Abstract

This study evaluated the effects of Guatemalan coffee extract (G) on the physicochemical, antioxidant, and sensory properties of Yanggaeng at different roasting levels (light, medium, and dark) and concentrations (0%, control group [CON]; 2%, 2; 4%, 4; and 6%, 6). Moisture, ash, fat, protein, and carbohydrate contents varied significantly with G concentration and roasting level, with light roasts exhibiting the highest moisture and fat content, but the lowest ash and carbohydrate content. Colorimetric properties showed a dose-dependent decrease in lightness and an increase in redness and yellowness with the addition of G. Additionally, pH levels increased in light and dark roasts, but decreased in medium roasts, whereas Brix values increased with G, peaking in dark roasts. Antioxidant activity, assessed by total phenolic content and 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenging, improved notably in the medium and dark roasts. Textural properties including hardness, resilience, and chewiness also benefited from the addition of G. Sensory evaluations favored Yanggaeng containing 4–6% G, especially in dark roasts, for attributes such as color, scent, and overall taste. Dark roast concentrations of 4% and 6% were identified as optimal for enhancing the properties of Yanggaeng, supporting the potential of G to develop innovative high-quality desserts tailored to modern consumer preferences.

1. Introduction

Coffee is one of the most popular beverages globally and is celebrated for its rich and appealing aroma, diverse flavors influenced by the roasting level and geographic origin, stimulant effects due to its caffeine content, and various physiological effects. The coffee industry continues to expand steadily worldwide, driven by the increasing consumption rates and evolving consumer preferences. Approximately 30–40% of the global population, or 1 billion people, consumes coffee daily [1]. In 2022, the global coffee market was valued at approximately USD 461 billion and has been projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, reaching an estimated USD 690 billion [1]. The intricate taste and alluring aroma of coffee are key factors contributing to its widespread popularity, making it a favorite beverage across different cultures and regions. Even within the same coffee variety, distinct flavors and aromas can be observed depending on the growing region, highlighting the importance of the terroir in coffee cultivation.

In Guatemala, coffee was introduced in the mid-18th century by Jesuit priests and was initially cultivated in small quantities for home use and ornamental purposes [2]. Today, coffee farms in Guatemala are predominantly situated at high altitudes ranging from 1300 to 2000 m above sea level, where diverse microclimates characterized by variations in rainfall, temperature, and soil conditions significantly influence the unique characteristics and quality of the coffee produced [3]. Guatemalan coffee is renowned for its complex flavor profiles, rich in chocolate, nutty, and fruity notes, and is often complemented by bright acidity [3]. In addition, coffee beans from Guatemala are highly versatile and can be roasted across a range of styles, from light to dark, while maintaining their distinctive flavor profiles and accommodating diverse consumer preferences [4].

The roasting of coffee beans is a critical process during which green beans undergo significant physical and chemical changes to develop their characteristic color, aroma, and flavor. During roasting, moisture evaporates from the beans, the structure becomes porous, and the density decreases [5]. Key chemical reactions such as the Maillard reaction, caramelization, lipid oxidation, and degradation of phenolic compounds drive the formation of complex flavors and physicochemical properties in coffee beans [6,7,8,9]. Light roasting preserves the original flavors and characteristics of beans, resulting in lower bitterness and higher acidity, which impart a vibrant and tangy flavor to coffee [10]. In contrast, dark roasting enhances the flavor developed during roasting, resulting in a more intense and robust taste profile [11]. Prolonged roasting processes lead to increased bitterness and reduced acidity, which contribute to a smoother and fuller-bodied flavor profile [12]. Furthermore, the antioxidant content of coffee beans varies depending on the roasting level. Light-roasted coffee generally contains higher levels of antioxidants such as chlorogenic acids, which degrade during extended roasting [13]. Alnsour et al. reported that light-roasted coffee beans exhibited the highest antioxidant activity, which decreased by 40–80% after prolonged roasting [14]. The roasted Guatemalan coffee extract used in this study contains a variety of bioactive compounds that are well known for their functional and sensory effects. The primary components—chlorogenic acids, caffeine, trigonelline, and melanoidins—have been reported to contribute to antioxidant activity, flavor development, and improvements in color and texture [15,16].

Yanggaeng, a traditional Korean dessert, is commonly prepared using sweetened red or white bean paste, along with agar—a source of dietary fiber—and sugar [17]. The dessert is valued for its water-retention properties, which promote a sense of fullness and its potential to relieve constipation [17]. In recent years, the popularity of coffee-based desserts has surged, driven by the growing number of coffee consumers across all age groups and the increasing trend of incorporating coffee flavors into various culinary creations. Examples of coffee-based desserts include coffee cake [18], coffee jelly [19], coffee butter [20], coffee ice cream [21], and coffee cookies [22]. The physicochemical properties of coffee extracts, such as pH, Brix values (solid soluble content), and colorimetric characteristics, are critical factors influencing the quality and sensory appeal of coffee-infused desserts. A detailed understanding of these properties is essential for optimizing formulations and ensuring consistent quality of the final products. Additionally, sensory attributes, including aroma, taste, and texture, play pivotal roles in shaping consumer preference and acceptance, making these factors essential considerations for product development and marketing strategies.

The present study aimed to investigate the physicochemical properties and sensory attributes of Yanggaeng infused with various concentrations of Guatemalan coffee extract after different roasting levels, including light, medium, and dark roasts. A comprehensive analysis was conducted encompassing proximate composition, physicochemical attributes, antioxidant capabilities, and textural properties, in comparison to conventional Yanggaeng. In addition, a survey was conducted to evaluate consumer preferences for these novel dessert variations. This study focused on elucidating the influence of roasting level on the physicochemical properties, sensory attributes, and antioxidant capabilities of coffee-infused Yanggaeng, thereby exploring the potential of coffee-infused Yanggaeng as an innovative dessert.

2. Materials and Methods

2.1. Materials, Roasting, and Coffee Extracts

The green coffee beans used in this study were of the Guatemala Atitlán SHB variety, harvested in 2024, and supplied by the Moi Coffee Company (Yongin, Republic of Korea). Roasting was performed using an Aillio Bullet R1 Roaster (Aillio, Taipei, Taiwan) preheated to 170 °C prior to loading the green beans. The degree of roasting was classified into three levels—light (Agtron 70.0), medium (Agtron 63.8), and dark (Agtron 59.0)—based on Agtron values measured using a CM-100 colorimeter (Lighttells, Zhubei, Taiwan) in accordance with the Specialty Coffee Association (SCA) standards [23] (Table 1). The roasted beans were stored at −18 °C until further use.

