Influence of Surface State in Micro-Welding of Copper by Nd:YAG Laser

Abstract

1. Introduction

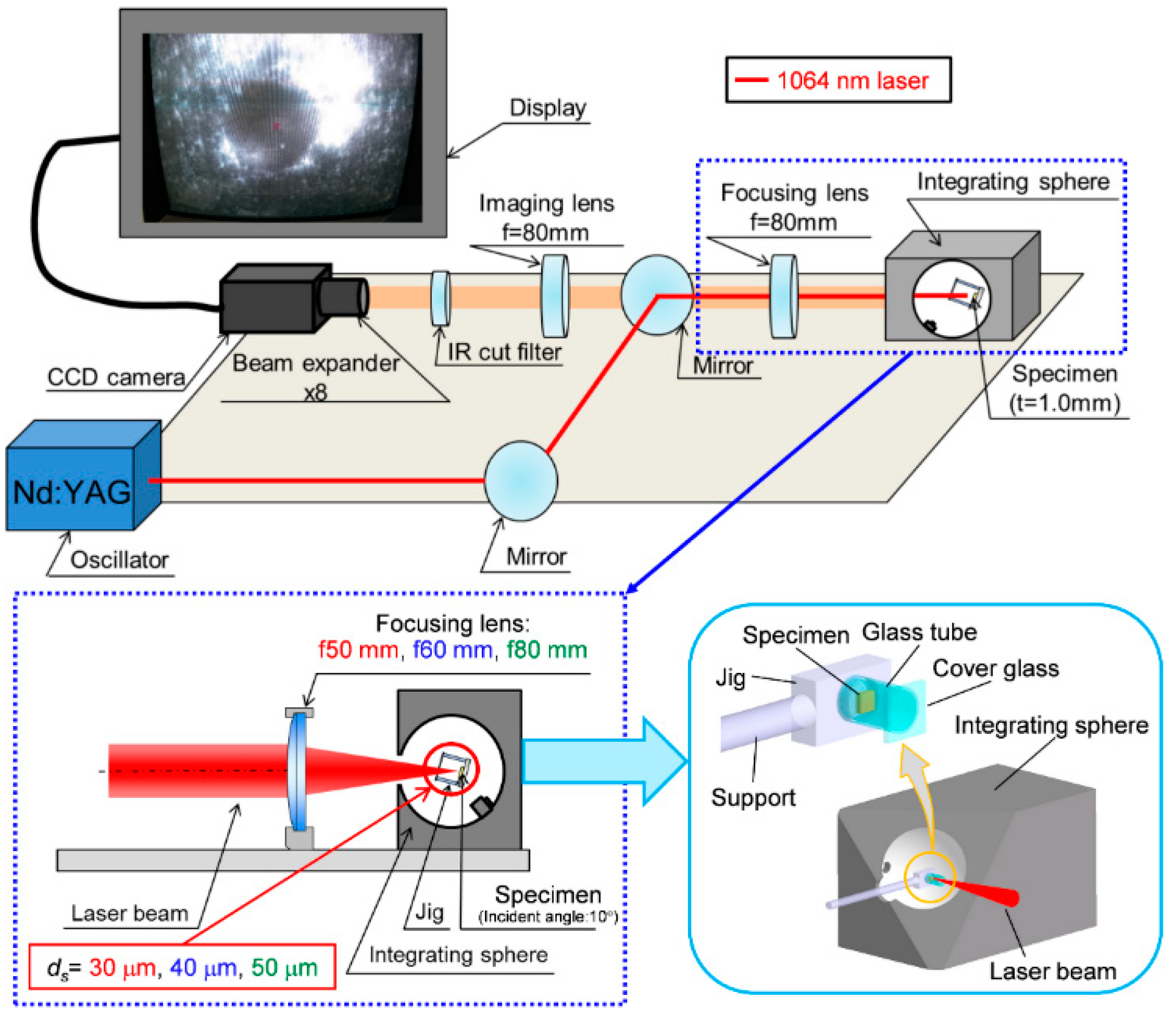

2. Materials and Methods

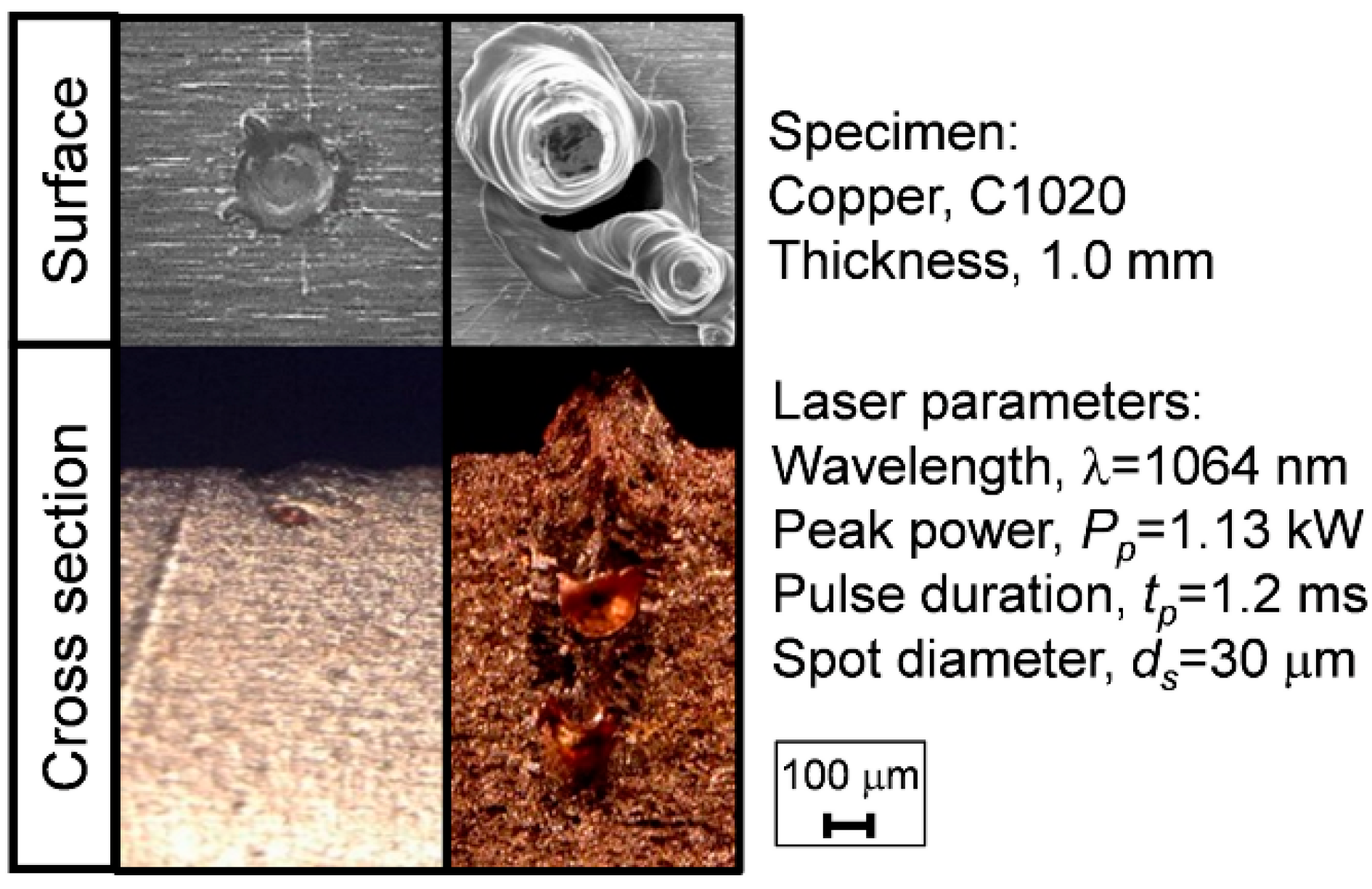

3. Results and Discussion

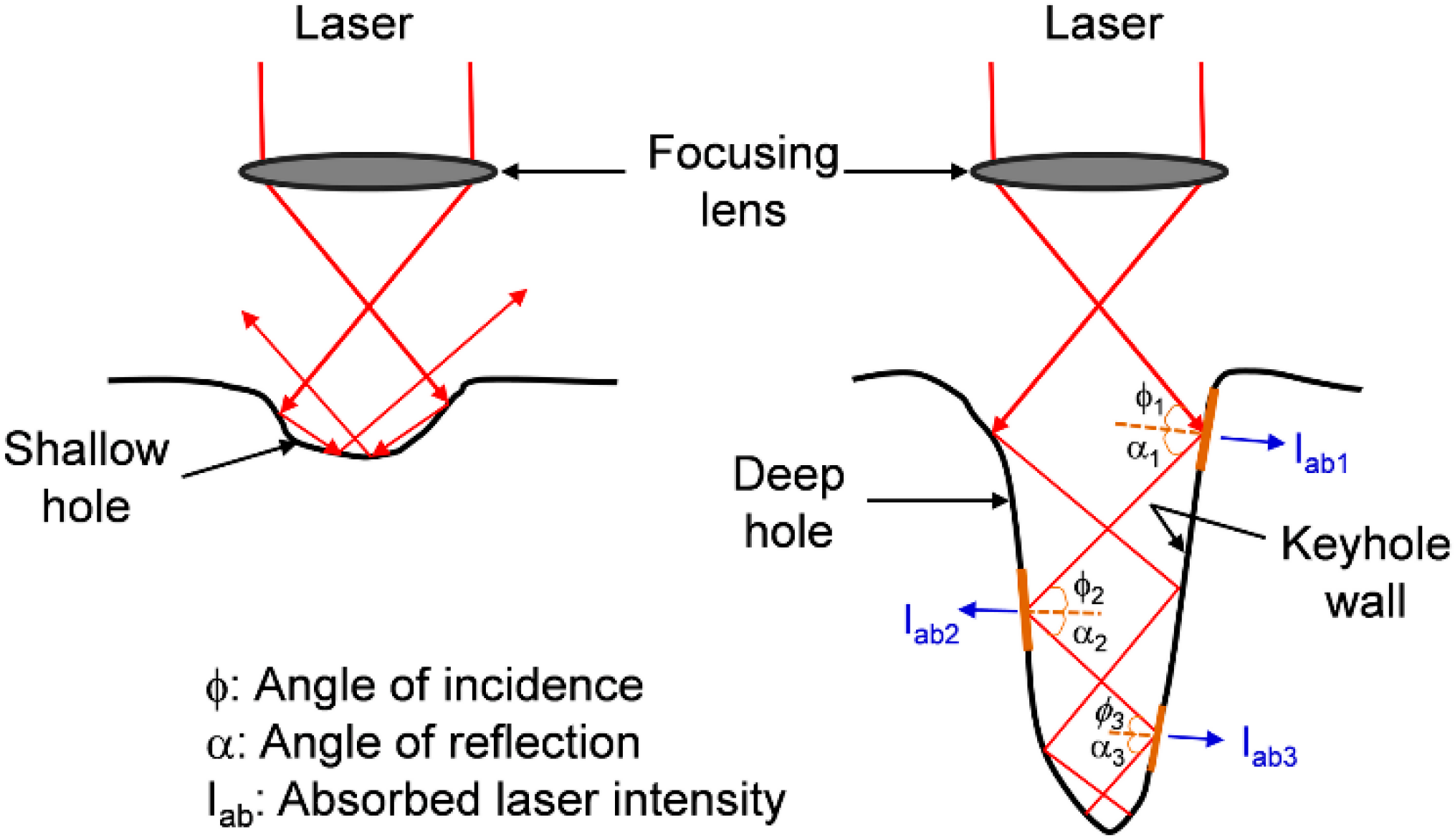

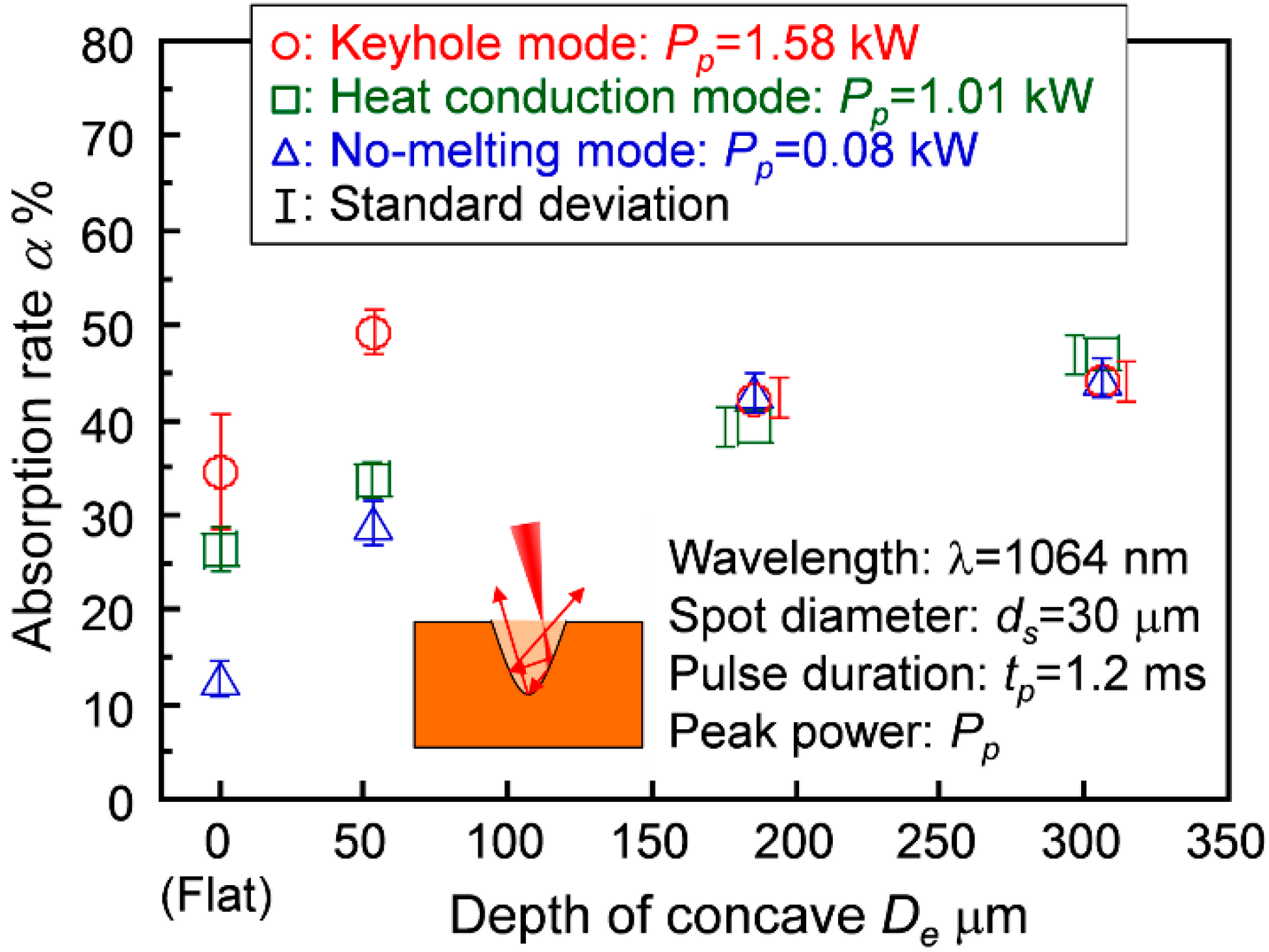

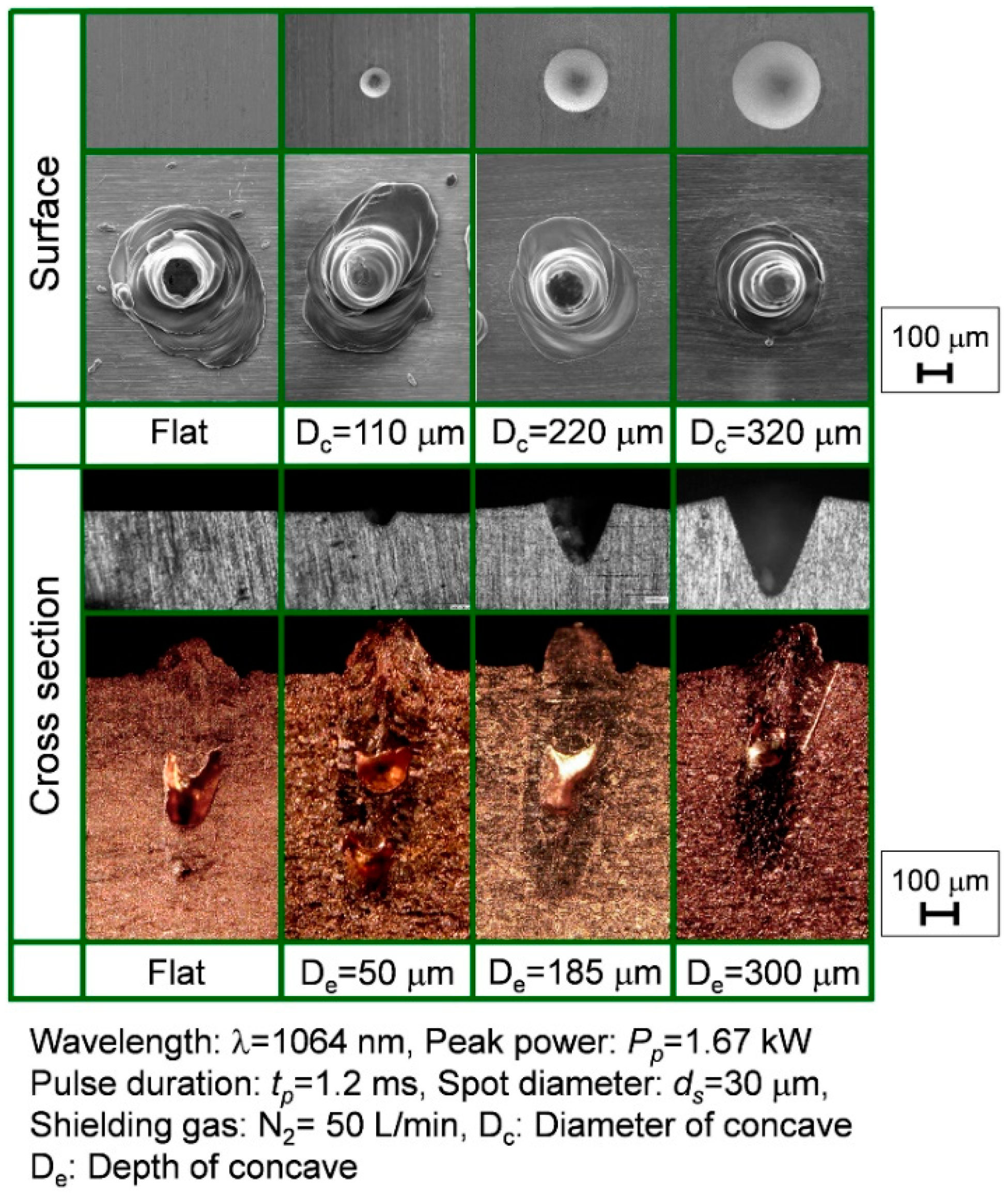

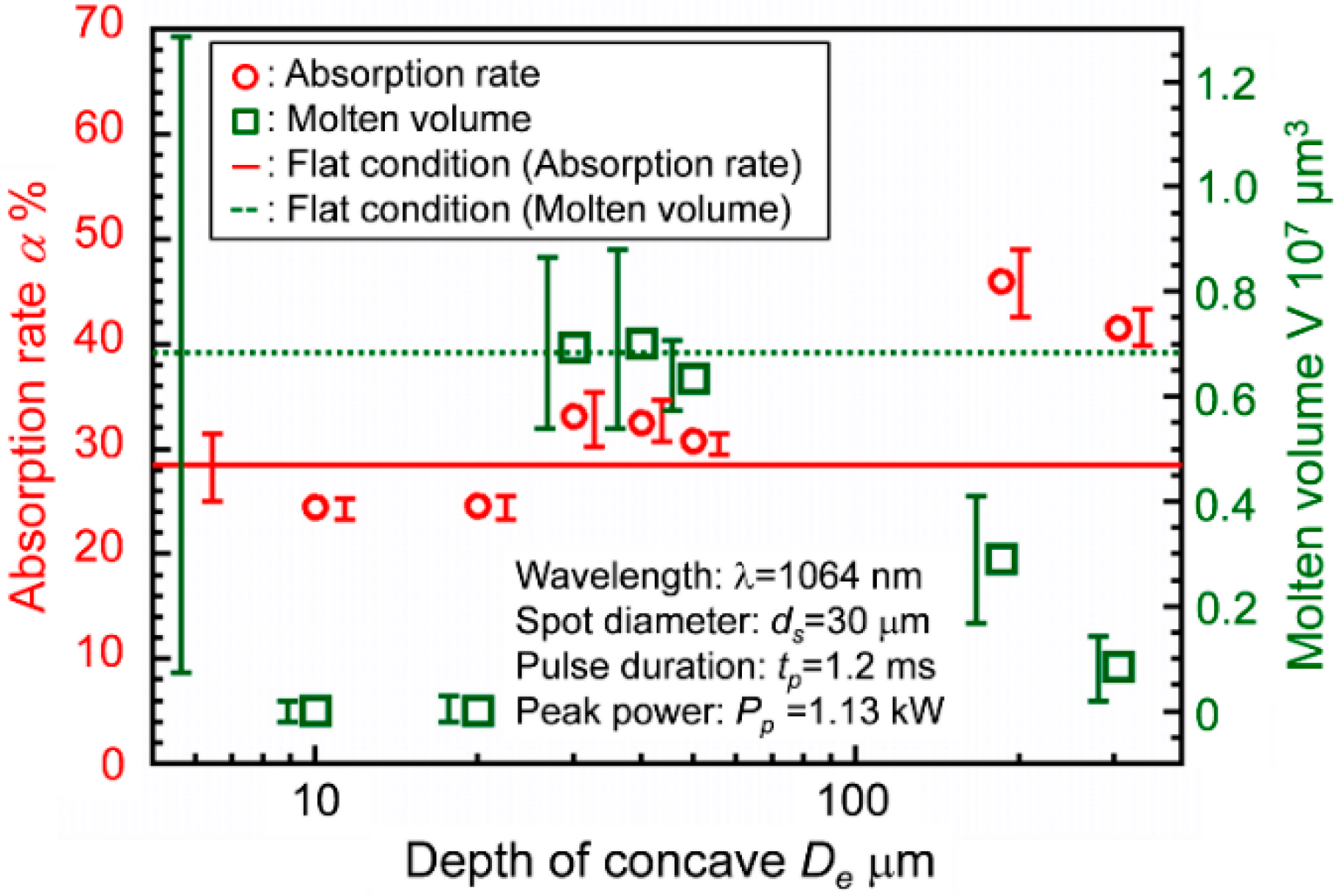

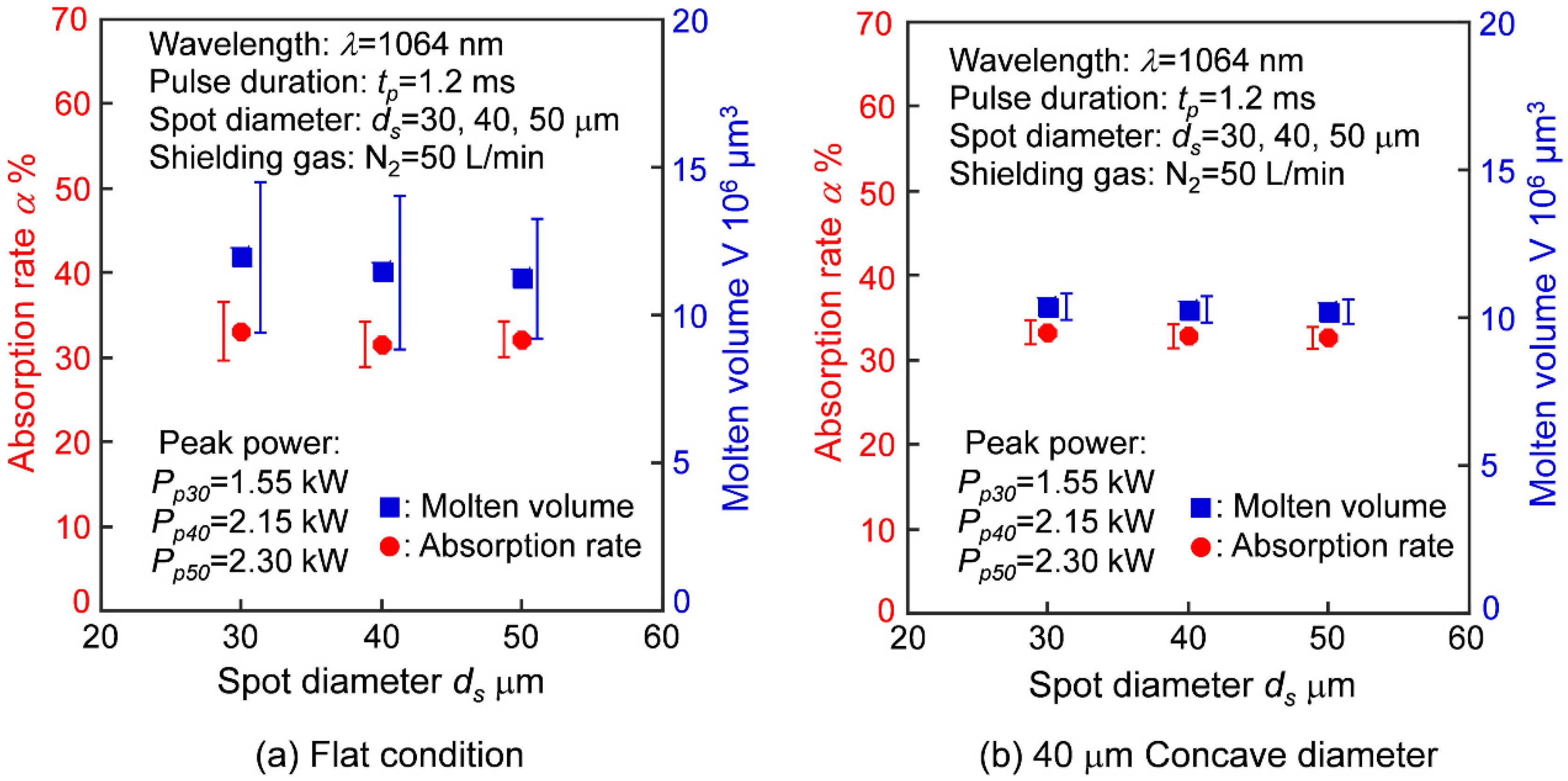

