Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Pollutants

2.2. Biosorbents

2.3. Adsorption Tests

2.4. Biosorbent Characterization

2.4.1. Biosorbent Point of Zero Charge

2.4.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.3. Scanning Electron Microscopy (SEM) Analyses

2.5. Experimental Design

2.6. Statistical Analysis of the Experimental Model

2.7. Cr Analysis

3. Results and Discussion

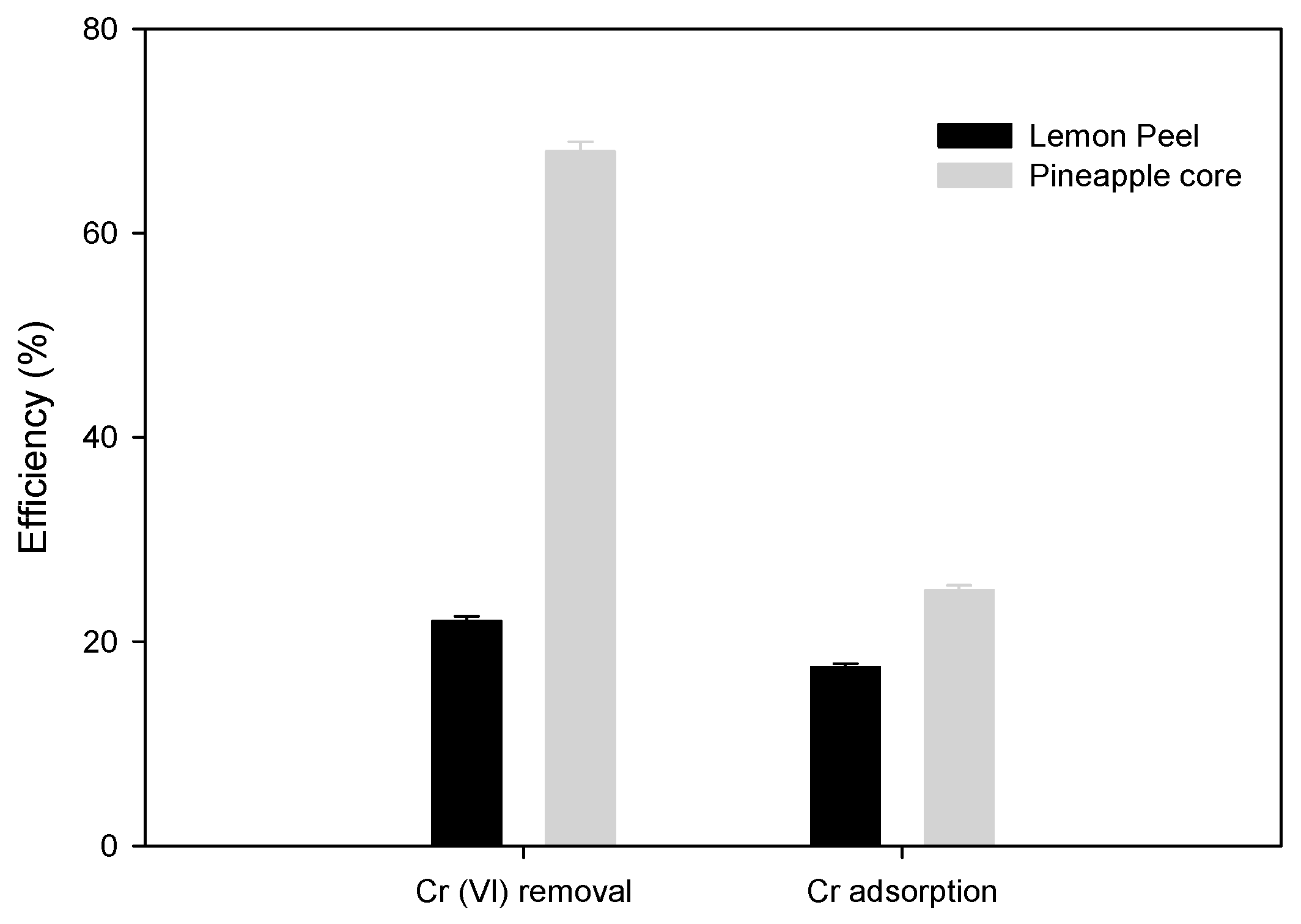

3.1. Screening of Biosorbents

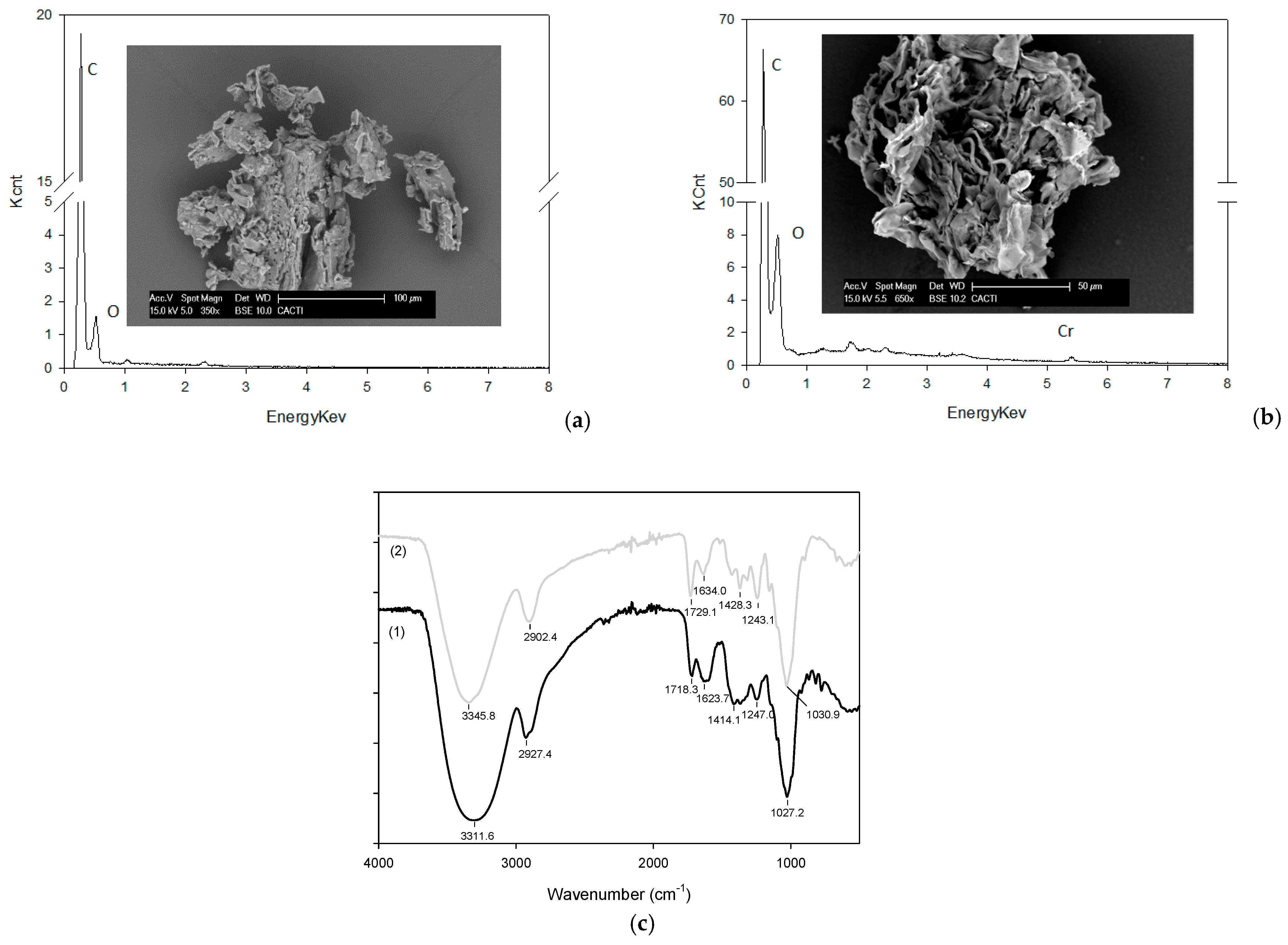

3.2. PP Characterization

3.3. Experimental Design

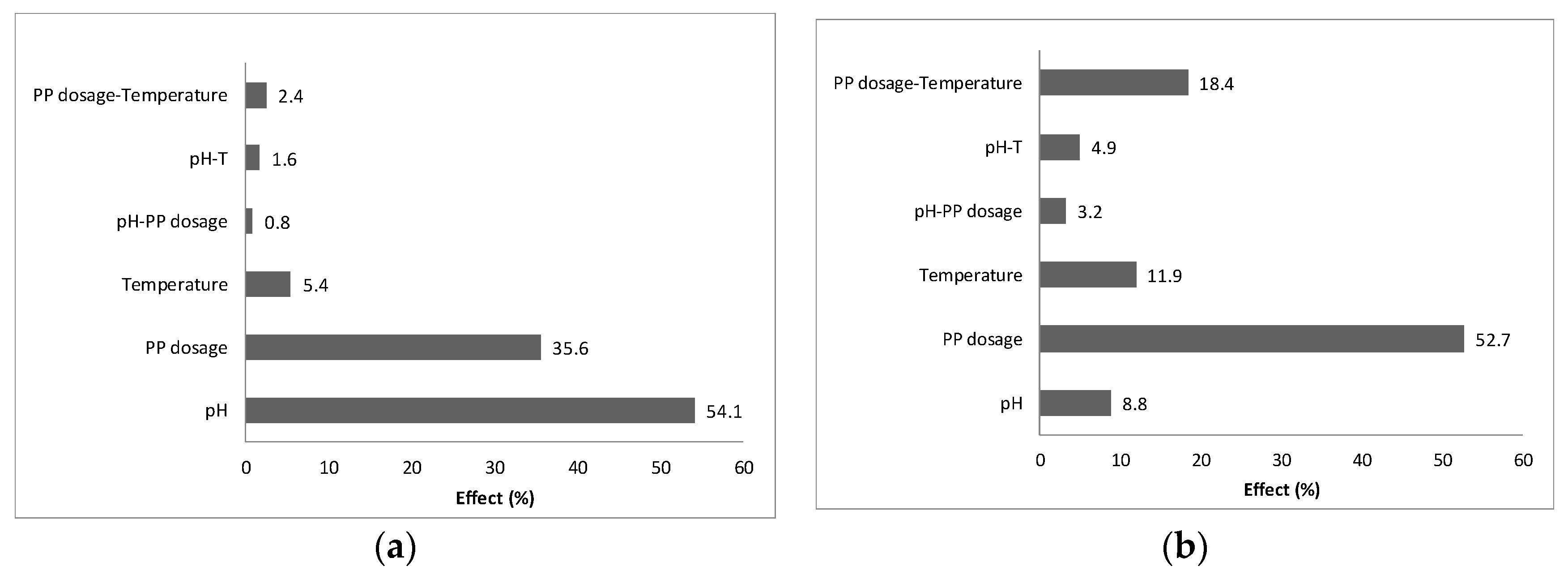

3.4. Box–Behnken Analysis

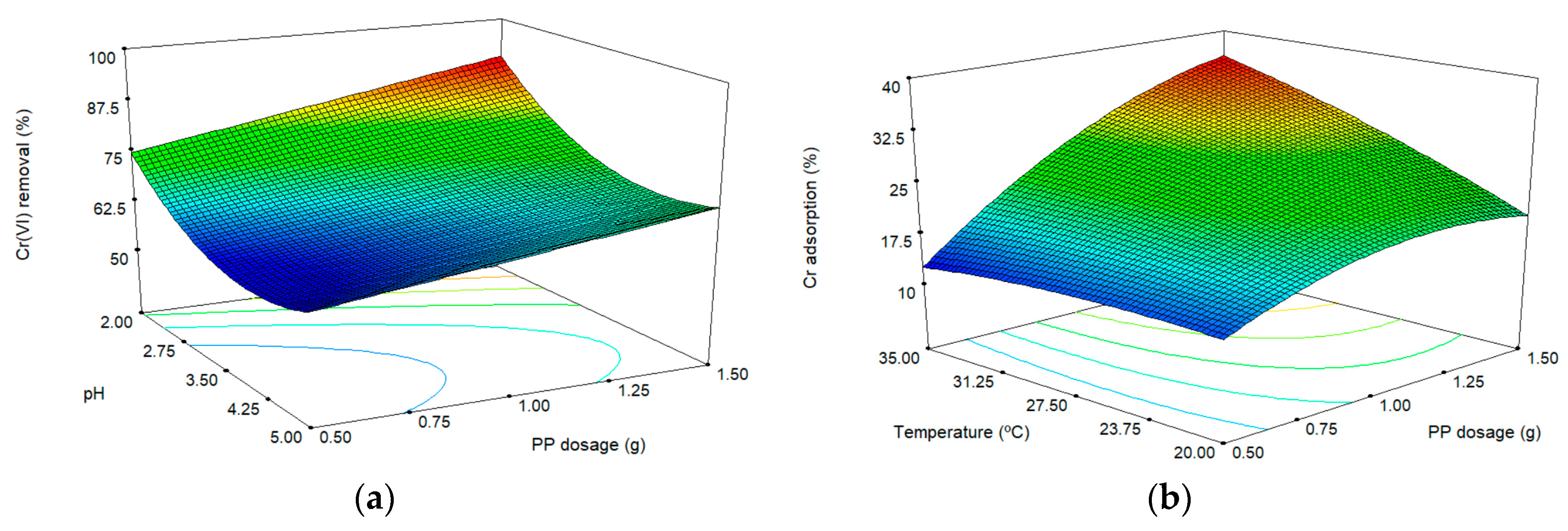

3.4.1. Cr(VI) Removal

3.4.2. Total Cr removal

3.4.3. Desirability Function and Validation