Table 1.

Roasting conditions of Guatemala Atitlan SHB coffee beans.

For coffee extraction, beans were ground to 45 mesh (Yang-Chia Machine Works Co., Ltd., Taipei, Taiwan) and extracted using a semi-automatic espresso machine (E98 President A2, Faema, Milano, Italy). Espresso was prepared by extracting 30 mL of distilled water from 27 g of ground coffee. Samples were prepared for each of three roasting levels: light (L), medium (M), and dark (D).

2.2. Formulation and Preparation of Yanggaeng

Yanggaeng was formulated following established protocols outlined in references [24,25]. To formulate the Yanggaeng base, 10 g of agar was dissolved in 400 g of water and allowed to hydrate for 10 min. Subsequently, the mixture was boiled over medium heat and maintained for approximately 2 min. Beyond the standard control sample (CON), additional Yanggaeng variants were developed by incorporating Guatemalan coffee extracts at concentrations of 2% (2), 4% (4), and 6% (6). These extracts were obtained from coffee beans subjected to different roasting levels (L, M, and D; Table 2).

Table 2.

Formula of Yanggaeng made with Guatemala coffee extracts.

After the addition of roasted Guatemalan coffee extract to the agar–water solution, white bean paste, and sugar were added to the mixture. White bean paste was used instead of red bean paste to provide a neutral background in terms of color and flavor, minimizing interference with the visual assessment of color changes caused by the coffee extract. The combined ingredients were then gently heated at low temperature for 10 min to ensure thorough integration. The resulting mixture was carefully poured into square molds with a uniform thickness of 2 cm and left to set. Following cooling for 2 h, the prepared Yanggaeng samples were ready for subsequent experimental analyses.

2.3. Proximate Analysis of Yanggaeng

The basic nutritional composition of Yanggaeng, including crude ash, crude fat, moisture, and crude protein, was quantified using standardized analytical procedures, as outlined previously [24]. Carbohydrate content was determined using the following calculation:

Carbohydrate content (%) = 100 − (crude ash + crude fat + moisture + crude protein).

2.4. Hunter’s Color Metrics and Physicochemical Characterization of Yanggaeng

Color measurements were conducted using a calibrated colorimeter (LC100, Tintometer Ltd., Amesbury, UK) to quantify lightness (L*), redness (a*), and yellowness (b*). The ΔE values were calculated using the following formula (ΔE = √[(L*1 − L*2)2 + (a*1 − a*2)2 + (b*1 − b*2)2]), based on the comparison between each sample’s mean L*, a*, and b* values and those of CON, which were determined from the average of triplicate measurements. To assess the pH and Brix values, a sample weighing 2 g of Yanggaeng was dissolved in 20 mL of distilled water following the procedural methodology outlined by Lee et al. [22]. The resulting solution was centrifuged at 3000× g for 10 min (Hanil Science Co., Ltd., Daejeon, Republic of Korea). Subsequently, 20 mL of the supernatant was collected for analysis. The pH levels were determined using an Orion Star pH meter (Thermo Fisher Scientific, Seoul, Republic of Korea) to ensure precise measurement of acidity or alkalinity. Brix values, which indicate the soluble solid content within the Yanggaeng samples, were measured using a Brix meter (Hanna Instruments, Woonsocket, HI, USA).

2.5. Assessment of Antioxidative Properties of Yanggaeng

Evaluation of the antioxidative characteristics of Yanggaeng involved dissolving 2.5 g of the dessert in 50 mL of 70% ethanol, followed by a 24 h incubation. The resulting mixture was centrifuged at 3000× g for 10 min to facilitate separation. Quantification of the total polyphenol content (TPC) and the 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity was conducted in accordance with established protocols as in [25]. Specifically, for the determination of DPPH radical scavenging activity, a DPPH solution with a concentration of 300 µM (Sigma-Aldrich Co., St. Louis, MO, USA) was incorporated into the sample solution, allowing for the assessment of antioxidative efficacy. The DPPH radical scavenging activity was assessed at 517 nm, a wavelength commonly used in food antioxidant studies to minimize interference from food matrix components such as carbohydrates and pigments [26]. Despite potential interference, the dose-dependent trends in antioxidant activity support the reliability of the assay in this study.

2.6. Texture Profile Analysis of Yanggaeng

Texture profile analysis of the Yanggaeng samples was performed by cutting the dessert into uniform dimensions of 2 cm × 2 cm. The analysis included several textural parameters, including hardness, adhesiveness, resilience, springiness, cohesiveness, gumminess, and chewiness. Measurements were conducted using a rheometer (Stable Micro Systems Co., Ltd., Surrey, UK) equipped with a flat-bottom probe with a 30 mm diameter. The testing parameters were set to a compression ratio of 60%, an automatic trigger force of 0.5 N, a test speed of 1 mm/s, and pre-test and post-test speeds of 2 mm/s. These settings ensured a consistent and accurate evaluation of the textural properties of each Yanggaeng sample.

2.7. Consumer Preference Evaluation of Yanggaeng

Consumer preferences were assessed using a cohort of 50 students from Dankook University. Ethical approval for this study was obtained from the Institutional Review Board of Dankook University (reference number: DKU-2023-10-037-002). Prior to the tasting session, the participants were instructed to use a 9-point hedonic scale to evaluate the Yanggaeng samples. The evaluation criteria included attributes such as color, scent, sweetness, bitterness, chewiness, overall taste, and overall acceptance.

2.8. Statistical Analysis

Statistical analysis of the Yanggaeng samples was conducted using IBM SPSS Statistics 26.0 (Statistical Package for the Social Sciences, IBM Corp., Armonk, NY, USA). Differences among samples resulting from various treatments were examined using Duncan’s post hoc test, with significance determined at a p-value of less than 0.05. Each experimental procedure was replicated three times to ensure the reliability of the results, and the average values and standard deviations were calculated to accurately represent the data.

3. Results and Discussion

3.1. Proximate Compositions of Yanggaeng

Table 3 shows the proximate analysis results for Yanggaeng samples prepared with varying concentrations and roasting levels of Guatemalan coffee extract. Moisture content was the highest in Yanggaeng samples containing L coffee extract compared to those with M and D roasts, irrespective of the coffee extract concentration (p < 0.05). Within the L group, the moisture content did not differ significantly across the different extract concentrations. In contrast, the moisture content decreased with the addition of coffee extract in both the M and D groups when compared to the CON group. The M6 sample exhibited the lowest moisture content among all samples, while within the D group, the D4 sample had the lowest moisture content (p < 0.05).

Table 3.

