Abstract

Granite is widely used in laboratory rockburst simulations due to its exceptional strength, brittleness, and uniform composition. This study employs a true triaxial loading system to replicate asymmetric stress states near free surfaces, allowing precise control of three-dimensional stresses to simulate strain-mode rockbursts. Advanced monitoring tools, such as acoustic emission (AE) and high-speed imaging, were used to investigate the evolution process, failure mechanisms, and monitoring strategies. The evolution of strain-mode rockbursts is divided into five stages: stress accumulation, crack initiation, critical instability, rockburst occurrence, and residual stress adjustment. Each stage exhibits dynamic responses and progressive energy release. Failure is governed by a tension–shear coexistence mechanism, where vertical splitting and diagonal shear fractures near free surfaces lead to V-shaped craters and violent rock fragment ejection. This reflects the brittle nature of granite under high-stress conditions. The AE monitoring proved highly effective in identifying rockburst precursors, with key indicators including quiet periods of low AE activity and sudden surges in AE counts, coupled with ‘V-shaped’ b-value troughs, offering reliable early warning signals. These findings provide critical insights into strain-mode rockburst dynamics, highlighting the transition from elastic deformation to dynamic failure and the role of energy release mechanisms.

1. Introduction

As economies grow and the demand for resources and energy continues to rise, deep underground engineering has become increasingly vital for mining, energy storage, and transportation infrastructure. However, these projects often face significant challenges, including intense rock dynamic hazards that frequently occur during construction, such as rockbursts. Notable cases of severe rockburst disasters have occurred in projects such as the Jinping II Hydropower Station tunnels (China), the Neelum-Jhelum TBM Tunnel (Pakistan), deep gold mines (South Africa), the Hongtoushan Copper Mine (China), and the Upper Silesian Coal Basin (Poland) [1,2,3,4,5,6], underscoring the challenges faced in high-stress underground environments. These incidents not only pose a significant threat to the safety of workers but also lead to equipment damage and project delays. This disruption affects both project outcomes and social harmony.

Rockbursts, a sudden and violent failure of rock, are typically classified into two types: strain-mode and slip-mode, depending on geological conditions and stress release mechanisms [6,7]. The strain-mode rockburst occurs when intense stress disturbance causes rock to rapidly release stored energy, leading to dramatic cracking and material breaking away. Although researchers have made progress in predicting and managing rockburst hazards, the exact mechanisms and warning signs of strain-mode rockbursts under complex stress conditions remain unclear. In particular, further exploration is needed to clarify how acoustic emission parameters can effectively capture and reflect the evolution of a strain-mode rockburst.

In recent years, scholars have conducted extensive research on rockburst disasters, yielding significant theoretical and experimental advancements. Studies in this field largely focus on laboratory experiments, field monitoring, numerical modeling, and theoretical analysis [8,9,10]. Among these approaches, laboratory simulations offer notable advantages, including precise control, high safety, accurate data collection, and shorter study durations [10]. These strengths make laboratory simulations particularly effective for investigating the mechanisms, identifying key influencing factors, and detecting early warning signs. For instance, Zhang et al. [11] conducted uniaxial loading tests, discussed the brittleness index and AE characteristics of dry and saturated granite samples, and revealed water’s role in reducing rockburst tendency. Gong et al. [12] performed uniaxial compression tests to investigate loading rate effects on rockburst proneness and concluded higher rates increase bursting liability through elastic strain energy release. Moreover, Wu et al. [13] employed the biaxial Hopkinson pressure bar system to investigate sidewall rockburst mechanisms in D-shape tunnels and concluded that static stress and impact load interactions trigger rockburst events. Wu et al. [13] utilized the biaxial Hopkinson pressure bar (BHPB) system to study the sidewall rockburst of a D-shape tunnel by applying various pre-stresses, including horizontal and vertical static stresses, to a sand prefabricated D-shape hole specimen, followed by impact loads. Si et al. [14] conducted true triaxial compression tests on pre-heated granite cubic samples containing a circular through-hole, and the micro camera was used to monitor and record the rockburst process in real time. Das and Singh [15] tested tunnel models under compression to analyze fracture patterns and identified a sharp decrease in the seismic “b-value” as a precursor for predicting rockburst hazards. Liu et al. [16] proposed the concept of “stress concentration” based on relevant data from a large number of engineering rockburst cases and established a new rockburst criterion that considered the stress–strength ratio and the stress gradient of the surrounding rock. Strain-mode rockbursts typically occur during the excavation process of underground engineering, where concentrated stress can trigger a critical release of elastic potential energy within the rock [17,18]. Intact and hard rock masses are particularly prone to these types of rockbursts. However, traditional uniaxial and biaxial rockburst experiments fail to adequately represent the complex stress conditions encountered in deep underground projects.

