Methodology for Studying the Reliability of Interlocking Devices in Bulgarian Railways

Abstract

Featured Application

Abstract

1. Introduction

2. Research Methods

- All points must be properly set and locked and must be kept locked as long as the train is allowed to run on them.

- Conflicting routes must be locked out.

- The route must be protected against unintended movements on converging tracks.

- All sections of the track through which the train is allowed to pass must be clear.

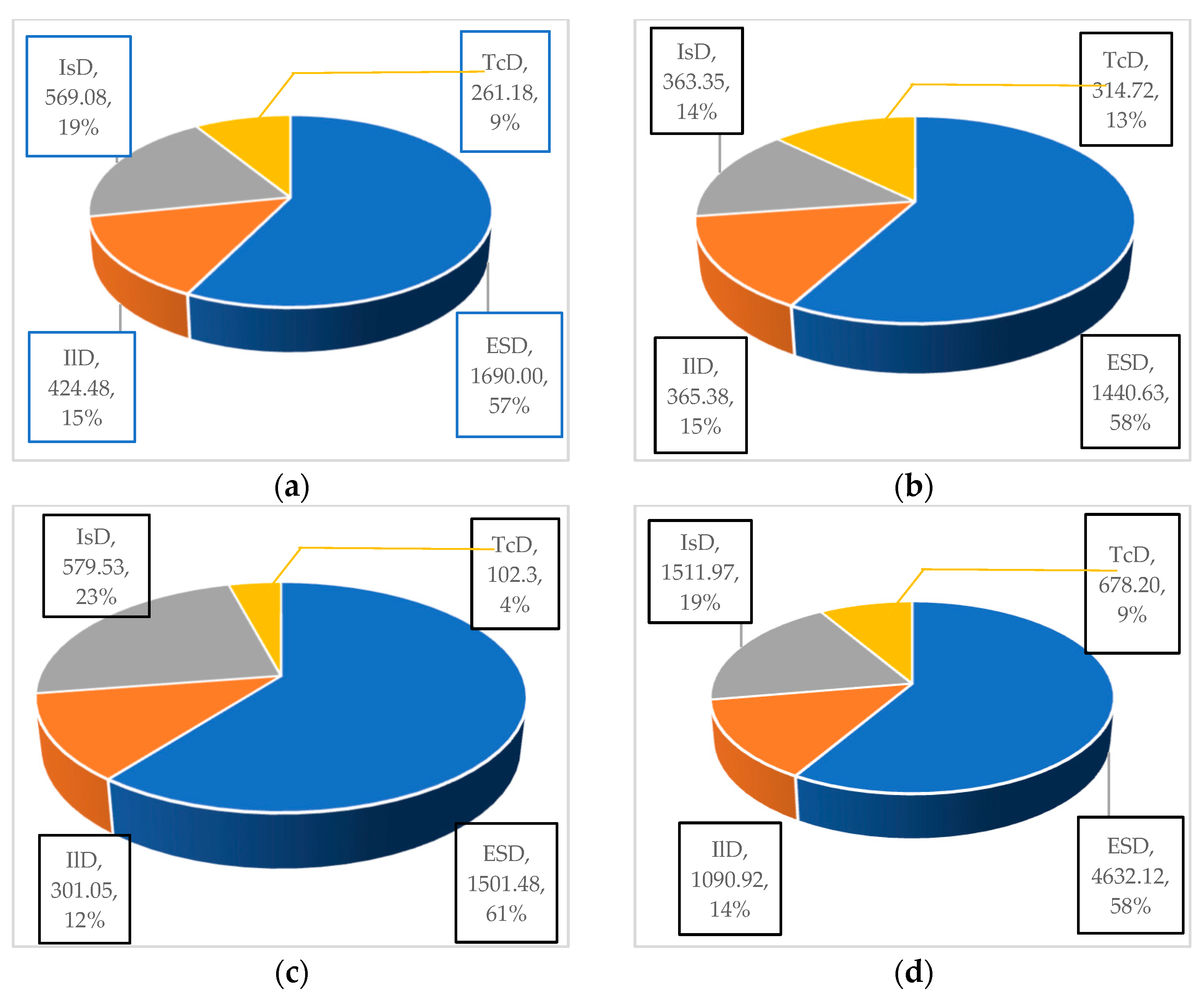

- external station devices (ESD)—point machines, rail current circuits, counter points, traffic lights, etc.;

- interstation devices (IsD)—automatic interlocking without passage signals (AB with axle counters), automatic interlocking with passage signals (type AB with rail circuits), relay semi-automatic interlocking (type PAB), automatic crossing devices (type APU), automatic locomotive signalling (type ALS), points on open road, etc.;

- telecommunications devices (TcD)—automatic telephone exchanges (type ATC), external lines, etc.

