1. Introduction

Previous research assessing ball tracking data from professional tennis matches has established typical inbound impact conditions that the ball experiences, particularly when impacting court surfaces [

1,

2]. Knowledge of the impact conditions enables replication of typical impact conditions in the laboratory. Previous efforts to understand the behaviour of the ball core in isolation has focused, almost exclusively, on normal impacts with a rigid surface as a means of validating finite element (FE) simulations [

3,

4,

5,

6,

7]. These simulations require characterisation of the mechanical behaviour of the rubber compound to predict the behaviour of the modelled ball core. Characterisation of ball core materials has so far been limited to quasi-static tensile, compressive, and stress relaxation testing. The issue with current test methods are the speeds and consequent achievable strain rates for testing. Typically, tensile tests have been conducted with a crosshead speed in the range of 50–999 mm∙min

−1 [

5]. Elastomeric materials are known to exhibit strain-rate-dependent behaviour, whereby stiffness increases as strain rate increases, particularly at high strain rates [

8,

9,

10]. When defining material behaviour for FE simulations, it is desirable to match the properties of the material when it is subjected to the strains and strain rates observed during use, especially if significant increases in stiffness are observed as strain rate increases.

Previous modelling techniques have utilised an iterative process, comparing artificial stiffening of stress–strain data and alterations to damping factors with high-speed video footage and force trace data of impacts to establish a material model providing a realistic representation of the ball during impact [

3,

5]. In part, the use of artificial stiffening is a result of the limitations of available material testing equipment. Only through simulation have maximum strains and strain rates during impact been estimated. Cordingley [

3] estimated maximum strains in the region of 0.5 with maximum strain rates in the region of 300 s

−1. Allen [

6] recorded maximum strains in the region of 0.3 for an impact against a rigid surface at 30 m∙s

−1.

Traditional strain measurement devices such as strain gauges and extensometers do not lend themselves to high velocity ball impacts due to the associated connected electronics and possible alterations in deformation caused by the sensor being in contact with the surface. Optical strain measurement techniques utilising digital image correlation (DIC), such as GOM Correlate Professional (GOM GmbH, Braunschweig, Germany), provides a means of three-dimensional surface strain measurement utilising multiple cameras. GOM Correlate identifies stochastic image information, referred to as facets, by evaluating the grey values present within the facet. Optimal facets have a distinct and equally distributed pattern, with maximum possible contrast in grey values within the facet [

11]. DIC could be employed to measure the strains and strain rates present during ball impacts and used to inform material characterisation testing, in turn enabling FE modelling to utilise, rather than techniques involving the artificial stiffening of quasi-static behaviour, material modelling techniques based on experimental data. Although not used to measure strain, GOM has been successfully implemented in a sporting context to measure golf ball and clubhead velocity [

12].

The aim of this investigation was to establish the strains and strain rates experienced by tennis ball cores during impact, whereby the impact conditions are representative of professional play, in turn establishing the effectiveness of non-contact DIC for strain measurement during high-velocity, high-deformation sports ball impacts. A further aim was to define the range of strains and strain rates that material characterisation tests should incorporate to understand the material behaviour during use.

3. Results

To determine the ideal test conditions for material characterisation tests it was necessary to understand the strains and strain rates present under the most extreme impact conditions, to endeavour to capture the material behaviour within that range. Consequently, a select number of the impact conditions tested have been analysed in detail in this paper. The following subset of test conditions described in

Table 3 were selected for analysis: 18° at 22.1 m∙s

−1; 40° at 52.5 m∙s

−1; 90° at 30.5 m∙s

−1, 90° at 52.5 m∙s

−1.

