Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set

Abstract

:1. Introduction

2. Composite Dispatching Rule

2.1. Priority Based on a Single Rule

- Scenario I: The greater the value of the job attribute, given by , the higher the job processing priority. For example, the job attribute “waiting time in buffer” is used to determine the job processing sequence when applying the dispatching rule “first-in first-out (FIFO)”. For a job, the longer the waiting time in the buffer, the higher the job processing priority. In this case, the priority is determined by rule :

- Scenario II: The smaller the value of the job attribute (), the higher the job processing priority. For example, the job attribute “due date” is used to determine the job processing sequence when applying the dispatching rule “earliest due date (EDD)”. For a job, the earlier the job’s due date, the higher the processing priority. In this case, the priority is determined by rule :where is the value of attribute of job , and and are the maximum and the minimum values of attribute of jobs waiting to be processed.

2.2. Integrated Priority Based on a Composite Rule

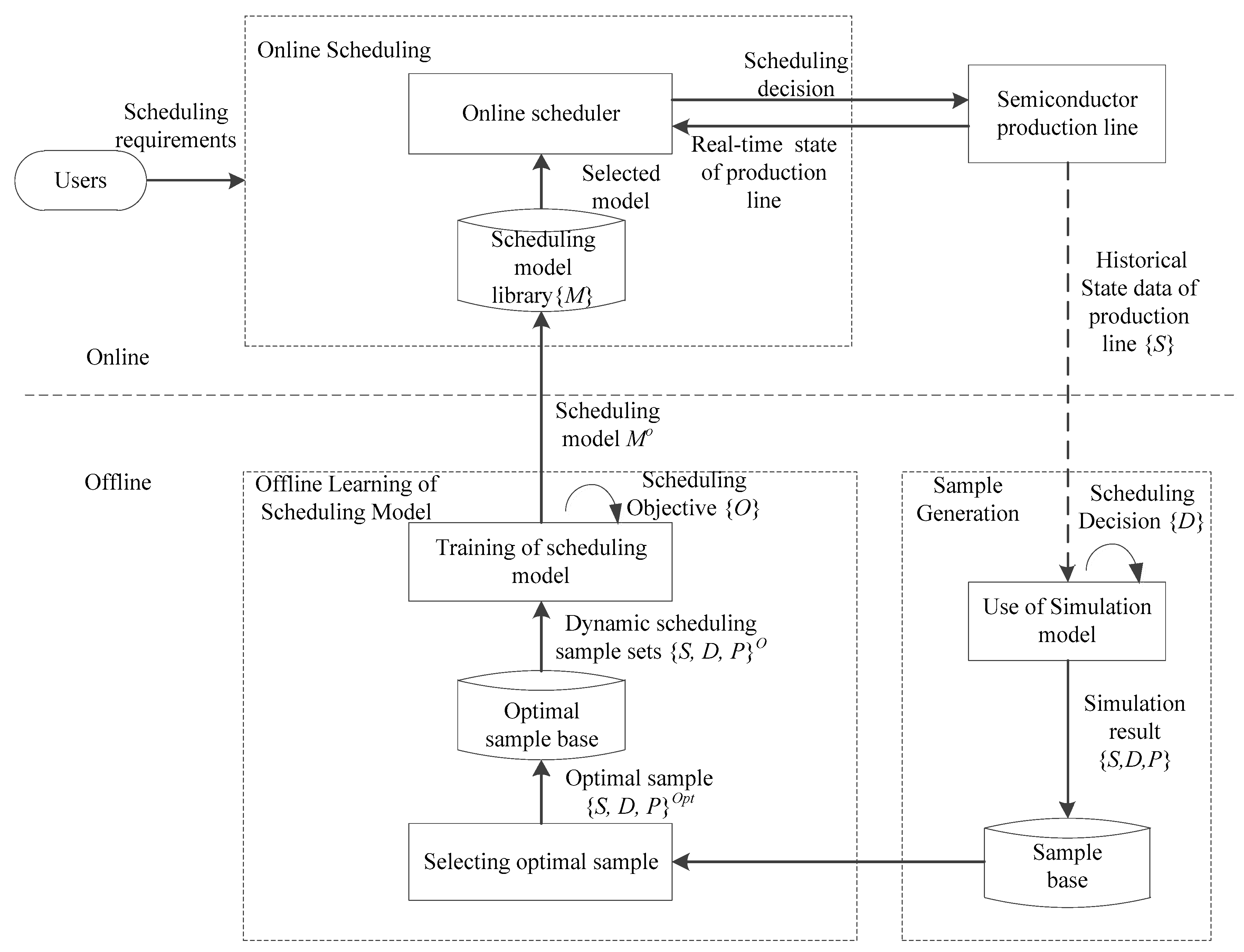

3. Learning Based Dynamic Scheduling

4. A SVR-Based Dynamic Scheduling Model

4.1. Generation of Training Data from Sample Base

4.2. Development of Scheduling Models

5. Case Study

5.1. Selection of Experimental Data Set

5.1.1. Production Features Set

5.1.2. Design of Composite Rule

5.1.3. Selection of Performance Indicators

5.2. Parameter Settings of the Experiment

5.3. Experiment Results and Data Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mouelhi-Chibani, W.; Pierreval, H. Training a neural network to select dispatching rules in real time. Comput. Ind. Eng. 2010, 58, 249–256. [Google Scholar] [CrossRef]

- Priore, P.; Gomez, A.; Pino, R.; Rosillo, R. Dynamic scheduling of manufacturing systems using machine learning: An updated review. Artif. Intell. Eng. Des. Anal. Manuf. 2014, 8, 83–97. [Google Scholar] [CrossRef]

- Shiue, Y.R.; Guh, R.S.; Tseng, T.Y. Study on shop floor control system in semiconductor fabrication by self-organizing map-based intelligent multi-controller. Comput. Ind. Eng. 2012, 62, 1119–1129. [Google Scholar] [CrossRef]

- Tsai, C.J.; Huang, H.P. A real-time scheduling and rescheduling system based on RFID for semiconductor foundry FABs. J. Chin. Inst. Ind. Eng. 2007, 24, 437–445. [Google Scholar] [CrossRef]