3. Results

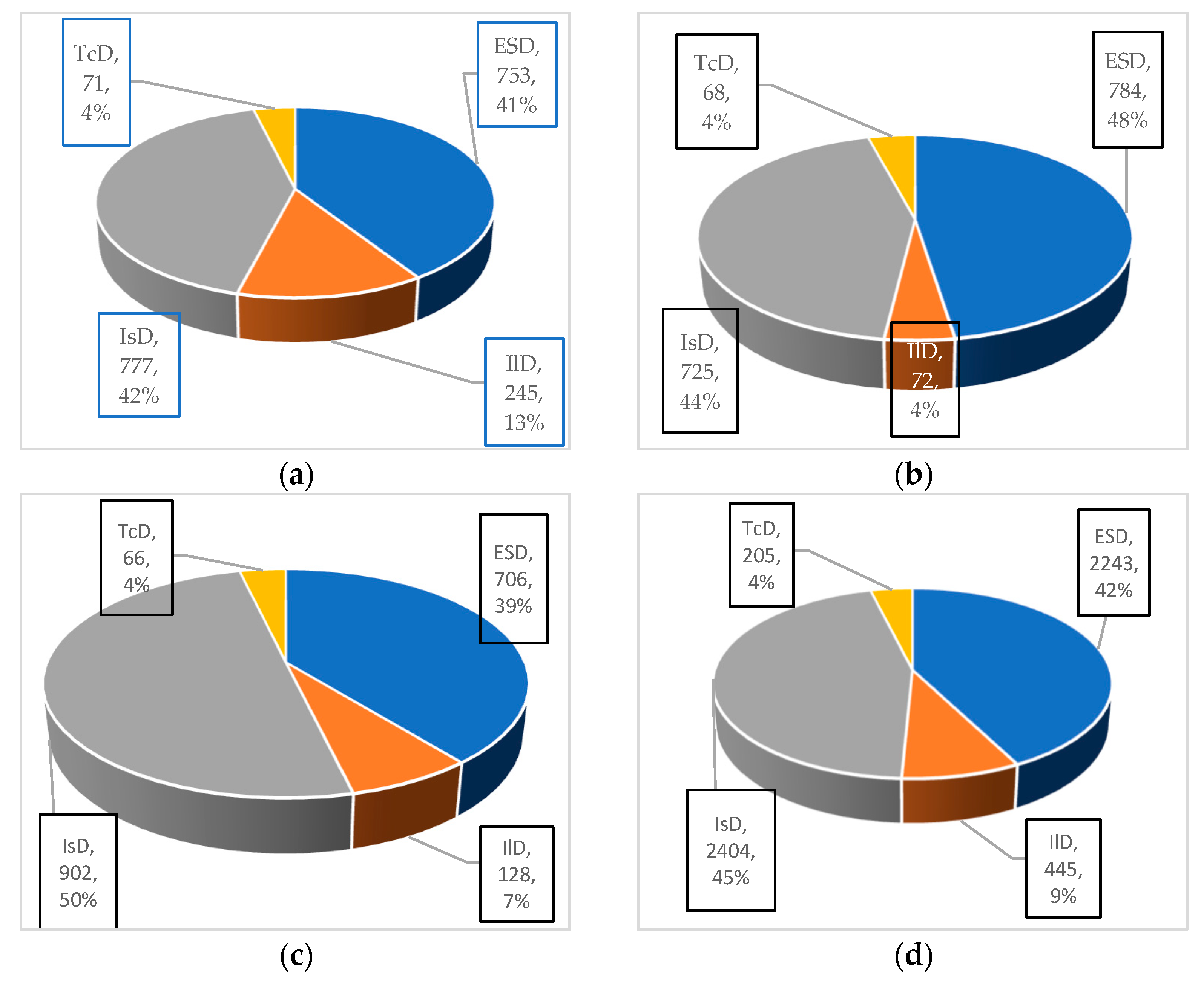

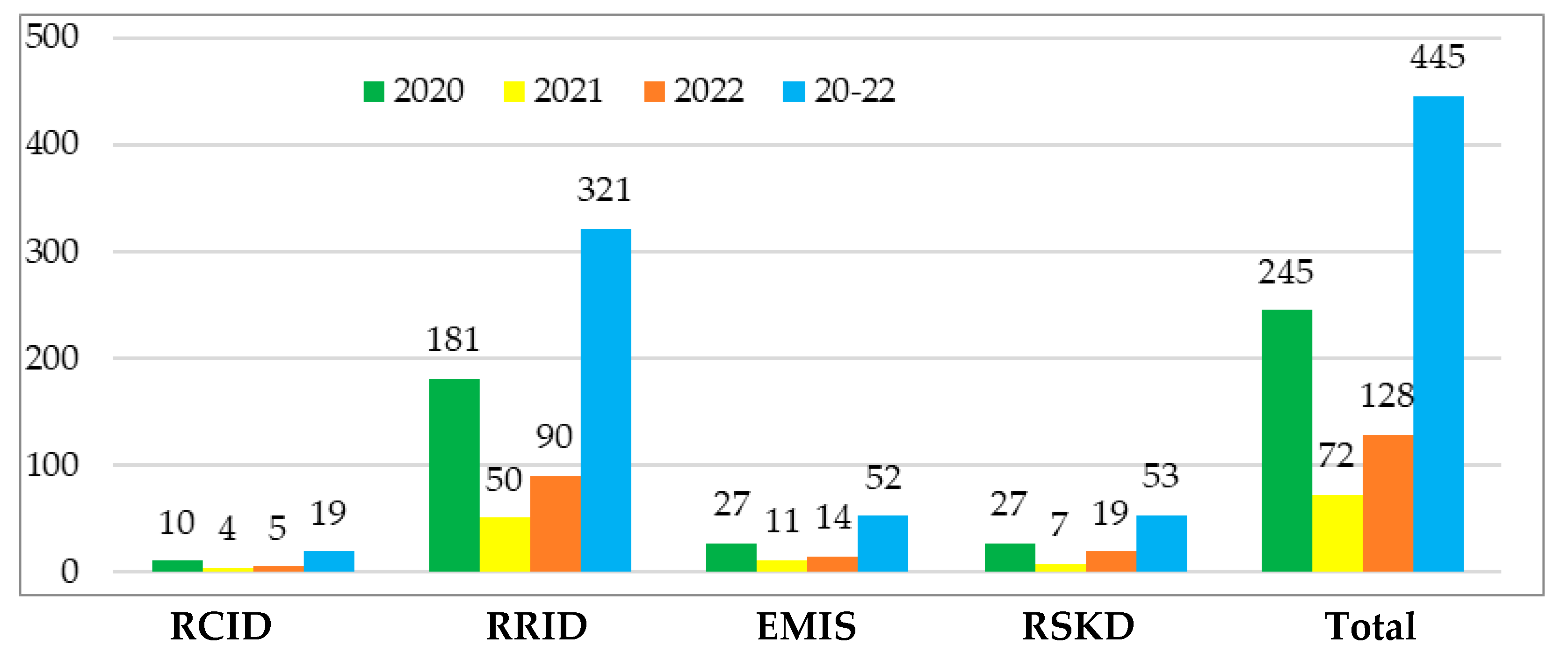

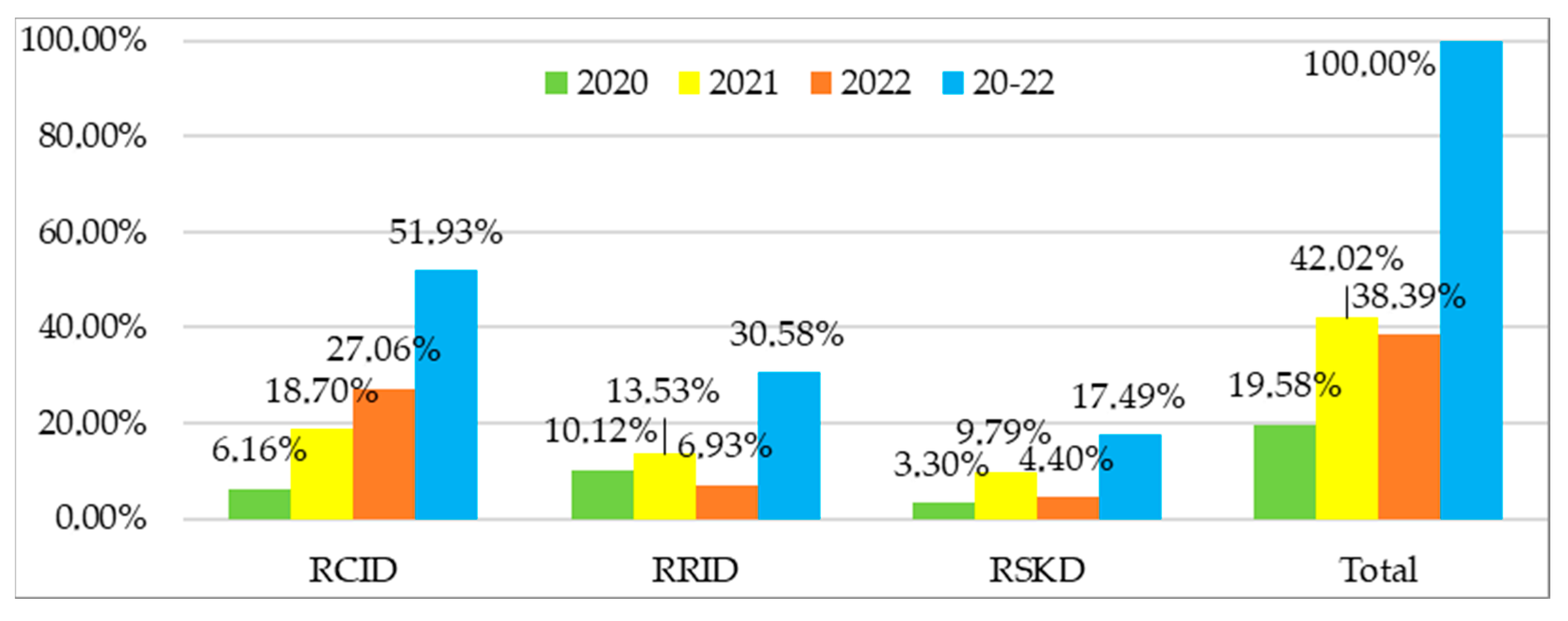

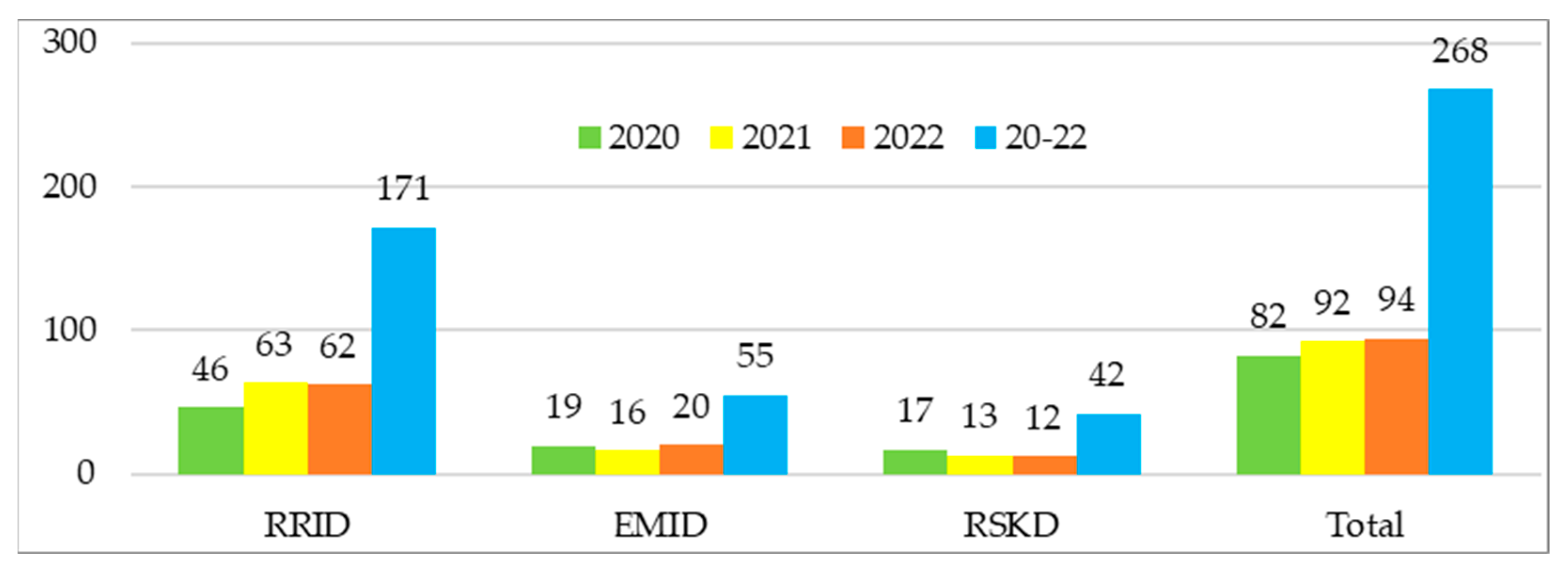

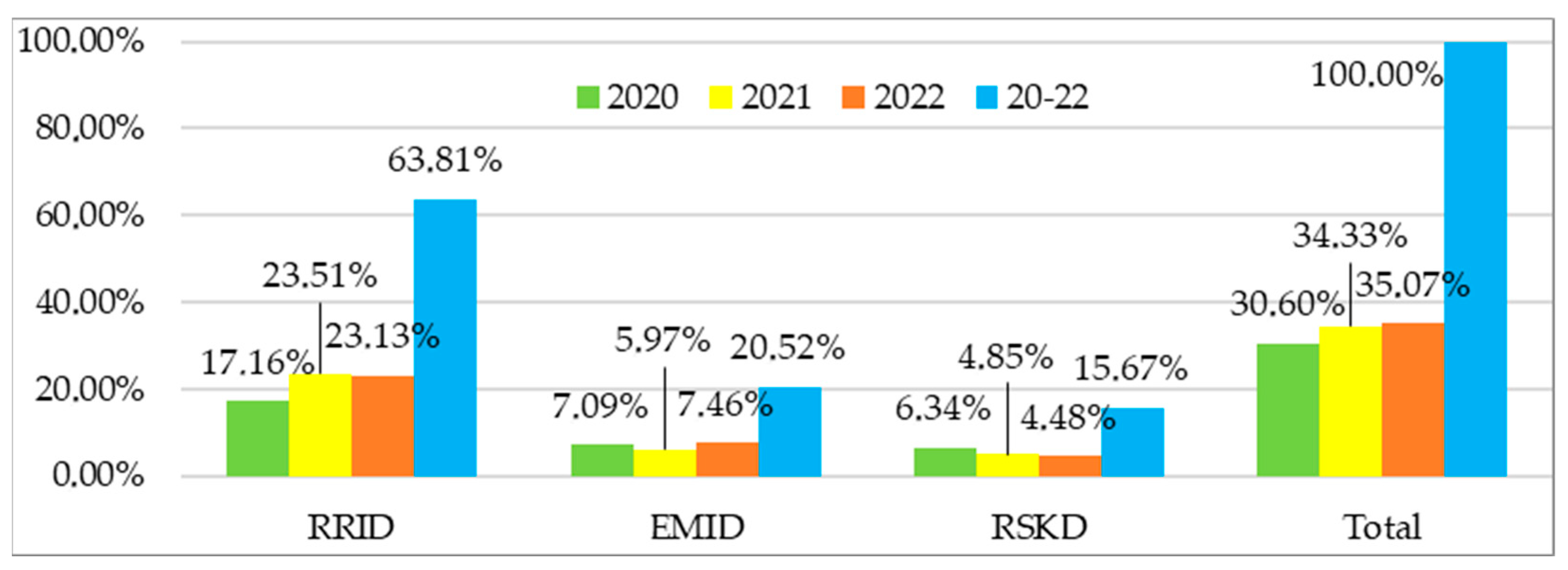

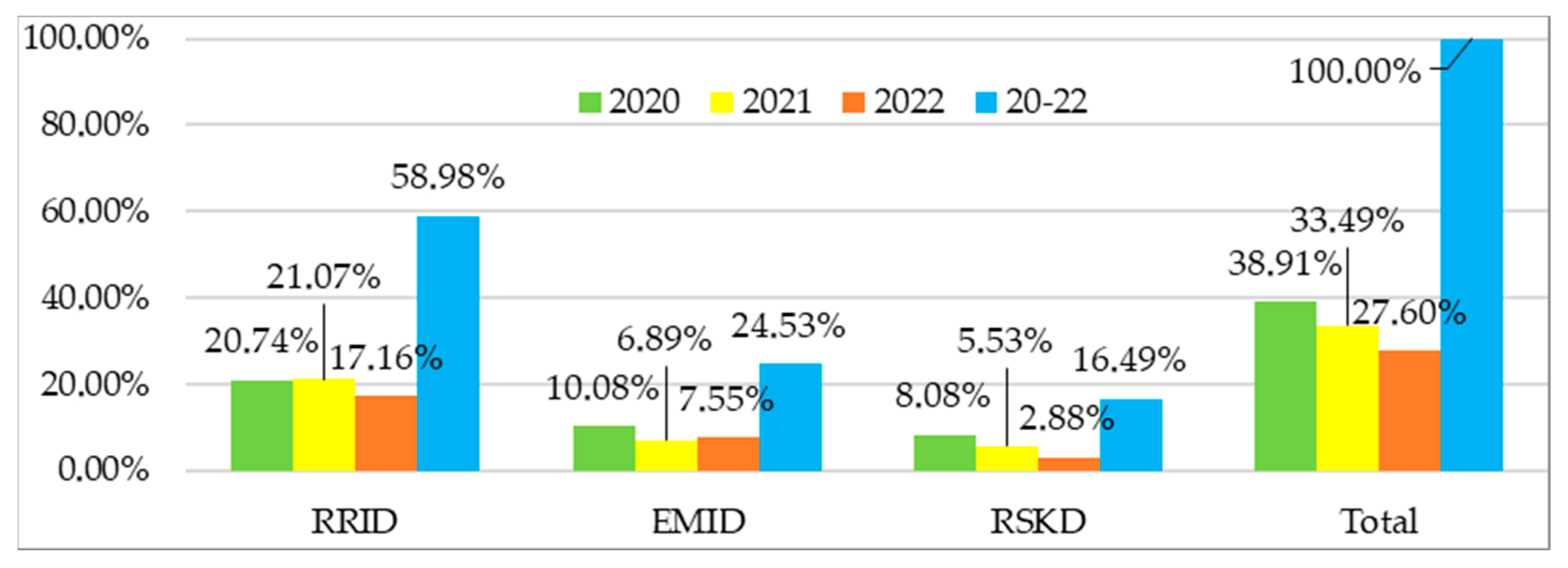

3.1. Statistical Assessment of Failures of the Interlocking Devices and Signallinig Equipment

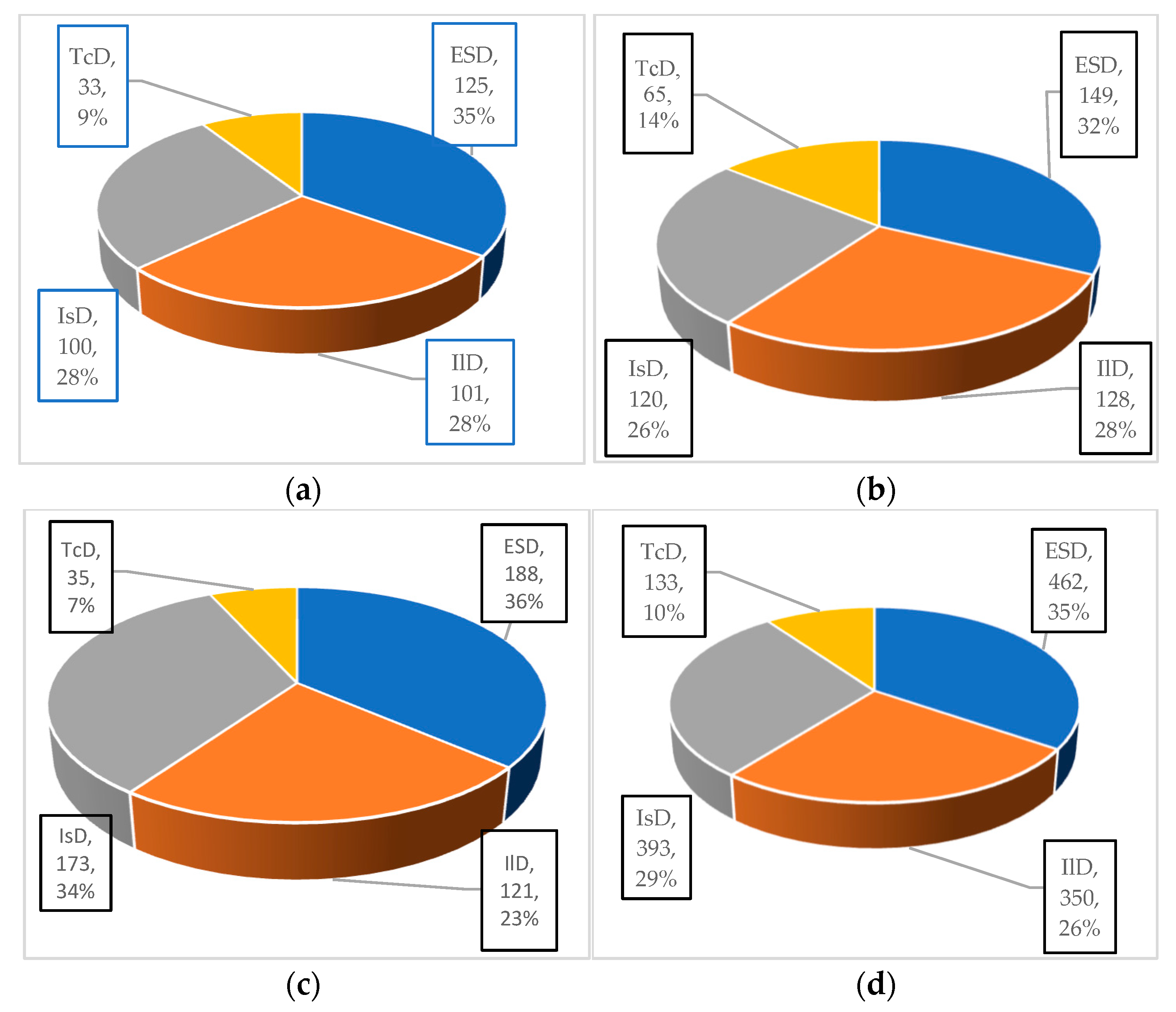