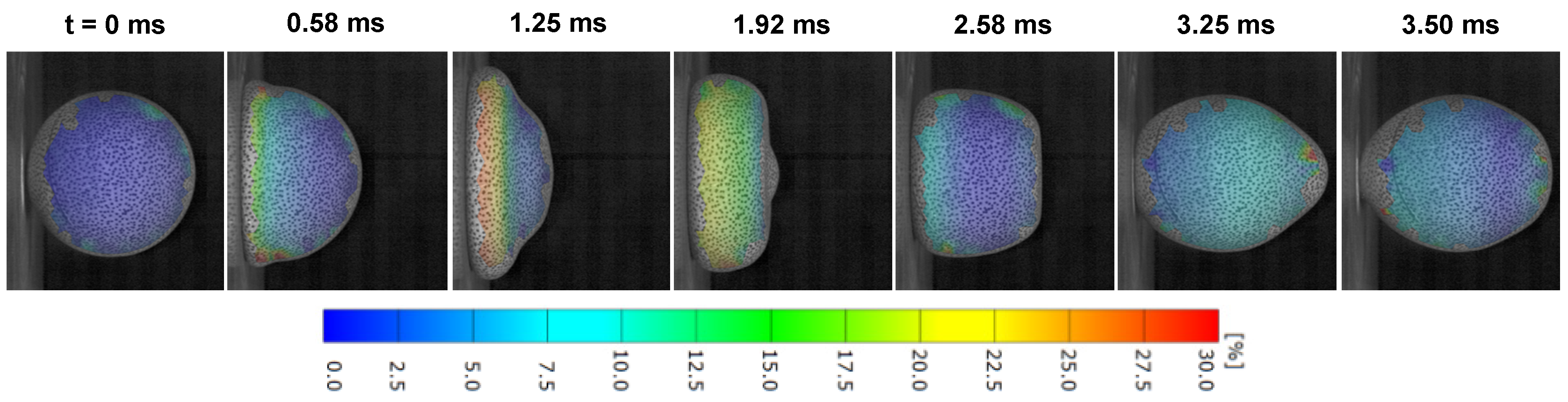

The largest mean strain during impact occurred for impacts at 40° and 52.5 m∙s

−1, warranting further analysis. Similarly, the largest mean strain rate during impact occurred for impacts at 90° and 52.5 m∙s

