Effects of Nanoparticle Materials on Prebreakdown and Breakdown Properties of Transformer Oil

Abstract

:Featured Application

Abstract

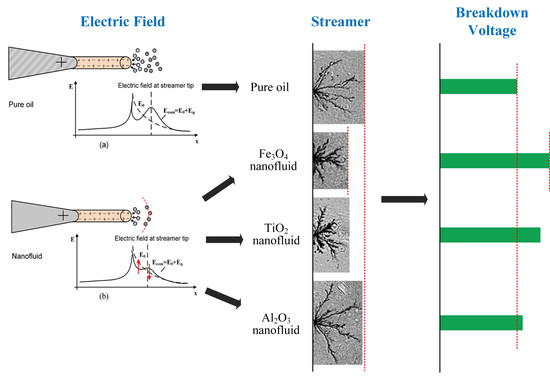

1. Introduction

2. Materials and Methods

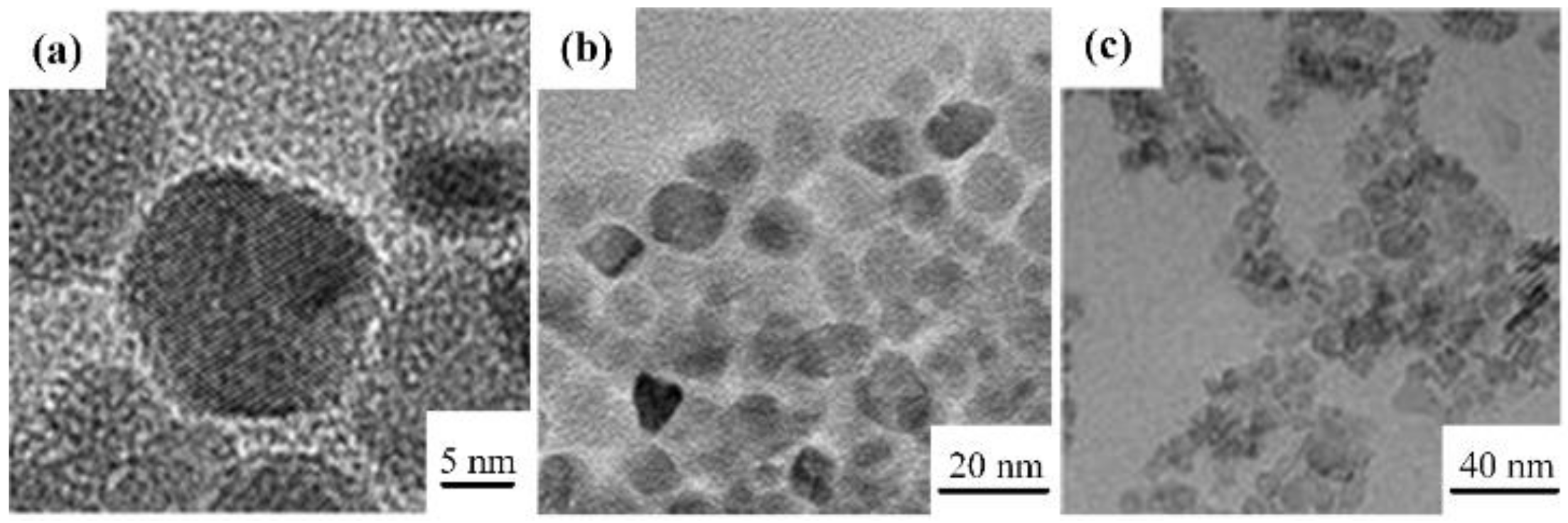

2.1. Nanofluid Preparation

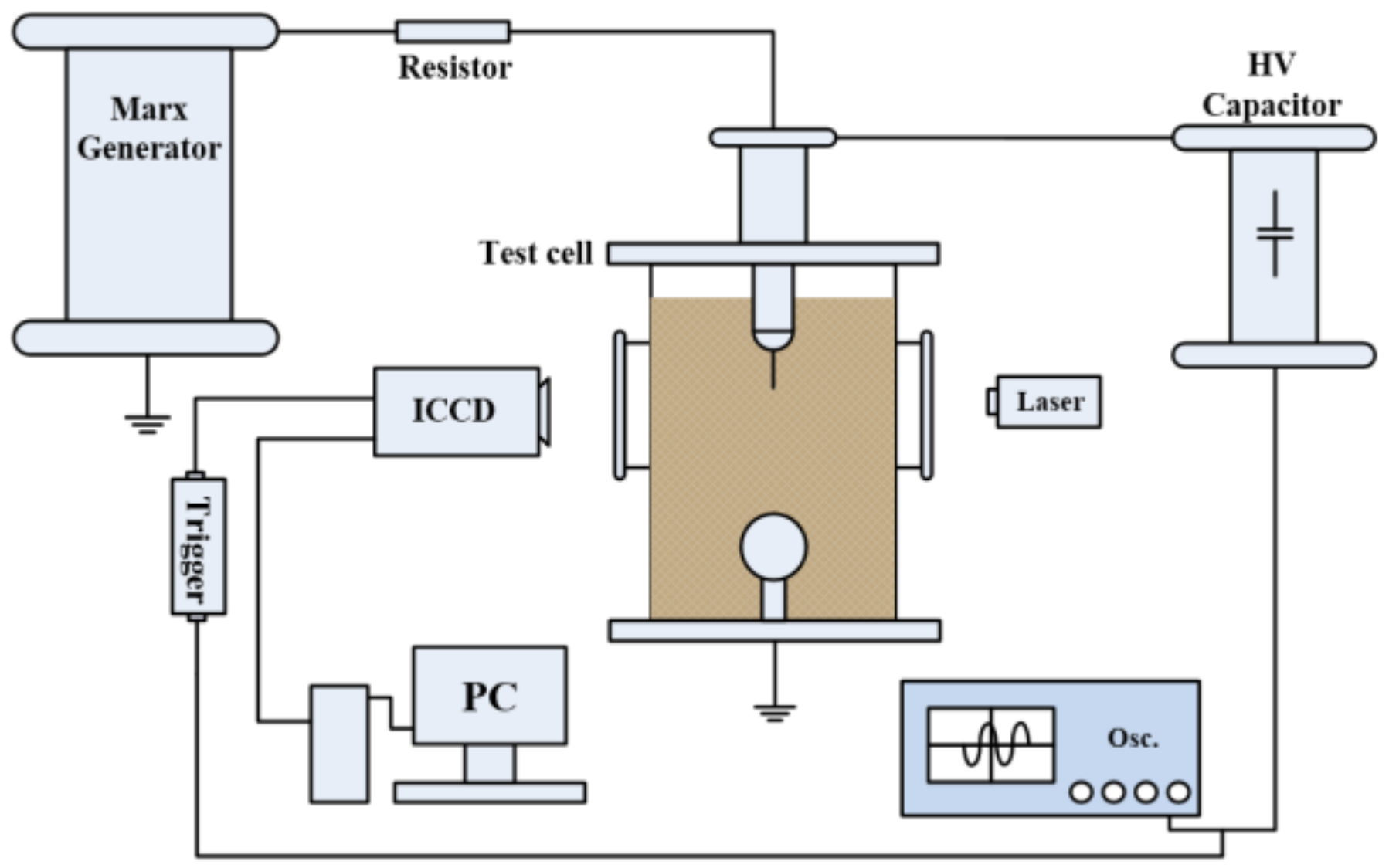

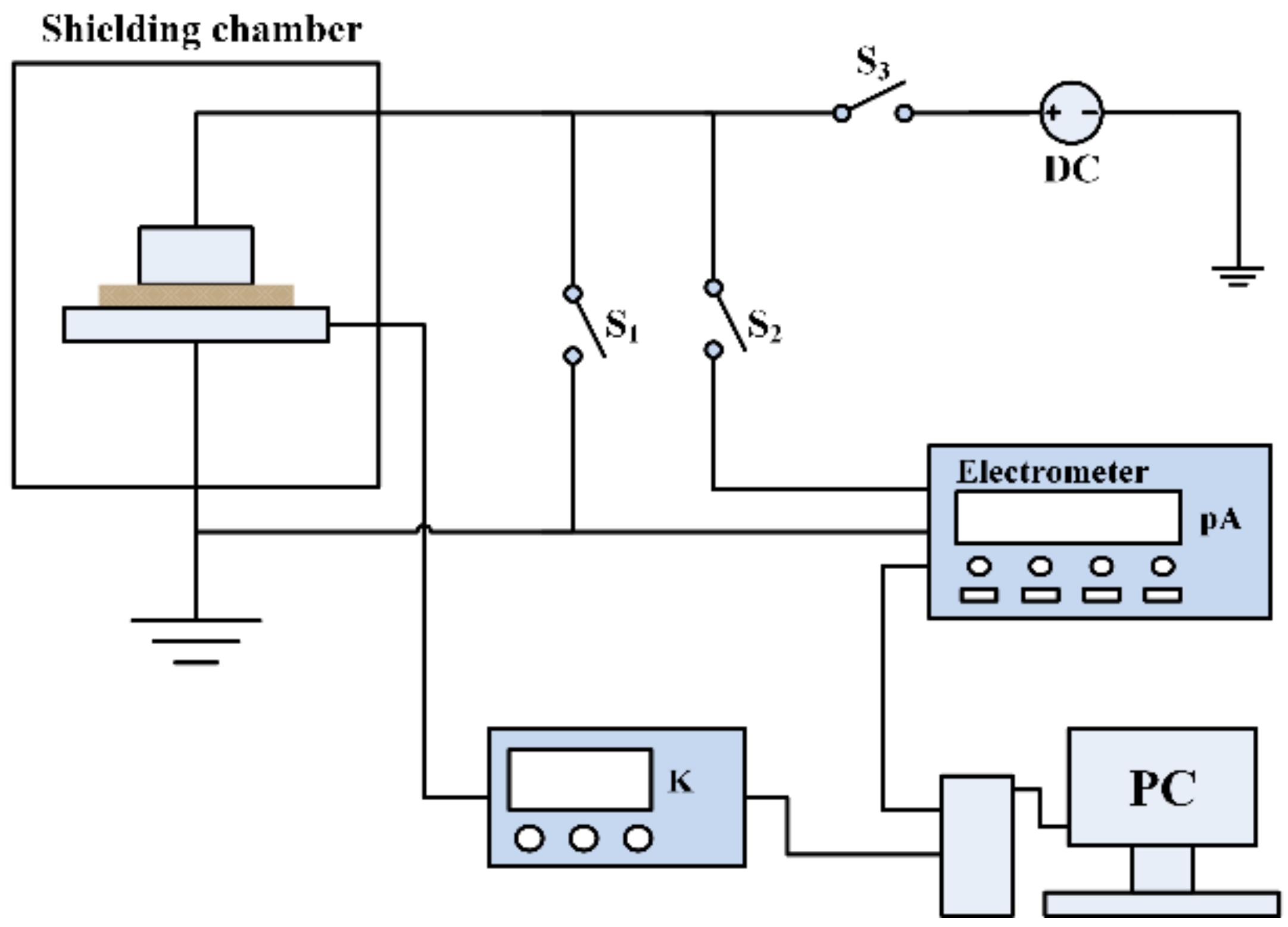

2.2. Experimental Setup and Measurements

3. Results

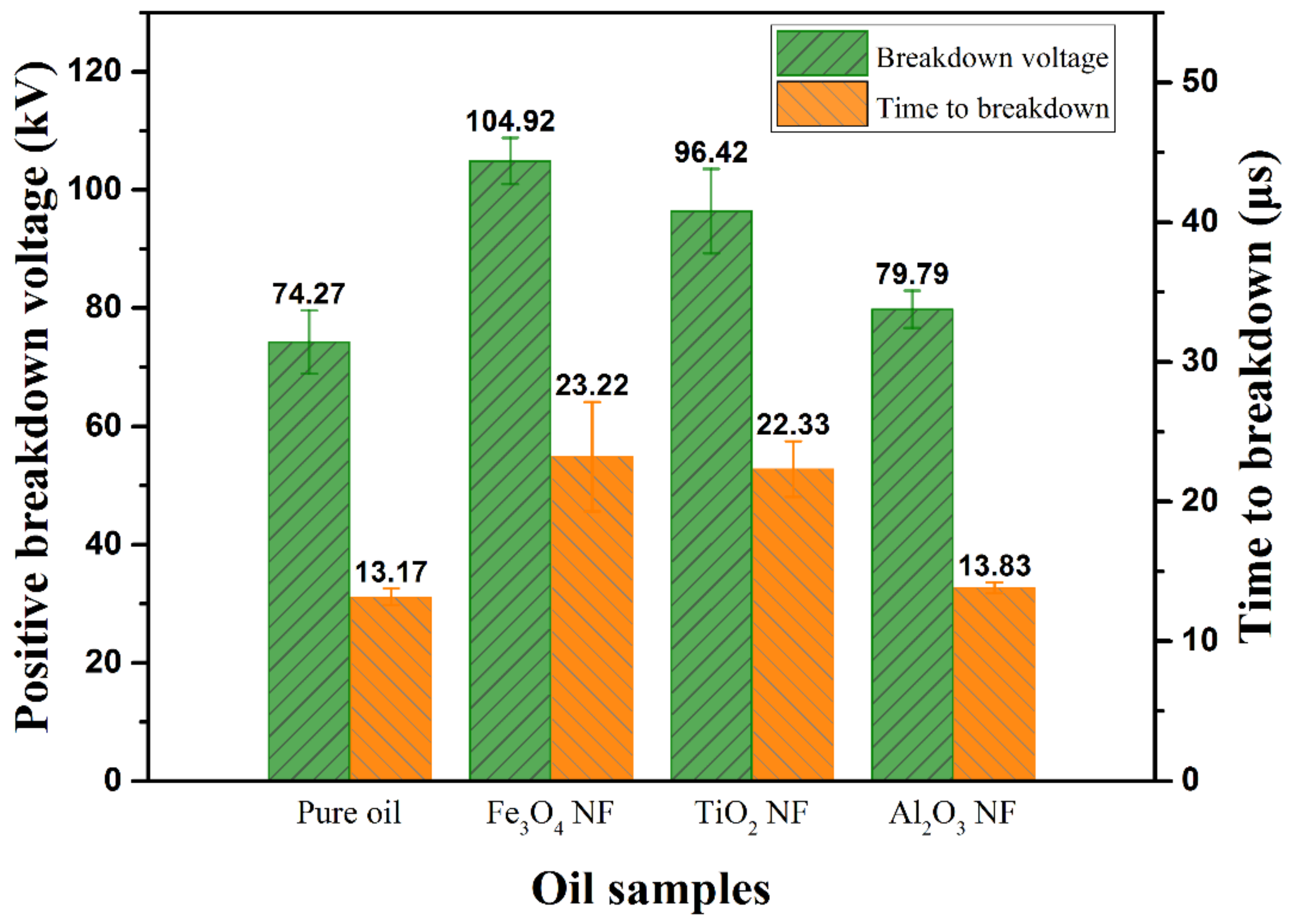

3.1. Breakdown Strength

3.2. Prebreakdown Streamers

3.2.1. Shape

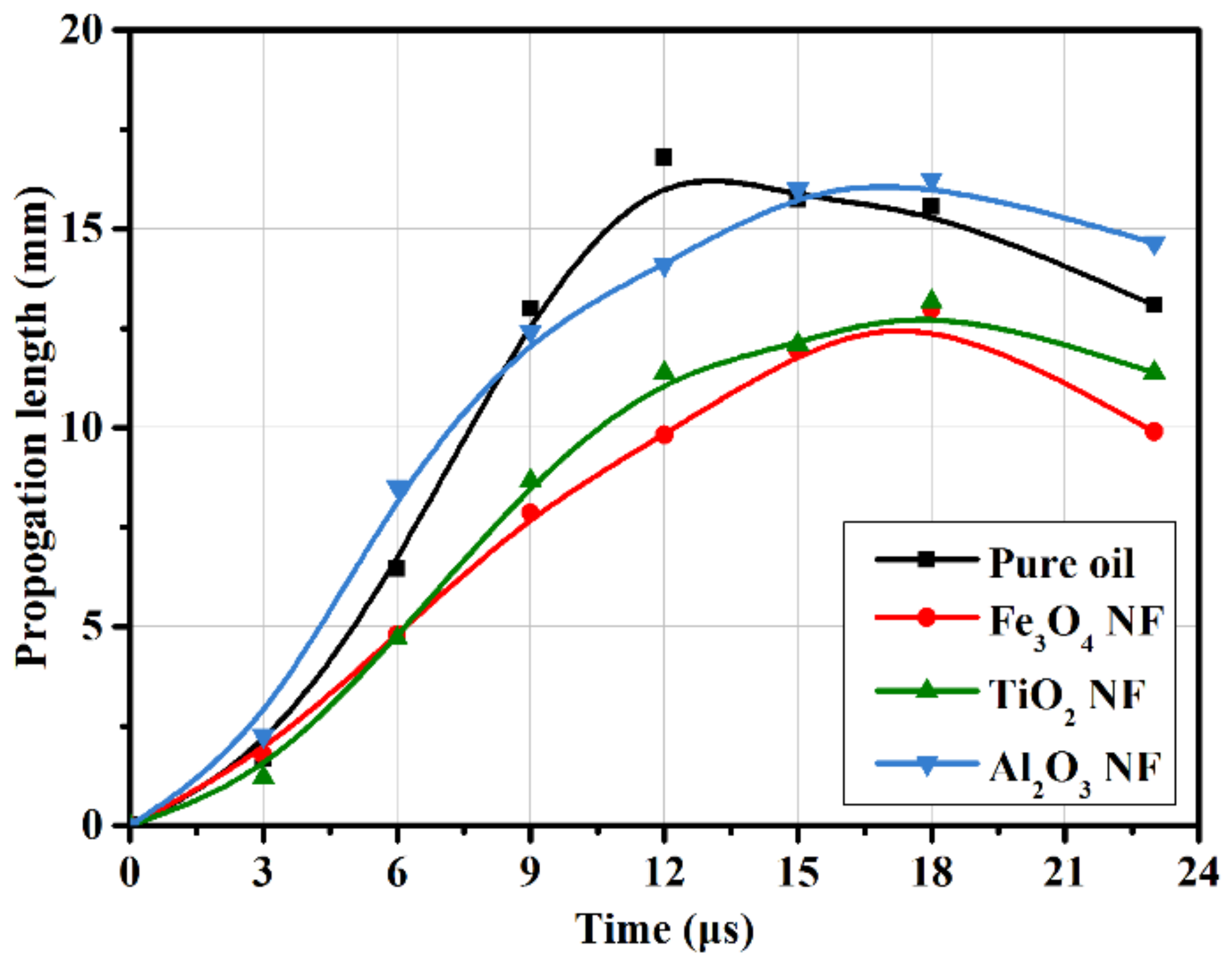