3.1. Influence of Surface Shape on Absorption Rate

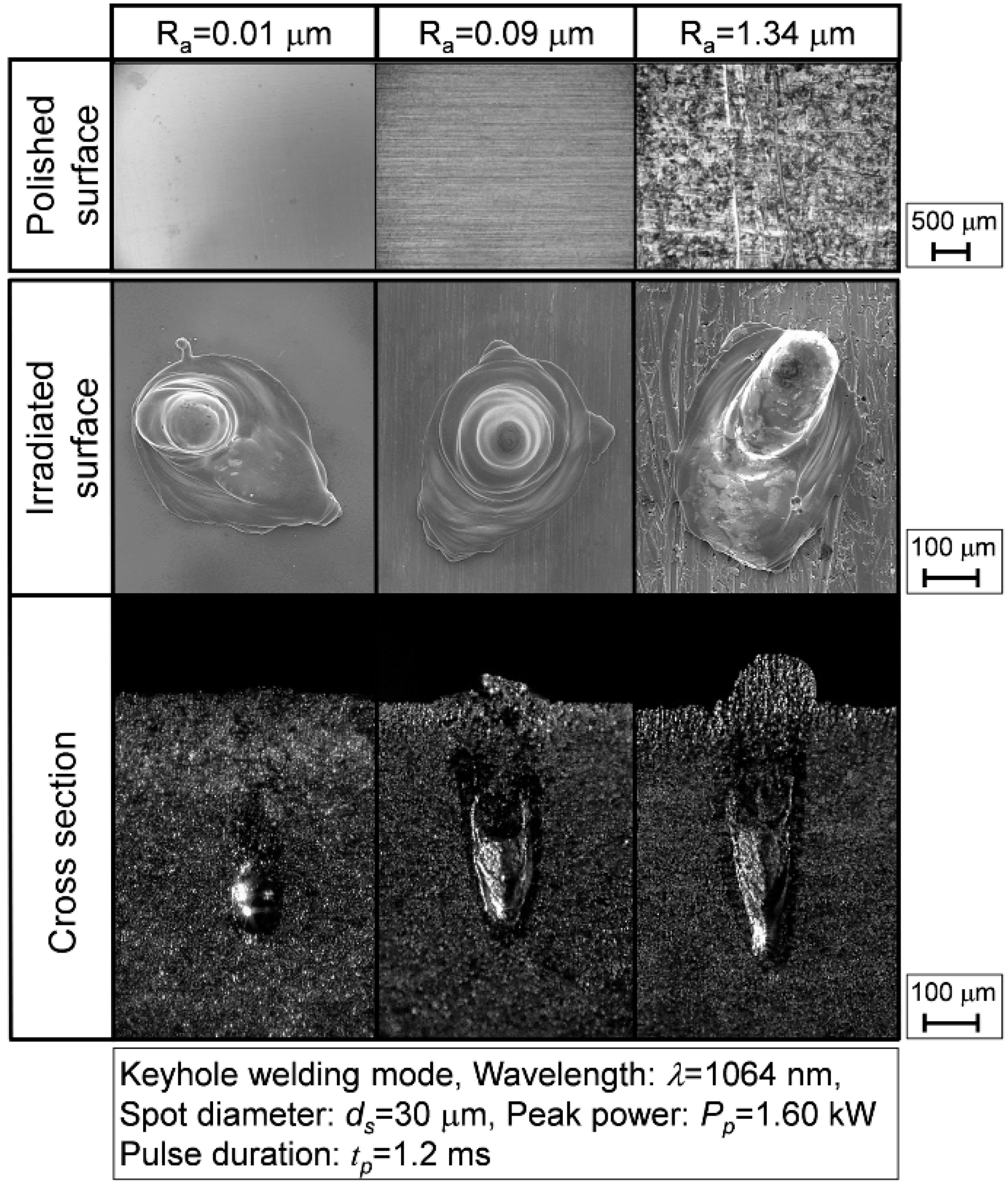

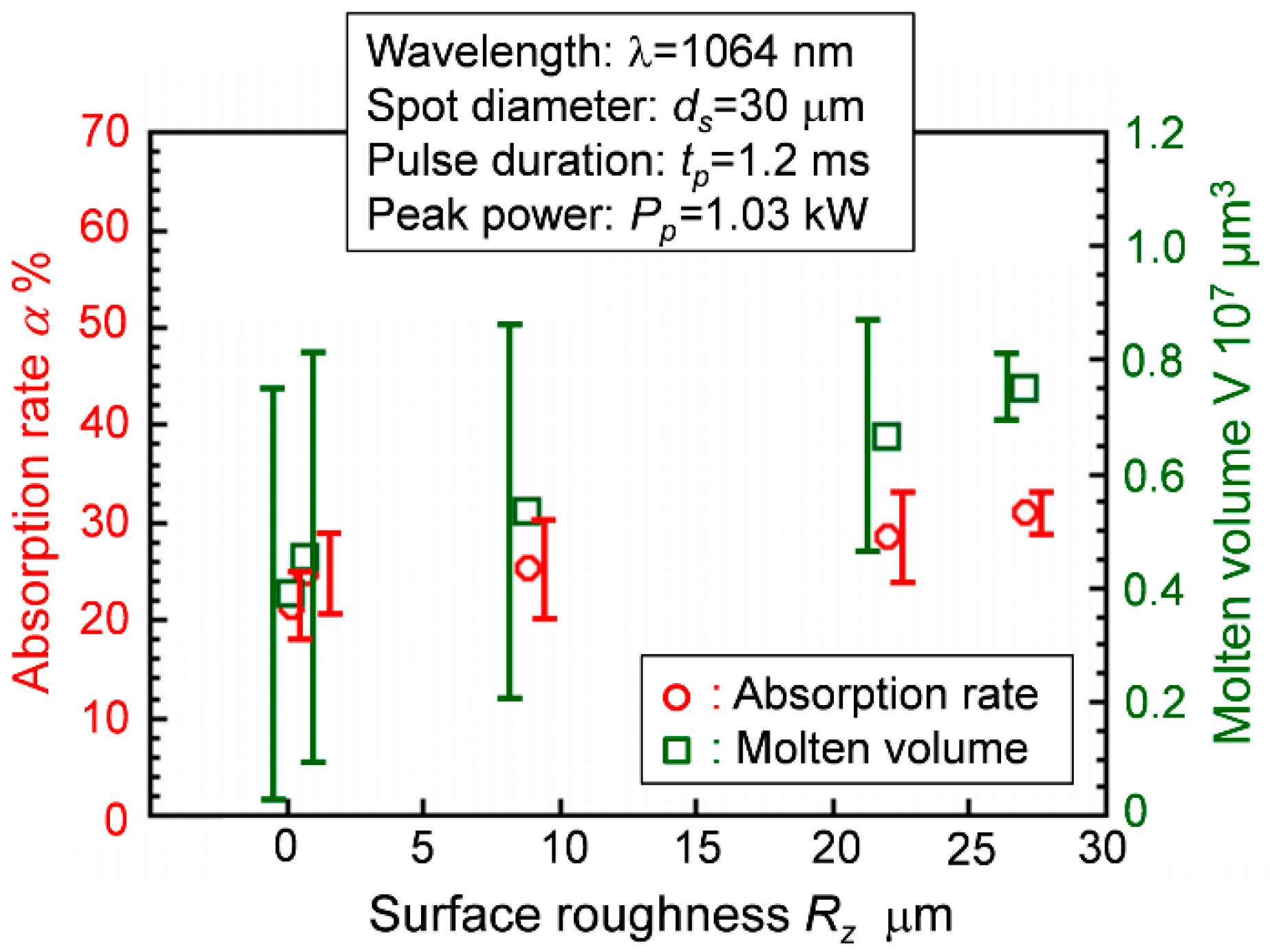

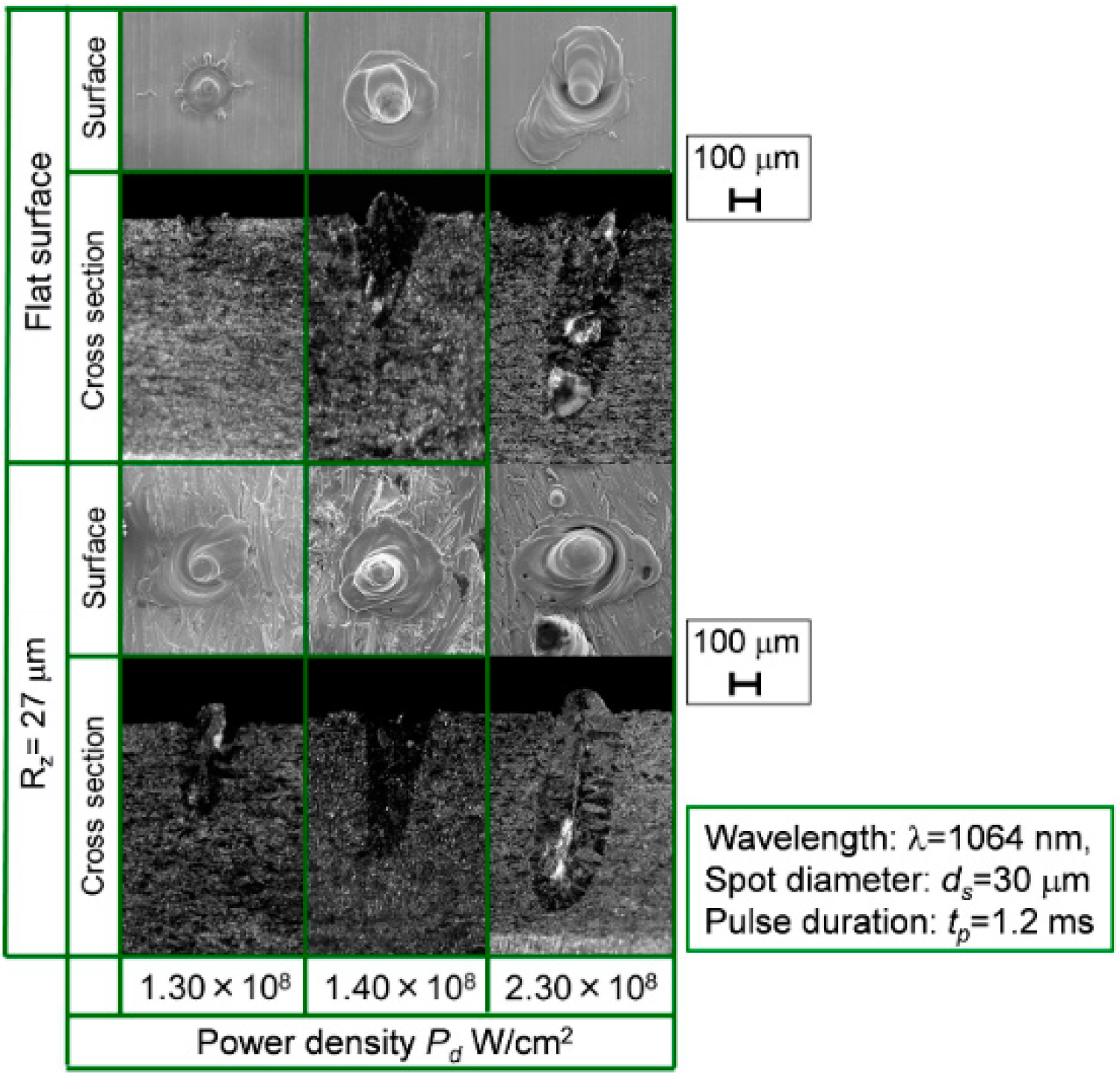

3.2. Influence of Surface Roughness on Absorption Rate

4. Conclusions

- Absorption rate and molten volume under 1064 nm wavelength laser is increased by controlled surface undulations such as creating appropriate concave holes, and by controlled surface roughness variations. There