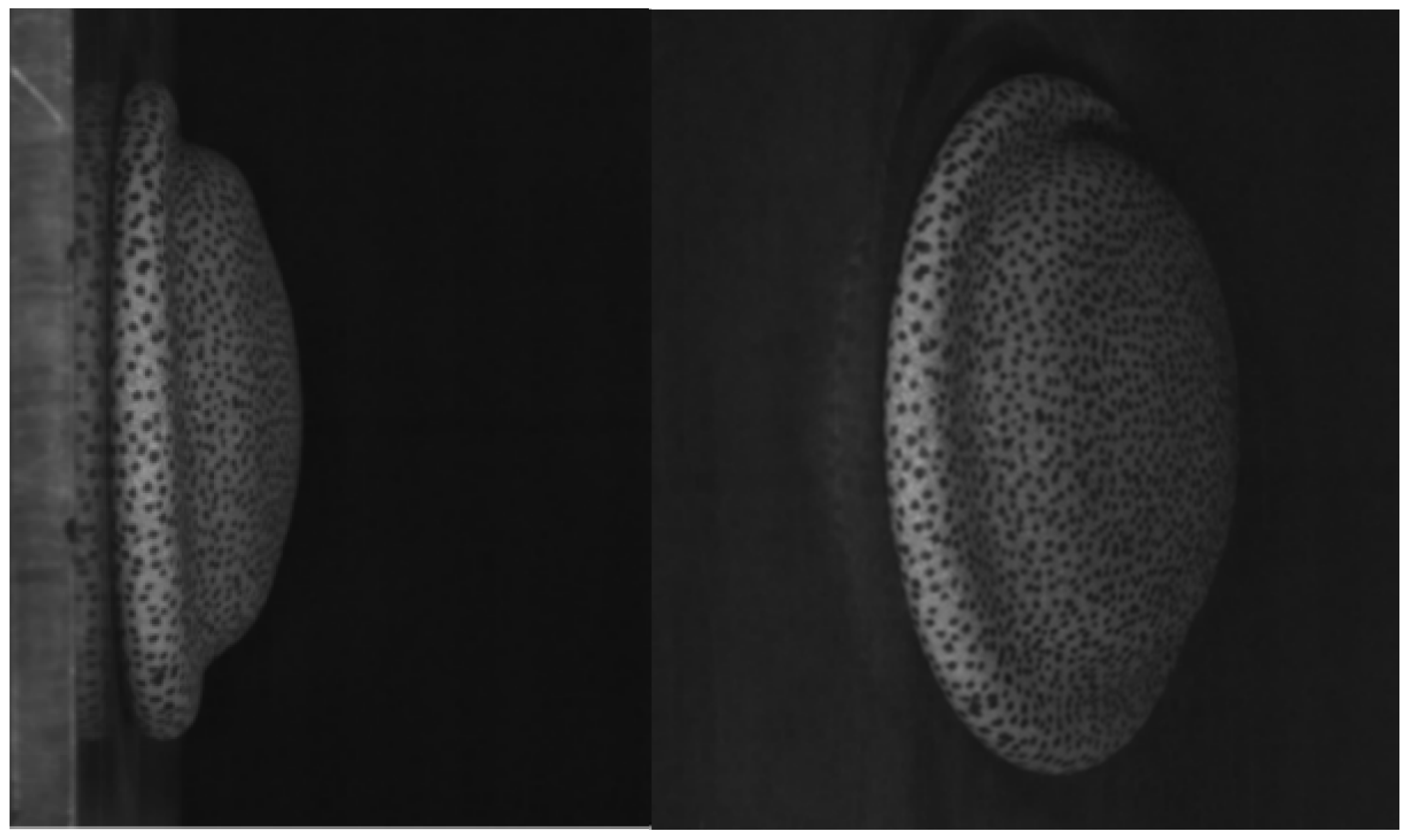

−1. Impacts tested at 90° with either of the two fastest impact speeds (43.1 m∙s

−1, 52.5 m∙s

−1) were found to lose surface tracking during impact, resulting in one or more frames where GOM was unable to compute a surface. Unlike impacts at 30.5 m∙s

−1 where the surface was tracked throughout impact duration (

Figure 5). Loss of surface tracking occurred for both pressurised and pressureless ball cores due to the extreme levels of deformation, as shown in

Figure 6. The 90° and 30.5 m∙s

−1 impact condition was selected to include impacts at 90° whereby the surface of the ball was tracked throughout impact as opposed to partially tracked. The impact condition representing the mean surface impact angle and ball speed found during professional play [

1] was included to provide a benchmark against a more typical impact scenario.

3.1. Impact Ball Speed

Ball speed prior to impact was dependent on the air pressure setting within the pneumatic cannon system, rather than setting ball speed directly. The pressure within the system drifts resulting in alteration of the air pressure prior to each impact, consequently, the actual ball speed on impact varied. Mean ball speed for each speed and angle impact combination are given in

Table 4. The maximum difference in mean ball speed to desired ball speed was −4.6 m∙s

−1 with a mean difference of −0.6 ± 1.4 m∙s

−1 when considering all impact conditions.