3.2.2. Propagation Length and Velocity

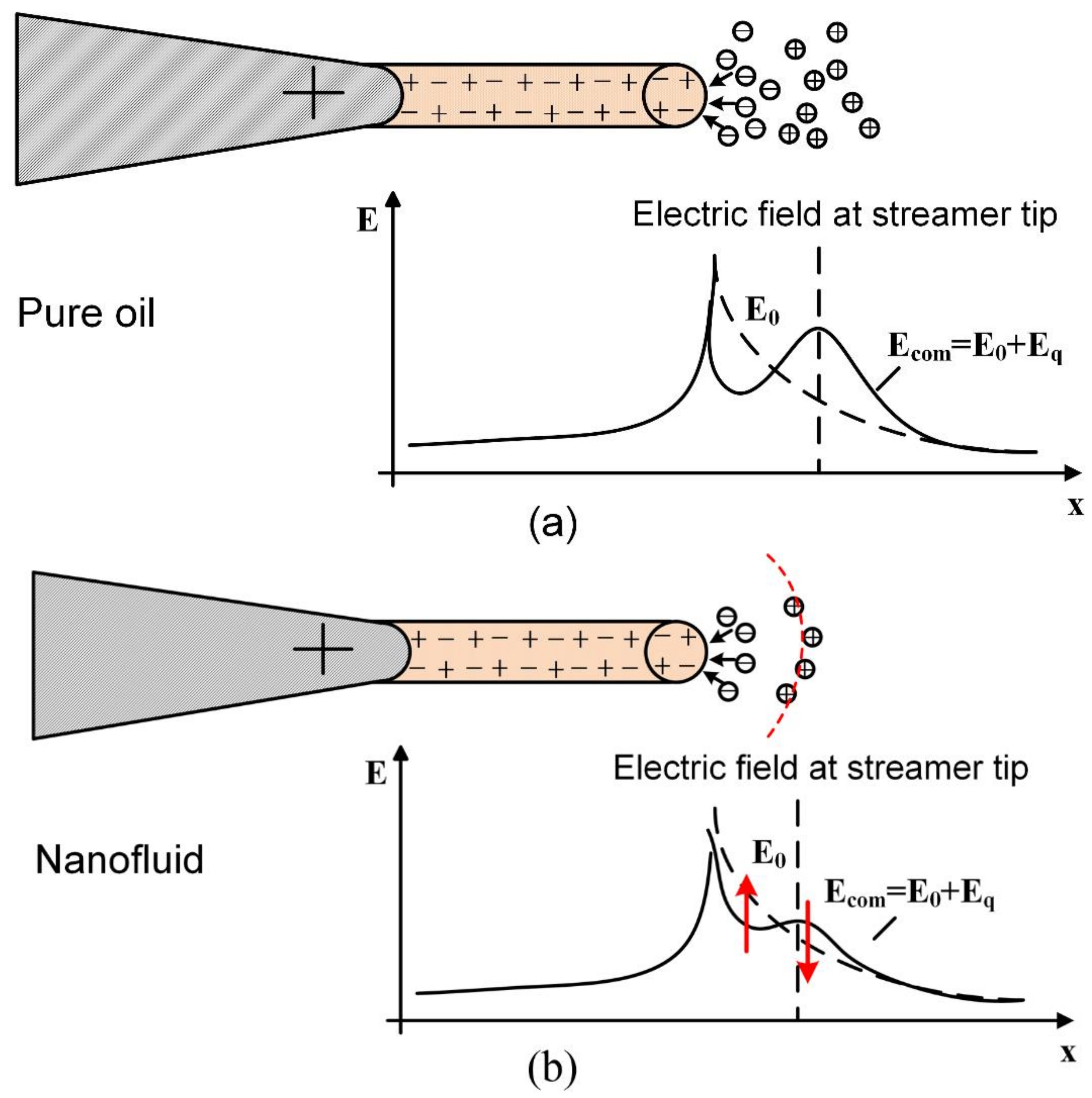

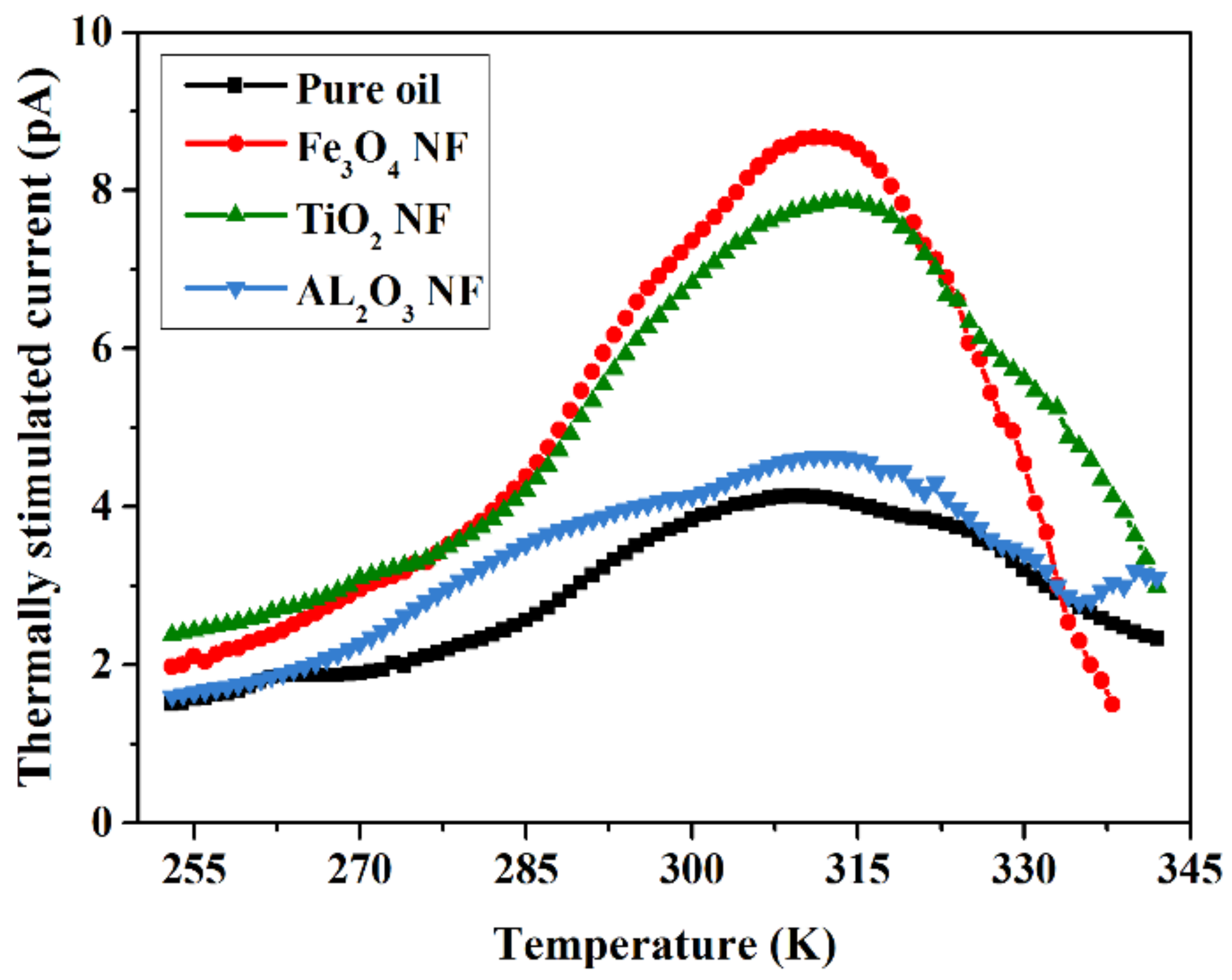

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wedin, P. Electrical breakdown in dielectric liquids—A short overview. IEEE Electr. Insul. Mag. 2014, 30, 20–25. [Google Scholar] [CrossRef]

- Devins, J.C. Breakdown and prebreakdown phenomena in liquids. Jpn. J. Appl. Phys. 1981, 52, 4531–4543. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.; Berg, G. Streamer propagation under impulse voltage in long point-plane oil gaps. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 447–458. [Google Scholar] [CrossRef]

