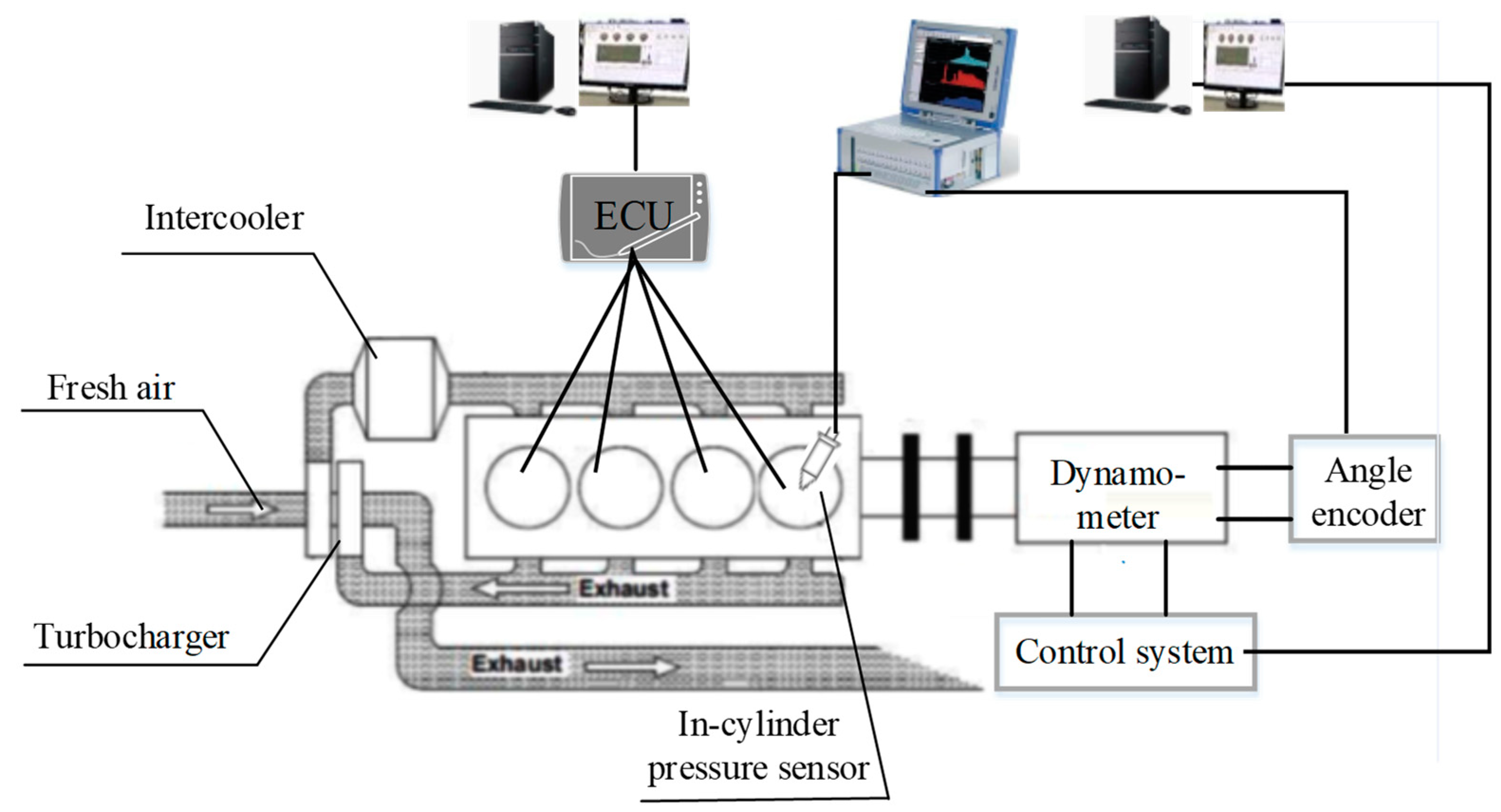

2.1. Research Engine Test Bench

2.2. Test Fuels

3. Results and Discussion

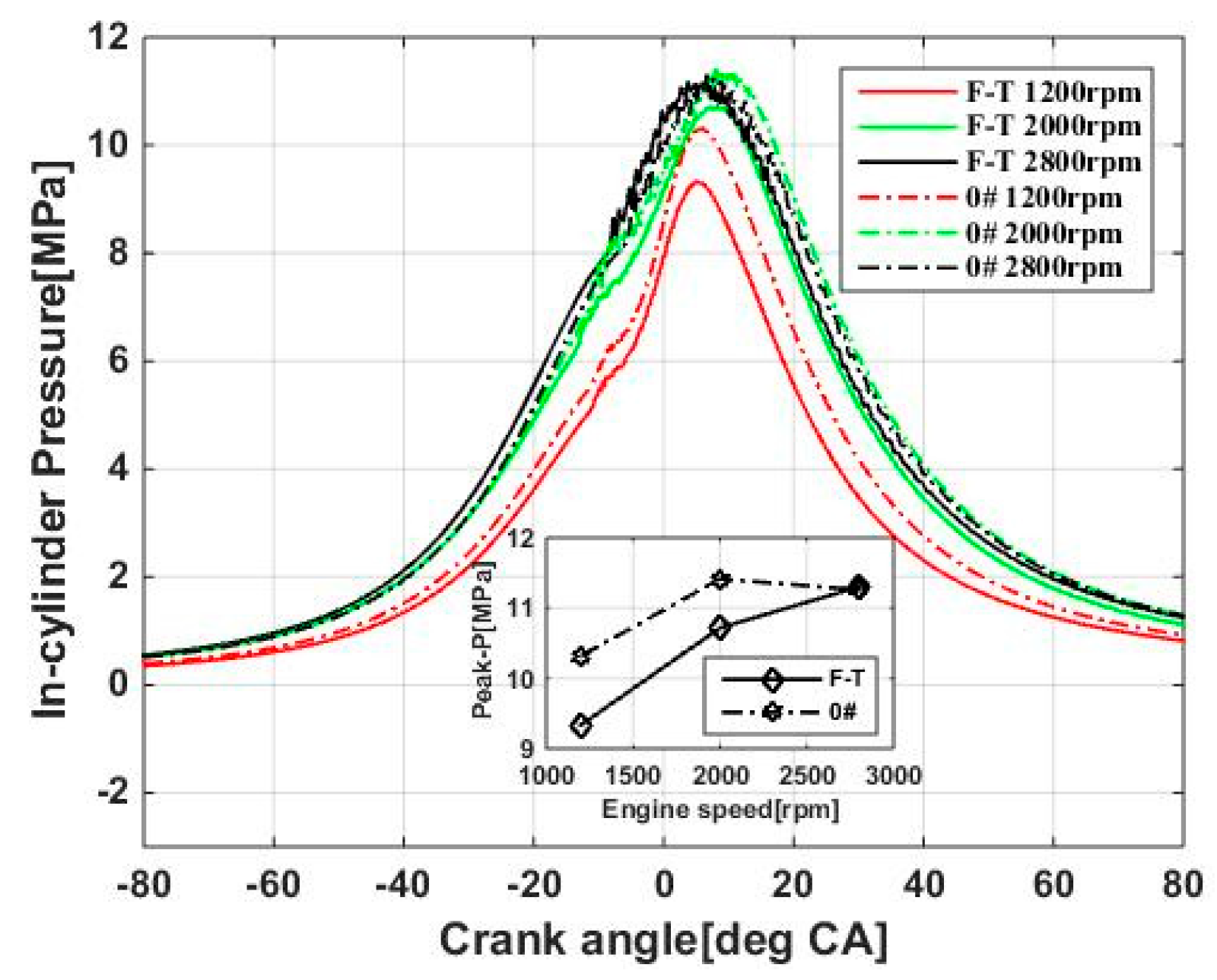

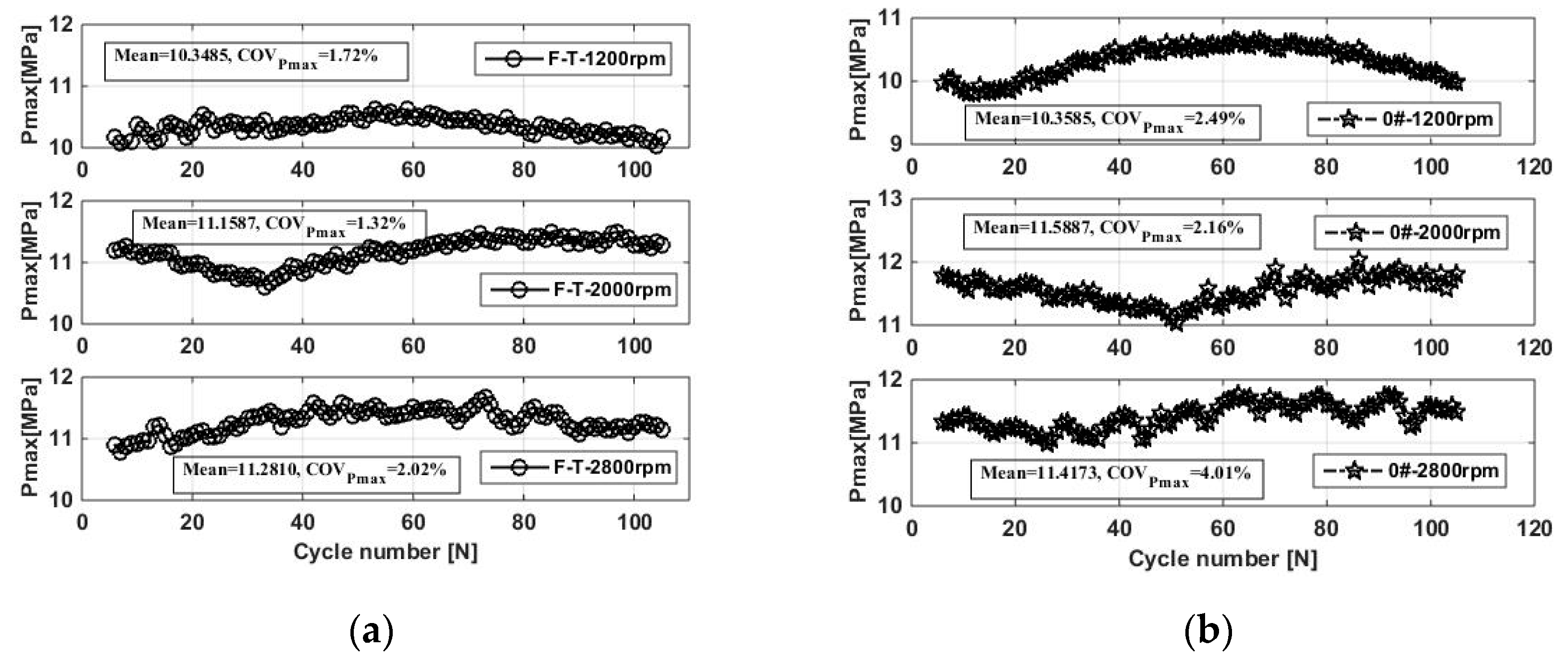

3.1. In-Cylinder Pressure

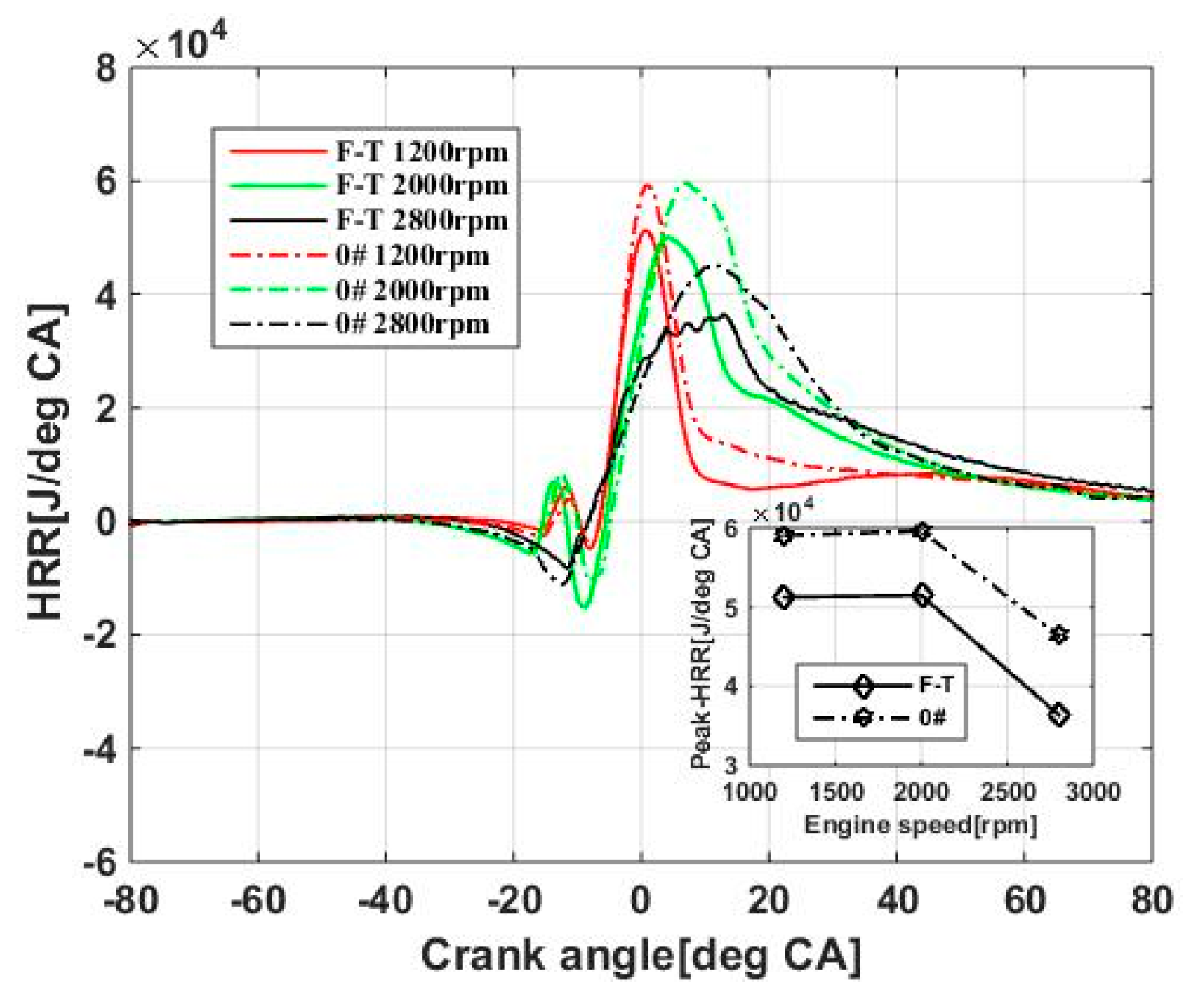

3.2. Heat Release Rate

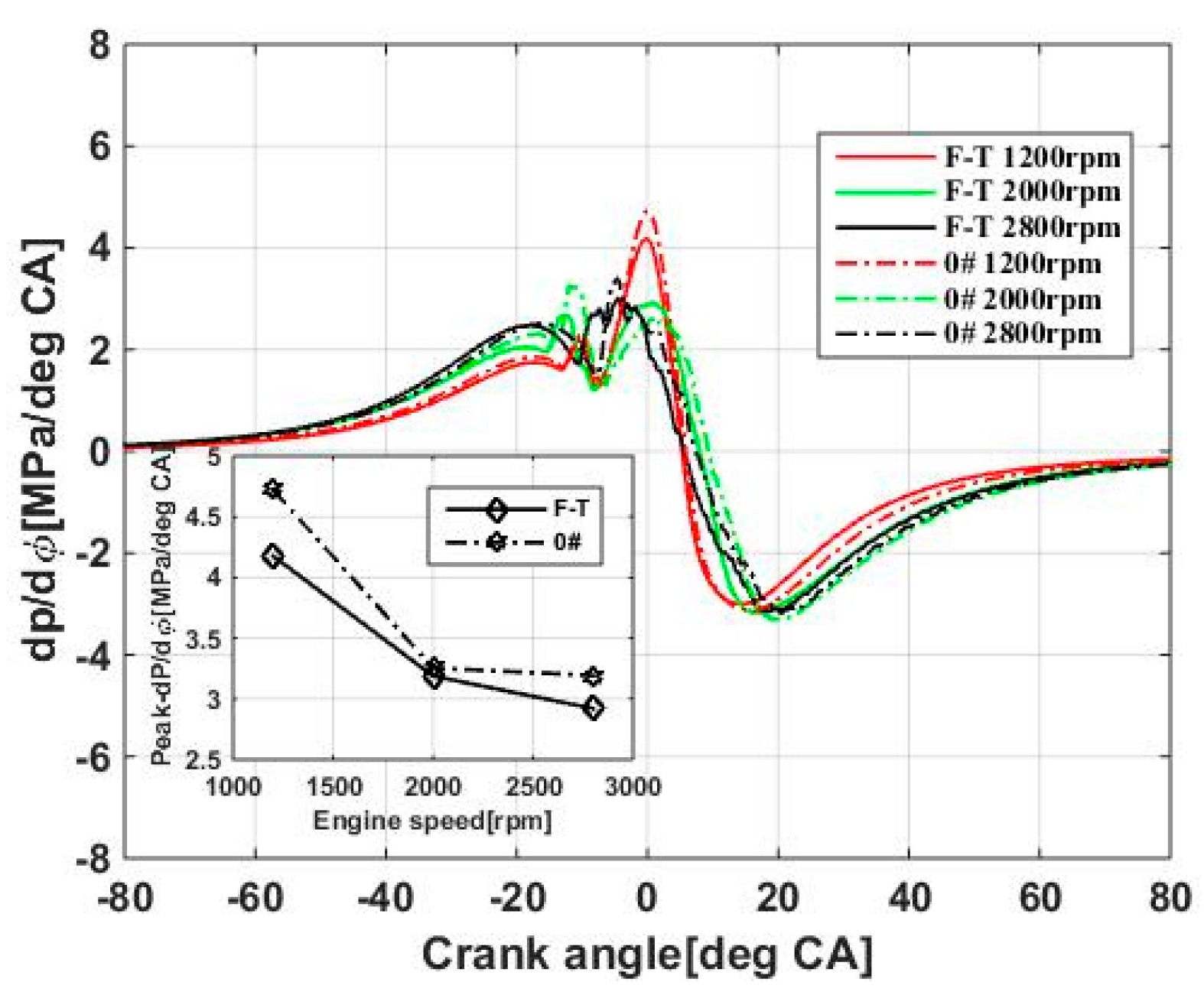