Proximate compositions of Yanggaeng treated with various concentrations of Guatemalan coffee extract.

The crude ash content was lower in group L than in groups M and D (p < 0.05). No significant variations in crude ash content were observed between the L and M groups at different coffee extract concentrations. The D4 sample exhibited the lowest crude ash content (0.12%). Regarding crude fat content, in the L group, the L6 sample demonstrated the highest crude fat content among the roasting levels (p < 0.05), whereas the D6 sample had the lowest crude fat content across all samples (p < 0.05).

Crude protein content remained consistent across different roasting levels, showing no overall significant differences. However, in the L group, the L2 sample had the highest crude protein content (p < 0.05). In groups M and D, the crude protein content did not vary significantly with different coffee extract concentrations. The carbohydrate content did not differ significantly across the extract concentrations in the L group. However, in the M group, the carbohydrate content increased with the addition of coffee extract compared to that in the control sample, regardless of the concentration (p < 0.05). In group D, only D4 showed a higher carbohydrate content than the other samples.

These findings demonstrate that both the roasting degree and concentration of the Guatemalan coffee extract significantly affect the proximate composition of Yanggaeng. Variations were observed in the moisture, ash, fat, protein, and carbohydrate content, indicating that the incorporation of coffee extract altered the nutritional profile of Yanggaeng depending on the roasting level and extract concentration.

3.2. Hunter’s Color Properties of Yanggaeng

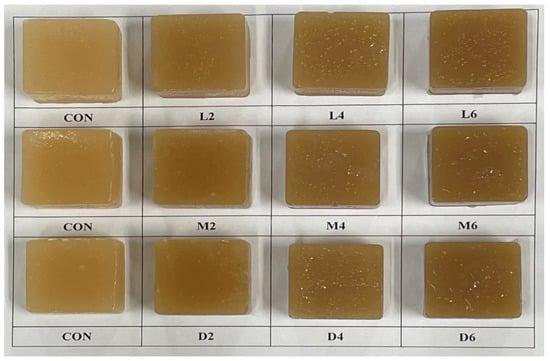

Figure 1 illustrates the external appearance of the Yanggaeng samples, while Table 4 presents the colorimetric values for samples prepared with G. Lightness (L*) values were the highest in CON compared to samples containing G. A statistically significant dose-dependent reduction in L* values was observed with increasing G concentrations across all roasting levels (light [L], medium [M], and dark [D]). Additionally, the D group demonstrated lower L* values than the L and M groups, irrespective of the treatment (p < 0.05).

Figure 1.

External features of Yanggaeng treated with various concentrations of Guatemalan coffee extracts.

Table 4.

Colorimetric properties of Yanggaeng treated with various concentrations of Guatemalan coffee extract.

The redness/greenness (a*) values shifted from negative (green) to positive (red) as the G concentration increased in the L and M groups, ranging from −2.23 to 1.77 and −2.20 to 2.90, respectively. In contrast, the D group started with a slightly negative a* value for the CON sample (−1.47) but shifted toward redness, reaching 3.13 for D4, indicating a pronounced red shift. The yellowness/blueness (b*) values remained positive and increased with increasing G concentration across all roasting levels. Specifically, b* values increased from 2.47 to 9.93 in group L, 2.33 to 10.30 in group M, and from 1.23 to 8.37 in group D, reflecting an overall enhancement in yellowness. The ΔE values calculated for each group, representing the color difference from the CON sample, are as follows: for the L group, ΔE values were 7.71 ± 0.64, 7.71 ± 0.19, and 8.98 ± 0.11; for the M group, ΔE values were 10.66 ± 1.14, 9.57 ± 0.29, and 14.67 ± 0.34; and for the D group, ΔE values were 12.03 ± 0.40, 13.60 ± 0.32, and 14.90 ± 0.24. The ΔE values indicate that significant color differences occurred as the G concentration increased, with darker roasts showing higher ΔE values, suggesting a greater perceptible color change compared to the CON.

The color analysis results demonstrated that the incorporation of G significantly modified the color properties of Yanggaeng, with the roasting levels and G concentrations exerting distinct effects on L*, a*, and b* values. The color transformation of coffee beans during roasting is attributed to several chemical reactions that occur upon heating. Amino acids and reducing sugars in coffee beans react to form melanoidins during roasting [27]. The Maillard reaction, which is primarily active during light roasting, initiates the initial browning process [28]. As the roasting temperature increases, sugars undergo caramelization, leading to further browning and decomposition into simpler compounds [29,30]. Consequently, the color of coffee deepens to a darker brown as roasting progresses. Additionally, moisture loss during dark roasting concentrates the remaining compounds, intensifying the color of coffee [31].

These findings indicate that the chemical components of coffee extracts significantly affect the color properties of Yanggaeng. Understanding these changes is crucial for developing coffee-infused desserts with desirable visual and sensory characteristics.

3.3. pH and Brix Values of Yanggaeng

Table 5 presents the pH and Brix values of Yanggaeng prepared with varying concentrations of G at different degrees of roasting. Group L exhibited the lowest pH value of 6.29. As the concentration of G increased, the pH increased in a dose-dependent manner, reaching 6.61 for 2%, 6.67 for 4%, and 6.75 for 6% concentrations (p < 0.05). Conversely, in the M group, pH values decreased with higher concentrations of G, declining to 6.19 in M4 and 5.99 in M6 compared to the CON value of 6.26 (p < 0.05). Group D had relatively stable pH values, with a CON value of 6.28. However, the addition of G significantly increased the pH initially, although higher concentrations led to a subsequent decrease, resulting in the lowest pH in the D6 sample within the D group (p < 0.05). Across all roasting degrees, group M consistently showed the lowest pH values compared to groups L and D.

Table 5.

Changes in pH and Brix of Yanggaeng treated with various concentrations of Guatemalan coffee extract.

Table 5 lists the Brix values of Yanggaeng samples. In the L group, Brix values increased with higher concentrations of G. For CON, the value was 3.03; for L2, it was 3.30; for L6, it was 3.50; and for L4, it reached the highest value of 3.70 (p < 0.05). The M group exhibited an initial increase in Brix values from 3.07 in CON to 3.40 in M2, followed by a slight decrease to 3.20 in M4, and a subsequent rise to 3.57 in M6. In group D, Brix values consistently increased with increasing concentrations of G, ascending from 3.07 in CON to 3.50 in D2, 3.70 in D4, and peaking at 3.90 in D6. When comparing roasting degrees, group D achieved the highest Brix values, followed by groups L and M (p < 0.05).