3.4.4. Characterization of PP after the Adsorption

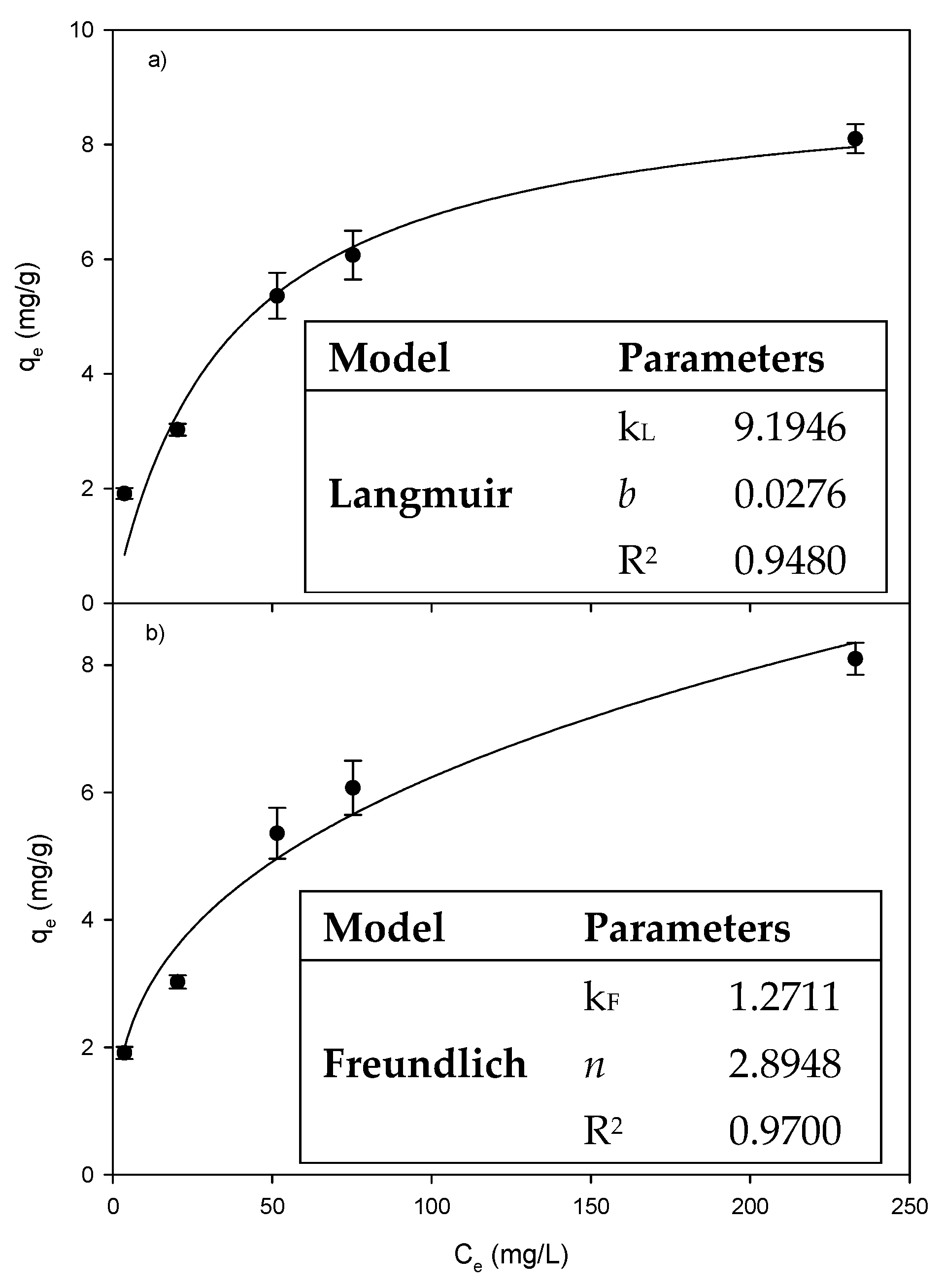

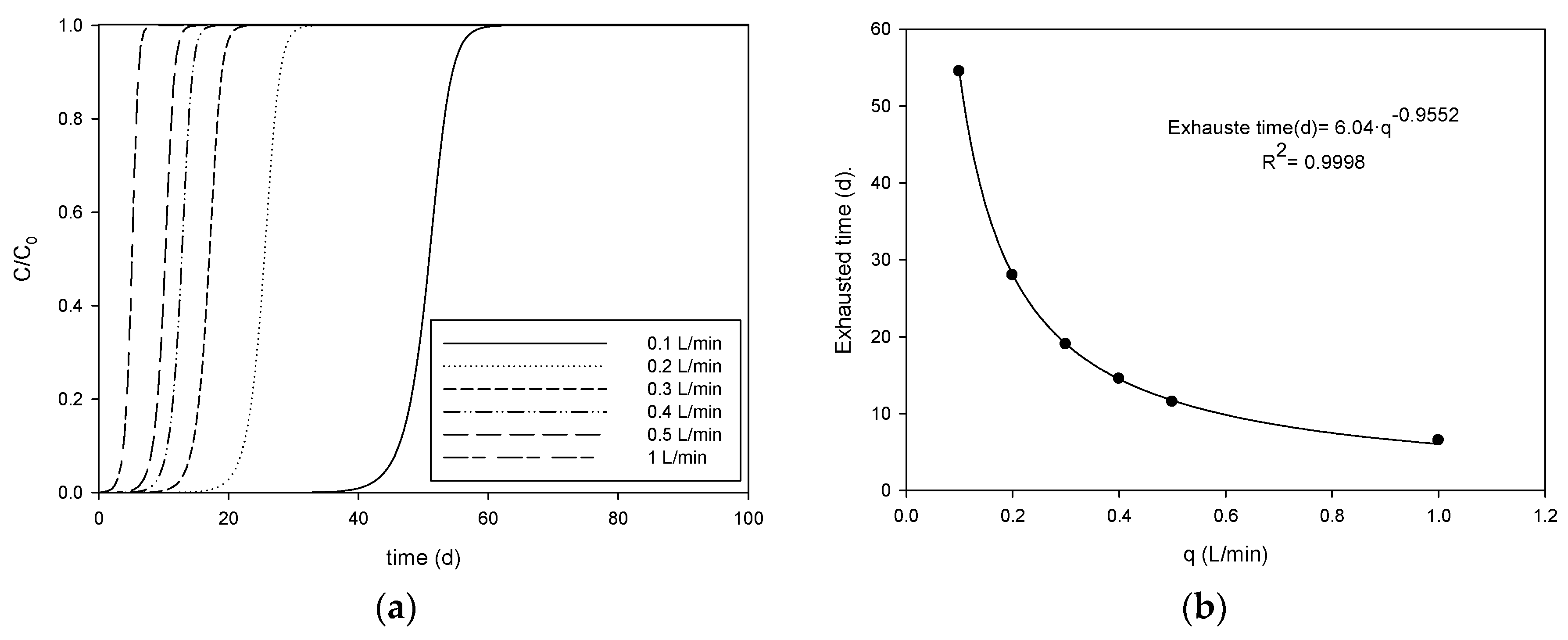

3.5. Adsorption in the Optimized Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fernández-López, J.A.; Angosto, J.M.; Roca, M.J.; Doval Miñarro, M. Taguchi design-based enhancement of heavy metals bioremoval by agroindustrial waste biomass from artichoke. Sci. Total Environ. 2019, 653, 55–63. [Google Scholar] [CrossRef]

- Lee, P.; Sims, E.; Bertham, O.; Symington, H.; Bell, N.; Pfaltzgraff, L.; Sjögren, P.; Wilts, H.; O’Brien, M. Towards a Circular Economy-Waste Management in the EU. Study IP/G/STOA/FWC/2013-001/LOT 3/C3; European Parliamentary Research Service: Brussels, Belgium, 2017. [Google Scholar]