Therefore, this study employs a true triaxial loading system to subject high-strength, highly brittle, and homogeneous granite to a three-directional and five-surface loading test, simulating the occurrence of strain-mode rockbursts following deep rock excavation. The experimental process and failure phenomena on the free surface of granite specimens were recorded and analyzed using an acoustic emission monitoring system and a high-speed camera. The research focuses on analyzing the failure phenomena and mechanisms at various stages of rockburst development, including stress accumulation, crack initiation, critical instability, rockburst occurrence, and residual stress adjustment. Additionally, it explores the acoustic emission characteristics during the incubation process of the strain-mode rockburst. The findings not only improve our understanding of how strain-mode rockbursts occur but also emphasize the importance of acoustic emission monitoring in predicting such events. This provides a scientific foundation and technical support for forecasting the risks of dynamic disasters like rockbursts in deep engineering projects.

2. Experiments

2.1. Experimental Material

In laboratory experiments simulating rockburst events, granite is commonly chosen as the test material due to its unique physical and mechanical properties, which align well with experimental needs [14,19]. Rockbursts are a type of brittle rock failure that occurs under high-stress conditions, often accompanied by a sudden release of energy. Granite’s high compressive strength (typically between 100 MPa and 300 MPa) and its tendency to fracture suddenly under stress make it an ideal candidate for studying these phenomena. Additionally, its high elastic modulus allows it to store significant amounts of elastic potential energy, making it particularly prone to sudden, rockburst-like failures when subjected to extreme stress. Granite is also known for its dense and uniform structure, which helps reduce random variations in test results, ensuring more consistent and reliable outcomes. Furthermore, granite is widely available worldwide, making it easy to obtain high-quality samples for research. While the specific composition and properties of granite can vary between regions, its overall mechanical behavior is remarkably consistent, meaning the findings from experiments using granite have broad applicability to real-world scenarios.

In this study, granite samples AG2 and AG3 were selected for the simulation experiment of a strain-mode rockburst, as shown in Figure 1. While maintaining sample representativeness and broad applicability, the number of experimental repetitions may be reduced based on the following considerations:

Figure 1.

The granite specimens AG2 and AG3.

- (1)

- Consistency of physical and mechanical properties. The granite specimens were obtained from a Liuyang City quarry (Hunan Province), renowned for its homogeneous, joint-free granite formations that minimize experimental variability. This consistent geological background ensured that similarities in mineral composition, density, and mechanical properties were exhibited by the samples, thus facilitating a more accurate reflection of the mechanical behavior of the rocks under similar loading conditions.

- (2)

- Typical rockburst characteristics. Granite samples AG2 and AG3 exhibited typical strain-mode rockburst phenomena during the experiments, consistent with descriptions in the literature [20,21], indicating that they are capable of effectively representing the rockburst behavior of this type of rock.

- (3)

- Rigorous experimental design. The granite samples were cut and polished into standard rectangular specimens measuring 100 mm × 100 mm × 200 mm. These specimens were designed to simulate the stress characteristics of rock mass elements exposed in underground spaces. To ensure accurate results, the surfaces of the specimens were finished to a high standard, avoiding uneven loading that could lead to localized stress concentrations.

- (4)

- Basis for preliminary analysis. Although only two samples were used, the data obtained are capable of providing valuable preliminary information for subsequent studies. Through a detailed analysis of these two samples, the key mechanisms behind rockburst occurrences can be identified, and a theoretical foundation can be established for the expansion of the sample size and the conduction of larger-scale experiments in the future.

2.2. Experimental Protocol

In underground engineering projects, such as tunnels or mining operations, the excavation process often leads to uneven stress distribution around exposed rock surfaces. Stress levels near these exposed surfaces, particularly in the direction of excavation, drop significantly [22]. This localized stress concentration and steep stress gradient are primary external factors that can lead to strain-mode rockbursts. In the study of rockbursts, true triaxial loading has emerged as a precise and widely used experimental method. It is particularly advantageous for studying the mechanical mechanisms and failure characteristics of strain-mode rockbursts in deep engineering projects. This technique allows researchers to apply independent stresses along three perpendicular directions, enabling accurate simulation of the non-uniform stress states in deep underground rock masses. For strain-mode rockbursts, rock failure near exposed surfaces often manifests as directional splitting and slabbing. Moreover, true triaxial loading makes it possible to simulate these conditions by reducing the stress on the exposed surface to nearly zero while maintaining high stress levels in other directions. This ability to replicate the directional failure patterns associated with strain-mode rockbursts provides a robust experimental platform for uncovering their underlying mechanisms.