3.3. In-Cylinder Pressure Increase Rate

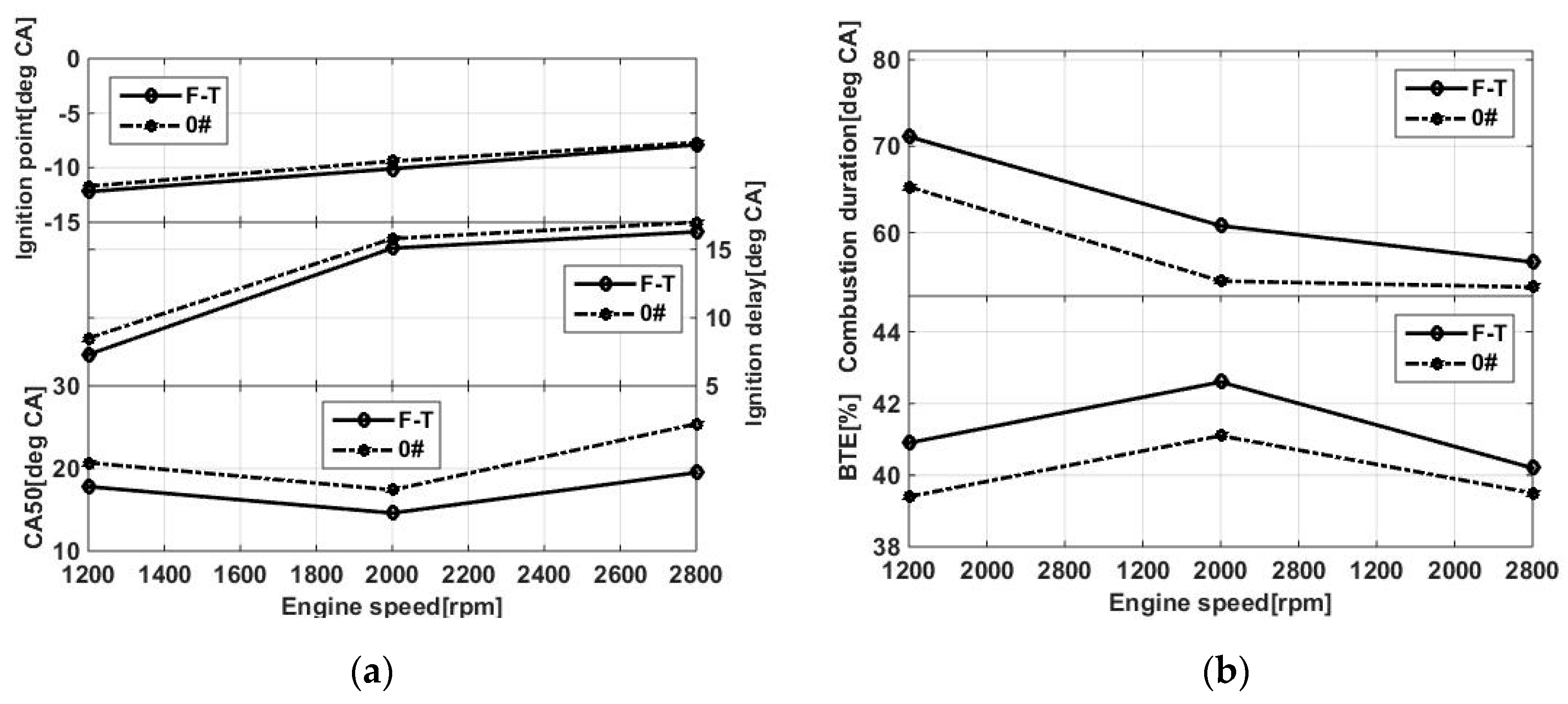

3.4. Combustion Parameters

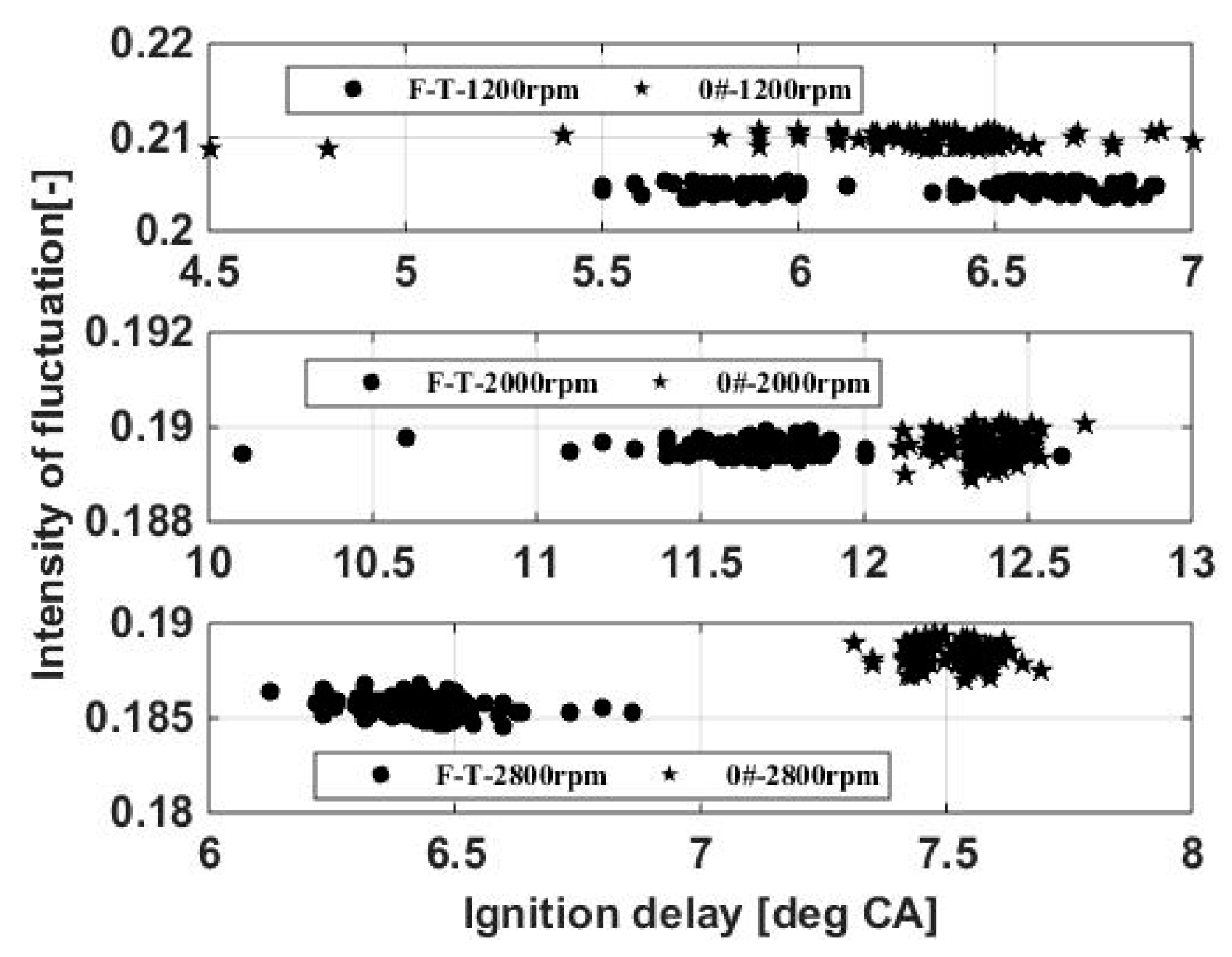

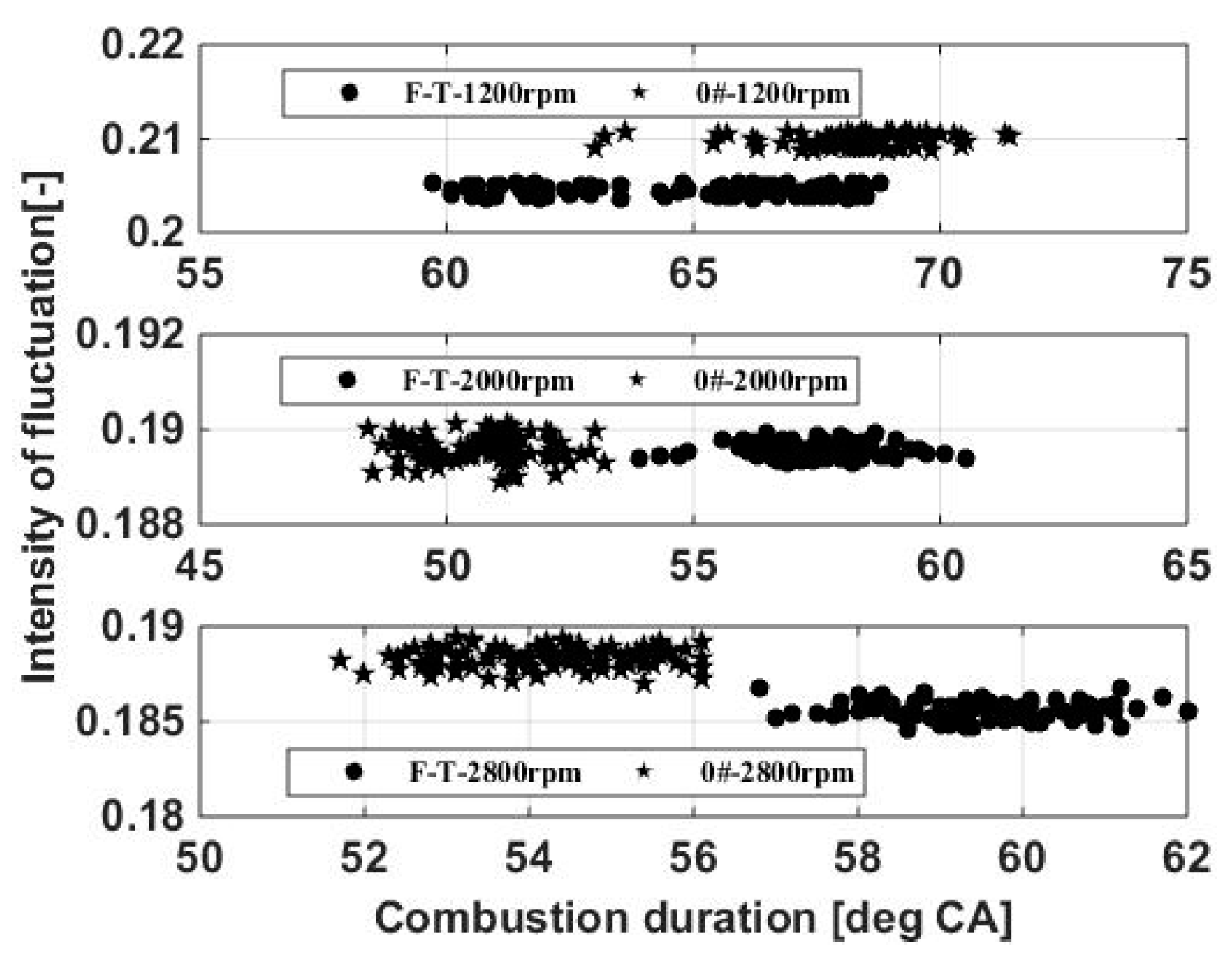

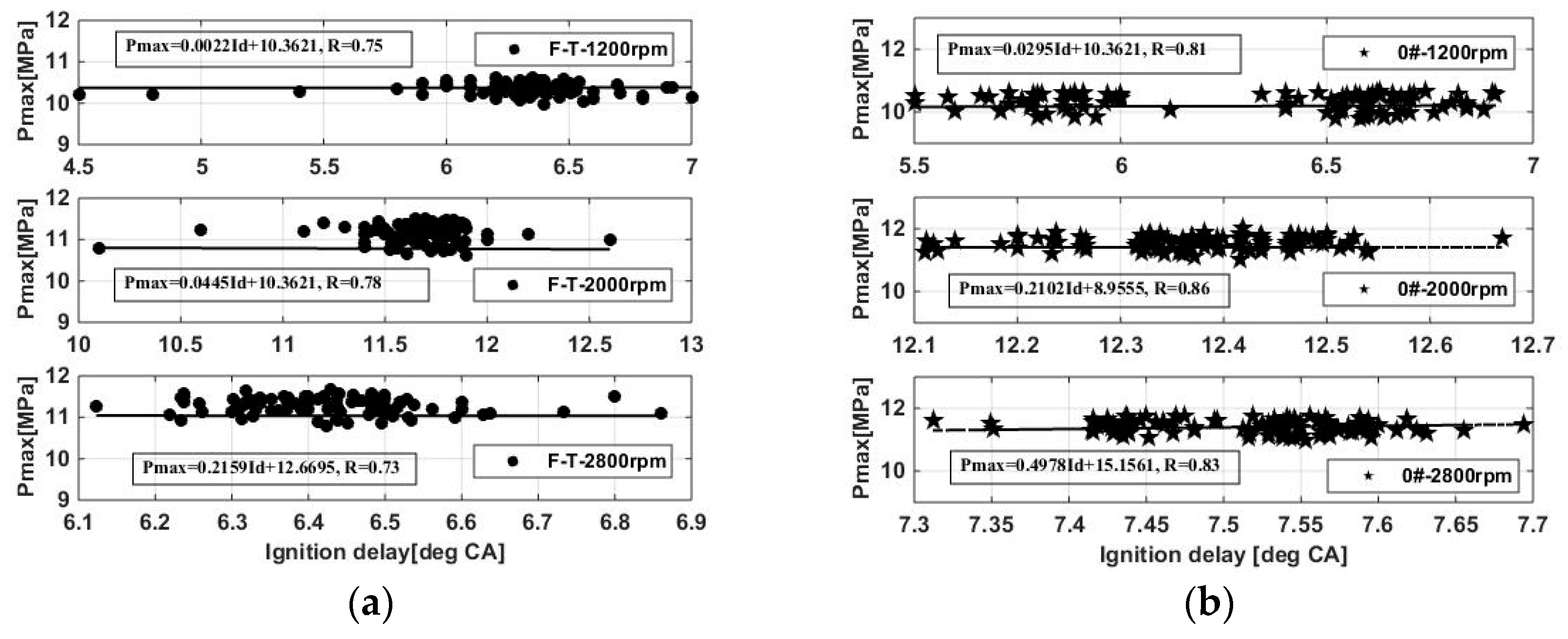

3.5. Cyclic Variation Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| CA | crank angle |