is correlation between the surface roughness and concave holes. Concave depth of around 30 μm and a similar value of surface roughness Rz leads to stabilization of the micro-welding process.

- For copper welding using 1064 nm laser, by optimizing the surface texture in transitional processing condition between heat conduction and keyhole welding, light absorption was improved and the process was stabilized leading to deep penetration and good surface quality.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chryssolouris, G. Laser Machining-Theory and Practice (Mechanical Engineering Series), 1st ed.; Springer-Verlag: New York, NY, USA, 1991; ISBN 0-387-97498-9. [Google Scholar]

- Athanasiou, C.E.; Hongler, M.-O.; Bellouard, Y. Unraveling Brittle-Fracture Statistics from Intermittent Patterns Formed During Femtosecond Laser Exposure. Phys. Rev. Appl. 2017, 8, 054013. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel-kovar, copper-steel and copper-aluminium. Mater. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Hess, A.; Schuster, R.; Heider, A.; Weber, R.; Graf, T. Continuous wave laser welding of copper with combined beams at wavelengths of 1030 nm and of 515 nm. Phys. Procedia 2011, 12, 88–94. [Google Scholar] [CrossRef]

- Otte, F.; Pamin, S.; Hermsdorf, J.; Kracht, D.; Kling, R. Enhancement of process stability for laser spot micro-welding by using 532 nm radiation. In Proceedings of the International Congress on Laser Advanced Materials Processing (LAMP), Kobe, Japan, 29 June–2 July 2009; pp. 09–114. [Google Scholar]

- Nakashiba, S.; Okamoto, Y.; Sakagawa, T.; Takai, S.; Okada, A. Micro-Welding of Copper Plate by Frequency Doubled Diode Pumped Pulsed Nd:YAG Laser. Phys. Procedia 2012, 39, 577–584. [Google Scholar] [CrossRef]

- Okamoto, Y.; Nakashiba, S.; Wada, T.; Sakagawa, T.; Nishi, N.; Okada, A. Characterization of Absorptivity in Micro-welding of Copper by Pulsed Green Nd:YAG Laser. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics ICALEO, San Diego, CA, USA, 19–23 October 2014. [Google Scholar] [CrossRef]

- Fabbro, R.; Coste, F.; Slimani, S.; Briand, F. Study of keyhole behaviour for full penetration Nd:YAG CW laser welding. J. Phys. D Appl. Phys. 2005, 38, 1881–1887. [Google Scholar] [CrossRef]