The observed pH variations indicate that the addition of G influences the acidity of Yanggaeng differently, based on the degree of roasting. Light roasting generally preserves more natural acids, resulting in higher pH values, whereas medium roasting slightly lowers the pH owing to the breakdown of organic acids. Dark roasting further reduces acidity levels as chlorogenic acid degrades into compounds such as quinic acid, affecting overall acidity [32,33,34]. Chlorogenic acid is most prominent during the early stages of roasting but diminishes as the roasting intensity increases. Consistent with these findings, Kim et al. reported an increase in pH with a stronger roasting of both espresso and drip coffee [35]. Additionally, Hu et al. demonstrated that dark-roasted coffee beans had increased acetic acid levels; however, the perception of acidity did not increase, because bitter compounds mask the acidic taste [36].

The pH values of Yanggaeng with added coffee extract revealed significant differences based on the degree of roasting. The Yanggaeng samples with coffee extract D exhibited the highest pH values, whereas those with coffee extract M showed the lowest pH values. In group L, the addition of G increased the pH, suggesting a buffering effect that reduced acidity. Conversely, in the M group, higher concentrations of G significantly decreased pH, indicating increased acidity. Group D initially showed an increase in pH. However, at higher concentrations, the enhanced formation of quinic acid likely played a major role in the subsequent pH decline. This pattern suggests interactions between acidic and buffering compounds that vary with the roasting level. These results indicate that the degree of roasting significantly influences both the acidity and flavor profiles of Yanggaeng. Specifically, Yanggaeng with medium roast, which exhibited the lowest pH, may impart a more pronounced acidic flavor, whereas those with light or dark roasts may offer a more balanced taste profile.

The Brix values, indicative of the soluble solid content, were influenced by both the concentration of G and the degree of roasting. In the L group, Brix values increased with higher concentrations of G, reaching the highest value in L4 (3.70) compared to CON (3.03), L2 (3.30), and L6 (3.50) (p < 0.05). The M group showed an initial increase in Brix values from CON (3.07) to M2 (3.40), a slight decrease at M4 (3.20), and a subsequent increase at M6 (3.57). In the D group, Brix values consistently rose with increasing concentrations of G, from 3.07 in CON to 3.50 in D2 and 3.70 in D4, and peaking at 3.90 in D6. Group D consistently exhibited the highest Brix values compared to groups L and M (p < 0.05).

The increasing trends in the Brix values suggest that the soluble solid content in Yanggaeng was affected by both the concentration of G and the degree of roasting. In Group D, the consistent increase in Brix values can be attributed to caramelization during dark roasting, where sugars in the coffee beans break down into simpler sugars and caramel compounds that are highly soluble in water. Additionally, the Maillard reaction contributes to the breakdown of proteins and solids into soluble compounds, further elevating Brix values [37]. The loss of moisture in dark-roasted coffee beans concentrates the remaining compounds, leading to higher Brix values when these beans are incorporated into Yanggaeng. In group L, the slight decrease in the Brix value observed at the highest concentration (L6) may indicate a saturation point, where additional coffee extract does not significantly contribute to the solid soluble content. Group M exhibited a more complex interaction, with an initial increase and a slight dip at M4, followed by a significant increase at M6, suggesting interactions between coffee extract and other components within the Yanggaeng matrix.

These findings underscore the importance of considering both the roasting degree and coffee extract concentration when developing coffee-infused desserts, such as Yanggaeng. Achieving the desired flavor balance and sweetness profile relies on understanding how these factors influence the acidity and soluble solid content, thereby affecting the overall sensory attributes of the final product.

3.4. Antioxidative Properties of Yanggaeng

Table 6 shows the TPC and DPPH free radical scavenging rates of the Yanggaeng samples. Coffee contains antioxidant compounds such as chlorogenic acid, hydroxycinnamic acid, melanoidins, and caffeine [38,39]. The antioxidant activity of coffee varies significantly, depending on its origin, roasting level, and extraction method. The TPC of the Yanggaeng samples increased significantly with the addition of G compared with that of CON, irrespective of the roasting levels. In the L group, L2 sample showed a 1.46-fold increase in polyphenol content relative to that in the CON group. In the M group, the TPC values progressively increased with higher concentrations of G, reaching the highest value in the M6 sample (CON: 15.60 < M2: 20.18 < M4: 21.99 < M6: 22.79). Similarly, in group D, samples D4 and D6 exhibited 1.65-fold and 1.61-fold increases in TPC, respectively, compared to the CON group. The increase in total polyphenol content may be attributed to the enhanced extractability of polyphenolic compounds. Roasting disrupts the cellular structure of coffee beans and reduces their moisture content, thereby improving the solubility of polyphenolic compounds [40]. Furthermore, the thermal degradation of coffee components during roasting may produce low-molecular-weight phenolic derivatives, which are readily measurable in the TPC assay [41]. Notably, no significant differences in TPC were observed when different roasting levels were compared, suggesting that the concentration of coffee extract had a more pronounced effect on polyphenol content than the roasting degree itself.

Table 6.

Antioxidative capacities of Yanggaeng treated with various concentrations of Guatemalan coffee extract.

Regarding DPPH radical scavenging ability, Yanggaeng samples in group L did not show significant changes with varying concentrations of G. However, only the M6 and D6 samples demonstrated significantly higher DPPH radical scavenging activity, likely due to elevated polyphenol levels. Across all roasting levels, group D consistently exhibited the lowest DPPH radical scavenging ability at all concentrations. The roasting of coffee significantly affects the content and composition of antioxidants. Dark roasting generally results in lower levels of chlorogenic acid and total polyphenols owing to prolonged roasting [42]. During roasting, increased intensity initially elevates chlorogenic acid levels, but prolonged roasting leads to its degradation into compounds such as quinic acid, which influences the acidity and antioxidant activity [32,33,34]. Chlorogenic acid effectively reduces free radicals; thus, Yanggaeng prepared with lower levels of roasted coffee beans may exhibit a reduced DPPH radical scavenging activity. These findings are consistent with those of Kim et al. [43], who reported a decrease in DPPH scavenging ability with increased roasting intensity for both espresso and drip coffee. Additionally, Jung et al. found that the DPPH radical scavenging ability significantly decreased in the order of light, medium, city, and French roasts [44]. The antioxidant activity of Yanggaeng containing G was attributed to the presence of TPC, with the antioxidant activity diminishing as roasting intensity increased.