- Rovani, S.; Censi, M.T.; Pedrotti, S.L.; Lima, T.C.; Cataluña, R.; Fernandes, A.N. Development of a new adsorbent from agro-industrial waste and its potential use in endocrine disruptor compound removal. J. Hazard. Mater. 2014, 271, 311–320. [Google Scholar] [CrossRef]

- Gadd, G.M. Biosorption: Critical review of scientific rationale, environmental importance and significance for pollution treatment. J. Chem. Technol. Biotechnol. 2009, 84, 13–28. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef]

- Abdolali, A.; Guo, W.S.; Ngo, H.H.; Chen, S.S.; Nguyen, N.C.; Tung, K.L. Typical lignocellulosic wastes and by-products for biosorption process in water and wastewater treatment: A critical review. Bioresour. Technol. 2014, 160, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Krishnani, K.K.; Ayyappan, S. Heavy metals remediation of water using plants and lignocellulosic agrowastes. Rev. Environ. Contam. Toxicol. 2006, 188, 59–84. [Google Scholar]

- Cobas, M.; Sanromán, M.A.; Pazos, M. Box-Behnken methodology for Cr (VI) and leather dyes removal by an eco-friendly biosorbent: F. vesiculosus. Bioresour. Technol. 2014, 160, 166–174. [Google Scholar] [CrossRef]

- Putnik, P.; Bursac Kovacevic, D.; Režek Jambrak, A.; Barba, F.J.; Cravotto, G.; Binello, A.; Lorenzo, J.M.; Shpigelman, A. Innovative “green” and novel strategies for the extraction of bioactive added value compounds from citruswastes-A review. Molecules 2017, 22, 680. [Google Scholar] [CrossRef]

- Pérez Marín, A.B.; Aguilar, M.I.; Meseguer, V.F.; Ortuño, J.F.; Sáez, J.; Lloréns, M. Biosorption of chromium (III) by orange (Citrus cinensis) waste: Batch and continuous studies. Chem. Eng. J. 2009, 155, 199–206. [Google Scholar] [CrossRef]

- Acar, F.N.; Malkoc, E. The removal of chromium(VI) from aqueous solutions by Fagus orientalis L. Bioresour. Technol. 2004, 94, 13–15. [Google Scholar] [CrossRef]

- Miretzky, P.; Cirelli, A.F. Cr(VI) and Cr(III) removal from aqueous solution by raw and modified lignocellulosic materials: A review. J. Hazard. Mater. 2010, 180, 1–19. [Google Scholar] [CrossRef]

- Gogoi, S.; Chakraborty, S.; Saikia, M.D. Surface modified pineapple crown leaf for adsorption of Cr(VI) and Cr(III) ions from aqueous solution. J. Environ. Chem. Eng. 2018, 6, 2492–2501. [Google Scholar] [CrossRef]