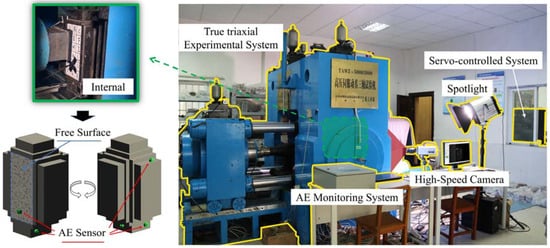

The experiment was performed using a high-stress servo true triaxial loading and unloading test system, as illustrated in Figure 2. This true triaxial machine, developed independently by Guangxi University, has a vertical stiffness of 9000 kN/mm and a horizontal stiffness of 5000 kN/mm. The maximum vertical loading capacity of the machine is 5000 kN, while the maximum horizontal loading capacity is 3000 kN. During the testing process, a PCI-II acoustic emission monitoring system with multiple channels (manufactured by the U.S. Physical Acoustics Corporation, West Windsor Township, NJ, USA) and a GigaView high-speed camera (manufactured by U.K. Southern Vision Systems, Rochester, England) were employed simultaneously. The acoustic emission monitoring system has a maximum sampling frequency of 40 MHz and an 18-bit digital-to-analog conversion capability. It can capture the complete waveform of acoustic emission and record various characteristic values such as count and energy. The high-speed camera was used to observe and record the experimental phenomena, while the AE monitoring instrument provided information on the development of microcracks and the release of energy.

Figure 2.

The true triaxial experimental system.

In the calibration and parameter settings of the acoustic emission monitoring system, the threshold has been set at 40 dB to accommodate environmental noise; the frequency range has been defined as 20 kHz to 1 MHz with a frequency resolution of 1 kHz; sensitivity has been adjusted to −50 dB/V; and gain has been established at 20 dB. Signal processing is conducted using a bandpass filter with a low cutoff frequency of 20 kHz and a high cutoff frequency of 1 MHz. The data sampling frequency has been established at 1 MHz, the dynamic range has been defined as 80 dB, and the recording interval has been set to every 100 ms, with a storage capacity of no less than 1 GB. These parameter settings are designed to ensure the efficiency and accuracy of the system during the testing process.

To simulate the evolution process of strain-mode rockbursts under complex excavating stress conditions, the researchers used the true triaxial experimental system to apply loading on five surfaces of the rectangular granite sample measuring 100 mm × 100 mm × 200 mm, leaving one surface free (as depicted in Figure 3). The stress on the rock specimen can be categorized into three types: vertical stress σz, transverse stress σx, and longitudinal stress σy. Before the test, load blocks were placed between the specimen and the triaxial testing machine. The AE sensors were attached to the surface of the rock or load block, with Vaseline applied evenly on the joint faces. The loading path is illustrated in Figure 3. The testing plans were as follows.

Figure 3.

The stress state and loading path.

During the initial loading stage, a pre-stress was applied in three directions to ensure the stabilization of the rock specimens. The vertical stress (σz) and transverse stress (σx) were gradually increased until reaching 600 kN, with a loading rate of 2.5 kN/s. The σz and σx were loaded to the desired stress levels, while the longitudinal stress (σy) was constrained at approximately 1 MPa and remained constant. Subsequently, the stresses in all three directions were maintained for a duration of 5 to 10 min to simulate stress redistribution following excavation. Finally, during the failure loading stage, the σz was incrementally increased at a loading rate of 2.5 kN/s until the rock experienced complete failure.

3. Experimental Results

3.1. Strain-Mode Rockburst Phenomenon

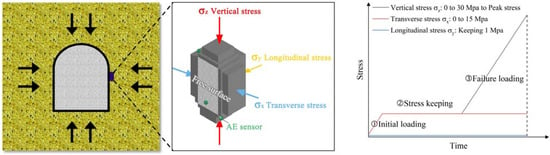

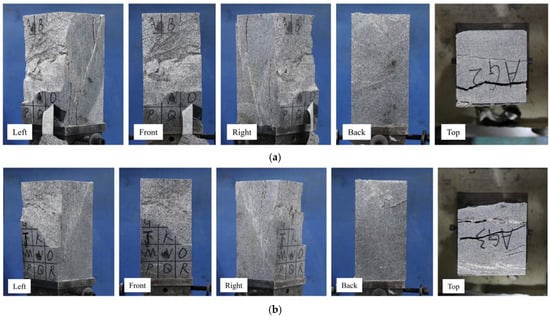

The strainmode rockburst simulation experiment employed a GigaView high-speed camera to observe and document the rockburst process. Granite samples AG2 and AG3 were selected for the study to analyze rockburst behavior and to conclude the observed phenomena and experimental results. The observed strain-mode rockburst phenomena are illustrated in Figure 4. From Figure 4, it is clear that strain-mode rockbursts occur in distinct phases, with each phase becoming shorter and more intense as the process unfolds.

Figure 4.

The stage and progression of strain-mode rockburst. (a) The granite specimen AG2. (b) The granite specimen AG3. (I–V) represent the various stages of rockburst.

(1) The stage of stress accumulation and elastic deformation (Stage I). In the initial stage, the surface of the granite sample is marked into zones, and at this point, the surface remains smooth and intact. At this point, the rock is under elastic deformation, with stress gradually accumulating. Microcracks are starting to appear in localized areas, but they have not grown enough to undermine the rock’s overall stability.

(2) The stage of crack initiation and stress concentration (Stage II). As the load increases, small particles begin to eject from the free surface. Rock fragments spall and eject from zones A through F at the top of the sample. At this stage, the rock gradually transitions into a plastic state, where macroscopic cracks increase in number and begin to propagate. The rock exhibits characteristics of nonlinear deformation.