3.5. Textural Properties of Yanggaeng

Table 7 presents the textural properties of Yanggaeng containing G. Incorporation of G into Yanggaeng resulted in significant increases in hardness, resilience, gumminess, and chewiness across all roasting levels (p < 0.05). Specifically, hardness exhibited a substantial increase in the Yanggaeng samples with 2% and 4% coffee extracts, particularly in the L and M groups. The M2 sample demonstrated the highest hardness at 619.04 g, which was likely linked to its elevated Brix level. Higher sugar concentrations have been shown to enhance the gel structure by promoting cross-linking between starch and protein molecules, resulting in a denser and firmer texture [45,46,47]. A logical postulation is that the increased cross-linking effect induced by the elevated sugar content is the primary mechanism responsible for the observed firmness, leading to a more cohesive gel network.

Table 7.

Textural properties of Yanggaeng treated with various concentrations of Guatemalan coffee extracts.

The adhesiveness remained consistently negative across all Yanggaeng samples, indicating a characteristic sticky texture. M4 showed the lowest adhesiveness compared to CON, M2, and M6, suggesting a less sticky texture in this variant. In contrast, no significant differences in adhesiveness were observed between the varying concentrations of G in groups L and D.

Resilience was highest among the 2% G samples in the L and M groups. However, within the D group, D6 exhibited the highest resilience, followed by D4, with D2 and CON showing similar resilience levels (p < 0.05). Cohesion was highest in the M4 sample at 0.17, while the D2 sample had the lowest cohesion at 0.10.

The springiness patterns mirrored those of resilience. Samples L2 and L6 demonstrated increased springiness compared to samples CON and L4. In the M group, M4 had the highest springiness, whereas M6 had the lowest springiness. In group D, springiness increased with increasing G concentration (p < 0.05).

Gumminess and chewiness were highest in the L2 and M2 samples. Conversely, in group D, D2 exhibited significantly lower gumminess and chewiness than D4 and D6 samples. The addition of G to Yanggaeng modifies its texture, potentially enhancing the overall sensory experience.

Texturally, the addition of coffee extract altered the hardness, resilience, gumminess, and chewiness of Yanggaeng. These changes are likely due to interactions between coffee compounds (such as sugars and melanoidins) and the starch–protein matrix of the dessert, leading to modifications in the gel structure. For instance, the increased hardness in certain samples can be attributed to a higher sugar content (as indicated by the increased Brix values), which may enhance gel cohesion.

The variability in adhesiveness, resilience, springiness, gumminess, and chewiness across different concentrations and roasting levels suggested complex interactions between the coffee extracts and the Yanggaeng matrix. Such interactions could involve modifications in moisture distribution, protein–starch interactions, and the formation of new compounds during the mixing and setting processes. Future studies should investigate the molecular interactions between coffee compounds and the starch matrix of white bean paste in order to better understand the observed textural changes. Additionally, exploring different cooking methods and combinations of other ingredients in Yanggaeng could provide further insights into its textural properties.

3.6. Consumer Preferences of Yanggaeng

Table 8 presents the consumer preferences for Yanggaeng prepared with varying concentrations of G for different roasting degrees. The evaluated attributes were color, scent, sweetness, bitterness, chewiness, overall taste, and overall acceptance. Consumer preferences were measured using a nine-point hedonic scale administered to untrained participants from the general public. The addition of G to Yanggaeng resulted in increased preferences for both color and scent compared to CON, regardless of the roasting degree and concentration. Specifically, the preference for color was highest at the 6% concentration across all roasting levels. In terms of scent, the D6 sample achieved the highest score of 5.46, although no significant differences were observed among the different concentrations of coffee extracts within the same roasting degree.

Table 8.

Consumer preferences of Yanggaeng treated with various concentration of Guatemalan coffee extracts.

Sweetness preference did not exhibit significant differences between the roasted groups L and D upon the addition of coffee extract. However, in the M group, the M6 sample demonstrated significantly higher sweetness scores than the other concentrations. When comparing roasting degrees, the highest sweetness preference was observed in the L2 sample. In contrast, the L6 sample had the lowest sweetness preference, whereas the M6 sample showed the highest sweetness. Bitterness levels increased with the addition of G compared to CON, with the D6 sample receiving the highest bitterness rating of 4.33. Preferences for chewiness did not show significant differences between groups L and D based on coffee extract concentration. In contrast, group M exhibited an increased preference for chewiness in the G treatment, with group M2 attaining the highest rating.

The overall taste scores increased with the addition of G in the M and D groups, excluding the L group, and reached the highest values at the 6% concentration. The overall acceptance of Yanggaeng generally improved with the addition of G, showing significant differences based solely on the concentration within the M group. Among the roasting degrees, group D achieved the highest overall acceptance, with D4 having the highest score of 5.46. These findings are consistent with those of previous studies that evaluated consumer preferences for roasted coffee. For example, research on Ethiopian coffee has reported that dark-roasted samples consistently achieved the highest preference scores [48]. Similarly, Kang et al. [49] demonstrated that medium- and dark-roasted coffee samples had the highest overall acceptance ratings. This finding suggests that the enhanced consumer acceptance of Yanggaeng prepared with dark-roasted coffee extract may be attributed to the broader appeal of flavor profiles associated with darker roasting degrees.

In summary, consumers generally preferred Yanggaeng with higher G concentrations, particularly in the 4–6% range. Yanggaeng prepared with dark-roasted coffee extract was especially favorable for color, scent, and taste attributes, whereas light roasting effectively maintained the desired chewiness of the product. These findings suggest that incorporating G into traditional tastes, such as Yanggaeng, can enhance consumer preferences. However, careful balancing of the coffee extract concentration and roasting degree is essential to achieve the desired flavor and textural attributes.

Consumer preference data indicated that both the concentration of coffee extract and the degree of roasting significantly influenced the sensory appeal of Yanggaeng. The superior color and scent preferences associated with higher concentrations of G, especially 6%, suggest that a more pronounced coffee aroma and hue may be desirable features for consumers. These sensory differences can be attributed to chemical transformations that occur during roasting. The Maillard reaction and caramelization processes in coffee beans lead to the formation of various volatile compounds such as pyrazines, furans, and phenolic compounds, which contribute to the characteristic roasted aroma and deeper color [50,51]. Darker roasts, which produce higher concentrations of these compounds, likely enhance the richness and complexity of coffee-infused Yanggaeng, aligning with the observed consumer preferences. The increase in sweetness preference in the M6 sample and the consistently highest overall acceptance in the dark-roasted group indicate a favorable impact of darker roasting on the flavor profile, likely due to the development of richer and more complex flavors during roasting.