- Simsek, E.B.; Özdemir, E.; Beker, U. Process optimization for arsenic adsorption onto natural zeolite incorporating metal oxides by response surface methodology. Water Air Soil Pollut. 2013, 224, 1614. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association, American Water Works Association (AWWA), Water Environment Federation (WEF): Washington, DC, USA, 1992. [Google Scholar]

- Krupka, K.M.; Kaplan, D.I.; Whelan, G.; Serne, R.J.; Mattigod, S.V. Understanding variation in partition coefficient, Kd, values. In Volume II: Review of Geochemistry and Available Kd Values, for Cadmium, Cesium, Chromium, Lead, Plutonium, Radon, Strontium, Thorium, Tritium (3H), and Uranium; EPA: Washington, DC, USA, 1999. [Google Scholar]

- Barkat, M.; Nibou, D.; Chegrouche, S.; Mellah, A. Kinetics and thermodynamics studies of chromium(VI) ions adsorption onto activated carbon from aqueous solutions. Chem. Eng. Process.: Process Intensif. 2009, 48, 38–47. [Google Scholar] [CrossRef]

- Pardo, M.; Casellis, E.; Escobedo, R.; García, E. Chemical Characterisation of the Industrial Residues of the Pineapple (Ananas comosus). J. Agric. Chem. Environ. 2014, 3, 53–56. [Google Scholar] [CrossRef]

- Park, D.; Ahn, C.K.; Kim, Y.M.; Yun, Y.S.; Park, J.M. Enhanced abiotic reduction of Cr(VI) in a soil slurry system by natural biomaterial addition. J. Hazard. Mater. 2008, 160, 422–427. [Google Scholar] [CrossRef]

- Park, D.; Lim, S.; Yun, Y.S.; Park, J.M. Development of a new Cr(VI)-biosorbent from agricultural biowaste. Bioresour. Technol. 2008, 99, 8810–8818. [Google Scholar] [CrossRef]

- Hossain, M.A.; Ngo, H.H.; Guo, W.S.; Nguyen, T.V.; Vigneswaran, S. Performance of cabbage and cauliflower wastes for heavy metals removal. Desalin. Water Treat. 2014, 52, 844–860. [Google Scholar] [CrossRef]

- Xu, F.; Yu, J.; Tesso, T.; Dowell, F.; Wang, D. Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: A mini-review. Appl. Energy 2013, 104, 801–809. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; John Wiley and Sons: New York, NY, USA, 2001. [Google Scholar]

- Li, R.; Zhang, Z.; Meng, Z.; Li, H. Biosorption of Cr (VI) by corn stalk biomass: Thermodynamics and mechanism. Huanjing Kexue Xuebao 2009, 29, 1434–1441. [Google Scholar]

- Prabhakaran, S.K.; Vijayaraghavan, K.; Balasubramanian, R. Removal of Cr(VI) ions by spent tea and coffee dusts: Reduction to Cr(III) and biosorption. Ind. Eng. Chem. Res. 2009, 48, 2113–2117. [Google Scholar] [CrossRef]

- Daneshvar, N.; Salari, D.; Aber, S. Chromium adsorption and Cr(VI) reduction to trivalent chromium in aqueous solutions by soya cake. J. Hazard. Mater. 2002, 94, 49–61. [Google Scholar] [CrossRef]

- Rawajfih, Z.; Nsour, N. Thermodynamic analysis of sorption isotherms of chromium(VI) anionic species on reed biomass. J. Chem. Thermodyn. 2008, 40, 846–851. [Google Scholar] [CrossRef]

- Segurola, J.; Allen, N.S.; Edge, M.; Mc Mahon, A. Design of eutectic photoinitiator blends for UV/visible curable acrylated printing inks and coatings. Prog. Org. Coat. 1999, 37, 23–37. [Google Scholar] [CrossRef]

- Rossi, R.J. Applied Biostatistic for the Health Sciencies; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Khuri, A.I.; Cornell, J.A. Response Surfaces; Dekker Inc.: New York, NY, USA, 1996. [Google Scholar]

- Prabhul, A.A.; Dhaneshwar, A.D.; Mrudula, C.M.; Kannan, N. Evaluation of process parameters for biosorption of chromium (VI) using full factorial design and response surface methodology. ESAIJ 2014, 9, 263–273. [Google Scholar]

- Anupam, K.; Dutta, S.; Bhattacharjee, C.; Datta, S. Adsorptive removal of chromium (VI) from aqueous solution over powdered activated carbon: Optimisation through response surface methodology. Chem. Eng. J. 2011, 173, 135–143. [Google Scholar] [CrossRef]

- Aksezer, C.S. On the sensitivity of desirability functions for multiresponse optimization. J. Ind. Manag. Optim. 2008, 4, 685–696. [Google Scholar] [CrossRef]