- Massala, G.; Lesaint, O. A comparison of negative and positive streamers in mineral oil at large gaps. J. Phys. D Appl. Phys. 2001, 34, 1525. [Google Scholar] [CrossRef]

- Dung, N.V.; Hoidalen, H.K.; Linhjell, D.; Lundgaard, L.E.; Unge, M. Effects of reduced pressure and additives on streamers in white oil in long point-plane gap. J. Phys. D Appl. Phys. 2013, 46, 25501. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Z.D. Streamer characteristic and breakdown in synthetic and natural ester transformer liquids under standard lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 285–294. [Google Scholar] [CrossRef]

- Chadband, W.G. The electrical breakdown of insulating oil. Power Eng. J. 1992, 6, 61–67. [Google Scholar] [CrossRef]

- Beroual, A.; Tobaz, R. Prebreakdown Phenomena in Liquid Dielectrics. IEEE Trans. Dielectr. Electr. Insul. 1986, 21, 613–627. [Google Scholar] [CrossRef]

- Babaeva, N.Y.; Kushner, M.J. Effect of inhomogeneities on streamer propagation: II. Streamer dynamics in high pressure humid air with bubbles. Plasma Sources Sci. Technol. 2009, 18, 35010–35013. [Google Scholar] [CrossRef]