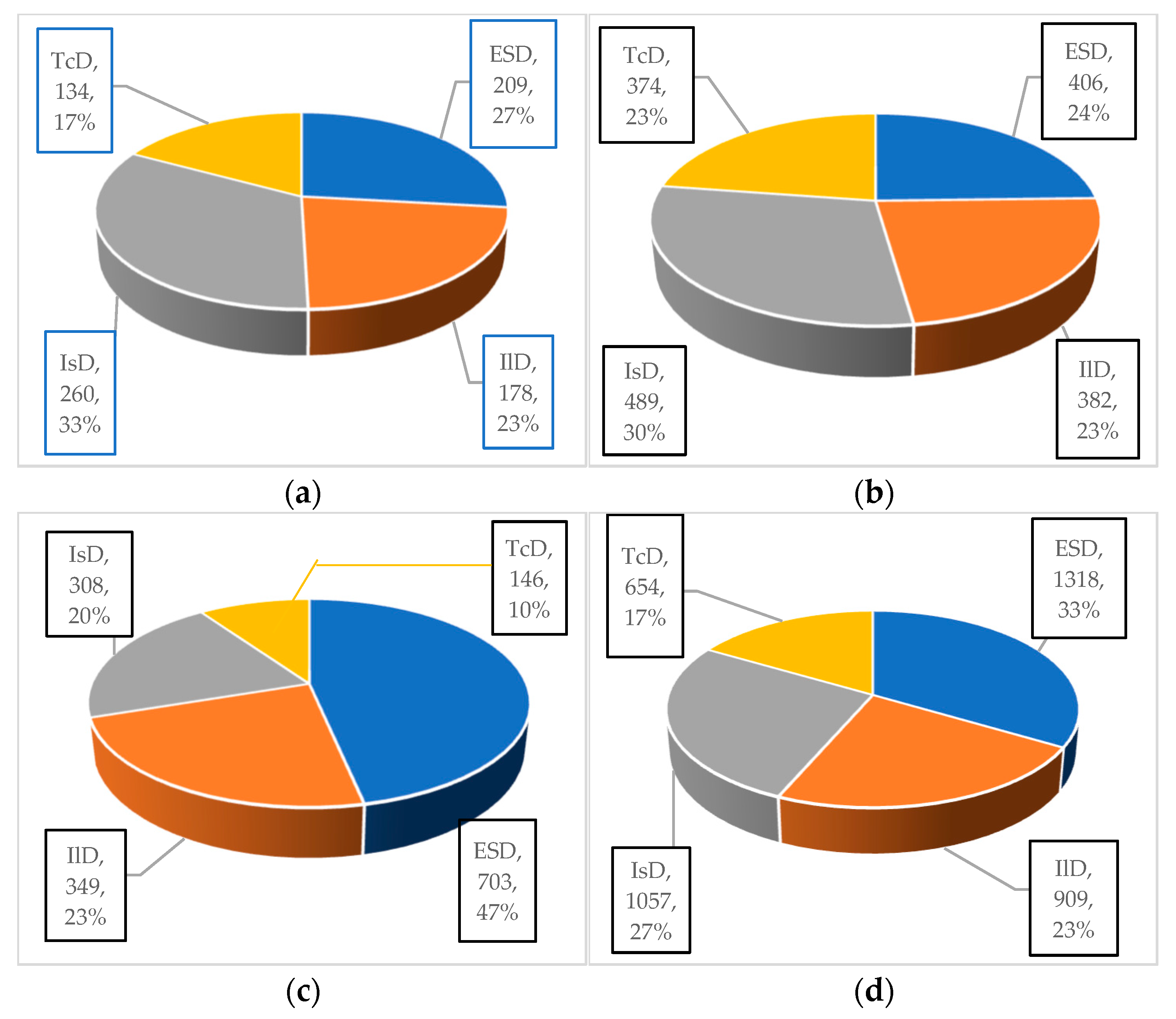

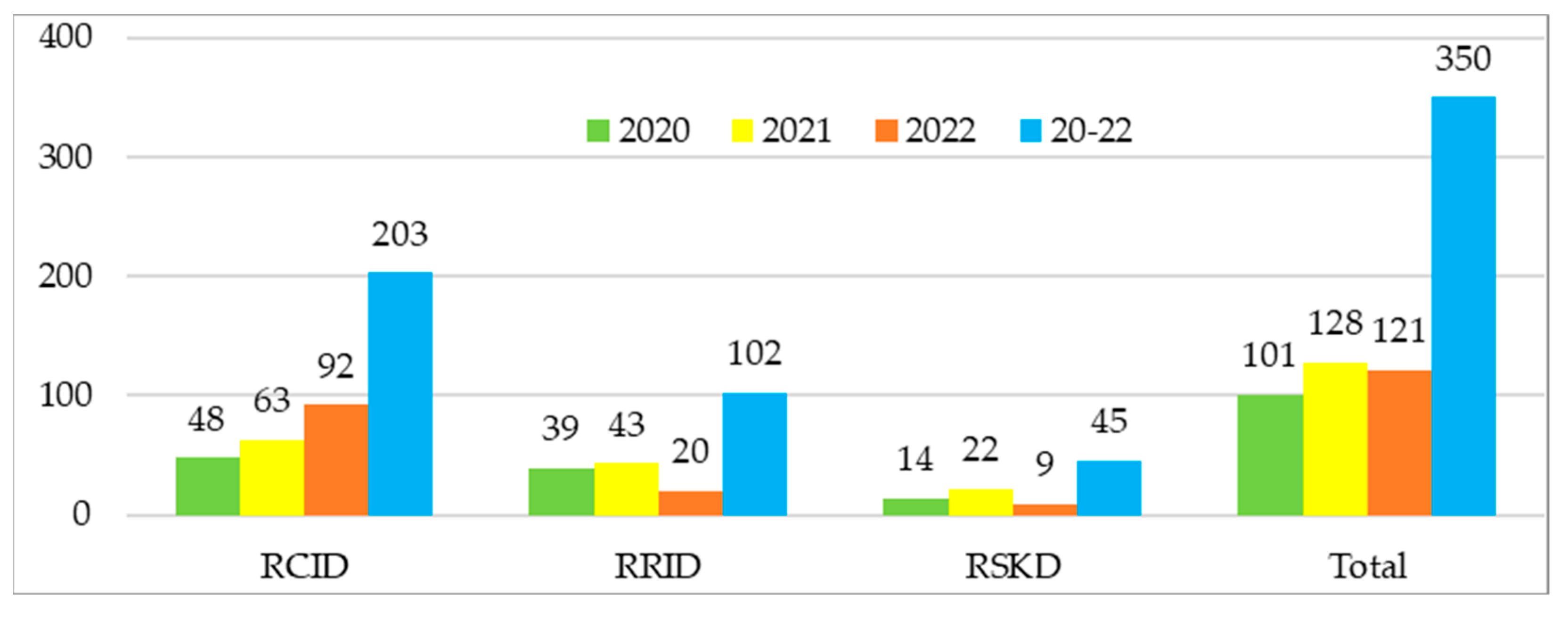

3.1.1. Statistical Assessment of Failures in STD—Sofia

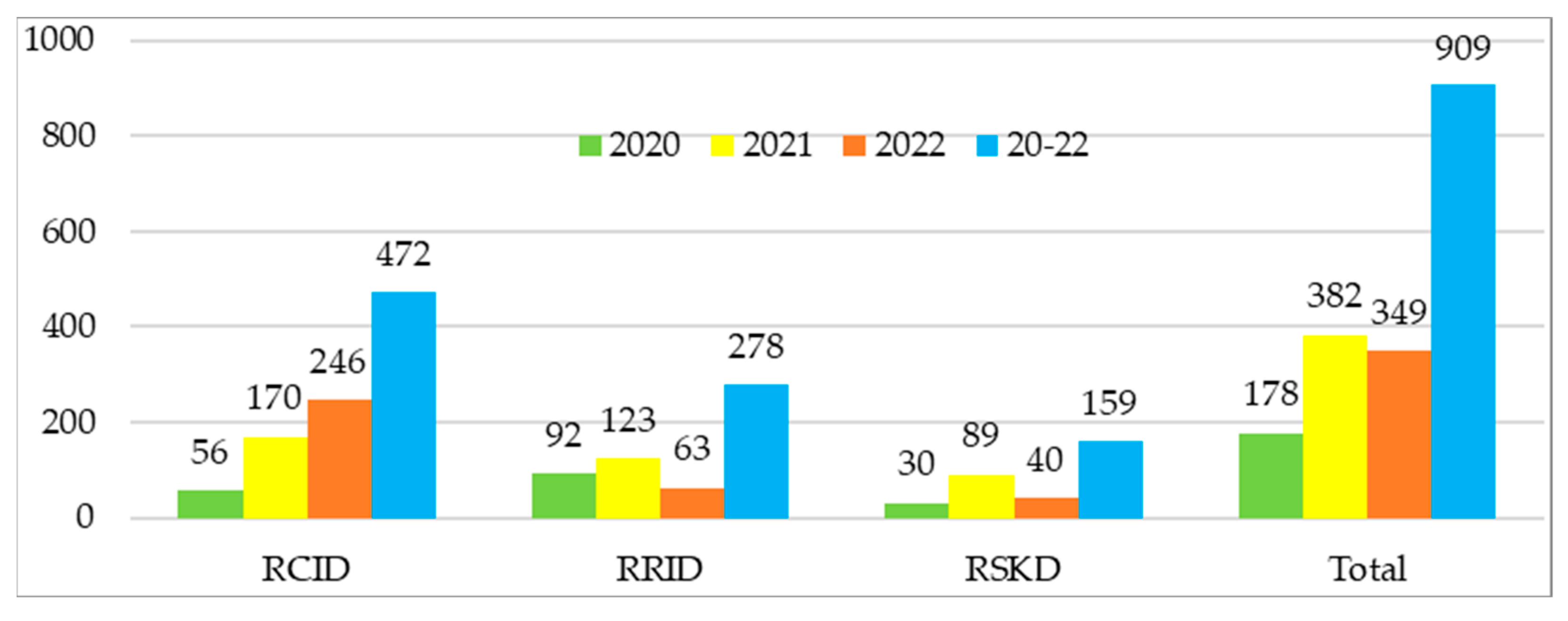

3.1.2. Statistical Assessment of Failures in STD—Plovdiv

3.1.3. Statistical Assessment of Failures in STD—Gorna Oryahovitsa

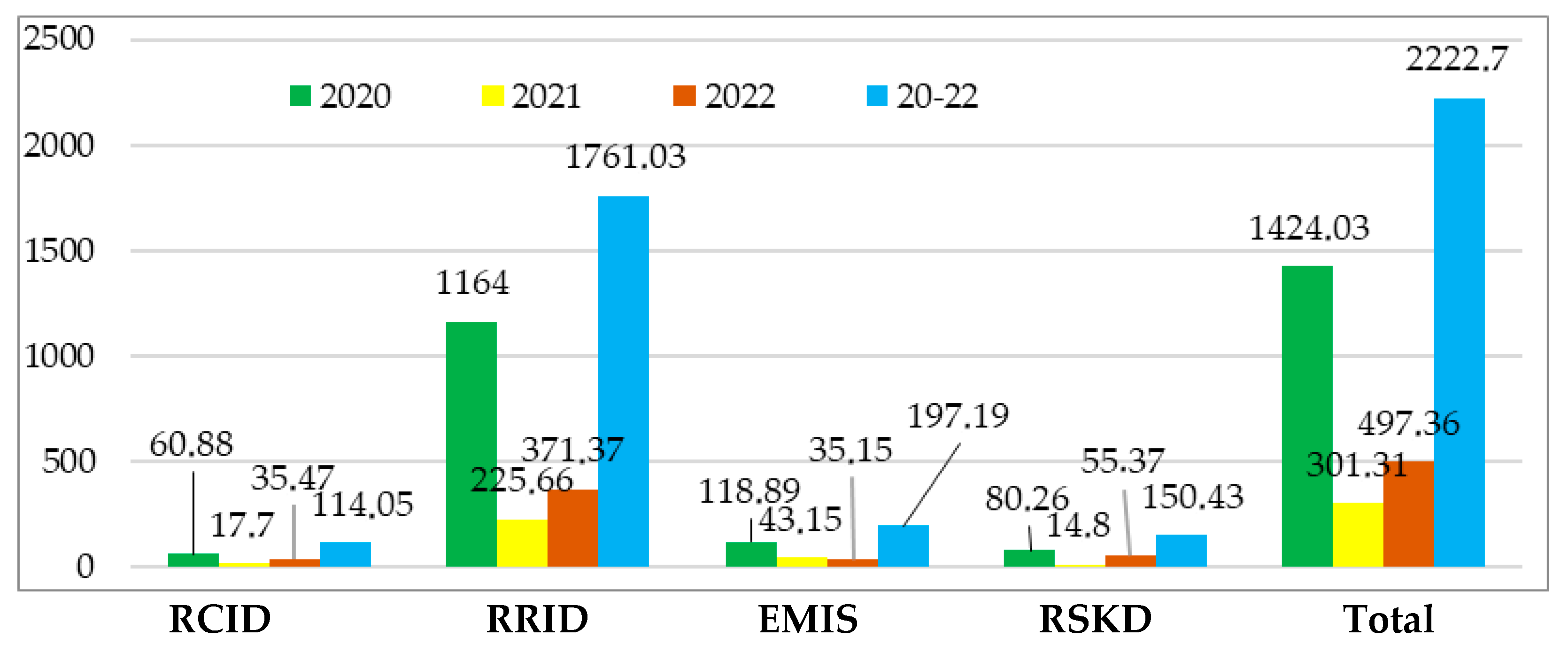

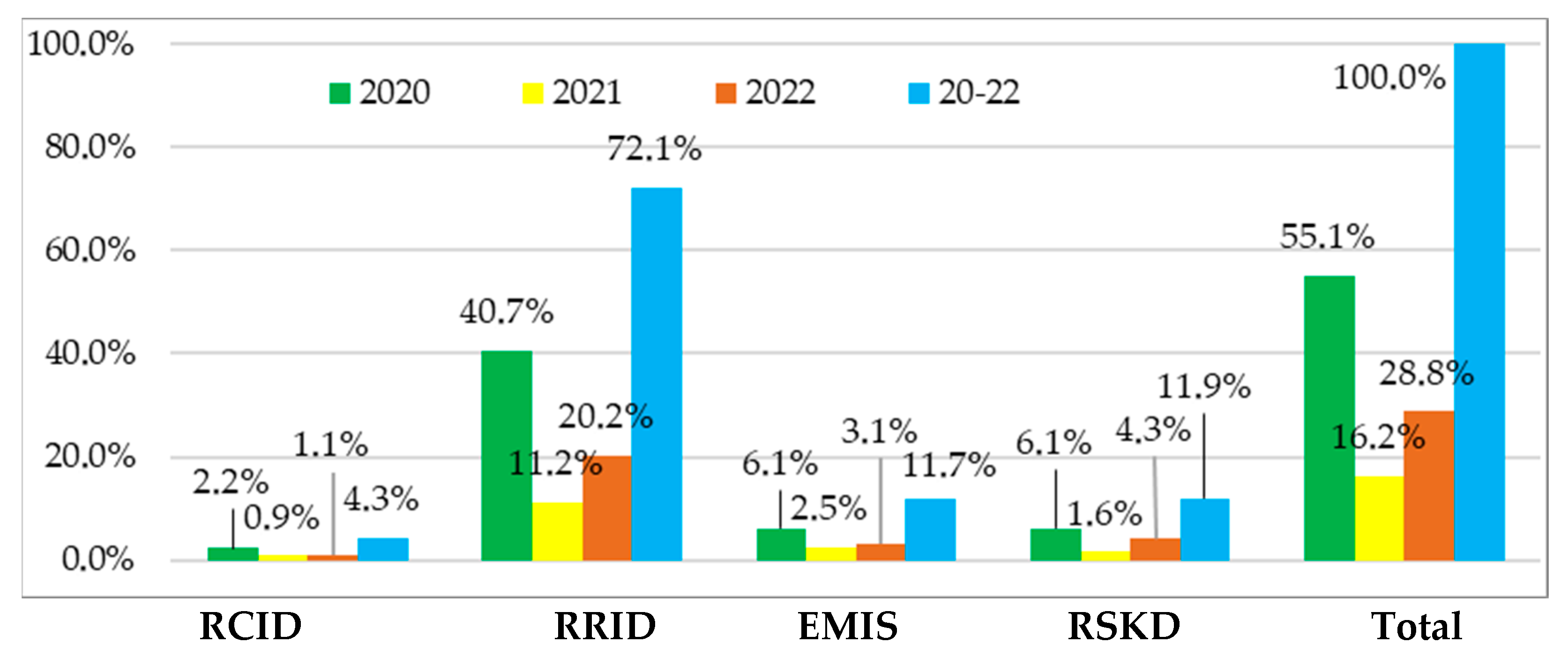