- Rosales, E.; Meijide, J.; Tavares, T.; Pazos, M.; Sanromán, M.A. Grapefruit peelings as a promising biosorbent for the removal of leather dyes and hexavalent chromium. Process Saf. Environ. Prot. 2016, 101, 61–71. [Google Scholar] [CrossRef]

- Gutha, Y.; Munagapati, V.S.; Naushad, M.; Abburi, K. Removal of Ni(II) from aqueous solution by Lycopersicum esculentum (Tomato) leaf powder as a low-cost biosorbent. Desalin. Water Treat. 2015, 54, 200–208. [Google Scholar] [CrossRef]

- Richard, D.; Delgado Núñez, M.d.L.; Schweich, D. Adsorption of complex phenolic compounds on active charcoal: Breakthrough curves. Chem. Eng. J. 2010, 158, 213–219. [Google Scholar] [CrossRef]

- Chen, G.Q.; Zeng, G.M.; Tu, X.; Niu, C.G.; Huang, G.H.; Jiang, W. Application of a by-product of Lentinus edodes to the bioremediation of chromate contaminated water. J. Hazard. Mater. 2006, 135, 249–255. [Google Scholar] [CrossRef]

- Elangovan, R.; Philip, L.; Chandraraj, K. Biosorption of chromium species by aquatic weeds: Kinetics and mechanism studies. J. Hazard. Mater. 2008, 152, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Liu, Y.; Zeng, G.; Xu, W.; Li, T.; Xia, W. Characterization of Cr(VI) removal from aqueous solutions by a surplus agricultural waste-Rice straw. J. Hazard. Mater. 2008, 150, 446–452. [Google Scholar] [CrossRef]

- Dupont, L.; Guillon, E. Removal of hexavalent chromium with a lignocellulosic substrate extracted from wheat bran. Environ. Sci. Technol. 2003, 37, 4235–4241. [Google Scholar] [CrossRef] [PubMed]

| Run | pH, x1 | PP Dosage (g), x2 | Temperature (°C), x3 | Cr(VI) Removal (%) | Total Cr Removal (%) | Uptake (mg/g) | KD (mL/g) |

|---|---|---|---|---|---|---|---|

| 1 | 3.5 | 1.5 | 20 | 69.81 | 20.04 | 1.00 | 8.35 |

| 2 | 3.5 | 1.5 | 35 | 77.96 | 35.79 | 1.79 | 18.58 |

| 3 | 3.5 | 1 | 27.5 | 66.47 | 24.03 | 1.80 | 15.82 |

| 4 | 2 | 1.5 | 27.5 | 89.85 | 35.02 | 1.75 | 17.96 |

| 5 | 3.5 | 0.5 | 35 | 59.46 | 12.89 | 1.93 | 14.80 |

| 6 | 2 | 1 | 20 | 79.34 | 25.54 | 1.92 | 17.15 |

| 7 | 3.5 | 1 | 27.5 | 64.88 | 26.8 | 2.01 | 18.31 |

| 8 | 5 | 1 | 35 | 68.52 | 27.88 | 2.09 | 19.33 |

| 9 | 3.5 | 0.5 | 20 | 58.48 | 14.58 | 2.19 | 17.07 |

| 10 | 2 | 0.5 | 27.5 | 75.29 | 16.03 | 2.40 | 19.09 |

| 11 | 5 | 0.5 | 27.5 | 60.55 | 12.32 | 1.85 | 14.05 |

| 12 | 2 | 1 | 35 | 88.44 | 28.03 | 2.10 | 19.47 |

| 13 | 3.5 | 1 | 27.5 | 62.34 | 24.95 | 1.87 | 16.62 |

| 14 | 3.5 | 1 | 27.5 | 66.42 | 26.64 | 2.00 | 18.16 |

| 15 | 5 | 1.5 | 27.5 | 70.99 | 24.03 | 1.20 | 10.54 |

| 16 | 5 | 1 | 20 | 65.29 | 16.34 | 1.23 | 9.77 |

| 17 | 3.5 | 1 | 27.5 | 65.89 | 24.95 | 1.71 | 16.62 |

| Wavelength (cm−1) | Bond Vibration | Related Structure |

|---|---|---|

| 3311 | O-H stretching | lignin [22] |

| 2900–3000 | C-H stretching | lignin [22] |

| 1720–1730 | C=O stretching | carbonyl group |

| 1624 | O-H bending | Polysaccharides |

| 1600 | N-H bending | amine amide |

| 1420 | C-H in-plane deformation | lignin [22] |

| 1370 | C-H bending | cellulose, hemicellulose, lignin [22] |

| 1247 | O-H bending | cellulose, hemicellulose [22] |

| 1030 | C-O, C=C, and C-C-O stretching | cellulose, hemicellulose, lignin [22] |

| 960 and 730 | Glycosidic linkage | cellulose, hemicellulose [22] |

| Cr(VI) Removal (%) | Total Cr Removal (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Values | p-Values | Sum of Squares | Degrees of Freedom | Mean Square | F-Values | p-Values |