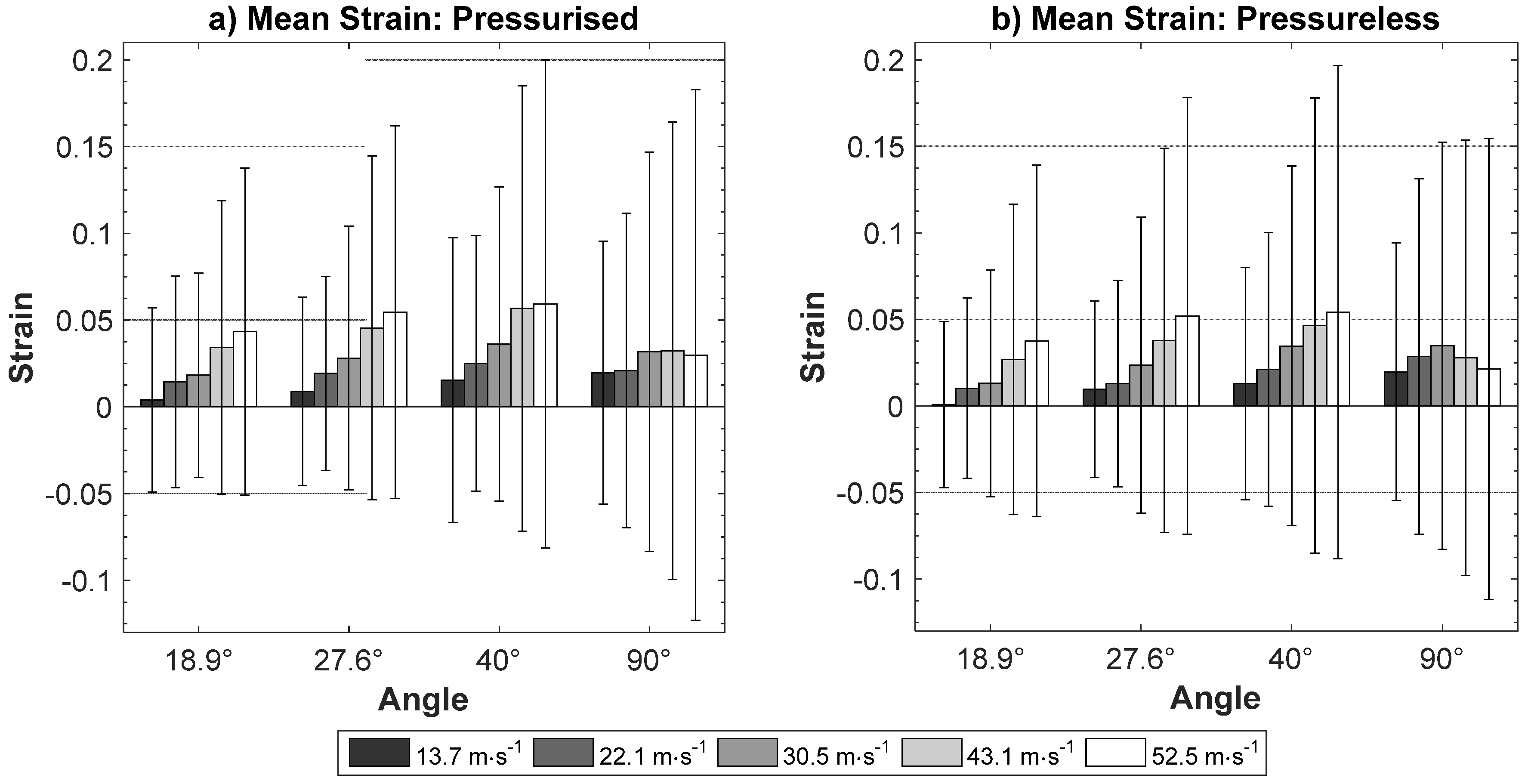

3.2. Impact Strain

Figure 7 highlights that mean strain during impact increased with both impact angle and, to a greater degree, impact velocity. The exception being the mean strain for impacts at 90° with an impact velocity of 43.1 m∙s

−1 or greater which showed either no increase or a reduction in mean strain, a likely consequence of loss of surface computation at the largest deformations (e.g.,

Figure 6). The maximum mean strain occurred for impacts at 40° and 52.5 m∙s

−1 for both pressurised (0.06 strain) and pressureless ball cores (0.054 strain). Similarly, the minimum mean strain value occurred for impacts at 18.9° with in impact velocity of 13.7 m∙s

−1.