These results have practical implications for product development. Manufacturers aiming to create coffee-infused Yanggaeng should consider using dark-roasted coffee extract at concentrations between 4% and 6% to optimize sensory attributes such as color, aroma, and overall taste. Additionally, these findings highlight the importance of balancing bitterness and sweetness because excessively high concentrations or roasting levels may lead to undesirable flavor outcomes.

Future research could explore the underlying chemical and physical interactions between coffee compounds and Yanggaeng ingredients, as well as consumer perception changes over time and across different demographic groups. Further understanding could guide the more precise tailoring of product formulations to enhance market acceptance and satisfaction.

4. Conclusions

The primary objective of this study was to evaluate the physicochemical properties and sensory attributes of Yanggaeng infused with varying concentrations of G under different roasting conditions (light, medium, and dark). In addition, this study aimed to determine the optimal concentration and roasting degree of G that would yield results comparable to those of the traditional Yanggaeng prototype (CON). Comprehensive analyses were conducted, including proximate composition, color properties, pH, Brix, antioxidative properties, textural characteristics, and consumer preferences.

Proximate analysis revealed that the moisture, ash, fat, protein, and carbohydrate contents in Yanggaeng were significantly influenced by both the concentration of coffee extract and the roasting level. Specifically, group L exhibited the highest moisture and fat content and the lowest ash and carbohydrate content. The addition of G demonstrated a dose-dependent effect on the colorimetric properties, resulting in decreased L* values and increased a* and b* values. Furthermore, pH levels were elevated in the L and D groups, whereas the M group showed a reduction in pH compared with the control. The Brix values consistently increased with the addition of G across all roasting degrees, with group D exhibiting the highest Brix values.

Assessment of the antioxidative properties indicated that the addition of G enhanced both the TPC and DPPH radical scavenging capacity, particularly in the M and D groups. Textural analysis demonstrated significant improvements in hardness, resilience, gumminess, and chewiness with the incorporation of G. Consumer preference evaluations highlighted that Yanggaeng samples containing 4–6% G, especially those with D, were most favored for attributes such as color, scent, and overall taste.

Based on these findings, D4 and D6 were the most suitable samples for enhancing the physicochemical, antioxidant, and sensory properties of Yanggaeng. The integration of G into Yanggaeng not only improved its nutritional and sensory profiles, but also offered a promising foundation for the development of novel food products with enhanced qualities. This study provides essential data that can guide future innovations in traditional dessert formulations by leveraging the benefits of coffee extracts to meet the evolving consumer preferences. In conclusion, incorporating roasted Guatemalan coffee extract into Yanggaeng significantly enhanced its antioxidant capacity and modified its physicochemical and sensory properties. These findings suggest that the extract may serve as a functional ingredient for the development of novel, health-oriented traditional desserts.

Author Contributions

Conceptualization, J.L. (Jisu Lee), I.K., C.D., M.D., and J.-H.H.; Methodology, J.L. (Jisu Lee), H.J., Y.-W.K., M.C., J.L. (Jiwoo Lee), and J.D.; Software, J.L. (Jisu Lee) and H.J.; Validation, J.L. (Jisu Lee), I.K., H.J., Y.-W.K., M.C., J.L. (Jiwoo Lee), and J.-H.H.; Formal Analysis, H.J., Y.-W.K., M.C., and J.L. (Jiwoo Lee); Investigation, J.L. (Jisu Lee), M.D., and J.-H.H.; Resources, J.-H.H.; Data Curation, J.L. (Jisu Lee), I.K., H.J., Y.-W.K., M.C., J.L. (Jiwoo Lee), M.D., and J.-H.H.; Writing—Original Draft Preparation, J.L. (Jisu Lee), I.K., H.J., Y.-W.K., M.C., J.L. (Jiwoo Lee), J.D., C.D., M.D., and J.-H.H.; Writing—Review and Editing, J.L. (Jisu Lee), I.K., H.J., Y.-W.K., M.C., J.L. (Jiwoo Lee), J.D., C.D., M.D., and J.-H.H.; Visualization, J.L. (Jisu Lee) and H.J.; Supervision, M.D. and J.-H.H.; Project Administration, J.-H.H.; Funding Acquisition, I.K. and J.-H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki and was approved by the Institutional Review Board of Dankook University (protocol code DKU-2023-10-037-002 on 20 December 2023).

Informed Consent Statement

Informed consent was obtained from all participants prior to their involvement in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Jaewook Do was employed by the company MOI Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Grand View Research. Coffee Market Size, Share & Trends Analysis Report By Distribution Channel (B2B, B2C), By Product (Roasted, Instant, RTD), By Nature (Conventional, Organic), By Region (Europe, Asia Pacific), And Segment Forecasts, 2023–2030. Available online: https://www.grandviewresearch.com/industry-analysis/coffee-market (accessed on 8 January 2025).

- Everything to Know and Love About Guatemalan Coffee. Available online: https://phillyfairtrade.com/blogs/learn/guatemalan-coffee (accessed on 8 January 2025).

- Akiyama, M.; Murakami, K.; Hirano, Y.; Ikeda, M.; Iwatsuki, K.; Wada, A.; Tokuno, K.; Onishi, M.; Iwabuchi, H. Characterization of Headspace Aroma Compounds of Freshly Brewed Arabica Coffees and Studies on a Characteristic Aroma Compound of Ethiopian Coffee. J. Food Sci. 2008, 73, C335–C346. [Google Scholar] [CrossRef]

- Lyman, D.J.; Benck, R.; Dell, S.; Merle, S.; Murray-Wijelath, J. FTIR-ATR Analysis of Brewed Coffee: Effect of Roasting Conditions. J. Agric. Food Chem. 2003, 51, 3268–3272. [Google Scholar] [CrossRef] [PubMed]

- Nakilcioğlu-Taş, E.; Ötleş, S. Physical Characterization of Arabica Ground Coffee with Different Roasting Degrees. An. Acad. Bras. Cienc. 2019, 91, e20180191. [Google Scholar] [CrossRef] [PubMed]

- Kocadağlı, T.; Göncüoğlu, N.; Hamzalıoğlu, A.; Gökmen, V. In Depth Study of Acrylamide Formation in Coffee during Roasting: Role of Sucrose Decomposition and Lipid Oxidation. Food Funct. 2012, 3, 970–975. [Google Scholar] [CrossRef]

- Oliviero, T.; Capuano, E.; Cämmerer, B.; Fogliano, V. Influence of Roasting on the Antioxidant Activity and HMF Formation of a Cocoa Bean Model Systems. J. Agric. Food Chem. 2009, 57, 147–152. [Google Scholar] [CrossRef]