| CA50 | crank angle at which 50% of the fuel has burnt |

| BTE | break thermal efficiency |

| ECU | electronic control unit |

| Pmax | maximum in-cylinder pressure |

| EGR | exhaust gas recirculation |

| TDC | top dead center |

| R | Pearson’s correlation efficiency |

| CN | cetane number |

| HRR | heat release rate |

| Id | ignition delay |

| Cd | combustion duration |

| CovPmax | coefficient of variation of maximum in-cylinder pressure |

References

- Ogunkoya, D.; Roberts, W.L.; Fang, T.; Thapaliya, N. Investigation of the effects of renewable diesel fuels on engine performance, combustion, and emissions. J. Fuel 2015, 140, 541–554. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Han, Z. Study on performance and emissions of a passenger-car diesel engine fueled with butanol–diesel blends. J. Energy 2013, 55, 638–646. [Google Scholar] [CrossRef]

- Shi, J.H.; Wang, T.; Zhao, Z.; Yang, T.T.; Zhang, Z.W. Experimental study of injection parameters on the performance of a diesel engine with Fischer–Tropsch fuel synthesized from coal. Energies 2018, 11, 3280. [Google Scholar] [CrossRef]

- Höök, M.; Aleklett, K. A review on coal-to-liquid fuels and its coal consumption. Int. J. Energy Res. 2010, 34, 848–864. [Google Scholar] [CrossRef]