(3) The stage of critical instability (Stage III). Between 0.03 and 1.20 s later, large rock slabs of granite split and spall away from the free surface, covering zones A through L. At this stage, the applied stress approaches the ultimate strength of the rock. Cracks near the free surface rapidly propagate and coalesce, pushing the granite into a quasi-unstable condition.

(4) The stage of rockburst occurrence (Stage IV). Then, in an instant (about 0.001 s), the detached rock slabs are violently flung outward at an extremely high speed, accompanied by small rock particles and clouds of rock dust. This sudden release is accompanied by intense explosion sounds, making the rockburst highly evident. At this stage, the elastic energy stored within the rock is suddenly released in the form of dynamic failure, resulting in the phenomenon known as a strain-mode rockburst.

(5) The stage of residual stress adjustment (Stage V). Finally, in the subsequent frames, chunks of rock that had been split and sheared are shot outward, along with a large quantity of rock fragments and powders. The intensity of the rockburst is so extreme that it even dislodged the acoustic emission sensors that had been tightly fixed to the bottom of the granite sample. This stage marks the late phase of the rockburst, during which the stress within the rock undergoes readjustment and rebalance. While the overall residual stress diminishes, certain areas may develop new stress concentrations, which could even lead to secondary rockbursts.

3.2. Tension vs. Shear Failure Mode

In the study of rockburst phenomena, analyzing crack propagation patterns is essential to understanding the mechanisms and evolution of rockbursts [23]. Through laboratory experiments that simulate strain-mode rockbursts, researchers can explore these propagation patterns to uncover the underlying mechanisms driving rock failure at both the micro and macro levels. This research not only deepens theoretical insights but also provides crucial guidance for hazard prediction and protective measures in engineering projects.

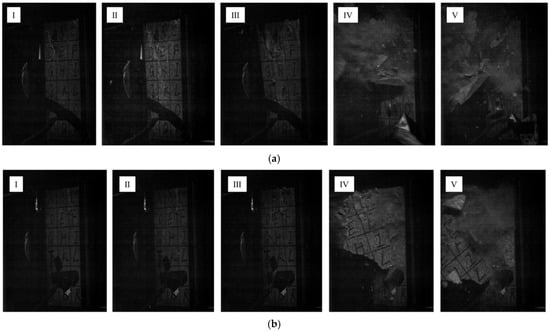

The results of strain-mode rockburst simulation tests on granite specimens AG2 and AG3 are shown in Figure 5. The tests reveal that under splitting forces, multiple vertical cracks develop and propagate through the specimens, causing rock slabs to detach. Under shear forces, diagonal shear cracks form, with multiple shear cracks penetrating the specimens and breaking them into distinct rock fragments. When energy accumulates to a critical level, it is abruptly released, ejecting pieces of rock and leaving behind characteristic V-shaped rockburst craters. Meanwhile, the surface of the rock displays splitting cracks parallel to the free surface, with through-going shear cracks along the diagonal of the specimens. Finally, the free surface becomes the primary rockburst failure plane, while the opposite side, which is supported and constrained, remains mostly intact.

Figure 5.

The experimental results and failure modes of strain-mode rockburst. (a) The granite specimen AG2. (b) The granite specimen AG3.

The overall failure characteristics of the rock specimens in the triaxial compression test exhibited a tension–shear coexistence mechanism. The primary failure mode was characterized by a dominant shear crack cutting diagonally through the entire granite specimen at a 45° angle. Several vertical splitting cracks, aligned parallel to the principal stress, formed and expanded in the vicinity of the shear fracture. If these tensile cracks fully penetrate the rock, large slabs of granite may spall off. When the shear and tensile cracks intersect, the detached slabs are further split into multiple rock fragments. Additionally, near the free surface, a shear–tension composite failure mechanism becomes more pronounced and intense. When vertical tensile cracks reach a certain length, the stress distribution in the surrounding material is reconfigured. The free surface effect leads to an increase in shear stress near the free surface, which causes the cracks to progressively extend and propagate in a diagonal direction.

This process manifests as large rock slab detachment accompanied by shear sliding, breaking into thinner rock fragments. These fragments, which stored excessive elastic potential energy, were violently ejected from the free surface. Rockburst craters formed V-shaped depressions or wedge-like indents on the free surface and displayed clear directional patterns and localized characteristics. Their formation is closely linked to the shear–tension composite crack propagation mechanism, the brittle characteristics of rock masses, and the influence of high-stress conditions. The V-shaped rockburst craters present an upside-down triangular wedge, characterized by sharp, tapered edges that vividly illustrate the progression of cracks from the surface into the interior. Its rough surface highlights the dynamic characteristics of rock failure under high strain rates. Inside the crater, the stepped structure reveals a gradual spalling pattern during the failure process. Generally, higher stress concentrations and more intense energy releases result in deeper craters with sharper edges.