- Arlorio, M.; Locatelli, M.; Travaglia, F.; Coisson, J.; Grosso, E.D.; Minassi, A.; Appendino, G.; Martelli, A. Roasting Impact on the Contents of Clovamide (N-caffeoyl-L-DOPA) and the Antioxidant Activity of Cocoa Beans (Theobroma cacao L.). Food Chem. 2008, 106, 967–975. [Google Scholar] [CrossRef]

- Kongor, J.E.; Hinneh, M.; Van de Walle, D.; Afoakwa, E.O.; Boeckx, P.; Dewettinck, K. Factors Influencing Quality Variation in Cocoa (Theobroma cacao) Bean Flavour Profile—A Review. Food Res. Int. 2016, 82, 44–52. [Google Scholar] [CrossRef]

- Yeager, S.E.; Batali, M.E.; Lim, L.X.; Liang, J.; Han, J.; Thompson, A.N.; Guinard, J.; Ristenpart, W.D. Roast Level and Brew Temperature Significantly Affect the Color of Brewed Coffee. J. Food Sci. 2022, 87, 1837–1850. [Google Scholar] [CrossRef] [PubMed]

- Fadri, R.A.; Sayuti, K.; Nazir, N.; Suliansyah, I. Sensory Quality Profile of Ranah Minang Arabica Coffee Specialty. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 281–290. [Google Scholar] [CrossRef]

- Alstrup, J.; Petersen, M.A.; Larsen, F.H.; Münchow, M. The Effect of Roast Development Time Modulations on the Sensory Profile and Chemical Composition of the Coffee Brew as Measured by NMR and DHS-GC-MS. Beverages 2020, 6, 70. [Google Scholar] [CrossRef]

- Kim, Y.K.; Lim, J.M.; Kim, Y.J.; Kim, W. Alterations in pH of Coffee Bean Extract and Properties of Chlorogenic Acid Based on the Roasting Degree. Foods 2024, 13, 1757. [Google Scholar] [CrossRef] [PubMed]

- Alnsour, L.; Issa, R.; Awwad, S.; Albals, D.; Al-Momani, I. Quantification of Total Phenols and Antioxidants in Coffee Samples of Different Origins and Evaluation of the Effect of Degree of Roasting on Their Levels. Molecules 2022, 27, 1591. [Google Scholar] [CrossRef]

- Viencz, T.; Acre, L.B.; Rocha, R.B.; Alves, E.A.; Ramalho, A.R.; Benassi, M.T. Caffeine, Trigonelline, Chlorogenic Acids, Melanoidins, and Diterpenes Contents of Coffea canephora Coffees Produced in the Amazon. J. Food Compos. Anal. 2023, 117, 105140. [Google Scholar] [CrossRef]

- Heo, J.; Adhikari, K.; Choi, K.S.; Lee, J. Analysis of Caffeine, Chlorogenic Acid, Trigonelline, and Volatile Compounds in Cold Brew Coffee Using High-Performance Liquid Chromatography and Solid-Phase Microextraction—Gas Chromatography-Mass Spectrometry. Foods 2020, 9, 1746. [Google Scholar] [CrossRef] [PubMed]

- Park, E.; Ryu, S.I.; Lee, M.; Lee, H.J.; Paik, J.K. Quality and Sensory Characteristics of Yanggaeng, a Healthy Snack Added with Pinus Koraiensis Needle Extract Powder for the Elderly. JFNR 2022, 10, 228–234. [Google Scholar] [CrossRef]

- Gomes, W.P.C.; Pires, J.A.; Teixeira, N.N.; Bortoleto, G.G.; Gutierrez, E.M.R.; Melchert, W.R. Effects of Green Coffee Bean Flour Fortification on the Chemical and Nutritional Properties of Gluten-Free Cake. J. Food Meas. Charact. 2022, 16, 3451–3458. [Google Scholar] [CrossRef]

- Kurniawan, A.W.; Tawali, A.B.; Fitri, F. The Effect of Gelatin and Xanthan Gum Concentration on Diversification of Dark Chocolate Praline Jelly Coffee Products. BIO Web Conf. 2024, 96, 01029. [Google Scholar] [CrossRef]

- Meerasri, J.; Sothornvit, R. Novel Development of Coffee Oil Extracted from Spent Coffee Grounds as a Butter Substitute in Bakery Products. JFPP 2022, 46, e16687. [Google Scholar] [CrossRef]

- Shazly, A.B.; Fouad, M.; Elaaser, M.; Sayed, R.; Abd El-Aziz, M. Probiotic Coffee Ice Cream as an Innovative Functional Dairy Food. JFPP 2022, 46, e17253. [Google Scholar] [CrossRef]

- Han, I.; Lee, C.S. Quality Properties and Bioactivities of American Cookies with Coffee Extract Residues. LWT 2021, 151, 112173. [Google Scholar] [CrossRef]

- The Ultimate Guide to Understanding Coffee Roast Levels. Available online: https://coffeebros.com/blogs/coffee/the-ultimate-guide-to-understanding-coffee-roast-levels (accessed on 9 January 2025).

- Lee, J.; Jang, H.; Kang, D.; No, C.; Doo, M.; Shin, E.-C.; Ha, J.-H. Physicochemical Properties and Sensory Attributes of Yanggaeng Treated with Citrus Peel Powder. Appl. Sci. 2023, 13, 11377. [Google Scholar] [CrossRef]

- Jang, H.; Lee, J.; Won, S.; Kim, Y.; Doo, M.; Kim, I.; Ha, J.-H. Physicochemical Properties, Antioxidant Capacities, and Sensory Evaluation of Yanggaeng Treated with Cissus quadrangularis. Appl. Sci. 2023, 13, 11092. [Google Scholar] [CrossRef]

- Kedare, S.B.; Singh, R.P. Genesis and Development of DPPH Method of Antioxidant Assay. J. Food Sci. Technol. 2011, 48, 412–422. [Google Scholar] [CrossRef] [PubMed]

- da Costa, D.S.; Albuquerque, T.G.; Costa, H.S.; Bragotto, A.P.A. Thermal Contaminants in Coffee Induced by Roasting: A Review. Int. J. Environ. Res. Public Health 2023, 20, 5586. [Google Scholar] [CrossRef]

- Bekedam, E.K.; Loots, M.J.; Schols, H.A.; Van Boekel, M.A.; Smit, G. Roasting Effects on Formation Mechanisms of Coffee Brew Melanoidins. J. Agric. Food Chem. 2008, 56, 7138–7145. [Google Scholar] [CrossRef]