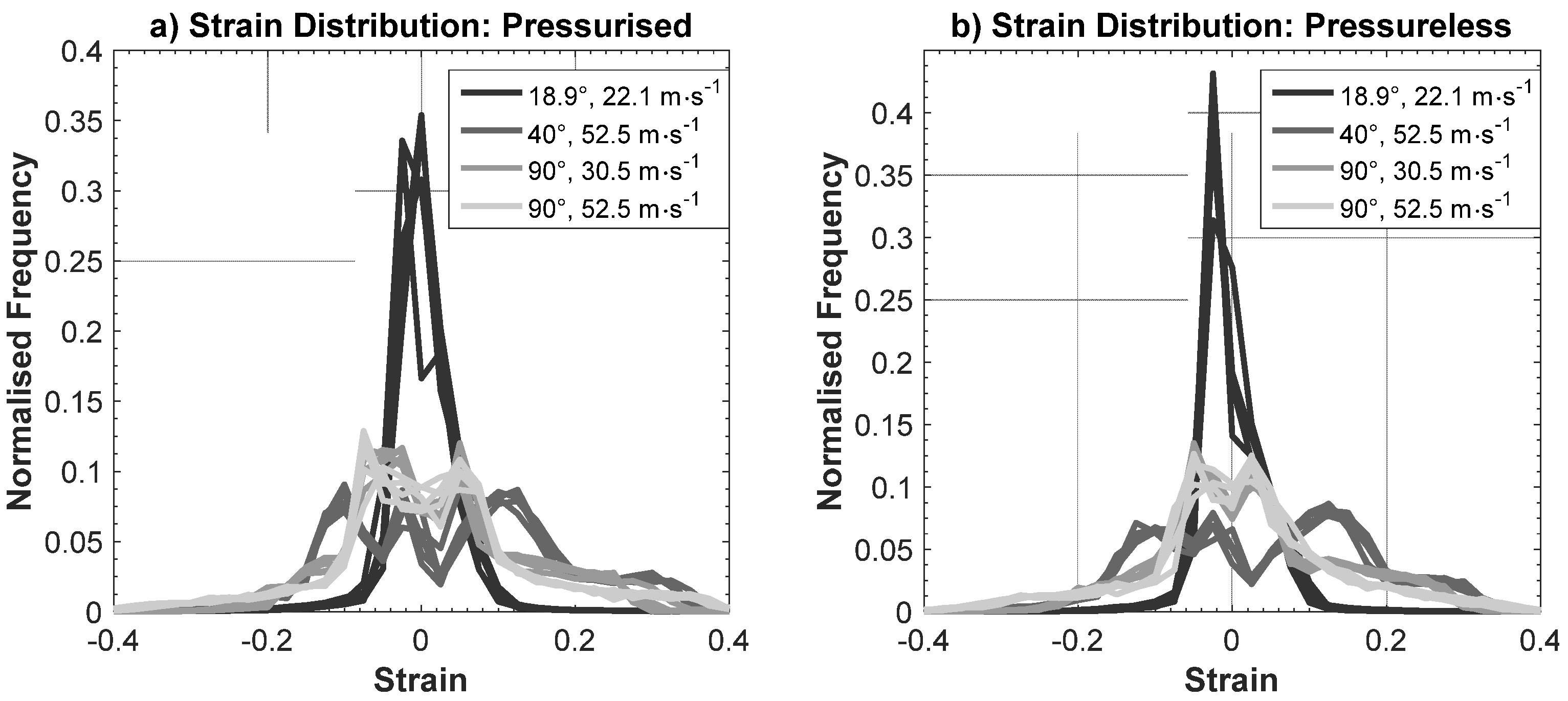

Over 95% of strain measured was distributed between −0.1 and 0.1 strain for impacts at 18.9° with an impact velocity of 22.1 m∙s

−1 (

Table 5). The remaining impact conditions at higher impact angles and faster impact speeds were more widely distributed (

Figure 8).

Table 5 also highlights a higher percentage of tensile (positive) strain is present than compressive (negative) strain, and was present to a greater degree at larger strains. For example, 8.4% of strain on average was distributed between 0.2 and 0.3 strain, compared to 2.1% for strains between −0.3 and −0.2, a trend present across all conditions except impacts at 18.9° and 22.1 m∙s

−1.