3.3. Acoustic Emission Evolution Characteristics

The acoustic emission count is an important parameter in acoustic emission technology, referring to the total number of signal oscillations that exceed a predefined threshold level. This counts as an indicator of stress wave activity released during the propagation of microcracks, fracturing, or plastic deformation within a material. It is closely tied to the activity of internal cracks in rocks. As the stress on a rock increases, the AE count rises, indicating the development of more or larger cracks. Notably, as the rock approaches ultimate failure, the AE count often surges dramatically—a phenomenon commonly referred to as a “precursory anomaly” [11,24]. The AE count, as an easily obtainable parameter, offers certain advantages in reflecting the frequency and cumulative changes of acoustic emission activity, which is particularly useful for providing quick early warnings during real-time monitoring. However, it is limited by its singular statistical scope, susceptibility to noise, and lack of deeper insights into fracture mechanisms or the distribution of fracture scales. By contrast, the acoustic emission b-value stands out for its ability to analyze the dynamics of crack propagation, identifying precursors to failure and facilitating interdisciplinary applications. Therefore, combining AE count analysis with b-value evaluation in practical applications offers a more comprehensive understanding of the rock fracture process.

In their research on global seismic activity, Gutenberg and Richter introduced the renowned Gutenberg–Richter (G-R) relationship (see Equation (1)), which describes the correlation between earthquake magnitude and frequency. In this relationship, the b-value is a constant that represents the function of the relative distribution of magnitudes and also serves as an indicator of the scale of crack propagation [25].

In the formula, N represents the frequency of earthquakes within the magnitude range ΔM, M denotes the earthquake magnitude, and a and b are constants.

To uncover the precursory characteristics of rock instability and failure, acoustic emission events occurring during the rock’s deformation and fracture process can be regarded as analogous to seismic activity. By analyzing the variations in the AE b-value to predict dynamic disasters in rock masses, researchers typically adapt the G-R relationship by replacing the earthquake magnitude M with the acoustic emission amplitude ML. This modified relationship can then be expressed as follows [26],

In the formula, ms represents the amplitude of the acoustic emissions detected during the loading process, while ML is analogous to the “magnitude” in the context.

Various methods can be used to calculate the AE b-value in rocks, including the exponential least squares method, maximum entropy spectrum method, linear least squares method, and maximum likelihood estimation method [27,28]. This study utilizes the linear least squares method to determine the b-value of acoustic emission signals, thereby facilitating the handling of large-scale data through a sliding window approach. Each window is composed of 500 AE events, with a step size of 100 events to maintain data continuity and statistical representativeness. Within each sliding window, AE events are initially organized by time, followed by the statistical analysis of their energy distribution and logarithmic transformation. The linear least squares method is subsequently employed for fitting, resulting in the b-value being identified as the slope of the energy distribution. By analyzing the b-values over different time periods, this research illuminates the damage characteristics and evolutionary patterns exhibited during the strain-mode rockburst process.

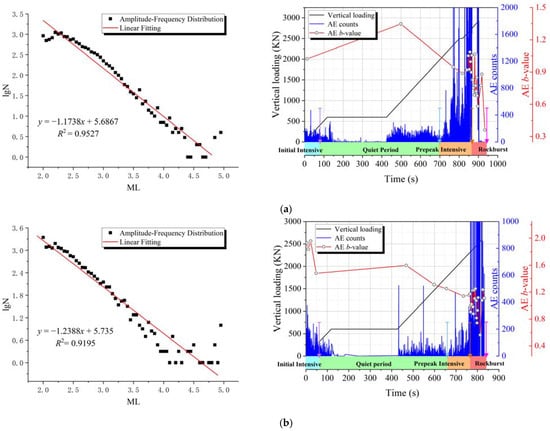

4. Discussion

Rockbursts are nonlinear, sudden, and complex geological events that can be better understood by dividing their progression into distinct periods. This phased approach allows for a systematic analysis of the characteristics and underlying mechanisms at each period. Moreover, as acoustic emission activity varies significantly across the different periods, identifying these patterns allows for more accurate real-time monitoring and early warnings. This is especially crucial during the critical prepeak intensive period and the rockburst period, where timely detection is essential for ensuring workplace safety. From Figure 6a, which illustrates the amplitude-frequency distribution of acoustic emissions, it can be observed that granite specimens AG2 and AG3 exhibit a strong linear relationship. The correlation coefficients R2 are 0.9527 and 0.9195, respectively, both exceeding 0.9, which aligns well with the Gutenberg–Richter (G-R) relationship. Furthermore, from an analysis of the variations in AE counts and b-values during the strain-mode rockburst tests (illustrated in Figure 6b), the following findings can be made:

Figure 6.

The AE amplitude-frequency distribution (left) and AE counts–b value relationship (right). (a) The granite specimen AG2. (b) The granite specimen AG3.

- (1)

- The acoustic emission signals reflect the generation, propagation, and coalescence of microcracks within a rock mass, revealing the progressive stages of its failure. Based on the intensity of acoustic emission activity, the experimental process can typically be divided into four phases: the initial intensive period, the quiet period, the prepeak intensive period, and the rockburst period.