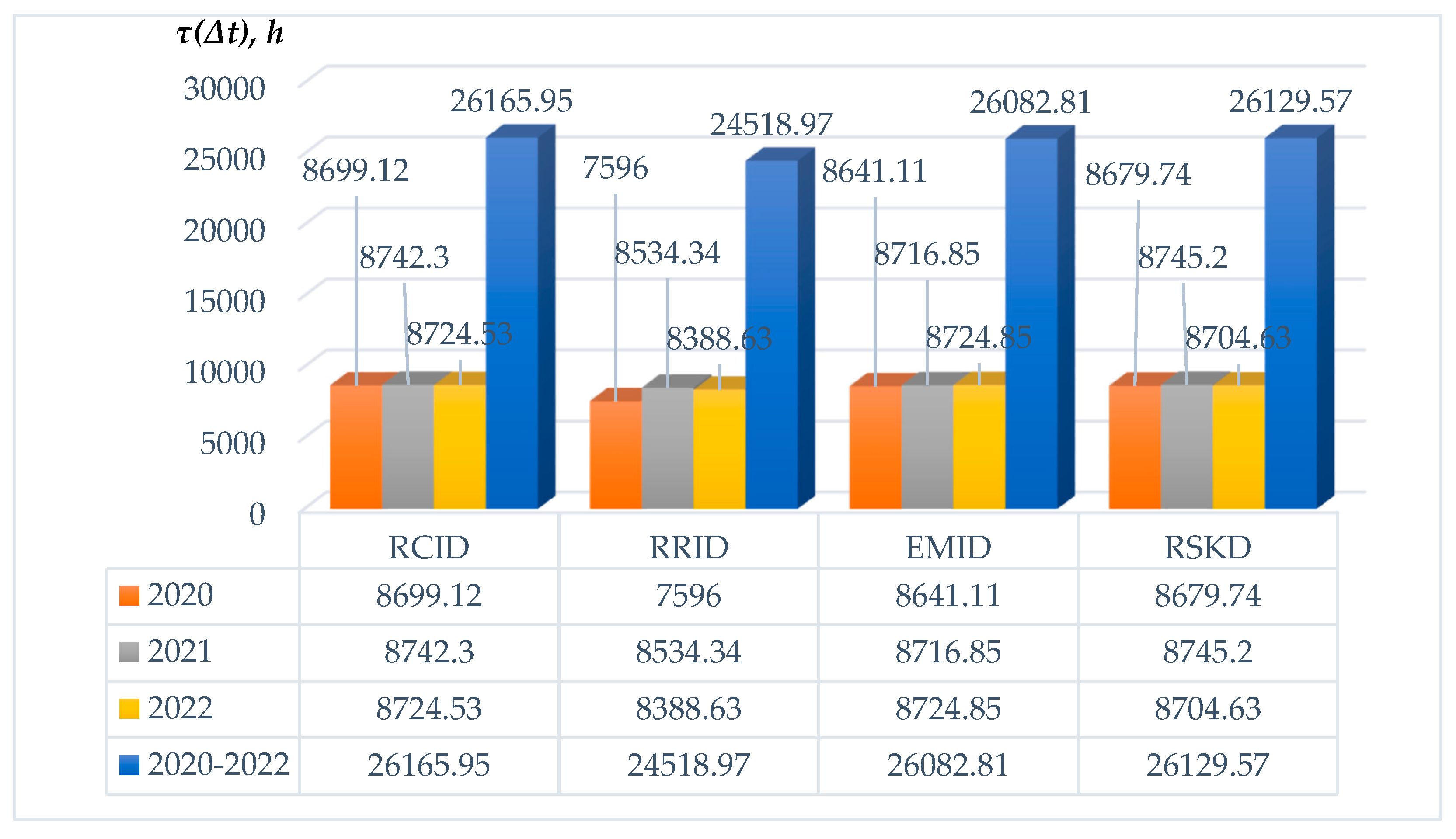

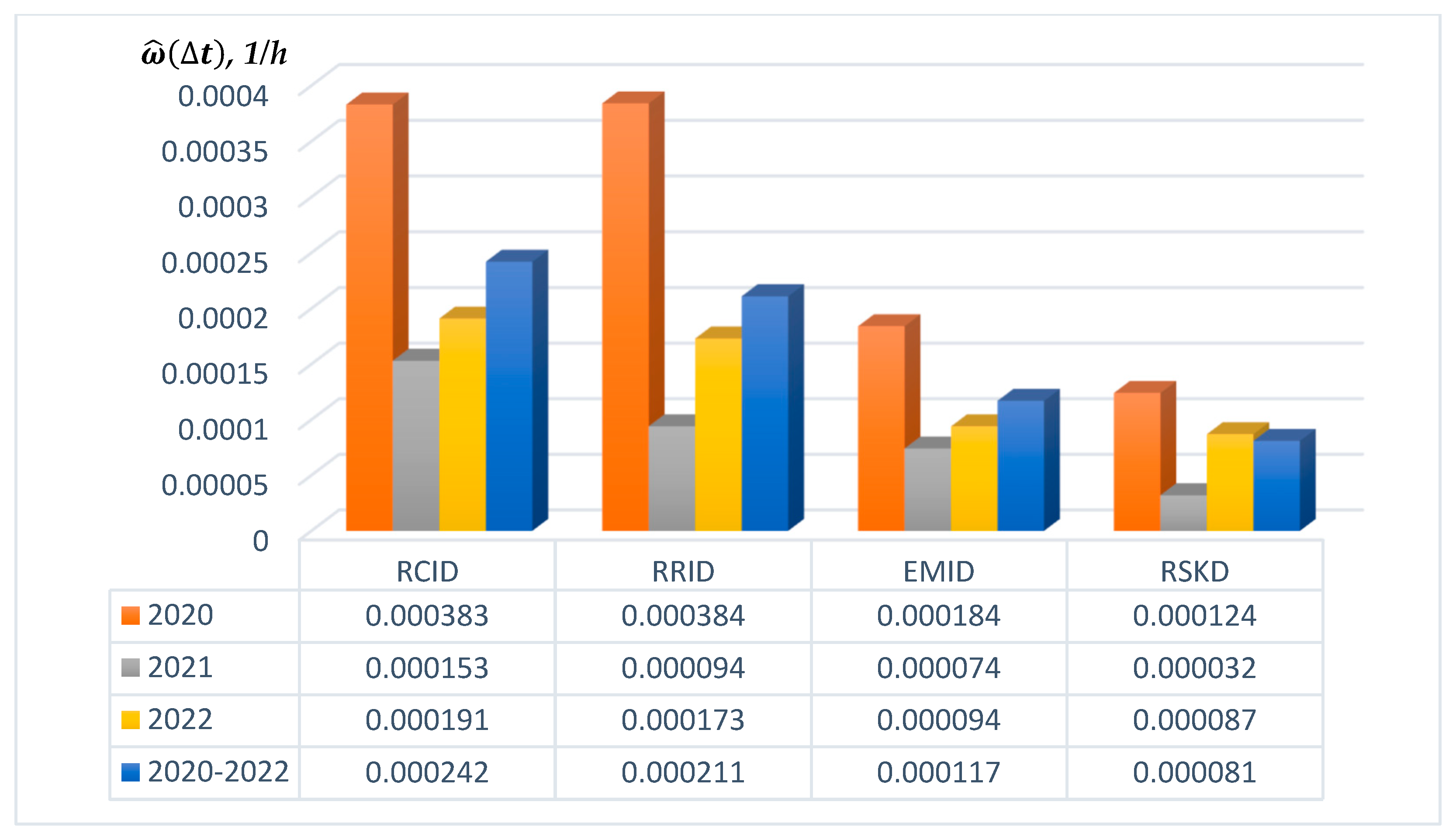

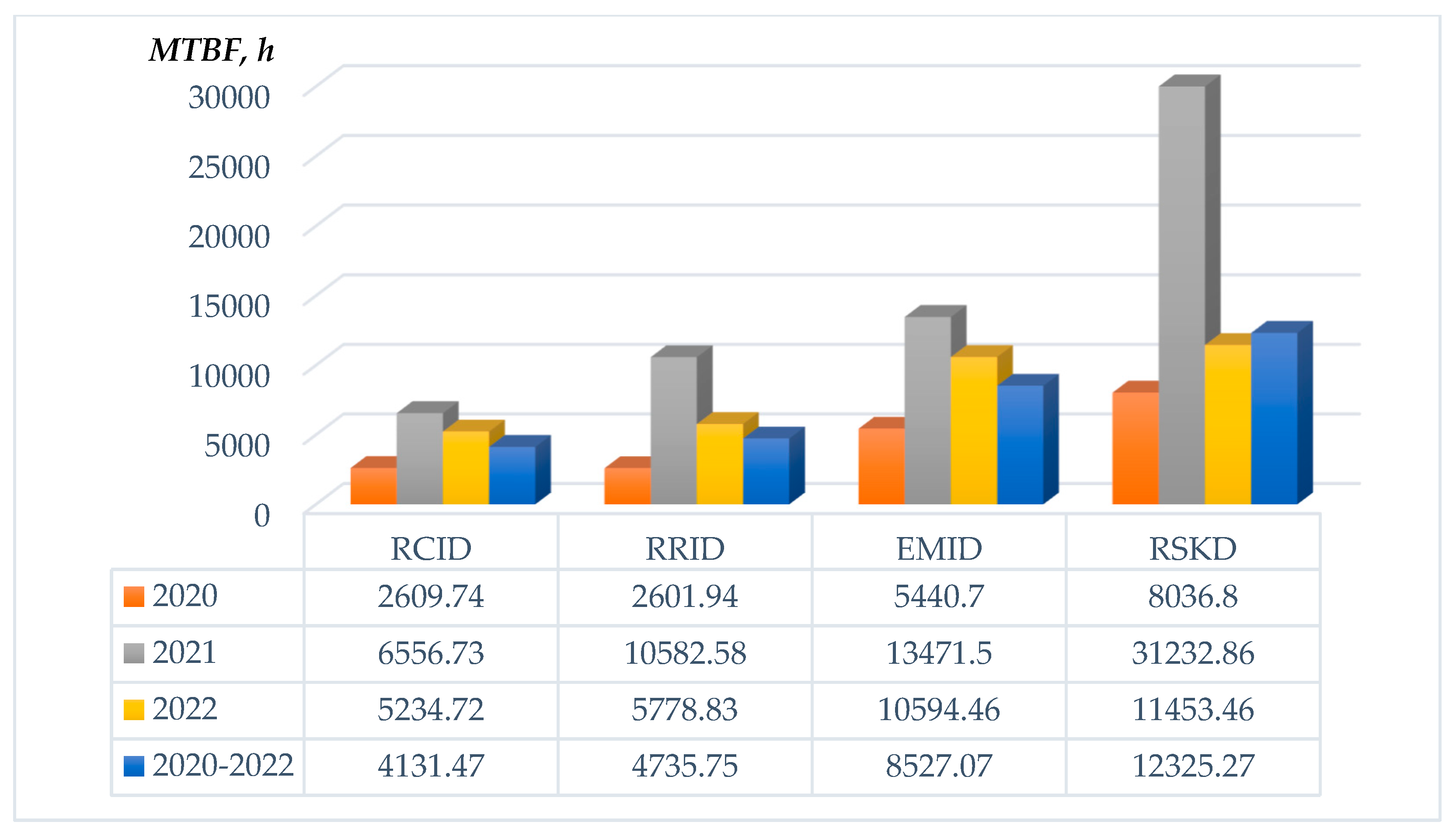

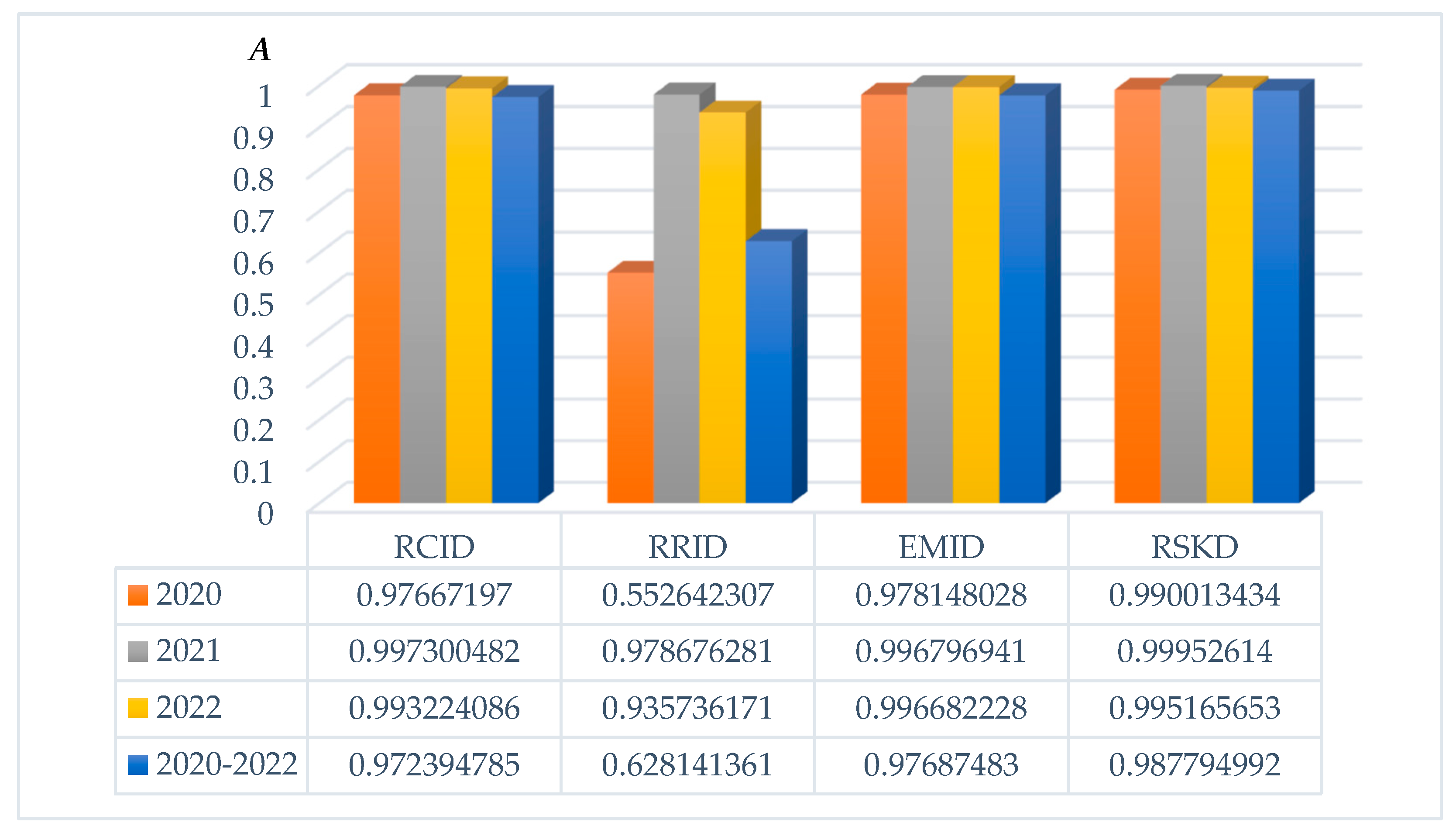

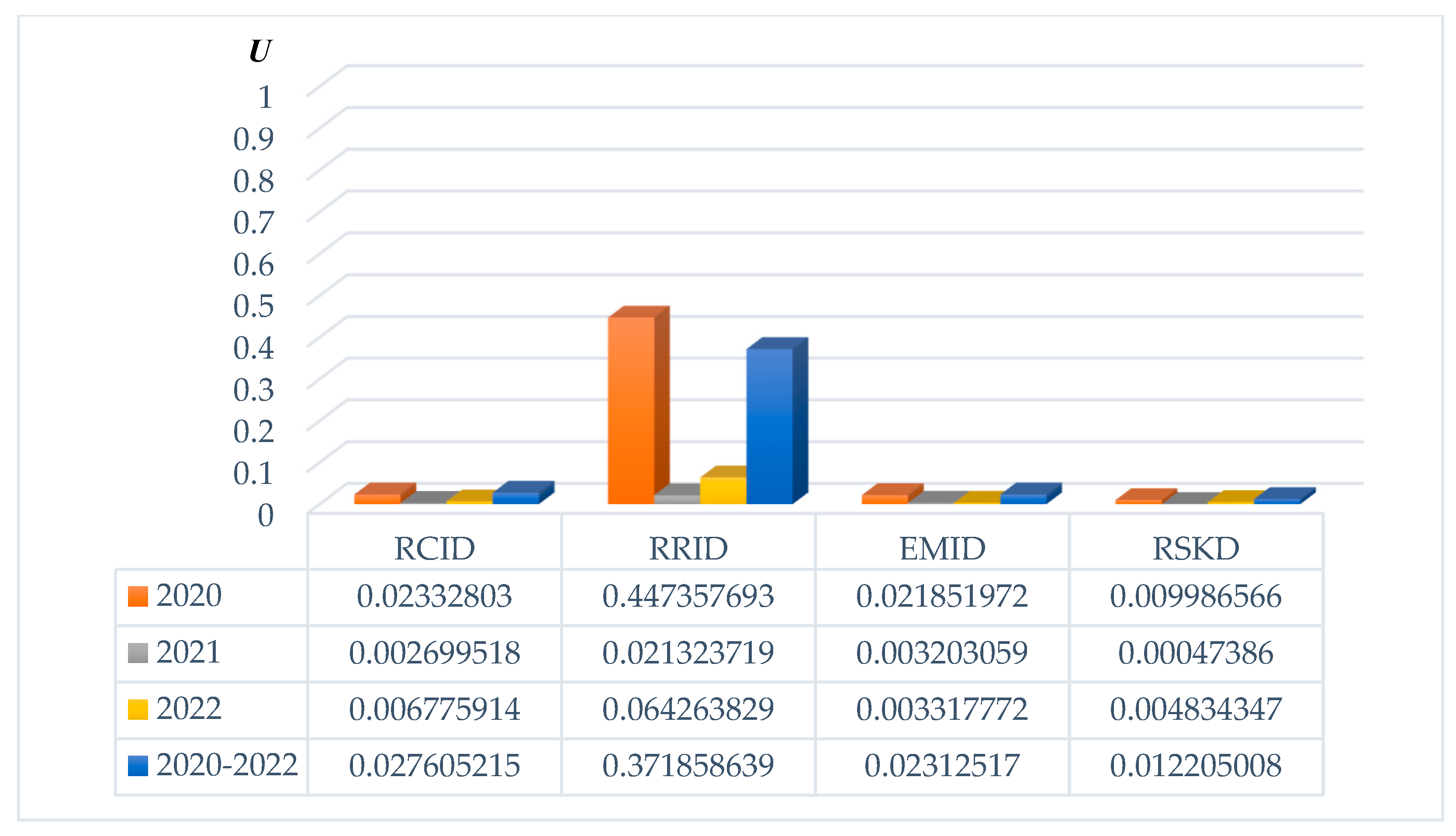

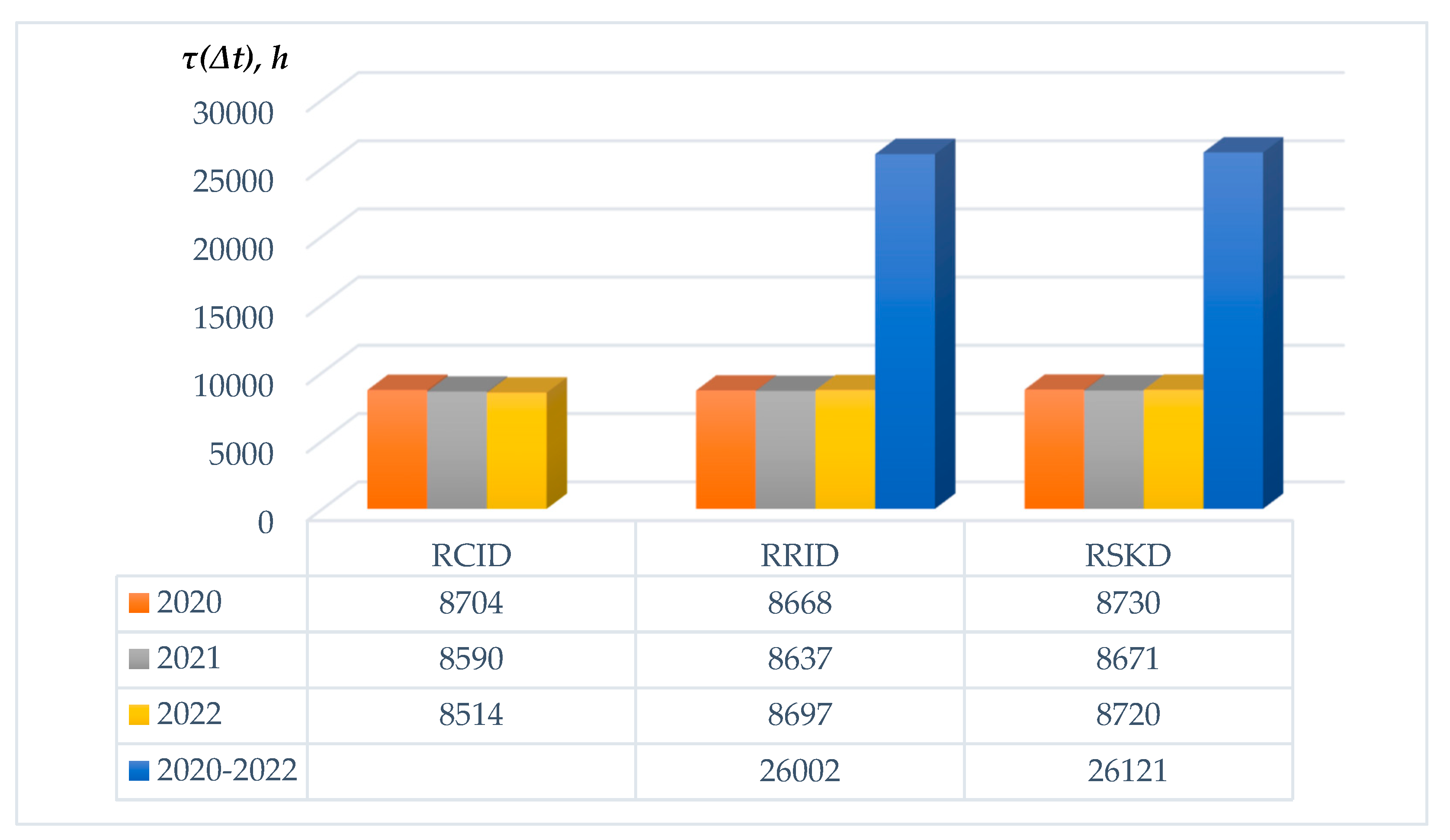

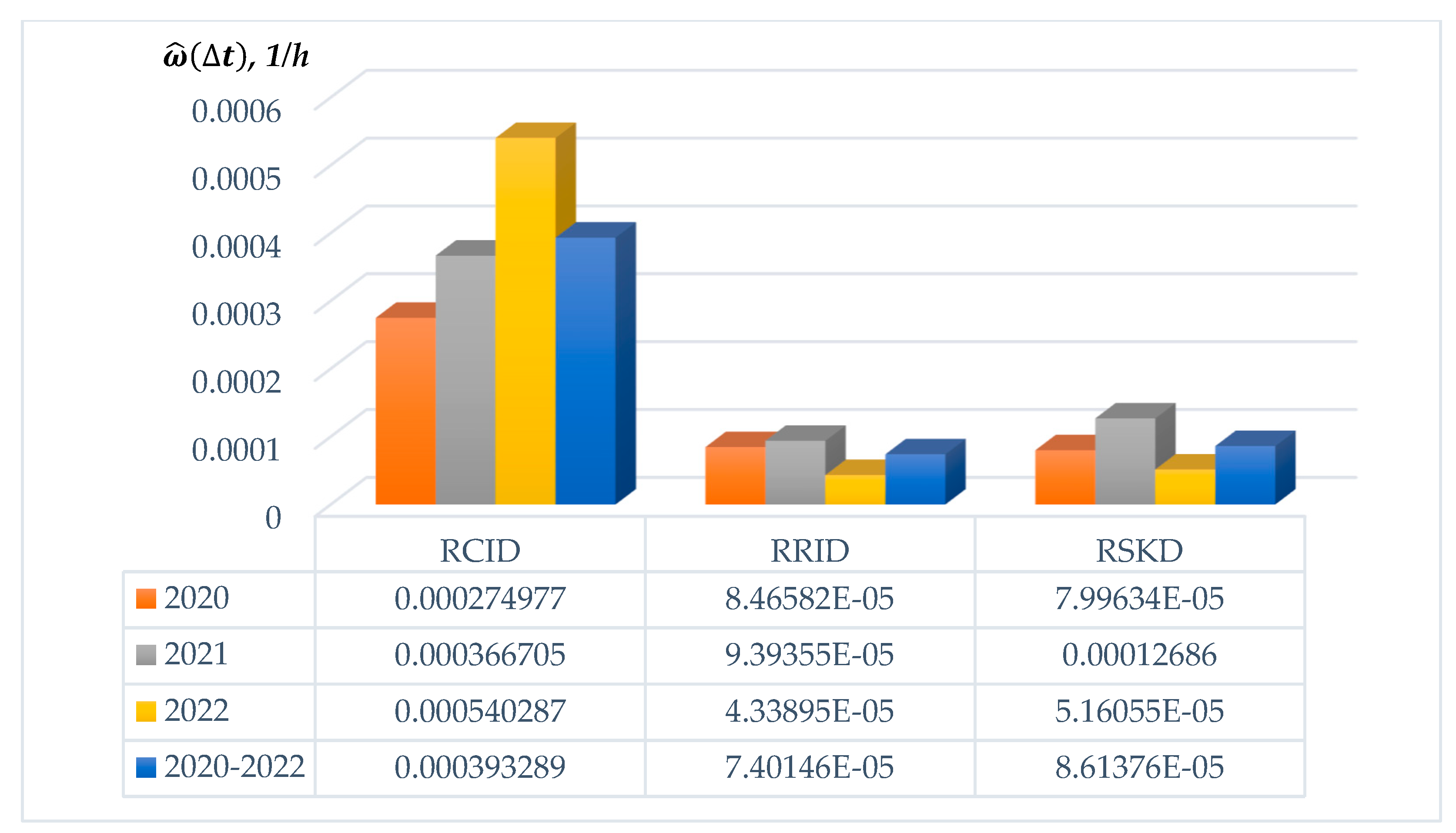

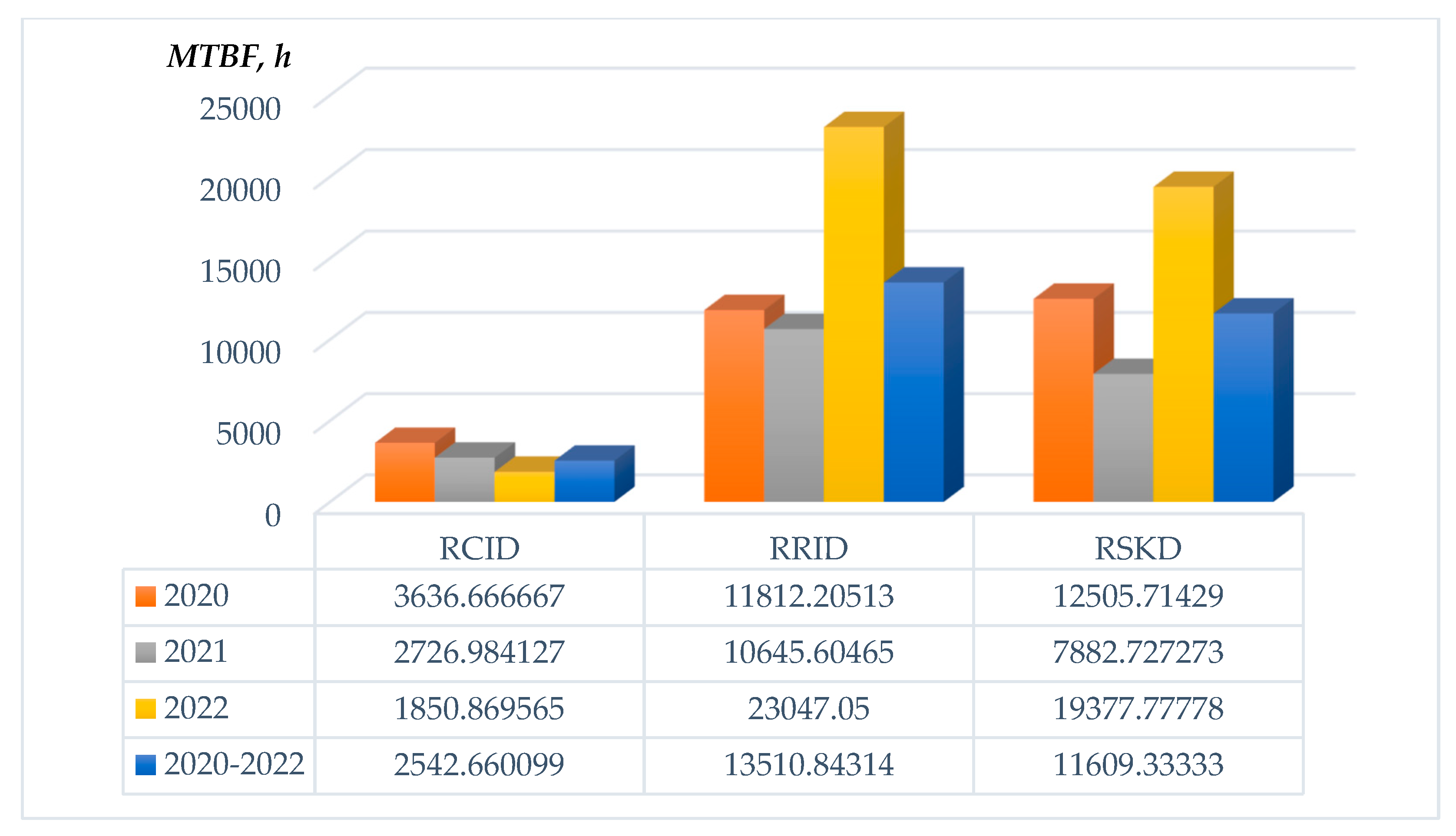

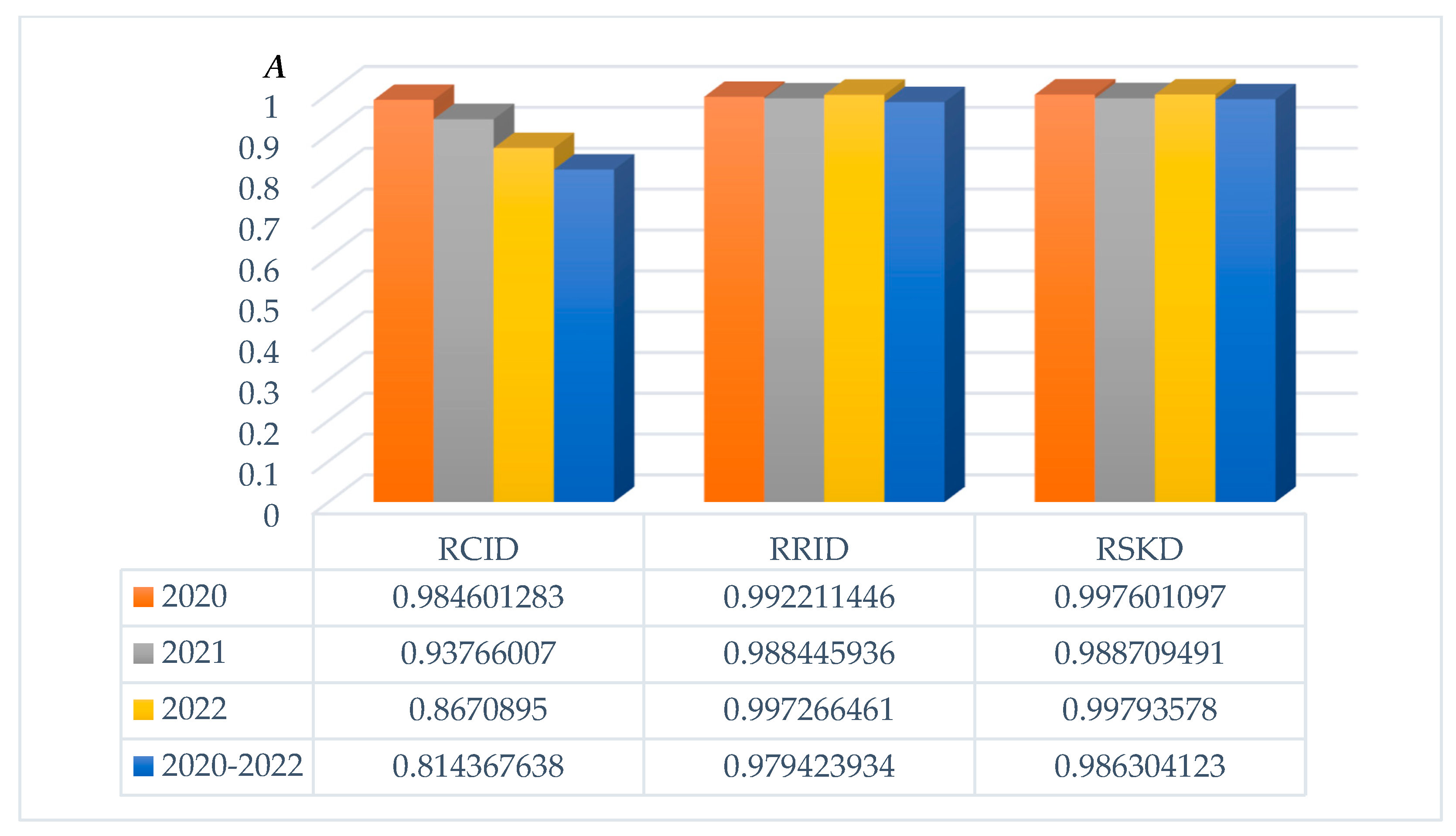

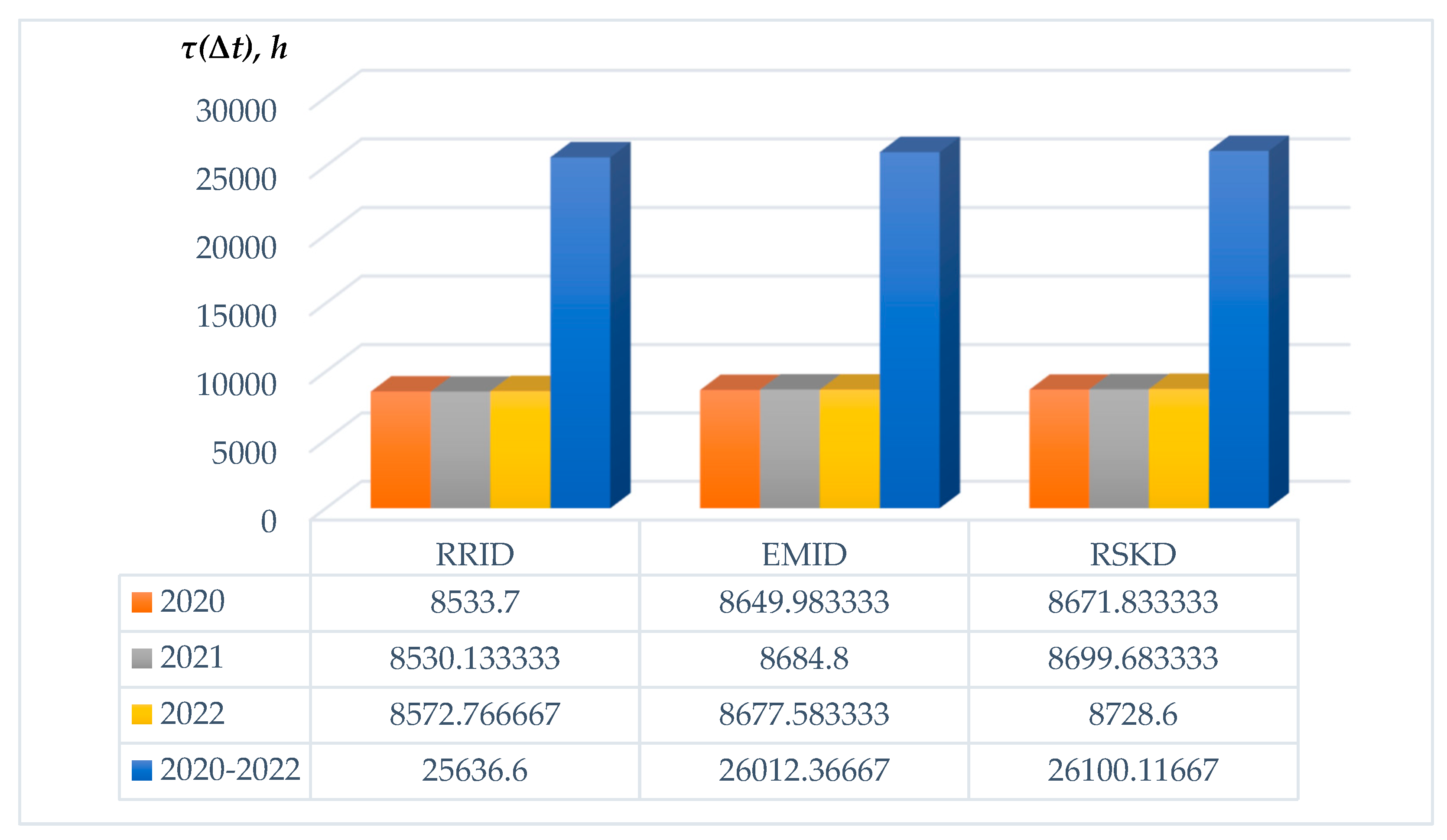