- Jae, Y.L.; Sung, H.K.; Dave, F.F.; Choong, D.Y. Mechanism of keyhole formation and stability in stationary laser welding. J. Phys. D Appl. Phys. 2002, 35, 1570–1576. [Google Scholar] [CrossRef]

- Dowden, J.; Kapadia, P.; Postacioglu, N. An analysis of the laser-plasma interaction in laser keyhole welding. J. Phys. D Appl. Phys. 1989, 22, 741–749. [Google Scholar] [CrossRef]

- Bono, P.D.; Metsios, I.; Blackburn, J.; Hilton, P. Laser processing of copper and aluminum thin sheets with green (532 nm) and infrared (1064 nm) pulsed laser beam sources. In Proceedings of the 32nd International Congress on Applications of Lasers and Electro-Optics (ICALEO 2013), Miami, FL, USA, 6–10 October 2013; Volume 616, pp. 520–528. [Google Scholar] [CrossRef]

- Chen, H.-C.; Bi, G.; Nai, M.L.S.; Wei, J. Influence of surface condition in fiber laser welding of pure copper. In Proceedings of the 31st International Congress on Applications of Lasers and Electro-Optics (ICALEO 2012), Anaheim, CA, USA, 23–27 September 2012; Volume 615, pp. 558–564. [Google Scholar] [CrossRef]

- Engler, S.; Ramsayer, R.; Poprawe, R. Process Studies on Laser Welding of Copper with Brilliant Green and Infrared Lasers. Phys. Procedia 2011, 12, 339–346. [Google Scholar] [CrossRef]

- Al-Kazzaz, H.; Medraj, M.; Cao, X.; Jahazi, M. Nd:YAG laser welding of aerospace grade ZE41A magnesium alloy: Modeling and experimental investigations. J. Mater. Chem. Phys. 2008, 109, 61–76. [Google Scholar] [CrossRef]

- Jung-Ho, C.; Suck-Joo, N. Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J. Phys. D Appl. Phys. 2006, 39, 5372–5378. [Google Scholar] [CrossRef]

- Bergstrom, D.; Powell, J.; Kaplan, A.F.H. A ray-tracing analysis of the absorption of light by smooth and rough metal surfaces. J. Appl. Phys. 2007, 101, 113504. [Google Scholar] [CrossRef]

- Millard Wire & Specialty Strip Company. Available online: https://www.millardwire.com/ (accessed on 2 August 2018).

- Japan Society of Thermophysical Properties (JSTP). Thermophysical Properties Handbook; Yokendo Co. Ltd.: Tokyo, Japan, 2008. [Google Scholar]

- John, C.I. Laser Processing of Engineering Materials–Principles, Procedure and Industrial Application; Elsevier Butterworth-Heinemann: London, UK, 2005; pp. 41–70, 395–401. ISBN 0-7506-6079-1. [Google Scholar]

- Steen, W.M. Laser Material Processing, 3rd ed.; Springer-Verlag: London, UK, 2003; pp. 83–105, 157–165. ISBN 1-85233-698-6. [Google Scholar]

- Nakashiba, S.; Okamoto, Y.; Sakagawa, T.; Harada, M.; Okada, A. The boundary of keyhole generation in micro-welding of aluminum alloy by pulsed Nd:YAG laser with superposition of continuous diode laser. J. Jpn. Soc. For. Precis. Eng. 2014, 80, 419–424. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A review on laser beam welding of copper alloys. Int. J. Adv. Manuf. Technol. 2018, 96, 475–490. [Google Scholar] [CrossRef]

- Katherine, C. Calibration of numerical aperture effects in interferometric microscope objectives. Appl. Opt. 1989, 28, 3333–3338. [Google Scholar] [CrossRef]

- Edmund Optics. Available online: https://www.edmundoptics.com/ (accessed on 3 October 2018).

- Horiba Scientific. Available online: https://www.horiba.com/ (accessed on 3 October 2018).

| Melting temperature | 1356 K |

| Thermal conductivity | 391.1 W/(m K) |

| Coefficient of thermal expansion | 17.6 × 10−6 (1/K) |

| Specific heat | 380 J/(kg⋅K) |

| Density | 8.94 g/cm3 |

| Electrical resistivity | 17.1 nΩ⋅m |

| Electrical conductivity | 59.1 MS/m |

| Poisson’s ratio | 0.33 |

| Young’s modulus | 120 GPa |

| Compression Force (N) | Depth of Concave (μm) | Diameter of Concave (μm) |

|---|---|---|

| 100 | 300 | 320 |

| 50 | 185 | 220 |

| 10 | 50 | 110 |

| 8.0 | 40 | 90 |

| 6.0 | 30 | 80 |

| 4.0 | 20 | 70 |

| 2.5 | 10 | 50 |

| 2.0 | 8.0 | 40 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maina, M.R.; Okamoto, Y.; Inoue, R.; Nakashiba, S.-i.; Okada, A.; Sakagawa, T. Influence of Surface State in Micro-Welding of Copper by Nd:YAG Laser. Appl. Sci. 2018, 8, 2364. https://doi.org/10.3390/app8122364

Maina MR, Okamoto Y, Inoue R, Nakashiba S-i, Okada A, Sakagawa T. Influence of Surface State in Micro-Welding of Copper by Nd:YAG Laser. Applied Sciences. 2018; 8(12):2364. https://doi.org/10.3390/app8122364

Chicago/Turabian StyleMaina, Martin Ruthandi, Yasuhiro Okamoto, Reiki Inoue, Shin-ichi Nakashiba, Akira Okada, and Tomokazu Sakagawa. 2018. "Influence of Surface State in Micro-Welding of Copper by Nd:YAG Laser" Applied Sciences 8, no. 12: 2364. https://doi.org/10.3390/app8122364

APA StyleMaina, M. R., Okamoto, Y., Inoue, R., Nakashiba, S.-i., Okada, A., & Sakagawa, T. (2018). Influence of Surface State in Micro-Welding of Copper by Nd:YAG Laser. Applied Sciences, 8(12), 2364. https://doi.org/10.3390/app8122364