- (2)

- Initial intensive period. In the initial stage of loading (primarily within the first 0 to 180 s), the primary cracks and pores within the rock sample undergo compaction and closure under external pressure. This process causes friction along fracture surfaces, releases elastic energy, and generates frequent acoustic emission signals. While the AE count shows concentrated activity, the overall intensity remains relatively low. Meanwhile, there is a slight decline observed in the AE b-value.

- (3)

- Quiet period. As loading continues, the granite specimen primarily undergoes elastic deformation under external stress. During this stage, the formation of internal fractures slows down significantly, resulting in a noticeable reduction in acoustic emission activity. This creates a relatively quiet period, when the AE counts are infrequent and occur at low levels. The acoustic emission characteristics observed during this period are evident in various rockburst experiments and field monitoring [29,30,31], gaining widespread recognition. This phase, marked by its extended duration, can serve as a precursor indicator of rockbursts. Notably, the b-value of acoustic emissions tends to rise, signaling a shift in the rock’s internal stress state.

- (4)

- Prepeak intensive period. As the rock mass approaches its ultimate bearing capacity, plastic deformation within the rock sample gradually becomes dominant. The macroscopic cracks that are formed as microfractures and voids inside the rock evolve, close, and eventually interconnect. This process generates a significant surge in acoustic emissions, with a dense clustering of AE counts. During this phase, the AE counts demonstrate a pronounced trend of intensive growth, serving as a potential precursor to an imminent rockburst. Concurrently, the AE b-value drops significantly, signaling the rock’s nearing failure, and the characteristics are found to be completely consistent with the b-value observed prior to the occurrence of a rockburst in the Sanhejian Coal Mine [32].

- (5)

- Rockburst period. When the rock mass reaches its ultimate failure threshold, the stored internal energy is released abruptly, causing rapid propagation of fractures that coalesce into through-going failures, ultimately triggering a rockburst. At this moment, AE counts reach their peak, accompanied by an exceptionally dense signal pattern. As the rockburst subsides, AE activity gradually diminishes. Meanwhile, the AE b-value fluctuates significantly and frequently exhibits a “V-shaped” trough signal. In severe rockburst events, the AE b-value falls off a cliff, reflecting its instability.

5. Conclusions

This study employed a true triaxial loading system and advanced monitoring tools to simulate and analyze a strain-mode rockburst in granite, exploring its evolution process, failure mechanisms, and monitoring approaches. The rockburst evolves through five stages, from stress accumulation to residual stress adjustment, marked by dynamic responses and energy release. Failure is characterized by a tension–shear coexistence mechanism, forming V-shaped craters through crack propagation and composite failure near free surfaces. Acoustic emission monitoring proved effective in identifying rockburst precursors, with AE signal patterns providing critical indicators for early warning systems. These findings enhance the understanding of strain-mode rockburst mechanisms and offer practical insights for deep rock engineering safety. The principal conclusions are as follows:

- (1)

- Experimental Method and Evolution Process of Strain-mode Rockburst. A true triaxial loading system was employed to simulate strain-mode rockbursts using granite samples due to their high compressive strength, elastic modulus, and uniform structure. This system replicates deep underground stress conditions, enabling precise analysis of directional splitting and failure. Advanced monitoring tools, including acoustic emission and high-speed imaging, ensured comprehensive observation of crack evolution and energy release during rockburst simulations. The evolution of strain-mode rockbursts progresses through five distinct stages: stress accumulation, crack initiation, critical instability, rockburst occurrence, and residual stress adjustment. Each stage exhibits increasingly intense dynamic responses, culminating in violent energy release and rock ejections. The transition from elastic deformation to dynamic failure highlights the critical role of crack propagation, stress concentration, and subsequent stress readjustment in the rockburst mechanism. This staged classification has been validated not only in laboratory settings but has also been consistently corroborated by numerous field cases [33,34,35], thereby underscoring the complexity and diversity of the strain-mode rockburst process.

- (2)

- Failure Modes, Mechanisms, and Acoustic Emission Characteristics. The failure modes of strain-mode rockbursts in granite exhibit a tension–shear coexistence mechanism, driven by the interaction of vertical splitting cracks and diagonal shear fractures. Shear–tension composite failure near the free surface leads to violent rock fragment ejections, forming V-shaped rockburst craters. These craters reflect the brittle behavior of rocks under high-stress conditions and dynamic energy release, providing critical insights into the mechanics of failure in extreme stress environments. Furthermore, the AE signals were found to be highly effective for monitoring rock mass failure, with their activity effectively indicating rockburst stages. Low and sparse AE counts during a quiet period signal potential precursors, while a sudden surge in AE counts, coupled with a “V-shaped” trough in the AE b-value, serves as a critical indicator of an impending strain-mode rockburst. These observations underscore the significant potential of AE monitoring as a reliable and practical tool for developing early warning systems in rock engineering applications.