- Orfanou, F.; Dermesonlouoglou, E.K.; Taoukis, P.S. Greek Coffee Quality Loss During Home Storage: Modeling the Effect of Temperature and Water Activity. J. Food Sci. 2019, 84, 2983–2994. [Google Scholar] [CrossRef]

- Syukri, D.; Sari, F.I.P. Roasting Conditions on Metabolic Profile of Black Honey Arabica Coffee (Coffea arabica). IOP Cont. Ser. Earth Environ. Sci. 2023, 1182, 012048. [Google Scholar] [CrossRef]

- Pittia, P.; Dalla Rosa, M.; Lerici, C.R. Textural changes of coffee beans as affected by roasting conditions. LWT-Food Sci. Technol. 2001, 34, 168–175. [Google Scholar] [CrossRef]

- Shan, J.; Suzuki, T.; Suhandy, D.; Ogawa, Y.; Kondo, N. Chlorogenic Acid (CGA) Determination in Roasted Coffee Beans by Near Infrared (NIR) Spectroscopy. EAEF 2014, 7, 139–142. [Google Scholar] [CrossRef]

- Pérez-Martínez, M.; Sopelana, P.; De Pena, M.P.; Cid, C. Changes in Volatile Compounds and Overall Aroma Profile during Storage of Coffee Brews at 4 and 25 Degrees. J. Agric. Food Chem. 2008, 56, 3145–3154. [Google Scholar] [CrossRef]

- Pérez-Martínez, M.; Sopelana, P.; de Peña, M.P.; Cid, C. Application of Multivariate Analysis to the Effects of Additives on Chemical and Sensory Quality of Stored Coffee Brew. J. Agric. Food Chem. 2008, 56, 11845–11853. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Jeong, Y.; Gu, S.; Song, K.Y.; Kim, I.; Kim, K.Y. Physicochemical Characteristics of Brazilian Coffea arabica cv. Catuai Coffee Extracts with Different Roasting Conditions. JKFN 2019, 48, 748–756. [Google Scholar] [CrossRef]

- Liang, N.; Kitts, D.D. Role of Chlorogenic Acids in Controlling Oxidative and Inflammatory Stress Conditions. Nutrients 2015, 8, 16. [Google Scholar] [CrossRef]

- Moreira, A.S.; Nunes, F.M.; Domingues, M.R.; Coimbra, M.A. Coffee Melanoidins: Structures, Mechanisms of Formation and Potential Health Impacts. Food Funct. 2012, 3, 903–915. [Google Scholar] [CrossRef]

- Kim, K.J.; Park, S.K. Changes in Major Chemical Constituents of Green Coffee Beans during the Roasting. Korean J. Food Sci. Technol. 2006, 38, 153–158. [Google Scholar]

- Casal, S.; Oliveira, M.B.; Ferreira, M.A. HPLC/Diode-Array Applied to the Thermal Degradation of Trigonelline, Nicotinic Acid, and Caffeine in Coffee. Food Chem. 2000, 68, 481–485. [Google Scholar] [CrossRef]

- Schouten, M.A.; Tappi, S.; Angeloni, S.; Cortese, M.; Caprioli, G.; Vittori, S.; Romani, S. Acrylamide Formation and Antioxidant Activity in Coffee during Roasting—A Systematic Study. Food Chem. 2021, 343, 128514. [Google Scholar] [CrossRef]

- Grzelczyk, J.; Fiurasek, P.; Kakkar, A.; Budryn, G. Evaluation of the Thermal Stability of Bioactive Compounds in Coffee Beans and Their Fractions Modified in the Roasting Process. Food Chem. 2022, 387, 132888. [Google Scholar] [CrossRef]

- Górecki, M.; Hallmann, E. The Antioxidant Content of Coffee and Its In Vitro Activity as an Effect of Its Production Method and Roasting and Brewing Time. Antioxidants 2020, 9, 308. [Google Scholar] [CrossRef]

- Kim, E.; Song, K.Y.; Kim, I.; Yun, H.Y.; Zhang, S.; Ha, J.-H.; Jeong, Y. Antioxidant Activities of Colombian Coffea arabica cv. Typica Caturra Coffee Extracts with Different Roasting Conditions. JKFN 2020, 49, 212–217. [Google Scholar] [CrossRef]

- Jung, S.; Kim, M.H.; Park, J.H.; Jeong, Y.; Ko, K.S. Cellular Antioxidant and Anti-Inflammatory Effects of Coffee Extracts with Different Roasting Levels. J. Med. Food 2017, 20, 626–635. [Google Scholar] [CrossRef] [PubMed]

- Ghebremedhin, M.; Seiffert, S.; Vilgis, T.A. Effects of Sugar Molecules on the Rheological and Tribological Properties and on the Microstructure of Agarose-Based Fluid Gels. Front. Soft Matter 2024, 4, 1363898. [Google Scholar] [CrossRef]

- Hassan, C.Z.; Ahmad, S.S.; Agbaje Rafiu, S. Effect of Sugar Concentration on Gelling Properties of Pectin from Malaysian Banana Peels (Musa Acuminata× Balbisiana). Int. J. Innov. Res. Sci. Eng. Technol. 2018, 3, 170–177. [Google Scholar]

- Huang, P.H.; Cheng, Y.T.; Lu, W.C.; Li, P.H. Optimization of Concentration-Time, Agar, and Sugar Concentration for Sweet Gelatinized Adzuki-Bean Jelly Cake (Yokan) by Response Surface Methodology. Gels 2022, 8, 540. [Google Scholar] [CrossRef]

- Chung, H.W.; Yoon, H.H. Quality Characteristics of Ethiopia Coffee according to Different Decaffeination Processes and Roasting Conditions. J. East Asian Soc. Diet. Life 2022, 32, 125–135. [Google Scholar] [CrossRef]

- Kang, G.W.; Piao, Z.Z.; Ko, J.Y. Effects of Water Types and Roasting Points on Consumer Liking and Emotional Responses toward Coffee. Food Qual. Prefer. 2022, 101, 104631. [Google Scholar] [CrossRef]

- Houessou, J.K.; Maloug, S.; Leveque, A.S.; Delteil, C.; Heyd, B.; Camel, V. Effect of Roasting Conditions on the Polycyclic Aromatic Hydrocarbon Content in Ground Arabica Coffee and Coffee Brew. J. Agric. Food Chem. 2007, 55, 9179–9726. [Google Scholar] [CrossRef]

- Yanagimoto, K.; Lee, K.G.; Ochi, H.; Shibamoto, T. Antioxidative Activity of Heterocyclic Compounds Found in Coffee Volatiles Produced by Maillard Reaction. J. Agric. Food Chem. 2002, 50, 5480–5484. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).