A Robotic Drilling End-Effector and Its Sliding Mode Control for the Normal Adjustment

Abstract

Featured Application

Abstract

1. Introduction

2. Dynamical Model for the Robotic Drilling End-Effector

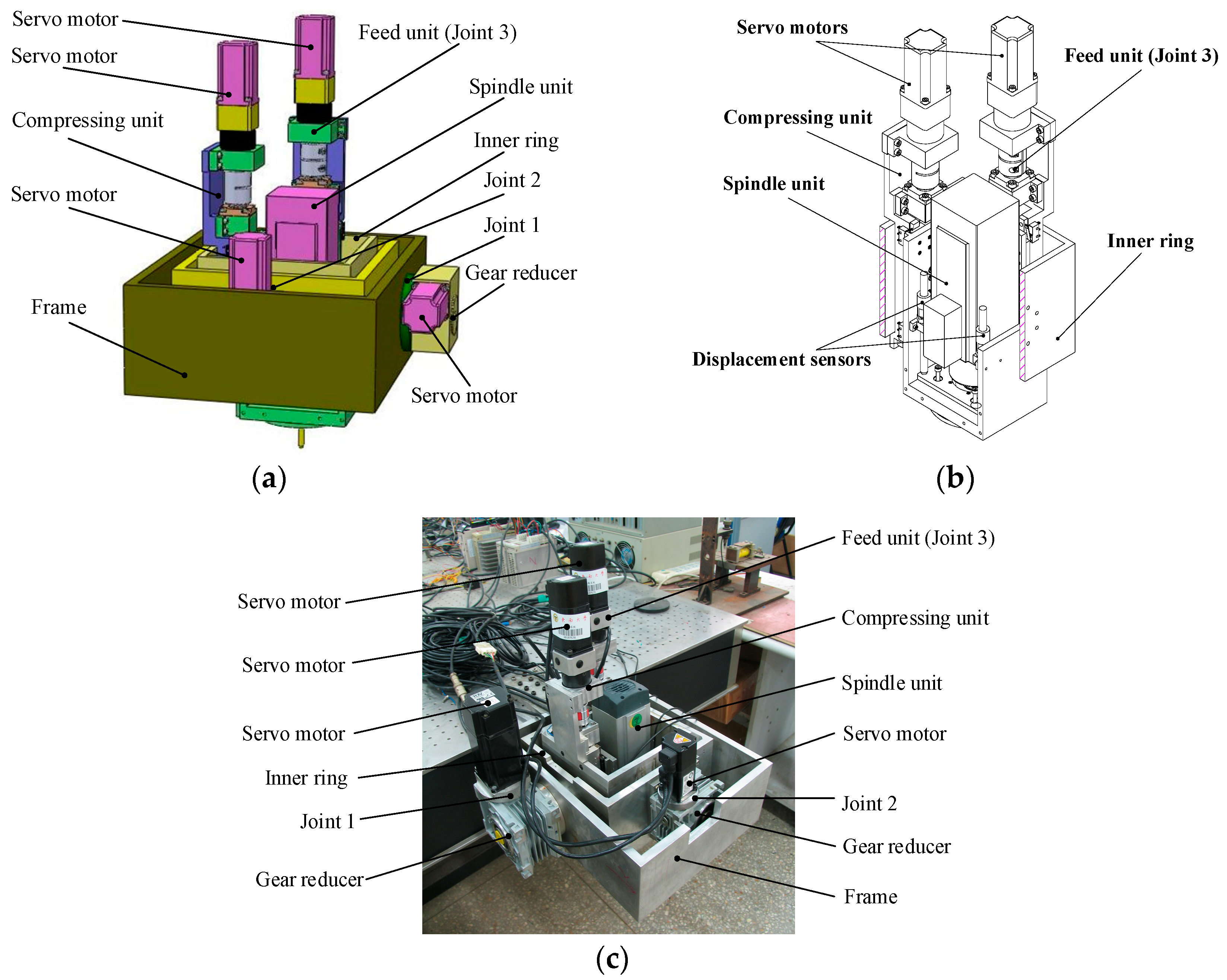

2.1. The Structure of the Robotic Drilling End-Effector

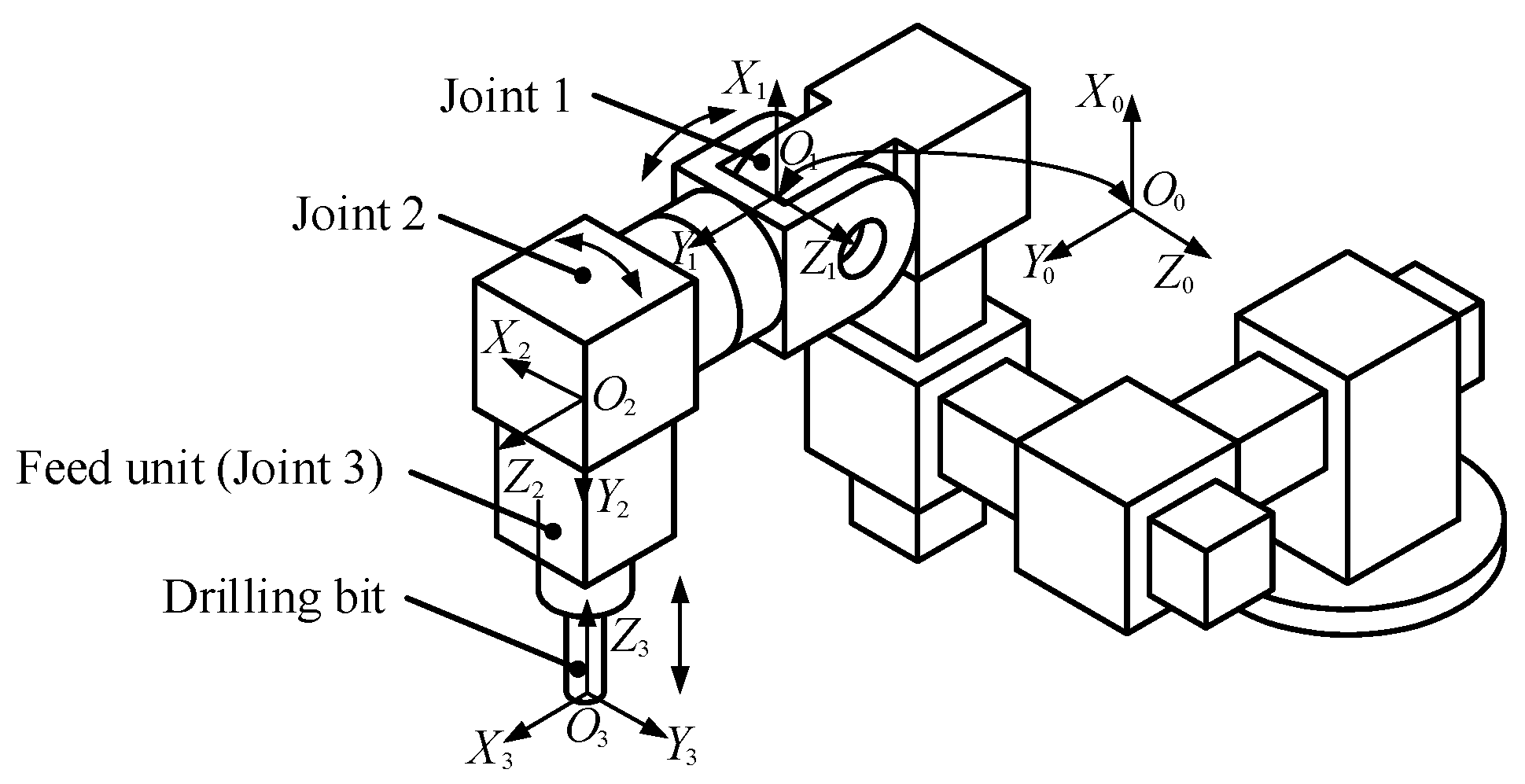

2.2. Motion Equations of the Robotic Drilling End-Effector

3. Sliding Mode Controller Design

3.1. Friction Compensation

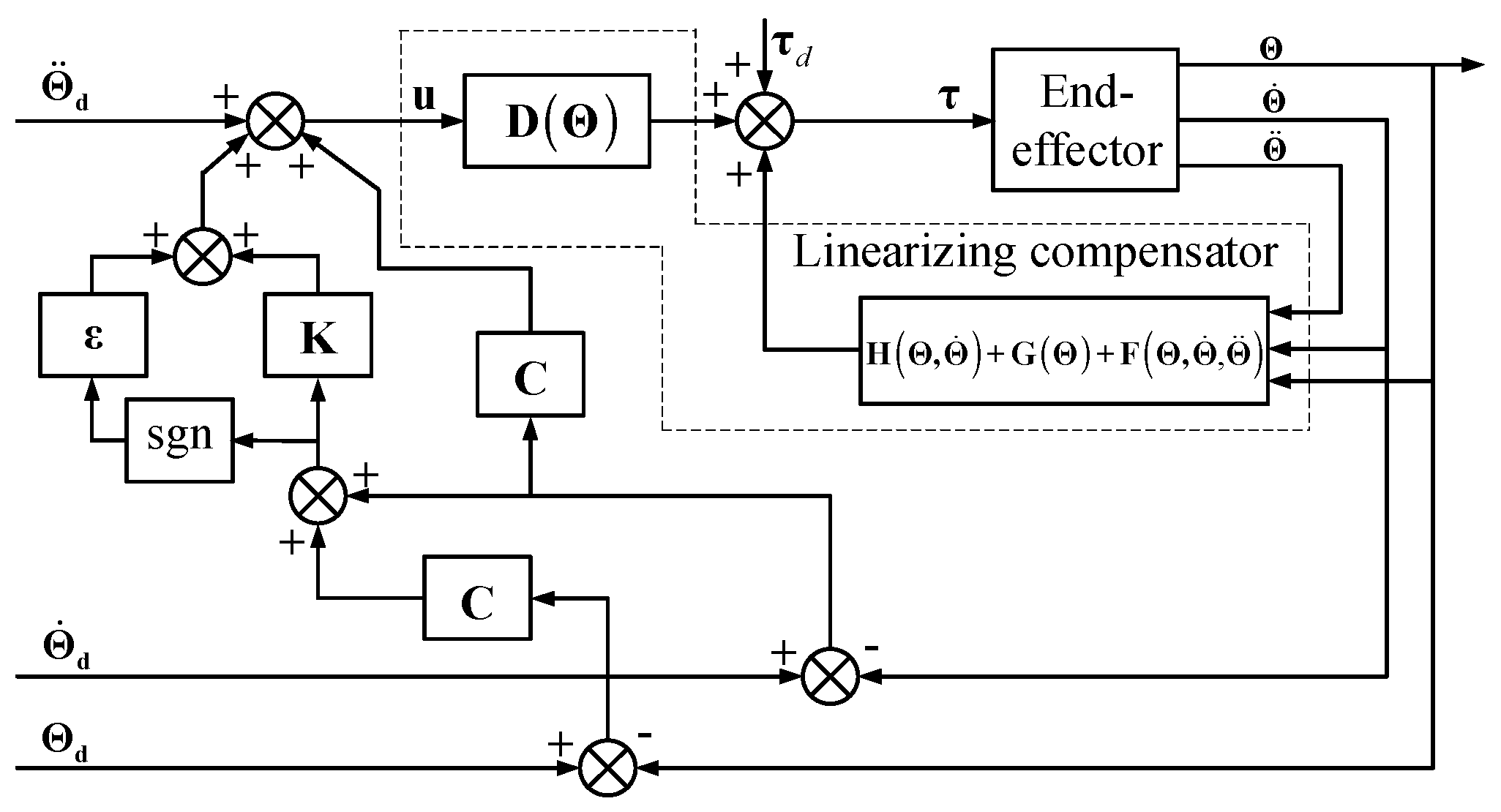

3.2. Sliding Mode Control Based on Model

3.3. Nonlinear Integration Chain Tracking-Differentiator

4. Simulations and Experiments Results and Discussion

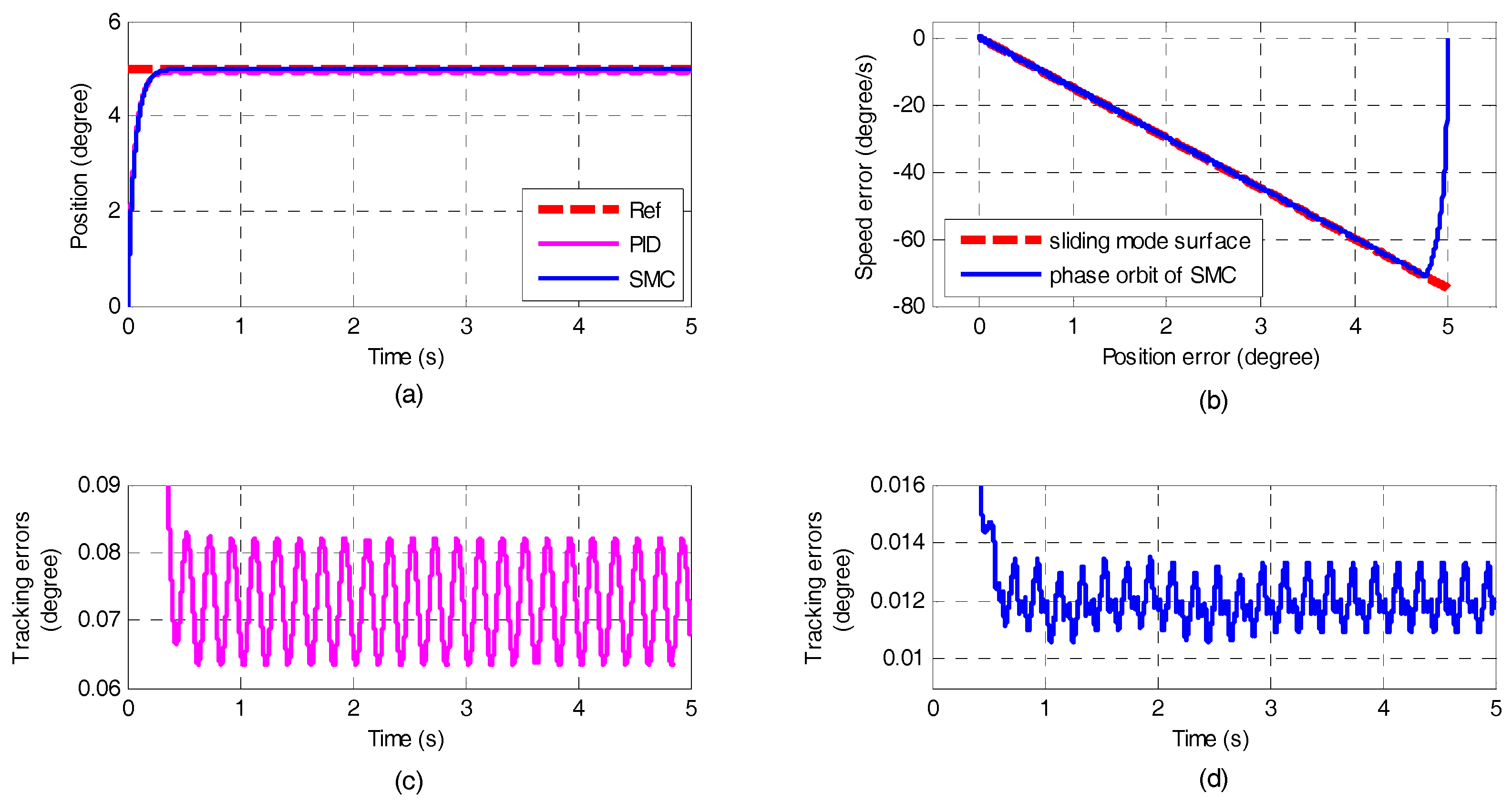

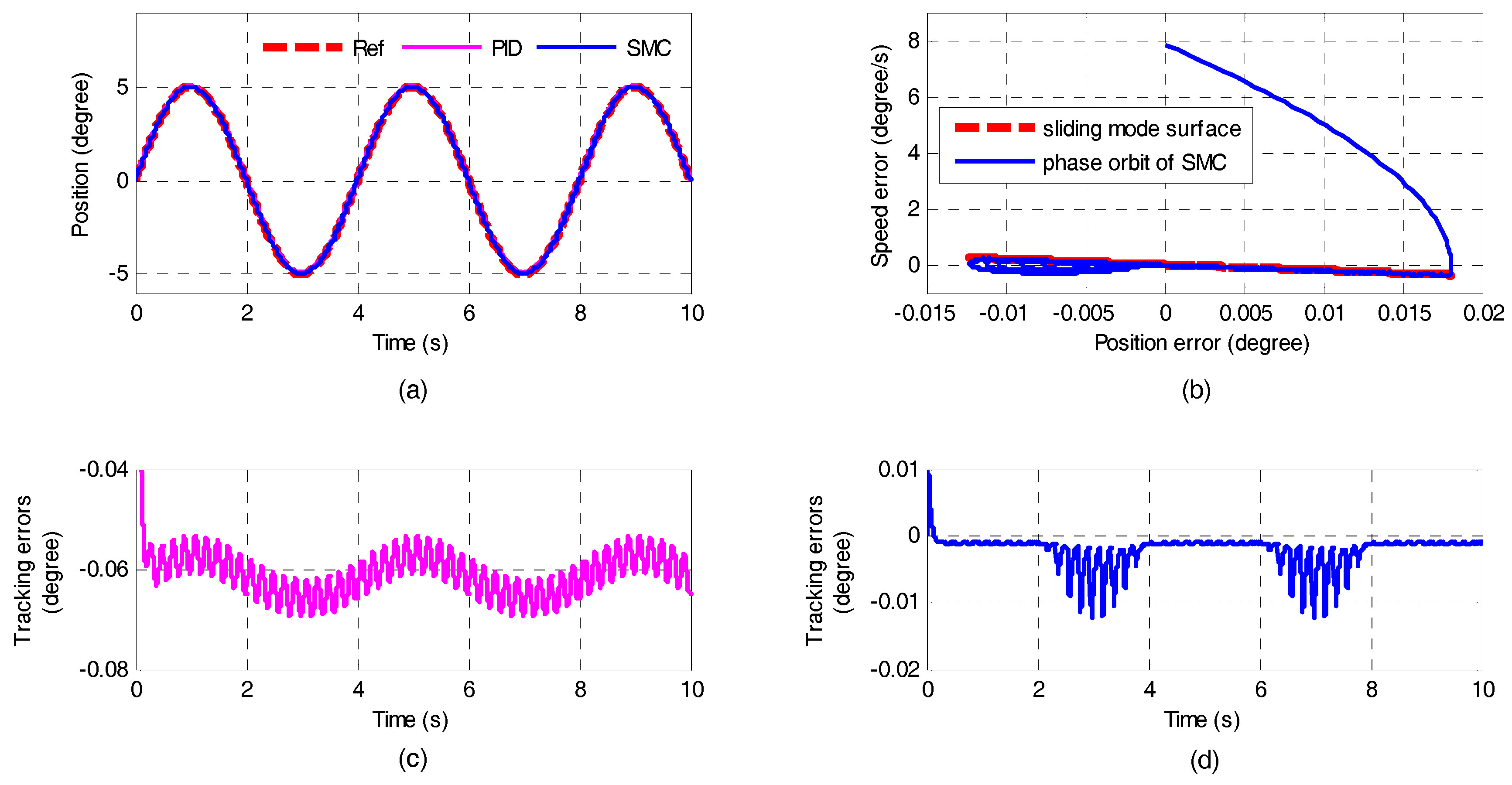