- Dung, N.V.; Hoidalen, H.K.; Linhjell, D.; Lundgaard, L.E.; Unge, M. Influence of Impurities and Additives on Positive Streamers in Paraffinic Model Oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1593–1603. [Google Scholar] [CrossRef]

- Lesaint, O.; Jung, M. On the relationship between streamer branching and propagation in liquids: Influence of pyrene in cyclohexane. J. Phys. D Appl. Phys. 2000, 33, 1360. [Google Scholar] [CrossRef]

- Lue, Y.-F.; Hung, Y.-H.; Li, F.-S.; Teng, T.-P.; Chen, S.-Y.; Wu, C.-H.; Ou, Y.-C. Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil. Appl. Sci. 2016, 6, 258. [Google Scholar] [CrossRef]

- Abhishek, R.; Hamouda, A.A. Effect of Various Silica Nanofluids: Reduction of Fines Migrations and Surface Modification of Berea Sandstone. Appl. Sci. 2017, 7, 1216. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhou, J.; Li, X. Effect of electron shallow trap on breakdown performance of transformer oil-based nanofluids. J. Appl. Phys. 2011, 110, 619–622. [Google Scholar] [CrossRef]

- Liu, R.; Pettersson, L.A.A.; Auletta, T.; Hjortstam, O. Fundamental research on the application of nano dielectrics to transformers. IEEE Conf. Electr. Insul. Dielectr. Phenom. 2011, 423–427. [Google Scholar]

- Sima, W.; Shi, J.; Yang, Q.; Huang, S.; Cao, X. Effects of conductivity and permittivity of nanoparticle on transformer oil insulation performance: Experiment and theory. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 380–390. [Google Scholar] [CrossRef]

- Council on Large Electric Systems (CIGRE). Effect of Particles on Transformer Dielectric Strength; Working Group 17 of Study Committee: Paris, France, 2000. [Google Scholar]