Furthermore, the existing literature indicates that the strength of granite decreases under saturated conditions, which increases the likelihood of rockbursts [11,36]. In our future research, we intend to develop multiphysics coupling models to accurately simulate the behavior of strain-mode rockbursts influenced by water.

Author Contributions

Conceptualization, Z.M. and F.M.; writing—original draft preparation, C.H.; writing—review and editing, Z.X.; formal analysis, Z.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets analyzed during the current study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to thank Guoshao Su and researcher Bingrui Chen for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sinkala, P.; Nishihara, M.; Nakayama, Y.; Fujii, Y.; Kodama, J.; Fukuda, D.; Chanda, E. Creep damage model for rockburst at mufulira mine in zambia. Min. Metall. Explor. 2022, 39, 1983–2000. [Google Scholar] [CrossRef]

- Mutshafa, N.; Manzi, M.S.D.; James, I.; Durrheim, R.J.; Jogee, B.A. Seismic imaging of deep-seated gold deposit and host rocks through a reappraisal of legacy seismic data in the fochville mining area, south africa. Geophys. Prospect. 2024, 73, 664–679. [Google Scholar] [CrossRef]

- Guangliang, F.; Jingang, M.; Bingrui, C.; Quan, J.; Pengxiang, L.; Manqing, L. Microseismic energy and intensity criterion of rockburst in deep tbm tunnels: A case study of the neelum-jhelum hydropower project. J. Cent. South Univ. 2023, 5, 1695–1709. [Google Scholar]

- Chen, X.; Yu, H. Rockburst prediction for deep tunneling near fault based on the pd-bem method. Tunn. Undergr. Space Tech. 2024, 147, 105725. [Google Scholar] [CrossRef]

- Wojtecki, U.; Iwaszenko, S.; Apel, D.B.; Cichy, T. An attempt to use machine learning algorithms to estimate the rockburst hazard in underground excavations of hard coal mine. Energies 2021, 14, 6928. [Google Scholar] [CrossRef]

- Wu, M.; Ye, Y.; Wang, Q.; Hu, N. Development of rockburst research: A comprehensive review. Appl. Sci. 2022, 12, 974. [Google Scholar] [CrossRef]

- Farhadian, H. A new empirical chart for rockburst analysis in tunnelling: Tunnel rockburst classification (trc). Int. J. Min. Sci. Technol. 2021, 31, 603–610. [Google Scholar] [CrossRef]

- Gong, F.; Dai, J.; Xu, L. A strength-stress coupling criterion for rockburst: Inspirations from 1114 rockburst cases in 197 underground rock projects. Tunn. Undergr. Space Tech. 2023, 142, 105396. [Google Scholar] [CrossRef]

- Shirani Faradonbeh, R.; Taheri, A.; Ribeiro E Sousa, L.; Karakus, M. Rockburst assessment in deep geotechnical conditions using true-triaxial tests and data-driven approaches. Int. J. Rock Mech. Min. 2020, 128, 104279. [Google Scholar] [CrossRef]

- He, M.; Cheng, T.; Qiao, Y.; Li, H. A review of rockburst: Experiments, theories, and simulations. J. Rock Mech. Geotech. Eng. 2023, 15, 1312–1353. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, J.; Sun, D.; Zhang, L.; Chen, Y. Ae characteristics of rockburst tendency for granite influenced by water under uniaxial loading. Front. Earth Sci. 2020, 8, 55. [Google Scholar] [CrossRef]

- Gong, F.; Ni, Y.; Ren, L. Effects of loading rate on rockburst proneness of granite from energy storage and surplus perspectives. Rock Mech. Rock Eng. 2022, 55, 6495–6516. [Google Scholar] [CrossRef]

- Wu, W.; Gong, F.; Zhang, Z.X. Sidewall rockburst of highly stressed d-shape hole tunnel triggered by impact load: An experimental investigation. Rock Mech. Bull. 2024, 3, 100094. [Google Scholar] [CrossRef]

- Si, X.; Luo, Y.; Gong, F.; Huang, J.; Han, K. Temperature effect of rockburst in granite caverns: Insights from reduced-scale model true-triaxial test. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 10–26. [Google Scholar] [CrossRef]

- Das, R.; Singh, T.N. A novel technique for temporal evolution of rockburst in underground rock tunnel: An experimental study. Environ. Earth Sci. 2022, 81, 420–431. [Google Scholar] [CrossRef]

- Liu, X.; Wang, G.; Song, L.; Han, G.; Chen, W.; Chen, H. A new rockburst criterion of stress–strength ratio considering stress distribution of surrounding rock. Bull. Eng. Geol. Environ. 2023, 82, 29. [Google Scholar] [CrossRef]

- Sun, F.; Guo, J.; Liu, X.; Zhang, H. Strain rockburst evolution process under true triaxial condition with single face unloading due to tunnel excavation. Comput. Geotech. 2023, 159, 105465. [Google Scholar] [CrossRef]