| Model | 1382.12 | 9 | 153.56 | 66.88 | <0.0001 significant | 778.51 | 9 | 86.50 | 60.46 | <0.0001 significant |

| x1 | 570.71 | 1 | 570.71 | 248.56 | < 0.0001 | 72.30 | 1 | 72.30 | 50.54 | 0.0002 |

| x2 | 375.79 | 1 | 375.79 | 163.67 | < 0.0001 | 436.01 | 1 | 436.01 | 304.77 | < 0.0001 |

| x3 | 57.57 | 1 | 57.57 | 25.07 | 0.0016 | 98.63 | 1 | 98.63 | 68.94 | < 0.0001 |

| x1x2 | 4.24 | 1 | 4.24 | 1.85 | 0.2162 | 13.25 | 1 | 13.25 | 9.26 | 0.0188 |

| x1x3 | 8.61 | 1 | 8.61 | 3.75 | 0.0940 | 20.48 | 1 | 20.46 | 14.31 | 0.0069 |

| x2x3 | 12.85 | 1 | 12.85 | 5.60 | 0.0499 | 76.04 | 1 | 76.04 | 53.15 | 0.0002 |

| x12 | 338.78 | 1 | 338.78 | 147.55 | < 0.0001 | 2.37·10−6 | 1 | 2.37·10−6 | 1.66·10−6 | 0.9990 |

| x22 | 0.000 | 1 | 0 | 0 | 1.0000 | 55.28 | 1 | 55.28 | 38.64 | 0.0004 |

| x32 | 6.34 | 1 | 6.34 | 2.76 | 0.1404 | 4.43 | 1 | 4.43 | 3.10 | 0.1219 |

| Std. Dev | 1.52 | R2 | 0.9885 | Std. Dev | 1.20 | R2 | 0.9873 | |||

| Mean | 70.00 | Adj R2 | 0.9737 | Mean | 23.29 | Adj R2 | 0.9710 | |||

| CV % | 2.16 | Pred R2 | 0.9385 | CV % | 5.14 | Pred R2 | 0.9021 | |||

| Adeq-Precision | 27.377 | Adeq-Precision | 25.601 | |||||||

| Adsorbent | Optimum Adsorption Conditions | Maximum Cr(VI) Removal (%) | Maximum Cr Uptake (mg/g) | Estimated KD (mL/g) | Reference | ||

|---|---|---|---|---|---|---|---|

| pH | Dosage (g/L) | Temp. (ºC) | |||||

| Chitosan | 3 | 13 | 24.85 | - | 7.94 | 82.04 | [5] |

| Pineapple core | 2 | 30 | 30.05 | 92.39 | 8.8 | 99.29 | This work |

| Lentinus edodes | 3.9–4.4 | 20 | 25 | - | 10 | - | [37] |

| Reed mat | 4.5–5.5 | 10 | 30 | 52.83 | 7.18 | 25.18 | [38] |

| Mangrove leaves | 4.5–5.5 | 10 | 30 | 99.35 | 8.87 | 189.02 | [38] |

| Water lily | 4.5–5.5 | 10 | 30 | 96.49 | 8.44 | 126.44 | [38] |

| Untreated rice straw | 2.0 | 10 | 27 | 69.25 | 3.15 | 45.49 | [39] |

| Lignocellulosic substrate from wheat bran | 3.1 | 8 | 25 | - | 9.9 | - | [40] |

| Activated carbon | 3.72 | 10 | 45 | 65.7 | 5.09 | 191.55 | [17] |

| Parameters | Unit | Value |

|---|---|---|

| Biosorbent | kg | 62500 |

| Bed density | g/cm3 | 0.45 1 |

| Particle density | g/cm3 | 1.25 1 |

| Particle diameter | mm | 0.2 |

| Flow rate | L/min | 0.1–1 |

| Influent concentration | mg/L | 40 |

| Freundlich constant (KF) | (mg/g)(L/mg)n | 1.2711 |

| Freundlich exponent (n) | 2.8948 | |

| Surface diffusion coefficient (Ds) | m2/s | 8.20·10−13 |

| Film diffusion coefficient (kL) | m2/s | 0.82-8.41·10−8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosales, E.; Escudero, S.; Pazos, M.; Sanromán, M.A. Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes. Appl. Sci. 2019, 9, 1967. https://doi.org/10.3390/app9101967

Rosales E, Escudero S, Pazos M, Sanromán MA. Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes. Applied Sciences. 2019; 9(10):1967. https://doi.org/10.3390/app9101967

Chicago/Turabian StyleRosales, Emilio, Silvia Escudero, Marta Pazos, and Mª Angeles Sanromán. 2019. "Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes" Applied Sciences 9, no. 10: 1967. https://doi.org/10.3390/app9101967

APA StyleRosales, E., Escudero, S., Pazos, M., & Sanromán, M. A. (2019). Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes. Applied Sciences, 9(10), 1967. https://doi.org/10.3390/app9101967