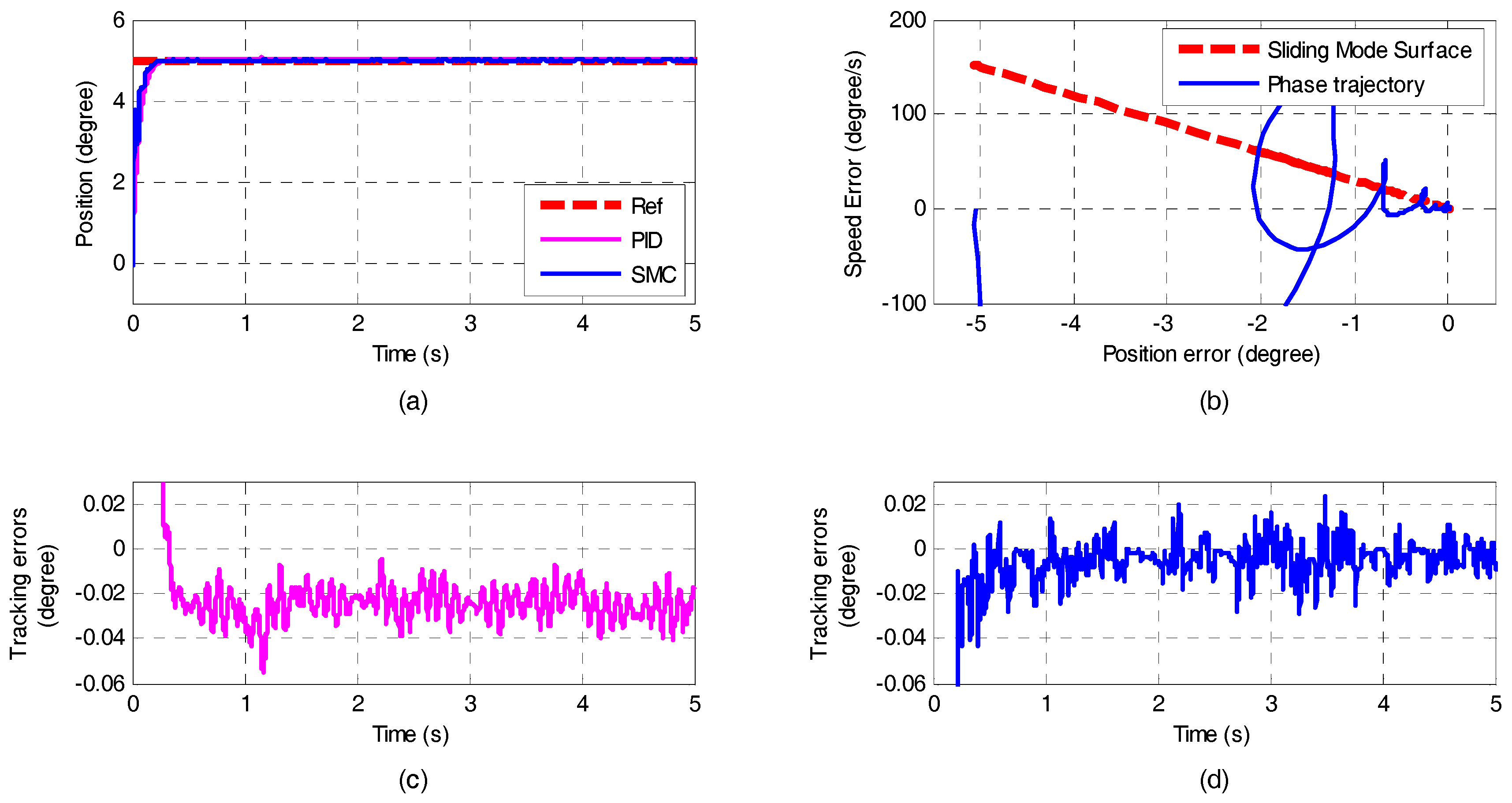

4.1. Simulations Results and Discussion

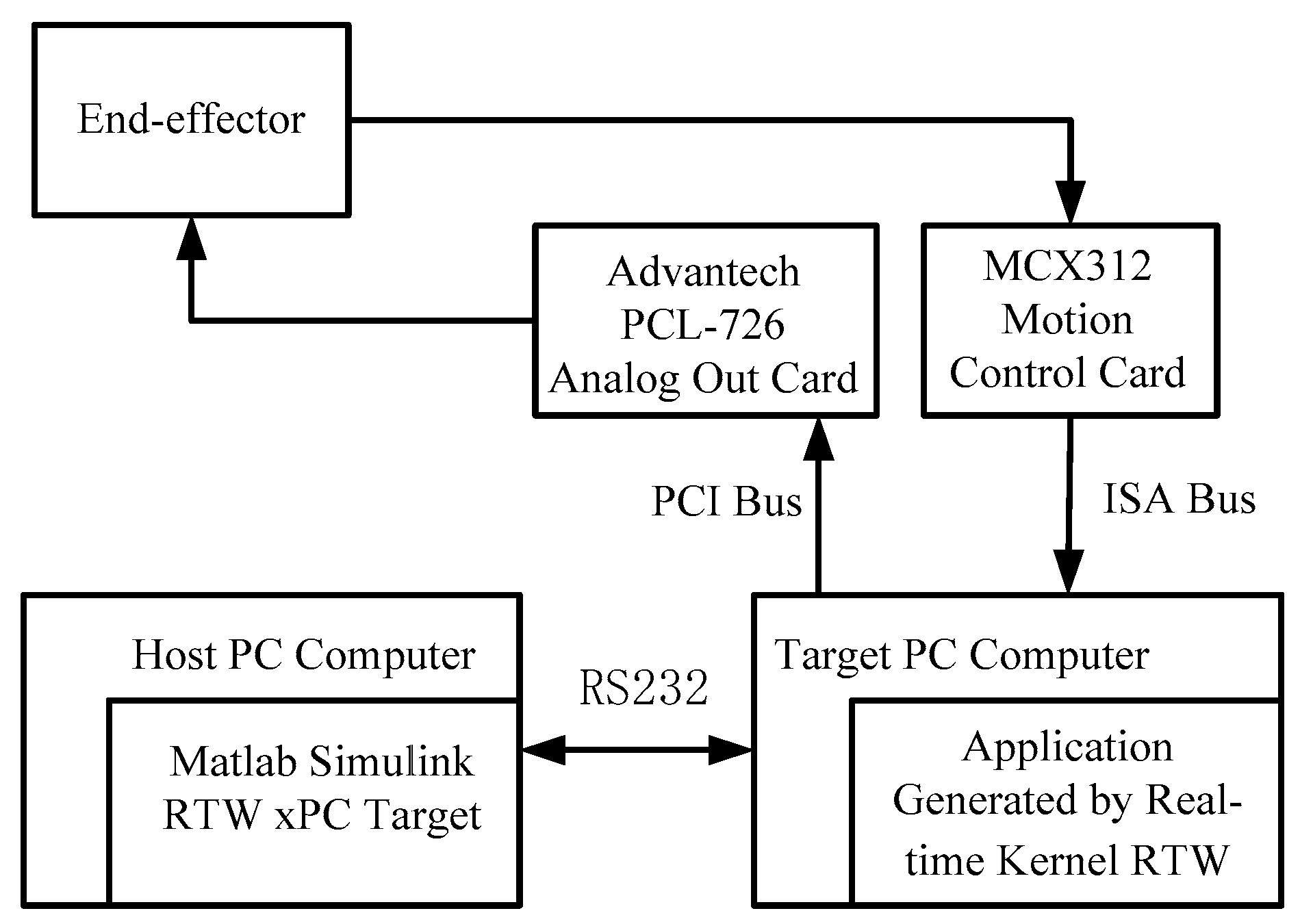

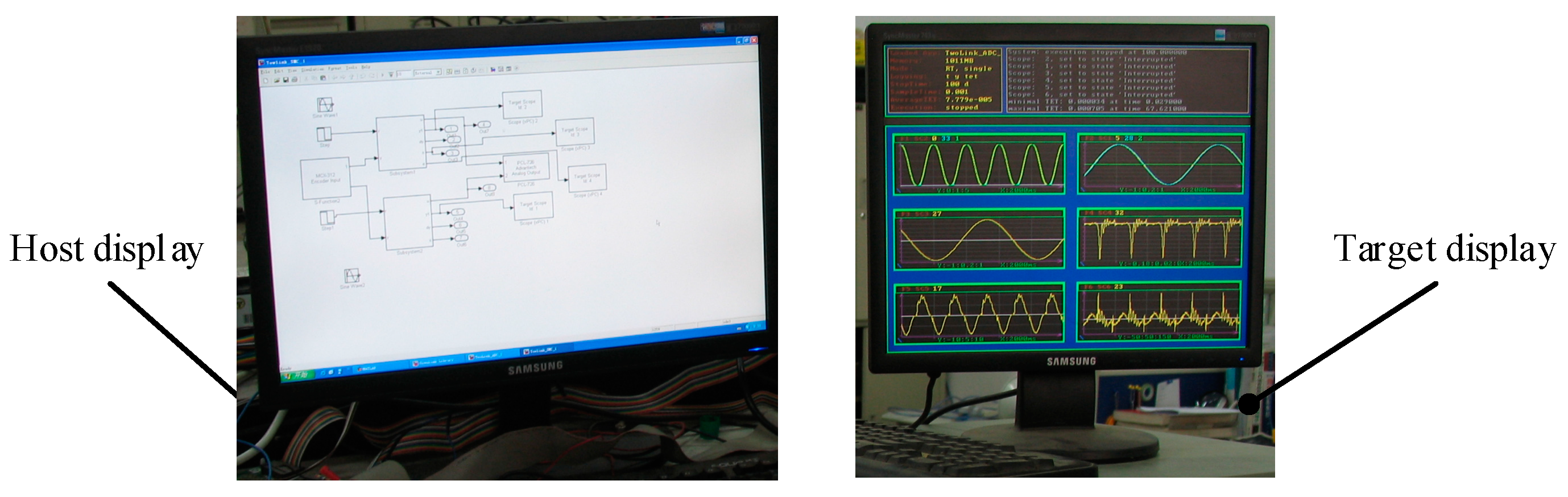

4.2. Establishment of Real-Time Experiment Platform

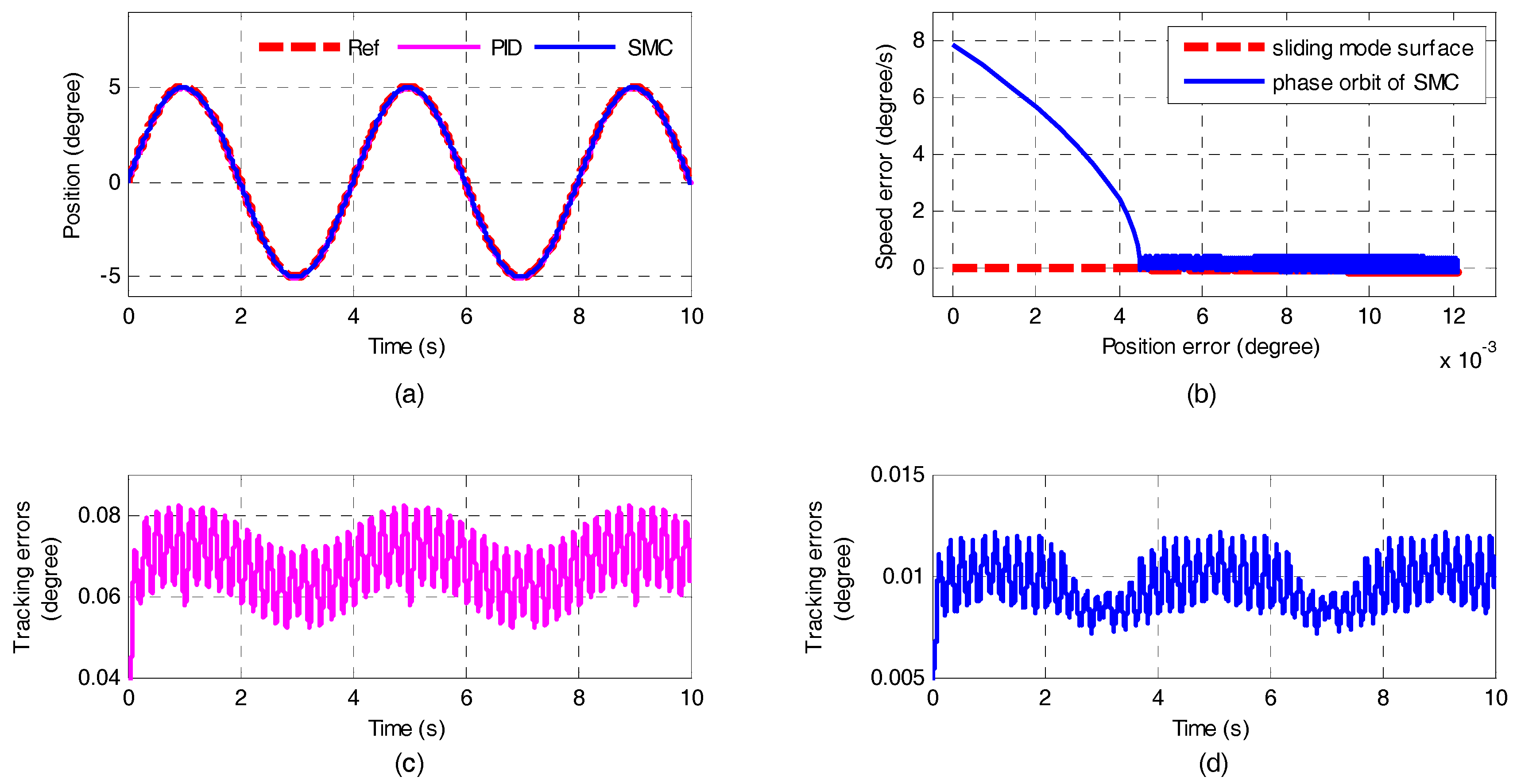

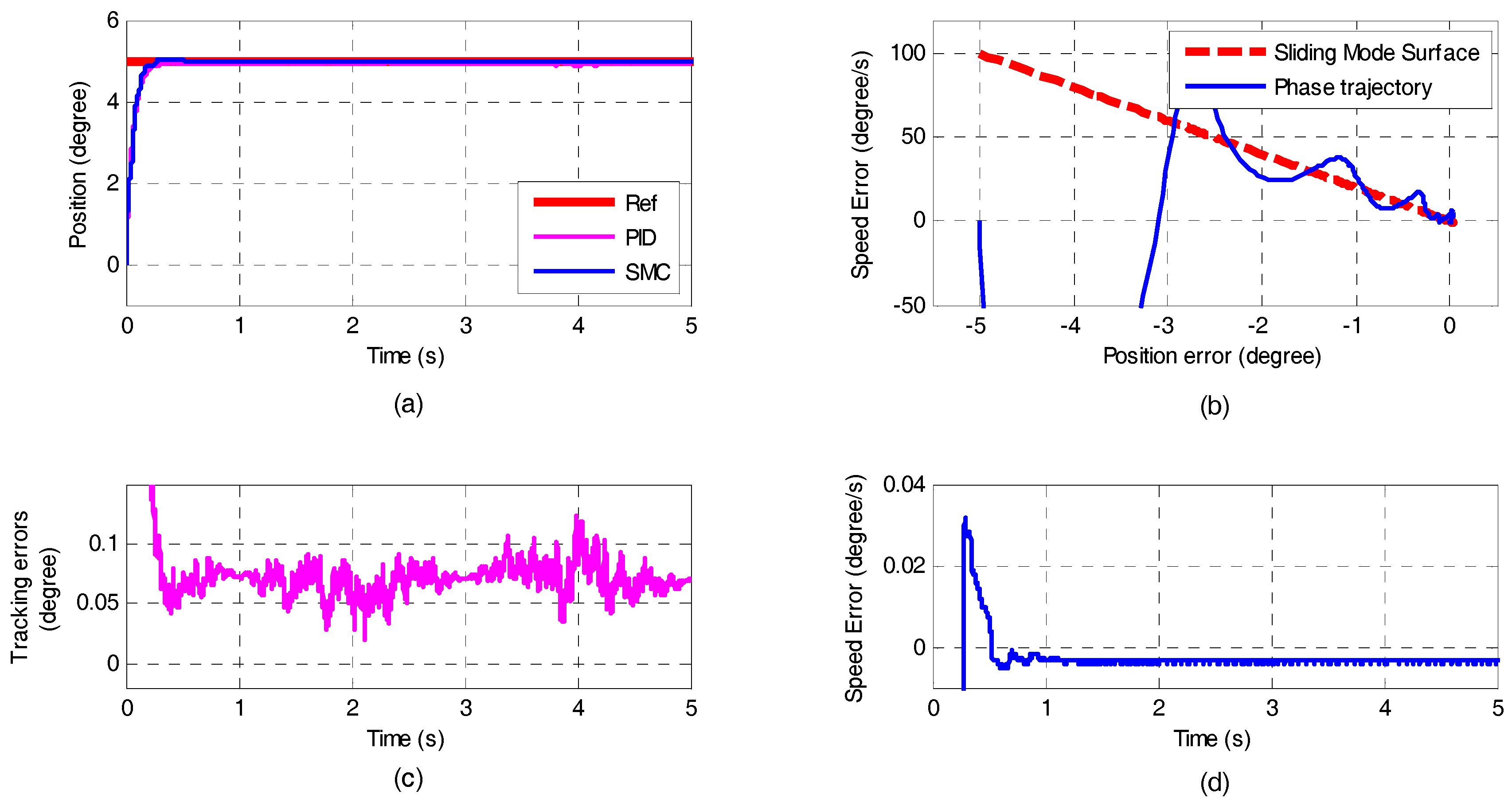

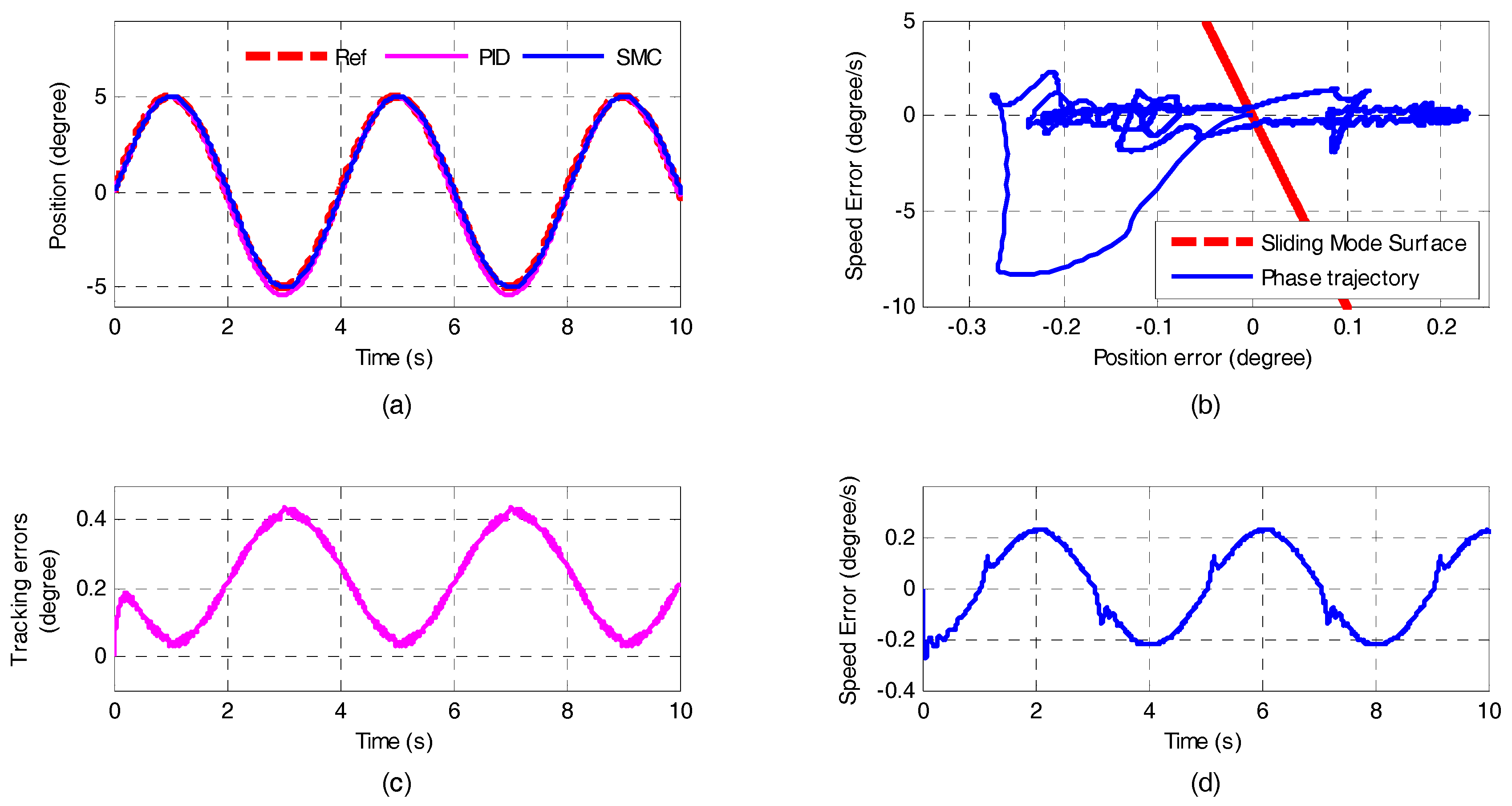

4.3. Experiments Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| SMC | Sliding mode controller |

| PID | Proportional-Integral-Derivative |

| D | Positive definite symmetric inertia matrix |

| H | Centrifugal and Coriolis force vector |

| G | Gravity vector |

| θ1 | Rotation angle of joint 1 |

| θ2 | Rotation angle of joint 2 |

| d3 | Linear displacement of prismatic joint 3 |