- Gill, S.S.; Tsolakis, A.; Dearn, K.D.; Rodríguez-Fernández, J. Combustion characteristics and emissions of Fischer-Tropsch diesel fuels in IC Engines. J. Prog. Energy Combust. Sci. 2011, 37, 503–523. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; Plá, B.; Mónico, L.F. Impact of Fischer–Tropsch and biodiesel fuels on trade-offs between pollutant emissions and combustion noise in diesel engines. J. Biomass Bioenergy 2013, 52, 22–33. [Google Scholar] [CrossRef] [Green Version]

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A review on biodiesel production, combustion, emissions and performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Armas, O.; Ballesteros, R.; Cardenas, M.D. Thermodynamic diagnosis of diesel and biodiesel combustion processes during load-increase transient sequences. J. Appl. Energy 2012, 97, 558–568. [Google Scholar] [CrossRef]

- Tijmensen, M.J.; Faaij, A.P.; Hamelinck, C.N.; van Hardeveld, M.R. Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. J. Biomass Bioenergy 2002, 23, 129–152. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, A. On-line thermodynamic diagnosis of diesel combustion process with paraffinic fuels in a vehicle tested under NEDC. J. Clean. Prod. 2016, 138, 94–102. [Google Scholar] [CrossRef]

- Alleman, T.L.; McCormick, R.L. Fischer−Tropsch Diesel Fuels Properties and Exhaust Emissions: A Literature Review; SAE: Thessaloniki, Greece, 2003. [Google Scholar] [CrossRef]

- Armas, O.; Yehliu, K.; Boehman, L.A. Effect of alternative fuels on exhaust emissions during diesel engine operation with matched combustion phasing. Fuel 2010, 89, 438–456. [Google Scholar] [CrossRef]

- Yehliu, K.; Boehman, L.A.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

- Yang, Z.; Steffen, T.; Stobart, R. Disturbance Sources in the Diesel Engine Combustion Process; SAE International: Michigan, MI, USA, 2013. [Google Scholar]

- Koizumi, I.; Gyakushi, N.; Takamoto, Y. Study on the cycle-by-cycle variation in diesel engines. Bull. Jsme 1977, 20, 7. [Google Scholar]

- Zhong, L.; Singh, I.P.; Han, J.S.; Lai, M.C.; Henein, N.A.; Bryzik, W. Effect of Cycle-to-Cycle Variation in the Injection Pressure in a Common Rail Diesel Injection System on Engine Performance; SAE International: Michigan, MI, USA, 2003. [Google Scholar] [CrossRef]

- Schmillen, K.; Wolschendorf, J. Cycle-to-Cycle variations of combustion noise in diesel engines. SAE Trans. 1989, 89, 60–70. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G.; Rakopoulos, D.C. Study of the short-term cylinder wall temperature oscillations during transient operation of a turbocharged diesel engine with various insulation schemes. Int. J. Engine Res. 2008, 9, 177–193. [Google Scholar] [CrossRef]

- Jakob, M.; Hülser, T.; Janssen, A.; Adomeit, P.; Pischinger, S.; Grünefeld, G. Simultaneous high-speed visualization of soot luminosity and OH chemiluminescence of alternative-fuel combustion in a HSDI diesel engine under realistic operating conditions. Combust. Flame 2012, 159, 2516–2529. [Google Scholar] [CrossRef]

- Sczomak, D.P.; Henein, N.A. Cycle-to-Cycle Variation with Low Ignition Quality Fuels in a CFR Diesel Engine; SAE International: Michigan, MI, USA, 1979. [Google Scholar] [CrossRef]

- Kyrtatos, P.; Zivolic, A.; Brückner, C.; Boulouchos, K. Cycle-to-cycle variations of NO emissions in diesel engines under long ignition delay conditions. J. Combust. Flame 2017, 178, 82–96. [Google Scholar] [CrossRef]

- Kyrtatos, P.; Hoyer, K.; Obrecht, P.; Boulouchos, K. Apparent effects of in-cylinder pressure oscillations and cycle-to-cycle variability on heat release rate and soot concentration under long ignition delay conditions in diesel engines. Int. J. Engine Res. 2014, 15, 325–337. [Google Scholar] [CrossRef]

- Eng, J.A. Characterization of Pressure Waves in HCCI Combustion; SAE International: California, CA, USA, 2002. [Google Scholar]

- Griffiths, J.F.; Whitaker, B.J. Thermokinetic interactions leading to knock during homogeneous charge compression ignition. J. Combust. Flame 2002, 131, 386–399. [Google Scholar] [CrossRef]

- Kyrtatos, P.; Bruckner, C.; Boulouchos, K. Cycle-to-cycle variations in diesel engines. Appl. Energy 2016, 171, 120–132. [Google Scholar] [CrossRef]

- Murayama, T.; Yamada, T.; Miyamoto, N.; Chikahisa, T. Nature and reduction of cycle-to-cycle combustion engine with ethanol–diesel fuel blends. J. Appl. Entomol. 1983, 135, 320–325. [Google Scholar]

- Yammamoto, k.; Tsuji, Y.; Aso, Y.; Hamasaki, T.; Shirahata, S.; Katakura, Y. Effect of diazinon exposure on antioxidant reactions in the silkmoth, Bombyx mori. J. Appl. Entomol. 2011, 135. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Yue, L.; Liu, H.F.; Zhu, Y.X.; Zhong, X.F.; Yao, M.F. Effect of two-stage injection on combustion and emissions under high EGR rate on a diesel engine by fueling blends of diesel/gasoline, diesel/n-butanol, diesel/gasoline/n-butanol and pure diesel. Energy Convers. Manag. 2015, 90, 1–11. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Li, J.; Zhou, D.Z. Modeling study of oxygenated fuels on diesel combustion: Effects of oxygen concentration, cetane number and C/H ratio. J. Energy Convers. Manag. 2015, 90, 261–271. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Bermudez, V. Sensitivity of diesel engine thermodynamic cycle calculation to measurement errors and estimated parameters. J. Appl. Therm. Eng. 2000, 20, 843–861. [Google Scholar] [CrossRef]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef]