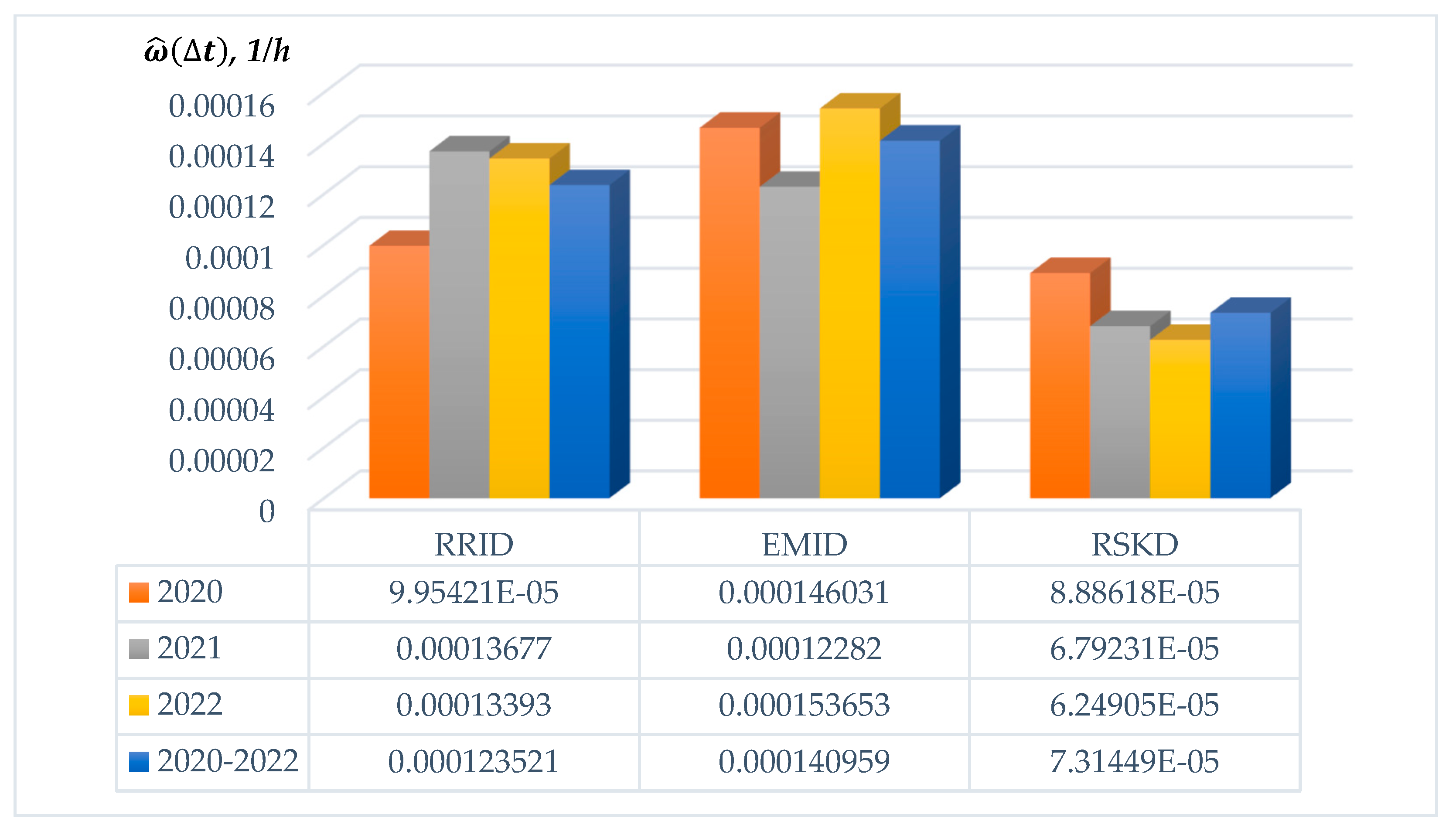

3.2. Reliability Analysis of Failures of the Interlocking Devices

3.2.1. Reliability Analysis of Failures of the IlDs in STD—Sofia

3.2.2. Reliability Analysis of Failures of the IlDs in STD—Plovdiv

3.2.3. Reliability Analysis of Failures of the IlDs in STD—Gorna Oryahovitsa

4. Discussion

5. Conclusions

- statistical analysis of data on the failures and their duration, with special attention paid to interlocking devices (RCIDs, RRIDs, EMIDs, RSKDs) and compared to external station devices (traffic lights, point machines, rail current circuits, and counter points), interstation devices (Type ALS, type PAB, AB with axle counters, AB with rail circuits, automatic crossing devices), telecommunications devices (automatic telephone exchanges, external lines);