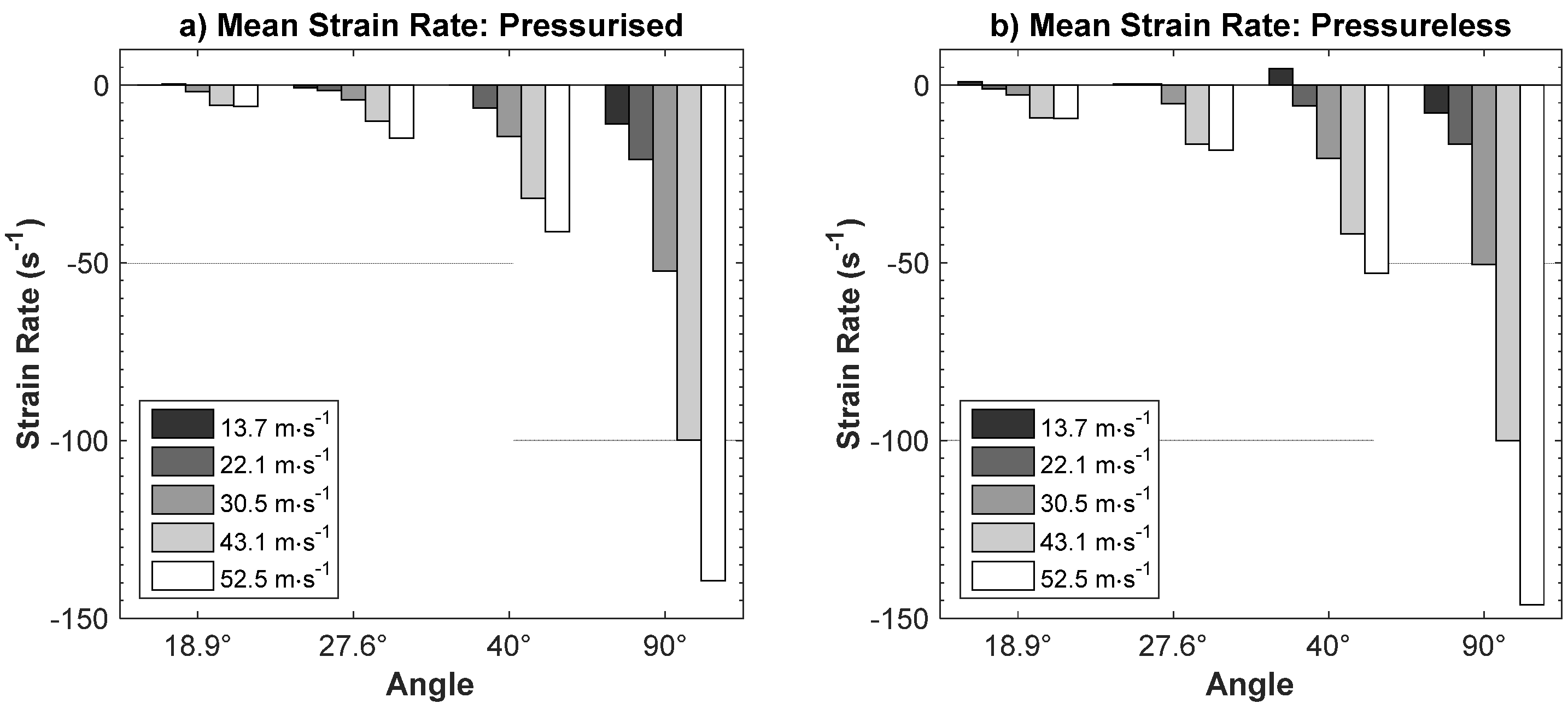

3.3. Impact Strain Rate

In general, mean strain rate during impact increased in magnitude (in the negative direction) as impact speed at a given angle increased (

Figure 9). Likewise, for a given impact speed the mean strain rate during impact increased in magnitude as the impact angle tended towards normal. Consequently, the mean strain rate of greatest magnitude occurred for impacts at 90° and 52.5 m∙s

−1 for both pressurised (−139 s

−1) and pressureless ball cores (−146 s

−1). The impact case representing the mean surface impact conditions (18.9°, 22.1 m∙s