- Stone, R. Introduction to Internal Combustion Engines; Macmillan Press Ltd.: London, UK, 1999; pp. 295–300. ISBN 0-333-74013-0. Tesseraux, I.; Toxicoll, Let., 2004, 149. [Google Scholar]

- Zhao, H. HCCI and CAI Engines for the Automotive Industry; Woodhead Publishing Limited: England, UK, 2007. [Google Scholar]

- Heywood, J.B. Internal Combustion Engines Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Maurya, R.K.; Agarwal, A.K. Experimental investigation on the effect of intake air temperature and air–fuel ratio on cycle-to-cycle variations of HCCI combustion and performance parameters. J. Appl. Energy 2011, 88, 1153–1163. [Google Scholar] [CrossRef]

- Uyumaz, A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. [Google Scholar] [CrossRef]

- Tsurushima, T. A new skeletal PRF kinetic model for HCCI combustion. J. Proc. Combust. Inst. 2009, 32, 2835–2841. [Google Scholar] [CrossRef]

- Amano, T.; Morimoto, S.; Kawabata, Y. Modeling of the Effect of Air/Fuel Ratio and Temperature Distribution on HCCI Engines; SAE Technical Paper: Michigan, MI, USA, 2001. [Google Scholar]

- Al-Dawody, M.F.; Bhatti, S.K. Effect of soybean oil biofuel blending on the performance and emissions of diesel engine using diesel-rk software. Int. J. Eng. Sci. Technol. 2011, 3, 4539–4555. [Google Scholar]

- Lu, X.C.; Ji, L.B.; Ma, J.J.; Huang, Z. Combustion stabilities and cycle-by-cycle variations of n-Heptane homogeneous charge compression ignition combustion. Energy Fuels 2007, 21, 1468–1473. [Google Scholar] [CrossRef]

- Lu, X.C.; Ji, L.B.; Ma, J.J.; Huang, Z. Experimental study on the cycle-by-cycle variations of homogeneous charge compression ignition combustion using primary reference fuels and their mixtures. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2007, 221, 859–866. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, F.; Zhao, Y.; Li, D.; Lei, X. Study on cycle-by-cycle variations in a diesel engine with dimethyl ether as port premixing fuel. Appl. Energy 2015, 143, 58–70. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, C.; Yao, A.; Dou, Z.C.; Wang, B.; Wei, H.Y.; Liu, M.J.; Chen, C.; Shi, J.J. The impact of methanol injecting position on cylinder-to-cylinder variation in a diesel methanol dual fuel engine. Fuel 2017, 191, 150–163. [Google Scholar] [CrossRef]

- Duan, X.B.; Liu, J.P.; Yuan, Z.P.; Guo, G.M.; Liu, Q.; Tang, Q.J.; Deng, B.D.; Guan, J.H. Experimental investigation of the effects of injection strategies on cycle-to-cycle variations of a DISI engine fueled with ethanol and gasoline blend. J. Energy 2018, 165, 455–470. [Google Scholar] [CrossRef]

- Maurya, R.K.; Agarwal, A.K. Statistical analysis of the cyclic variations of heat release parameters in HCCI combustion of methanol and gasoline. Appl. Energy 2012, 89, 228–236. [Google Scholar] [CrossRef]

| Specifications | - |

|---|---|

| Model | Electronically controlled |

| Type | Water cooled, turbo-charged |

| Engine displacement (L) | 3.298 |

| Bore × Stroke (mm × mm) | 100 × 105 |

| Fuel injection system | Common Rail fuel system |

| Compression ratio | 17.5 |

| Calibration power (kW)/speed(rpm) | 85/3200 |

| Maximum torque (Nm)/speed(rpm) | 315/1600‒2400 |

| Instrument | Parameters | Range | Accuracy | Uncertainty (%) |

|---|---|---|---|---|

| Electric eddy current dynamometer | Torque Speed | 0–600 (nm) 0–8000 (rpm) | 0.4% 0.1% | - |

| Fuel consumption meter | Fuel mass | 0–20 (kg) | 0.4% | - |

| Pressure sensor | In-cylinder pressure | 0–250 (MPa) | 0.05 (MPa) | 0.3 |

| Specifications | 0#-Diesel | FT-Diesel |

|---|---|---|

| Density (g/cm3) | 0.81 | 0.76 |

| Initial boiling point (°C) | 200 | 180.5 |

| End boiling point (°C) | 375 | 311.5 |

| Sulfur content (ppm) | 10 | 0 |

| Aromatic content (%) | ≤7 | 0.009 |

| Heating value (J/g) | 42,652 | 47,128 |

| CN | 55.8 | 62.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Wang, T.; Zhao, Z.; Wu, Z.; Zhang, Z. Cycle-to-Cycle Variation of a Diesel Engine Fueled with Fischer–Tropsch Fuel Synthesized from Coal. Appl. Sci. 2019, 9, 2032. https://doi.org/10.3390/app9102032

Shi J, Wang T, Zhao Z, Wu Z, Zhang Z. Cycle-to-Cycle Variation of a Diesel Engine Fueled with Fischer–Tropsch Fuel Synthesized from Coal. Applied Sciences. 2019; 9(10):2032. https://doi.org/10.3390/app9102032

Chicago/Turabian StyleShi, Jinhong, Tie Wang, Zhen Zhao, Zhifei Wu, and Zhengwu Zhang. 2019. "Cycle-to-Cycle Variation of a Diesel Engine Fueled with Fischer–Tropsch Fuel Synthesized from Coal" Applied Sciences 9, no. 10: 2032. https://doi.org/10.3390/app9102032

APA StyleShi, J., Wang, T., Zhao, Z., Wu, Z., & Zhang, Z. (2019). Cycle-to-Cycle Variation of a Diesel Engine Fueled with Fischer–Tropsch Fuel Synthesized from Coal. Applied Sciences, 9(10), 2032. https://doi.org/10.3390/app9102032