| Iabi | Product of inertia in respect to a pair of orthogonal axes a and b, a, b denote x, y or z, i denotes joint number |

| mi | Mass of Joint i |

| cai | Centroid coordinate on axis a, a denotes x, y or z, i denotes joint number |

| τ1 | acts on joint 1 |

| τ2 | Torque acts on joint 2 |

| f3 | Force acts on prismatic joint 3 |

| τd | Disturbance torque vector |

| τ | Computation torque vector |

| v | Motion velocity during friction |

| vs | Stribeck velocity |

| Ff | Friction force |

| Fe | Driving force |

| Fs | Maximum static friction force |

| Fc | Coulomb friction force |

| Fv | Viscous frictional torque coefficient |

| u | Controlled quantity vector |

| V | Liapunov’s function |

| S | Switch function |

| C | Proportional coefficient matrix in switch function |

| e | Position tracking error matrix |

| ɛ | Exponent matrix in reaching law |

| K | Proportional coefficient matrix in reaching law |

References

- Wilson, M. Robots in the aerospace industry. Aircr. Eng. Aerosp. Technol. 1994, 66, 2–3. [Google Scholar] [CrossRef]

- Cirillo, P.; Marino, A.; Natale, A.; Marino, E.D.; Chiacchio, P.; Maria, G.D. A low-cost and flexible solution for one-shot cooperative robotic drilling of aeronautic stack materials. IFAC-PapersOnLine 2017, 50, 4602–4609. [Google Scholar] [CrossRef]

- Olsson, T.; Haage, M.; Kihlman, H.; Johansson, R.; Nilsson, K.; Robertsson, A.; Björkmsn, M.; Isaksson, R.; Ossbahr, G.; Brogårdh, T. Cost-efficient drilling using industrial robots with high-bandwidth force feedback. Rob. Comput. Integr. Manuf. 2010, 26, 24–38. [Google Scholar] [CrossRef]