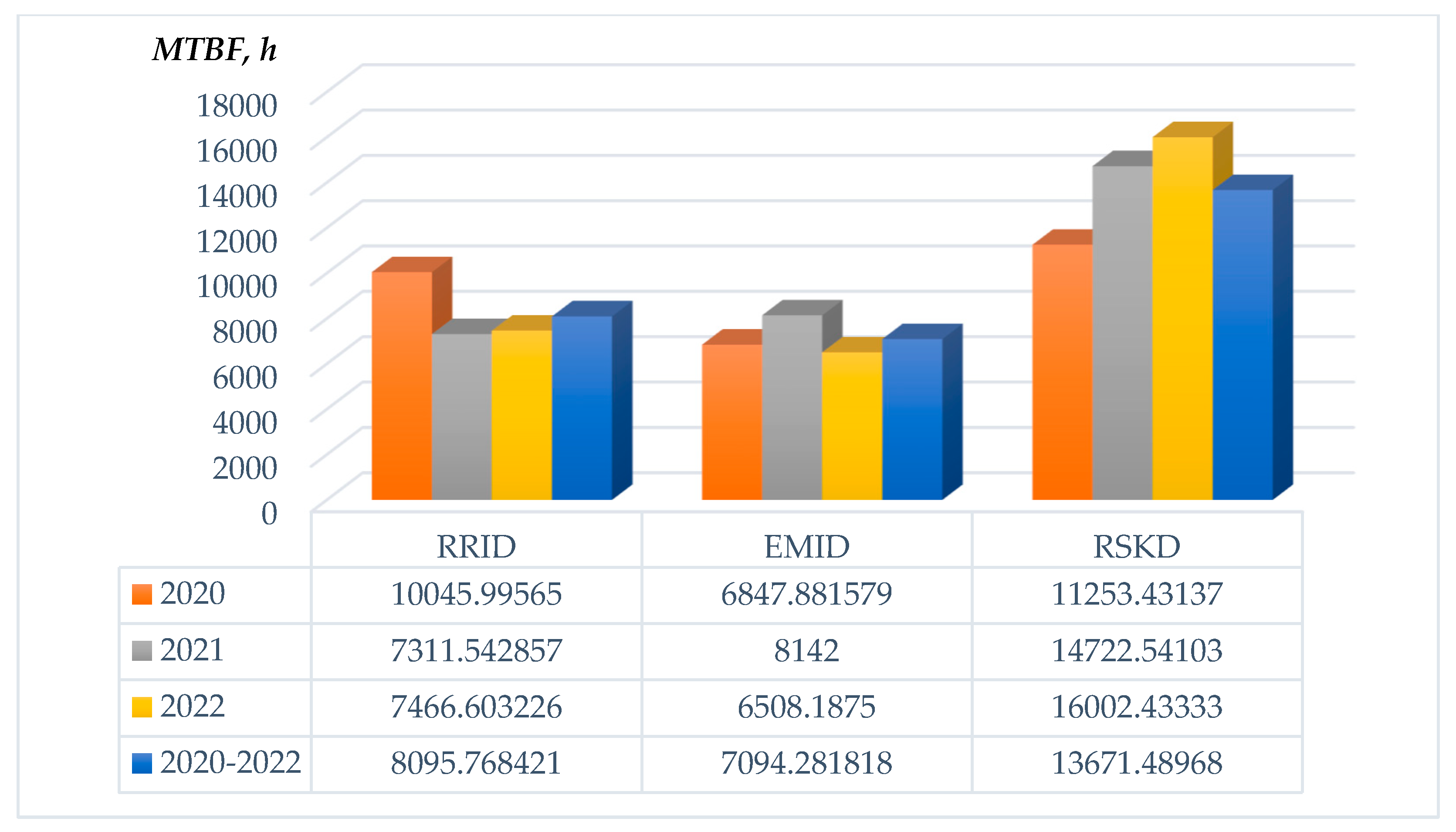

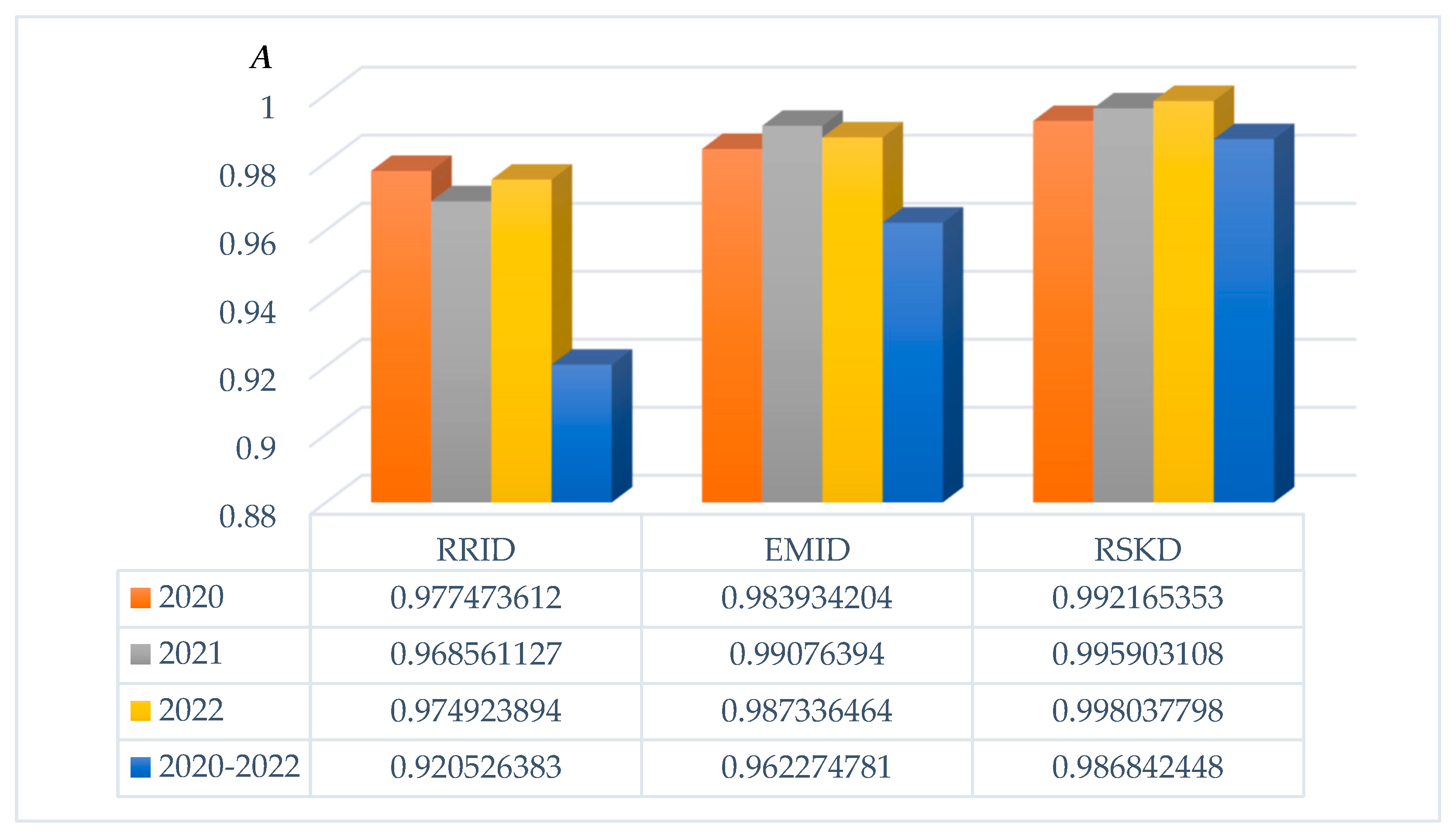

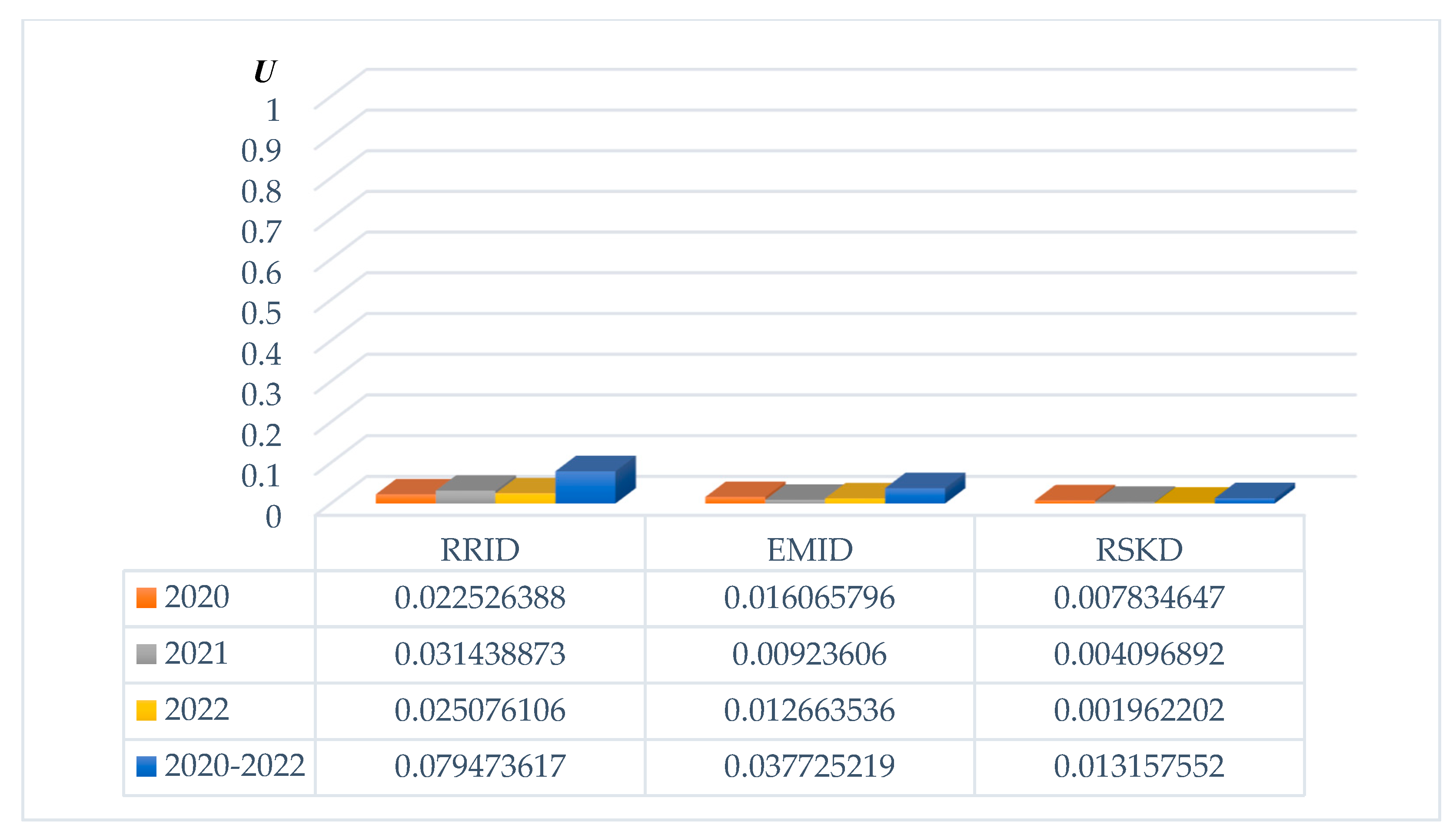

- reliability analysis of interlocking devices, including the determination of the time for failure-free operation τ(Δt), the statistical assessment of the failure flow intensity , the Mean Time Between Failures MTBF and finally—the stationary indicators of availability and unavailability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EMID | Electromechanical Interlocking Devices |

| ESD | External Station Devices |

| IlD | Interlocking Devices |

| IsD | Interstation Devices |

| NRIC | National Railway Infrastructure Company (of Bulgaria) |

| RCID | Route-Computer Interlocking Devices |

| RRID | Route-Relay Interlocking Devices |

| RSKD | Relay Systems For Key Dependences |

| STD | “Signalling and Telecommunications” Department |

| TcD | Telecommunications Devices |

References

- Efanov, D.V.; Osadchy, G.V.; Aganov, I. Fundamentals of Implementation of Safety Movement of Trains under Integration of Control Systems with Hardware for Railway Infrastructure Facilities Monitoring. In Proceedings of the 2021 11th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Cracow, Poland, 22–25 September 2021; pp. 391–396. [Google Scholar] [CrossRef]