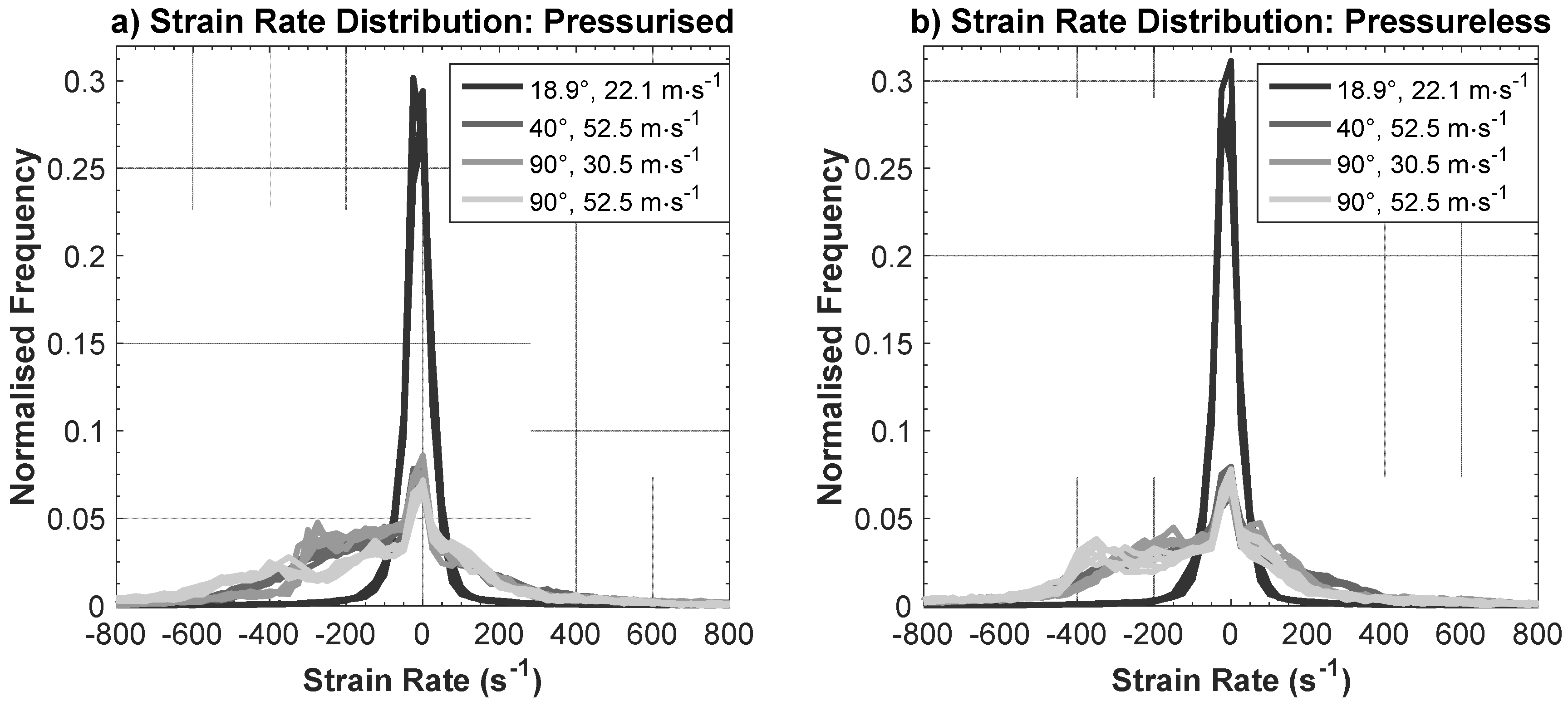

−1) was distributed evenly either side of zero. All other impact conditions were shifted in the negative direction, with negative strain rates accounting for around 60% of the distribution (

Figure 10). No impact condition was found to have greater than 1% of the distribution whereby the strain rate was greater in absolute magnitude than 800 s

−1 (

Table 6).

4. Discussion

The results of this investigation highlight that both compressive and tensile strains were experienced during impact with a rigid plate. Regarding maximum strain values, tensile strains above 0.4 were uncommon, with frequency distributions highlighting that no frequency bin above a 0.4 strain contained more than 1% of the distribution. Consequently, material characterisation of ball core rubber in tension should test at a 0.4 strain to encapsulate the range seen during impact.

Experimental impacts of the pressurised ball core at 40° and 90° with an impact ball speed of 52.5 m·s

−1 had approximately 5% of strain distributed between 0.3 and 0.4, further evidence that 0.4 strain is the minimum desirable tensile strain for testing tennis ball rubber. These findings are slightly lower than the findings of Cordingley [

3], who suggested that strains in the region of 0.5 can be observed during impact, which is more in keeping with the results of Allen [

6].

Assessing the observed tensile strain rate measured by GOM highlighted that all impact conditions other than the mean surface impact condition (18°, 22.1 m∙s

−1) had around 1% of the distribution between 500 and 600 s

−1, no frequency bin above 300 s

−1 accounted for more than 3.5%. Cordingley [

3,

4] reported maximum strain rates during ball core impacts of approximately 300 s

−1. The results presented in this investigation indicated that tensile strain rates in the region of 600 s

−1 were apparent, but to a limited degree (<1%). The ability to characterise the material at this rate would be optimal, but capturing material behaviour with a strain rate up to and including rates in the region of 500 s

−1 would capture the vast majority of tensile strain rates experienced during impact.