- Schneider, U.; Drust, M.; Ansloni, M.; Lehmann, C.; Pellicciari, M.; Leali, F.; Gunnink, J.W.; Verl, A. Improving robotic machining accuracy through experimental error investigation and modular compensation. Int. J. Adv. Manuf. Technol. 2016, 85, 3–15. [Google Scholar] [CrossRef]

- Shi, Z.; Yuan, P.; Wang, Q.; Chen, D.; Wang, T. New design of a compact aero-robotic drilling end effector: An experimental analysis. Chin. J. Aeronaut. 2016, 29, 1132–1141. [Google Scholar] [CrossRef]

- DeVlieg, R.; Sitton, K.; Feikert, E.; Inman, J. ONCE (one-sided cell end effector) robotic drilling system. SAE Tech. Pap. 2002. [Google Scholar] [CrossRef]

- Atkinson, J.; Hartmann, J.; Jones, S.; Gleeson, P. Robotic drilling system for 737 aileron. SAE Tech. Pap. 2007. [Google Scholar] [CrossRef]

- Webb, P.; Chitiu, A.; Fayad, C.; Gindy, N.; Mckeown, C. Flexible automated riveting of fuselage skin panels. SAE Trans. 2001, 110, 218–221. [Google Scholar]

- Hempstead, B.; DeVlieg, R.; Mistry, R.; Sheridan, M. Drill and drive end effector. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

- Liang, J.; Bi, S. Design and experimental study of an end effector for robotic drilling. Int. J. Adv. Manuf. Technol. 2010, 50, 399–408. [Google Scholar] [CrossRef]

- Devlieg, R. High-accuracy robotic drilling/milling of 737 inboard flaps. SAE Int. J. Aerosp. 2011, 4, 1373–1379. [Google Scholar] [CrossRef]

- Gray, T.; Orf, D.; Adams, G. Mobile automated robotic drilling, inspection, and fastening. SAE Tech. Pap. 2013. [Google Scholar] [CrossRef]

- Olsson, T.; Robertsson, A.; Johansson, R. Flexible force control for accurate low-cost robot drilling. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007; IEEE: New York, NY, USA, 2007. [Google Scholar]

- Tian, W.; Zhou, W.; Zhou, W.; Liao, W.; Zeng, Y. Auto-normalization algorithm for robotic precision drilling system in aircraft component assembly. Chin. J. Aeronaut. 2013, 26, 495–500. [Google Scholar] [CrossRef]

- Mei, B.; Zhu, W.; Yuan, K.; Ke, Y. Robot base frame calibration with a 2D vision system for mobile robotic drilling. Int. J. Adv. Manuf. Technol. 2015, 80, 1903–1917. [Google Scholar] [CrossRef]