- Peppas, G.D.; Charalampakos, V.P.; Pyrgioti, E.C.; Gonos, I.F. Electrical and optical measurements investigation of the pre-breakdown processes in natural ester oil under different impulse voltage waveforms. IET Sci. Meas. Technol. 2016, 10, 545–551. [Google Scholar] [CrossRef]

- Mccluskey, F.M.J.; Denat, A.; Lesaint, O. Breakdown and prebreakdown phenomena in liquids under positive impulse voltages. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 377–382. [Google Scholar] [CrossRef]

- Sima, W.; Liu, C.; Yang, M.; Shao, Q.; Xu, H.; Liu, S. Plasma model of discharge along a dielectric surface in N2/O2 mixtures. Phys. Plasmas 2016, 23, 63508. [Google Scholar] [CrossRef]

- Torshin, Y.V. Schlieren registration of electrohydrodynamics phenomena in dielectric liquids under lightning impulse. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 470–474. [Google Scholar] [CrossRef]

- Hwang, J.G.; Zahn, M.; Pettersson, L.A.A. Mechanisms behind positive streamers and their distinct propagation modes in transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 162–174. [Google Scholar] [CrossRef]

- Jadidian, J.; Zahn, M.; Lavesson, N.; Widlund, O.; Borg, K. Impulse breakdown delay in liquid dielectrics. Appl. Phys. Lett. 2012, 100, 909. [Google Scholar] [CrossRef]

- Akishev, Y.; Arefikhonsari, F.; Demir, A.; Grushin, M.; Karalnik, V.; Petryakov, A. The interaction of positive streamers with bubbles floating on a liquid surface. Plasma Sources Sci. Technol. 2015, 24, 65021. [Google Scholar] [CrossRef]

- O’Sullivan, F.; Hwang, J.G.; Zahn, M.; Hjortstam, O. A Model for the Initiation and Propagation of Positive Streamers in Transformer Oil. In Proceedings of the 2008 IEEE International Symposium on Electrical Insulation, Vancouver, BC, Canada, 9–12 June 2008; pp. 210–214. [Google Scholar]

- Chen, R.; Kirsh, Y. Analysis of Thermally Stimulated Processes; Pergamon Press: Oxford, UK, 1981; pp. 78–92. [Google Scholar]

- Lu, J.; Ding, L.; Li, C.R.; Wang, W. Study on the trap distribution characteristic of alumina ceramics. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kitchener, ON, Canada, 14–17 October 2001; pp. 381–384. [Google Scholar]

- Unge, M.; Singha, S.; Van Dung, N.; Linhjell, D.; Ingebrigtsen, S.; Lundgaard, L.E. Enhancements in the lightning impulse breakdown characteristics of natural ester dielectric liquids. Appl. Phys. Lett. 2013, 102, 172905. [Google Scholar] [CrossRef]

| Oil Samples | Total Trapped Charges (nC) | Trap Level (eV) |

|---|---|---|

| Pure oil | 7.86 | 0.340 |

| Fe3O4 NF | 13.01 | 0.345 |

| TiO2 NF | 12.50 | 0.346 |

| Al2O3 NF | 9.01 | 0.346 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Ge, Y.; Wang, L.; Sun, Z.; Zhou, Y.; Huang, M.; Li, C.; Yuan, J.; Qi, B. Effects of Nanoparticle Materials on Prebreakdown and Breakdown Properties of Transformer Oil. Appl. Sci. 2018, 8, 601. https://doi.org/10.3390/app8040601

Lv Y, Ge Y, Wang L, Sun Z, Zhou Y, Huang M, Li C, Yuan J, Qi B. Effects of Nanoparticle Materials on Prebreakdown and Breakdown Properties of Transformer Oil. Applied Sciences. 2018; 8(4):601. https://doi.org/10.3390/app8040601

Chicago/Turabian StyleLv, Yuzhen, Yang Ge, Lei Wang, Zhen Sun, You Zhou, Meng Huang, Chengrong Li, Jinsha Yuan, and Bo Qi. 2018. "Effects of Nanoparticle Materials on Prebreakdown and Breakdown Properties of Transformer Oil" Applied Sciences 8, no. 4: 601. https://doi.org/10.3390/app8040601

APA StyleLv, Y., Ge, Y., Wang, L., Sun, Z., Zhou, Y., Huang, M., Li, C., Yuan, J., & Qi, B. (2018). Effects of Nanoparticle Materials on Prebreakdown and Breakdown Properties of Transformer Oil. Applied Sciences, 8(4), 601. https://doi.org/10.3390/app8040601