- Kamakshi, T.; Pritika, K. Smart Railway Infrastructure: Fusion of IoT, RFID and VANET for Enhanced Safety and Operational Efficiency. In Proceedings of the 2023 Second International Conference on Advances in Computational Intelligence and Communication (ICACIC), Puducherry, India, 7–8 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Pop, I.; Festila, C. Railway Safety, from a Set of Rules to Cyber Physical Systems. In Proceedings of the 2024 IEEE International Conference on Automation, Quality and Testing, Robotics (AQTR), Cluj-Napoca, Romania, 16–18 May 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Efanov, D.V.; Khóroshev, V.V.; Osadchy, G.V. Principles of Safety Signalling and Traffic Control Systems Synthesis on Railways. In Proceedings of the 2023 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 15–19 May 2023; pp. 634–638. [Google Scholar] [CrossRef]

- Efanov, D.V.; Mikhailiuta, E.M.; Khóroshev, V.V. Reliability Models for a Safe Train Traffic Control Systems Accounting the Railway Infrastructure States. In Proceedings of the 2023 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 10–16 September 2023; pp. 266–270. [Google Scholar] [CrossRef]

- Zamouche, D.; Aissani, S.; Omar, M.; Saad, N. Safety-Oriented Train Control Systems Monitoring in Smart Railway Transportation: A Review. In Proceedings of the 4th International Conference on Pattern Analysis and Intelligent Systems (PAIS), Oum El Bouaghi, Algeria, 12–13 October 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Baranov, L.A.; Godyaev, A.I. Potential Estimation of Train Spacing when Using Railway Safety Management Systems Based on a Radio Channel. In Proceedings of the 2019 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 1–4 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Kún, G.; Wührl, T. Classification of Communication Interfaces in Railway Systems. In Proceedings of the 2023 IEEE 17th International Symposium on Applied Computational Intelligence and Informatics (SACI), Timisoara, Romania, 23–26 May 2023; pp. 000749–000754. [Google Scholar] [CrossRef]

- Yang, J.; Cheng, X.; Wu, Y.; Qin, Y.; Jia, L. Railway Comprehensive Monitoring and Warning System Framework Based on Space-air-Vehicle-Ground Integration Network. In Proceedings of the 2018 Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018; pp. 1314–1319. [Google Scholar] [CrossRef]

- Samantaray, R.R.; Azeez, A.; Yeshwanth, K.; Althaf, K.; Tarun, H.; Sudhakar, Y. Advanced IoT and Machine Learning Solutions for Railway Safety, 2nd. In Proceedings of the International Conference on Networking, Embedded and Wireless Systems (ICNEWS), Bangalore, India, 22–23 August 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Abduvaytov, A.; Abdu Kayumbek, R.M.; Jeon, H.S.; Oh, R. The Real Time Railway Monitoring System suitable for Multi-View Object based on Sensor Stream Data Tracking. In Proceedings of the International Conference on Information Science and Communications Technologies (ICISCT), Tashkent, Uzbekistan, 4–6 November 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Priyadharshini, D.; Yamuna, R.; Banu, G.; Bensam, S.D. IoT-based Railway Level Crossing Gate Control System. In Proceedings of the 2024 Second International Conference on Intelligent Cyber Physical Systems and Internet of Things (ICoICI), Coimbatore, India, 28–30 August 2024; pp. 293–297. [Google Scholar] [CrossRef]

- Kiruthika, S.; Sariba Munovara, A.; Nikitha, K.; Saranya, M. Enhanced Safety System for Unprotected Level Crossings: Train Distance Indicator and Opposite Train Detection. In Proceedings of the 10th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 14–15 March 2024; pp. 335–340. [Google Scholar] [CrossRef]

- Struchalin, V.G.; Narusova, E.Y.; Paruleva, I.V. Development of Labor Safety Information Systems for Railway Transport. In Proceedings of the 2023 International Conference on Quality Management, Transport and Information Security, Information Technologies (IT&QM&IS), Petrozavodsk, Russia, 25–29 September 2023; pp. 69–73. [Google Scholar] [CrossRef]

- ALawad, H.; Kaewunruen, S. Unsupervised Machine Learning for Managing Safety Accidents in Railway Stations. IEEE Access 2023, 11, 83187–83199. [Google Scholar] [CrossRef]

- Amjath MI, M.; Kuhanesan, S. TrackWarn: An AI-driven warning system for railway track workers. In Proceedings of the 2021 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 16 September 2021; pp. 124–128. [Google Scholar] [CrossRef]

- Atanasov, I.; Pencheva, E. Operation and Maintenance Services in an Intelligent Railway Control System Architecture. In Proceedings of the 2024 International Conference on Control, Automation and Diagnosis (ICCAD), Paris, France, 15–17 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Vatakov, V.; Pencheva, E.; Dimitrova, E. Recent Advances in Artificial Intelligence for Improving Railway Operations. In Proceedings of the 2022 30th National Conference with International Participation (TELECOM), Sofia, Bulgaria, 27–28 October 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Narasimha Swamy, S.; Kushaal, S.; Kumar, S.; Aithal, R.; Vijayalakshmi, M.N. Enhancing Railway Safety Through Human Activity Recognition. In Proceedings of the 2024 8th International Conference on Computational System and Information Technology for Sustainable Solutions (CSITSS), Bengaluru, India, 7–9 November 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Markovits, T.G.; Rácz, G. Safety principles for designing a generic product for railway signalling systems. In Proceedings of the Fifth World Conference on Smart Trends in Systems Security and Sustainability (WorldS4), London, UK, 29–30 July 2021; pp. 134–139. [Google Scholar] [CrossRef]

- Yu, J. A Domestical Safety Computer Platform for Railway Signal System. In Proceedings of the 2021 IEEE 5th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 March 2021; pp. 26–30. [Google Scholar] [CrossRef]

- Zhang, L. Research and Design of the Safety Control Platform for the Railway Signaling. In Proceedings of the 2023 IEEE 7th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 15–17 September 2023; pp. 339–342. [Google Scholar] [CrossRef]

- Narusova, E.Y.; Struchalin, V.G.; Paruleva, I.V. Development of Hardware and Software to Ensure Process Safety and Reliability in Railway Transport. In Proceedings of the 2023 International Conference on Quality Management, Transport and Information Security, Information Technologies (IT&QM&IS), Petrozavodsk, Russia, 25–29 September 2023; pp. 59–63. [Google Scholar] [CrossRef]

- Schmid, P.; Assaf, K.; Tiedt, C.; Reiter, F.; Friedenberger, D.; Polze, A. Managing Complexity in Safety-critical Railway Signaling Systems using Simplex Architectures. In Proceedings of the 2024 IEEE 27th International Symposium on Real-Time Distributed Computing (ISORC), Tunis, Tunisia, 22–25 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Dimitrova, E.A.; Dimitrov, V.D. Systems for remote monitoring and control of objects in railway transport. In Proceedings of the International Conference Automatics and Informatics, Sofia, Bulgaria, 4–5 October 2016; John Atanasoff Society of Automatics and Informatics: Sofia, Bulgaria, 2016; pp. 45–48. [Google Scholar]

- Pachl, J. Railway Signalling Principles; Digitale Bibliothek Braunschweig: Braunschweig, Germany, 2020. [Google Scholar]

- Theeg, G.; Vlasenko, C. Railway Signalling and Interlocking, 3rd ed.; PMC Media House GmbH: Hamburg, Germany, 2020. [Google Scholar]

- Nedelchev, N.; Hristov, H. Electrical Interlocking Stations, 2nd ed.; Todor Kableshkov University of Transport: Sofia, Bulgaria, 2008. [Google Scholar]

- Rouaud, M. Probability, Statistics and Estimation; Creative Commons: Mountain View, CA, USA, 2013. [Google Scholar]

- Ash, R.B. Basic Probability Theory; Dover Publications: Mineola, NY, USA, 2008. [Google Scholar]

- Ross, S.M. Introduction to Probability Theory. In Introduction to Probability Models, 13th ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Sapozhnikov, V.; Sapozhnikov, V.l.; Efanov, D. Fundamentals of Reliability Theory and Technical Diagnostics; Lan: San Mateo, CA, USA, 2019. [Google Scholar]

- Balagurusamy, E. Reliability Engineering—Ch. 1: Basic Concept of Reliability; McGraw-Hill Education: Noida, Uttar Pradesh, India, 2010. [Google Scholar]

- Hu, C.; Youn, B.D.; Wang, P. Basic Concepts of Reliability. In Engineering Design Under Uncertainty and Health Prognostics; Springer Series in Reliability Engineering; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Ram, M.; Pham, H. Advances in Reliability Analysis and its Applications; Springer Series in Reliability Engineering; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Unnikrishnan Nair, N.; Sankaran, P.G.; Balakrishnan, N. Reliability Modelling and Analysis in Discrete Time; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Yampurin, N.; Baranova, A. Fundamentals of reliability of Electronic Devices; Publishing Center “Academy”: Moscow, Russia, 2010. [Google Scholar]

- Petrov, N. Reliability Studies of Risky Technical Systems; Publishing House “Zhelyo Uchkov”: Yambol, Bulgaria, 2007. [Google Scholar]

- Hristov, H.; Trifonov, V. Reliability and Security of Communications; Publishing House “Novi znania”: Sofia, Bulgaria, 2005. [Google Scholar]

- Verma, A.K.; Ajit, S.; Karanki, D.R. Reliability and Safety Engineering, 2nd ed.; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Kumar, V.; Singh, L.; Tripathi, A.K. Reliability analysis of safety—Critical and control systems: A state-of-the-art review. IET Softw. 2018, 12, 1–18. [Google Scholar] [CrossRef]

- Petrov, N. Exploitation Reliability in Risky Technical Systems; University Prof. Dr. Asen Zlatarov: Burgas, Bulgaria, 2002. [Google Scholar]

- Sapozhnikov, V.; Sapozhnikov, V.l.; Shamanov, V. Reliability of Systems for Railway Automation, Remote Control and Communication; Publishing House Marshrut: Moscow, Russia, 2003. [Google Scholar]

- Gindev, E. Assurance Procedures in Reliability. In Introduction to Reliability Theory and Practice; Academic Publishing House “Prof. Marin Drinov”: Sofia, Bulgaria, 2002. [Google Scholar]

- Balagurusamy, E. Reliability mathematics. In Reliability Engineering; McGraw-Hill Education: Noida, Uttar Pradesh, India, 2010. [Google Scholar]

- Pang, S.; Bian, Z.; Zhang, Z.; Meng, L.; Jiao, J. A Safety Analysis Method Based on Model Checking. In Proceedings of the 2024 10th International Symposium on System Security, Safety, and Reliability (ISSSR), Xiamen, China, 16–17 March 2024; pp. 61–65. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Y.; Lu, C.; Fei, C. Operational reliability assessment of complex mechanical systems with multiple failure modes: An adaptive decomposition-synchronous-coordination approach. Reliab. Eng. Syst. Saf. 2024, 253, 110494. [Google Scholar] [CrossRef]

- Bouissou, M.; Rogovchenko-Buffoni, L.; Thiele, B. From design to dependability: A bridge between physical simulation and risk analysis. In Proceedings of the Lambda Mu 20, Saint Malo, France, 11–14 October 2016. [Google Scholar]

- Havryliuk, V. Model of Propagation of Traction Current Harmonics from Trains to a Track Circuit Receiver. In Proceedings of the International Symposium on Electromagnetic Compatibility (APEMC), Nusa Dua—Bali, Indonesia, 27–30 September 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Saiapina, I.; Holub, H.; Kulbovskyi, I. Improving Noise Immunity of Audio Frequency Track Circuits Using Neural Networks and Data Classification. In Transbaltica XIII: Transportation Science and Technology; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Tarasov, E.; Nadezhkin, V.; Nadezhkina, S. Insulating joints as a destabilizing factor in the operation of the track circuit. In Proceedings of the 6th International Conference APEC 2023, Moscow, Russia, 10 August 2023; E3S Web of Conferences. Volume 41110. Art. No. 01019. [Google Scholar]

| Type of IlD | STD—Sofia | STD—Plovdiv | STD—G.Or. | Total |

|---|---|---|---|---|

| RCID | 3 | 20 | - | 23 |

| RRID | 62 | 53 | 54 | 169 |

| EMID | 17 | - | 15 | 32 |

| RSKD | 25 | 20 | 22 | 67 |

| Total | 107 | 93 | 91 | 291 |

| Type of IlD | ||||

|---|---|---|---|---|

| RCID | 0.9723948 | 0.9890655 | 0.0276052 | 0.0109345 |

| RRID | 0.6281414 | 0.8223516 | 0.3718586 | 0.1776484 |

| EMID | 0.9768748 | 0.9905424 | 0.0231252 | 0.0094576 |

| RSKD | 0.9877950 | 0.9949017 | 0.0122050 | 0.0050983 |

| Type of IlD | ||||

|---|---|---|---|---|

| RCID | 0.814367638 | 0.929783618 | 0.185632362 | 0.070216382 |

| RRID | 0.979423934 | 0.992641281 | 0.020576066 | 0.007358719 |

| RSKD | 0.986304123 | 0.994748789 | 0.013695877 | 0.005251211 |

| Type of IlD | ||||

|---|---|---|---|---|

| RRID | 0.9205264 | 0.973652878 | 0.0794736 | 0.026347122 |

| EMID | 0.9622748 | 0.987344869 | 0.0377252 | 0.012655131 |

| RSKD | 0.9868424 | 0.995368753 | 0.0131576 | 0.004631247 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimitrova, E.; Dimitrov, V. Methodology for Studying the Reliability of Interlocking Devices in Bulgarian Railways. Appl. Sci. 2025, 15, 4178. https://doi.org/10.3390/app15084178

Dimitrova E, Dimitrov V. Methodology for Studying the Reliability of Interlocking Devices in Bulgarian Railways. Applied Sciences. 2025; 15(8):4178. https://doi.org/10.3390/app15084178

Chicago/Turabian StyleDimitrova, Emiliya, and Vasil Dimitrov. 2025. "Methodology for Studying the Reliability of Interlocking Devices in Bulgarian Railways" Applied Sciences 15, no. 8: 4178. https://doi.org/10.3390/app15084178

APA StyleDimitrova, E., & Dimitrov, V. (2025). Methodology for Studying the Reliability of Interlocking Devices in Bulgarian Railways. Applied Sciences, 15(8), 4178. https://doi.org/10.3390/app15084178