- Frommknecht, A.; Kuehnle, J.; Effenberger, I.; Pidan, S. Multi-sensor measurement system for robotic drilling. Rob. Comput. Integr. Manuf. 2017, 47, 4–10. [Google Scholar] [CrossRef]

- Qin, C.; Tao, J.; Wang, M.; Liu, C. A Novel Approach for the Acquisition of Vibration Signals of the End Effector in Robotic Drilling. In Proceedings of the 2016 IEEE International Conference on Aircraft Utility Systems (AUS), Beijing, China, 10–12 October 2016; IEEE: New York, NY, USA, 2016. [Google Scholar]

- Garnier, S.; Subrin, K.; Waiyagan, K. Modelling of robotic drilling. Procedia CIRP 2017, 58, 416–421. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X. A novel algorithm of normal attitude regulation for the designed end-effector of a flexible drilling robot. J. Southeast Univ. 2012, 28, 29–34. [Google Scholar]

- Olsson, H.; Åström, K.J.; Wit, C.C.D.; Gäfvert, M.; Lischinsky, P. Friction models and friction compensation. Eur. J. Control 1998, 4, 176–195. [Google Scholar] [CrossRef]

- Hung, J.Y.; Gao, W.; Hung, J.C. Variable structure control: A survey. IEEE Trans. Ind. Electron. 1993, 40, 2–22. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Cai, K. Tracking control for a velocity-sensorless VTOL aircraft with delayed outputs. Automatica 2009, 45, 2876–2882. [Google Scholar] [CrossRef]

- Karafyllis, I.; Kravaris, C. On the observer problem for discrete-time control systems. IEEE Trans. Ind. Electron. 2007, 52, 12–25. [Google Scholar] [CrossRef]

- Drakunov, S.; Utkin, V. Sliding Mode Observers Tutorial. In Proceedings of the 34th IEEE Conference on Decision and Control, New Orleans, LA, USA, 13–15 December 1995; IEEE: New York, NY, USA, 1995. [Google Scholar]

- Ma, R.; Zhang, G.; Krause, O. Fast terminal sliding-mode finite-time tracking control with differential evolution optimization algorithm using integral chain differentiator in uncertain nonlinear systems. Int. J. Robust Nonlinear Control 2018, 28, 625–639. [Google Scholar] [CrossRef]

- Vasiljevic, L.; Khalil, H. Differentiation with High-Gain Observers the Presence of Measurement Noise. In Proceedings of the 45th IEEE Conference on Decision and Control, San Diego, CA, USA, 13–15 December 2006; IEEE: New York, NY, USA, 2007. [Google Scholar]

- Alwi, H.; Edwards, C. An adaptive sliding mode differentiator for actuator oscillatory failure case reconstruction. Automatica 2013, 49, 642–651. [Google Scholar] [CrossRef]

- Wang, X.; Lin, H. Design and analysis of a continuous hybrid differentiator. IET Control Theory Appl. 2011, 5, 1321–1334. [Google Scholar] [CrossRef]

- Listmann, K.D.; Zhao, Z. A Comparison of Methods for Higher-Order Numerical Differentiation. In Proceedings of the 2013 European Control Conference (ECC), Zurich, Switzerland, 17–19 July 2013; IEEE: New York, NY, USA, 2013. [Google Scholar]

- Wang, X.; Chen, Z.; Yuan, Z. Design and analysis for new discrete tracking-differentiators. Appl. Math. A J. Chin. Univ. 2003, 18, 214–222. [Google Scholar] [CrossRef]

- Meshram, P.M.; Kanojiya, R.G. Tuning of PID Controller Using Ziegler-Nichols Method for Speed Control of DC Motor. In Proceedings of the IEEE-International Conference on Advances in Engineering, Science and Management (ICAESM-2012), Nagapattinam, Tamil Nadu, India, 30–31 March 2012; IEEE: New York, NY, USA, 2012. [Google Scholar]

- Low, K.H.; Wang, H.; Wang, M.Y. On the Development of a Real Time Control System by Using xPC Target: Solution to Robotic System Control. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Edmonton, AB, Canada, 1–2 August 2005; IEEE: New York, NY, USA, 2005. [Google Scholar]

- Grepl, R. Real-Time Control Prototyping in MATLAB/Simulink: Review of Tools for Research and Education in Mechatronics. In Proceedings of the 2011 IEEE International Conference on Mechatronics, Istanbul, Turkey, 13–15 April 2011; IEEE: New York, NY, USA, 2011. [Google Scholar]

| Parameters | i = 1 | i = 2 | i = 3 |

|---|---|---|---|

| Ixxi (m4) | 0.03 | 0.04 | 0.03 |

| Ixyi (m4) | 0 | 0.01 | 0 |

| Ixzi (m4) | 0 | −0.01 | 0 |

| Iyxi (m4) | 0 | 0.01 | 0 |

| Iyyi (m4) | 0.09 | 0.11 | 0.04 |

| Iyzi (m4) | 0 | 0 | 0 |

| Izxi (m4) | 0 | −0.11 | 0 |

| Izyi (m4) | 0 | 0 | 0 |

| Izzi (m4) | 0.06 | 0.11 | 0.01 |

| mi (kg) | 5.8 | 7.6 | 8.6 |

| cxi (m) | 0.05 | 0.02 | 0 |

| cyi (m) | 0 | 0.02 | 0 |

| czi (m) | 0 | −0.01 | 0.14 |

| α | 0.01 |

| a1 | 1 |

| Fs1 | 0.1 N·m |

| Fs2 | 0.05 N·m |

| Fc1 | 0.04 N·m |

| Fc2 | 0.02 N·m |

| Kv1 | 0.02 |

| Kv2 | 0.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Dhupia, J.S.; Wu, M.; Huang, H. A Robotic Drilling End-Effector and Its Sliding Mode Control for the Normal Adjustment. Appl. Sci. 2018, 8, 1892. https://doi.org/10.3390/app8101892

Zhang L, Dhupia JS, Wu M, Huang H. A Robotic Drilling End-Effector and Its Sliding Mode Control for the Normal Adjustment. Applied Sciences. 2018; 8(10):1892. https://doi.org/10.3390/app8101892

Chicago/Turabian StyleZhang, Laixi, Jaspreet Singh Dhupia, Mingliang Wu, and Hua Huang. 2018. "A Robotic Drilling End-Effector and Its Sliding Mode Control for the Normal Adjustment" Applied Sciences 8, no. 10: 1892. https://doi.org/10.3390/app8101892

APA StyleZhang, L., Dhupia, J. S., Wu, M., & Huang, H. (2018). A Robotic Drilling End-Effector and Its Sliding Mode Control for the Normal Adjustment. Applied Sciences, 8(10), 1892. https://doi.org/10.3390/app8101892