- Zhai, S.; Su, G.; Yin, S.; Zhao, B.; Yan, L. Rockburst characteristics of several hard brittle rocks: A true triaxial experimental study. J. Rock Mech. Geotech. Eng. 2020, 12, 279–296. [Google Scholar] [CrossRef]

- Jiang, J.; Su, G.; Zhang, X.; Feng, X.T. Effect of initial damage on remotely triggered rockburst in granite: An experimental study. Bull. Eng. Geol. Environ. 2020, 79, 3175–3194. [Google Scholar] [CrossRef]

- Li, J.; Liu, D.; He, M.; Guo, Y. Experimental investigation on rockburst energy characteristics of true triaxial unloading in sandstone under high stress. Rock Mech. Rock Eng. 2024, 57, 6031–6046. [Google Scholar] [CrossRef]

- Gong, F.; Luo, S.; Jiang, Q.; Xu, L. Theoretical verification of the rationality of strain energy storage index as rockburst criterion based on linear energy storage law. J. Rock Mech. Geotech. Eng. 2022, 14, 1737–1746. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.P.; Liu, Q.Q.J.C. Microseismic characteristic and development mechanism of fault-slip rockburst in a deep-buried tbm excavated tunnel: A case study. Tunn. Undergr. Space Tech. 2023, 142, 105451. [Google Scholar] [CrossRef]

- Stukhlyak, P.D.; Buketov, A.V.; Panin, S.V.; Maruschak, P.O.; Moroz, K.M.; Poltaranin, M.A.; Vukherer, T.; Kornienko, L.A.; Lyukshin, B.A. Structural fracture scales in shock-loaded epoxy composites. Phys. Mesomech. 2015, 18, 58–74. [Google Scholar] [CrossRef]

- Liu, X.; Liang, Z.; Zhang, Y.; Liang, P.; Tian, B. Experimental study on the monitoring of rockburst in tunnels under dry and saturated conditions using ae and infrared monitoring. Tunn. Undergr. Space Tech. 2018, 82, 517–528. [Google Scholar] [CrossRef]

- Suzuki, A.N. Gutenberg–richter law for internetquakes. Phys. A Stat. Mech. Its Appl. 2003, 319, 552–556. [Google Scholar]

- Wesseloo, J. Evaluation of the spatial variation of b-value. J. S. Afr. Inst. Min. Metall. 2014, 114, 823–828. [Google Scholar]

- Dong, L.; Zhang, L.; Liu, H.; Du, K.; Liu, X. Acoustic emission b value characteristics of granite under true triaxial stress. Mathematics 2022, 10, 451. [Google Scholar] [CrossRef]

- Bazzi, A.; Slock, D.T.M.; Meilhac, L. Efficient maximum likelihood joint estimation of angles and times of arrival of multiple paths. In Proceedings of the 2015 IEEE Globecom Workshops, San Diego, CA, USA, 6–10 December 2015. [Google Scholar]

- Hu, X.; Su, G.; Chen, G.; Mei, S.; Feng, X.; Mei, G.; Huang, X. Experiment on rockburst process of borehole and its acoustic emission characteristics. Rock Mech. Rock Eng. 2019, 52, 783–802. [Google Scholar] [CrossRef]

- Hu, C.; Mei, F.; Hussain, W.; Xiao, Z. Mechanical modes and acoustic emission fractal characteristics of marble failure under true-triaxial loading. Eng. Fract. Mech. 2025, 319, 110985. [Google Scholar] [CrossRef]

- Xin, J.; Jiang, Q.; Zhai, D.; Feng, G.; He, B.; Li, S. Shear-induced rockburst of double-tunnel rocks subjected to shear loading: A comparative analysis. J. Cent. South Univ. 2023, 30, 4207–4229. [Google Scholar] [CrossRef]

- Li, J.; Gong, S.; He, J.; Cai, W.; Zhu, G.; Wang, C.; Chen, T. Spatio-temporal assessments of rockburst hazard combining b values and seismic tomography. Acta Geophys. 2017, 65, 77–88. [Google Scholar] [CrossRef]

- Hu, X.; Su, G.; Li, Z.; Xu, C.; Yan, X.; Liu, Y.; Yan, L. Suppressing rockburst by increasing the tensile strength of rock surface: An experimental study. Tunn. Undergr. Space Tech. 2021, 107, 103645. [Google Scholar] [CrossRef]

- Wu, W.; Gong, F.; Zhang, Z. Sidewall rockburst characteristics of highly stressed circular tunnel under impact load. J. Rock Mech. Geotech. Eng. 2024, 16, 4909–4924. [Google Scholar] [CrossRef]

- Wu, W.; Gong, F.; Zhang, Z. Experimental investigation on rockburst characteristics of highly stressed d-shape tunnel subjected to impact load. Undergr. Space 2024, 19, 153–168. [Google Scholar] [CrossRef]

- Luo, S.; Gong, F.; Peng, K.; Liu, Z. Influence of water on rockburst proneness of sandstone: Insights from relative and absolute energy storage. Eng. Geol. 2023, 323, 107172. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).