Maximum observed compressive strains from GOM analysis suggested that strains up to −0.4 were present for impacts at 90° and 52.5 m∙s−1, accounting for around 1% of the distribution. Negligible amounts of strain (<0.2%) were measured for compressive strains greater in magnitude than −0.4. The results suggest that material characterisation in compression would encapsulate the vast majority (>95%) of observed compressive strain during impact if tested to strains of −0.4, whilst testing to strains of −0.3 may be sufficient depending on the severity of the impact conditions.

Only impacts at 90° and 52.5 m·s

−1 had more than 1% of the distribution greater in magnitude than −800 s

−1. The remaining impact conditions highlighted a maximum compressive strain rate closer to −700 s

−1. Frequency bins between −400 and −800 s

−1 for the 90°, 52.5 m·s

−1 impact condition account for more than double the percentage of the other impact conditions. Missing frames or obstructed surface coverage likely resulted in an overrepresentation of results between −400 and −800 s

−1. These results appear to be consistent with results in the literature. Allen [

6] highlighted a maximum strain for simulation at 30 m·s

−1 of 0.3, consistent with GOM results for 90° and 30.5 m·s

−1, whereby all frequency bins above a 0.3 strain contained less than 1% of the distribution.

GOM distributions for the mean surface impact test case (18°, 22.1 m∙s−1) appear to follow a normal distribution, but the remaining cases do not. For strain, these distributions have multiple peaks rather than one distinct peak around zero, whilst the strain rate distributions are skewed in the negative direction, with negative strain rates accounting for around 60% of the distribution.

The strain rates presented in this investigation are in the 100–1000 s

−1 order of magnitude, at which strain-rate-dependent behaviour has been observed in vulcanised rubbers [

8,

9,

10]. To test at rates in this order of magnitude, a bespoken test rig (similar to that used by Hoo Fatt & Bekar [

9]) or more complex testing equipment, such as a split Hopkinson pressure bar, is required. Characterisation at strain rates between 100–1000 s

−1 would confirm if this rate-dependent behaviour is present in ball core rubber under the conditions experienced during use. Should significant rate dependence be observed, the incorporation of more complex material models (compared to hyperelastic models) incorporating this behaviour can be utilised in finite element models of ball impacts. Furthermore, should minimal strain rate dependence be observed, the process of artificial stiffening of hyperelastic material models to represent ball core rubber, as utilised previously [

3,

4,

5], should no longer be employed. Additionally, different material compounds can be compared at representative strain and strain rates when assessing potential new compounds for use as ball core rubber.

GOM is limited by the surface coverage, which is dependent on camera positions and relative placement. Clearly with one camera pair, it is not possible to obtain full surface coverage, particularly as the underside of the ball is obscured by the impact plate. Furthermore, it is only possible to measure parts of the object that are visible, so strains through the thickness of the material and on the inside surface of the cavity cannot be measured.

Increased ball coverage could be achieved using additional cameras. A calibration of each camera ‘pair’ would be required in addition to the calibration of a global reference frame, to which all surface analysis could be transposed and combined to achieve more complete coverage. The time required to capture and process the data would greatly increase, however, and access to multiple high-speed cameras with each pair of cameras requiring matching lenses would be required.

5. Conclusions

DIC has been shown to be a useful tool in determining the strains and strains rates present during the impact of tennis ball cores against a rigid surface; however, at the upper limits (52.5 m∙s−1, 90°), deformations can become too large to maintain surface coverage.

The results suggest that material characterisation testing to a maximum strain of 0.4 and a maximum rate of 500 s−1 in tension and a maximum strain of −0.4 and a maximum rate of −800 s−1 in compression would encapsulate the demands placed on the material during impact.

Knowledge of the strains and strain rates present during impact allows for material characterisation under these conditions. In turn, material modelling techniques capable of capturing the strain-rate-dependent behaviour can be employed. Furthermore, the surface strain analysis can be utilised as a means of validating FE simulations of the ball core.