- Olafsson, S.; Li, X.N. Learning effective new single machine dispatching rules from optimal scheduling data. Int. J. Prod. Econ. 2010, 128, 118–126. [Google Scholar] [CrossRef]

- Ma, Y.M.; Chen, X.; Qiao, F. The Research and Application of a Dynamic Dispatching Strategy Selection Approach based on BPSO-SVM for Semiconductor Production Line. In Proceedings of the 11th IEEE International Conference on Networking, Sensing and Control (ICNSC2014), Miami, FL, USA, 7–9 April 2014; pp. 74–79. [Google Scholar]

- Qiao, F.; Ma, Y.M.; Gu, X. Attribute selection algorithm of data-based scheduling strategy for semiconductor manufacturing. In Proceedings of the IEEE International Conference on Automation Science and Engineering, (CASE 2013), Madison, WI, USA, 17–20 August 2013; pp. 410–415. [Google Scholar]

- Li, L.; Sun, Z.J.; Zhou, M.; Qiao, F. Adaptive Dispatching Rule for Semiconductor Wafer Fabrication Facility. IEEE Trans. Autom. Sci. Eng. 2013, 10, 354–364. [Google Scholar] [CrossRef]

- Lee, Y.F.; Jiang, Z.B.; Liong, H.C. A smart adaptive production control system for semiconductor foundry fab. In Proceedings of the 8th World Multi-conference on System, Cybernetics and Informatics (SCI 2004), Florida, FL, USA, 18–21 July 2004. [Google Scholar]

- Pickardt, C.W.; Hildebrandt, T.; Branke, J.; Heger, J. Evolutionary generation of dispatching rule sets for complex dynamic scheduling problems. Int. J. Prod. Econ. 2013, 145, 67–77. [Google Scholar] [CrossRef]

- Bouri, A.E.; Amin, G.R. A combined OWA-DEA method for dispatching rule selection. Comput. Ind. Eng. 2015, 88, 470–478. [Google Scholar] [CrossRef]

- Yu, Y.H.; Wang, Y.H. Design and Implementation of a Real-Time Job shop Scheduling System. In Proceedings of the International Asia Conference on Industrial Engineering and Management Innovation (IEMI2012), Beijing, China, 10–11 August 2012. [Google Scholar]

- Chen, T. An effective dispatching rule for bi-objective job scheduling in a wafer fabrication factory—considering the average cycle time and the maximum lateness. Int. J. Adv. Manuf. Technol. 2013, 67, 1281–1295. [Google Scholar] [CrossRef]

- Dabbas, R.M.; Fowler, J.W. A new scheduling approach using combined dispatching criteria in wafer fabs. IEEE Trans. Semicond. Manuf. 2003, 16, 501–510. [Google Scholar] [CrossRef]

- Kai, Y.; Qiao, F.; Ma, Y.M. General structure of the semiconductor production scheduling model. Appl. Mech. Mater. 2010, 20–23, 465–469. [Google Scholar]

- Devor, R.E.; Chang, T.; Sutherland, J.W. Statistical Quality Design and Control: Contemporary Concepts and Methods, 2nd ed.; Prentice Hall: New York, NY, USA, 2006; ISBN 9780130413444. [Google Scholar]

- Huang, T.M.; Kecman, V.; Kopriva, I. Kernel Based Algorithms for Mining Huge Data Sets; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 3540316817, 9783540316817. [Google Scholar]

- Campbell, C.; Ying, Y. Learning with support vector machines. Synth. Lect. Artif. Intell. Mach. Learn. 2011, 10, 1–95. [Google Scholar] [CrossRef]

- Ma, Y.M.; Qiao, F.; Chen, X. A dynamic scheduling approach based on SVM for semiconductor production line. Comput. Integr. Manuf. Syst. 2015, 21, 733–739. [Google Scholar] [CrossRef]

- Jiang, Z.B. Modeling and Optimal Scheduling Control of Semiconductor Manufacturing System; Shanghai Jiaotong University Press: Shanghai, China, 2011; ISBN 7313063156, 9787313063151. [Google Scholar]

| ID | GR_GR | GR_SPT | GR_LS | RSM | Scheduling Method Proposed |

|---|---|---|---|---|---|

| 1 | 67,452 | 83,350 | 83,983 | 90,612 | 89,706 |

| 2 | 76,773 | 89,605 | 89,821 | 94,796 | 93,744 |

| 3 | 89,285 | 89,028 | 89,484 | 90,181 | 86,574 |

| 4 | 85,014 | 84,864 | 85,486 | 87,154 | 85,411 |

| 5 | 91,270 | 91,348 | 91,307 | 92,915 | 92,714 |

| 6 | 67,936 | 84,244 | 83,610 | 88,961 | 86,851 |

| 7 | 67,246 | 88,544 | 89,900 | 95,145 | 93,224 |

| 8 | 91,279 | 89,851 | 91,114 | 91,478 | 92,111 |

| 9 | 91,053 | 93,165 | 94,757 | 93,165 | 94,828 |

| 10 | 101,650 | 100,736 | 101,902 | 104,383 | 104,516 |

| Average | 82,896 | 89,474 | 90,136 | 92,879 | 91,968 |

| Optimization degree | 0.893 | 0.963 | 0.970 | 1.000 | 0.990 |

| Scheduling Decisions | GR_GR | GR_SPT | GR_LS | RSM | Scheduling Method Proposed |

|---|---|---|---|---|---|

| MCT (day) | 44.86 | 44.97 | 44.76 | 46.38 | 45.81 |

| PR (%) | 0.3267 | 0.3338 | 0.3322 | 0.3561 | 0.3523 |

| MOV (step) | 85,231 | 89,569 | 90,383 | 92,868 | 92,011 |

| WIP (piece) | 72,051 | 72,046 | 72,048 | 72,030 | 71,186 |

| OEE (%) | 0.2917 | 0.3072 | 0.3097 | 0.3202 | 0.3114 |

| Scheduling Decisions | GR_GR | GR_SPT | GR_LS | RSM | Scheduling Method Proposed |

|---|---|---|---|---|---|

| MCT | 0.9367 | 0.8732 | 1 | 0 | 0.3527 |

| PR | 0 | 0.2401 | 0.1855 | 1 | 0.8711 |

| MOV | 0 | 0.5681 | 0.6746 | 1 | 0.8878 |

| WIP | 1 | 0.9942 | 0.9956 | 0.9749 | 0 |

| OEE | 0 | 0.5439 | 0.6316 | 1 | 0.6912 |

| Comprehensive value | 0.2342 | 0.5563 | 0.6229 | 0.7500 | 0.7007 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Qiao, F.; Zhao, F.; Sutherland, J.W. Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set. Appl. Sci. 2017, 7, 1052. https://doi.org/10.3390/app7101052

Ma Y, Qiao F, Zhao F, Sutherland JW. Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set. Applied Sciences. 2017; 7(10):1052. https://doi.org/10.3390/app7101052

Chicago/Turabian StyleMa, Yumin, Fei Qiao, Fu Zhao, and John W. Sutherland. 2017. "Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set" Applied Sciences 7, no. 10: 1052. https://doi.org/10.3390/app7101052

APA StyleMa, Y., Qiao, F., Zhao, F., & Sutherland, J. W. (2017). Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set. Applied Sciences, 7(10), 1052. https://doi.org/10.3390/app7101052